SURVEYING INSTRUMENTS.

Punctuation has been standardised, and possible typographical errors have been changed.

Archaic, variable and inconsistent spelling and hyphenation have been preserved.

SURVEYING AND LEVELLING

INSTRUMENTS

FOR CONSTRUCTION, QUALITIES, SELECTION, PRESERVATION, ADJUSTMENTS, AND USES; WITH OTHER APPARATUS AND APPLIANCES USED BY CIVIL ENGINEERS AND SURVEYORS IN THE FIELD.

BY

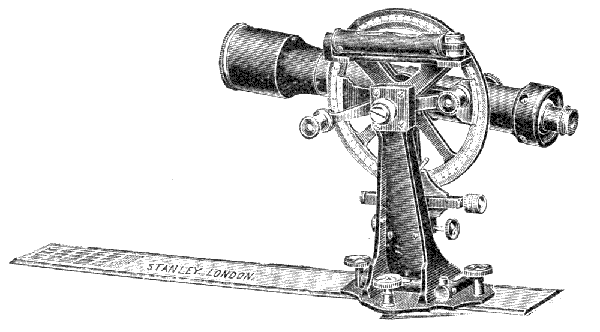

WILLIAM FORD STANLEY

OPTICIAN, MANUFACTURER OF SURVEYING AND DRAWING INSTRUMENTS,

AUTHOR OF A TREATISE ON DRAWING INSTRUMENTS, PROPERTIES AND MOTIONS OF FLUIDS, NEBULAR THEORY, ETC.

FOURTH EDITION

Revised by H. T. TALLACK.

LONDON: E. & F. N. SPON, LTD., 57, HAYMARKET, S.W.

NEW YORK: 123, LIBERTY STREET

AND OF

W. F. STANLEY & CO., LIMITED

286, High Holborn, London, W.C.

1914

Notes were taken for many years before the production of this work of queries that came before the author for reply relative to functional parts of surveying instruments. These bore most frequently reference to optical and magnetic subjects, and to the qualities and action of spirit level tubes, also occasionally to graduation and the qualities of clamp and tangent motions. It was therefore thought that it would be useful to give notes upon these subjects in detail as far as possible in the early chapters. As the work proceeded it was found that this plan saved much space in avoiding the necessity for separate descriptions when parts of complex instruments were afterwards described.

To show the state of the art and render the work useful, it was necessary that the structure of surveying instruments should be given with sufficient detail to be worked out by the skilful manufacturer. Beyond this it was thought to be most important that the professional man, who must have limited experience of the qualities of workmanship, should be supplied with as many simple tests as possible for assuring the qualities of the instruments he might purchase or use, with details also of their adjustments. This matter is therefore carried into detail for one instrument at least of each class, as very little[iv] general information is to be found on the subject in our literature. In fact, large groups of instruments in extensive use, such as those used for mining surveying, and subtense measuring instruments, have remained heretofore nearly undescribed in our language.

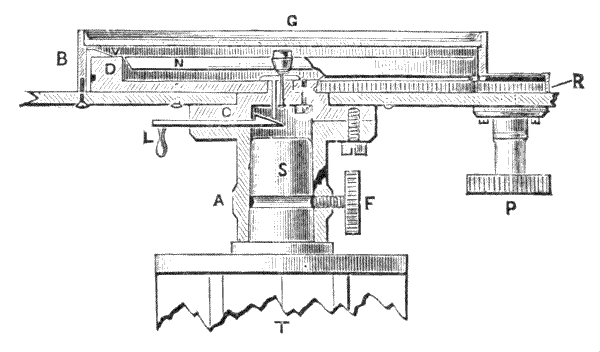

The technical principles followed in working out details in these pages are given by illustrations of such parts of important instruments as present any difficulty of observation from an exterior view of the engraving of the entire instrument. The plans of construction in general use are selected for illustration. Certain constructions that are liable to failure are pointed out. Many recent improvements in instruments are recognised and some are suggested, but no attempt has been made to record the little differences of construction, often meritorious, which give only a certain amount of style to the work of each country and of each individual. Upon this point it must occur that the work done in any workshop must vary from other work according to the skill and judgment of the master. It is intended, therefore, that distinctly typical instruments only should be described, in a manner that details may be worked out therefrom. To make this matter as clear as possible, with few exceptions these pages were written with the instruments described upon my table, and the illustrations, when not taken directly from the instruments, were taken from workshop drawings to a reduced scale.

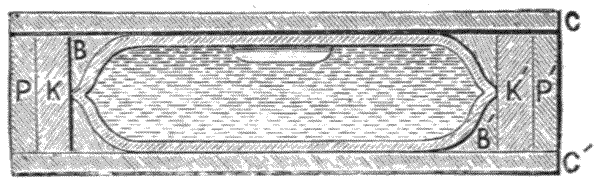

In practice it is found that instruments performing similar functions may be very much varied in construction, bearing reference frequently to the conditions under which they are to be used. The same may be said of the functional parts of instruments. We may also observe that English instruments differ in detail from foreign ones, and upon this point[v] there is no doubt much may be learned by comparison of some details of English with foreign work, although our own is admitted to rank high. Comparisons are therefore freely made in the following pages, and suggestions offered after study abroad of foreign work, and careful inspection of nearly the whole literature upon the subject, in which it is very observable that some modern continental books, treating upon parts of the subject, are much in advance of our own.

The surveying instruments described in these pages are nearly limited to those used in the field. Instruments for plan drawing and calculation of areas, which the surveyor uses in the office, have been described in the author's work on Drawing Instruments (now in Seventh Edition), to which this is intended to be the complement of the subject.

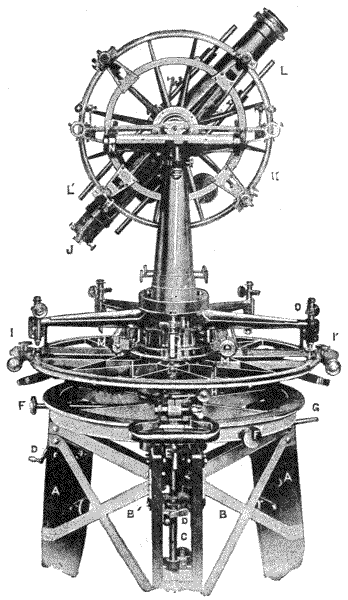

To render the work as complete as possible, it was thought necessary to give briefly the manner of using many instruments in practical surveying. This part of the subject, from the author's very limited experience in the field, is largely taken from inspection of the best works on surveying. The author, however, is very pleased to acknowledge the kindness of many professional friends for assistance on this and many other points, and for historical notes. For the description of the 36-inch theodolite, given in Chapter VII. (now X.), the author is indebted to the late Col. A. Strange, F.R.S., who gave every detail of his design and discussed many points. The author is also indebted to Mr. Thomas Cushing, F.R.A.S., Inspector of Scientific Instruments for India, who has given information and his opinions upon many subjects from his large practical experience. Also to Prof. George Fuller, C.E., who has kindly read proofs, examined formulæ, and made some technical points clearer. Also to[vi] Mr. W. N. Bakewell, M.Inst.C.E.; Major-General A. De Lisle, R.E.; Right Hon. Lord Rayleigh, F.R.S., for assistance on several technical points.

In this First Edition, entirely from manuscript, there will no doubt be errors and omissions; therefore the author will feel obliged by the receipt of any notes that he may make use of for future corrections, should another Edition be demanded.

W. F. S.

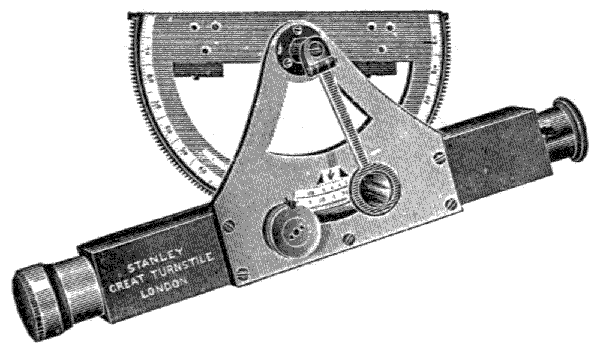

Great Turnstile, 1890.

The note at the end of the First Edition of this work referred to on the preceding page has brought the author many letters from professional men, who have kindly taken interest in the work by offering suggestions which are now incorporated as far as practical in this Edition, and for which thanks are tendered.

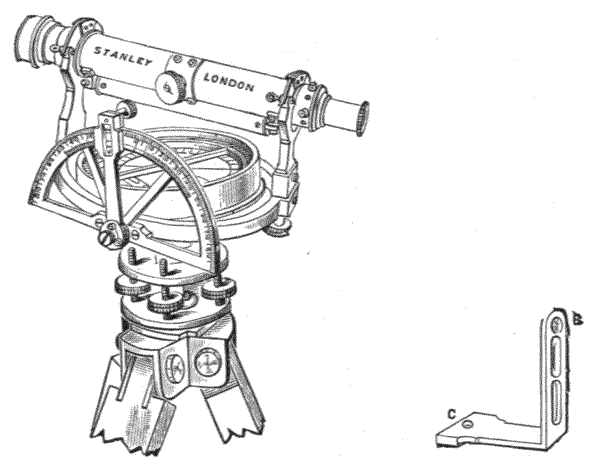

One important improvement of late years in the construction of surveying instruments is due to the greater perfection of modern machinery, and the adoption of special machines to shape out many parts of the work from the solid which were formerly screwed together in many pieces, which made the instruments heavier and also liable to become loose in parts by jars, so as to cause the necessity of frequent readjustments.

Another important improvement in modern surveying instruments is in their lightness, due to the discovery of permanent aluminium alloys, by which many parts of instruments that are shaped out in the solid may be reduced to one-third the weight of the gun-metal castings formerly used entirely for these parts.

In the present Edition, which represents forty-seven years of experience of the author's life devoted to the details of the[viii] subject, it is hoped that some permanent improvements in surveying instruments may be shown, and that many new designs now first described, founded upon this experience, may merit trial.

The author is pleased to acknowledge the zealous aid his working manager and at present co-director, Mr. H. T. Tallack, has given in perfecting this work to bring it to its present state.

W. F. S.

Great Turnstile, 1901.

Since the publication of the Third Edition of this work, the author has been taken from us, and it has fallen to my lot to revise it and bring it up to the present time. This work I have approached with the greatest diffidence, having to follow one who had such profound knowledge of the subject, and I have earnestly endeavoured, as closely as possible, to act as I think he would have done had he been alive, and having enjoyed over twenty years of the happiest and closest business relations with him—actively co-operating in bringing many of the instruments to their present state, I venture to hope that I have to some extent carried out what his wishes would have been.

I have carefully read over and corrected the whole work, and the additions to it are only in the nature of bringing it up to date.

H. T. Tallack.

286, High Holborn,

June, 1914.

| CHAPTER I. | |

| PAGE | |

| Introduction:—Historical Sketch—Classification of the Subject—Purposes and Qualities of Instruments—Workmanship—Metals—Aluminium—Framing—Tools—Axes of Instruments—Soldering—Finishing—Bronzing—Lacquering—Graduating —Engraving—Style—Glass-Work—Woodwork—Lubrication—Preservation of Instruments—Packing | 1 |

| CHAPTER II. | |

| The Telescope as a Part of a Surveying Instrument:—General Description—Qualities—Optical Principles—Refraction of Glass—Limit of Refraction—Reflection—Prisms—Lenses, Convex and Concave—Aberration—Formation of Images—Dispersion—Achromatism—Curvature of Lenses—Telescopes—Eye-pieces—Powers—Dynameter—Construction of the Telescope—Diaphragm—Webs—Lines—Points—Parallax—Examination and Adjustment | 24 |

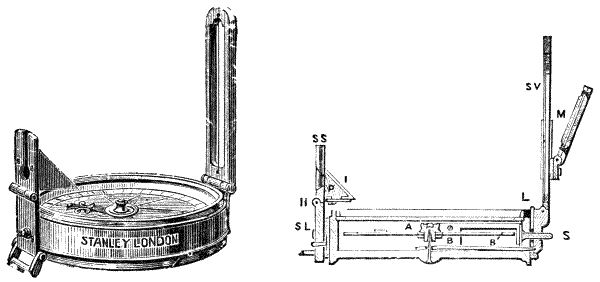

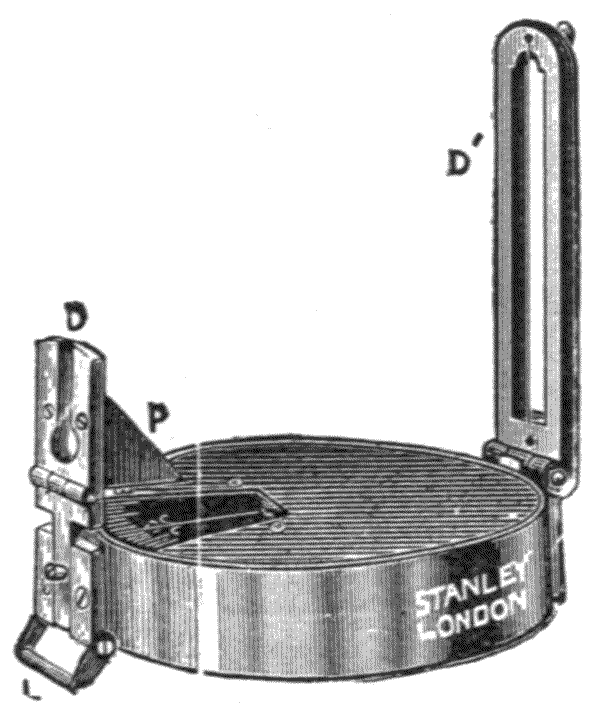

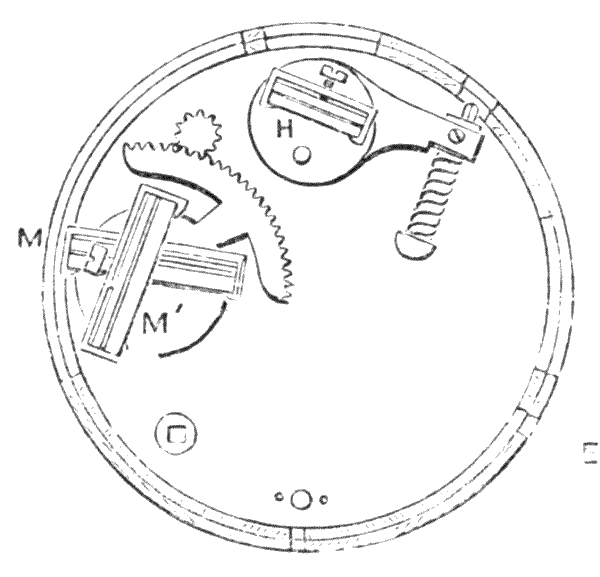

| CHAPTER III. | |

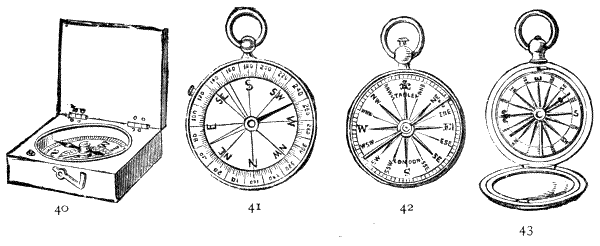

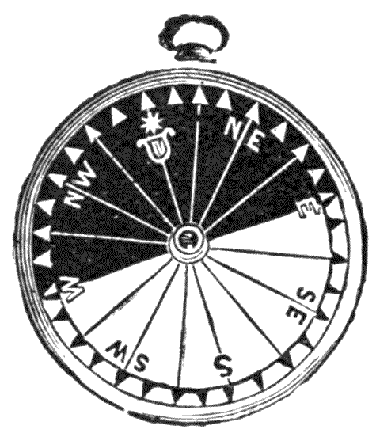

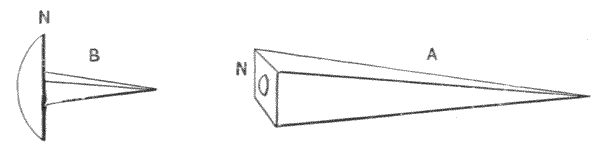

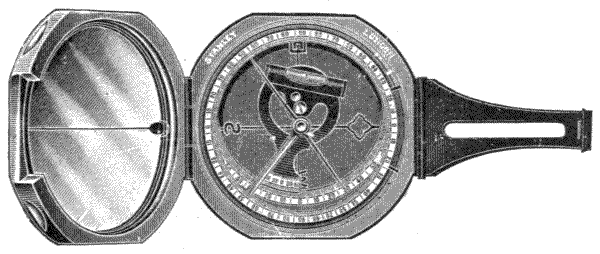

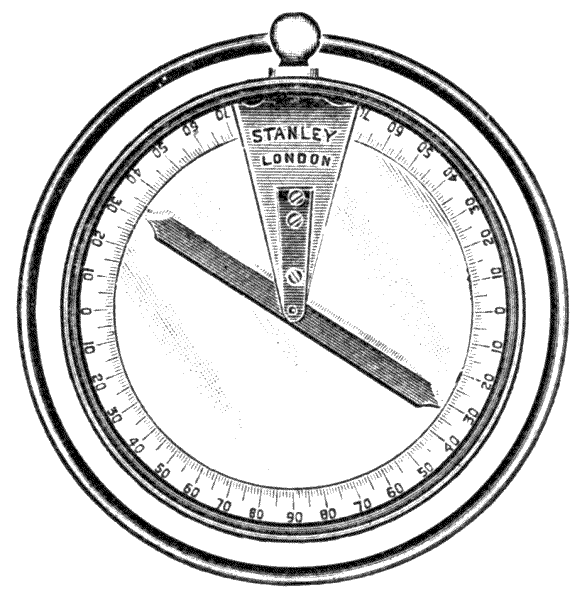

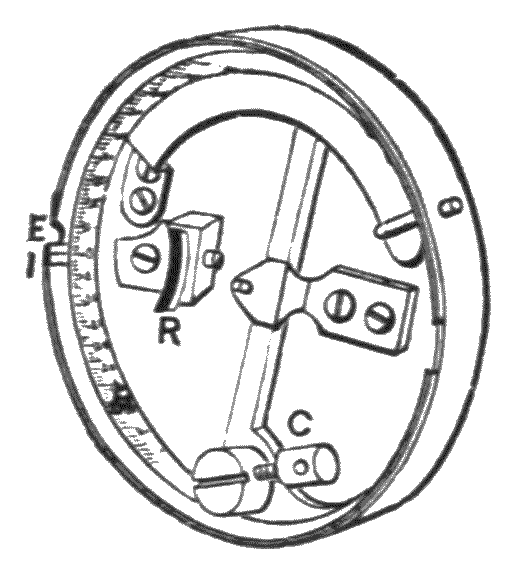

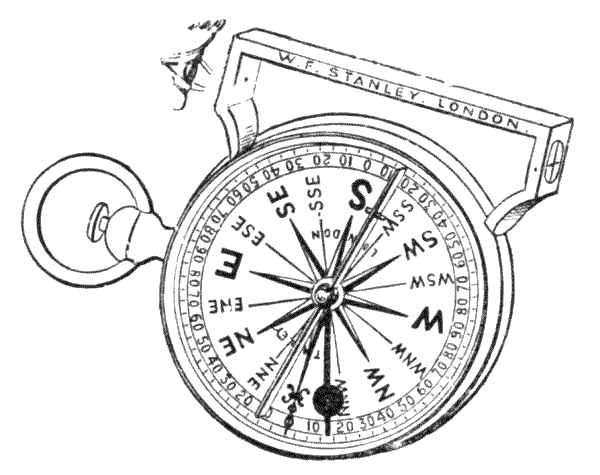

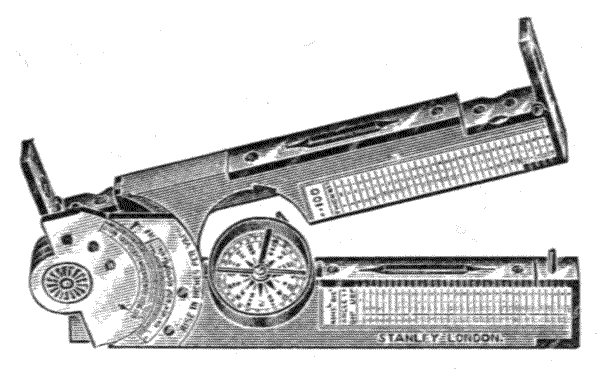

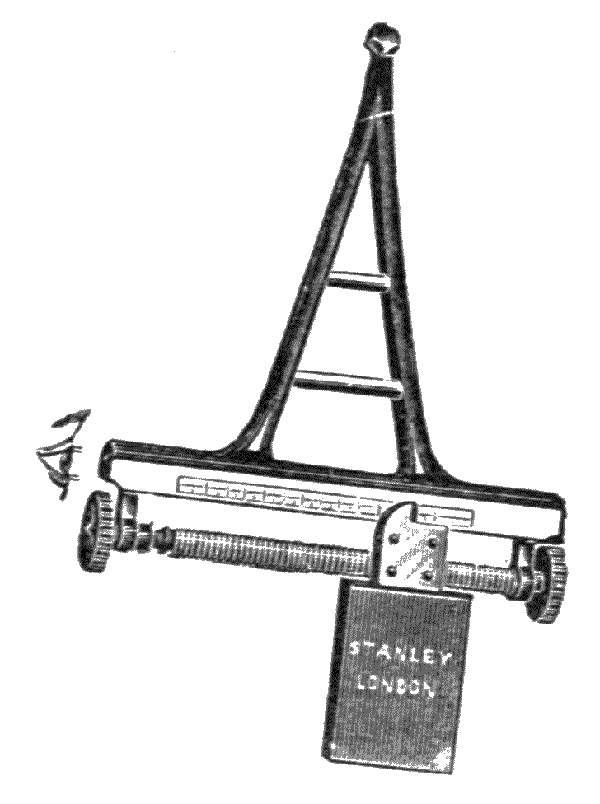

| The Magnetic Compass as a Part of a Surveying Instrument or Separately:—Broad and Edge-bar Needles—Manufacture of the Needle—Magnetisation—Suspension—Dip and Adjustment—Lifting—Inclination—Declination—Variation—Correction— Compass-Boxes—Description of Compasses—Ring Compasses—Trough Compasses—Prismatic Compasses—Stand—Surveying with Compass—Pocket Compasses | 59 |

| [xii] | |

| CHAPTER IV. | |

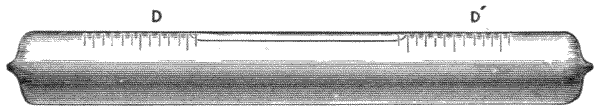

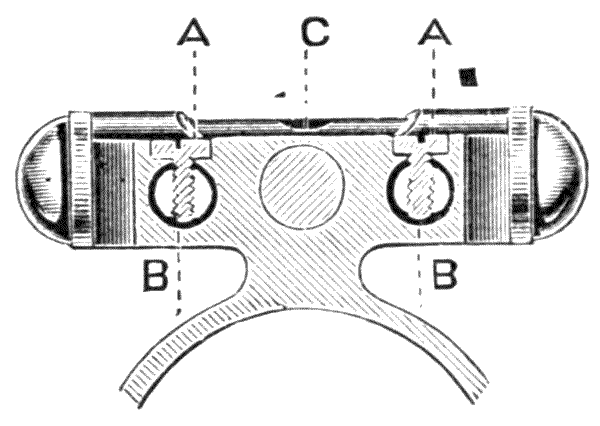

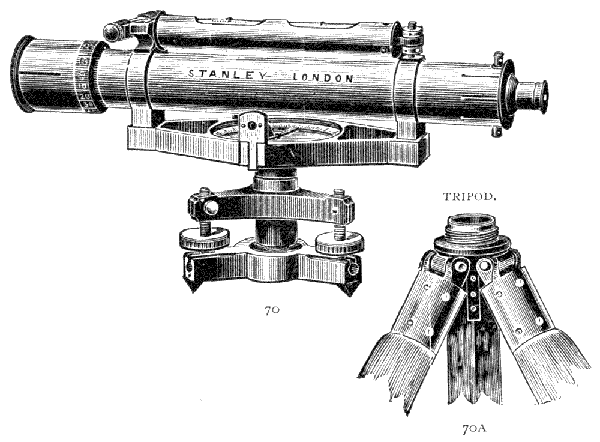

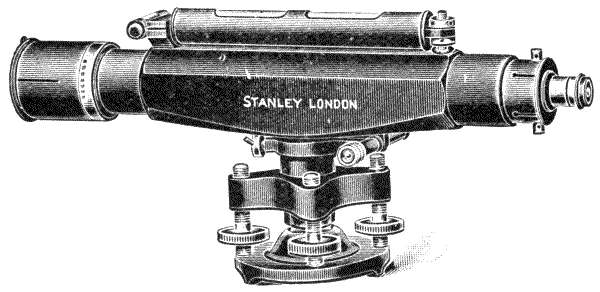

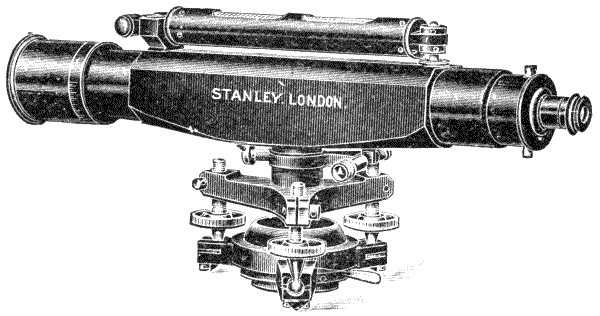

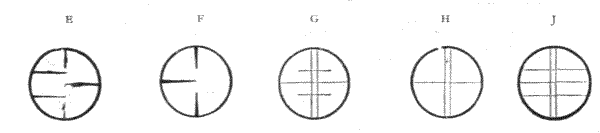

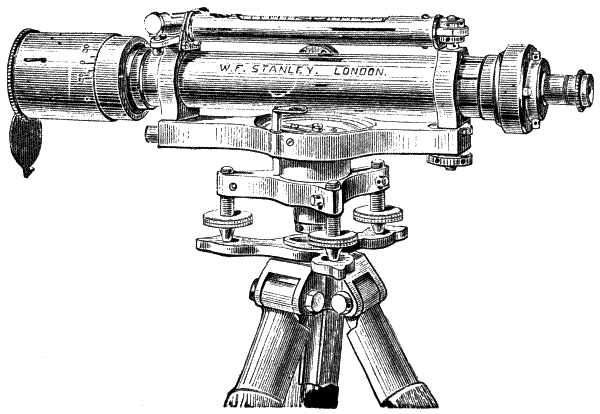

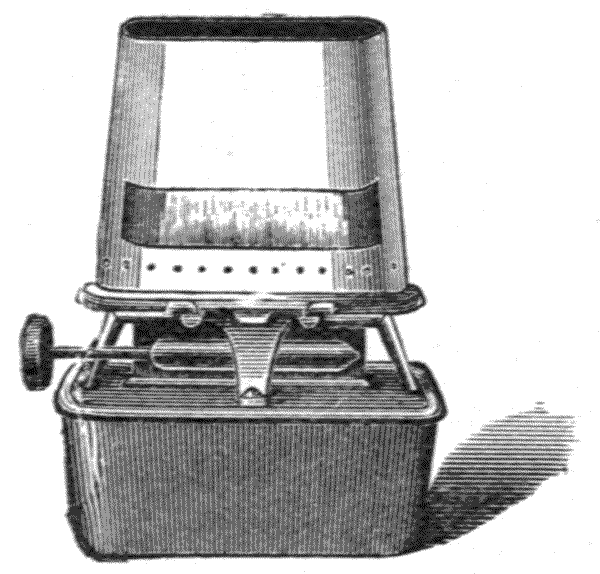

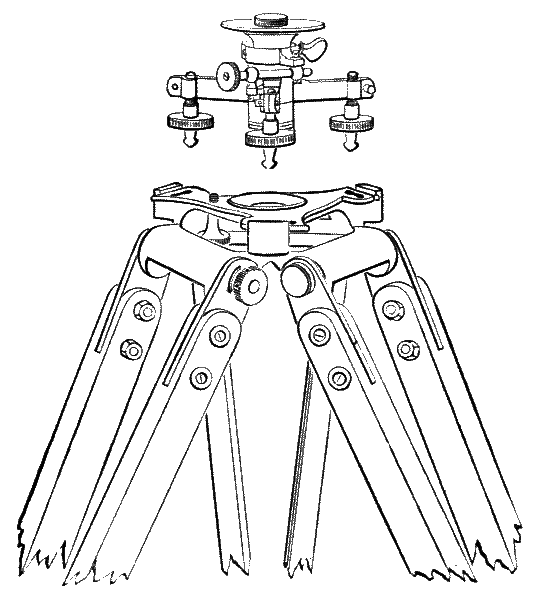

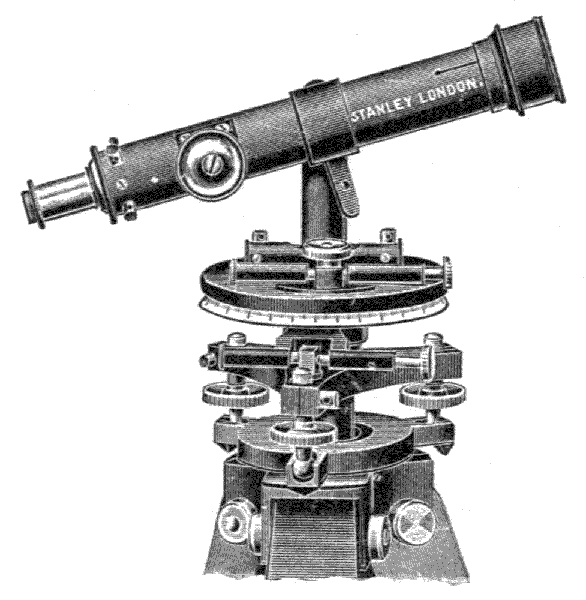

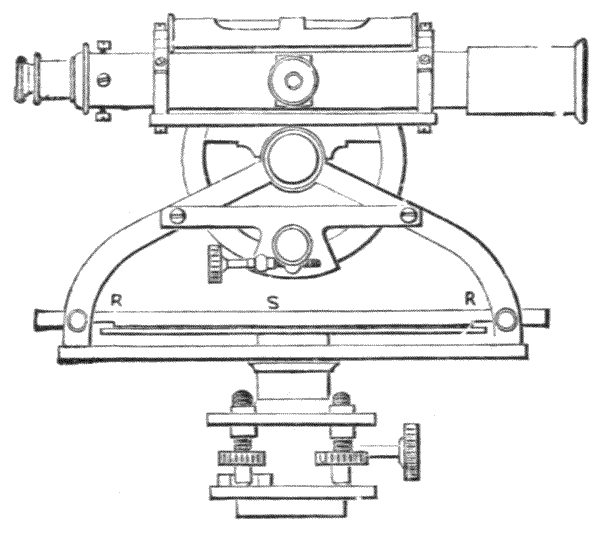

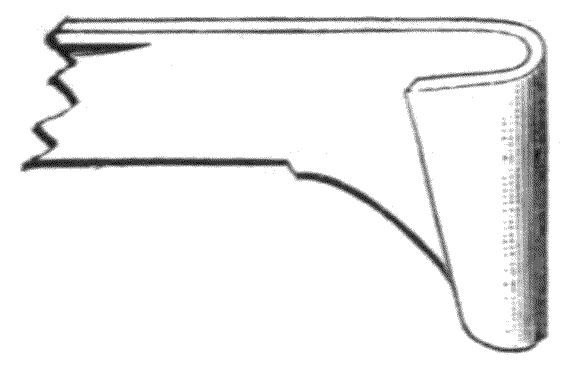

| Levels:—Methods of Ascertaining—Level Tubes—Manufacture—Curvature—Sensitiveness—Testing—Reading—Circular Levels—Surveyors' Levels—Y-Levels—Parallel Plates—Adjustments of Y-Levels—Suggested Improvements—Dumpy Levels—Tripod Stands—Adjustment of Dumpy—Collimator—Improvements in Dumpy Levels—Tribrach Head—Diaphragms—Cushing's Levels—Cooke's Levels—Cheap Forms of Level—Hand Levels—Reflecting Levels—Water Levels | 85 |

| CHAPTER V. | |

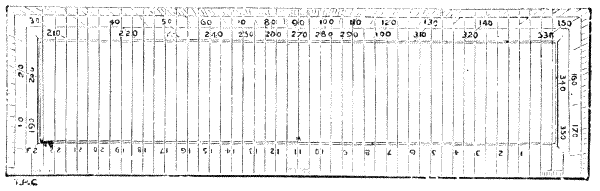

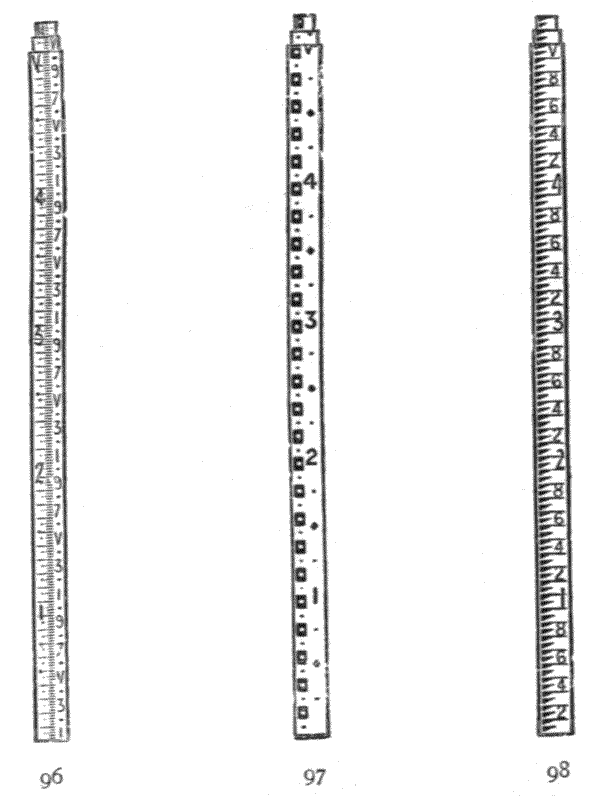

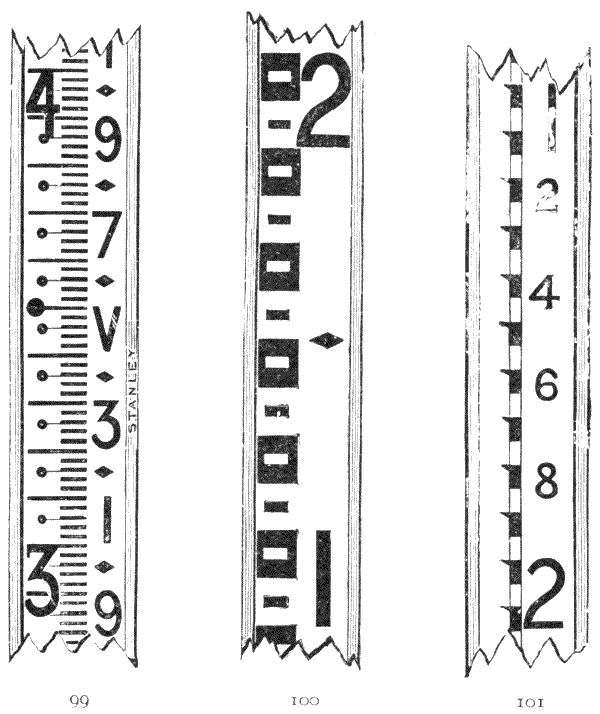

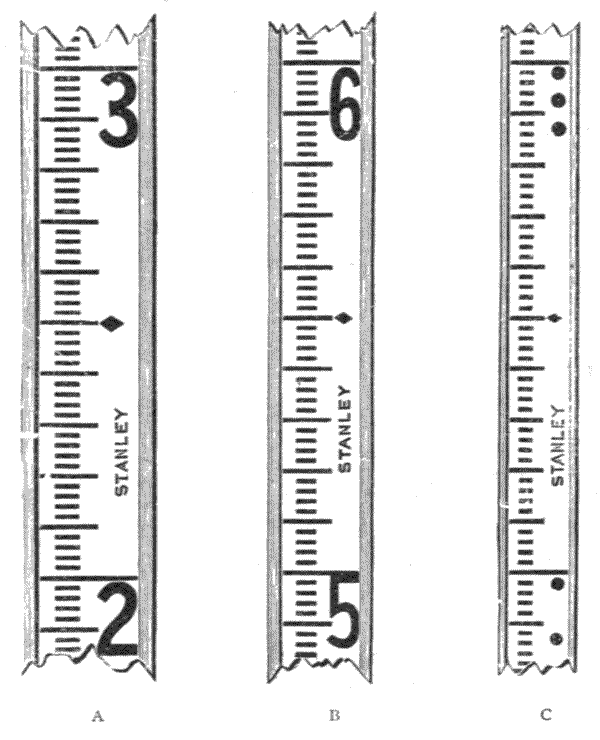

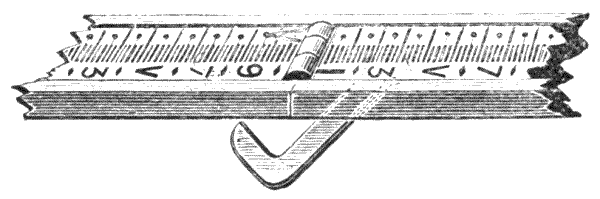

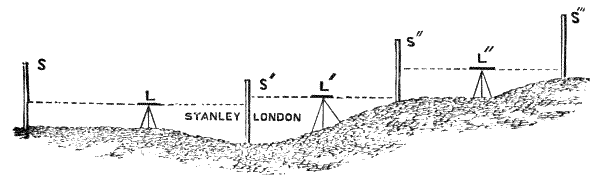

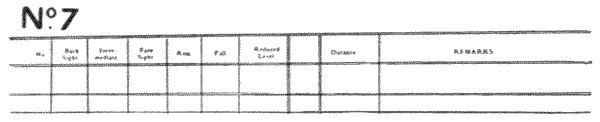

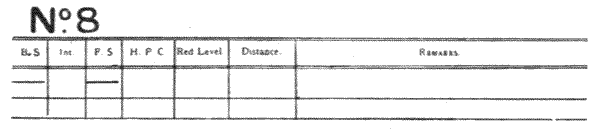

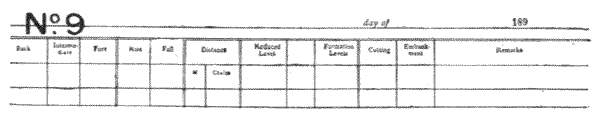

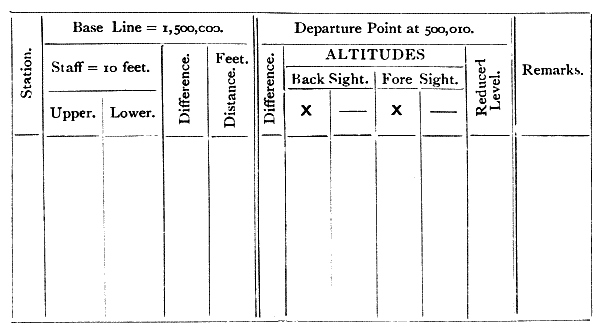

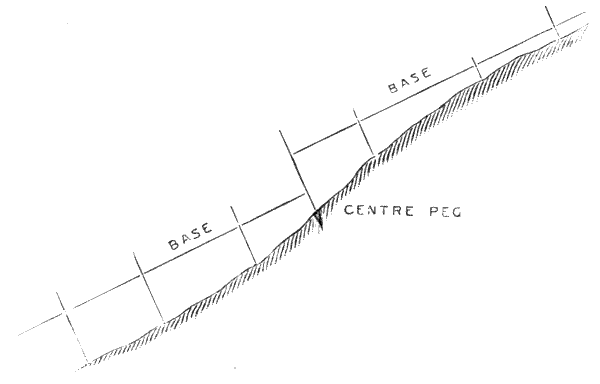

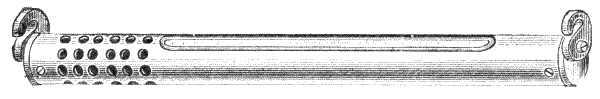

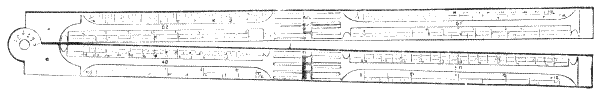

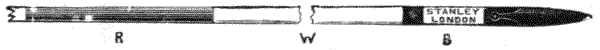

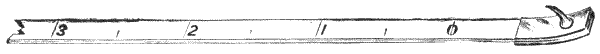

| Levelling Staves:—Construction—Various Readings Discussed—Sopwith's—Field's—Strange's—Stanley's New Metrical— Simple Construction—Mining Staff—Papering Levelling Staves—Preservation—Packing Pads—Staff Plate—Staff Level— Practice of Levelling—Index of Bubble—Lamp—Curvature Corrections—Station Pegs—Refinement of Levelling—Levelling Books | 148 |

| CHAPTER VI. | |

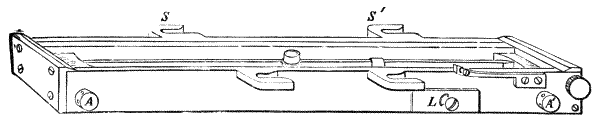

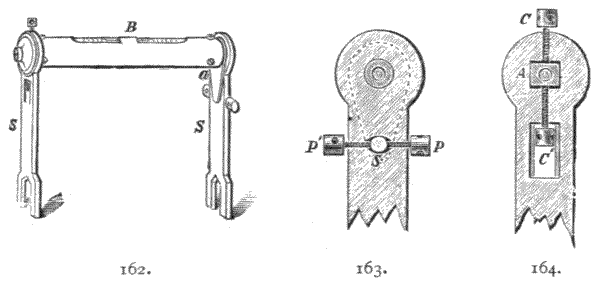

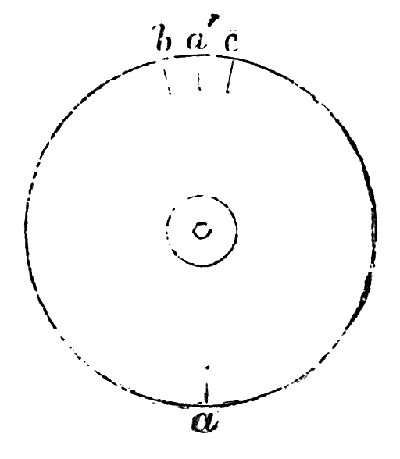

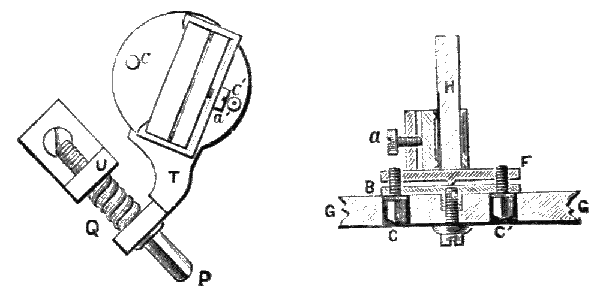

| Division of the Circle and Methods Employed in Taking Angles:—Dividing Engine—Surfaces for Graduation—Vernier—Various Sections—Reading Microscopes—Shades—Micrometers—Clamp and Tangent Motions—of Limbs— of Axes—Use and Wear—Difference of Hypotenuse and Base | 175 |

| CHAPTER VII. | |

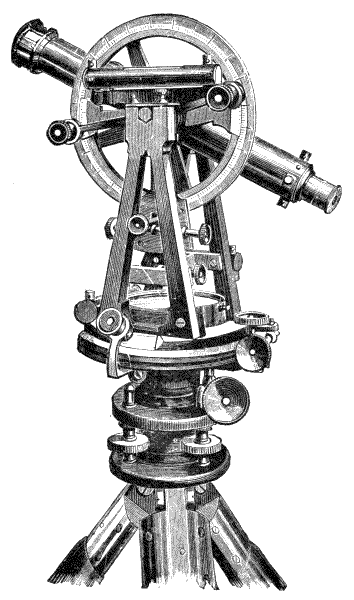

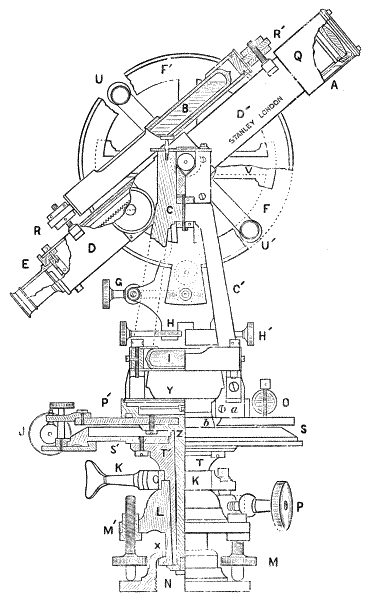

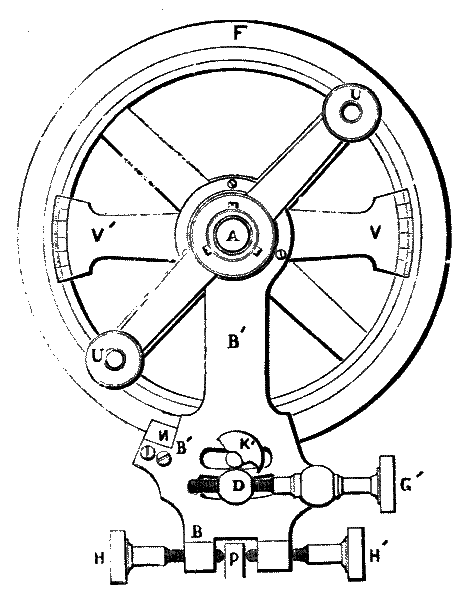

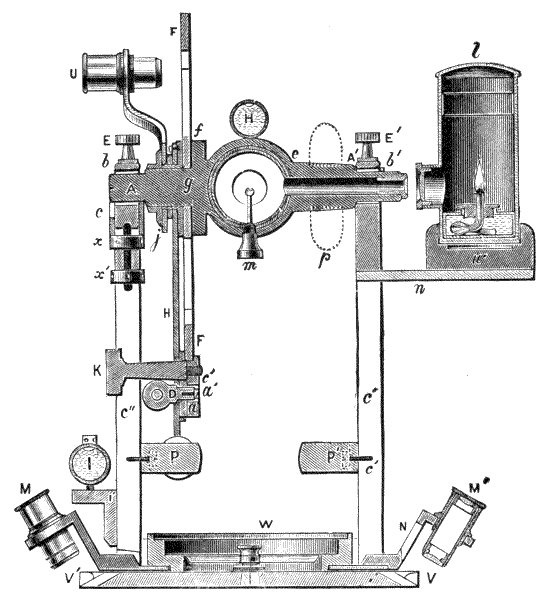

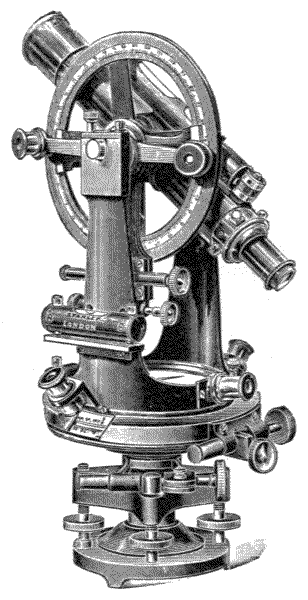

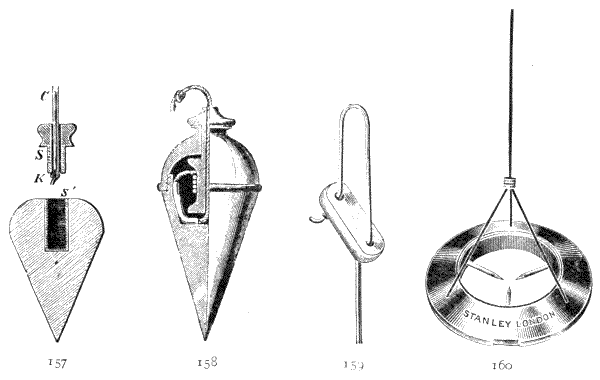

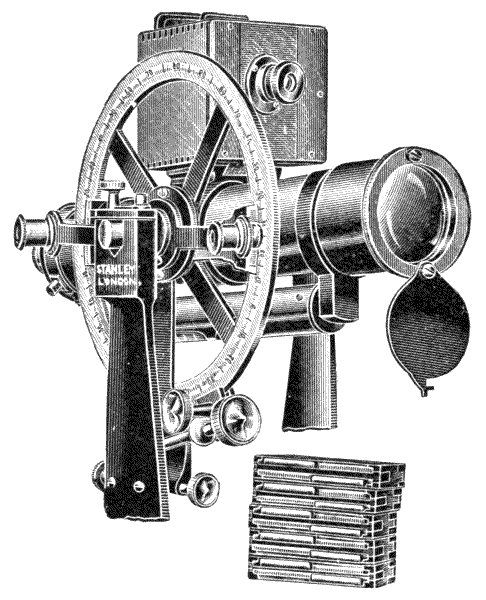

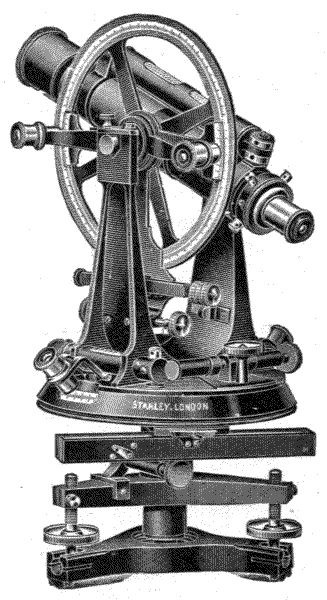

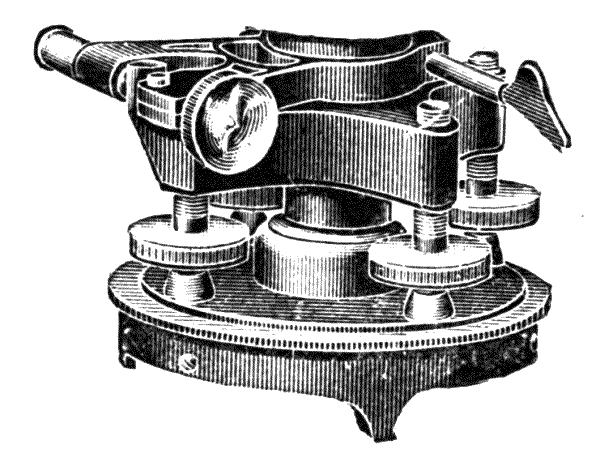

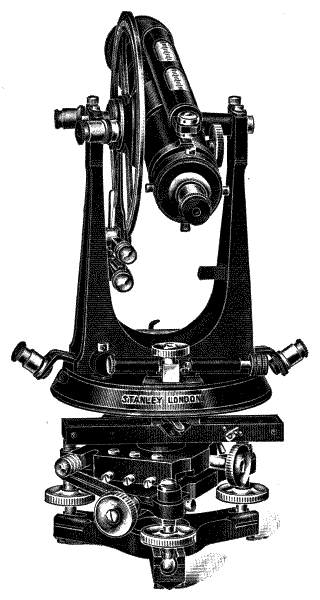

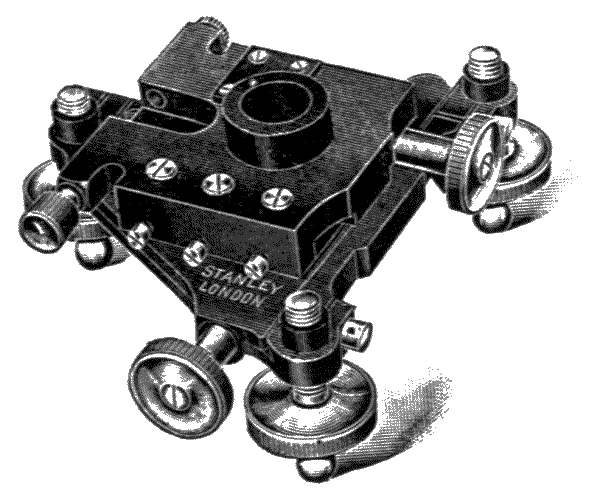

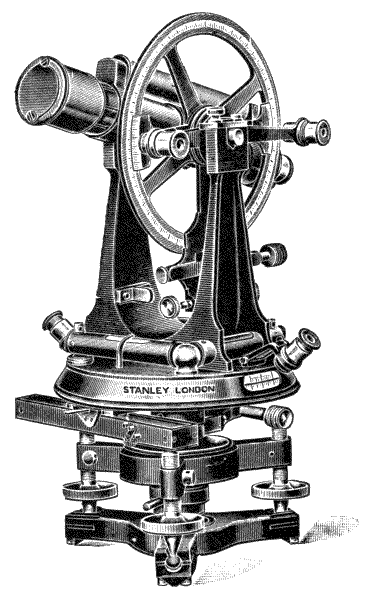

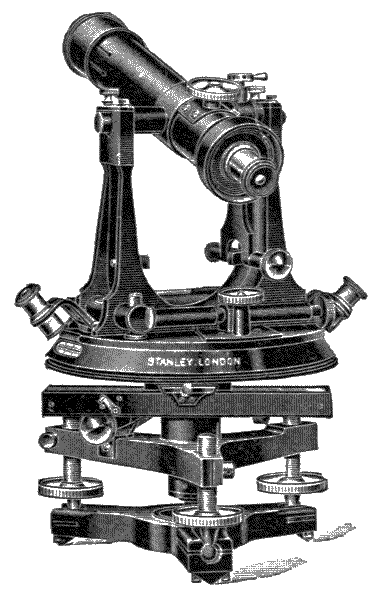

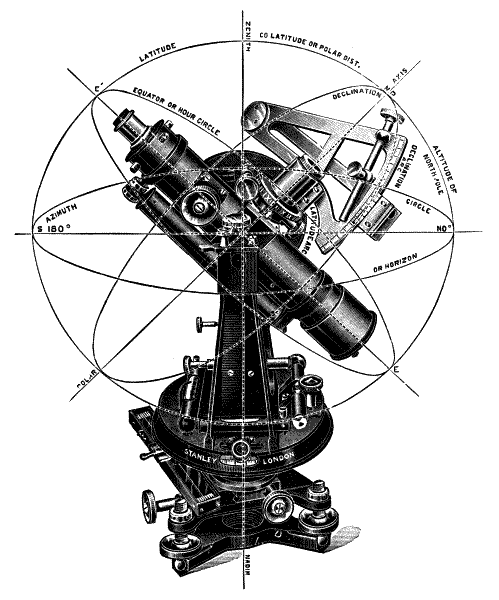

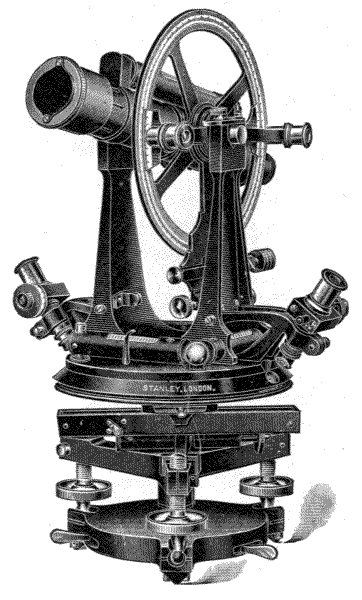

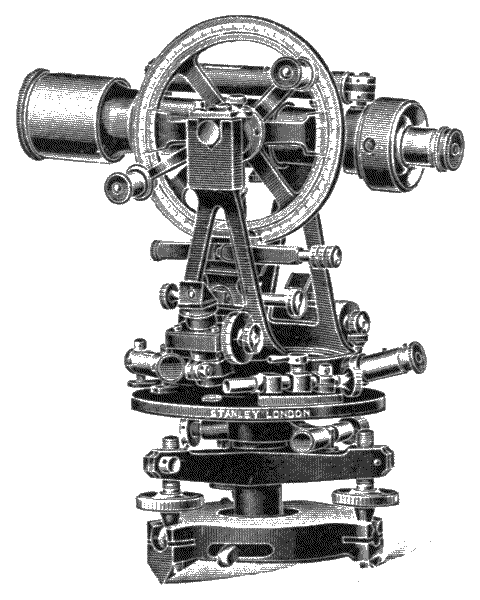

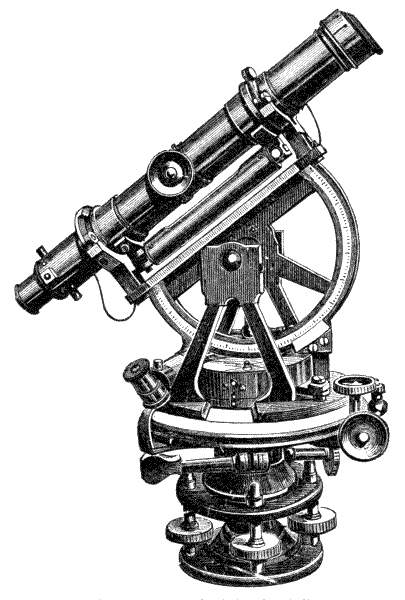

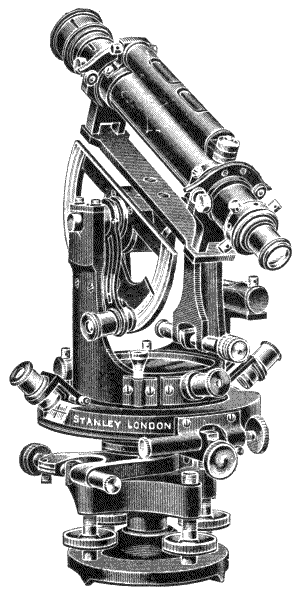

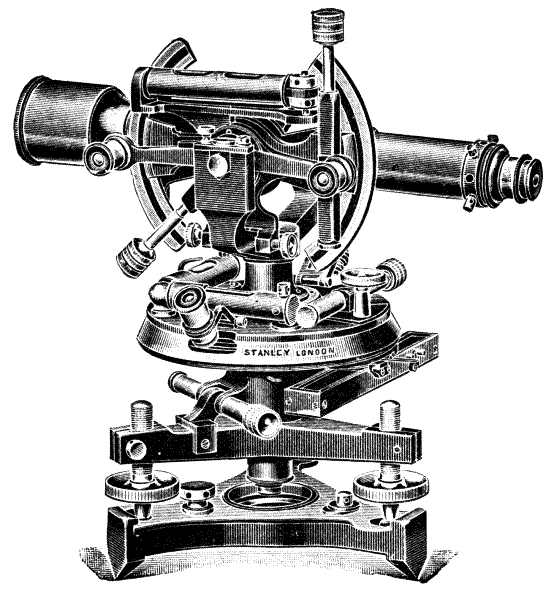

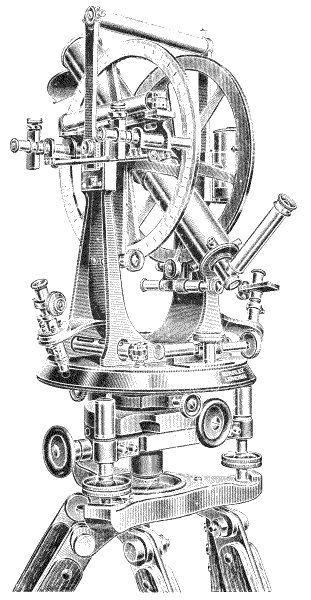

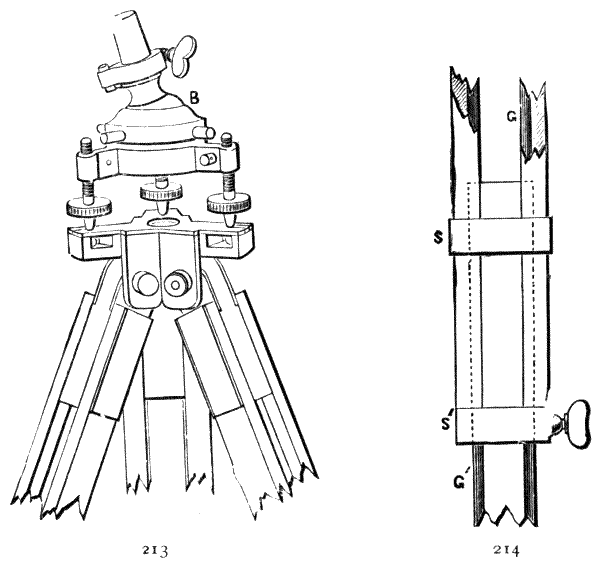

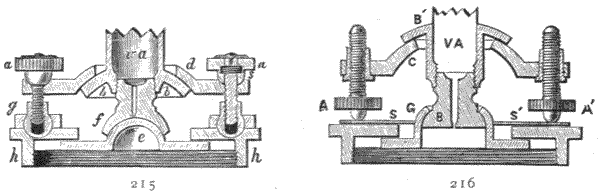

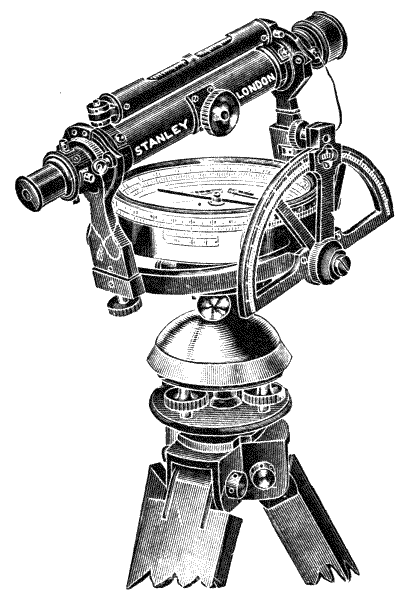

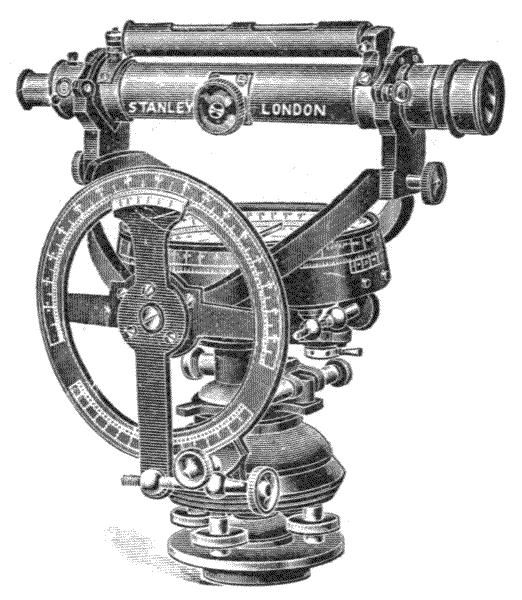

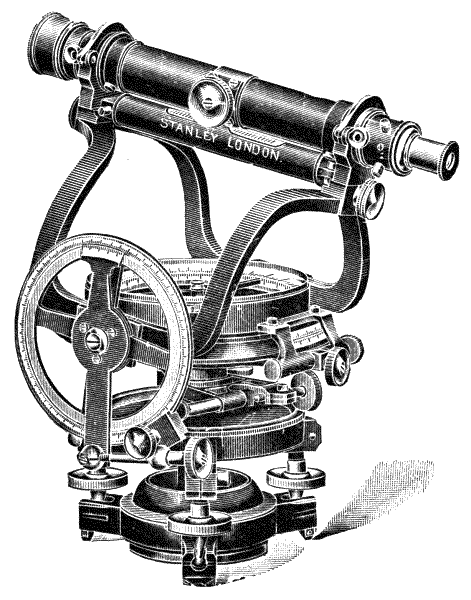

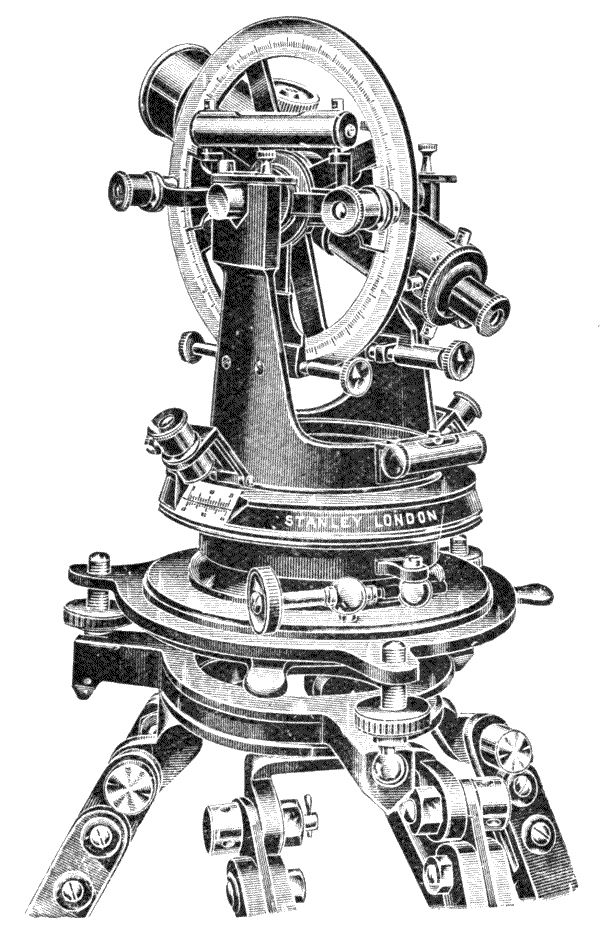

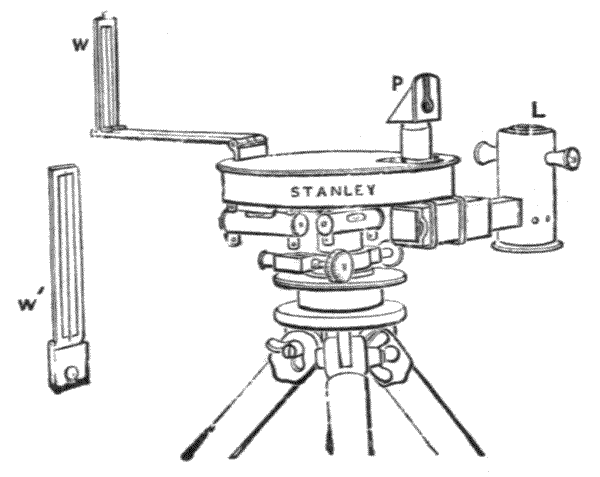

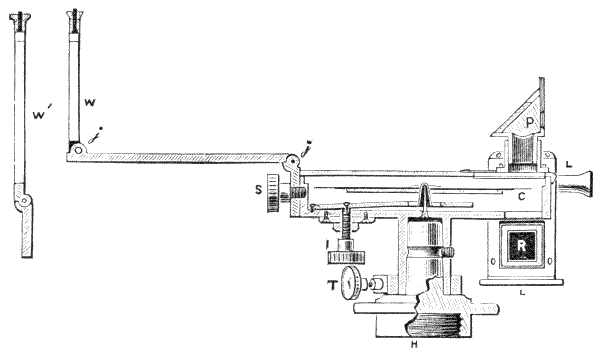

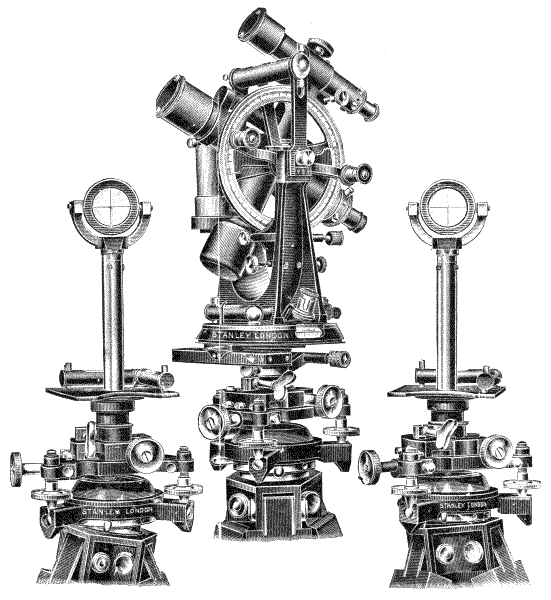

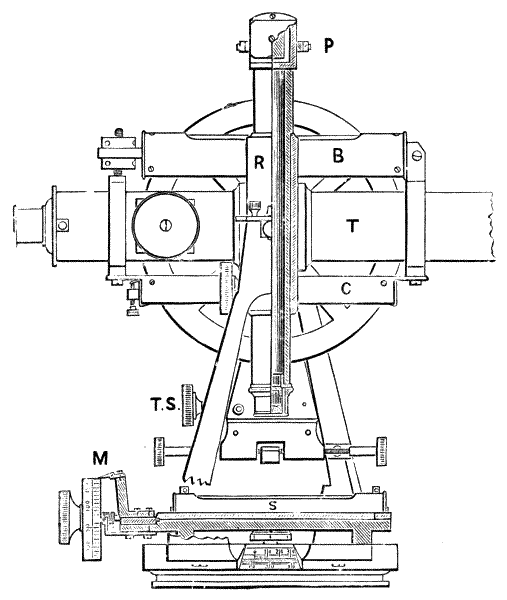

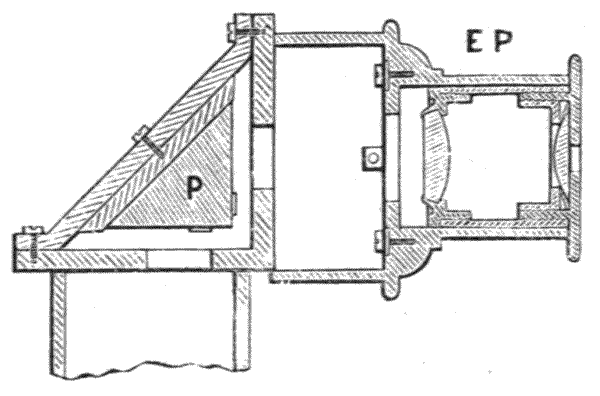

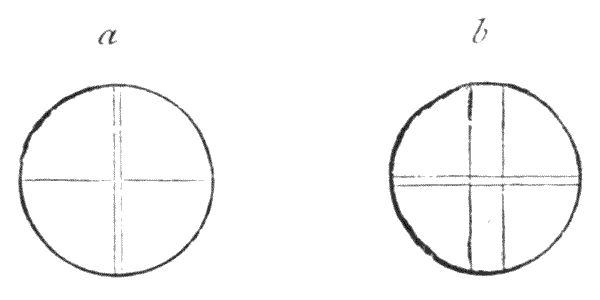

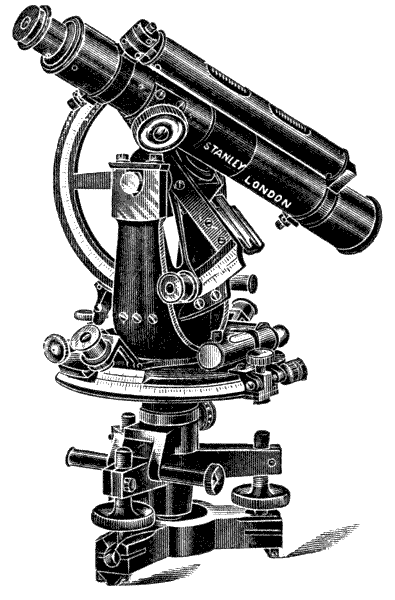

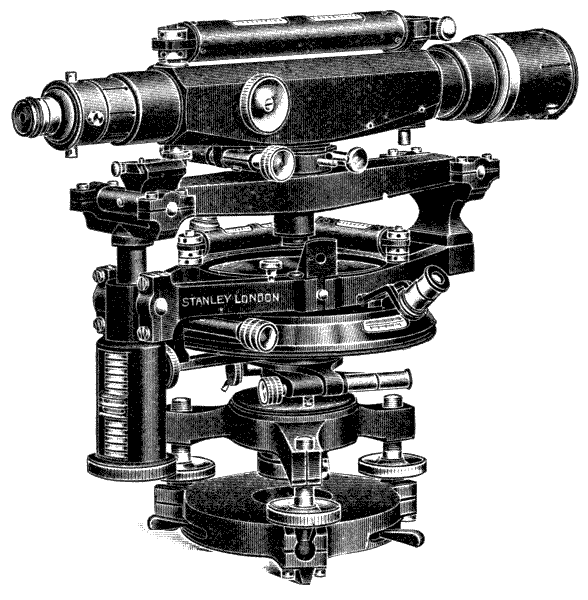

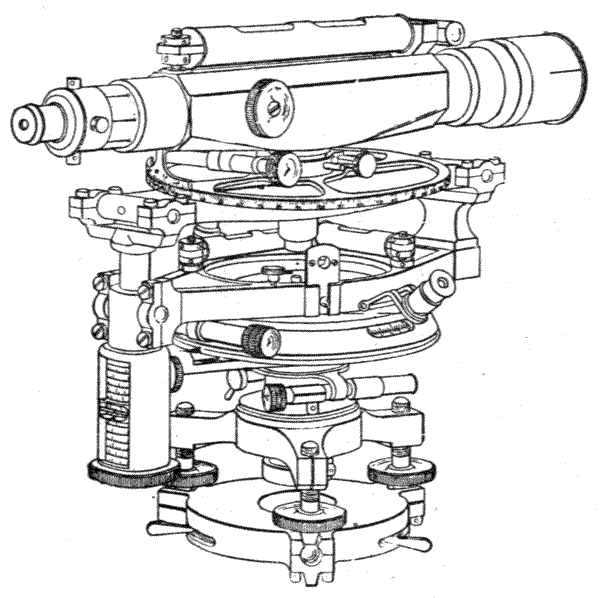

| Theodolites:—Constructive Details of 5-inch and 6-inch Transits—Special Additional Parts—Old Form with Four Screws—Improved Form—Additional Parts—Plummets—Striding Level—Lamp—Adjustments over a Point—Solar Attachment—Photographic Attachment | 214 |

| CHAPTER VIII. | |

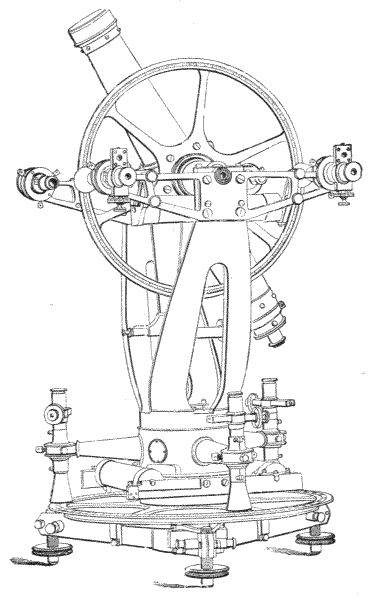

| Specialties in Modern Forms of Transit:—Theodolites for General Surveying—Railway Work—Exploring | 246 |

| [xiii] | |

| CHAPTER IX. | |

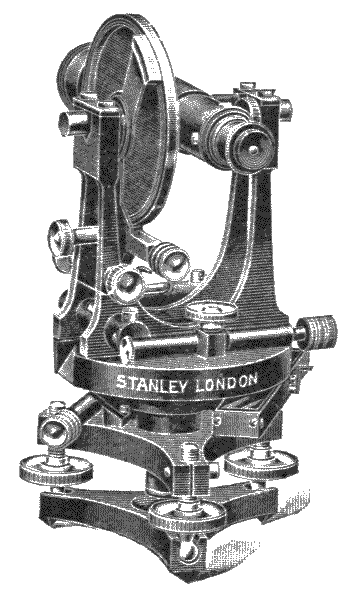

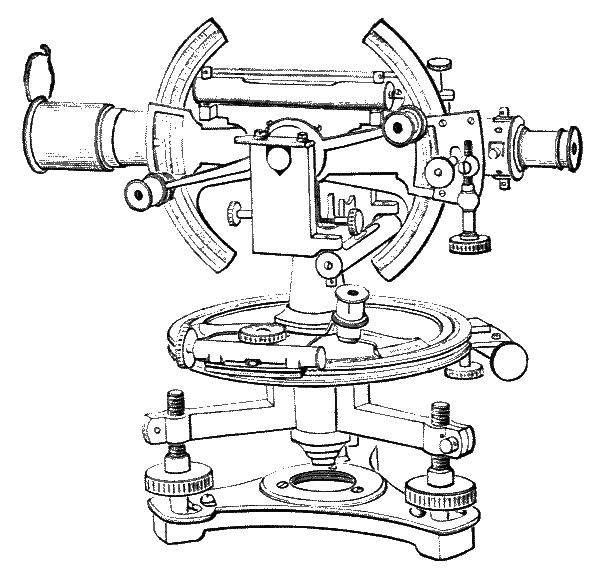

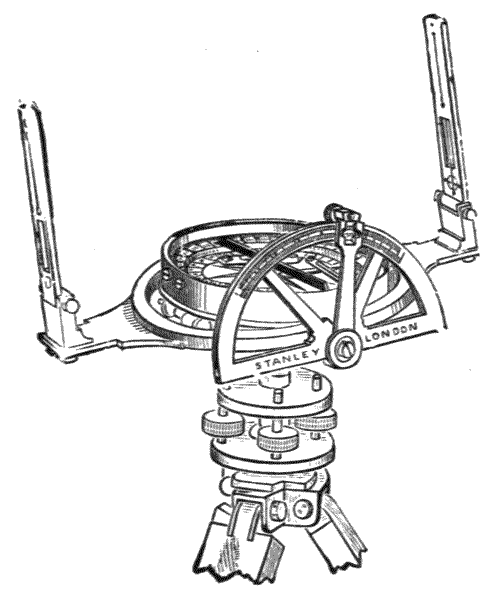

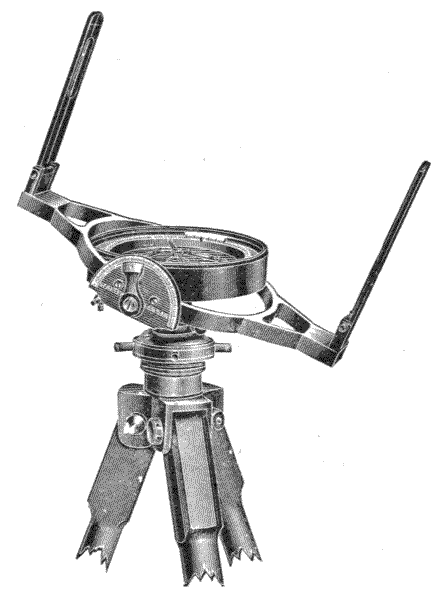

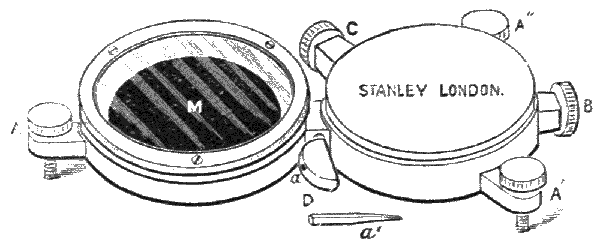

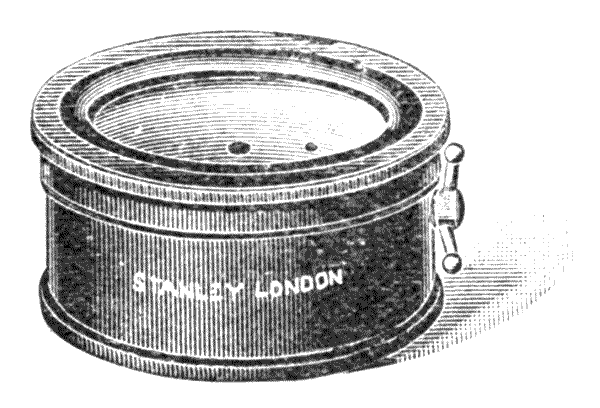

| Plain Theodolites in which the Transit Principle is not Employed:—The Plain Theodolite—Improved Construction—Everest's Simple—Adjustments and Examination of Theodolites | 267 |

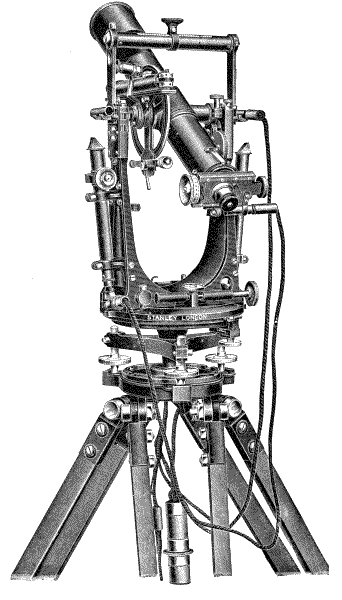

| CHAPTER X. | |

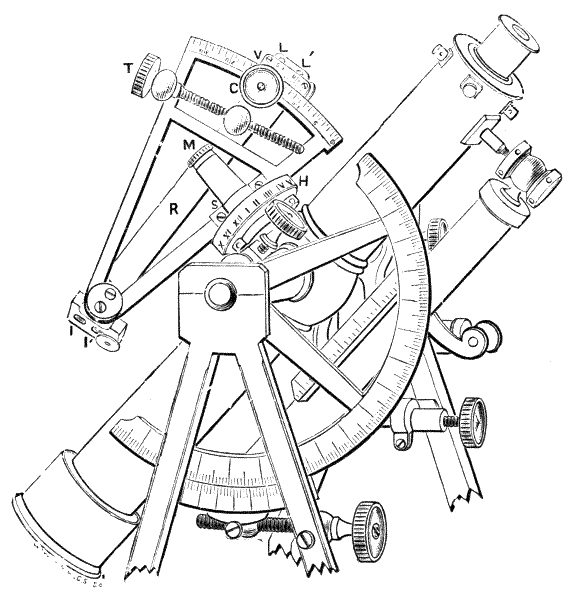

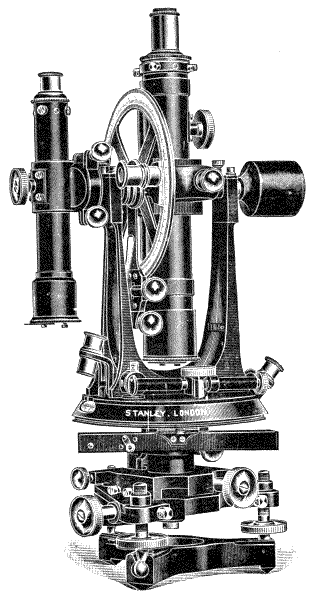

| Large Theodolites used only for Geodetic Surveys:—Stanley's 10- and 12-inch—14-inch Altazimuth—Col. Strange's 36-inch Theodolite | 293 |

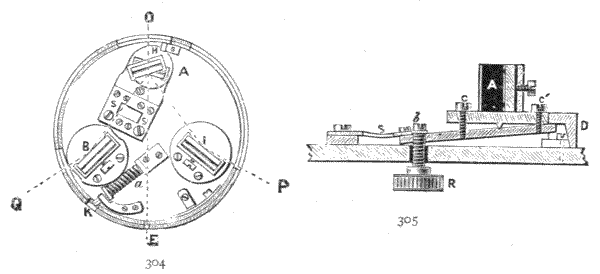

| CHAPTER XI. | |

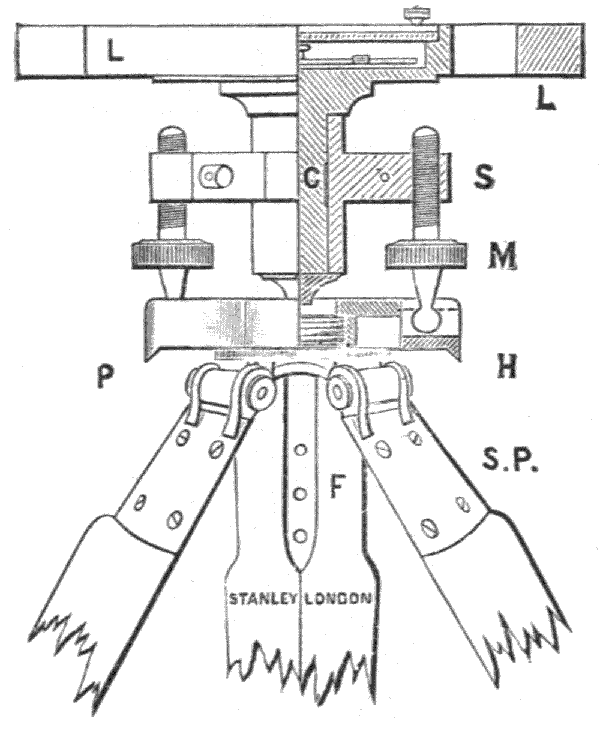

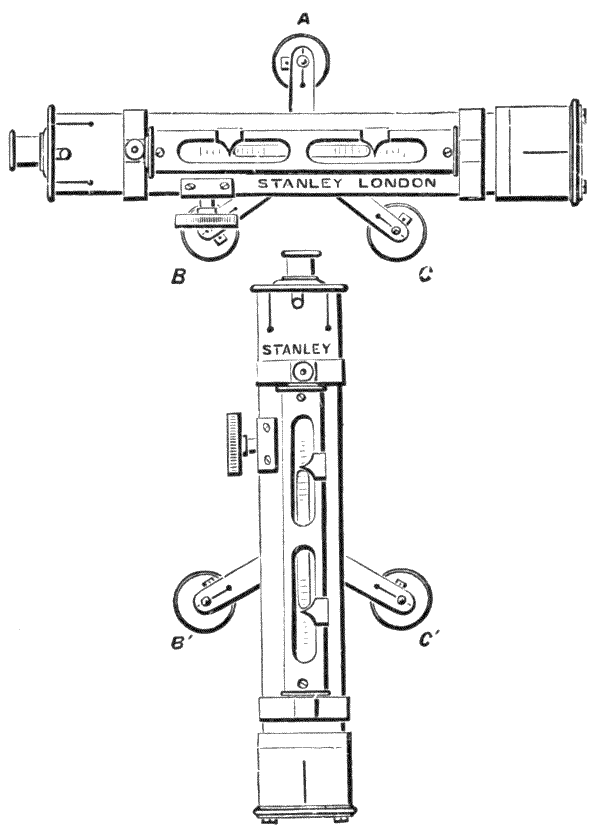

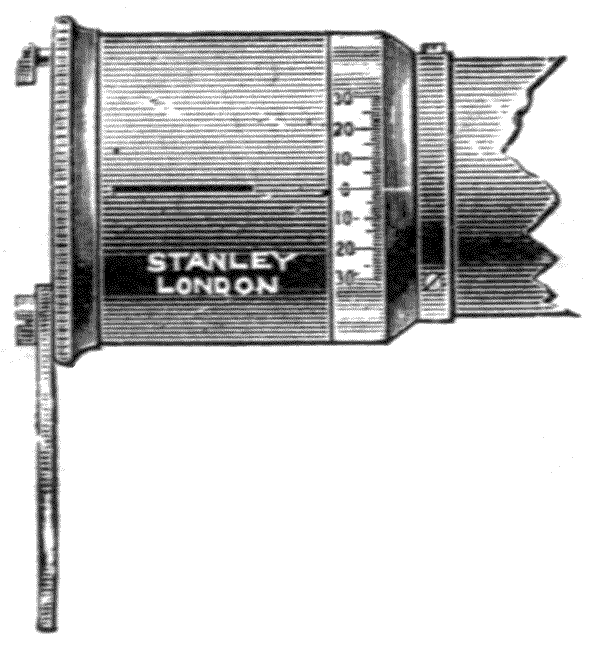

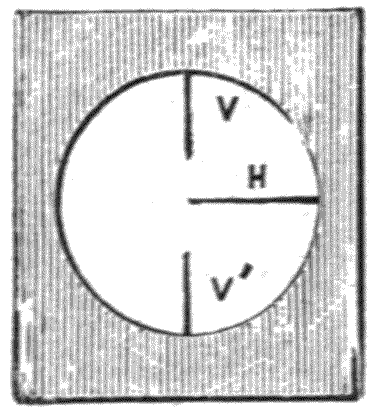

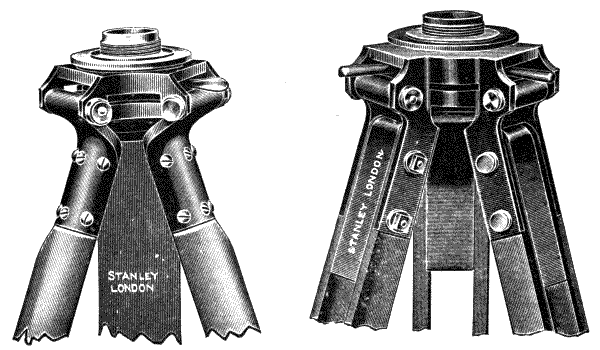

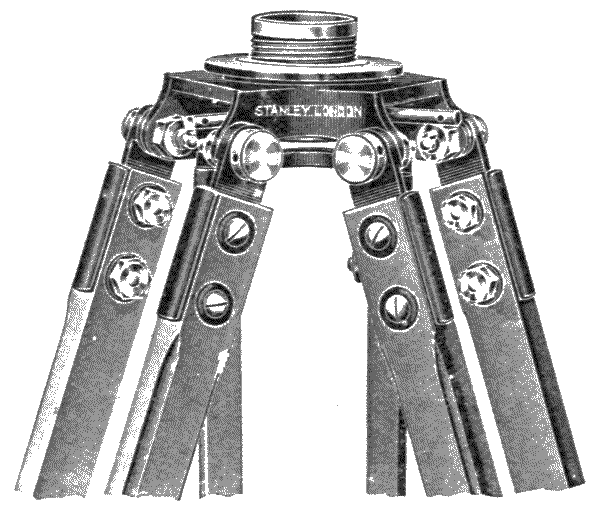

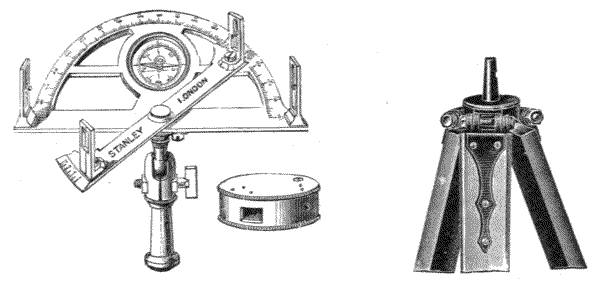

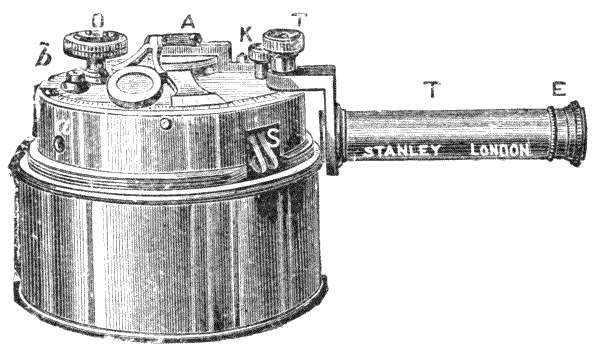

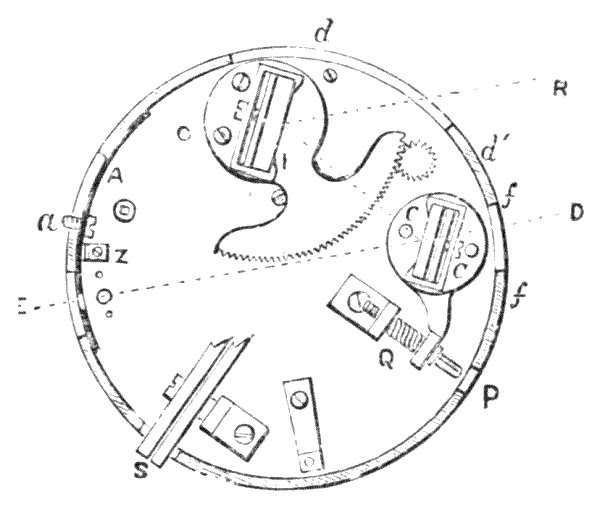

| Mining Survey Instruments:—Circumferentors—Plain Miner's Dial—Sights—Tripod Stand—Adjustments—Henderson's Dial—Lean's Dial—Adjustments— Hedley's Dials—Additional Telescope—Improved Hedley—Tribrach and Ball Adjustment—Reflectors—Continental Forms—Théodolite Souterrain— Tripod Tables—Stanley's Mining Theodolite—Pastorelli's and Hoffmann's Adjustable Tripod Heads—Mining Transit Theodolites—Stanley's Prismatic Mining Compass—Hanging Dial—Hanging Clinometer—Semi-circumferentor—Mining Lamps | 307 |

| CHAPTER XII. | |

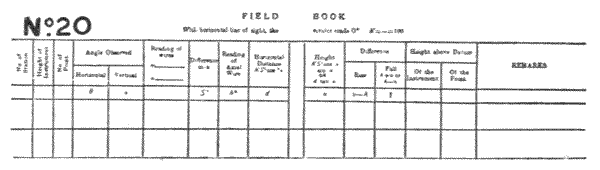

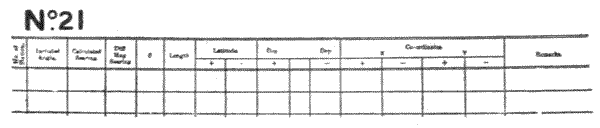

| Instruments to Measure Subtense or Tangential Angles to Ascertain Distances:—Historical Notes of the Method—Principles Involved—Stadia Measurements, Direct and by the Ordinary Telescope—Corrections for Refraction of the Object Glass—Stanley's Subtense Diaphragm—Anallatic Telescope of Porro—Tacheometers—Stadia—Omnimeter—Field book—Bakewell's Subtense Arrangement | 355 |

| CHAPTER XIII. | |

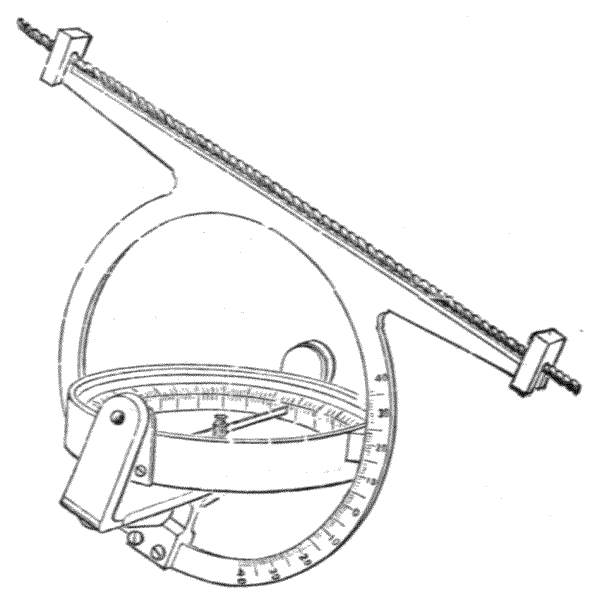

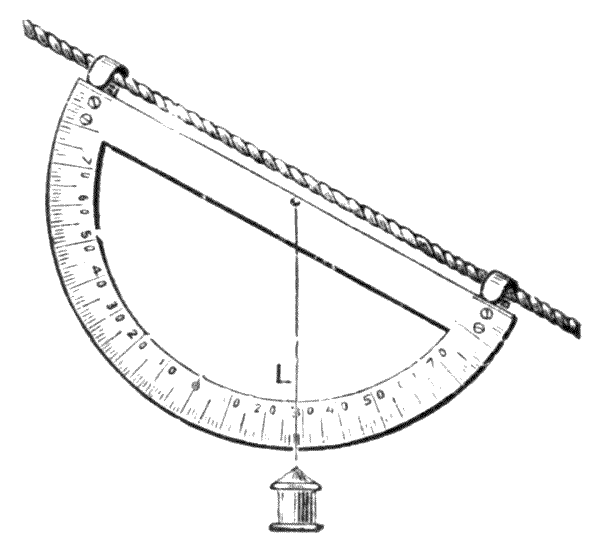

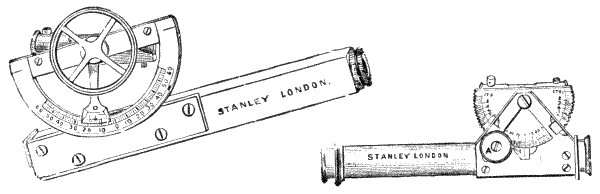

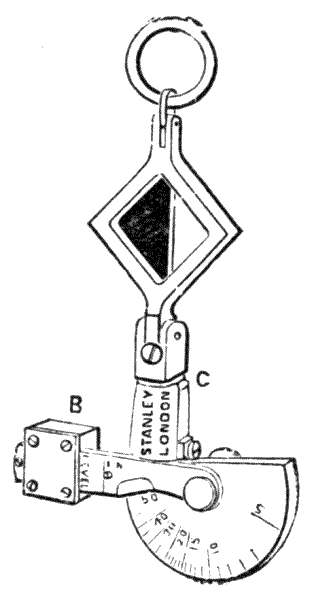

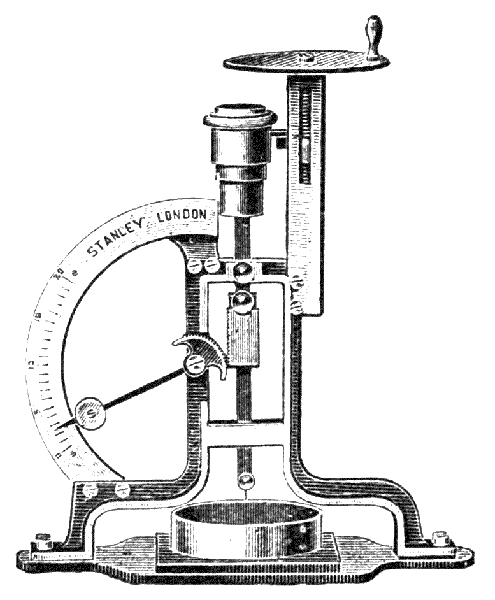

| Instruments Constructed Especially for Facility of Taking Inclinations:—Inclinometer Theodolite—Gradiometer—Clinometers: Abney's—Troughton's—De Lisle's—Stanley's—Barker's—Burnier's—Watkin's—Clinometer Sights—Rule Clinometer—Road Tracer | 389 |

| [xiv] | |

| CHAPTER XIV. | |

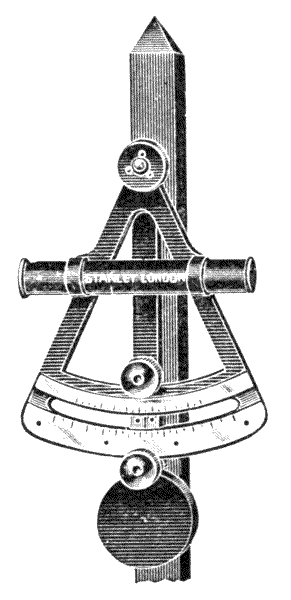

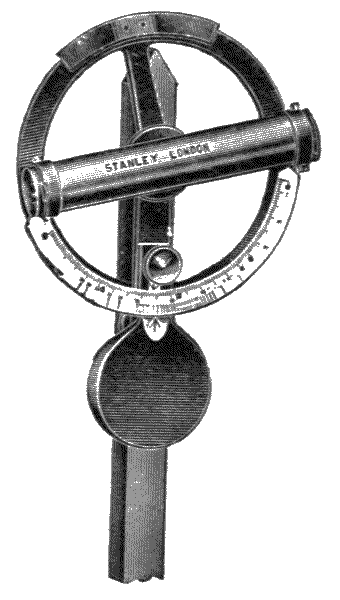

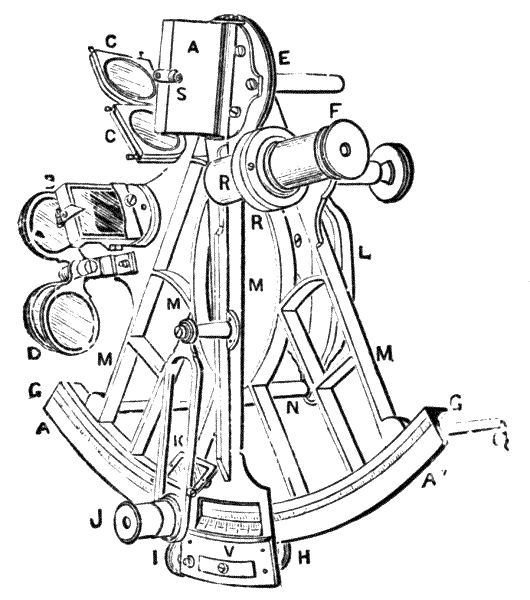

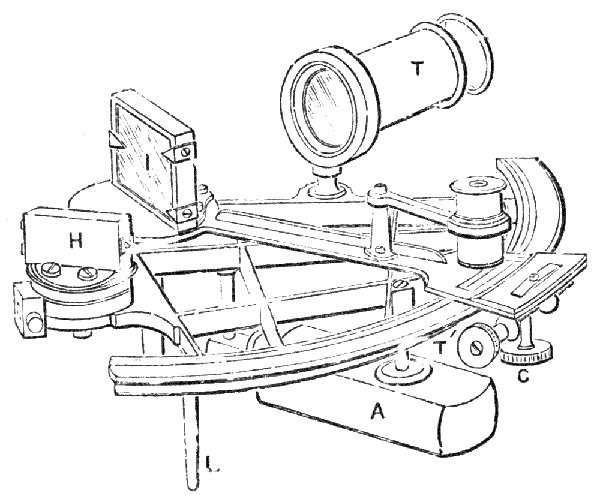

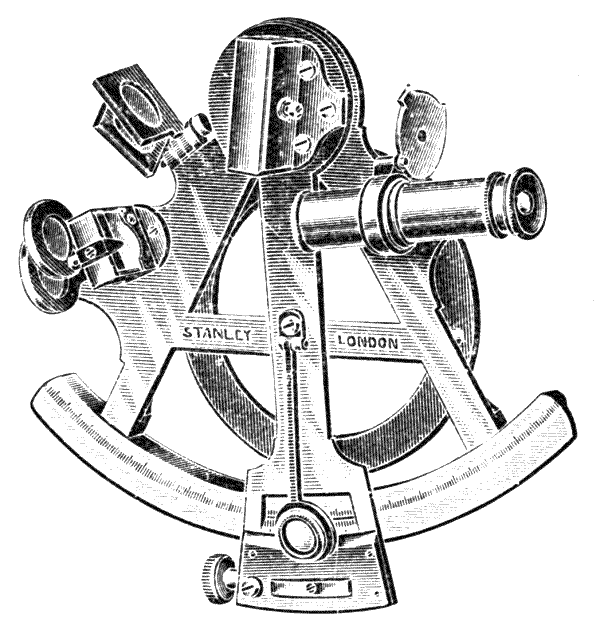

| Instruments of Reflection:—Octant or Quadrant—Reflecting Circle—Sextant—Principle—Parallax— Construction—Examination—Adjustment—Artificial Horizon—Sounding Sextant—Box-Sextant—Supplementary Arc—Improvements upon this—Optical Square—Optical Cross—Apomecometer | 422 |

| CHAPTER XV. | |

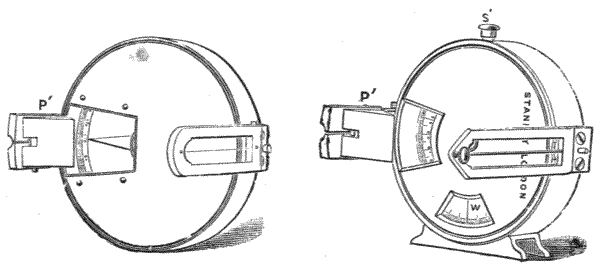

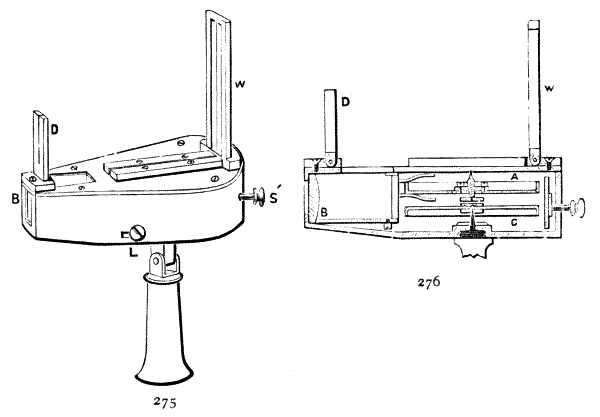

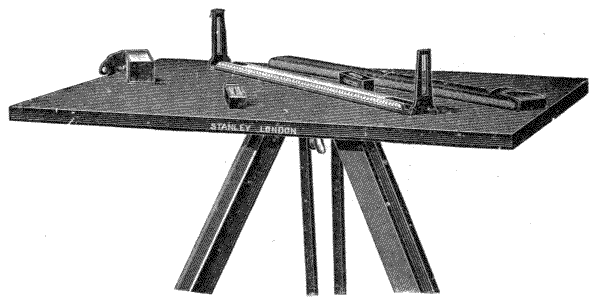

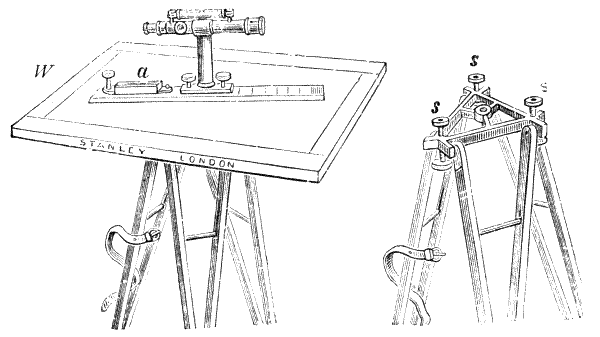

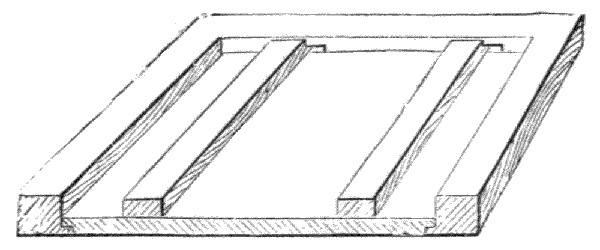

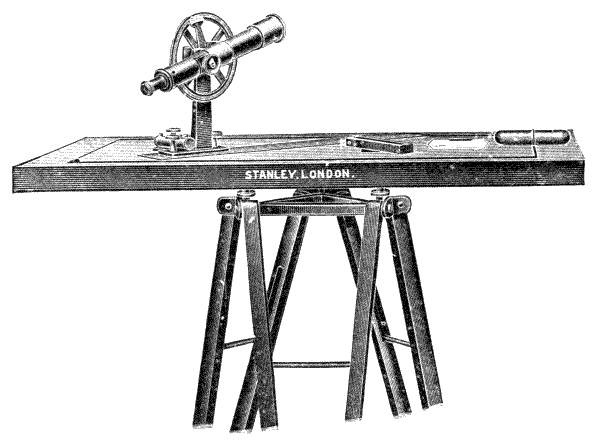

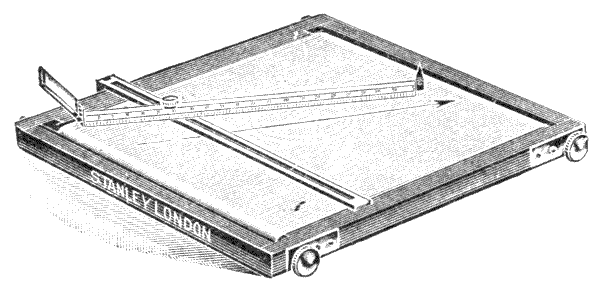

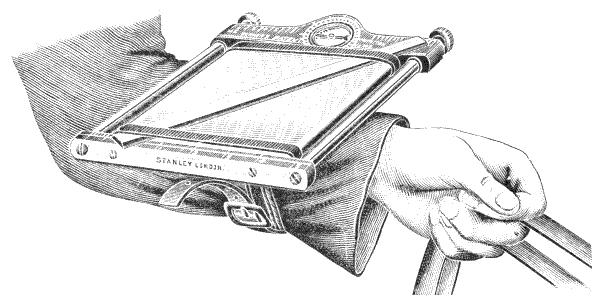

| Graphic Surveying Instruments and Appliances Connected therewith:—Plane Tables—Alidades—Telescopic Arrangements—Subtense Measurements—Various Devices for Holding the Paper—Continuous Papers—Adjustment of Tripod Heads—Method of Using—Edgeworth's Stadiometer—Sketching Protractor—Sketching Case—Camera Lucida, etc. | 472 |

| CHAPTER XVI. | |

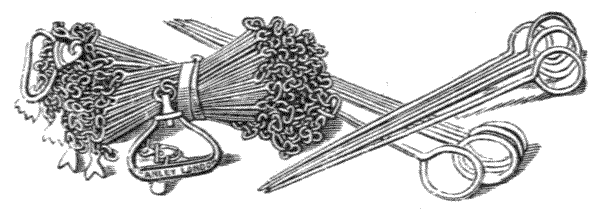

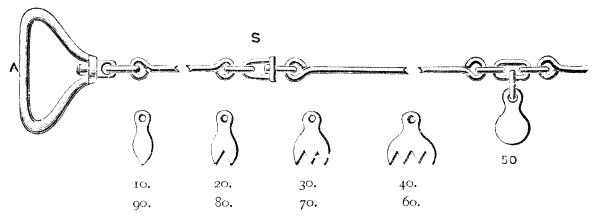

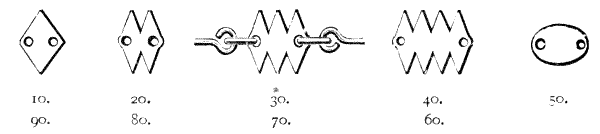

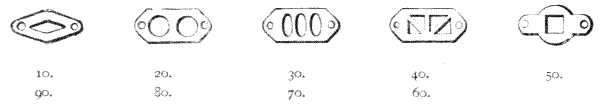

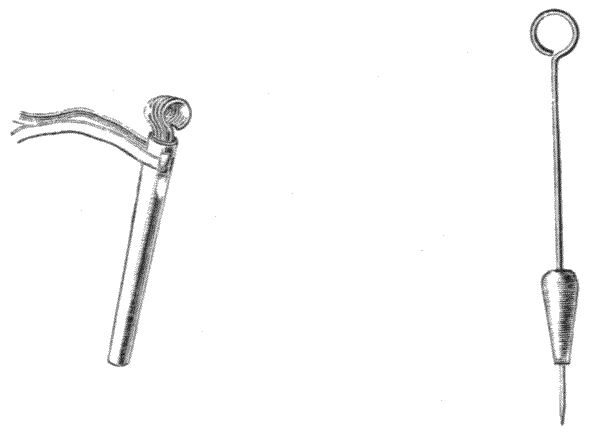

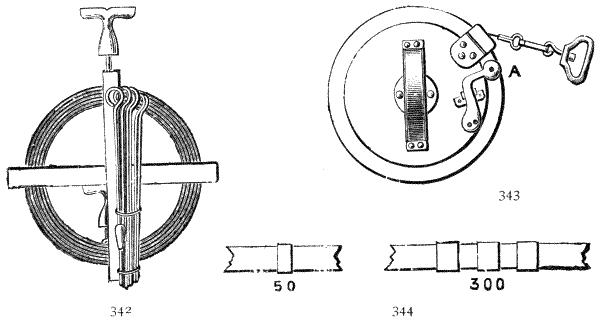

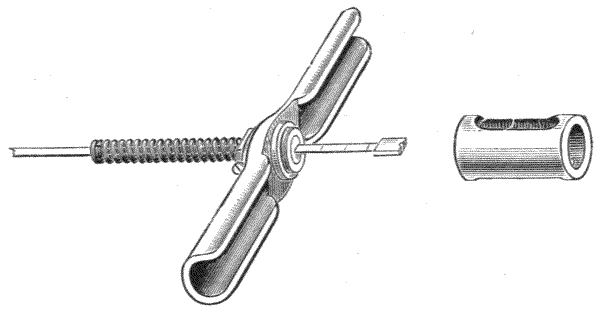

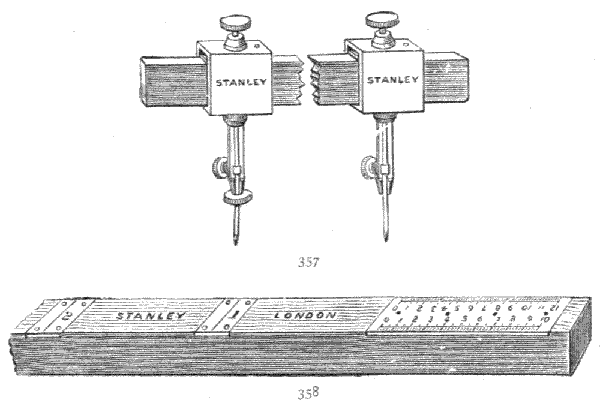

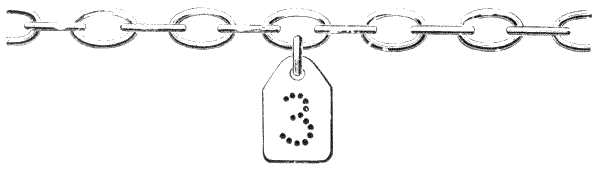

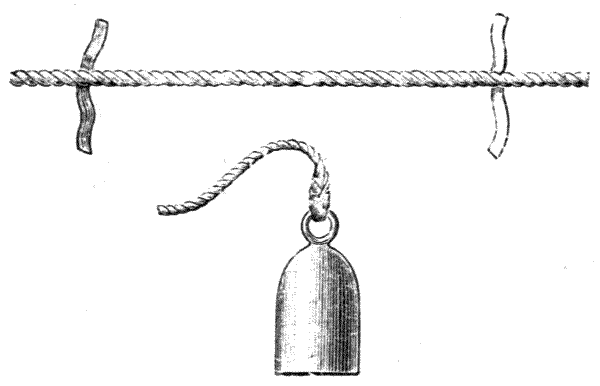

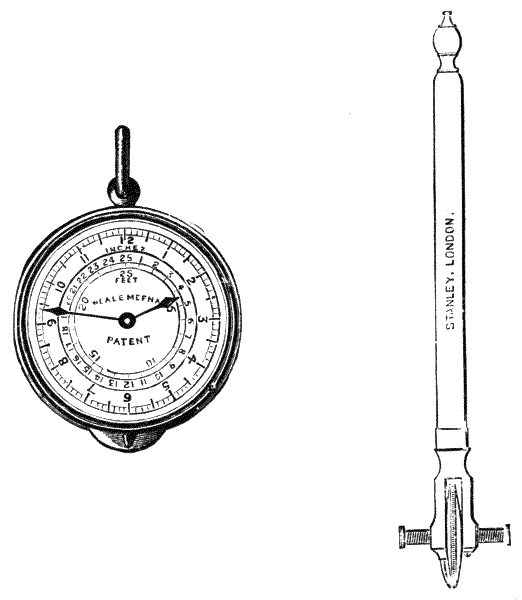

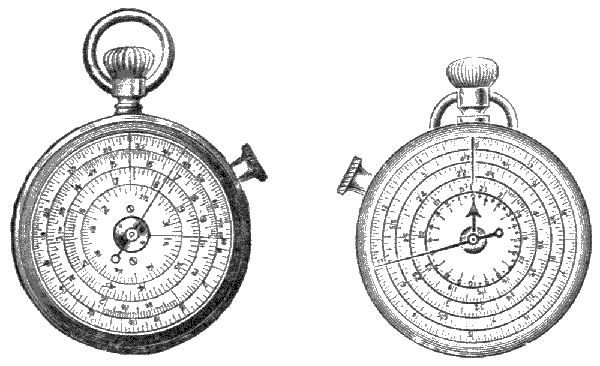

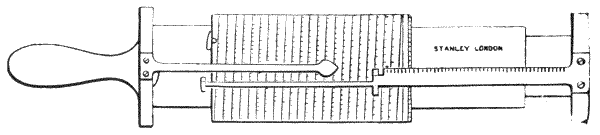

| Instruments for Measuring Land and Civil Works Directly:—Chains—Various Tellers—Standard Chains—Arrows—Drop Arrows—Vice for Adjusting Chain—Caink's Rule for Inclines—Steel Bands—Wire Land Measures—Linen Tapes—Offset Rods—Pine Standard Rods—Rods with Iron Core—Beam Compass Rods—Coincidence Measurements—Compensated Rods—Base Line Apparatus—Coast Survey Lines—Perambulator—Pedometer—Passometer—Sounding Chains—Sounding Lines—Telemeters—Hand Rods—Rules | 490 |

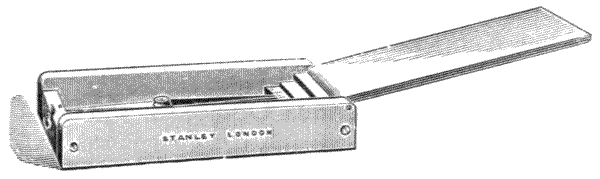

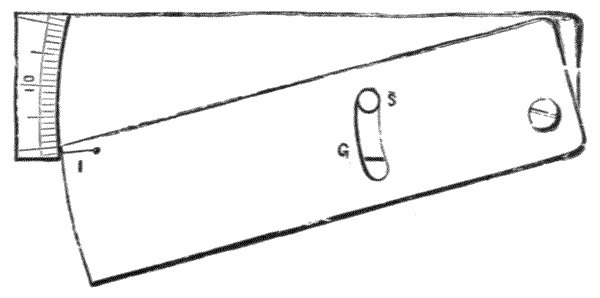

| CHAPTER XVII. | |

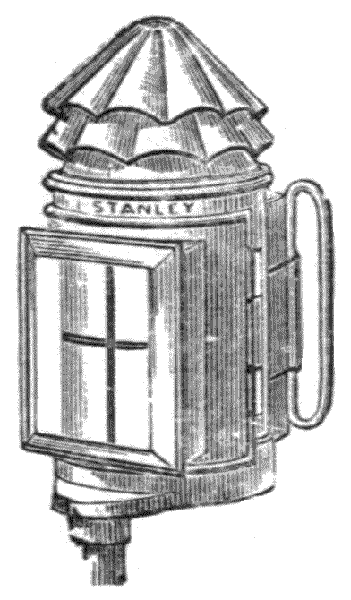

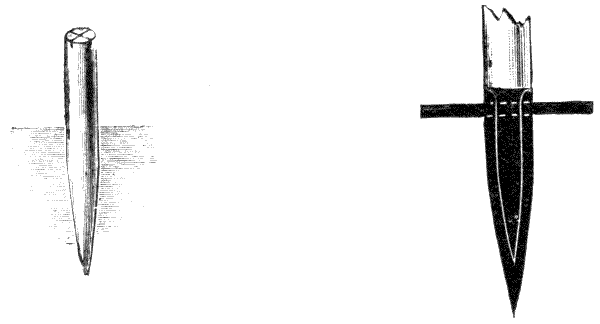

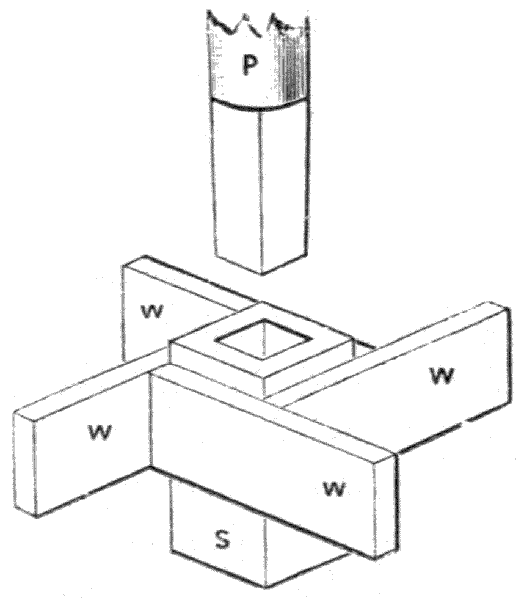

| Stations of Observation:—Pickets—False Picket—Permanent Stations—Referring Object—Heliotrope—Heliostat—Heliograph Signalling—Morse Alphabet—Night Lights—Oil Lanterns—Magnesium Light | 533 |

| CHAPTER XVIII. | |

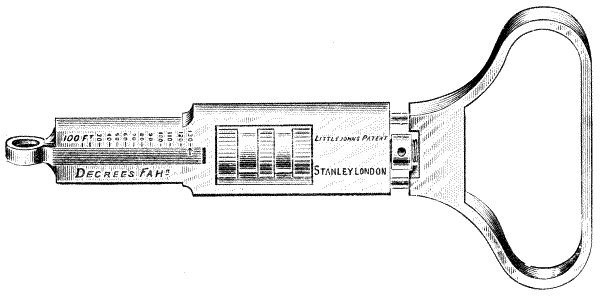

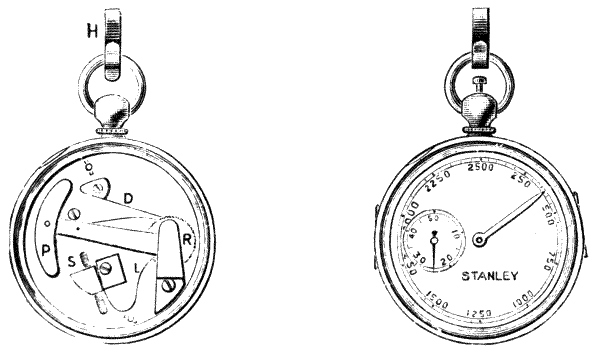

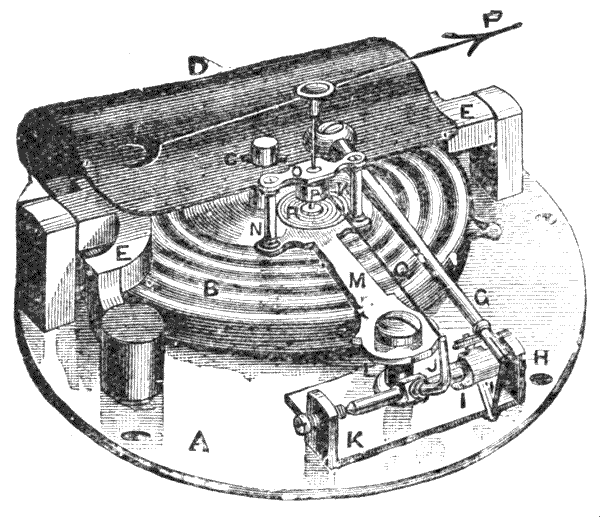

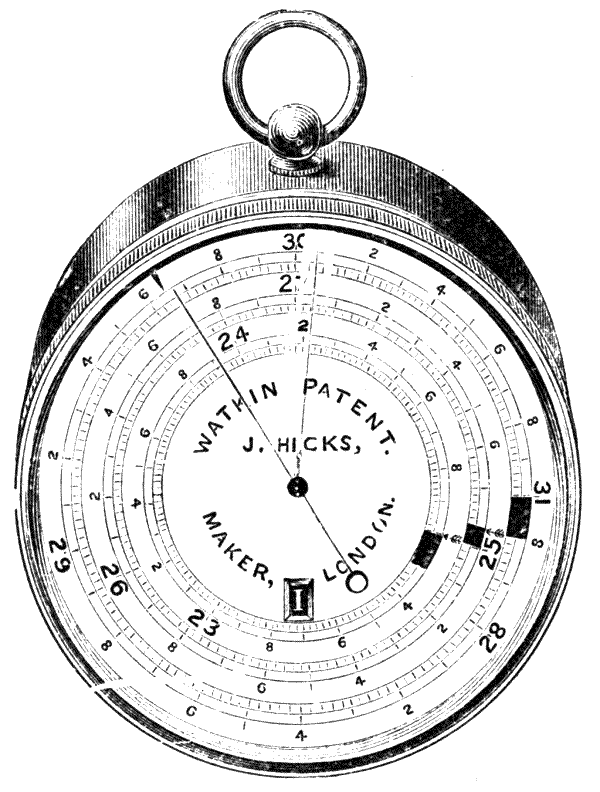

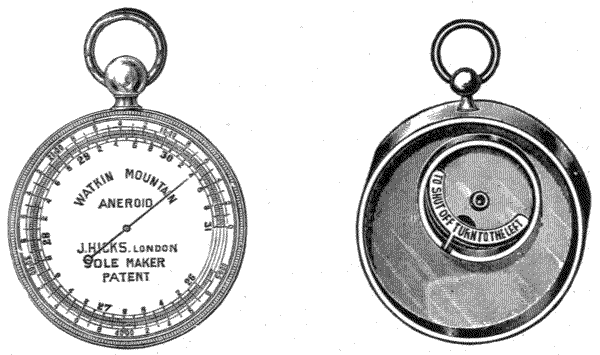

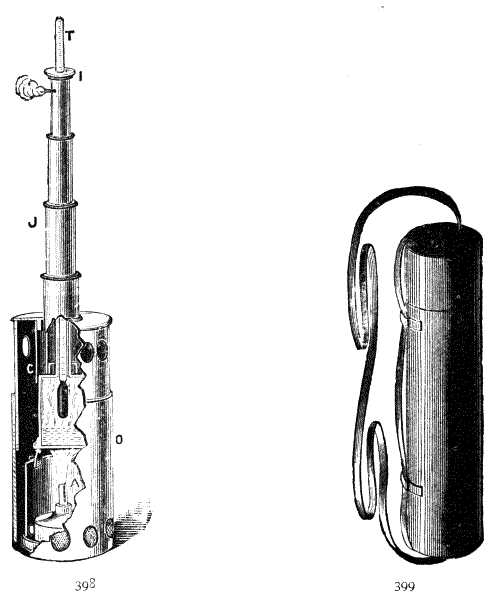

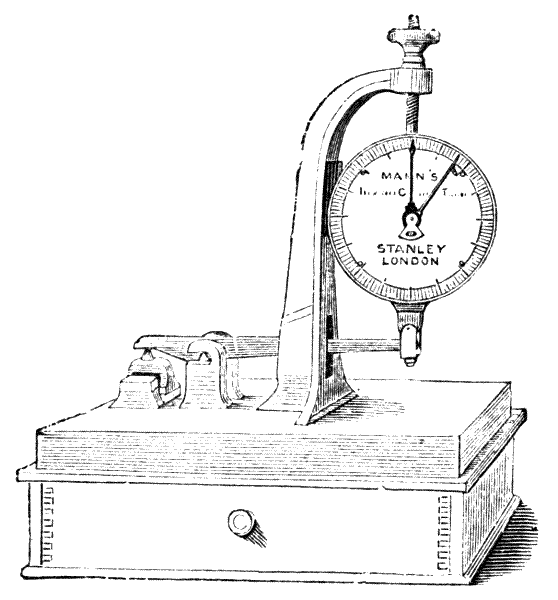

| Measurement of Altitudes by Differences of Atmospheric Pressure:—Historical Note—Mercurial Barometer—Construction—Operation—Aneroid Barometer—Construction—Various Improvements—Hypsometer | 548 |

| [xv] | |

| CHAPTER XIX. | |

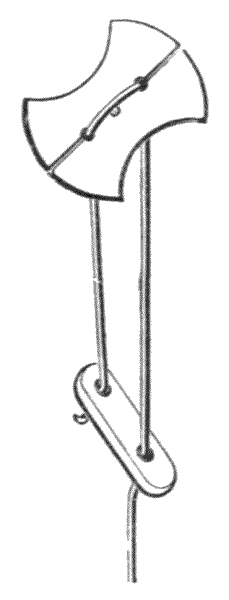

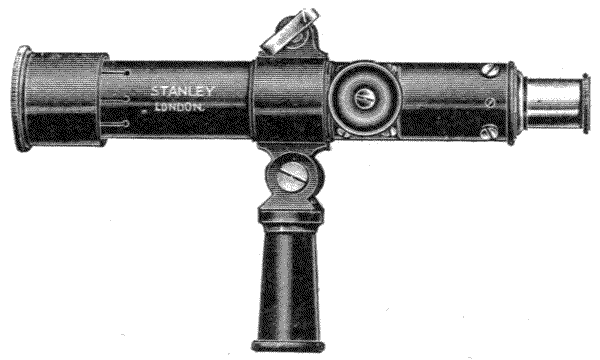

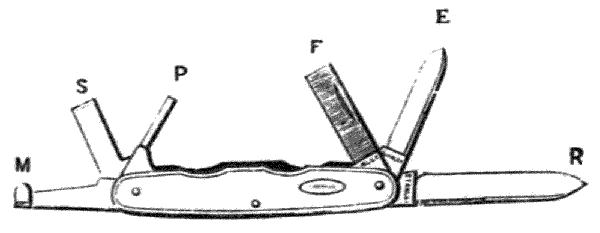

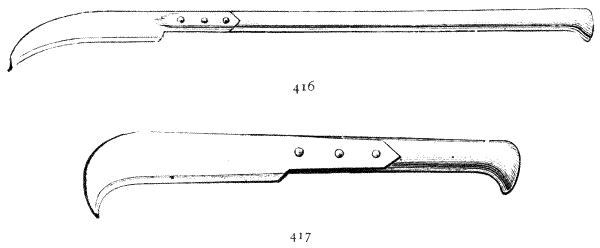

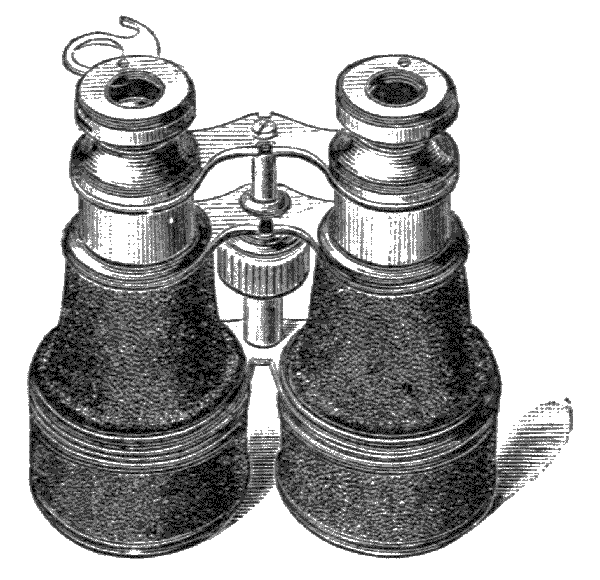

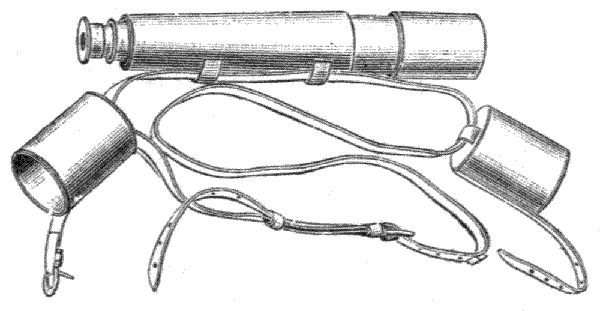

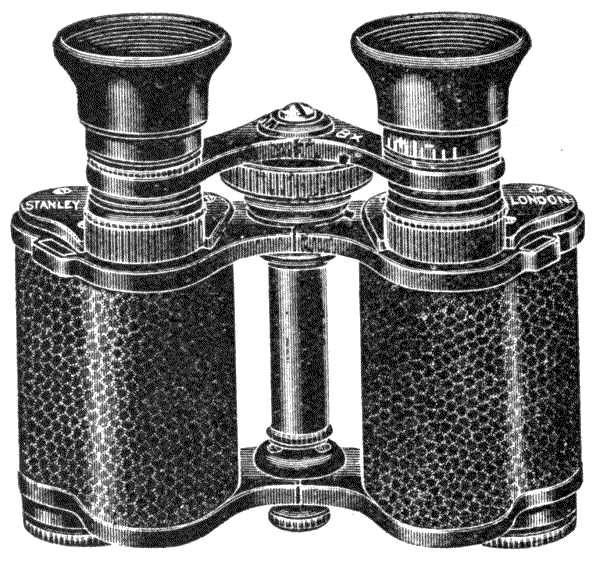

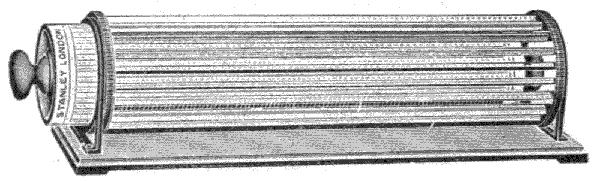

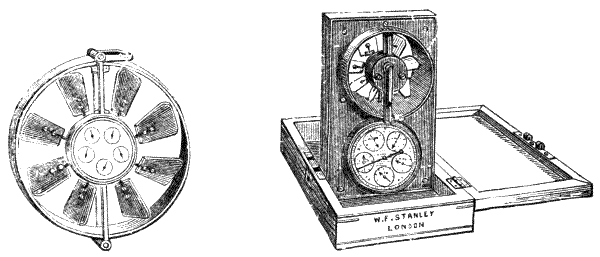

| Miscellaneous Surveyors' and Engineers' Instruments, Appliances, and Accessories:—Cross Staff—Mechanics' Levels—Boning Rods—Footner's Railway Gauge—Girth Strap for Timber Measurement—Girth Tapes—Timber Marker—Slashing Knife—Bill-Hook—Reconnoitring Glass—Telescope—Sun Spectacles—Whistles—Pioneer Tools—Sketch Block Book—Camera—Geological Tools—Wealemefna—Opisometer—Boucher's Calculator—Slide Rules—Fuller's Calculator—Engineers' Pocket-Books—Chronometer—Outfits | 573 |

| Index | 601 |

HISTORICAL SKETCH—CLASSIFICATION OF THE SUBJECT—PURPOSES AND QUALITIES OF INSTRUMENTS—WORKMANSHIP—METALS—ALUMINIUM—FRAMING—TOOLS—AXES OF INSTRUMENTS—SOLDERING—FINISHING—BRONZING—LACQUERING—GRADUATING—ENGRAVING—STYLE—GLASS-WORK—WOODWORK—LUBRICATION—PRESERVATION OF INSTRUMENTS—PACKING.

1.—Historical Sketch.—Although the aim of this work is to show the state of the art it is intended to represent at the present period, a large amount of literature, ancient and modern, has been consulted for its production, principally with the object that the authorship, as far as possible, should be given of the instruments described which have come into general use. Many of these instruments have been brought to their present state of perfection by small consecutive improvements upon older forms. Therefore, it is hoped, a brief historical sketch of the literature of the subject may be thought to form a fit introduction.

2.—Land surveying was possibly first practised in Egypt, where landmarks were liable to be washed away or displaced by the overflow of the Nile. That it was also used otherwise is shown in that there is extant in Turin a papyrus giving the[2] plan of a gold mine of about 1400 B.C. The earliest surveying instrument of which we have record is the diopter of Hero of Alexandria, about 130 B.C. This instrument appears to have been a wooden cross, with sights to take right angles. In the astrolabe of Hipparchus, we have a divided quadrant of a circle sighted from the centre. In Tycho Brahé's Astronomica Instaurata Mechanica, 1598, we have descriptions and engravings of the astrolabe of Hipparchus, Ptolemy, Alhazen, and of his own instruments. These all embrace the principle of the quadrant, but the sighting of the star or object with the instrument by movable parts is effected in various ways. These instruments were made at first only for astronomical observations; but they appear to have been applied, at a very early date, with slight modifications, to topographical surveying.

3.—In Thomas Digges' Pantometrie, 1571, we have several instruments described for surveying purposes:—The geometrical quadrant is an arc of 90°, with sights to the 90° radius, and a plummet from the radiant angle to read degrees of elevation. The geometrical square, sighted upon one edge, with an alidade centred from the corner from which the 90° radiate to take horizontal angles. In another instrument the two instruments described above are combined. The theodolitus—the origin of the theodolite, a word probably derived from theodicæa, taken in the sense of perfection, as being the most perfect instrument. It consists of a complete circle divided and figured to 360°, mounted upon a stand, with a sighted alidade moving upon its centre and reading across the circle into opposite divisions. An artificial horizon is also described for ascertaining altitudes by reflection.

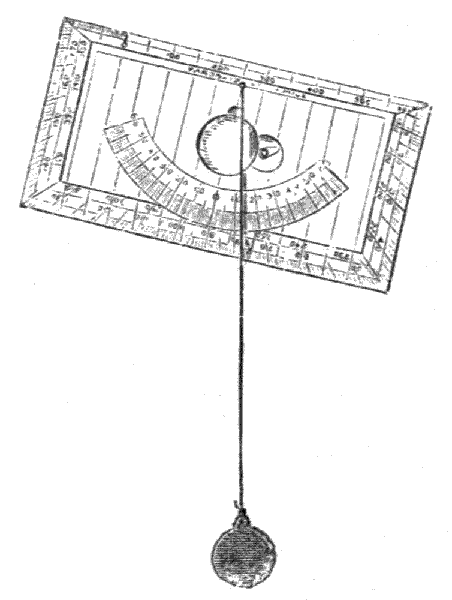

4.—In 1624, Edmund Gunter, to whom science is indebted for the invention of the slide rule, sector, and chain of 100 links, published a work giving descriptions of the cross-staff, his improved form of quadrant, with improvements on some other instruments. In 1686 we have the first treatise[3] on mine surveying, the Geometria Subterranea of Nicolaus Voigtel, published in Leipzig, in which we have the hanging compass, still much in use on the Continent, described. Beyond this, few improvements are recorded upon surveying instruments in the seventeenth century.

5.—Near the commencement of the eighteenth century we have a somewhat important work, published in Paris, written by Nicolaus Bion, Constructions des Instruments de Mathematique, 1718. This treatise was translated into English by Edm. Stone, who made many additions to it in 1723. It formed an important work in its day, and is excellently illustrated. In this we find an account of the circumferenters, plane tables, magnetic compasses, and other instruments then in use. The next important work treating upon the subject is Gardiner's Practical Surveyor, 1737. In this we have the theodolite much improved and brought to nearly its present form by Jonathan Sisson, but it was not, however, perfected until the introduction of the achromatic telescope by John Dollond, about 1760. Gardiner gives also a careful consideration of the best instruments employed generally in the practice of surveying. Nothing from this time appears except transcriptions and incidental descriptions of instruments in works on surveying, until the publication of Geo. Adams's important Geometrical and Graphical Essays, Containing a Description of Mathematical Instruments, in 1791. In this work we have an able discussion of the best surveying instruments then in use. It was much extended in later editions by the descriptions of the great improvements made in the construction of instruments by Jesse Ramsden, as also by the invention of the box-sextant by Wm. Jones. The last edition carries the subject well up to date at the beginning of the last century (1803).

6.—In the last century no original work appeared on the subject till F. W. Simms's treatise on Mathematical Instruments, 1834. This small work is limited to descriptions[4] of popular instruments for land surveying and levelling. It was probably called hurriedly into existence to supply a want at the commencement of the railway mania. Another small popular work, by the late J. F. Heather, 1849, appeared in Weale's Rudimentary Series. This was almost entirely compiled, old and even then obsolete engravings being used. No work in the English language, from an early date in the last century, is found to treat the subject comprehensively, or to bring it nearly up to date with the advanced work of our best opticians of the period at which it was published.

7.—In Germany we have recent works of an altogether higher order in Die Instrumente und Werkzeuge der hoheren und niederen Messkunst, sowie der geometrichen Zeichnenkunst; ihre Theorie, Construction, Gebrauch und Prufung, by C. F. Schneitler, 1848; and a work upon the larger instruments, Die geometrischen Instrumente, by Dr. G. C. Hunäus, 1864. These works are original, and enter ably into constructive details. The authors, however, do and mention, and were possibly unacquainted with, many excellent instruments in the hands of the British surveyor. As regards reflecting instruments, which derive their first principles from Hadley's sextant, there is no work in which these are treated so ably as that of the Italian, Captain G. B. Magnaghi, in Gli Strumenti a Reflessione per Misurare Angoli, 1875. The consideration of these instruments is, however, in this work more in reference to astronomical and nautical observations than to surveying.

8.—The important class of subtense instruments, the use of which was first proposed by our countryman, James Watt, in 1771, and brought out by Wm. Green in 1778, since reinvented in Italy by J. Porro, 1823, of which we have a description in his work, La Tachéomètre, ou l'Art de lever les Plans et de faire les Nivellements, 1858, is now in extensive use on the Continent, and to some extent in America. Their use is becoming more general in this country but they are not nearly so well known as they should be. One of the first was[5] Edgecombe's little-used stadiometer, of which we have descriptions, without any recognition of the optical correction always required to render this instrument practical; and some descriptions of Eckhold's omnimeter, given generally with an illustration of an early abandoned form of the instrument. More recently we have the subject of subtense instruments ably discussed in a paper by B. H. Brough, C.E., on "Tacheometry," as it is termed, read before the Inst. C.E.s, 1887.

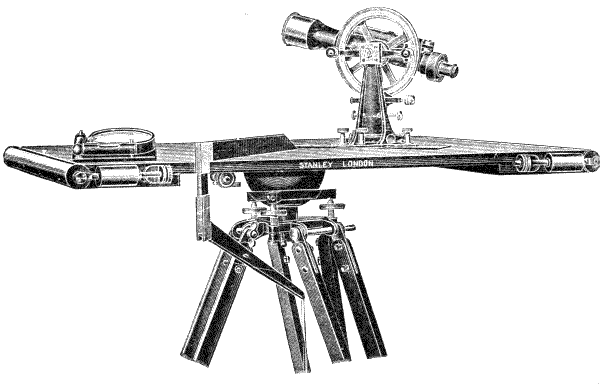

9.—Classification.—The surveying instruments necessary to be employed on any particular survey will depend, in a great measure, upon the nature of the work to be performed. Thus, if it is for a simple plan of an estate, the surveyor requires to ascertain the positions of buildings and important objects, the internal divisions of the land, and the surrounding boundaries of the estate, placing all parts in their true horizontal positions and bearings in relation to the points of the compass. If it is for a topographical survey of great extent, he requires these matters in less detail, but, in addition to the above, means of finding the true latitudes and longitudes, and the relative altitudes of the parts of his work. If for a railway, a canal, or water-works, he requires to ascertain, besides the general horizontal plan, especially the altitudes of all parts of his work very exactly. If it is for coast survey, he requires, besides the bearings, the exact relative trigonometrical positions of all parts of the coast-line, as also the relative soundings on the sea front. If for a mining survey, he requires to ascertain, besides the horizontal plan, sections showing the position and depths of strata, faults, veins, etc.; and, as the work is principally underground, it is necessary that he should be able to take his observations by artificial light. It becomes, therefore, clear that special instruments can be adapted, more or less perfectly, to these various kinds of work without that amount of complication and of weight which would be required in any single instrument constructed to perform many of the above-named functions.

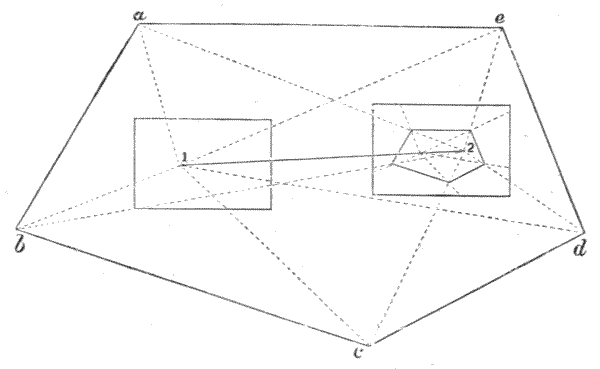

10.—Taking the subject in a general way, the instrumental aid of the greatest importance in the work a surveyor has to perform is such as will provide measurements of distances and of angles by which he may be enabled to make a horizontal plan or map of the ground he surveys to a measurable scale. The method employed to secure this object is by taking linear measurements in certain lines to fixed positions, or stations, as they are termed, and by taking angles in relation thereto from such stations to prominent points of view, which may be either natural or artificial objects. To obtain this end, he requires means of measuring such lines, and some instrument that will take angles of position in the horizontal plane, or, as it is termed, in azimuth.

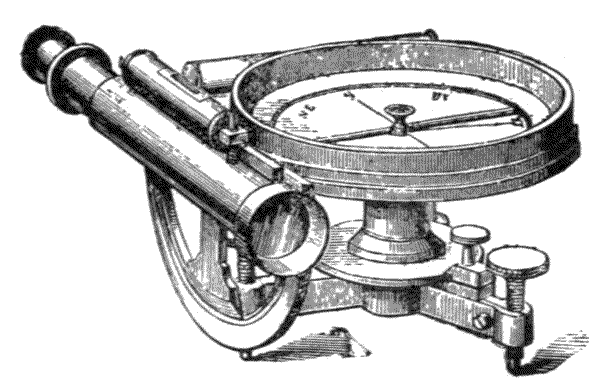

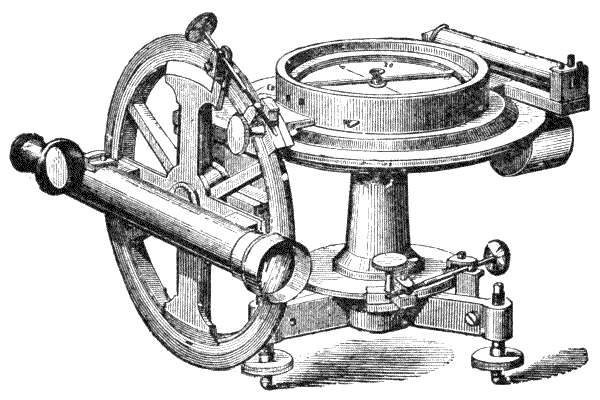

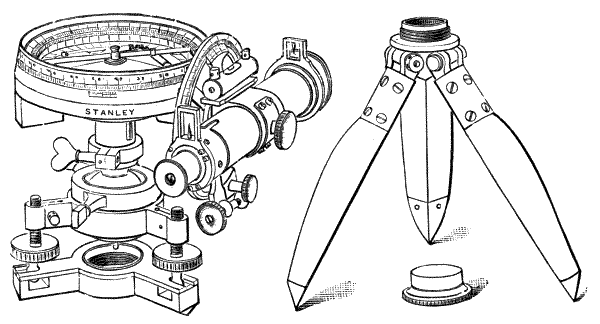

11.—The instruments used in practice for measuring the complete circle in angles of azimuth are the various kinds of theodolites, including transits, omnimeters, tacheometers, circumferenters, also mining-dials of various kinds, prismatic compasses, and plane-tables. Instruments limited to measuring angles upon the plane, within a segment of a circle, are sextants, box-sextants, and semi-circumferenters. Instruments adapted to take certain fixed angles only are the optical square (90°), the cross-staff (90° and 45°), the apomecometer (45° only). The theodolite being a universal instrument, is used for taking angles in altitude as well as in plane. The sextant is also adapted to this. Circumferenters and mining dials are generally constructed to measure altitudes less exactly than the theodolite. In extensive surveys of countries a constant check is required by taking the latitude and longitude, for which a good transit instrument is required to take observations of celestial bodies, and a reliable chronometer.

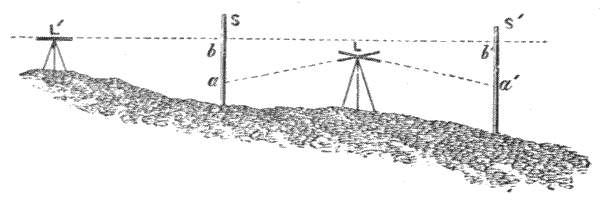

12.—Practically for taking altitudes for railway, canal, road, and drainage survey, a telescopic level is used, either with or without a magnetic compass. For topographical work and measurements of great altitudes in extensive surveys, the theodolite, aneroid or mercurial barometer, or boiling-point[7] thermometer is used. In important surveys of mountainous countries, all of these instruments are used, the one as a check upon the other. For taking merely angles of inclination of surface, angles of embankment or cutting, and dip of strata, a clinometer of some kind is used. Some general details of construction will be considered in this chapter before proceeding with the details of the instruments mentioned above, and some particulars also which it would be difficult to introduce hereafter.

13.—Qualities of Work.—The qualities that instruments should possess will be separately discussed, with the description of each special instrument. It may be stated generally that much of the quality of surveying instruments depends upon the perfection of the tools used in their manufacture, but very much also depends upon the character of the man who produces them—not only upon his intellect, but whether his chief object is the perfection of his work, or the amount of profit he can obtain from it. It is generally known in all branches, as a rule, that the cheaper kinds of work, from the less care required in details, secure the greatest profits. In the author's and some other optical works, a completely fitted engineer's shop is employed to keep tools in perfect order, make special tools, and produce the heavier class of work, for which the engineer is better adapted than the mathematical framer. It is also advantageous at all times to have at least one skilled engineer, who is styled the engineer, in a workshop where as many as fifty men are employed.

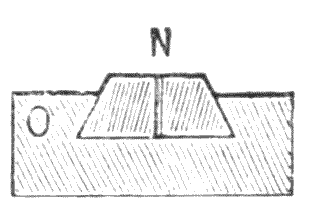

14.—Metals.—The alloys generally used in the construction of surveying instruments are brass, gun-metal, bell-metal, and occasionally electrum or German silver, silver, aluminium, gold, and platinum. These are required to possess certain qualities, and, where the magnetic needle is used, to be perfectly pure or free from iron. The certainty of copper alloys being quite free from iron is one of the great troubles with which the manufacturer of magnetic instruments has to[8] contend when obtaining his castings from the ordinary commercial founder. This has led the author, and some others in his line of business, to cast their own metals as the only means of getting them pure. Where the metal is had from the commercial founder, every part of the casting should be carefully brought within the influence of a delicately-suspended magnetic needle. If the slightest attraction be found in any part of the casting it should be rejected.

15.—Aluminium, from its much lower price of production than formerly, and from its extreme lightness and freedom from tendency to oxidation, except when exposed to sea air, as the presence of common salt appears to completely decompose the surface, is now recognised as a metal which may be used for the manufacture of parts of surveying instruments. This metal, in its pure state, is too soft and malleable to be used advantageously for many parts of these instruments. It, however, appears to alloy with many metals, some of which increase its hardness and stiffness without making its specific weight more than one-third that of gun-metal, and without greater liability to oxidation. The following alloys are now offered in commerce:—Aluminium-nickel, al-chromium, al-tungsten, al-titanium. These possess many distinct qualities, and may be found, under judicious handling, useful for many parts of these instruments. There is, however, from the fineness of grain of aluminium, even in its alloys, a tendency to fret in surfaces exposed to friction. This can be avoided in many cases by lining such parts with a suitable metal without materially changing the general lightness of the instrument. The author has devoted much time to forming and testing aluminium alloys, particularly with nickel, but there is no doubt there is still much to be learned of the alloys of this beautiful metal, as it is still, comparatively, so new to manufacturers. The author has found many difficulties to be overcome in obtaining fine solid castings, and, as far as his experience goes, there are[9] only very imperfect solders offered for it in commerce. It therefore remains advisable to work up all parts in the solid in this metal as far as possible, and where there is risk of exposure to salt air to confine the aluminium alloys to such parts of the instrument as may not be seriously injured by surface oxidation. On the whole this metal is only recommended where lightness is of more importance than durability.

16.—The general object to be obtained in the distribution of metals to the various parts of an instrument is to get good wearing surface with solidity, and an even balance of the moving parts with moderate lightness. In practice, such parts as can be thoroughly hammered, drawn, or rolled in a cold state will form stiff, elastic, and durable parts in brass. For the composition of this metal the author uses copper ·69, zinc ·30, tin ·01. The tin is used in place of the lead of the ordinary founder, and produces thereby a stiffer alloy. For such parts as require stiffness, where sufficient hammering is impossible, or the metal is in considerable mass, gun-metal should be used. The author has found the best practical mixture for this—pure copper ·88, tin ·12. For centres requiring great rigidity, as those of the theodolite, level, or sextant, bell-metal is used by all the best makers. This should be of such composition that it cannot be permanently bent without immediate fracture. It should possess about the hardness and stiffness of untempered steel. The best alloy the author has found for the bell-metal for these instruments is copper ·83, tin ·17. If very small castings are made with this alloy they are somewhat brittle, probably from the rapid cooling of the surface in the mould, therefore, for small castings, a safer alloy is copper ·85, tin ·15.

17.—In making all the above alloys, for the best results the metals are assumed to be commercially pure. The introduction of a little uncertain scrap, which the ordinary founder is so fond of using to make his metal run down, will[10] often foul a pot of metal. In all cases of copper alloys the copper should be entirely melted before the addition of the zinc or tin, after which it should be thoroughly stirred with a charred stick or earthenware rod, and then be cast in small ingots, to be re-melted and cast a second or, even better, a third time before melting for the final castings.

18.—Workmanship.—It would be quite impossible, within the limits of this work, to give such particulars of the workmanship in surveying instruments as to enable a person to manufacture them without practical knowledge of the manipulation of the various branches of the art, but it is thought that a general sketch of the various operations entailed, which vary somewhat in different workshops, may be useful. Some of these particulars may be also useful to the surveyor, not only as general knowledge of the instruments he uses, but in some cases of accidents and emergencies, and for the sake of keeping his instruments in order when he is far away from the manufacturing optician.

19.—Framing Work.—The ordinary turning and filing of metals, and some knowledge of the workmanship of the business, are assumed to be understood by those who may use this book for special constructive details. The tools in a mathematical or philosophical instrument-maker's workshop, where high-class work is done, nearly resemble in every way those of a good engineer's shop, except that on an average the tools are much lighter, and run at a higher speed. Where the works are extensive, steam-power, a gas engine, or electric-motors are used. In small shops the foot lathe is the only important tool. There is a great advantage in using power for good work, as the oscillation of the tool, which is always caused by the action of the foot, produces what is termed a chatter upon the work. For turning brass and silver, a high speed is desirable with a lathe of sufficient rigidity to give no sensible vibration. A surface cut speed of about 250 feet per minute should be aimed at. For turning gun-metal, German silver,[11] and mild wrought-iron, about 100 feet per minute is required. For turning bell-metal and cast-steel, a very slow speed is required—about 16 feet per minute. The lathe should therefore possess means of ensuring these differences by back gear, overhead motions or otherwise.

20.—Tools.—The lathe of the most suitable construction for surveying instruments has the upper surfaces of the bed, one side of Λ section, and the other flat—not both flat as in many engineers' lathes. This ensures the certainty that rests and other tools can be firmly clamped down without possibility of lateral shake. The slide-rest should have a broad base and be provided with direct perpendicular and rotatory motions, with means of clamping the motive parts not in immediate use, as smooth cuts can only be obtained on copper alloys by perfect rigidity of all parts of the tools. The lathe should also possess a bed-screw and overhead motions suitable for applying flying cutters and milling-tools in every desired direction upon the piece of work when it is once chucked in the lathe. A universal shaping machine and a milling machine generally replace the planing machine of the engineer. These tools are sufficient for producing the flat surfaces for all ordinary work. Even when power is generally used, small hand planing and shaping machines, worked with a lever, are very useful for working up single pieces and small parts. A circular saw and a good grindstone are also indispensable. With good rigid tools, well applied, very little work is left for the rough or bastard file; on many instruments none whatever—only a little fine scraping, superfine filing and stoning being required.

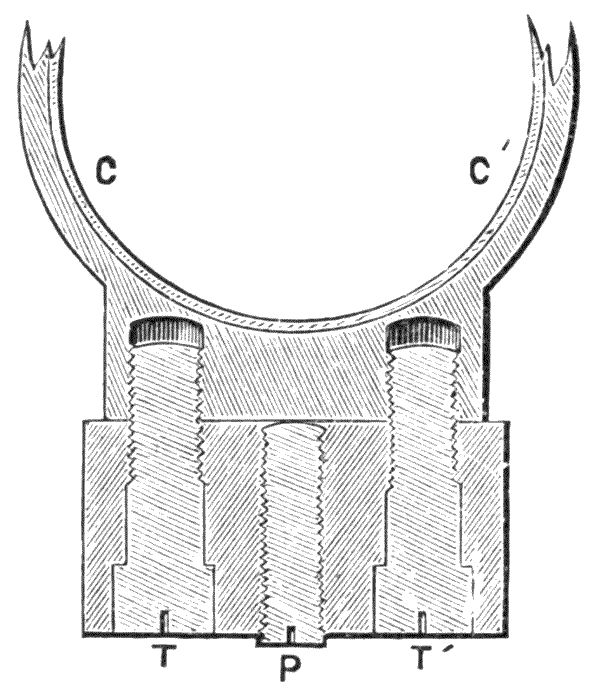

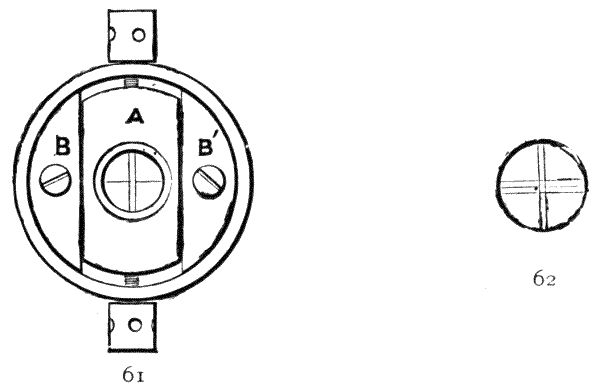

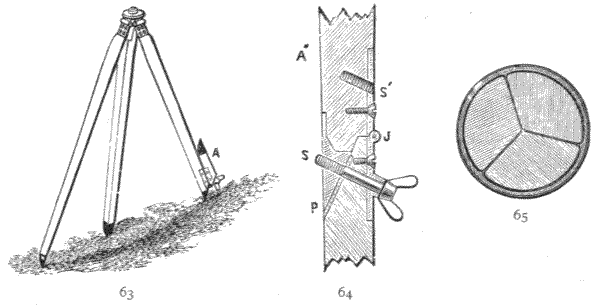

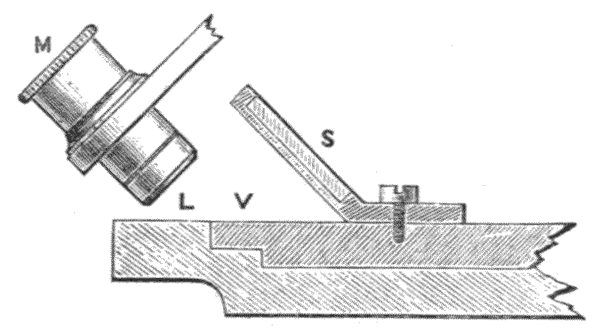

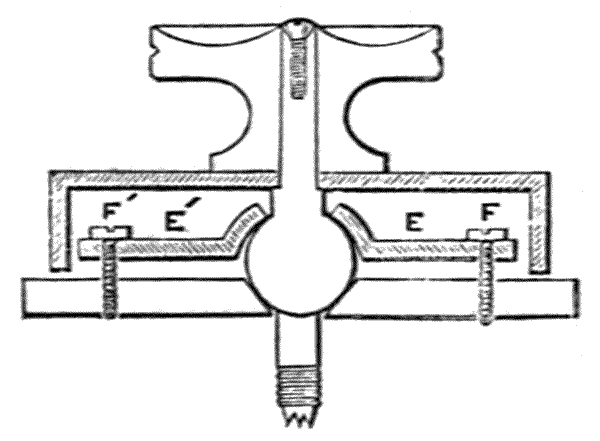

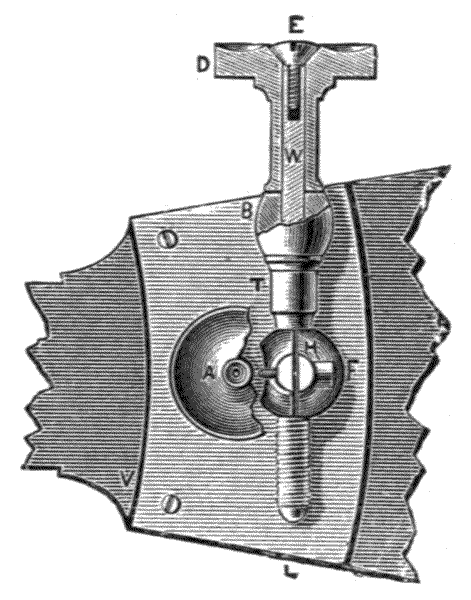

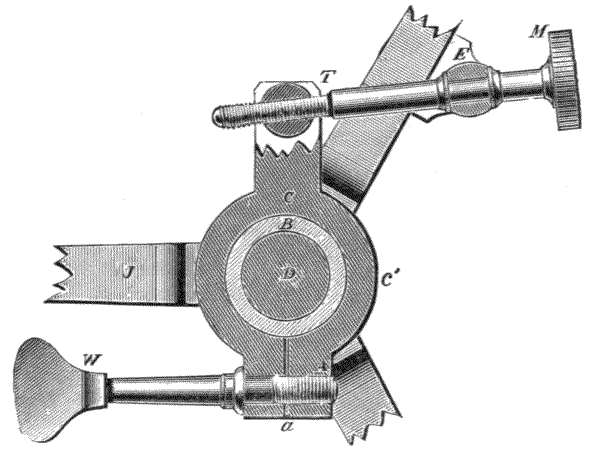

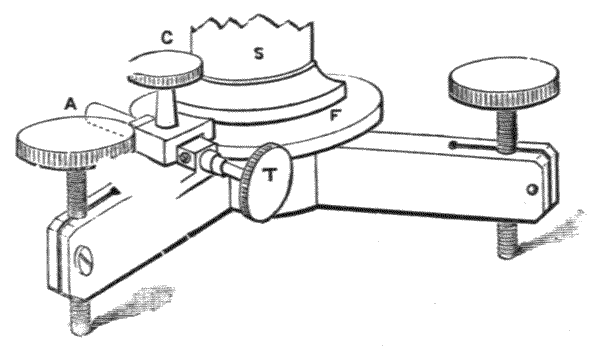

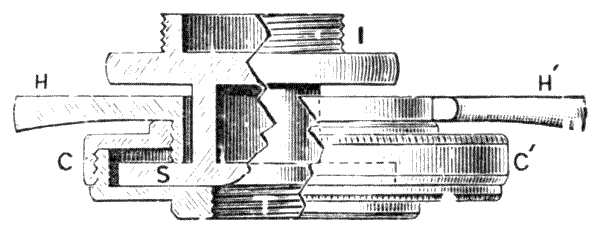

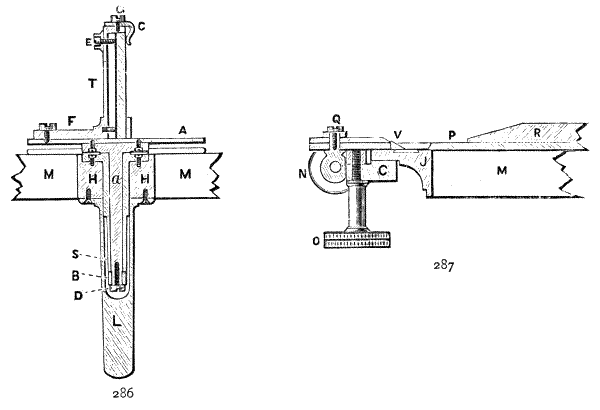

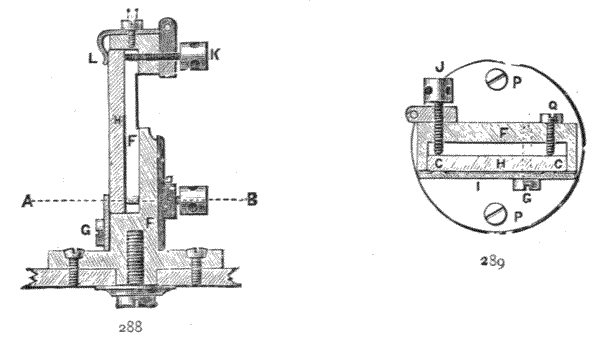

21.—The greatest technical skill required in the manufacture of surveying instruments is in the principal axes of these instruments, particularly in theodolites, tacheometers, sextants, and some kinds of mining dials, wherein a class of work is demanded which must be performed by a skilful, experienced, and careful workman. The axis of these instruments, as already mentioned, should be formed of a casting[12] of good bell-metal. This axis must be turned upon its own centres, which should be drilled up sufficiently to keep a steady bearing, so that the truth of the work is quite independent of any fault there may be in the lathe. The turning must be performed with a point-tool, the upper angle of which should be about 60°. This should be kept constantly sharp, and be allowed to take only the finest possible cut at a slow speed. The slide-rest should be set to the exact angle of the taper of the axis. The socket, if it is not very stout, should be placed in a massive metal box and embedded in plaster of Paris, which must be allowed to set perfectly hard before use. The socket is turned out, if possible, or otherwise it is roughed out with a hard steel fluted cutter, and finally cut up by another fluted cutter which has been carefully ground to the correct cone intended for the finished axis. The axis is chambered back in its central part, so that it may fit the socket for about from half to three quarters of an inch, only at its extreme ends. After turning and boring as correctly as possible, the axis and socket are ground together with soft oil-stone dust to true form. After this, the surface is turned, or scraped entirely off, with a sharp tool, and the axis is again fitted by rubbing contact only. It is most important to be sure that no grit remains embedded in the metal from the grinding, as this will be sure to work out and abrade the axis afterwards.

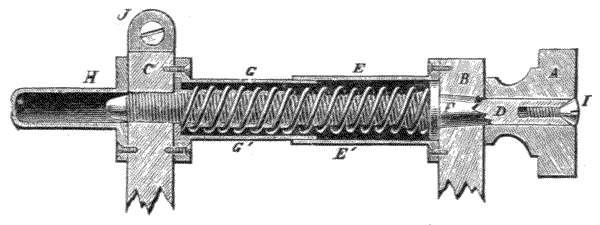

22.—The same care as is necessary to be bestowed upon the centres of instruments, is required for tangent motion screws when these act directly without counter springs. These should be made, if possible, of hard drawn wire. They should be turned on their own centres, the cut of the tool being extremely light to avoid flexure, all screws of over 1/8-inch diameter should be cut direct in a light screw-cutting lathe, although it is advantageous to run a pair of dies lightly over them afterwards to make the thread smooth, and ensure a perfect fit in the nut.

23.—Soldering.—Besides the tubes of instruments, all parts which are difficult or impossible to be formed advantageously in a single casting, are hard soldered or brazed together where this will render the part of the instrument more rigid than by screw attachment. The pins of all screws should be made of drawn metal, to which the part to form the milled head may be a casting. Hard soldering in this country is now generally performed with one of Fletcher's gas blow-pipes, the parts of the instrument, if large, being embedded in a pan of charcoal. The author uses a pair of gas blow-pipes, taking the blast of a centrifugal blower driven by an electric motor. These blow-pipes are placed opposite to each other, so that the pieces being soldered together are entirely surrounded by the flames projected from both sides. The flames of the gas blow-pipe may, with this apparatus, be reduced to mere points for small pieces. The solder employed for ordinary work is fine spelter with a flux of ground borax. The most convenient method of using this is to put about a quarter of a pound of spelter and an ounce of ground borax in a saucer, and add sufficient water to cover it. The borax and spelter may then be taken up together with a small spoon and placed directly upon the clean part of the metal which is to be soldered. With deep or difficult joints it is well to soak the whole of the pieces an hour or so in a saturated solution of borax before commencing the soldering.

For soldering very small pieces, or for soldering steel to brass, silver solder is better than spelter; it appears to bite the steel more firmly and it runs at a lower heat.

24.—Soft Soldering, or what is termed in the trade sweating, should be resorted to as seldom as possible. It is necessary in making attachments to drawn tubes, as the heat of hard soldering would destroy the rigidity of the tube, due to the drawing processes. In this case, where soft solder is employed, the tube should be, if possible, surrounded by a band of solid metal, which forms a part of the attachment, or[14] the attached part should be well secured with screws, tapped dry, before the soldering is commenced. Soft soldering on brass is generally very deceptive; the solder may form a glaze round the joint with no attachment within. Many surveyors will recognise this who may have had one of the slop-made soldered-up levels fall to pieces in their work by a simple jar accidentally given to the instrument.

25.—Finishing mathematical work: the surface as it leaves the superfine file is brought up by cutting it down to a mat with Water of Ayr stone, and finally clearing with soft grey slate-stone.

26.—Polishing.—Where brightness is desirable, particularly for steel work, wash-emery and French polishing paper are used. Heads of screws and small turned parts are better finished off by a clean cut or with the burnisher on the lathe.

27.—Optical Black.—The interior parts of telescopes are painted over with a dull black paint, the object of which is to cut off the reflection of extraneous light entering the object-glass obliquely. Optical black is made by finely grinding drop-black in turps or spirits upon a stone with a muller, this is afterwards strained through fine muslin; if it is ground in turps a little good gold-size is added; if in spirit, a little spirit varnish. The black should be tested. It should appear quite dull, and yet be sufficiently firm to bear the finger rubbing upon it without soiling. For eye-pieces, the dull black generally employed is due to oxidation obtained by burning off an acid solution of cuprous-nitrate in a gas flame.

28.—Bronzing.—For the protection of finished metal work in surveying instruments the surface is generally bronzed, as it is termed, leaving bright only such parts as are required to be easily seen, such as milled-heads, heads of screws, etc. The dark gray of the bronze is also much more pleasant to the eye than a bright surface, particularly when out in the sunlight, so that bright instruments have gone nearly out of use.[15] The bronzing is effected by the application of a liquid that will corrode the metal and, at the same time, leave a dark pulverent deposit upon it. There are a great number of bronzes to be had, but that which the author has found to be the most permanent and safest from after corrosion is platinic-chloride, dissolved in sufficient water. This bronze is well known, but is not used so frequently as it should be from its great expense. The bronzes which are to be particularly avoided are those containing mercuric-dichloride. These are very cheap, and they give a fine dark surface; but they are certain to rot the brass and produce a pitted or spotted appearance after the instrument has been much exposed. The bronze, whatever kind is used, is put on with a brush upon the surface of the metal, which must be quite clean to receive it. After the colour is well brought up by passing the brush over the work several times, the work is then thoroughly gone over with a hard brush and fine black lead until every trace of free corrosive liquid is removed, as far as possible, from the surface, and the work is left quite dry in all parts. Some makers put a thin coat of asphaltum, dissolved in turpentine, over this, which produces a light black surface. Some, to save trouble and expense, simply paint the instrument with black varnish without bronzing. This looks very smart at first, but the black is very liable to chip off in use and make the instrument unsightly.

29.—Lacquering.—All parts of instruments intended to be left bright, as well as all properly bronzed parts, are separately covered with a thin coating of lacquer, the application of which is technically termed varnishing. The metal is raised to an equal temperature of about 200° Fahr., and the varnish is applied with a fine, flat camel-hair brush. The process requires considerable skill, so that only a few workmen do it to perfection. Special varnishes are made for the philosophical and mathematical instrument trades, all of which have a base of fine shellac, dissolved in absolute alcohol.

30.—Engraving of figures, words, etc., where there is much repetition, is best done by the engraving machine—general work by the ordinary skilled engraver.

The method employed for the graduation of instruments will be considered further on in the discussion of instruments reading with a vernier scale.

31.—Style.—This must, of course, depend upon the taste of the manufacturer. In modern machinery, and in scientific instruments, there is a strong tendency to avoid all useless mouldings or ornaments, and to finish all parts of the work uniformly with clean smooth cuts. In surveying instruments which have to be handled, it is desirable to avoid angles as much as possible, both by form and by rounding off all corners neatly, so as to produce a general feeling of smoothness over the whole instrument; useless metal, as, for instance, in milled heads of screws, should be hollowed away to avoid weight, and this object should be observed in the general distribution of metal, never neglecting at the same time to insure the firmness of the instrument. Parts shaped out of the solid may be made much lighter than when screwed together in separate pieces and are of greater rigidity, and admit of better style. The leading makers all have a style of their own, some more graceful than others; most of the smaller makers make bad copies of these designs.

32.—Glass-Work.—The most important technical work, except perhaps the graduation in surveying instruments, is found in the optical parts, of which only a brief description can be given. The glass used for the lenses, particularly for the achromatics, is that manufactured by Messrs. Chance Bros., of Birmingham, or by M. Mantois, of Paris, both of which firms use the process discovered by Guinard, of Solothurn, in Switzerland, which was afterwards much improved by Geo. Bontemps. This glass is nearly white and transparent, of uniform density, and free from veins and striæ. It is also perfectly annealed, which is important. The following[17] kinds of glass are usually employed for the object-glasses of surveying instruments:—

| Density. | Index of Spectrum Lines. | ||||

|---|---|---|---|---|---|

| C | D | F | G | ||

| Hard Crown | 2·485 | 1·5146 | 1·5172 | 1·5232 | 1·5280 |

| Dense Flint | 3·660 | 1·6175 | 1·6224 | 1·6348 | 1·6453 |

These particulars are given by the glass-makers who supply the glass. For cheapness the optical crown-glass is often replaced by common plate-glass. A specially clear and hard glass is made by Shott, of Jena, but early specimens of this glass did not appear to stand climatic influences. This defect is now remedied, and the glass is very pure in body, but not free from air-bubbles.

33.—Two pairs of tools are used for glass-grinding for every curve. These possess two spherical surfaces, one of each pair resembling a shallow basin, and the other, of the same diameter, fitting into this. After turning the tools they are ground together, and are afterwards kept in order by constant regrinding together. These tools may be of cast-iron or brass. The working surface of the tool is, of course, of the reverse curvature to that of the glass to be ground in it. When the glass is ground by hand, each tool possesses a screwed socket by which it can be screwed to a stump or post, fixed in the ground, or to a short knob-handle to be used as the upper tool by hand. For working a glass, or several glasses, it or they are cemented upon a hand tool or holder, which is of less curvature than the working tool. The working is performed by rubbing in a straight alternately with a circular direction, with a certain stroke difficult to describe, at the same time walking round the post to reverse all positions.[18] The grinding is continued over the spherical tool until the surface of the glass is brought up to its curvature, being supplied at first with coarse emery, 60-hole, which is kept in a very moist state, and afterwards with finer emery, 100-hole, and then by eight or ten still finer grades, carefully washing off between the processes, and reserving the mud most carefully for wash-emery, which is used in completing the grinding. Where machinery is employed, hand motions are imitated as nearly as possible by the motion of the tools, particularly for the forming processes.

34.—The wash-emery is formed of particles which are held suspended for a minute or so when the mud is stirred in a large vessel of water. This water is drawn off for final settlement to form the wash. The final grinding with the wash is continued until the emery appears jet black on the surface of the glass, which has then a semi-polished, almost metallic, lustre.

35.—Polishing.—This is performed in various ways, generally moist cloth is placed over the tool. The better way is to cover the polishing tool with patches of hard pitch, which are made to take the form of the hand tool by having the fellow tool to that used in working pressed upon the surface while the pitch is still warm, using a sheet of moist tissue-paper to prevent adhesion. The polishing is effected in the same manner as the grinding, but with peroxide of tin (putty powder), or rouge.

36.—The great difference in the value of achromatic lenses depends upon the truth of the curvature due to the accuracy of the tools and the continuity of the grinding processes until a perfect surface is produced before polishing, so that a given lens may have treble the labour bestowed upon it to one of inferior quality in the grinding only. Beyond this its ultimate perfection will depend much upon the polish.

37.—It may be well here to note how this may be observed. A good test is to throw the shadow of a thin object,[19] as that of a piece of wire upon the surface obliquely. This should show clear edges when the lens is changed to all positions for reflection. The test of polish is really only the test of brightness of the surface of the glass, which may be distinguished in many ways that will readily suggest themselves. The importance of the perfect grinding is that to which attention is desired to be drawn.

38.—Centring—Figuring and Testing.—After the above described processes, the glass is centred by grinding off the edges until its axis is exactly central with the periphery, so that it can be mounted in its cell. It is then tested for figure. The technical difficulties of figuring are too great to be discussed briefly in this treatise; much of this work is performed by the skilled workman in the manner he works his tool and applies his grinding and polishing material, every stroke giving a slightly different figure. Some method, however, may be given of testing, which will be useful in estimating the quality of a lens, irrespective of its manufacture. To test the objective it may be mounted in its telescope and focussed upon a star, or more practically in workshops, upon the reflection of the sun as this is seen in the mercury of a small bulb of a thermometer placed conveniently on a black background at as great a distance as it is clearly visible in the telescope—a common distance is 20 feet. The telescope is made to traverse the sighted object so as to cross the field of view. If the focus under this test remains constant, so that the image of the sun in the mercury bulb appears sharp and without colour, the objective is fairly corrected. Further information on this subject may be gained from a very important paper read by Sir Howard Grubb, the eminent optician, before the Royal Institution.[1]

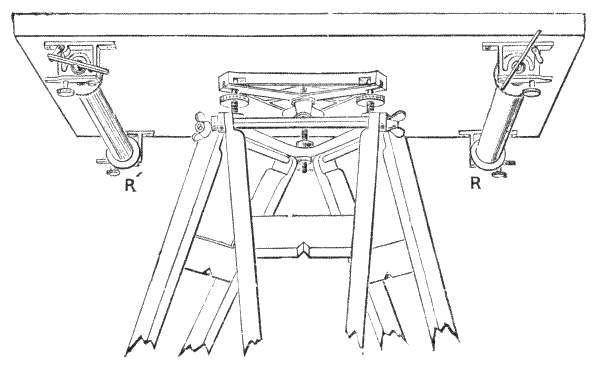

39.—The Woodwork of the Stands of instruments made in this country is generally of straight-grained Honduras mahogany. For occasional work the mahogany is better if [20] seasoned for three or four years in boards which are cut to thicknesses increasing by quarter inches, so that about the thickness of the finished work in one dimension may be used. Where a number of stands of constant dimensions, as for ordinary theodolites and levels, is required, it is better to cut the mahogany a little over finishing size directly from the fresh log, and then allow it to season three or four years. In this manner any natural warp of the wood takes place before it is worked up, which causes it to stand well afterwards.

40.—Lubrication of Instruments.—For the lubrication of all screws, good watch oil should be used. Where this cannot be obtained, salad oil filled up in its bottle with fresh-cut shavings of lead will produce a perfect oil free from acidity. For working centres and collars, a grease is better—that extracted from pork fat, by leaving it in the sunshine, answers very well, but what the author has found best for the purpose is pure vaseline. This keeps its greasiness, and appears to be perfectly non-corrosive. For the collars of tangent screws, a mixture of tallow, wax, and soap is employed. This mixture does not fret out to cause a bite upon the surfaces. As the instrument-maker leaves the working centres of instruments they will generally perfectly maintain their lubrication for four or five years, and it is not well to disturb them; so that this note may be considered only for the restoration of old instruments to order, or for cleaning them up generally, which is nevertheless best done by skilful hands.

41.—Preservation of Instruments.—Instruments that have by any accident become splashed, or dirty by exposure to rain and dust or otherwise, may be washed with damp wash-leather. If a piece of soft, dry leather be afterwards moistened with a little linseed-oil, and this rubbed over the instrument when it is quite dry, it will restore the original brightness, and tend to preserve it. For wiping[21] object-glasses some prefer a piece of clean old linen, others an old silk handkerchief; either will answer if kept quite clean. If the glasses are only dusty, the application of a soft camel hair brush is all that is necessary, and this is quite safe from carrying grit. If glasses are stained by slight corrosion, this can be partially removed by clean spirit. In replacing glasses, it is important to observe that the notch marks, if any, on the edges of the glass agree, and that the double-convex lens is placed outwards in the telescope.

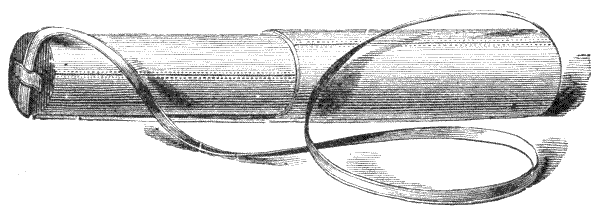

42.—Packing of Instruments.—This is really a very important matter seldom estimated at its proper value. An instrument should lie or stand in its case in such a manner that its most solid parts only take the bearing surfaces, and thus perfectly secure it. When this is effected there should be no possibility of an exceptional jar on any delicate part from the jolting of the conveyance of the instrument. Great care should be taken to note how the parts of the instrument were originally arranged by the packer, and this arrangement should always be followed in replacing the instrument in its case to its position, into which it should fall with perfect ease. Instruments are frequently strained by being placed wrongly in their cases. Even with all these precautions, the wood of the case may shrink or warp to a certain extent, particularly in tropical climates, so that the instrument may be exposed to external pressure from closing the case or otherwise, so as to injure it or to spoil its adjustment. In such cases it is better to examine the packing occasionally, and, if the case does not easily and perfectly close, there is a risk that the instrument is being strained. If this is the case, assuming the instrument to be in its correct position, the bearing surfaces should be lowered with the penknife or other tool, so that it is just free, but not to shake. The author was the first to place a piece of cork under each bearing surface. This gives a certain amount of elasticity, with sufficient rigidity for support, to preserve the instruments from injurious jar, and it[22] may afterwards be cut away more easily with the penknife than wood.

43.—With complicated instruments there are always a number of loose pieces which are used occasionally upon or with the instrument. These, for compactness of packing, are often placed one above the other, and are liable to get astray. It is very desirable that complete parts should be arranged, as far as possible, to go into their cases in any state of adjustment,—this is, however, not always possible. As a rule, before putting an instrument or any portions of it by, all movable parts, such as the telescope, eyepieces, etc., should be closed in their closest form. Parallel plates should be left square to the instrument, with the screws loose. Generally the packer leaves little liberty. Instruments are often packed so that they will go into their cases only just in one state of adjustment, and in one position of the movable parts. In this case, great care must be taken at first in examining the position in which the instrument and its parts arrive from the maker. The late M. Gavard, of Paris, who was celebrated for his delicate pentagraphic instruments, and to whom the writer owes many useful hints, put initial letters on the parts of his instruments, and placed printed labels on the parts of the cases where these should go. Mr. Hennessey, First Assistant in the great Trigonometrical Survey of India, gives some excellent notes upon the subject of packing in his Topographical Instructions for the use of the Survey Department. He recommends upon opening a case that a sketch should be made of the contents as they lie, and all possible particulars should be recorded; but his most useful hint is, always to replace an instrument gently, and in no case to use force if the instrument will not fall into its place. Unless the packings have been damaged in some way, the instrument will go easily into its case, and if it does not, it shows that some part is not in its proper position, and this must be carefully looked into to avoid injury.

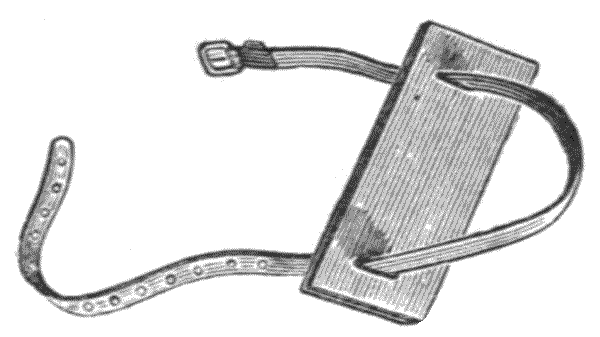

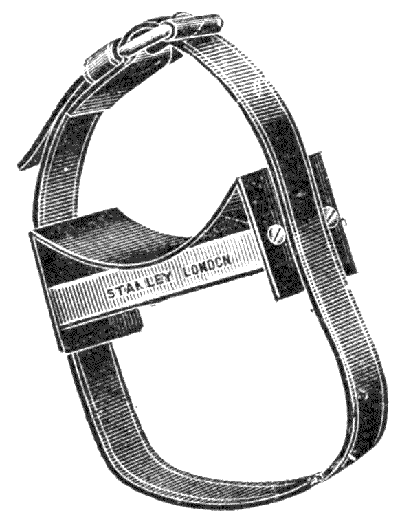

44.—Leather Over Cases.—For an instrument for use in the field it is better to have a solid leather case over the ordinary mahogany one. This acts as a kind of buffer, and takes off the jar of an accidental blow upon the case, which might otherwise injure the instrument. It also protects the mahogany case from the warping effect of direct sunshine and rain, and closes the meeting-joint to keep out the dust.

Solid leather cases are also general for all light instruments, rendering a stiff case of wood or pasteboard unnecessary. These admit most perfectly of straps being placed conveniently to adapt them to the person for carrying.

Waterproof Covers.—In very rainy climates a waterproof cover for a delicate instrument is desirable. This can be thrown over the instrument instantly in case of a sudden storm, and the instrument left ready for continuing the work when it clears up.

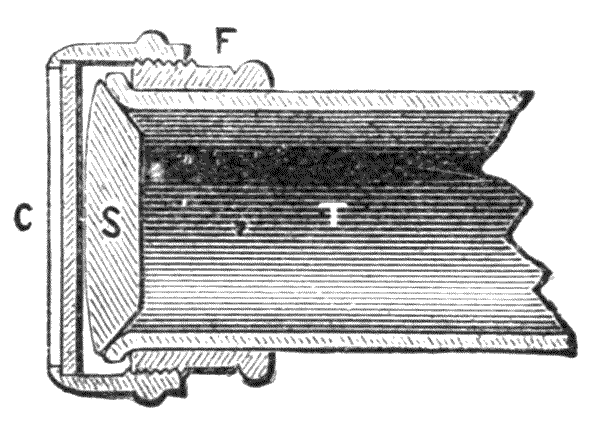

THE TELESCOPE AS A PART OF A SURVEYING INSTRUMENT—GENERAL DESCRIPTION—QUALITIES—OPTICAL PRINCIPLES—REFRACTION OF GLASS—LIMIT OF REFRACTION—REFLECTION—PRISMS—LENSES, CONVEX AND CONCAVE—ABERRATION—FORMATION OF IMAGES—DISPERSION—ACHROMATISM—CURVATURE OF LENSES—TELESCOPES—EYE-PIECES—POWERS—DYNAMETER—CONSTRUCTION OF THE TELESCOPE, DIAPHRAGM—WEBS—LINES—POINTS—PARALLAX—EXAMINATION AND ADJUSTMENT.

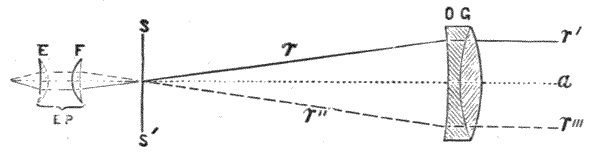

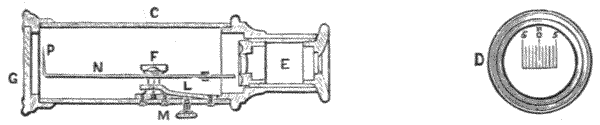

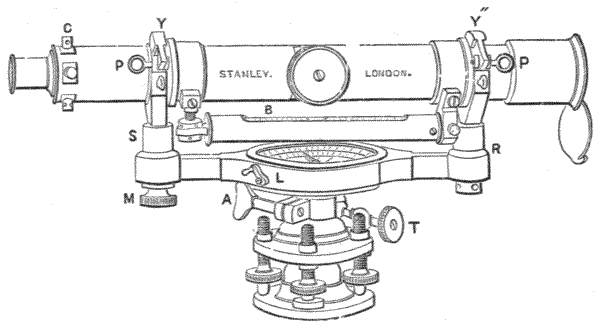

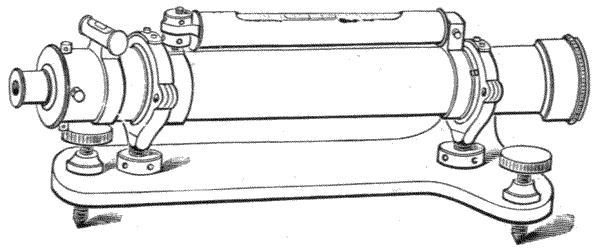

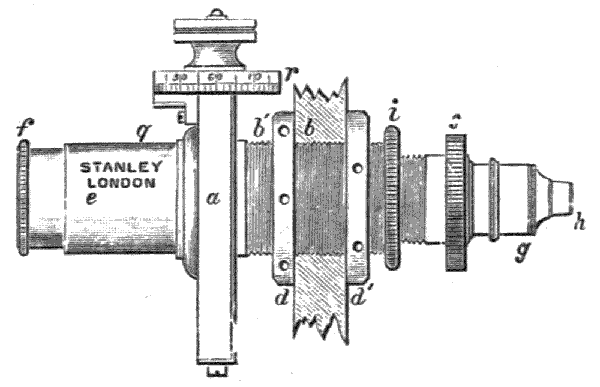

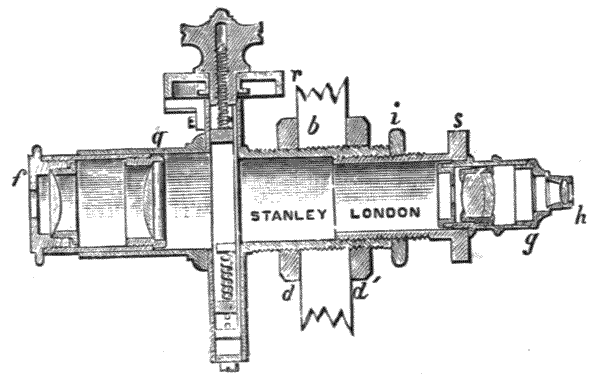

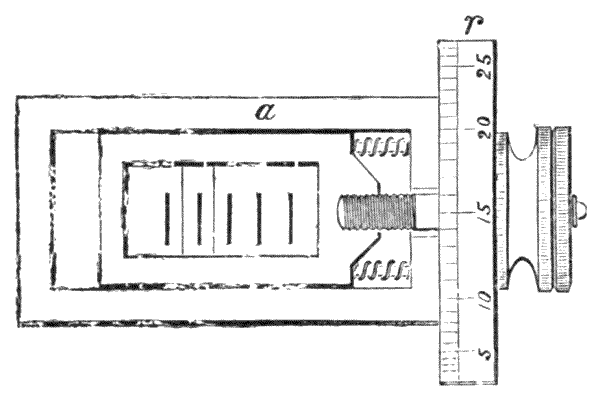

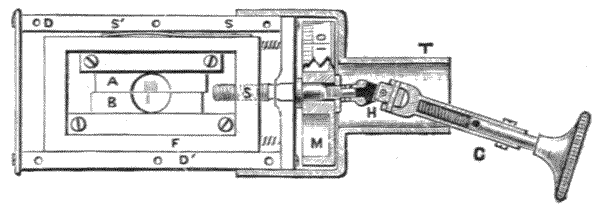

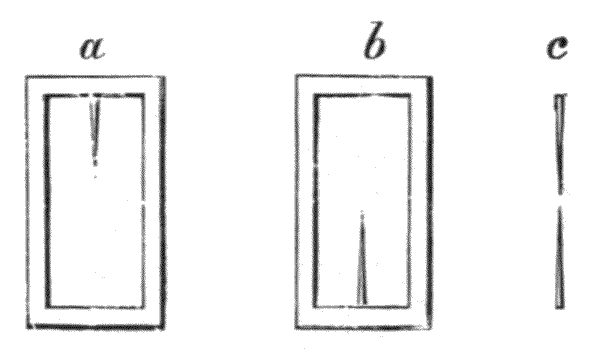

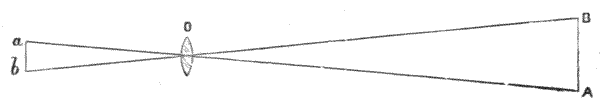

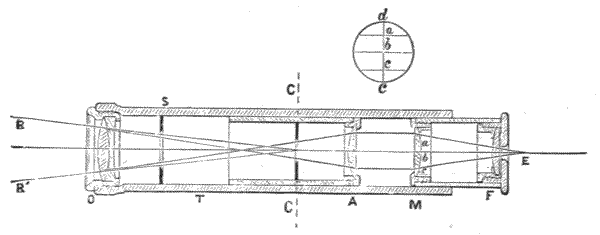

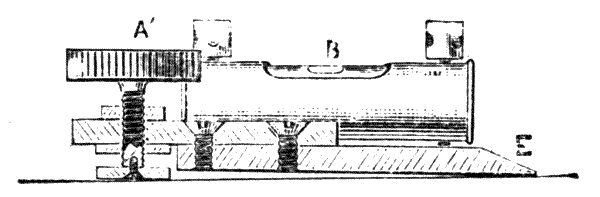

45.—General Description of the Telescope.—This instrument forms part of the theodolite, level, some kinds of miner's dials, sextants, plane tables, and other surveying instruments. For this purpose it is made of similar construction to that of the refracting telescope used for astronomical purposes. The great object desirable in the telescope, when used as a part of a surveying instrument, is that it shall assist vision in obtaining the true direction, or pointing to the position of an object in such a manner that it can be employed to ascertain the angular position of two or more objects in relation to the position of the centre of the instrument upon which it is fixed; also to obtain relative altitude to this centre in relation to a distant station by the reading of a divided measure or staff placed thereon.

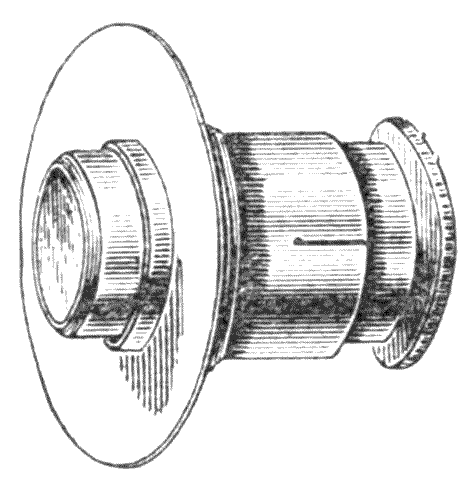

46.—The qualities desirable in a surveying telescope are, that sufficient rays of light may be collected from the object[25] observed for it to be clearly seen as a whole, and in some cases that sufficient magnifying power should be available, in order that details or divisions painted upon a staff may be sharply defined. The amount of light received by the eye which is effective in producing distinct vision is in proportion to the extent of active surface of the object-glass converging the light rays. The magnifying power is regulated by the sum of the convexities of the lenses of the eye-piece upon principles to be explained. The surveying telescope is required to possess only a very limited field of view, but very great focal range, so that objects may be seen at any distance.

By the necessary optical arrangement of the telescope, which will be further described, the object observed is generally inverted. This inversion of the image as it appears, at first presents a little difficulty to the learner, but in practice this soon becomes so familiar as not to be even recognised mentally.

47.—Optical Principles involved in the Telescope.—To commence with the optical construction of the telescope, that this may be thoroughly understood, it is necessary to give brief details of some first principles upon which it is constructed, assuming that optics have not been made a special subject of study.

48.—Refraction of Glass.—The properties of a lens depend entirely upon the fact that a ray of light passing from air obliquely into the surface of a dense transparent medium (in this case of glass) and equally from the glass into air is bent, or, as it is termed, refracted, to a certain angle at the surface of contact of the air and glass. The ray of light entering the glass is termed the incident ray, that proceeding from it the emergent ray.

49.—There is no known medium, glass or other, which refracts a ray of white light at one uniform angle. The white ray is universally separated upon refraction,[26] or dispersed, as it is termed, into rays of all colours of the rainbow. In considering refraction, therefore, in its simplest aspect we are compelled to take the refraction of one uniform ray which is distinguished by one colour, that forms a part of the white ray, as for instance the red, yellow, green, or blue, that is, a monochromatic ray, as it is termed, which gives a sharp refraction of its own coloured light only in its ray. Incandescent soda produces monochromatic rays, but in practice an intense flame behind a bright-coloured glass will answer the same purpose, as the coloured glass may be arranged to absorb all, or nearly all, parts of the white ray, except that of its own colour.

50.—Every transparent medium has a special quality of refraction. Therefore, different kinds of glass refract in different degrees within certain limited angles which will be hereafter considered. The refraction is uniformly in the plane containing the incident ray, and the perpendicular to the surface separating the two media. Every medium refracts monochromatic light equally according to the following law for any angle of refraction:—

Whatever the obliquity of the incident ray may be, when it passes from a rarer to a denser medium the ratio which the sine of the angle of incidence bears to the sine of the angle of refraction is constant for any two transparent media.

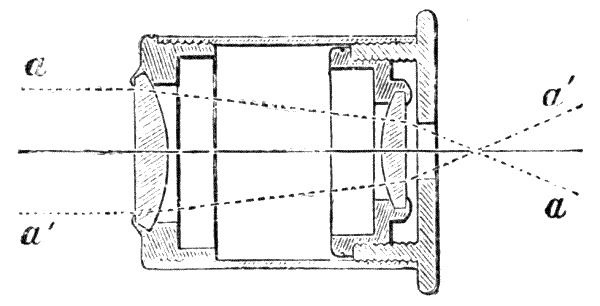

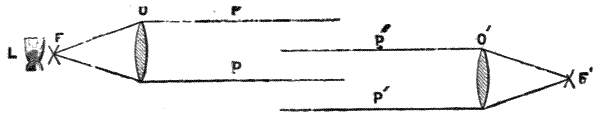

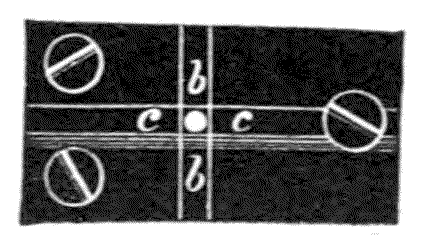

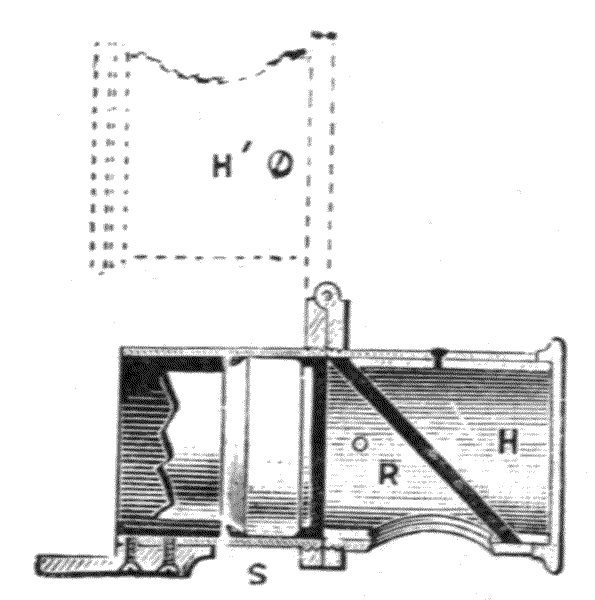

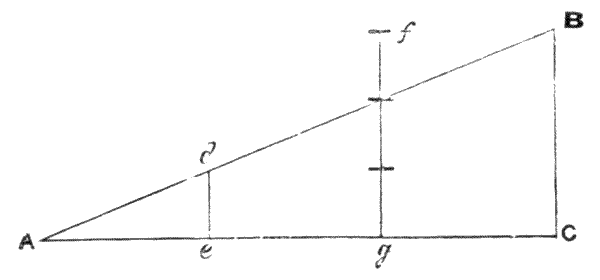

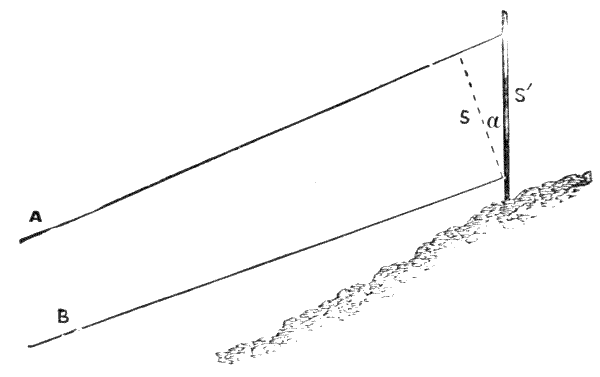

51.—The natural law by which the power of refraction of any medium may be shown, and consequently the magnifying power of a lens in the ratio of its curvative through this refraction may be exemplified, is illustrated by the diagram on the following page (Fig. 1).

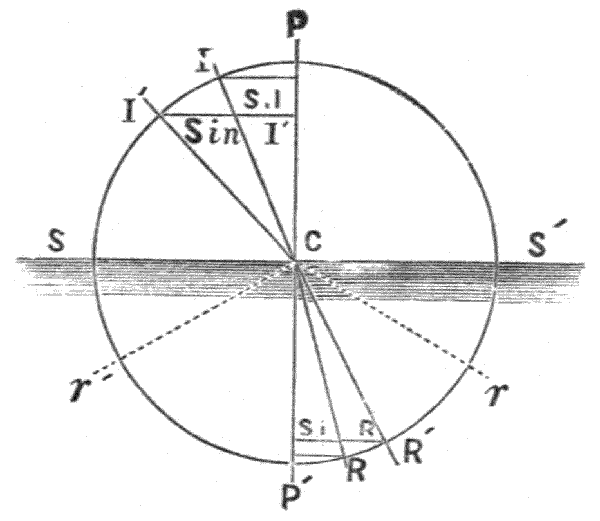

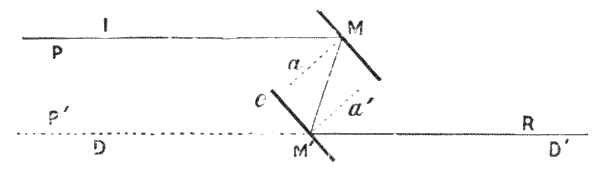

PP′, a line perpendicular to the surface of the plane of the medium (glass) with air above it, a ray of light would pass directly P to P′ through the glass surface SS′ without refraction, and so for all perpendicular incidences or emergences. By this perpendicular line PP′, termed the normal, all refractions are measured. The incident ray I to C is[27] refracted to R. Then if we call the angle ICP I, and the angle RCP′ R, it is found by experiment that the perpendicular from I on PP′ (or sin I) bears a certain proportion to the perpendicular from R on PP′ (or sin R) according to the density of the glass. This proportion is generally expressed by the formula—sin I = µ sin R. Another incident ray I′ to C would be refracted to R′, and using similar notation to the above we have sin I′ = µ sin R′, and from this it follows that (sin I)/(sin R) = (sin I′)/(sin R′) = µ, which is called the index of refraction. Thus, if in a certain glass the sine of I measure 3 equal parts on any scale of length, and the sine R 2 parts on the same scale, the index of refraction of this glass would be 3 divided by 2 or 1·5.

Fig. 1.—Diagram of Refraction and Reflection.

If the above process be reversed, and the ray of light R be refracted on passing from the glass to the air, it will be projected to I in the emergent ray, and follow the same law as that given above.

52.—Limit of Refraction—Reflection.—The sines to the angles ICP and I′CP′ being constantly greater in proportion to the obliquity in the case of glass we are considering by 1/3 than the sine of the angles RCP′ and R′CP′ of the[28] rays of incidence thrown upward upon the surface SS′, it will be seen that at a certain angle or that in which the sine is 2/3 the radius, namely, 41° 48′ 37″, the equation given above makes sin I = 1 its maximum value; therefore, at any angle of incidence greater than this, the sine of refraction to continue in proportion would exceed the radius—an impossibility. The refraction, if possible, would carry the ray into the substance of the glass. This is therefore called the critical angle or angle of total reflection. At this point we may consider what must happen. By our rule, refraction must cease at the angle refraction becomes impossible by increase of sine, and as light cannot be extinguished in a transparent medium it must be reflected. Thus the ray r cannot be refracted in the proportion according to the rule given for sine I to sine R, as this would exceed the greatest sine, that is SC the radius, this ray will therefore be reflected at the surface from the point C, and pass in the direction r′. This property of refraction, continuing, as it were, into reflection, is made use of in many instruments.

53.—It may be worthy of repeating, as it is a mistake occasionally made by persons designing instruments for special purposes (as telemeters), that the refractions are not equal for varying angles of incidence, but only, as before stated, in the ratio of the sines. Thus there is no refraction P to P′ a certain refraction I to R, and a greater refraction I′ to R′, the refraction constantly increasing with the angle of incidence.

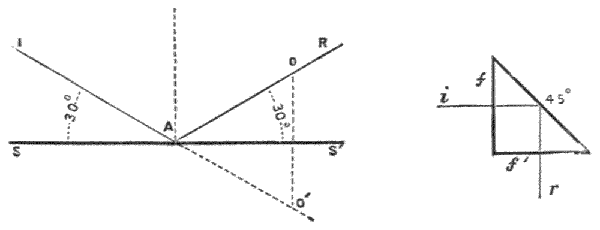

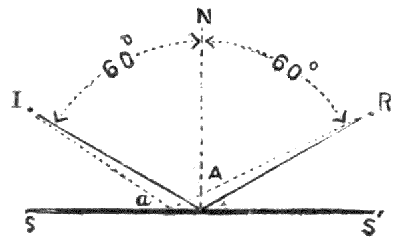

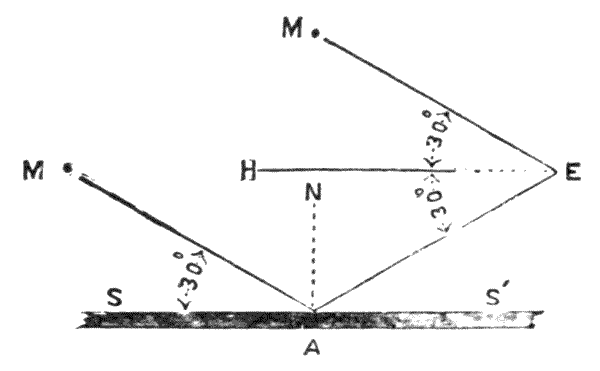

54.—The Reflection of Light follows a very simple law, viz.:—The angle of reflection of a ray of light from a reflecting surface is equal and opposite to the angle of incidence upon it. Thus, in Fig. 2, let a ray of light IA fall upon the reflecting surface SS′ at 30° of inclination to this surface, then this ray will be reflected from A to R at the angle RAS′, which is also 30°. If an object be at O, and the eye at I, then the object will appear as though it were at O′, as the eye only recognises the object in the direction from which it actually[29] receives the light. The apparent angle S′AO′ is equal to IAS, so that the point of a mirror from which an object reflected is received is in direct line between the eye and the apparent object. This observation will be found useful in placing mirrors.

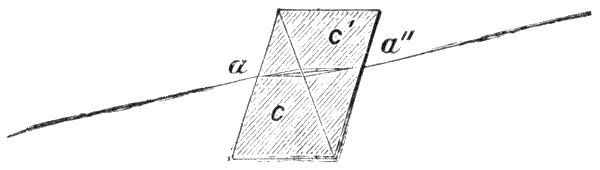

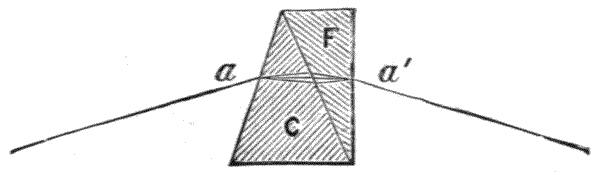

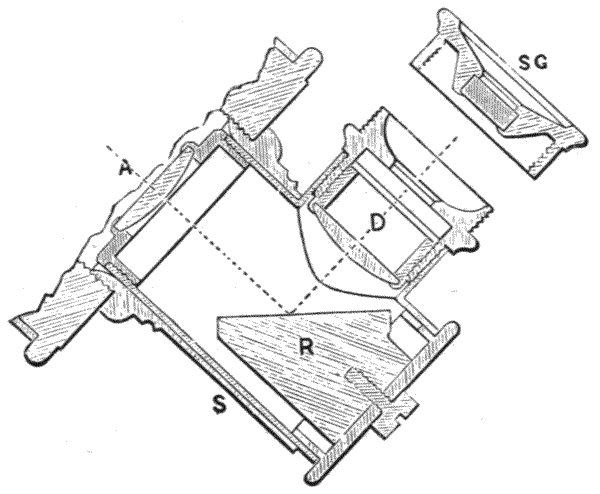

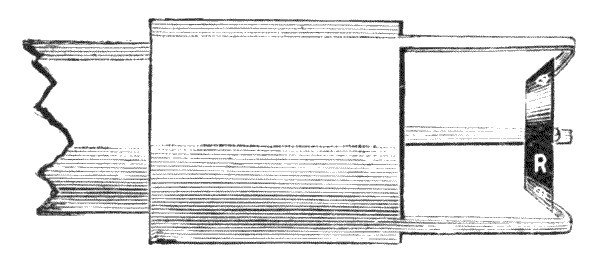

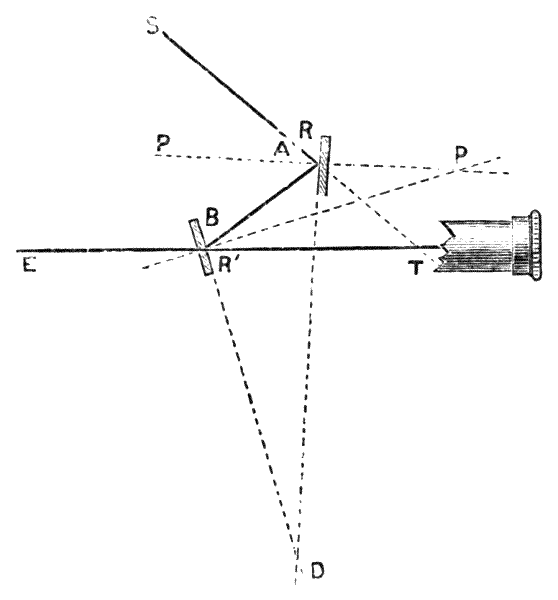

55.—Prismatic Reflection. The same law as given above applies to internal reflection from glass. Let Fig. 3 represent the section of a prism ff′, two plain surfaces of glass at right angles to each other, and the third side making an angle of 45° with each of the other two. The ray i will therefore pass perpendicularly through the plane f without refraction to meet the plane 45° and the angle of reflection, being equal to the angle of incidence, will leave this plane at 45°, and reach r. The angle of glass here given of 45° being greater than 41° 49′, its extreme angle of refraction, the internal reflection will be therefore perfect.

56.—Prismatic Reflection, as this is termed, is largely used in optics in preference, where practicable, to open reflecting surfaces, from the certainty of keeping the reflecting surface clean; as dirt exterior to the reflecting surface of the prism does not affect the internal reflection in any degree.

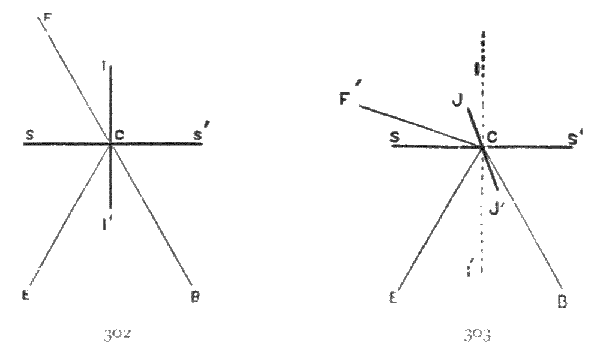

57.—The reflection is shown for clearness from the plane (Fig. 2) as it actually occurs, or as it is measurable, independent of theory. In optics it is found much more convenient to take the reflection in relation to an imaginary line drawn[30] perpendicular to the plane. In Fig. 4 NA is termed the normal. Taking the angles as before as 30° to the plane, the optical expression of this would be 60° to the normal, and the reflection of the incident ray IA to R would be in the angle IAR 60° + 60° = 120°, the amount the incident ray is deflected from its former course. This principle is important to be understood in the construction of the sextant and other reflecting instruments. In reflection the ray is found to follow the shortest path,—that is, the path I to R by reflection is shorter in the lines IAR, placed at equal angles to the normal, than it would be by any other possible path. As, for instance, it is shorter than IaR, shown by dotted lines.

Fig. 4.—Measurement of angle of reflection in optics.

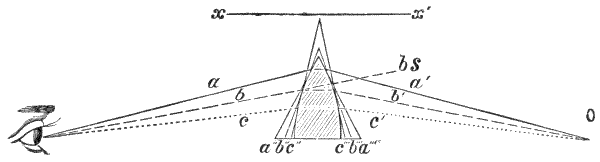

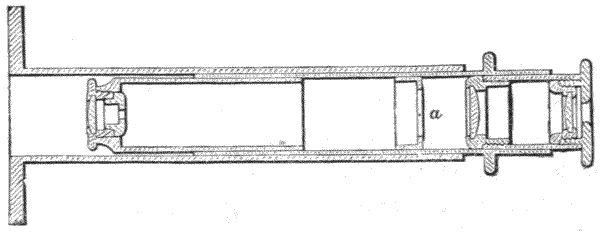

Fig. 5.—Diagram illustrating the principle of the lens.

58.—Passage of a Ray of Light through a Prism or a Lens—Convex Refraction. If we comprehend the law of refraction exemplified above, art. 51, the path of a monochromatic ray through a prism or a lens is easily determined, taking into consideration the refraction index of the glass. In Fig. 5 let a″a‴ be the base of an equilateral prism, which[31] base may also represent the axis of a lens linear or parallel with the direction from the centre of the eye to O. Now, if a ray of light pass from a small luminous object at O in the path a′ to the prism, we may assume all other parts of the prism covered, and the refraction of the glass be such that the ray will pass through it from this position in a horizontal direction, or that parallel to the assumed axis a″a‴, then the same ray will pass through the prism to equal distance from the centre of the prism,—that is, to the position of the eye shown by the ray continuing in the path a, the angles to or from the prism being equal; so that if we cover up all parts of this prism except a line parallel with its base joining the ends of the lines aa′, where it is shown passing through the prism, any ray of light from O, under the conditions given, will appear as a spot of light on the plane parallel to the base of the prism; or if we place our eye at the position shown, we shall see the image of the light O. If we take a prism of the same kind of glass, but of less angle, whose base is b″b‴, the refraction would then be less (that is in the ratio of the sines), that is if the ray pass through the prism at less distance from the base, so that the ray Ob′ would pass through horizontally as before, and emerge from the prism in the path b, also with equally less refraction, so that the ray would reach the eye at the same point as the more refracted ray. In like manner, if the prism were of still less angle with base c″c‴ and pass through the prism at a lower position, the refraction would be proportionally less, and therefore reach the eye at the same point.

59.—If we take the half lens shown in section in the figure, this may be considered to touch the surface of the prisms described tangentially in the lines a″a‴, b″b‴, and c″c‴, where the angles of contact of O, a, b, or c upon the prism would be equal to those upon the lens for an infinitely small extent of surface. Therefore, if we make the lens of such form that a ray of light may pass from any single point[32] upon the line of its axis, and be refracted by every point of the surface of the lens to a single point or focus on the opposite side of the axis, such form would be a perfect lens. For simplicity of demonstration the refractions given above are made parallel with the axis of the lens. This parallelism could only occur with the object and the eye at equal distance from the centre of the lens, and with this distance also proportional to the amount of refraction of the glass used in the construction. If the rays were all parallel to each other upon incidence they would still be bent in the same ratio (to the sines of the angles of contact and departure), and this would bring the focus nearer to the glass; but it is evident the same principles would hold.

60.—As regards the action of the eye in this matter, it can only recognise the direction from which it receives the light, and not the processes the rays may have undergone before reaching it. Therefore the ray proceeding from O in the path b′, passing through the lens or prism and emerging in the path b, is recognised by the eye as the ray b only. So that the point of light O appears visually as proceeding from the direction bs, and this convergence or expansion of the point O, with its coincidence from the opposite side of the lens, produces the effect of magnification of the object represented by O.

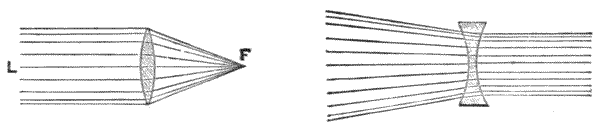

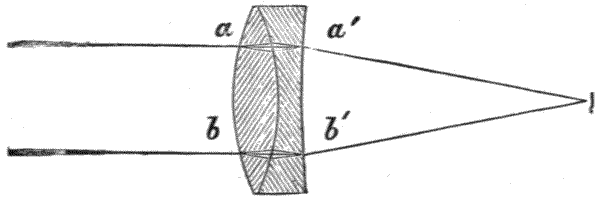

61.—Concave Refraction.—In Fig. 6 a convex lens is shown in which the parallel rays L are drawn to a focus at F upon the principles just demonstrated. If the lens were made concave, as shown in section Fig. 7, by the same principles of refraction, it is evident that the rays would diverge, as the refraction bends the ray uniformly towards the thickest section of the glass. If two lenses are brought together, one with convex face, and one of the same radius of curvature, but with concave face, the rays in passing through would not be refracted. In this case the lens would be said to be corrected. A convex lens has a focus where the[33] rays converge. A concave lens is said to have a negative focus equal to the focus of the convex lens, that will correct it, or make it equal, as regards refraction, to plane parallel glass.

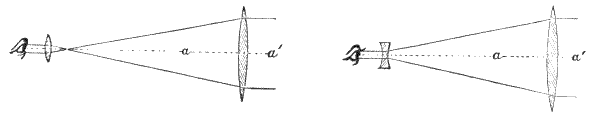

62.—Spherical Aberration.—If the surfaces of convex lenses are truly spherical, it is found, by an analysis too complex to be described in this work, that the rays which pass through at different distances from the axis converge to slightly different points of distance. This subject was at one time seriously discussed for the proper formation of objectives for telescopes; but at present it is entirely neglected by the optician, as it is found practically to be as difficult to make a lens truly spherical as one of the convergent or divergent form required under the special conditions present. The spherical form, as it is approximately produced from the grinding with spherical tools, being always nearly correct, the correct forms of object-glasses are made by figuring, which has been already referred to, art. 38. In eye-pieces the spherical aberration would cause some confusion were the glasses not adjusted in such a manner as largely to prevent this.

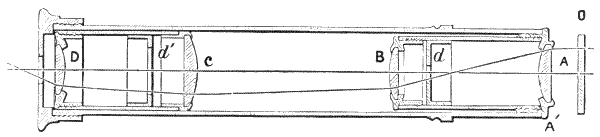

63.—The Formation of Images by Refraction from a Convex Lens.—If we take any double convex lens, as that shown in section Fig. 6, we find, if it is held towards the sun at a certain distance from a solid surface, we form a burning-glass,—that is, we produce an image of the sun where his rays of light and heat are refracted by the whole of the surfaces of the glass. The distance from the centre of the lens to the point of greatest light is called the solar focus of the[34] lens,—that is, the point at which it concentrates or converges parallel rays, and forms the image of the sun. With parallel rays from the sun, the distance of focus is less than if these rays were divergent in any degree. Consequently the solar focus is less than that subtended by any object on the earth.

Fig. 8.—Diagram of the convergence of rays of light.

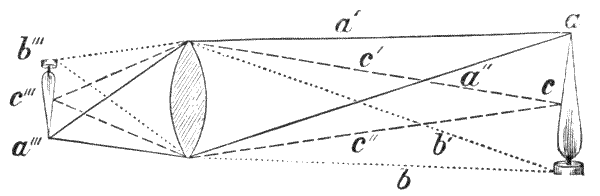

64.—In the diagram, Fig. 8, a candle-flame at acb forms its focus at a‴c‴b‴, where all rays converge to form an image in the following manner:—Every point of the candle throws its light upon every point of the surface of the lens, and, therefore, throws the image of each point to its focal position behind the lens, according to the direction of its refractions; so that, if we take all the separate points of light thrown from the candle, we then have a perfect image of it formed by an infinite number of separate focal points, and as the rays by their direction necessarily cross over the axis the image is in an inverted position.

65.—The whole of these lines would form a confusion if shown in a diagram. We may, therefore, take for illustration the exterior of a cone of rays proceeding from three points only. Thus the clear lines aa′ and aa″ from the point of the flame would refract to the lower part of the image a‴. The dotted lines bb′ would proceed to the upper part of the image, as shown by the continuation of the dotted lines to b‴, whereas the central dash lines c′c″ would form their images in the centre following the dash lines to c‴, and thus, from the number of luminous points, the whole image of the candle[35] would be produced at the foci b‴c‴a‴ in an inverted position.

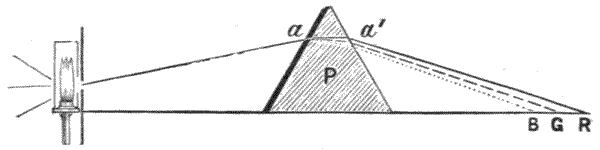

66.—Dispersion of Light.—The conditions stated above for refraction of monochromatic light would not answer for perfect vision, which is only possible in clear white light. It therefore becomes necessary in practice to correct the quality of dispersion which light suffers in refraction through any dense medium. The evidence of dispersion by glass may be shown by a prism, as in the following diagram:—

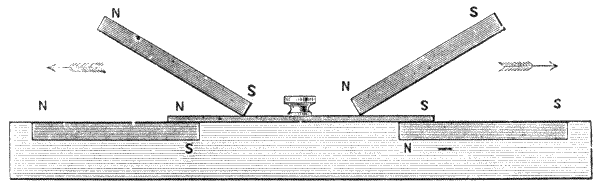

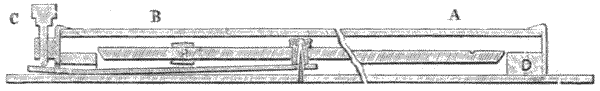

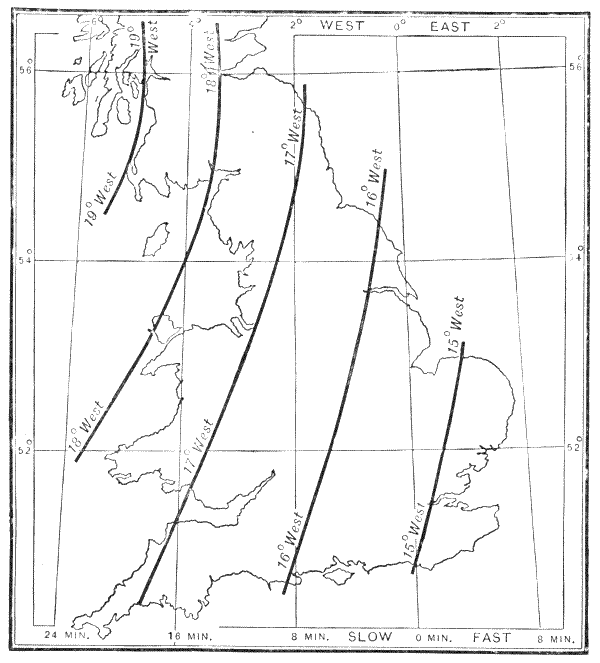

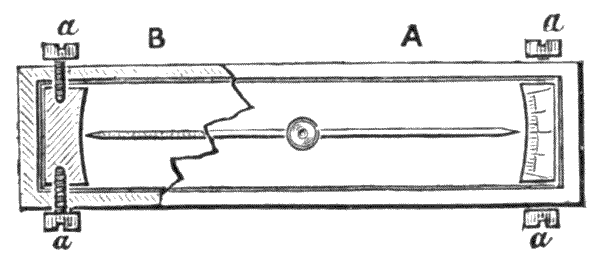

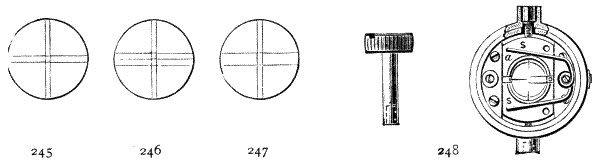

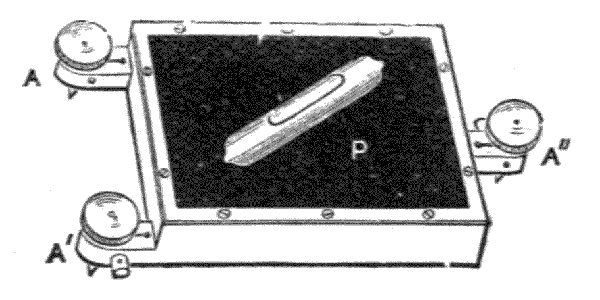

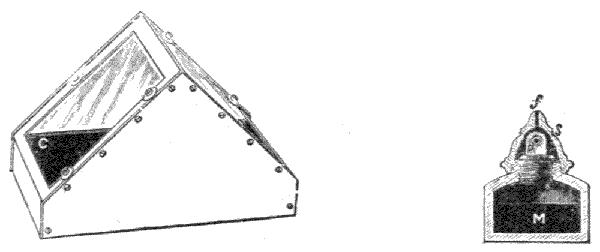

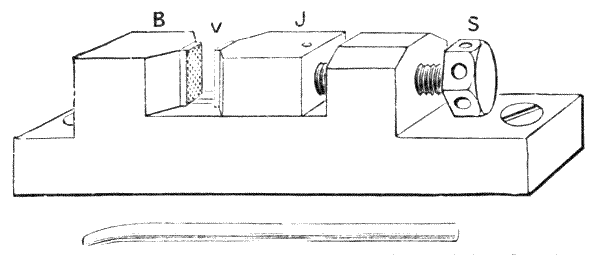

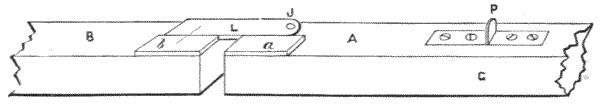

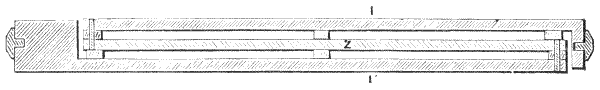

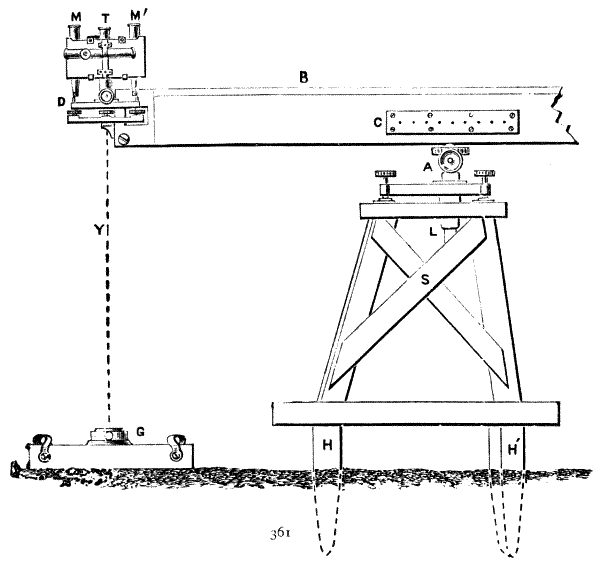

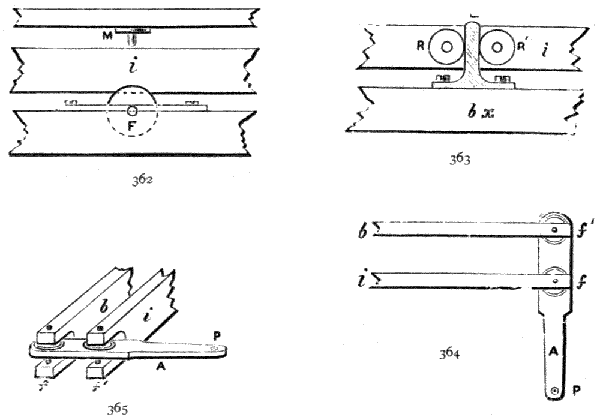

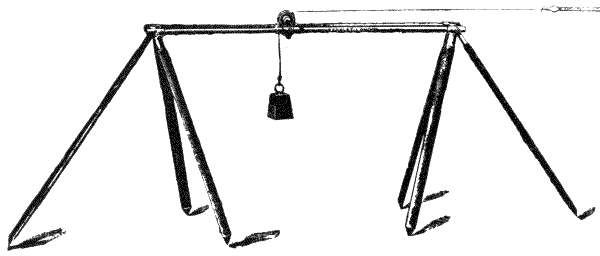

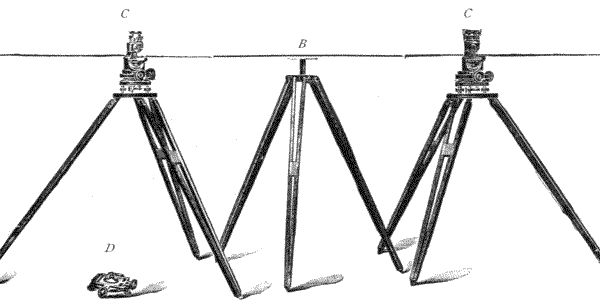

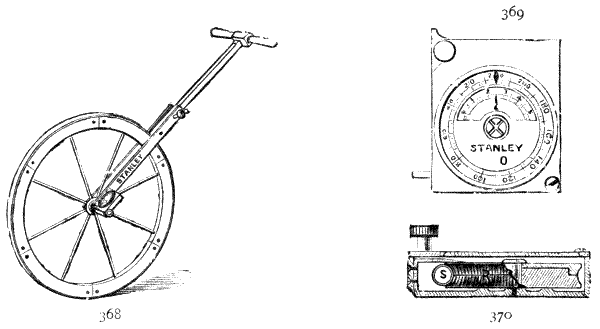

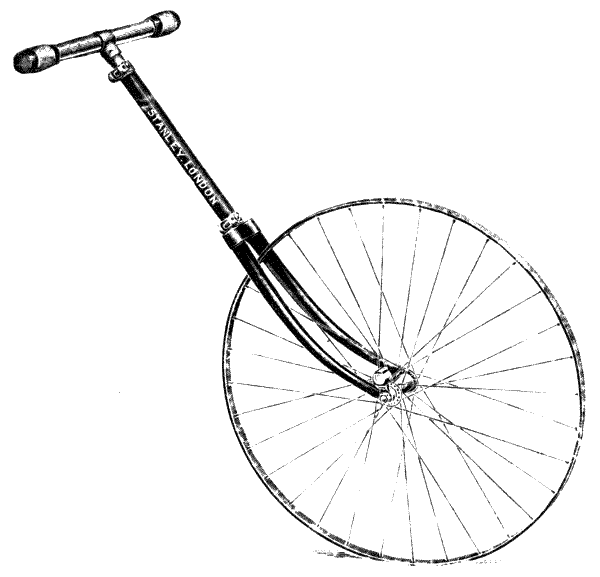

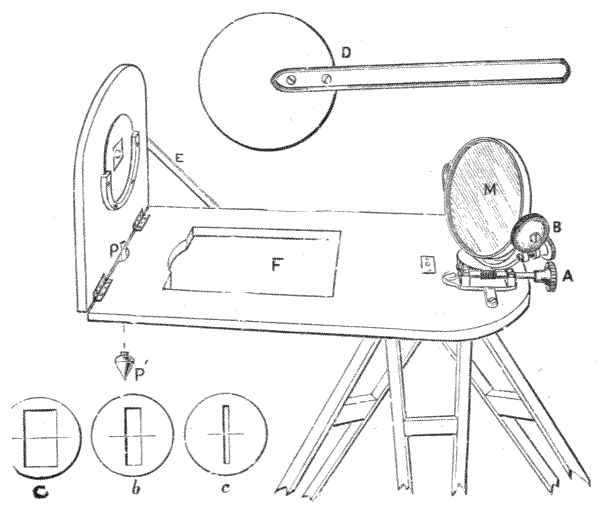

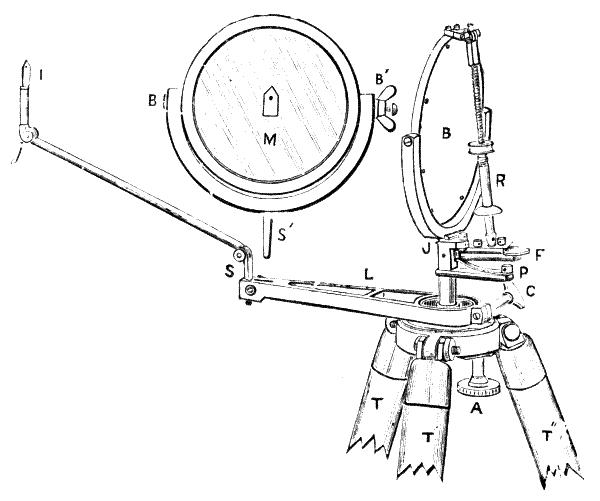

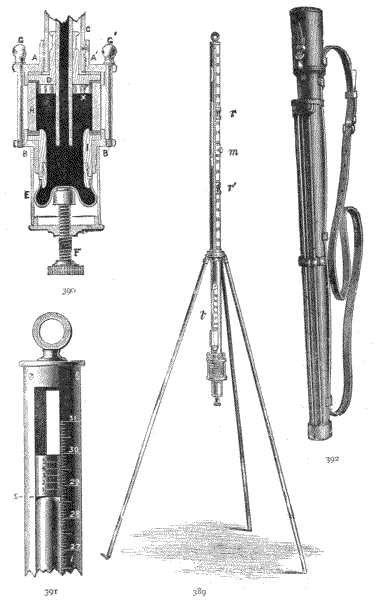

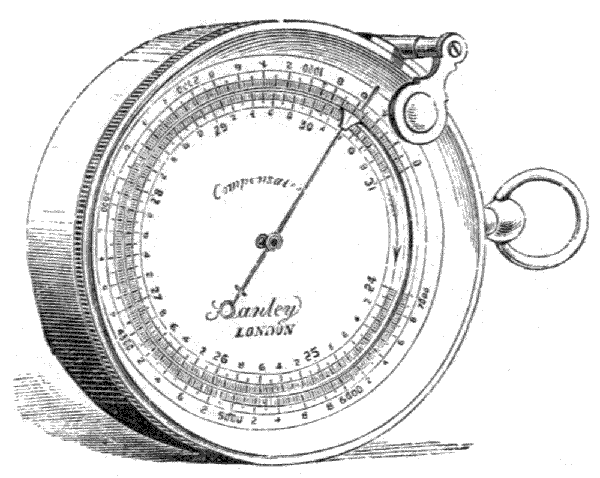

Fig. 9.—Diagram showing chromatism of light by the prism.