The Project Gutenberg EBook of A Text-book of Tanning, by Henry R. Procter

This eBook is for the use of anyone anywhere in the United States and most

other parts of the world at no cost and with almost no restrictions

whatsoever. You may copy it, give it away or re-use it under the terms of

the Project Gutenberg License included with this eBook or online at

www.gutenberg.org. If you are not located in the United States, you'll have

to check the laws of the country where you are located before using this ebook.

Title: A Text-book of Tanning

A treatise on the conversion of skins into leather both

practical and theoretical.

Author: Henry R. Procter

Release Date: February 19, 2018 [EBook #56601]

Language: English

Character set encoding: ISO-8859-1

*** START OF THIS PROJECT GUTENBERG EBOOK A TEXT-BOOK OF TANNING ***

Produced by Chris Curnow, Tom Cosmas and the Online

Distributed Proofreading Team at http://www.pgdp.net (This

file was produced from images generously made available

by The Internet Archive)

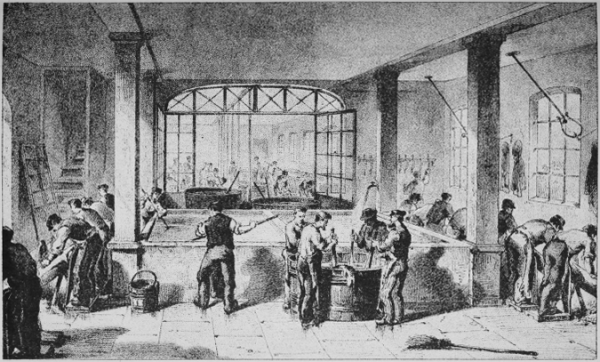

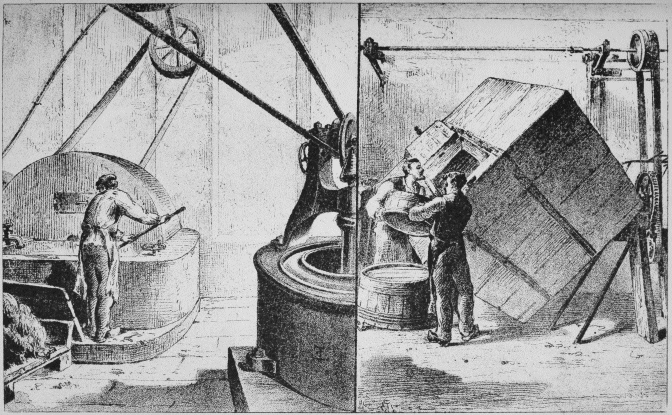

Pl. I.

LIME PITS AND RINSING TANKS.

A

TEXT-BOOK OF TANNING:

A TREATISE ON THE

CONVERSION OF SKINS INTO LEATHER,

BOTH PRACTICAL AND THEORETICAL.

BY

HENRY R. PROCTER, F.C.S.,

OF LOWLIGHTS TANNERY;

EXAMINER IN TANNING TO THE CITY AND GUILDS TECHNICAL INSTITUTE.

With 8 Plates and numerous Illustrations.

E. & F. N. SPON, 125, STRAND, LONDON.

NEW YORK: 35, MURRAY STREET.

1885.

The aim of the following handbook is two-fold; to give, in a compendious form, such a summary of our scientific knowledge as may be useful to the practical tanner; and such a sketch of manufacturing processes as may enable the chemist to apply his knowledge to their improvement. Each may, therefore, find some superfluous matter, for which his indulgence is asked. The book is an expansion of a short article which appeared in Spons' 'Encyclopædia of the Industrial Arts,' and to some extent still bears traces of its origin; and, having been written under stress of limited leisure, and defective eyesight, is very far from being so perfect as I should desire. For the sake of completeness it has been necessary to describe many processes which are outside the range of my own manufacturing experience, and in doing so I have generally referred to the sources of my information. Chapters III. and XXIV. are written by Mr. C. G. Warnford Lock, to whose kind assistance I am much indebted. It may be well to state in conclusion, that while the work is not intended for a cram-book for technical students, it is hoped that it may be an assistance to teachers of the subject.

HENRY R. PROCTER.

Tynemouth,

August 1885.

| PAGE | |

| INTRODUCTORY NOTE | 1 |

CHAPTER I. |

|

| Anatomical Structure of Hide | 2 |

CHAPTER II. |

|

| Chemical Composition of Hide | 17 |

CHAPTER III. |

|

| Commercial Tanning Materials | 23 |

CHAPTER IV. |

|

| The Chemistry of Tannins | 57 |

CHAPTER V. |

|

| Water as used in Tanning | 83 |

CHAPTER VI. |

|

| Methods of Chemical Analysis for the Tannery | 90 |

CHAPTER VII. |

|

| Sole-leather:—Preparing the Hides | 132 |

CHAPTER VIII.

« viii » |

|

| Sole-leather:—Unhairing Hides | 139 |

CHAPTER IX. |

|

| Sole-leather:—Tanning Materials | 157 |

CHAPTER X. |

|

| Sole-leather:—Treatment in the Tan-house | 169 |

CHAPTER XI. |

|

| Sole-leather:—Treatment in the Shed | 179 |

CHAPTER XII. |

|

| Dressing Leather | 184 |

CHAPTER XIII. |

|

| Currying | 193 |

CHAPTER XIV. |

|

| Enamelled, Patent, or Japanned Leather | 203 |

CHAPTER XV. |

|

| Morocco Leather | 206 |

CHAPTER XVI. |

|

| Russia Leather | 208 |

CHAPTER XVII. |

|

| Chamois or Wash-leather | 210 |

CHAPTER XVIII.

« ix » |

|

| Crown Leather, or Preller's Leather | 213 |

CHAPTER XIX. |

|

| Mineral-tanned Leather | 218 |

CHAPTER XX. |

|

| Calf-Kid | 223 |

CHAPTER XXI. |

|

| Glove-Kid | 225 |

CHAPTER XXII. |

|

| Construction and Maintenance of Tanneries | 231 |

CHAPTER XXIII. |

|

| Drying-sheds for Leather | 243 |

CHAPTER XXIV. |

|

| Commerce, Statistics, and Bibliography | 255 |

| Index | 275 |

Leather manufacture may be broadly divided into two stages: "tanning," in which the raw hide is converted into the imputrescible and more or less flexible material known as "leather"; and "currying," in which this leather is further manipulated, and treated with fatty matters, to soften and render it more waterproof, and to improve its appearance. Glove-kid, and certain other leathers, however, are not tanned at all, but "tawed," or prepared with a mixture in which alum and salt are the most active ingredients; chamois, "shammy," or "wash" leather, is produced by fulling with oil alone, and many leathers can scarcely be said to be curried, although more or less oil is used in the final processes of "finishing" or "dressing." The first subject to be treated of in this work will be the operation of tanning, properly so called, taking for example the tannage of sole- and belting-leather. This demands thorough explanation, in both its practical and theoretical aspects, not only because it is one of the most important branches of the trade, but because the principles involved are those which equally underlie all other tanning methods. The next to be dealt with will be the modifications of the process which are necessary in tanning the more flexible leathers used for boot-uppers, hose-pipes, and saddlery purposes; then the currying of these leathers; and finally, the manufacture of moroccos, Russian, and japanned leathers, calf- and glove-kid, &c.

ANATOMICAL STRUCTURE OF HIDE.

Before speaking of actual processes of manufacture, it is necessary to devote some attention to the structure and chemical constitution of hide or skin, which forms the raw material. Although a great variety of skins are employed in tanning, they are all constituted on the same general type, and an anatomical description of the hide of the ox will apply almost equally to those of the calf, sheep, and goat; but from differences in thickness and closeness of texture, their practical uses differ widely. Fig. 1 shows a section of ox-hide, cut parallel with the hair, magnified about 50 diam.: a, epithelial layer or epidermis, consisting of horny layer above, and rete malpighi below; b, pars papillaris, and c, pars reticularis of corium, derma, or true skin; d, hairs; e, sebaceous or fat-glands; f, sudoriferous or sweat-glands; g, opening of ducts of sweat-glands; h, erectores pili muscles, for erecting the hair.

The fresh hide consists of 2 layers: an outer, the epidermis; and an inner, the true skin. The epidermis is very thin as compared with the true skin which it covers, and is entirely removed preparatory to tanning; it nevertheless possesses important functions. It is shown in Fig. 1 at a, and more highly magnified in Fig. 2. Its inner mucous layer b, the rete malpighi, which rests upon the true skin c, is soft, and composed of living nucleated cells, which are elongated in the deeper layers, and gradually become flattened as they approach the surface, where they dry up, and form the horny layer a. This last is being constantly worn away, and thrown off as dead scales of skin; and as constantly renewed from below, by the continued multiplication of the cells. It is from « 3 » this epithelial layer that the hair, as well as the sweat- and fat-glands, are developed. It will be seen in Fig. 1 that each hair is surrounded by a sheath, which is continuous with the epidermis. In embryonic development, a small knob of cells forms on the under side of the epidermis, and this enlarges, and sinks deeper into the true skin, while the root of the young hair is formed within it; this is shown in Fig. 3, a b. Smaller projections also form on the stalk of the knob, and in due time produce the sebaceous glands. The process of development of the sudoriferous glands is very similar to that of the hairs. There is a great analogy between this process and that of the ordinary renewal of hair in the adult animal. « 4 » At d1 Fig. 1, is seen an old and worn-out hair. It is shrunken and elongated, and is almost ready to fall out. It will be noticed that its sheath or follicle projects somewhat below the hair to the right. This is the first production of a young hair, and is quite analogous to the knob of epithelium which has been described as forming the starting-point of a hair in embryo. At d2, the same process is seen further advanced, the young hair being already formed, and growing up into the old sheath. At d3, it is complete, the old hair having fallen out, and the young one having taken its place.

The hair itself is covered with a layer of overlapping scales, like the slates on a roof, but of irregular form. These give it a serrated outline at the sides, strongly developed in wool. Within these scales, which are sometimes called the "hair cuticle," is a fibrous substance, which forms the body of the hair; and sometimes, but not always, there is also a central and cellular pith, which is mostly transparent, though under the microscope it frequently appears black and opaque, from the optical effect of imprisoned air. On boiling or long soaking in water, alcohol, or turpentine, these air-spaces become saturated with the liquid, and then appear transparent.

The fibrous part of the hair is made up of long spindle-shaped cells, and contains the pigment which gives the hair its colour. The hair of the deer differs from that of most other animals in being almost wholly formed of polygonal cells, which, in white hairs, are usually filled with air. At its « 5 » base, the hair swells into a bulb, which is hollow, and rests on a sort of projecting knob of the corium, called the hair-papilla. This has blood-vessels and nerves, and supplies nourishment to the hair. The hair-bulb is composed of round, soft cells, which multiply rapidly; as they grow, they press upward through the hair-sheath, become elongated and hardened, and form the hair. In dark hairs, both the cells of the hair itself and those of its follicle or sheath are strongly pigmented, but the hair much the more so, and hence the bulb has usually a distinct dark form. The dark-haired portions of a hide from which the hair has been removed by liming still remain coloured, from the pigmented cells of the hair-sheaths, which can only be got out completely by bating and scudding. The cells outside the bulb, shown at f, in Fig. 4, pass upwards as they grow, and form a distinct coating around the hair, which is called the "inner root-sheath." This again consists of 2 separate layers, of which the inner is "Huxley's," the outer, "Henle's." They arise from the same cells in the base of the hair; but in the inner layer, these remain polygonal and nucleated, while in the outer, they become spindle-shaped and without nuclei. The inner root-sheath does not extend to the surface of the skin, but dies away below the sebaceous glands. This figure represents an ox-hair root, mag. 200 diam.: a, fibrous substance of hair; b, hair cuticle; c, inner root-sheath; d, outer root-sheath; e, dermic coat of hair-sheath; f, origin of inner sheath; g, bulb; h, papilla.

Outside the inner root-sheath is a layer of nucleated cells, continuous with those of the epidermis, and of the same « 6 » character. This is the "outer root-sheath," and is shown at d, Fig. 4. This, together with the whole of the epidermis, is covered next the corium with an exceedingly fine membrane, called the "hyaline" or glassy layer. It is possible that this forms the very thin buff-coloured "grain" of tanned leather, which evidently is of different structure from the rest of the corium, since, if it gets scraped off before tanning, the exposed portion of the pars papillaris remains nearly white, instead of colouring. The whole of the hair-sheath is enclosed in a coating of elastic and connective-tissue fibres, which are supplied with nerves and blood-vessels, and form part of the corium. Near the opening of the hair-sheaths to the surface of the skin, the ducts of the sebaceous or fat-glands (e, Fig. 1), pass into them, and secrete a sort of oil to lubricate the hair. The glands themselves are formed of large nucleated cells, arranged somewhat like a bunch of grapes; one is shown highly magnified in Fig. 5: a, sebaceous gland; b, hair-stem; c, part of erector pili muscle. The upper and more central cells are most highly charged with fat, which is shown by the darker shading.

As already remarked, the sudoriferous or sweat-glands are also derived from the epidermis layer. They are shown at f, Fig. 1, and on a larger scale (200 diam.) in Fig. 6: a, windings laid open in making section; they consist, in the ox and sheep, of a large wide tube, sometimes slightly twisted. In this, they differ considerably from those of man, which form a spherical knot of extremely convoluted tube. The walls of these glands are formed of longitudinal « 7 » fibres of connective tissue of the corium, lined with a single layer of large nucleated cells, which secrete the perspiration. The ducts, which are exceedingly narrow, and with walls of nucleated cells like those of the outer hair-sheaths, sometimes open directly through the epidermis, as shown at g, Fig. 1, but more frequently into the orifice of a hair-sheath, just at the surface of the skin. Each hair is provided with a slanting muscle (h, Fig. 1), called the arrector or erector pili, which is contracted by cold or fear, and causes the hair to "bristle," or stand on end; by forcing up the attached skin, it produces the effect known as "goose-skin." The muscle, which is of the unstriped or involuntary kind, passes from near the hair-bulb to the epidermis, and just under the sebaceous glands, which it compresses.

The corium or true skin is principally composed of interlacing bundles of white fibres, of the kind known as "connective tissue"; these are composed of fibrils of extreme fineness, cemented together by a substance of different composition from the fibres themselves. This may be demonstrated by steeping a small piece of hide for some days in a stoppered bottle in lime-, or baryta-water, in which the inter-fibrillar substance is soluble, and then teasing a small fragment of the fibre with needles on a glass microscope-slide, and examining with a power of at least 200-300 diam. In the middle portion of the skin, these bundles of fibre are closely interwoven; but next the body, they gradually become looser and more open, forming the pars reticularis (or netted part); and the innermost layer is a mere network of « 8 » loose membrane, generally loaded with masses of fat-cells, and hence called adipose tissue.

It is this adipose tissue which is removed in the "fleshing" process. On the other hand, the outermost layer, just beneath the epidermis, is exceedingly close and compact, the fibre-bundles that run into it being separated into their elementary fibrils, which are so interlaced that they can scarcely be recognised. This is the pars papillaris, and forms the lighter-coloured layer, called (together with its very fine outer coating) the "grain" of leather. It is in this part that the fat-glands are embedded, while the hair-roots and sweat-glands pass through it into the looser tissue beneath.

Besides the connective-tissue fibres, the skin contains a small proportion of fine yellow fibres, called "elastic" fibres. If a thin section of hide be soaked for a few minutes in strong acetic acid, and then examined under the microscope, the white connective-tissue fibres become swollen and transparent, and the yellow fibres may then be seen, as they are scarcely affected by the acid. The hair-bulbs and sweat- and fat-glands are also rendered distinctly visible.

The nerves of the skin are very numerous, each hair being supplied with fibres passing into both the papilla and sheath. They also pass into the skin papillæ. They cannot readily be seen, without special preparation, and, so far as is known, exercise no influence on the tanning process. "Breaking the nerve" is a technical term, which signifies a thorough stretching and softening of the skin, but has nothing to do with nerves properly so called. The blood- and lymph-vessels are, from the present point of view, somewhat more important. They may often be seen in sections, and are lined with nucleated cells, similar to those of the glands. These are surrounded by coatings of unstriped muscular fibre, running both around and lengthways, and also by connective-tissue fibres. In the arteries, the muscular coating is much stronger than in the veins.

It may be thought that the space devoted to a discussion of the anatomical structure of the skin is disproportionately « 9 » large; but there can be no doubt that, in order to make improvements, nothing is of more importance than a clear conception, even to the smallest details, of the materials and causes to be dealt with. The illustrations are from actual specimens, and enable the various parts of the hide to be identified under the microscope.

As this instrument is a most useful means of investigation in the tanning industry, and one likely to be of increasing importance, it will be well, before proceeding further, to say a few words, both on the selection of a suitable instrument, and on its manipulation in general.

To do useful work, it is not necessary to possess a very elaborate or expensive instrument, but it is essential that the microscope be well made and good of its kind. As high powers are often required in the examination, both of hide sections and of ferments, which are the principal objects of investigation in a tannery, it is of the first importance that the fine adjustment should be perfectly steady, without vibration or backlash. This, in the writer's experience, is never the case with cheap microscopes, in which the fine adjustment is made by a screw at the side of the tube moving the nose by means of a lever. A much more satisfactory arrangement is that in which the whole body of the microscope is raised or lowered by a screw in a pillar at the back of the stand on which it slides. A rack for the coarse adjustment is useful, but not essential. If a sliding tube only is provided, it must be tight enough not to slip, but must move easily up and down with a sort of screwing movement. A mechanical stage is not at all necessary, and for most purposes one of black glass is better as well as cheaper. The diaphragm for regulating the light should be as near level with the surface of the stage as possible, and when examined with a low power should appear in the centre of the field. For research work on the minuter ferments, an achromatic condenser and the finest oil- or water-immersion lenses are necessary, but directions for this are beyond the scope of the present work. It may, however, be mentioned that Prof. « 10 » Flügge,[A] a first-class authority on the subject, especially recommends Abbé's illuminating apparatus as made by Zeiss.

[A] "Fermente und Mikroparasiten," Leipzig, 1883.

A frequent defect in cheap English microscopes is that the mirror for substage illumination does not bring the rays of a lamp to a focus exactly on the slide, but frequently some inches above it. This may be to a great extent overcome by the use of a bulls'-eye condenser between the lamp and the microscope. Another defect is that sometimes the centre of the mirror is not in a line with that of the microscope body.

The objectives (or lenses at the lower end of the microscope) are the most important part of the instrument, and however good it may be in all other respects, if these are defective the whole is useless. The most useful lenses for our purpose, if only two are to be selected, are a 1-in., magnifying about 50 diam., and a 1/4-in., magnifying about 200 to 400, according to the eye-piece; a 1/8-in. giving, say, twice this magnification will be needed to see the smaller bacteria distinctly, but it is possible just to see even the small putrefaction bacteria with a really fine 1/4-in. In any case, the highest power should be as perfect and of as large an angle as attainable. A good 1/4-in. should resolve Pleurosigma angulatum with direct light, and should show the movement of the granules of protoplasm in the round corpuscles which are present in saliva. In using the latter test, it must be remembered that the motion only lasts a very short time on a cold slide.

About 5l. is the very least for which a microscope can be obtained which is suitable for tanners' use; where it can be afforded, a better one is advisable.

Without disparaging other makers, it may be mentioned that the writer has generally used both the eye-pieces and objectives of Dr. Hartnack of Potsdam; and that they are moderate in price, at least for the dry combinations, and perfectly satisfactory for all technical purposes. Numbers 2, 5, and 8 objectives with No. 3 eye-piece, are sufficient for all ordinary work. If only 2 objectives are to be obtained, « 11 » Nos. 3 and 7 would be perhaps the best selection. It is always better to use objectives on the stand, and with the eye-pieces for which they are intended, but in case Hartnack's objectives are used on an English stand (which is easily done by means of an adaptor ring), it is important to remember that they are constructed to work with a shorter tube than that customary on English microscopes, and that they will not perform well if its length is much more than 6 in.; these objectives are not provided with a movable adjustment for thickness of cover-glasses, which for technical purposes is not required, and in inexperienced hands is apt to prove troublesome. Extra-thin covers must therefore always be used. Where this adjustment is provided, the object must be accurately focused, and then, maintaining this focus with the fine focusing-screw, the collar must be cautiously turned till the best definition is obtained. Practically it will be best to make this adjustment accurately once for all, and to take care to use covers selected of a uniform thickness.

High-power objectives of wide angle (which condition is essential to good defining power) necessarily work extremely close to the object, and it is always best to use the thinnest cover-glasses which can be got. Even then, with such glasses as Hartnack's No. 8, unless the sections are very thin, it will be impossible to examine their lower parts; and one of the greatest difficulties of microscopic research is to obtain them thin enough. It will be obvious, from what has been said, that the greatest care is needed to avoid screwing the objective down on the cover, and so breaking one or both of them. One way to avoid this is to screw down as close as possible to begin with, and then focus upwards. Another plan, when the object on the slide is small, is to keep continuously moving the slide gently with the fingers, while looking into the tube. It is then easy to notice when the dust and small particles on the slide come into focus, and if the point should happen to be overstepped the contact will generally be felt before serious damage is done.

Illumination is one of the most important points in practical microscopy. With powers of not less than 1/2-in. focus, objects may generally be examined by light thrown upon them from above by a bulls'-eye condenser, or by good daylight. In this case they need not be transparent; and the plan is often convenient for a mere surface examination. In examining bodies illuminated in this way, prominences often appear as hollows and vice versâ, by a sort of optical illusion, which, once established, is very difficult to overcome. By remembering the direction of the light, and that this appears reversed in the microscope, it is easy to decide the truth.

For all finer work and higher powers, and most generally with the low powers also, it is necessary to render the object transparent, and to examine it by light transmitted from the mirror below the stage.

Good daylight is least trying to the eyes. Where artificial light must be used, that of a small paraffin lamp is best; and a blue chimney, or blue glass interposed between the stage and mirror, or lamp and microscope, spares the sight, and makes it easier to distinguish colours. The light should be sufficient, but not too dazzling. Work should never be prolonged after the least strain is felt, nor should the microscope be used for some little time after a meal. It is well to accustom oneself to keep both the eyes open while observing.

If it be required to see how far the cellular structures of the hide, such as hair-sheaths and fat-glands, are affected or destroyed in any stage of liming or bating, the following ready method may be employed. If a strip of hide be cut 2/3 through from the grain side, as shown at a in Fig. 7, and the flap be turned down, and held between the finger and thumb, the fibrous tissue will be put on the stretch, and will then allow a moderately thin shaving (including the grain and parts immediately below it) to be cut by a sharp razor. The hide should be held in the positions shown, and a steady drawing cut be made from flesh to grain, the razor being « 13 » steadied on the tip of the forefinger, and its hollow surface flooded with water. If the thin section be now placed on a glass slide, moistened with a drop of water, and examined on the microscope under a strong light from above, with a 1-in. objective, the fat-glands will be seen as yellow masses, embedded in the white fibrous tissue. If a drop of a mixture of equal vols. of strong acetic acid, glycerin, and water be used to moisten the section, the fibrous tissue will become quite transparent, and whatever remains of the cellular tissue will be easily visible, and may even be studied under tolerably high powers if covered with a thin glass, and lighted by the mirror from below. (The cover-glass must be carefully cleaned by rubbing with a linen handkerchief, and placed in position with a pair of tweezers, one side being supported by a needle, which is gradually withdrawn, so as to avoid air-bubbles.) Care must be taken that this mixture does not touch the brass-work of the microscope; even the vapour is apt to tarnish, so that the preparation must not remain longer than necessary on the microscope. The same method is applicable for ascertaining the completeness of the tannage of leather, and to decide whether the hide fibre is really tanned, or only dyed. Actually tanned leather is unaffected by the acetic acid, but raw or only stained hide swells and becomes transparent.

To prepare the very thin sections necessary for detailed study of the hide, more complicated methods are required. Small slips of hide, not exceeding 1/4 in. wide, and cut exactly « 14 » across the lie of the hair, are placed first in weak alcohol (equal parts methylated spirit and water), and, after a few hours, are removed into strong methylated spirit. It is then kept for some days in absolute alcohol, which must be repeatedly changed, until the hide is hard enough to give fine shavings, and may be cut either when held as above described, between cork or pith, or when embedded in paraffin wax. This is accomplished by placing the piece of hide in a little paper-box and covering it with melted paraffin (candle), which is just beginning to stiffen. The piece of hide may be fixed in position with a needle, which must of course be withdrawn before cutting. When hard, the paraffin is shaved away till the object is exposed, when it may be cut. The razor must be wet with alcohol, and the section be made exactly in the plane of the hair-roots, which may be seen with a hand-lens. (The use of a microtome for hide-sections is rarely successful, as it is almost impossible to fix the fragment of hide so that it is cut exactly with the hairs.) The slices may now be stained by placing them in a watch-glass with water and a few drops of the logwood or picrocarmine staining-mixtures sold by opticians, and afterwards either examined in glycerin, or, after soaking some hours in absolute alcohol, may be transferred to clove-oil, and afterwards to a slide, and covered with a drop of dammar varnish or Canada balsam dissolved in chloroform. The sections moistened with glycerin may also be mounted in Farrant's solution or glycerin jelly, under a cover-glass for permanent preservation. If picrocarmine be used, the connective-tissue fibres (gelatinous fibres) and the nuclei of the cells will be coloured red, and the cells themselves of both epidermis and glands, together with the muscles and elastic fibres, will be yellow.

Franz Kathreiner, who has made very elaborate researches on skin, and the changes which take place in it during the processes of tanning, employs a mixture of osmic and chromic acids for hardening, and at the same time staining the tissue. This mixture was first used by a German histologist « 15 » with whose name I am not acquainted, in a research on the internal organs of hearing, and was applied by Kathreiner in 1879 to the investigation of skin, and communicated by him to the writer in the autumn of that year. His method is briefly as follows. The pieces of hide to be examined must, if salted, be well washed, or if dry, be thoroughly softened. For the study of hide in its unaltered and natural condition, it is essential that it be quite fresh, and taken from the animal as soon as possible after death. In any case the Panniculus adiposus or fatty layer is, as far as possible, removed with scissors, the hair cut short, and the skin cut up into little pieces of 3-4 millimetres wide by 10-12 millimetres long (about 1/8 in. by 1/2 in.); the hair must lie exactly across these pieces.

They are then placed for 4-8 days, according to the thickness of the hide, in about 12 times their volume of a solution consisting of

| 0·2 | parts osmic acid.[B] |

| 0·5 | " chromic acid. |

| 200·0 | " water. |

[B] Solution of osmic acid is best preserved in sealed tubes in the dark. If obtained in solution it is rarely of full strength, for which allowance may have to be made. Care must be taken to avoid inhaling its fumes, which are very irritating to the eyes and to the respiratory organs, producing severe catarrh.

This solution must be kept from dust and light, in a glass stoppered bottle, and in a cool place. On removing the hide-pieces from this solution, they are placed in about 12 times their volume of absolute alcohol for 4-8 days, during which time the spirit must be at least 3 times renewed. The sections are cut with a razor flooded with absolute alcohol, so that the thin shavings float without friction upon it. The hide-pieces may be held either between soft cork, or, as is generally preferable, simply between the forefinger and thumb as shown in Fig. 7. The cut must be made exactly parallel with the direction of the hair roots, and from the grain towards the flesh; and the sections cannot possibly be too thin. After lying for 1/2-1 hour in « 16 » absolute alcohol, the sections are soaked till quite clear in clove oil (which must be pale and of the purest kind), and may then be mounted in dammar varnish, or solution of Canada balsam.

In these sections, fat and the oily contents of the fat glands are stained black, and the limits of the cells both of these glands and of other elements of the hide (rete malpighi, hair-bulb, &c.) are made very distinct, so as to be capable of the most delicate investigation under the highest powers; but the beginner will learn most easily to recognise the different tissues by studying at first some sections stained with picrocarmine as before described. The method is admirably adapted for the study of hide as affected by the limes and bates.

CHEMICAL COMPOSITION OF HIDE.

The chemical composition of skin is very imperfectly understood. The bulk of the skin is, as has long been known, converted by boiling into gelatin or glue. The yellow fibres and cellular tissue remain undissolved. Müntz, who made some interesting researches on the subject, found that completely dried hide contained—3·086 per cent. of cellular tissue insoluble in hot water, 1·058 of fat, 0·467 of mineral matter, and 95·395 of matters soluble in hot water. Müntz counts the whole of the tissue soluble in hot water as converted into glue; but this is not strictly the case. Gelatin is not identical with the fibre of the hide, which is only converted into it by boiling. The nature of the change is not well understood; but it is either simply molecular, or depends on the addition of one or more molecules of water. The gelatin of bones seems identical with that of skin and connective tissue, but that of cartilage differs slightly from it, and is called chondrin. Raw hide, unhaired and purified, contains, according to Müntz—carbon, 51·43 per cent.; hydrogen, 6·64; nitrogen, 18·16; oxygen, 23·06; ash, 0·71; while gelatin has—carbon, 50·1 per cent.; hydrogen, 6·6; nitrogen, 18·3 (Mulder); carbon, 50 per cent.; hydrogen, 6·5; nitrogen, 17·5 (Fremy). Probably, however, neither substance was quite pure.

Gelatin is insoluble in alcohol, ether, and cold water, but swells in the last, absorbing about 40 per cent. It is soluble in hot water, but is reprecipitated on the addition of a sufficient quantity of alcohol, resembling in this respect gum, dextrin, and many other substances. It is soluble in glycerin, with the aid of heat, and in concentrated sulphuric « 18 » acid in the cold. Moist gelatin exposed to the air rapidly putrefies. It first becomes very acid, from formation of butyric (and perhaps other) acids, but afterwards alkaline, from evolution of ammonia. Boiled with concentrated potash, it yields leucin (amidocaproic acid, C6H15NO2), glycocin (sugar of gelatin), and other substances. The same products are obtained by boiling with sulphuric acid, and probably also more gradually, and in greater or less proportions, by the prolonged action of lime or barium hydrate, by putrefaction, and by any other influence which tends to resolve the gelatin molecule into its simpler parts. Gelatin is precipitated by all tannins, even from very dilute solution. A solution containing 2/10000 parts is rendered turbid by infusion of gall-nuts or gallotannic acid. The precipitate is soluble in excess of gelatin. Solution of gelatin dissolves considerable quantities of lime phosphate, hence this is always largely present in common glue. Gelatin is precipitated by mercuric chloride, in this respect resembling peptones; but not by potassium ferrocyanide, by which it is distinguished from albuminoids; and it differs from albumen in not being coagulated by heat. On the contrary, by prolonged boiling glue loses the property of gelatinising, and becomes soluble in cold water, being split up into two peptones; semi-glutin, which is insoluble in alcohol, and precipitated by platinic chloride; and hemicollin, which is soluble in alcohol, and not precipitated by platinic chloride. Both are precipitated by mercuric chloride (see Hofmeister, abst. Chem. Soc. Jour. 1881, p. 294). Gelatin or glue with about 3 per cent. of potassium dichromate becomes insoluble when exposed to the light, from the formation of a chromium compound. This reaction is the base of several modern photographic processes, and has been used for waterproofing and for cementing glass, &c.

The connective-tissue fibres are partially converted into gelatin by the action of strong acids and alkalies, as well as by heat. By weak acids, they are swollen and gradually dissolved, and Reimer[C] has found that the material may « 19 » be reprecipitated by lime-water. It forms an irregular fibrous mass, which has not the sticky feel of gelatin, but is at once converted into that body by boiling. Rollet has demonstrated that when hide and other forms of connective tissue are soaked in lime- or baryta-water, the fibres become split up into finer fibrils, and as the action proceeds, these again separate into still finer, till the ultimate fibrils are as fine as can be distinguished under a powerful microscope. At the same time, the alkaline solution dissolves the substance which cemented the fibres together, and this may be recovered by neutralising the solution with acetic acid, when it comes down as a flocculent precipitate. This was considered by Rollet to be an albuminoid substance; but Reimer has shown that it is much more closely allied to the gelatigenous fibres, if indeed it is not actually produced from them by the action of the alkaline solution. Reimer used limed calf-skin for his experiments, and subjected it to prolonged cleansing with distilled water, so that all soluble parts must have been pretty thoroughly removed beforehand. He then digested it in closed glasses with lime-water for 7-8 days, and precipitated the clear solution with dilute acetic acid. He found that the same portion of hide might be used again and again, without becoming exhausted, which strongly supports the supposition that it is merely a product of the partial decomposition of the hide fibre. The substance, which he called "coriin," was purified by repeated solution in lime-water, and reprecipitation by acetic acid. It was readily soluble by alkalies, but insoluble in dilute acids, though in some cases it became so swollen and finely divided as to appear almost as if dissolved. It was, however, very soluble in common salt solution of about 10 per cent., though it was precipitated both by the addition of much water, and by saturating the solution with salt. Reimer found that a 10 per cent. salt solution was equally effective with lime-water in extracting it from the hide, and that it was partially precipitated on the addition of acid, and completely on saturating the acidified solution with salt. « 20 » Other salts of the alkalies and alkaline earths acted in a similar manner, so that Reimer was at first deceived when experimenting with baryta-water, because, being more concentrated than lime-water, the coriin remained dissolved in the baryta salt formed on neutralising with acid, and it was necessary to dilute before a precipitate could be obtained. The slightly acid solution of coriin gave no precipitate with potassium ferrocyanide, nor was it precipitated by boiling, being thus distinguished from albuminoids. The neutral or alkaline solution was not precipitated by iron or mercuric chloride, copper sulphate, nor by neutral lead acetate; but was precipitated by basic lead acetate, basic iron sulphate, and excess of tannin. Its elementary composition is—carbon, 45·91: hydrogen, 6·57; nitrogen, 17·82; oxygen, 29·60; and Reimer proposes the following equation as representing its relation to hide fibre:—

| Hide fibre. | Water. | Coriin. | ||

| C30H46N10O12 | + O + | 2H2O | = | C30H50N10O15. |

[C] Dingler's Polyt. Journal, vol. 220, p. 167.

Hide Albumen.—The fresh hide, besides this coriin (which, very possibly, is only evolved by the action of the lime), contains a portion of actual albumen, viz. that of the blood serum and of the lymph, which is not only contained in the abundant blood-vessels, but saturates the fibrous connective tissue, of which it forms the nourishment. This albumen is mostly removed by the liming and working on the beam, which is preparatory to tanning. Probably for sole-leather, the albumen itself would be rather advantageous if left in the hide, as it combines with tannin, and would assist in giving firmness and weight to the leather. It is, however, for reasons which will be seen hereafter, absolutely necessary to get rid of any lime which may be in combination with it. The blood also must be thoroughly cleansed from the hide before tanning, as its colouring matter contains iron, and, in combination with the tannin, would give a bad colour.

The reactions of blood and lymph albumen are very similar to those of ordinary white of egg. It is precipitated by « 21 » strong mineral acids, especially nitric, and also by boiling. The precipitate produced by strong hydrochloric acid redissolves by the aid of heat to a blue or purple solution. Tribasic phosphoric, tartaric, acetic, and most other organic acids, do not precipitate moderately dilute solutions of albumen, but convert it into a sort of jelly, which, like gelatin, does not coagulate, but liquefies on heating. It is precipitated by neutral salts of the alkali metals. Blood-albumen slightly acidified (with acetic acid) is precipitated by potassium ferrocyanide. It is not precipitated by dilute infusions of oak bark, but is rendered uncoagulable by heat, hence it cannot be employed to remove tannins from their solutions.

Elastic Fibres.—The elastic or yellow fibres of the hide are of a very stable character. They are not completely dissolved even by prolonged boiling, and acetic acid and hot solutions of caustic alkalies scarcely attack them. Probably they do not combine with tannin, and are very little changed in the tanning process.

Hair, Epidermis, and Glands.—These are, as has been seen, all derived from the epithelial layer, and hence, as might be inferred, have much in common in their chemical constitution. They are all classed by chemists under one name, "keratin," or horny tissue, and their ultimate analysis shows that in elementary composition they nearly agree. It is evident, however, that the horny tissues are rather a class than a single compound.

The keratins are gradually loosened by prolonged soaking in water, and, by continued boiling in a Papin's digester, are dissolved to an extract which does not gelatinise on cooling. Keratin is dissolved by caustic alkalies; the epidermis and the softer horny tissues are easily attacked, while hair and horn require strong solutions and the aid of heat to effect complete solution. The caustic alkaline earths act in the same manner as dilute alkaline solutions; hence lime easily attacks the epidermis, and loosens the hair, but does not readily destroy the latter. Alkaline sulphides, on the other hand, seem to attack the harder tissues with at least the same « 22 » facility as the soft ones, the hair being often completely disintegrated, while the epidermis is still almost intact; hence their applicability to unhairing by destruction of the hair. Keratins are dissolved by fuming hydrochloric acid, with the production of a blue or violet coloration, like the albuminoids. They also resemble albumen, in the fact that their solution in sulphuric acid is precipitated by potassium ferrocyanide. By fusion with potash, or prolonged boiling with dilute sulphuric acid, keratin is decomposed, yielding leucin, tyrosin, ammonia, &c. The alkaline solution of keratin (hair, horns, &c.) is precipitated by acids, and, mixed with oil and baryta sulphate, is employed under Dr. Putz's patent as a filling material for leather, for which purpose it acts in the same way as the egg-yolks and meal used in kid-leather manufacture. Eitner attempted to use it for the same purpose with bark-tanned leather, but without much success. Putz has also proposed to precipitate the material after working its solution into the pores of the leather.

COMMERCIAL TANNING MATERIALS.

Algarobilla.—The seed-pods of Prosopis pallida and P. Algarrobo are known as algarobilla, the two kinds being distinguished as negro and blanco. The trees are abundant in mountainous parts of South America, notably Chili and the Argentine Republic. The pods contain up to 50 per cent. of a bright-yellow tannin, somewhat resembling that of myrobalans. The friable tannin is readily soluble in cold water, and is so loosely held in the fibrous network of the pod, that great loss is sustained by careless handling. The commerce in algarobilla does not figure in the official trade returns; but J. Gordon & Co., Liverpool, obligingly state that they imported 50 tons, at an average value of 18l. 10s. a ton, in 1880. Widow Duranty & Son, also of Liverpool, are good enough to add that they received 160 tons in 1881, the first that had reached them for a long time. Havre imported 50 tons in 1881. The name algarrobo is also applied to Balsamocarpon brevifolium in Chili, and to Hymenæa Courbaril in Panama.

Chestnut-extract.—The wood of the chestnut (Castanea vesca) contains 14-20 per cent. of a dull-brown tannin. It is quite different from the bark and bark-extract of the American chestnut-oak (Quercus sessiliflora). Its extract is used largely to modify the colour produced by hemlock-extract, and for tanning and dyeing. The pulverised wood is also extensively employed in France. The imports are included in barks and extracts, p. 39.

Cork-bark. See Oak-barks.

Cutch, Catechu, or Terra Japonica (Fr., Cachou; Ger., Catechu).—The term kát, kut, or "cutch," is applied to « 24 » the dried extract, containing 45-55 per cent. of dark-coloured mimo-tannic acid, prepared chiefly from 2 trees:—(1) Acacia Catechu [Mimosa Catechu, M. sundra], a tree of 30-40 ft., common in most parts of India and Burma, growing also in the hotter and drier districts of Ceylon, and abundant in tropical East Africa—the Soudan, Sennar, Abyssinia, the Noer country and Mozambique, though the utilisation of its tannin is restricted to India; (2) A. [M.] Suma, a large tree inhabiting South India (Mysore), Bengal, and Gujerat.

The process for preparing cutch varies slightly in different districts. The trees are reckoned to be of proper age when their trunks are about 1 ft. diam. They are then cut down, and the whole of the woody part, with the exception of the smaller branches and the bark, is reduced to chips: some accounts state that only the darker heart-wood is thus used. The chips are placed with water in earthen jars, arranged in a series over a mud fire-place, usually in the open air. Here the water is made to boil, the liquor as it becomes thick and strong being decanted into another vessel, in which the evaporation is continued until the extract is sufficiently inspissated, when it is poured into moulds made of clay, or of leaves pinned together in the shape of cups, or in some districts on to a mat covered with the ashes of burnt cow-dung, the drying in each case being completed by exposure to the sun and air. The product is a dark-brown extract, which is the usual form in which cutch is known in Europe.

In Kumaon, North India, a slight modification of the process affords a drug of very different appearance. Instead of evaporating the decoction to the condition of an extract, the inspissation is stopped at a certain point, and the liquor is allowed to cool, coagulate, and crystallise over twigs and leaves thrown into the pots for the purpose. By this method is obtained from each pot about 2 lb. of kath or catechu, of an ashy-whitish appearance. In Burma, the manufacture and export of cutch form one of the most important items of forest revenue. The quantity of cutch exported from the province in 1869-70 was 10,782 tons, valued at 193,602l., of « 25 » which nearly half was the produce of manufactories situated in British territory. The article is imported in mats, bags, and boxes, often enveloped in the large leaf of Dipterocarpus tuberculatus. It is brought down from Berar and Nepal to Calcutta. That of Pegu has a high reputation.

Our imports of cutch in 1880 were 5155 tons, value 173,040l., from the British East Indies; 539 tons, 15,572l., from other countries; total, 5694 tons, 188,612l. Our exports in the same year were:—892 tons, 28,527l., to Germany; 676 tons, 24,562l., to the United States; 478 tons, 15,505l., to France; 303 tons, 10,537l., to Holland; 177 tons, 5859l., to Russia; 141 tons, 4835l., to Belgium; 245 tons, 8719l., to other countries; total, 2912 tons, 98,544l. The approximate London market value of Pegu cutch is 21-42s. a cwt.

An astringent extract prepared from the areca nut (Areca Catechu) is said to contribute to commercial cutch; if so, it is a totally distinct product from those just described.

Divi-divi, or Libi-dibi.—These names are applied to the seed-pods of Cæsalpinia coriaria, a tree of 20-30 ft., indigenous to several of the West Indies, Mexico, Venezuela, and North Brazil, and naturalised in Madras and Bombay Presidencies, and in the North-West Provinces. The pod may be known by its drying to the shape of a letter S; it contains 30-50 per cent. of a peculiar tannin, somewhat similar to that of valonia. It is cheap, and may be used in admixture with barks; but it is dangerously liable to undergo fermentation, suddenly staining the leather a dark-red colour, and is therefore not in extensive use. The imports of it are mainly from Maracaibo, Paraiba, and St. Domingo. Maracaibo, in 1880, exported 197,674 lb. of divi-divi, value 32221/4 dol. (4s. 2d.), to New York. Our imports of divi-divi into Liverpool, according to figures kindly furnished by Haw & Co., were 2200 tons in 1877, 1740 in 1878, 2132 in 1879, and 780 in 1880. The approximate market value is 12-17l. a ton.

Galls.—The generic term "gall" is applied to those excrescences on plants which are produced by the punctures « 26 » of insects, for the purpose of depositing their eggs. The excrescences are usually considered to be a diseased condition of vegetable tissue, resulting from the injection of some secretion of the insects. But this has been combated by A. S. Wilson, of Aberdeen, who considers that all insect galls are in reality leaf-buds, or fruit-buds, and not mere amorphous excrescences. The vascular lines which would form leaves can easily be followed up in the structure of the oak-leaf galls. And in cases where the egg has been deposited in the tissue of a young branch, the cap of the gall is sometimes surmounted by a leaf 2-3 in. long. But in the large blue Turkish galls, many lacunæ occur where the fleshified leaves have not filled up the spaces between them. If a dissection be made of one of the weevil-galls on the bulb of the turnip, the second or third slice will show the outer foliations, exactly similar to those of the root-buds. When the centre has been reached, where the maggot will be found, there will also be a vascular pencil running up from a medullary ray in the bulb, and bearing on its top a bud of the same description as that produced by a ray running out from a root. The insertion of the ovipositor brings a medullary ray into action, producing a tuberculated bud, and it is only the bud which the larva feeds upon. The growth of a bud is an intelligible cause of the growth of a gall, but nothing can be inferred from the injection of a fluid. The analogy to leaves is further shown by the fact that various microscopic fungi are matured in the interior of imperforate galls.

The principal commercial kinds of gall are oak-galls and Chinese galls.

Oak-galls, Nut-galls, Aleppo or Turkey-galls (Fr., Noix de Galle, Galle d'Alep; Ger., Levantische or Aleppische Gallen, Galläpfel).—These are formed by the punctures of Cynips [Diplolepis] Gallæ tinctoriæ on Quercus lusitanica var. infectoria [Q. infectoria], a shrubby tree of Greece, Cyprus, Asia Minor, and Syria, and probably other varieties and even species of oak. The female insect is furnished with a delicate ovipositor, by means of which she pierces the tender shoots of « 27 » the tree, and lays her eggs therein. In the centre of the full-grown gall, the larva is hatched and undergoes its transformations, finally (in 5-6 months) becoming a winged insect, and boring for itself a cylindrical exit-hole. The best commercial galls are those which have been gathered while the insect is still in the larval state. Such have a dark olive-green colour, and are comparatively heavy; but after the fly has escaped, they become yellowish-brown in hue, and lighter. Hence they are distinguished in the London market as "blue" or "green," and "white." In Smyrna, they are classified as "white," "green," and "black," the first two sorts generally fetching nearly the same price, while the black obtain considerably more, the approximate quotations being: white and green, per Turkish oke (of 2·83 lb.), 81/2-9 piastres (of 2d.); black, 131/2-14 piastres. The "nuts" come mostly from Melemen, Cassaba, and Magnesia, also from the Syrian coasts, being plentiful on the east of the river Jordan, and are chiefly forwarded to France, England, and Salonica. The triennial yield is said to be invariably the best. They begin to reach Smyrna from the interior towards the end of July. The crop of 1880 was estimated at over 50,000 okes. The province of Aleppo, which used to afford 10,000-12,000 quintals (of 2 cwt.) annually, only exported 3000 in 1871. The galls collected in the Kurdistan mountains are marketed at Diarbekir, and sent thence to Trebizonde for shipment. Bussora, Bagdad, and Bushire also export considerable quantities.

Knoppern, a species of gall formed from the immature acorns of Quercus pedunculata and Q. sessiliflora, are largely used for tanning throughout Austria.

The exports from Aleppo (including yellow berries) in 1880 were:—60 tons, 3600l., to Great Britain; 322 tons, 19,320l., France; 15 tons, 900l., Italy; 44 tons, 2640l., Austria; 55 tons, 3300l., Turkey; 30 tons, 1800l., Egypt; total, 526 tons, 31,560l. In 1878, the figures were 673 tons, 38,400l. Alexandretta exported in 1879 (including yellow berries):—41 tons, 2460l., to England; 299 tons, 17,940l., France; 20 tons, 1200l., Italy; 25 tons, 1500l., Austria; « 28 » 87 tons, 5220l., Turkey; 6 tons, 360l., Egypt; total 478 tons, 28,680l. The shipments from Trebizonde by steamer in 1880 were (from Turkey):—47 sacks (of 2 cwt.), 188l., to Turkey; 240 sacks, 960l., Great Britain; 264 sacks, 1056l., France; 103 sacks, 412l., Austria and Germany; 26 sacks, 104l., Greece; total, 680 sacks, 2720l.; (from Persia): 25 sacks, 100l., Great Britain; 31 sacks, 124l., France; 30 sacks, 120l., Austria and Germany; total, 86 sacks, 344l. Bushire despatched 5000r. worth to India in 1879. Syra sent 248l. worth to Great Britain in 1879. Venice exported 1745 tons of gall and bark, value 34,906l., in 1879.

The best oak-galls contain 60-70 per cent. of tannic or gallotannic acid, and 3 per cent. of gallic acid. "Rove" is a small crushed gall, containing 24-34 per cent. of gallotannic acid. There are many other varieties of non-commercial oak-gall.

Chinese or Japanese Galls.—These are vesicular protuberances formed on the leaf-stalks and branches of the Rhus semialata [Bucki-amela], a tree of 30-40 ft., common in North India, China, and Japan, ascending the outer Himálaya and the Khasia Hills to 2500-6000 ft., by punctures of the female of Aphis chinensis. The galls are collected when their green colour is changing to yellow, and are then scalded. They are light and hollow, 1-21/2 in. long, and of very varied and irregular form. The Japanese are the smaller and paler, and usually more esteemed. The galls contain about 70 per cent. of tannic or gallotannic acid, and 4 per cent. of another tannin. They are consumed mainly in Germany, for the manufacture of tannic acid.

Hankow exported 30,949 piculs (of 1331/3 lb.) in 1872; and 21,611 piculs, value 136,214 taels (of about 6s.), in 1874. In 1877, the total Chinese export did not exceed 17,515 piculs. Hankow exported 24,7421/2 piculs in 1878, and 28,392 piculs, 59,614l., in 1879; Pakhoi, 62l. worth in 1879; Canton, 31551/3 piculs in 1877, 1939 in 1878, 31631/2 in 1879; Ichang, 1001/2 piculs, 132l., in 1878, 4021/2 piculs, 586l., in 1879; Shanghai, 27,6591/2 piculs in 1879.

In China trade returns, they are always miscalled "nut-galls" or "gall-nuts": correctly, they are wu-pei-tze. Oak-galls are exported from China resembling those of Western Asia. Japanese galls, kifushi, are sent in increasing quantities from Hiogo.

Our imports of galls in 1880 were:—24,590 cwt., 68,697l., from China; 17,311 cwt., 60,648l., from Turkey; 9182 cwt., 9013l., from other countries: total, 51,083 cwt., 138,358l. Our re-exports in the same year were:—6260 cwt., 18,479l., to Holland; 6022 cwt., 18,147l., to Germany; 3214 cwt., 11,002l., to France; 3045 cwt., 8598l., to Belgium; 2651 cwt., 11,004l., to the United States; 1625 cwt., 5205l., to other countries; total, 22,817 cwt., 72,435l. The approximate London market values of galls are:—Bussora, blue, 82-102s. a cwt.; do., white and in sorts, 50-90s.; China, 50-70s.; Japan, 55-56s.

Gambier, Pale Catechu, or Terra Japonica (Fr., Gambir, Cachou jaune; Ger., Gambir).—These names are conferred upon an extract from the leaves of Uncaria Gambier [Nauclea Gambir] and U. acida, containing 36-40 per cent. of a brown tannin, which rapidly penetrates leather, and tends to swell it, but alone gives a soft porous tannage; it is largely used in conjunction with other materials for tanning both dressing- and sole-leather. The plants are stout climbing shrubs, the first-named being a native of the countries bordering the Straits of Malacca, and especially the islands at the eastern end, though apparently not indigenous to any of the islands of the volcanic band, growing also in Ceylon, where no use is made of it; while the second, probably a mere variety, flourishes in the Malay islands.

The shrubs are cultivated in plantations, often formed in jungle clearings; the soil is very rapidly exhausted, and further injured by excessive growth of the ineradicable lalang-grass (Andropogon caricosus). It is found advantageous to combine pepper-culture with that of gambier, the boiled leaves of the latter forming excellent manure for the former. The gambier-plants are allowed to grow 8-10 ft. high, and « 30 » as their foliage is always in season, each plant is stripped 3 or 4 times in the year. The tools and apparatus for the manufacture of the extract are of the most primitive description. A shallow cast-iron pan about 3 ft. across is built into an earthen fire-place. Water is poured into the pan, a fire is kindled, and the leaves and young shoots, freshly plucked, are scattered in, and boiled for about an hour. At the end of this time, they are thrown on to a capacious sloping trough, the lower end of which projects into the pan, and are squeezed with the hand so that the absorbed liquor may run back into the boiler. The decoction is then evaporated to the consistence of a thin syrup, and baled out into buckets. When sufficiently cool, it is subjected to curious treatment: instead of simply stirring it round, the workman pushes a stick of soft wood in a sloping direction into each bucket; and, placing two such buckets before him, he works a stick up and down in each. The liquid thickens round the stick, and, the thickened portion being constantly rubbed off, while at the same time the whole is in motion, it gradually sets into a mass, a result which, it is said, would never be produced by simple stirring: it is reasonable to suppose that this manner of treating the liquor favours the crystallisation of the catechin in a more concrete form than it might otherwise assume. The thickened mass, resembling soft yellowish clay, is now placed in shallow square boxes; when somewhat hardened, it is cut into cubes, and dried in the shade. The leaves are boiled a second time, and finally washed in water, which is saved for another operation.

A second plan is as follows:—The leaves are boiled, and bruised in a wooden mortar (lesong), from which they are put into a kind of basket of rattan open-work, which is pressed by a long piece of wood acting as a lever; the liquid is received into a trough, and there allowed to settle. When the sediment has acquired sufficient substance, it is put into a kulit-kayo, formed like a tub without a bottom, which lets the superfluous water drain off; when that is done, it is taken out, made into small cakes, and dried for use. A « 31 » plantation employing 5 labourers contains 70,000-80,000 shrubs, and yields 40-50 catties (of 11/3 lb.) of gambier daily.

Plantations were commenced in Singapore in 1829, and once numbered 800; but owing to scarcity of fuel, abundance of which is essential to the manufacture, and dearness of labour, the culture was fast declining in 1866. In 1872, it had much recovered. It is largely pursued on the mainland (Johore), and in the Rhio-Lingga Archipelago, S.-E. of Singapore; on Bintang, the most northerly of the group, there were 1250 plantations of it in 1854. None is cultivated in Sarawak, though found wild in many parts; the foreign export from Sarawak in 1879 had a total value of 88,148 dol. The best kind is brought largely from Sumatra, but is often adulterated with sago. The Rhio product is also thus sophisticated, and rendered heavier by the Chinese purposely packing it in baskets lined with wet cajangs, occasioning a loss to the purchaser of about 30 per cent.

Singapore is the great emporium for gambier, and exported 34,248 tons in 1871, 19,550 tons having been imported, chiefly from Rhio and the Malay Peninsula. In 1876, the export increased to over 50,000 tons of pressed block, and 2700 tons of cubes. In 1877, it fell to 39,117 tons, owing to differences with the Chinese dealers concerning adulteration; of this quantity, 21,607 tons were for London, 7572 for Liverpool, and 2345 for Marseilles. The United Kingdom imports in 1872 were 21,155 tons, 451,737l., almost all from the Straits Settlements; in 1880, they were 26,061 tons, 461,781l., from the Straits, and 352 tons, 6468l., from other countries; total, 26,413 tons, 468,249l. Our re-exports in 1880 were:—2487 tons, 48,507l., to Holland; 1591 tons, 31,542l. to Germany; 1137 tons, 23,694l., to Russia; 594 tons, 12,026l., to other countries; total, 5809 tons, 115,769l. The approximate London market values are 15s. 6d.-21s. 6d. a cwt. for block, 18-24s. for pressed cubes, and 23-27s. for free cubes.

Hemlock.—The bark of the hemlock or hemlock spruce (Abies canadensis), of Canada and the United States, contains nearly 14 per cent. of tannin. The stripping of the bark « 32 » commences in the southern parts of the United States in spring, and lasts during April-May; in New York, Michigan, and Wisconsin, the season is June-July; and farther north, it is still later. It is said that the best product is obtained farthest south. The destruction of the hemlock forests is fast approaching. Within the last 25 years, the preparation of an extract from the bark, containing 18-25 per cent. of a deep-red tannin, giving considerable weight and firmness to leather, has superseded the export of crude bark. One mode of preparing the extract is as follows:—The bark in pieces 1/2-1 in. thick, and several inches long, is soaked for about 15 minutes in water at 200° F. (93° C.); it is then fed into a hopper, which conducts it to a 3-roller machine, something like a sugar-cane mill, through which it passes, coming out lacerated and compressed; it next falls into a vat of hot water, where it is agitated by a wheel, that the tannin from the crushed cells may be dissolved in the water; hence it is raised by a series of buckets on an endless chain, somewhat in the manner of a grain-elevator, to another hopper, whence it is fed to another 3-roller mill; here it receives its final compression, and comes out in flakes or sheets, like coarse paper, and almost free from tannin. The buckets are made of coarse wire, that the water may drip through during the elevation. In order to avoid the blackening action of iron, wherever this metal will come into contact with the solutions it is thickly coated with zinc. The solution is evaporated to a solid consistency, generally by vacuum-pans. About 2 tons of bark are represented by 1 bar. (of less than 500 lb.) of extract. The chief makers are A. S. Thomas, Elmira, N.Y.; S. Brown & Co., New York; Canada Tanning Extract Co., St. Leonard and Bulstrode; J. Miller & Co., Millerton, New Brunswick. The total production is probably over 10,000 tons annually, ranging in value between 14l. and 20l. a ton. Our imports are included in barks and extracts.

Kino (Fr., Kino; Ger., Kino).—The term "gum kino" is applied to a class of astringent extracts of varied origin, none of which can accurately be called either resins or gums.

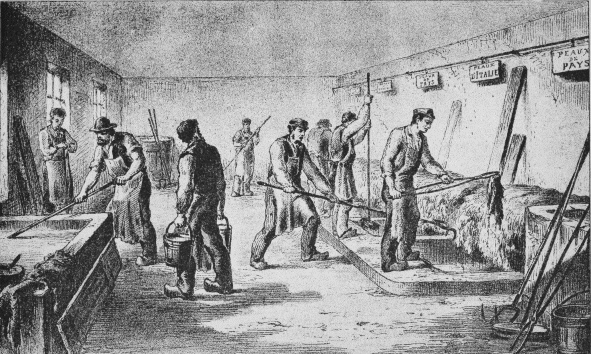

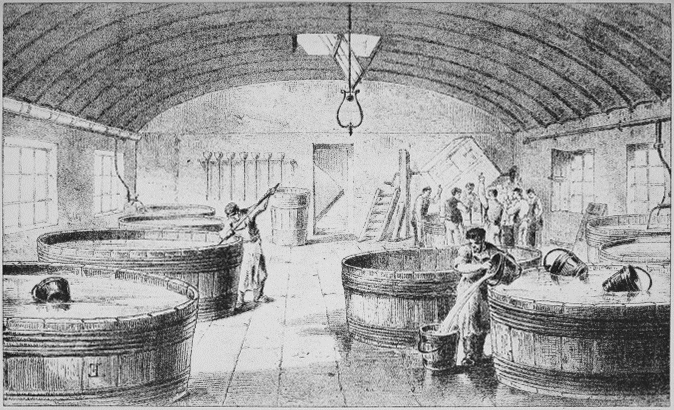

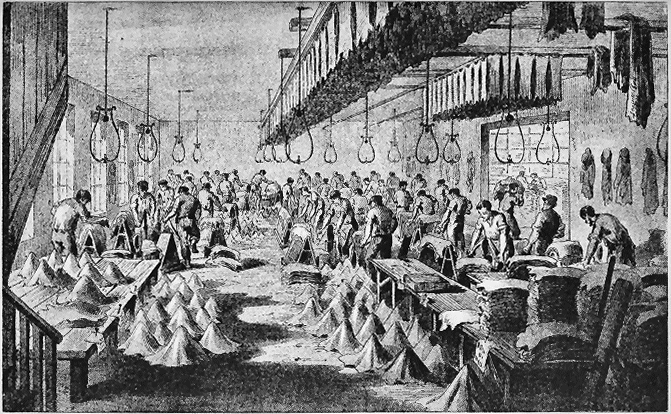

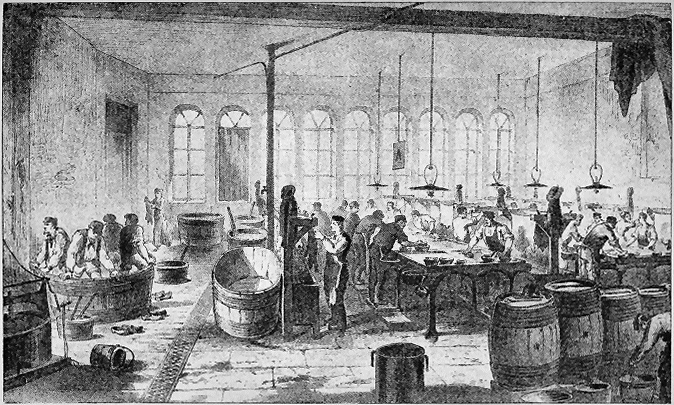

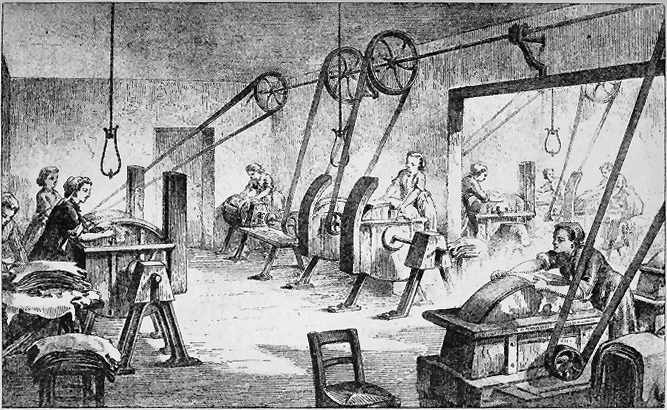

Pl. II.

REMOVING THE HAIR; SCRAPING AND CLEANING THE SKINS.

(1) East Indian or Amboyna Kino.—This is obtained from Pterocarpus Marsupium, a common tree in the central and southern parts of the Indian peninsula, and in Ceylon; and a liquid kind from P. indicus, of South India, Burma, Malacca, Penang, the Andamans, and Malaysia. The collection of the juice is effected in the following manner. A perpendicular incision, with lateral offshoots, is made in the stem of the tree when blossoming has set in, and a receptacle is placed at the foot of the incision. The exuding juice appears like red-currant jelly, but it soon thickens by exposure to the air, and when sufficiently dried, is packed into wooden boxes for exportation. It is one of the reserved timber-trees of the Government forests in Madras, and its juice is collected by natives, who pay a small fee for the permission. The hardened juice consists of blackish-red, angular, pea-like grains, partially soluble in water, almost entirely in spirit of wine of sp. gr. 0·838, readily in caustic alkaline solutions, and largely in a saturated solution of sugar. The liquid kino produces a very inferior article on drying. The annual collection of kino in Madras probably does not exceed 1-2 tons. Its approximate London market value is 60-150s. a cwt. It is employed medicinally, and in the manufacture of wines, and might be employed as a source of tannin in dyeing and tanning, if sufficiently cheap.

(2) Butea, Bengal, Palas or Dhak Kino.—This variety is afforded by the palas or dhak tree (Butea frondosa), common throughout India and Burma, and affording a dyestuff, and a fibre, as well as by B. superba and B. parviflora. During the hot season, there issues from natural fissures and from wounds made in the bark of the stem, a red juice, which quickly hardens to a ruby-coloured, brittle, astringent mass. It occurs in small drops or tears, and in flat pieces which have been dried on leaves, and is almost always mixed with bark-fragments. It is transparent, freely soluble in cold water, and does not soften in the mouth. It is unknown in European commerce, but is employed in India as a substitute for the kind first described.

(3) African or Gambia Kino.—This is derived from Pterocarpus erinaceus, a native of Tropical West Africa, from Senegambia to Angola. The juice exudes naturally from fissures in the bark, but more abundantly from incisions, and soon coagulates to a blood-red and very brittle mass, known to the Portuguese of Angola as sangue del drago ("dragon's-blood"). It is practically undistinguishable from the officinal kind first described, but is not a regular article of commerce.

(4) Australian, Botany Bay, or Eucalyptus Kino.—Several species of Eucalyptus afford astringent extracts, those from the "red," "white," or "flooded" gum (E. rostrata), the "blood-wood" (E. corymbosa), and E. citriodora, being quite suitable for replacing the officinal kind. It is chiefly obtained by woodcutters, being found in a viscid state in flattened cavities in the wood, and soon becoming inspissated, hard, and brittle. Minor quantities are procured in a liquid state by incising the bark of living trees, forming a treacly fluid yielding 35 per cent. of solid kino on evaporation. It is imported from Australia, but there are no statistics to show in what quantity.

Mimosa- or Wattle-bark.—The bark of numerous species of Acacia, natives of Australia, contains considerable percentages of deep-red mimo-tannic acid, which forms a hard and heavy tannage if used strong, though soft upper-leathers may be tanned with it in weak liquors. The chief kinds are as follows:—The common wattle (Acacia decurrens), including its variety A. mollissima, is known also under the names of green, black, and feathery, but must not be confounded with the silver wattle (A. dealbata), though but doubtfully a distinct species. The bark is obtainable in vast abundance, and is much used by tanners. The trees are stripped in September and the 2 or 3 months following, and the bark, being allowed to dry, is then in a marketable condition. This tree, which grows in the uplands, affords a larger percentage of tannin than the silver wattle.

Blackwood or lightwood (A. melanoxylon) yields tanners' « 35 » bark, which, is inferior, however, to that from A. decurrens. The bark of A. penninervis yields of tannic acid 17·9 per cent., and of gallic acid 3·8 per cent. The bark of the native hickory (A. suppurosa) yields of tannic acid 6·6 per cent., and of gallic acid 1·2 per cent.

The bark of A. saligna, of South-Western Australia, is much used by tanners, as it contains nearly 30 per cent. of mimo-tannin. A. harpophylla, of South Queensland, furnishes a considerable share of the mercantile wattle-bark for tanning purposes. The bark of A. lophantha contains only about 8 per cent. of tannin.

The broad-leaved or golden wattle (A. pycnantha), of Victoria and South Australia, deserves extensive cultivation. It is of rapid growth, will succeed even in sandy tracts, and yields seed copiously, which germinates with the greatest ease. The perfectly-dried bark contains about 25 per cent. of tannin. The aqueous infusion of the bark can be reduced by boiling to a dry extract, which in medicinal and other respects is equal to the best Indian cutch. It yields approximately 30 per cent. of tannin, about half of which, or more, is mimo-tannic acid. Probably no other tanning plants give so quick a return in cultivation as the A. pycnantha and A. decurrens of Australia. The latter varies in its proportions of tannin from 8 to 33 per cent. In the mercantile bark, the percentage is somewhat less, according to the state of its dryness, it retaining about 10 per cent. of moisture. The bark of the silver wattle (A. dealbata) is of less value, often even fetching only half the price of that of the black wattle. The bark improves by age and desiccation, and yields 40 per cent. of tannin, rather more than half of which is tannic acid.

Amongst all the kinds, the bark of the broad-leaved wattle is considered the most valuable, containing the greatest quantity of tannin; that of the silver wattle is not so valuable, being deficient in tannin; the black wattle is considered the most productive species; it can be barked at 8 years of age, and will produce 40-60 lb. dried bark, and full-grown trees will yield 100-150 lb. per tree.

The cultivation of wattles for commercial purposes has till now remained undeveloped; but no doubt, as soon as it is understood, the utilisation of many acres of land lying waste, or which have already been exhausted and rendered unfit for the growth of cereals, will be effected by the cultivation of the wattle. It requires so little attention as to make it very profitable, and wattle-growing and grazing can be combined satisfactorily. After the first year, when the young trees in the plantation have reached the height of 3-4 ft., sheep can be turned in.

Wattles grow in almost any soil, even the poorest, but their growth is most rapid on loose sandy patches, or where the surface has been broken for agricultural purposes. When the soil is hard and firm, plough furrows should be made at a regular distance of 6-8 ft. apart, into which the seeds are dropped. The seed should be sown in May, having been previously soaked in hot water, a little below boiling temperature, in which they may be allowed to remain for a few hours. The seed should be dropped at an average distance of 1 ft. apart along the furrow, in which case, about 7200 seeds would suffice for one acre of land. The seed should not be covered with more than about 1/4 in. of soil.

On loose sandy soil, it might even be unnecessary to break up the soil in any way; the furrows may be dispensed with, and the seed sown broadcast after the land is harrowed. After the plants have come up, they should be thinned so that they stand 6-8 ft. apart. When the young trees have attained the height of 3-4 ft., the lower branches should be pruned off, and every effort afterwards made to keep the stem straight and clear, in order to facilitate the stripping, and induce an increased yield of bark. It is advisable that the black and broad-leaved should be grown separately, as the black wattle, being of much larger and quicker growth, would oppress the slower-growing broad-leaved one. Care should be taken to replace every tree stripped by re-sowing, in order that there should be as little variation in the yield as possible. The months of September-December, in Victoria, « 37 » are those in which the sap rises without intermission, and the bark is charged with tannin. Analysis proves that the bark from trees growing on limestone is greatly inferior in tannin to that obtained from other formations, differing 10-25 per cent.

The estimated expenditure on a wattle-bark plantation of 100 acres during 8 years is:—

| £ | s. | d. | |

| Rent of 100 acres for 8 years at 6s. per acre per annum | 240 | 0 | 0 |

| Ploughing 100 acres in drills 10 ft. apart | 25 | 0 | 0 |

| Sowing wattles and actual cultivation, including cost of seed | 37 | 10 | 0 |

| Supervision for 8 years (nominal), say 10l. per annum | 80 | 0 | 0 |

| Pruning the trees, taking off useless wood (necessary for 2 years), 10s. per annum | 50 | 0 | 0 |

| Incidental and unforeseen expenses | 27 | 10 | 0 |

| Interest on the whole amount expended during 8 years | 240 | 0 | 0 |

| 700 | 0 | 0 | |

| Actual cost of stripping and carting, as shown below | 1515 | 0 | 0 |

| £2215 | 0 | 0 |

The receipts derivable from a wattle plantation of 100 acres, planted in the manner proposed, would be:—

| £ | s. | d. | |

| Each acre planted with wattles, 10 ft. apart, would carry 400 trees, and at end of 5th year trees would yield say 56 lb. matured bark: stripping only every 3rd tree, 332 trees would be obtained off 100 acres: this, at 4l. per ton, would give for 1st stripping | 1332 | 0 | 0 |

| In the 6th or following year, a similar number of trees would be stripped: the bark having increased in weight (say 14 lb.), the increased yield of 2nd stripping would be 400 tons at 4l. per ton | 1600 | 0 | 0 |

| In the 7th year, the remaining trees would be stripped, from which a still greater increase would be obtained, say 480 tons at 4l. per ton | 1920 | 0 | 0 |

| Total yield of bark | 4852 | 0 | 0 |

| The cost of stripping would not exceed 15s. per ton, on account of the facilities presented by the regularity of the trees, while carting would represent another 10s. per ton: these combined charges would be 25s. per ton, and on 1215 tons, would be | 1515 | 0 | 0 |

| Leaving a clear profit on the 100 acres of | £2637 | 0 | 0 |

The exports of mimosa-bark in 1876 were 11,899 tons from Victoria, 4758 from South Australia, and 1735 from Tasmania. Later returns are included in barks, p. 39. Shanghai imported 7038 piculs (of 1331/3 lb.) in 1879. The approximate London market values of mimosa-bark are:—Ground, 6-13l. a ton; chopped, 5-12l.; long, 5l.-9l. 10s. A very superior extract has been made from this bark.

Myrobalans or Myrabolams.—The fruits of several species of Terminalia constitute the myrobalans of commerce; they are chiefly T. Chebula and T. Bellerica, natives of India, the former being a tree 40-50 ft. high, and esteemed for its timber also. The fruits contain 30-35 per cent. of gallotannic and ellagitannic acids, producing a soft and porous tannage, and good samples giving a bright-yellow colour. The tannin exists in the pulp, and is absent from the very hard "stone." The dried fruits are known locally as har, harra, or bahera, and are used commonly for dyeing, but not for tanning.

Our imports of myrobalans in 1880 were:—238,151 cwt., 121,465l., from Bombay and Sind; 115,670 cwt., 51,339l., from Madras; 11,020 cwt., 4717l., from Bengal and Burma; 3520 cwt., 1402l., from other countries; total, 368,361 cwt., 178,923l. Our re-exports in 1880 were 8015 cwt., 4328l., to Germany; 16,127 cwt., 8515l., to other countries; total, 24,142 cwt., 12,843l. The approximate London market values of myrobalans are 7-14s. a cwt. for good, and 5-10s. for common. Shanghai imported 4403 piculs (of 1331/3 lb.) in 1879.

Oak-barks (Fr., Écorces de Chêne; Ger., Eichenrinden).—The barks of several species of oak have valuable tanning properties. They are chiefly:—The common oak (Quercus Robur, varieties: sessiliflora, Ger. Traubeneiche; pedunculata, Ger. Stieleiche), which is of even greater importance as a timber-tree; the cork-oak (Q. Suber); the evergreen oak (Q. Ilex); and the American chestnut-oak (Q. Castanea). These barks are among the most esteemed tannins as regards quality of leather, but are incapable of giving much weight, and from their bulk are costly to handle, containing only 10-12 per « 39 » cent. of tannin (quercitannic acid). They give a reddish fawn-coloured leather, and deposit a good deal of bloom, but yield little or no gallic acid. The barks of the cork-oak and evergreen oak from Southern Europe, are stronger and darker-coloured than English bark. The American chestnut-oak contains a peculiar fluorescent principle like æsculin.

Our imports of unspecified barks for tanners' and dyers' use in 1880 were:—189,399 cwt., 101,108l., from Australia; 123,302 cwt., 32,974l., Belgium; 57,232 cwt., 20,988l., United States; 22,100 cwt., 6030l., Holland; 18,648 cwt., 3676l., Italy; 16,151 cwt., 6972l., Algeria; 22,669 cwt., 8838l., other countries; total, 449,501 cwt., 180,586l. Our imports of unenumerated bark-extracts in the same year were valued at:—516,578l. from Holland, 92,654l. France, 30,187l. United States, 16,315l. British North America, 12,796l. Belgium, 13,769l. other countries; total, 682,299l. Our re-exports of barks in 1880 were:—19,548 cwt., 10,348l., to Germany; 14,627 cwt., 7425l., France; 4555 cwt., 3041l., Holland; 10,304 cwt., 6080l., other countries; total, 49,034 cwt., 26,894l.

With regard to cork-tree bark, James Gordon & Co., Liverpool, obligingly write that very little comes to England, the great bulk going direct to Ireland, where the consumption is large. The imports at Liverpool in 1880 were 186 tons, average value 8l. per ton. Of oak-bark, Hungary, in 1877, produced 25,000 tons, of which, 20,000 were exported to Germany for tanning purposes. The approximate London market values of oak-bark are:—English, 12-16l. per load of 45 cwt.; Foreign, tree, 5-8l. a ton; ditto, coppice, 6-8l. In 1879, Algiers exported 12,660,047 kilo. (of 2·2 lb.) of tanning bark.