image

(399 kB).VOL. I.

The Project Gutenberg EBook of Modern Machine-Shop Practice, Vol. I (of 2), by Joshua Rose This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org Title: Modern Machine-Shop Practice, Volumes I and II Author: Joshua Rose Release Date: March 21, 2012 [EBook #39225] Language: English Character set encoding: ISO-8859-1 *** START OF THIS PROJECT GUTENBERG EBOOK MODERN MACHINE-SHOP PRACTICE, VOL 1 *** Produced by Ben Beasley, Harry Lamé and the Online Distributed Proofreading Team at http://www.pgdp.net

Please see Transcriber’s Notes at the end of this document.

| Large image (399 kB).VOL. I. |

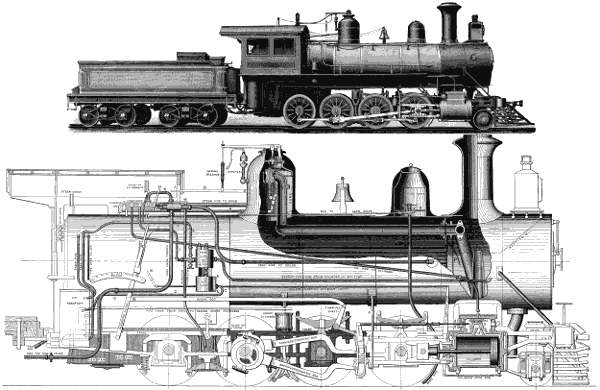

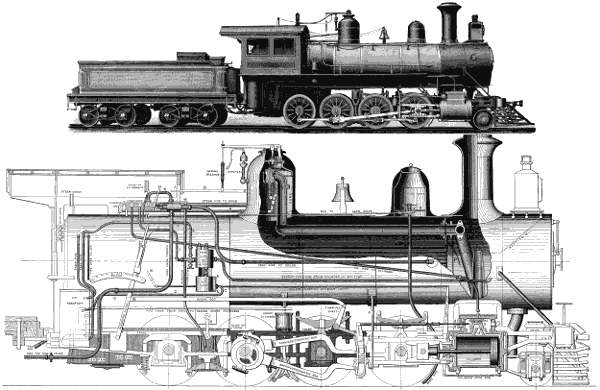

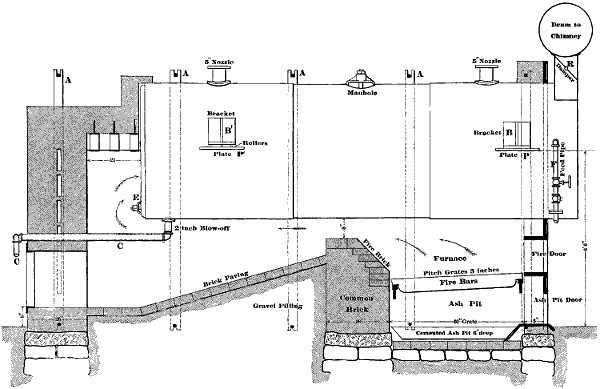

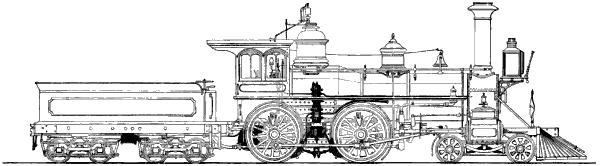

MODERN MACHINE‑SHOP PRACTICE. | FRONTISPIECE |

|

||

| Copyright, 1887 by Charles Scribner’s Sons. | ||

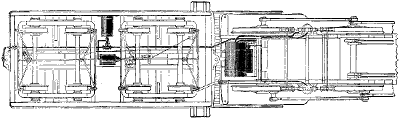

| MODERN AMERICAN FREIGHT LOCOMOTIVE. | ||

BY

JOSHUA ROSE, M.E.

ILLUSTRATED WITH MORE THAN 3000 ENGRAVINGS

VOLUME I.

NEW YORK

CHARLES SCRIBNER’S SONS

1887

Copyright, 1887, by

CHARLES SCRIBNER’S SONS

Press of J. J. Little & Co.

Astor Place, New York.

Modern Machine-Shop Practice is presented to American mechanics as a complete guide to the operations of the best equipped and best managed workshops, and to the care and management of engines and boilers.

The materials have been gathered in part from the author’s experience of thirty-one years as a practical mechanic; and in part from the many skilled workmen and eminent mechanics and engineers who have generously aided in its preparation. Grateful acknowledgment is here made to all who have contributed information about improved machines and details of new methods.

The object of the work is practical instruction, and it has been written throughout from the point of view, not of theory, but of approved practice. The language is that of the workshop. The mathematical problems and tables are in simple arithmetical terms, and involve no algebra or higher mathematics. The method of treatment is strictly progressive, following the successive steps necessary to becoming an intelligent and skilled mechanic.

The work is designed to form a complete manual of reference for all who handle tools or operate machinery of any kind, and treats exhaustively of the following general topics: I. The construction and use of machinery for making machines and tools; II. The construction and use of work-holding appliances and tools used in machines for working metal or wood; III. The construction and use of hand tools for working metal or wood; IV. The construction and management of steam engines and boilers. The reader is referred to the Table of Contents for a view of the multitude of special topics considered.

The work will also be found to give numerous details of practice never before in print, and known hitherto only to their originators, and aims to be useful as well to master-workmen as to apprentices, and to owners and managers of manufacturing establishments equally with their employees, whether machinists, draughtsmen, wood-workers, engineers, or operators of special machines.

The illustrations, over three thousand in number, are taken from modern practice; they represent the machines, tools, appliances and methods now used in the leading manufactories of the world, and the typical steam engines and boilers of American manufacture.

The new Pronouncing and Defining Dictionary at the end of the work, aims to include all the technical words and phrases of the machine shop, both those of recent origin and many old terms that have never before appeared in a vocabulary of this kind.

The wide range of subjects treated, their convenient arrangement and thorough illustration, with the exhaustive Table of Contents of each volume and the full Analytical Index to both, will, the author hopes, make the work serve as a fairly complete ready reference library and manual of self-instruction for all practical mechanics, and will lighten, while making more profitable, the labor of his fellow-workmen.

| CHAPTER I. | |||

| THE TEETH OF GEAR-WHEELS. | |||

| PAGE | |||

| Gear-Wheels. Spur-wheels, bevel-wheels, mitre-wheels, crown-wheels, annular or internal wheels | 1 | ||

| Trundle-wheels, rack and pinion-wheel and tangent screw, or worm and worm-wheel | 1 | ||

| The diameter of the pitch circle of | 1 | ||

| Gear-Wheel Teeth. The face, the flank, the depth or height | 1 | ||

| The space, the pitch line, the point, the arc pitch, the chord pitch, the line of centres | 2 | ||

| Rules for finding the chord pitch from the arc pitch; table of natural sines; diametral pitch; finding the arc from the diametral pitch; table of arc and diametral pitches | 3 | ||

| Gear-Wheels. The driver and follower, a train of gears | 3 | ||

| Intermediate gears | 3 | ||

| The velocity of compounded wheels | 4 | ||

| Finding the diameters of the pitch circles of | 4 | ||

| Considered as revolving levers | 5 | ||

| Calculating the revolutions of, and power transmitted by | 5 | ||

| The angular velocity of | 6 | ||

| Gear-Wheels. Hunting tooth in, stop motion of | 7 | ||

| Gear-Wheel Teeth. The requirements and nature of the teeth curves | 7 | ||

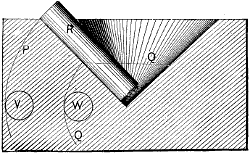

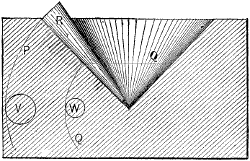

| Cycloidal curves for the faces of; epicycloidal and involute curves; the hypocycloidal curve; method of forming or generating the epicycloidal and hypocycloidal curves for the faces and flanks of gear teeth | 8 | ||

| Applications of the epicycloidal and hypocycloidal curves in the formation of gear teeth | 9 | ||

| The diameter of the circle for generating the epicycloidal and hypocycloidal curves; graphical demonstration that the flank curves are correctly formed to work with the face curves of the other wheel | 10 | ||

| Graphical demonstration that the curves are correct independent of either the respective sizes of the wheels, or of the curve generating circles | 11 | ||

| Gear-Wheels. Hand applications of the rolling or generating circle to mark the tooth curves for a pair of wheels | 12 | ||

| Gear-Wheel Teeth. The variation of curve due to different diameters of wheels or of rolling circles | 12 | ||

| Tracing the path of contact of tooth upon tooth in a pair of gear-wheels; definition of the “arc of approach;” definition of the “arc of recess;” demonstration that the flanks of the teeth on the driver or driving-wheel have contact with the faces of the driven wheel during the arc of approach, and with the flanks of the driven wheel during the arc of recess | 13 | ||

| Confining the action of the teeth to one side only of the line of centres, when motion rather than power is to be conveyed | 13 | ||

| Demonstration that the appearance or symmetry of a tooth has no significance with regard to its action | 14 | ||

| Finding how many teeth will be in constant action, the diameter of the wheels, the pitch of the teeth, and the diameter of the rolling circle being given | 15 | ||

| Example of the variation of tooth form due to variation of wheel diameter | 15 | ||

| Gear Teeth. Variation of shape from using different diameters of rolling circles | 16 | ||

| Thrust on the wheel shafts caused by different shapes of teeth | 16 | ||

| Gear-Wheels. Willis’ system of one size of rolling circle for trains of interchangeable gearing | 16 | ||

| Conditions necessary to obtain a uniform velocity of | 16 | ||

| Gear Teeth. The amount of rolling and of sliding motion of | 16 | ||

| The path of the point of contact of | 16 | ||

| The arcs of approaching and of receding contact | 16 | ||

| Lengths of the arcs of approach and of recess | 16 | ||

| The influence of the sizes of the wheels upon the arcs of contact | 17 | ||

| Influence of the size of the rolling circle upon the amount of flank contact | 18 | ||

| Demonstration that incorrectly formed teeth cannot correct themselves by wear | 18 | ||

| The smaller the diameter of the rolling circle, the less the sliding motion | 18 | ||

| Influence of the size of the rolling upon the number of teeth in contact in a given pair of wheels | 19 | ||

| Demonstration that the degrees of angle the teeth move through exceed those of the path of contact, unless the tooth faces meet in a point | 19 | ||

| Influence of the height of the teeth upon the number of teeth in contact | 20 | ||

| Increasing the arc of recess without increasing the arc of approach | 20 | ||

| Wheels for transmitting motion rather than power | 21 | ||

| Clock wheels | 21 | ||

| Forms of teeth having generating or rolling circles, as large or nearly as large as the diameters of the wheels | 21 | ||

| Gear-Wheels. Bevel | 21 | ||

| The principles governing the formation of the teeth of bevel- wheels | 22 | ||

| Demonstration that the faces of the wheels must be in line with the point of intersection of the axis of the two shafts | 22 | ||

| Gear Teeth. Method of finding the curves of, for bevel gear | 22 | ||

| Gear-Wheels. Internal or annular | 23 to 27 | ||

| Demonstration that the teeth of annular wheels correspond to the spaces of spur-wheels | 23 | ||

| Gear-Wheels Internal. Increase in the length of the path of contact on spur-wheels of the same diameter, and having the same diameter of generating or rolling circle | 23 | ||

| Demonstration that the teeth of internal wheels may interfere when spur-wheels would not do so | 23 | ||

| Methods of avoiding the above interference | 23 | ||

| Comparison of, with spur-wheels | 23 | ||

| The teeth of: demonstration that it is practicable to so form the teeth faces that they will have contact together as well as with the flanks of the other wheel | 24 | ||

| Intermediate rolling circle for accomplishing the above result | 24 | ||

| The application of two rolling circles for accomplishing the above result | 24 | ||

| Demonstration that the result reached by the employment of two rolling circles of proper diameter is theoretically and practically perfect | 24 | ||

| Limits of the diameters of the two rolling circles | 25 | ||

| Increase in the arc of contact obtained by using two rolling circles | 25 | ||

| Demonstration that the above increase is on the arc of recess or receding contact, and therefore gives a smooth action | 25 | ||

| Demonstration that by using two rolling circles each tooth has for a certain period two points of contact | 25 | ||

| The laws governing the diameters of the two rolling circles | 25 | ||

| Practical application of two rolling circles | 26 | ||

| Demonstration that by using two rolling circles the pinion may contain but one tooth less than the wheel | 26 | ||

| The sliding and rolling motion of the teeth of | 27 | ||

| CHAPTER II. | |||

| THE TEETH OF GEAR-WHEELS (Continued). | |||

| Worm and Worm-Wheel, or wheel and tangent screw | 28 to 31 | ||

| General description of | 28 | ||

| Qualifications of | 28 | ||

| The wear of | 28 | ||

| Worm-Wheel Teeth, the sliding motion of | 28 | ||

| When straight have contact on the centres only of the tooth sides | 28 | ||

| That envelop a part of the worm circumference | 28 | ||

| The location of the pitch line of the worm | 28 | ||

| [I-viii] | The proper number of teeth in the worm-wheel | 29 | |

| Locating the pitch line of the worm so as to insure durability | 29 | ||

| Rule for finding the best location for the pitch line of the worm | 29 | ||

| Increasing the face of the worm to obtain a smoother action | 29 | ||

| Worms, to work with a square thread | 29 | ||

| Worm-Wheels, applications of | 30 | ||

| Gear-Wheels with involute teeth | 31 to 34 | ||

| Gear Teeth. Generating the involute curve | 31 | ||

| Templates for marking the involute curve | 32 | ||

| Involute Teeth, the advantages of | 34 | ||

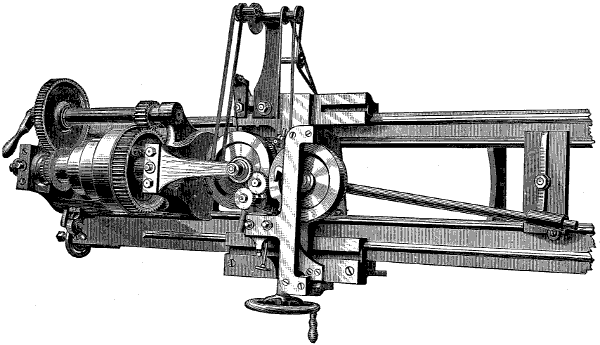

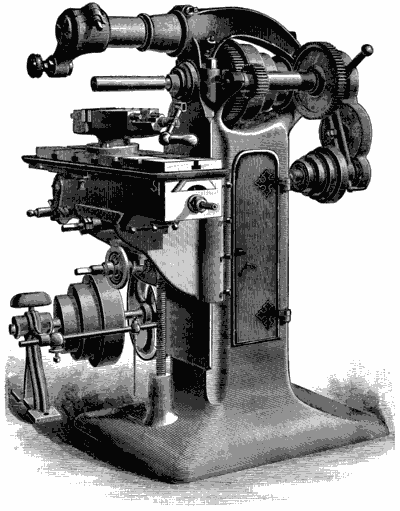

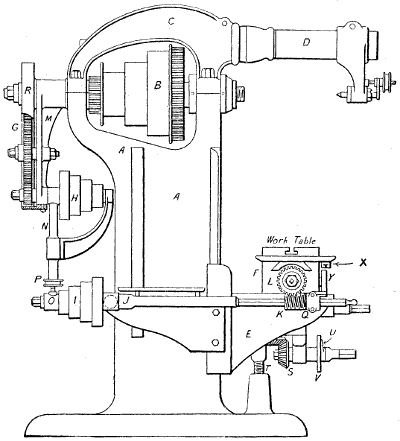

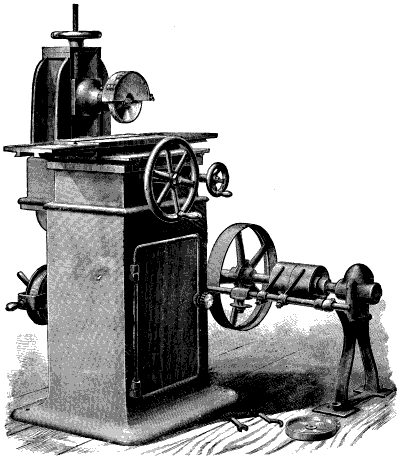

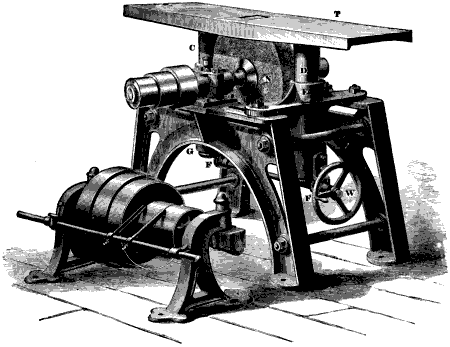

| Gear Teeth, Pratt and Whitney’s machine for cutting templates for | 35 | ||

| CHAPTER III. | |||

| THE TEETH OF GEAR-WHEELS (Continued). | |||

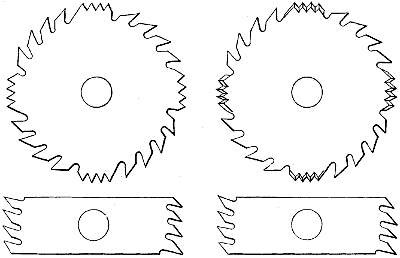

| Gear Teeth, revolving cutters for | 37 | ||

| Pantagraph engine for dressing the cutters for | 38 | ||

| Numbers of cutters used for a train of wheels | 39 | ||

| Gear-Wheel Teeth. Table of equidistant value of cutters | 41 | ||

| Depth of, in the Brown and Sharpe system | 42 | ||

| Cutting the teeth of worm-wheels | 42 | ||

| Finding the angle of the cutter for cutting worm-wheels | 43 | ||

| The construction of templates for rolling the tooth curves | 43 | ||

| Rolling the curves for gear teeth | 43 | ||

| Forms of templates for gear teeth | 44 | ||

| Pivoted arms for tooth templates | 44 | ||

| Marking the curves by hand | 45 | ||

| Former or Template of the Corliss bevel gear-wheel engine or cutting machine | 45 | ||

| The use of extra circles in marking the curves with compasses | 46 | ||

| Finding the face curves by geometrical constructions | 47 | ||

| The Willis odontograph for finding the radius for striking the curves by hand | 47 | ||

| The method of using the Willis odontograph | 48 | ||

| Professor Robinson’s odontograph | 49 | ||

| Method of using Professor Robinson’s odontograph | 49 | ||

| Application of Professor Robinson’s odontograph for trains of gearing | 51 | ||

| Tabular values and setting numbers for Professor Robinson’s odontograph | 51 | ||

| Walker’s patent wheel scale for marking the curves of cast teeth | 51 | ||

| The amount of side clearance in cast teeth | 53 | ||

| Filleting the roots of epicycloidal teeth with radial flanks | 53 | ||

| Scale of tooth proportions given by Professor Willis | 54 | ||

| The construction of a pattern for a spur-wheel that is to be cast with the teeth on | 54 | ||

| Template for planing the tooth to shape | 54 | ||

| Method of marking the curves on teeth that are to be glued on | 55 | ||

| Method of getting out the teeth of | 56 | ||

| Spacing the teeth on the wheel rim | 56 | ||

| Methods of accurately spacing the pattern when it has an even number of teeth | 58 | ||

| Method of spacing the wheel rim when it has an odd number of teeth | 58 | ||

| Gear-Wheels, Bevel Pinion, drawings for | 59 | ||

| Getting out the body for a bevel-wheel | 59 | ||

| Template for marking the division lines on the face of the wheel | 59 | ||

| Marking the lines of the division on the wheel | 60 | ||

| Gear-Wheels, Pinion, with dovetail teeth | 60 | ||

| Testing the angle of bevel-wheels while in the lathe | 60 | ||

| Gear-Wheels, Skew Bevel. Finding the line of contact | 61 | ||

| Marking the inclination of the teeth | 61 | ||

| Gear-Wheels, Bevel, drawing for built up | 61 | ||

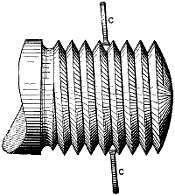

| Gear-Wheels, Worm, or endless screw | 62 | ||

| Constructing a pattern from which the worm is to be cast | 62 | ||

| Tools for cutting the worm in a lathe | 62 | ||

| Cutting the teeth by hand | 62 | ||

| Gear-Wheels, Mortise or cogged | 63 | ||

| Methods of fastening cogs | 63 | ||

| Methods of getting out cogs for | 63 | ||

| Gear-Wheel Teeth, calculating the strength of epicycloidal | 64 | ||

| Factors of safety for | 64 | ||

| Tredgold’s rule for calculating the strength of | 65 | ||

| Cut, calculating the strength of | 65 | ||

| Gear-Wheel Teeth. The strength of cogs | 66 | ||

| The thickness of cogs | 66 | ||

| The durability of cogs | 66 | ||

| Table for calculating the strength of different kinds of | 67 | ||

| The contact of cast teeth | 67 | ||

| Table for determining the relation between pitch diameter, pitch, and number of teeth in gear-wheels | 68 | ||

| Examples of the use of the above table | 68 | ||

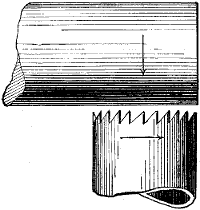

| With stepped teeth | 69 | ||

| Angular or helical teeth | 69 | ||

| End thrust of angular teeth | 69 | ||

| Herring-bone angular teeth | 69 | ||

| For transmitting motion at a right angle by means of angular or helical teeth | 69 | ||

| Cutting helical teeth in the lathe | 69 | ||

| For wheels whose shaft axes are neither parallel nor meeting | 70 | ||

| Elliptical | 70 | ||

| Elliptical, marking the pitch lines of | 70 | ||

| Elliptical, drawing the teeth curves of | 73 | ||

| For variable motion | 74 | ||

| Form of worm to give a period of rest | 74 | ||

| Various applications of | 74 | ||

| Gear-Wheels, arrangement of, for periodically reversing the direction of motion | 75 | ||

| Watt’s sun and planet motion | 75 | ||

| Arrangements for the rapid multiplication of motion | 75 | ||

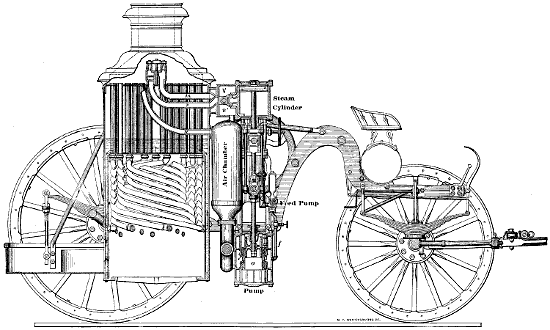

| Arrangement of, for the steering gear of steam fire-engines | 75 | ||

| Various forms of mangle gearing | 79 | ||

| Gear-Wheel and Rack, for reciprocating motion | 77 | ||

| Friction Wheels. | 77 | ||

| The material for | 77 | ||

| Paper | 78 | ||

| For the feed motion of machines | 78 | ||

| The unequal wear upon grooved | 79 | ||

| Form of, for relieving the journals of strain | 79 | ||

| Cams, for irregular motion | 80 | ||

| Finding the pitch line of | 80 | ||

| Finding the working face of | 80 | ||

| The effect the diameter roller has upon the motion produced by a cam | 80 | ||

| Demonstration of the different motion produced by different diameters of rollers upon the same cam | 80 | ||

| Diagram of motion produced from the same cam with different diameters of rollers | 81 | ||

| Return or backing | 82 | ||

| Methods of finding the shape of return or backing | 82 | ||

| Cam Motion, for an engine slide valve without steam lap | 83 | ||

| For a slide valve with steam lap | 83 | ||

| Groove Cams, proper construction of | 84 | ||

| The wear of | 84 | ||

| Brady’s improved groove cam with rolling motion and adjustment for wear | 84 | ||

| CHAPTER IV. | |||

| SCREW-THREADS. | |||

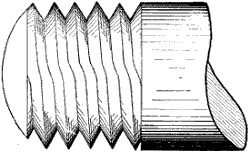

| Screw Threads, the various forms of | 85 | ||

| The pitch of | 85 | ||

| Self-locking | 85 | ||

| The Whitworth | 86 | ||

| The United States standard | 86 | ||

| The Common V | 86 | ||

| The requirements of | 86 | ||

| Tools for cutting | 87 | ||

| Variation of pitch from hardening | 87 | ||

| The wear of thread-cutting tools | 88 | ||

| Methods of producing | 88 | ||

| Alteration of shape of, from the wear of the tools they are cut by | 89 | ||

| Screw Thread Cutting Tools. The wear of the tap and the die | 89 | ||

| Improved form of chaser to equalize the wear | 90 | ||

| Form of, to eliminate the effects of the wear in altering the fit | 90 | ||

| Originating standard angles for | 91 | ||

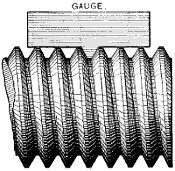

| Standard micrometer gauge for the United States standard screw thread | 91 | ||

| Standard plug and collar gauges for | 91 | ||

| Producing gauges for | 92 | ||

| Table of United States standard for bolts and nuts | 93 | ||

| Table of standard for the V-thread | 93 | ||

| United States standard for gas and steam pipes | 93 | ||

| Taper for standard pipe threads | 95 | ||

| Tables of the pitches and diameters at root of thread, of the Whitworth thread | 95 | ||

| Table of Whitworth’s screw threads for gas, water, and hydraulic piping | 96 | ||

| Whitworth’s standard gauges for watch and instrument makers | 96 | ||

| Screw-cutting hand tools | 96 | ||

| Thread-Cutting Tools. American and English forms of stocks and dies | 97 | ||

| Adjustable or jamb dies | 98 | ||

| The friction of jamb dies | 98 | ||

| The sizes of hobs that should be used on jamb dies | 99 | ||

| Cutting right or left-hand thread with either single, double, or treble threads with the same dies | 99 | ||

| Hobs for hobbing or threading dies | 100 | ||

| [I-ix] | Various forms of stocks with dies adjustable to take up the wear | 101 | |

| Dies for gas and steam pipes | 101 | ||

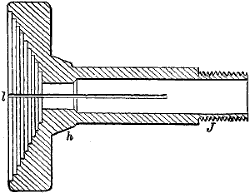

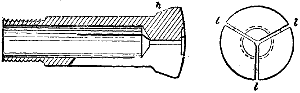

| Thread-Cutting Tool Taps. The general forms of taps | 102 | ||

| Reducing the friction of | 102 | ||

| Giving clearance to | 102 | ||

| The friction of taper | 103 | ||

| Improved forms of | 103 | ||

| Professor J. E. Sweet’s form of tap | 104 | ||

| Adjustable standard | 104 | ||

| The various shapes of flutes employed on taps | 105 | ||

| The number of flutes a tap should have | 105 | ||

| Demonstration that a tap should have four cutting edges rather than three | 106 | ||

| The position of the square or driving end, with relation to the cutting edges | 106 | ||

| Taper taps for blacksmiths | 106 | ||

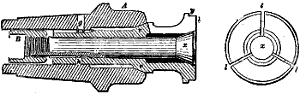

| Collapsing taps for use in tapping machines | 107 | ||

| Collapsing tap for use in a screw machine | 107 | ||

| The alteration of pitch that occurs in hardening | 108 | ||

| Gauging the pitch after the hardening | 108 | ||

| Correcting the errors of pitch caused by the hardening | 109 | ||

| For lead | 109 | ||

| Elliptical in cross section | 109 | ||

| For very straight holes | 109 | ||

| Tap wrenches solid and adjustable | 110 | ||

| Thread-Cutting. Tapping | 110 | ||

| Appliances for tapping standard work | 111 | ||

| CHAPTER V. | |||

| FASTENING DEVICES. | |||

| Bolts, classification of, from the shapes of their heads | 112 | ||

| Classification of, from the shapes of their bodies | 112 | ||

| Countersunk | 112 | ||

| Holes for, classification of | 112 | ||

| For foundations, various forms of | 113 | ||

| Hook bolts | 113 | ||

| The United States standard for finished bolts and nuts | 113 | ||

| The United States standard for rough bolts and nuts, or black bolts | 114 | ||

| The Whitworth standard for bolts and nuts | 114 | ||

| Screws | 114 | ||

| Studs | 115 | ||

| Set Screws | 115 | ||

| Bolts for quick removal | 116 | ||

| That do not pass through the work | 117 | ||

| That self-lock in grooves and are readily removable | 117 | ||

| Heads and their bedding | 117 | ||

| Nuts, the forms of, when they are to be steam tight | 118 | ||

| Various forms of | 118 | ||

| Jamb nuts and lock nuts | 119 | ||

| Differential Threads for locking purposes | 119 | ||

| For fine adjustments | 119 | ||

| Nuts, taking up the wear of | 120 | ||

| Securing devices | 120 | ||

| Securing by taper pins | 121 | ||

| Securing by cotters | 121 | ||

| Securing by notched plates | 121 | ||

| Pins. Securing for exact adjustments | 121 | ||

| And double eyes fitting | 121 | ||

| Fixed | 122 | ||

| Working | 122 | ||

| Bolts, removing corroded | 122 | ||

| Nuts, removing corroded | 122 | ||

| Washers, standard sizes of | 122 | ||

| Wrench, the proper angles of | 123 | ||

| Box | 124 | ||

| Monkey | 125 | ||

| Adjustable, various forms of | 125 | ||

| Sockets | 125 | ||

| Novel for carriage bolts | 125 | ||

| Pin | 126 | ||

| Improved form of | 126 | ||

| Keys, the various kinds of | 126 | ||

| The bearing surfaces of | 126 | ||

| Set Screws, application of, to hubs or bosses | 127 | ||

| Keys, with set-screws | 127 | ||

| The draught of | 127 | ||

| Feathers, and their applications | 127 | ||

| Keys, for parallel rods | 128 | ||

| Taper Pins, proper position of, for locking purposes | 128 | ||

| Improved method of fitting | 128 | ||

| CHAPTER VI. | |||

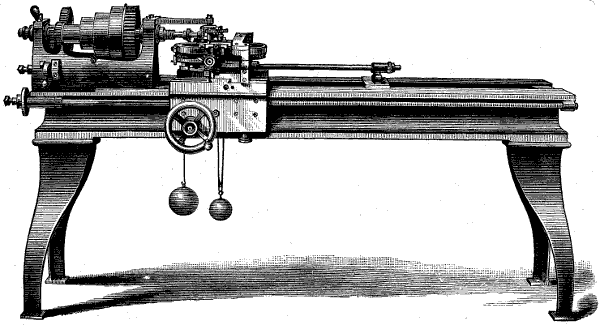

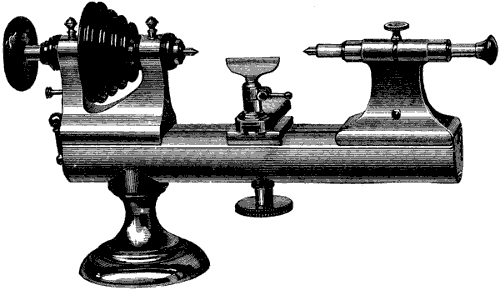

| THE LATHE. | |||

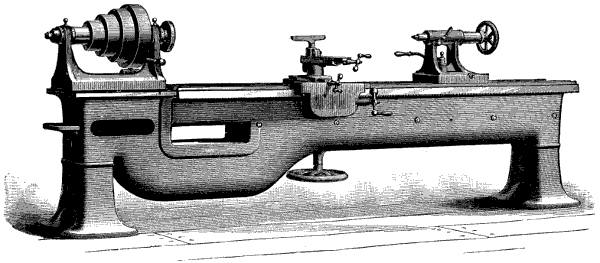

| Lathe, the importance and advantages of | 129 | ||

| Classification of lathes | 129 | ||

| Foot | 130 | ||

| Methods of designating the sizes of | 130 | ||

| Bench | 130 | ||

| Power | 130 | ||

| Hand | 130 | ||

| Slide Rest for | 131 | ||

| American form of, their advantages and disadvantages | 132 | ||

| English forms of | 132 | ||

| For spherical work | 132 | ||

| Methods of taking up lost motion of | 133 | ||

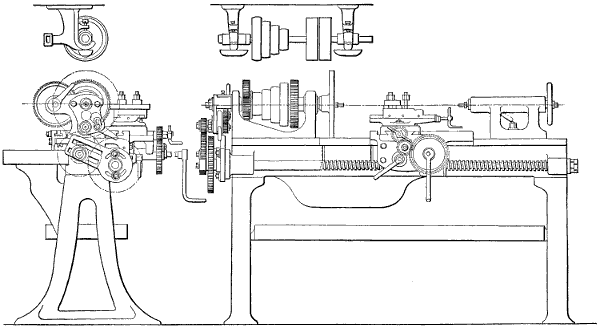

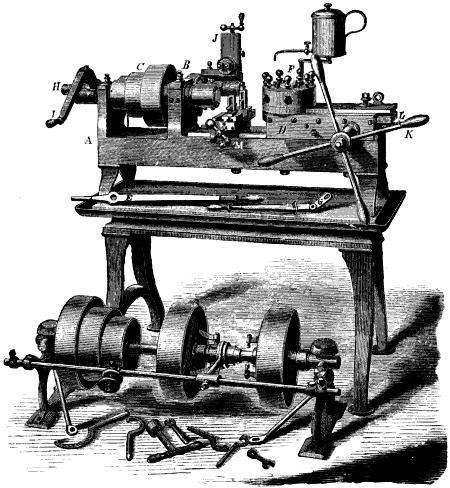

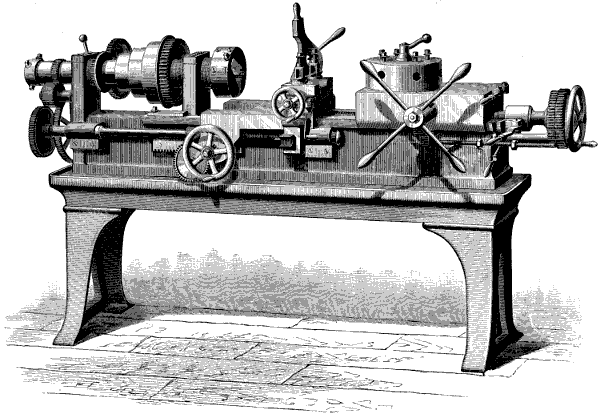

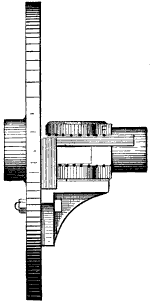

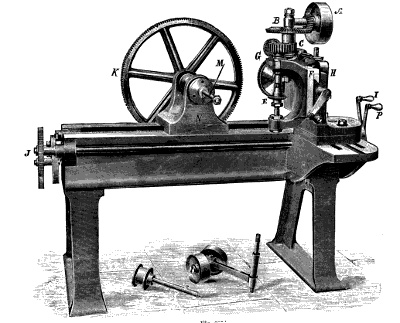

| Engine Lathe, general construction of | 133 | ||

| The construction of the shears of | 134 | ||

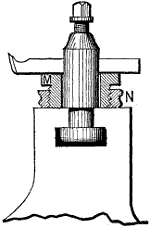

| Construction of the headstock | 134 | ||

| Construction of the bearings | 134 | ||

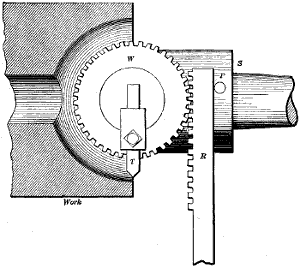

| Construction of the back gear | 135 | ||

| Means of giving motion to the feed spindle | 135 | ||

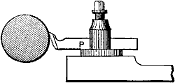

| Construction of the tailstock | 135 | ||

| Method of rapidly securing and releasing the tailstock | 136 | ||

| Lathe Tailstock, setting over for turning tapers | 136 | ||

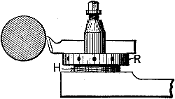

| Engine Lathe, construction of carriage | 137 | ||

| Feed motion for carriage or saddle | 137 | ||

| Lathe Apron, Construction of the feed traverse | 138 | ||

| Construction of the cross-feed motion | 138 | ||

| Engine Lathe, lead screw and change wheels of | 139 | ||

| Feed spindle and lead screw bearings | 139 | ||

| Swing frame for lead screw | 139 | ||

| Lead screw nuts | 140 | ||

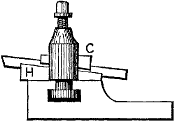

| With compound slide rest | 140 | ||

| Construction of compound slide rest | 141 | ||

| Advantages of compound slide rest | 141 | ||

| For taper turning | 142 | ||

| Taper-turning attachments | 142 | ||

| With compound duplex slide rest | 143 | ||

| Detachable slide rest | 143 | ||

| Three-tool slide rest for turning shafting | 143 | ||

| With flat saddle for chucking work on | 143 | ||

| The Sellers Lathe | 143 | ||

| Construction of the headstock and treble gear | 144 | ||

| Construction of the tailstock and method of keeping it in line | 145 | ||

| Construction of the carriage and slide rest | 145 | ||

| Methods of engaging and disengaging the feed motions | 146 | ||

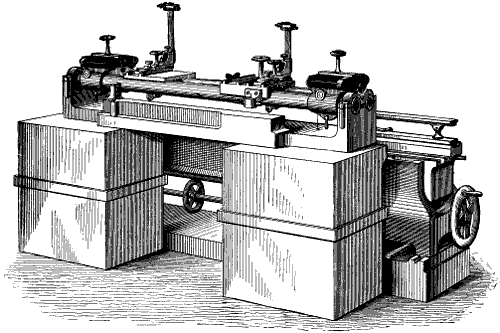

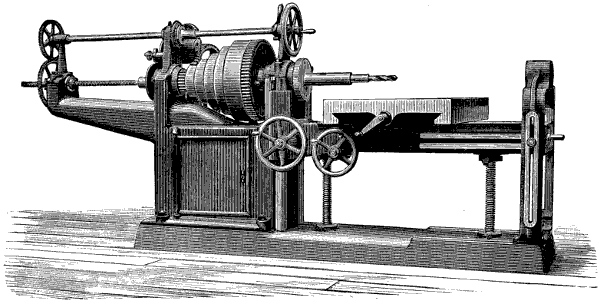

| Car Axle Lathe, with central driving motion and two slide rests | 147 | ||

| The feed motions of | 148 | ||

| Self-Acting Lathe, English form of | 148 | ||

| Pattern Maker’s Lathe | 148 | ||

| Brake for cone pulley | 149 | ||

| With wooden bed | 149 | ||

| Slide rest for | 149 | ||

| Chucking Lathe, English | 149 | ||

| Feed motions of | 150 | ||

| Pulley Lathe | 150 | ||

| Gap or Break Lathe | 151 | ||

| Extension Lathe | 151 | ||

| Wheel Lathe | 151 | ||

| Chucking Lathe for boring purposes | 152 | ||

| Lathe for turning crank axles | 152 | ||

| Construction of the headstock | 153 | ||

| Construction of the feed motions | 154 | ||

| For turning crank, Arrangements of the slide rests | 154 | ||

| Application of the slide rest to a crank | 155 | ||

| CHAPTER VII. | |||

| DETAILS IN LATHE CONSTRUCTION. | |||

| Live Spindle of a lathe, the fit of | 157 | ||

| With coned journals | 157 | ||

| Methods of taking up the end motion of | 158 | ||

| Arranging the swing frame for the change gears | 158 | ||

| Taking up the wear of the back bearing | 158 | ||

| The wear of the front bearing of | 158 | ||

| The Taper for the live centre | 159 | ||

| Methods of removing the lathe centres | 159 | ||

| Tapers for the live centres | 159 | ||

| Methods of removing the dead centre | 159 | ||

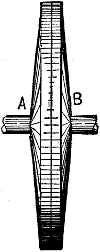

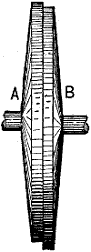

| Driving Cone, arranging the steps of | 159 | ||

| Requirements of proportioning the steps of | 159 | ||

| Rules for proportioning the diameters of the steps of, when the two pulleys are exactly alike and are connected by an open belt | 159 to 161 | ||

| When the two pulleys are unlike | 161 to 164 | ||

| Back Gear, methods of throwing in and out | 165 | ||

| Conveying motion to the lead screw | 165 | ||

| Attaching the swing frame | 166 | ||

| Feed Gear. Arrangement for cutting worm threads or tangent screws | 167 | ||

| Feed Motion for reversing the direction of tool traverse in screw cutting | 168 | ||

| For lathe aprons | 168 | ||

| Slide Rest, weighted elevated | 168 | ||

| Double tool holder for | 169 | ||

| [I-x] | Gibbed elevating | 169 | |

| Examples of feed motions | 170 | ||

| Feed Regulators for screw cutting | 171 | ||

| The star feed | 172 | ||

| Ratchet Feeds | 173 | ||

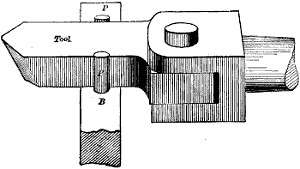

| Tool Holding devices, the various kinds of | 173 | ||

| Tool Rest swiveling | 174 | ||

| Tool Holder for compound slide rests | 174 | ||

| For octagon boring tools | 175 | ||

| Lathe Lead and Feed Screws | 175 | ||

| Lead screws, supporting, long | 176 | ||

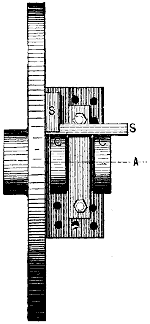

| Position of the feed nut | 177 | ||

| Form of threads of lead screws | 177 | ||

| The effect the form of thread has in causing the nut to lock properly or improperly | 177 | ||

| Example of a lead screw with a pitch of three threads per inch | 177 | ||

| Example of a lead screw with five threads per inch | 178 | ||

| Example with a lead screw of five threads per inch | 179 | ||

| Device for correcting the errors of pitch of | 179 | ||

| Table for finding the change wheels for screw cutting when the teeth in the change wheels advance by four | 180 | ||

| For finding the change wheels when the teeth in the wheels advance by six | 180 | ||

| Constructing a table to cut fractional threads on any lathe | 181 | ||

| Finding the change wheels necessary to enable the lathe to cut threads of any given pitches | 181 | ||

| Finding the change wheels necessary to cut fractional pitches | 181 | ||

| Determining the pitches of the teeth for change wheels | 182 | ||

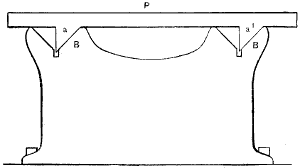

| Lathe Shears or beds | 182 | ||

| Advantages and disadvantages of, with raised V-guide-ways | 182 | ||

| Examples of various forms of | 183 | ||

| Lathe Shears with one V and one flat side | 183 | ||

| Methods of ribbing | 184 | ||

| The arrangement of the legs of | 184 | ||

| Lathe Tailblock | 185 | ||

| With rapid spindle motion | 185 | ||

| With rapid fastenings and releasing devices | 185 | ||

| The wear of the spindles of | 185 | ||

| Spindles, the various methods of locking | 186 | ||

| Testing, various methods of | 187 | ||

| CHAPTER VIII. | |||

| SPECIAL FORMS OF THE LATHE. | |||

| Watchmaker’s Lathes | 188 | ||

| Construction of the headstock | 188 | ||

| Construction of chucks for | 188 | ||

| Expanding chucks for | 188 | ||

| Contracting chucks for | 188 | ||

| Construction of the tailblock | 189 | ||

| Open spindle tailstocks for | 189 | ||

| Filing fixture for | 189 | ||

| Fixture for wheel and pinion cutting | 189 | ||

| Jewelers’ rest for | 189 | ||

| Watch Manufacturers’ Lathe | 190 | ||

| Special chucks for | 190 | ||

| Pump centre rest | 190 | ||

| Lathe, hand | 191 | ||

| Screw slotting | 192 | ||

| With variable speed for facing purposes | 192 | ||

| Cutting-off machine | 193 | ||

| Grinding Lathes | 193 | ||

| With elevating rest | 194 | ||

| Universal | 195 | ||

| Special chucks for | 196 | ||

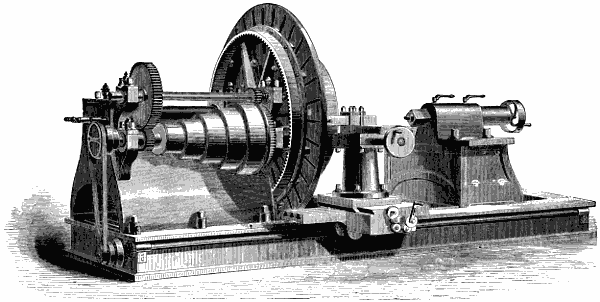

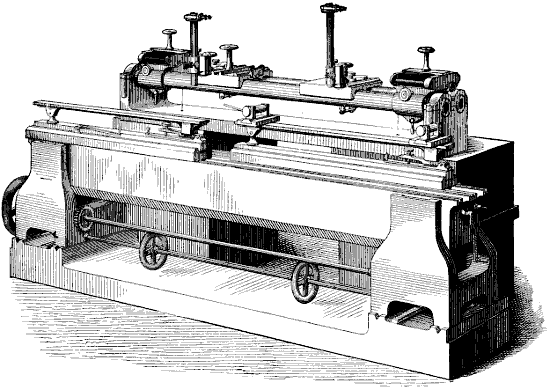

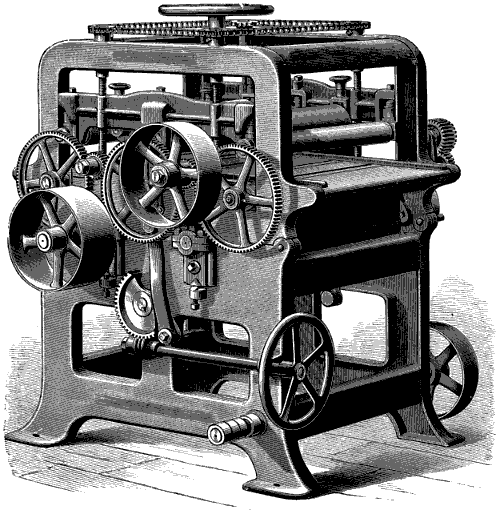

| The Morton Poole calender roll grinding lathe | 196 | ||

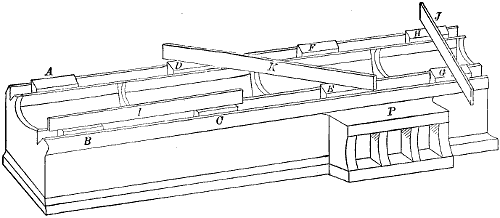

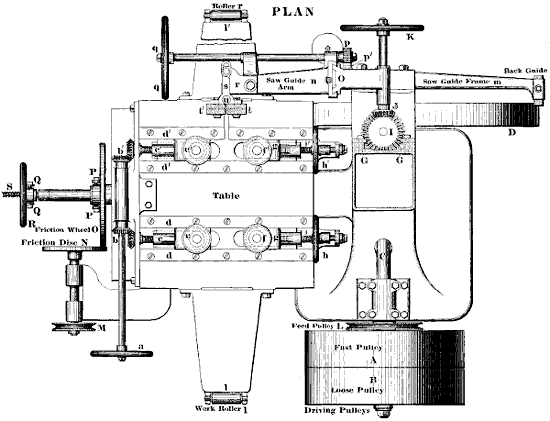

| The construction of the bed and carriages | 197 | ||

| Principles of action of the carriages | 197, 198 | ||

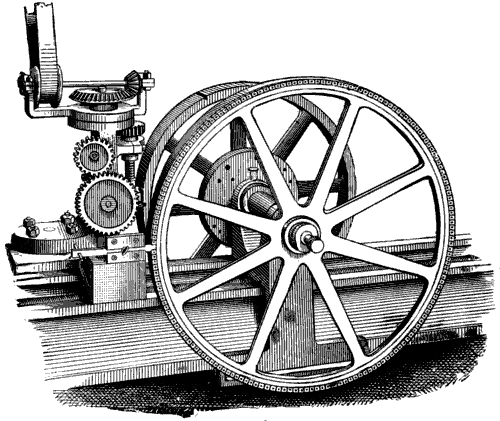

| Construction of the emery-wheel arbors and the driving motion | 198, 199 | ||

| The advantages of | 199 | ||

| The method of driving the roll | 200 | ||

| Construction of the headstock | 200 | ||

| The transverse motion | 200 | ||

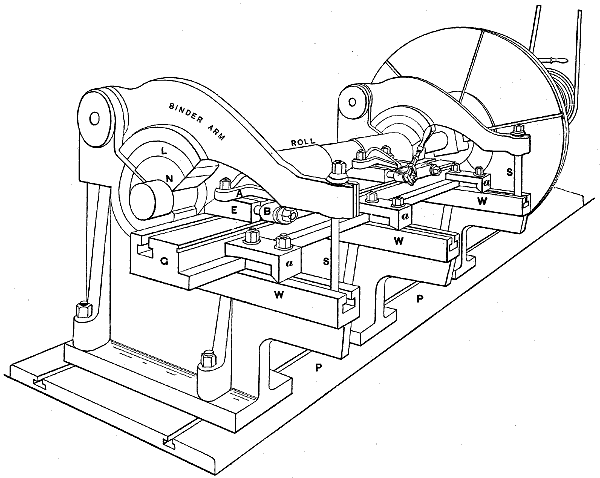

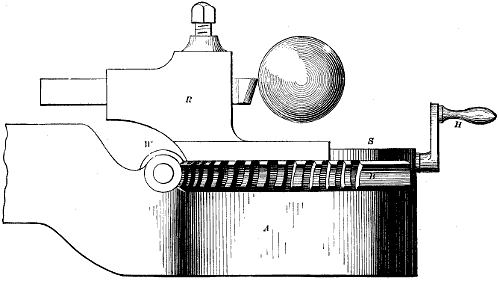

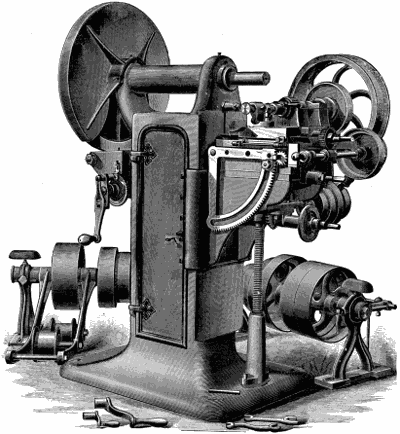

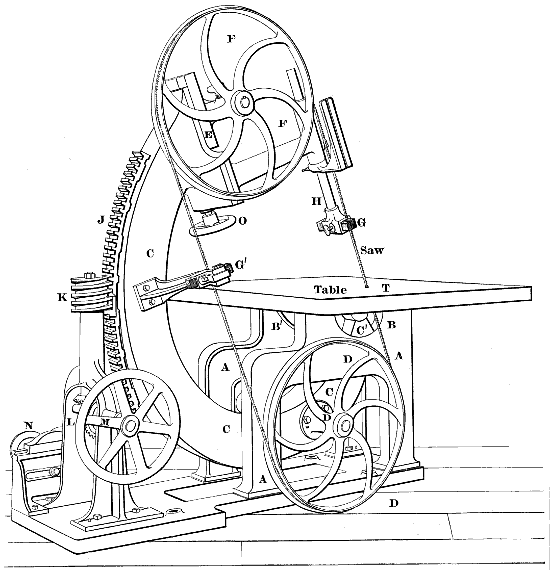

| The Brown and Sharpe Screw Machine, or screw-making lathe | 200 | ||

| Threading tools for | 203 | ||

| Examples of the use of | 203 | ||

| The Secor Screw Machine, construction of the headstock | 204 | ||

| The chuck | 205 | ||

| The feed gear | 205 | ||

| The turret | 205 | ||

| The cross slide | 205 | ||

| The stop motions | 206 | ||

| Pratt and Whitney’s Screw Machine | 206 | ||

| Parkhurst’s wire feed, construction of the headstock, chuck and feed motion | 207 | ||

| Box tools for | 208 | ||

| Applications of box tools | 208 | ||

| Threading tool for | 208 | ||

| Cutting-off tool for | 208 | ||

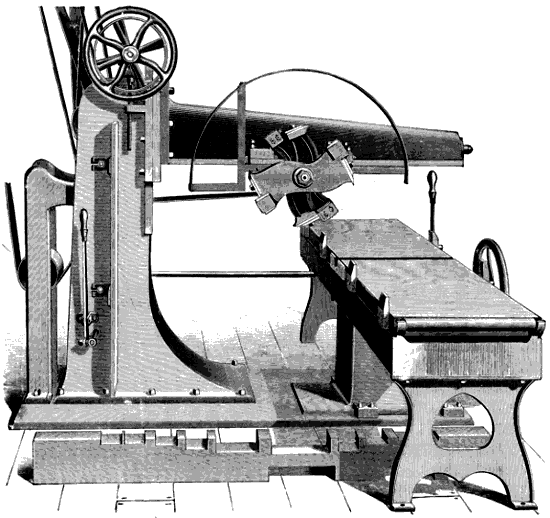

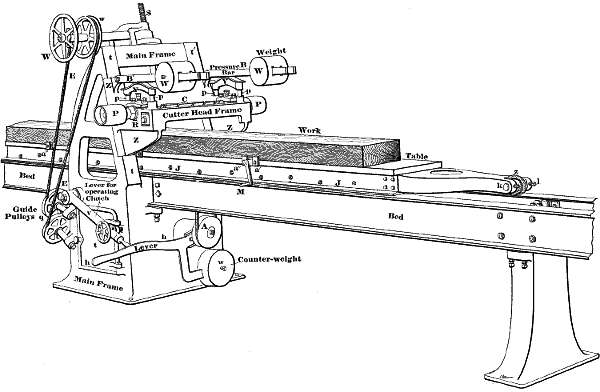

| Special Lathe for wood working | 208 | ||

| The construction of the carriage and reducing knife | 209 | ||

| Construction of the various feed motions | 209 | ||

| Construction of the tailstock | 209 | ||

| Lathes for irregular forms | 210 | ||

| Axe-handle | 210 | ||

| Back knife gauge | 210 | ||

| Special, for pulley turning | 211 | ||

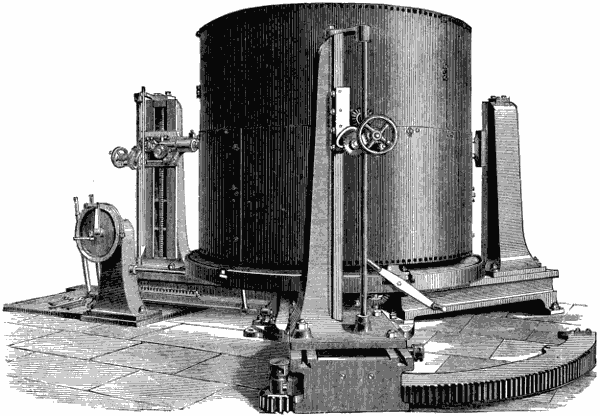

| Boring and Turning mill or lathe | 211 | ||

| Construction of the feed motions | 213 | ||

| Construction of the framing and means of grinding the lathe | 214 | ||

| Construction of the vertical feed motions | 215 | ||

| The Morton Poole roll turning lathe | 215 | ||

| Construction of the slide rest | 216 | ||

| The tools for | 216 | ||

| Special Lathes for brass work | 216, 217 | ||

| Boring Lathe with traversing spindle | 218 | ||

| For engine cylinders | 219 | ||

| Cylinder, with facing slide rests | 219 | ||

| With double heads and facing rests | 220 | ||

| Lathe for turning Wheel hubs | 221 | ||

| CHAPTER IX. | |||

| DRIVING WORK IN THE LATHE. | |||

| Drivers, carriers, dogs, or clamps, and their defects | 222 | ||

| Lathe clamps | 222 | ||

| Equalizing drivers | 223 | ||

| The Clements driver | 223 | ||

| Driver and face plate for screw cutting | 223 | ||

| Forms of, for bolt heads | 224 | ||

| Adjustable, for bolt heads | 224 | ||

| For threaded work | 225 | ||

| For steady rest work | 225 | ||

| For cored work | 225 | ||

| For wood | 225 | ||

| Centres for hollow work | 226 | ||

| For taper work | 226 | ||

| Lathe Mandrels, or arbors | 227 | ||

| Drivers for | 227 | ||

| For tubular work | 227 | ||

| Expanding mandrels | 227 | ||

| With expanding cones | 228 | ||

| With expanding pieces | 228 | ||

| Expanding, for large work | 228 | ||

| For threaded work | 228 | ||

| For nuts, various forms of | 229 | ||

| For eccentric work | 229 | ||

| Centring devices for crank axles | 230 | ||

| The Steady Rest or back rest | 231 | ||

| Steady rest, improved form of | 232 | ||

| Cone chuck | 232 | ||

| Steady rest for square and taper work | 233 | ||

| The cat head | 233 | ||

| Clamps for | 233 | ||

| Follower rests | 234 | ||

| Chucks and Chucking | 234 | ||

| Simple forms of chucks | 234 | ||

| Adjustable chucks for true work | 235 | ||

| Two-jawed chucks | 236 | ||

| Box body chucks | 237 | ||

| Reversible jawed chucks | 237 | ||

| Three and four-jawed chucks | 237 | ||

| Combination chucks | 237 | ||

| The wear of scroll chuck threads | 237 | ||

| Universal chucks | 238 | ||

| The wear of chucks | 240 | ||

| Special forms of chucks | 241 | ||

| Expanding chucks for ring-work | 241 | ||

| Cement chuck | 241 | ||

| Chucks for wood-working lathes | 242 | ||

| Lathe Face Plates | 243 | ||

| Face plates, errors in, and their effects | 243 | ||

| Work-holding straps | 244 | ||

| Face plate, clamping work on | 245 | ||

| Forms of clamps for | 245 | ||

| Examples of chucking work on | 246, 247 | ||

| For wood work | 247 | ||

| Special Lathe Chuck for cranks | 248 | ||

| Face Plate Work, examples of | 249 | ||

| Errors in chucking | 250 | ||

| Movable dogs for | 250 | ||

| The angle plate | 251 | ||

| Applications of | 251 | ||

| Angle plate chucking, examples of | 251 | ||

| Cross-head chucking | 251-253 | ||

| CHAPTER X.[I-xi] | |||

| CUTTING TOOLS FOR LATHES. | |||

| Principles governing the shapes of lathe tools | 254 | ||

| Diamond-pointed, or front tool | 254 | ||

| Principles governing use of tools | 254 | ||

| Front rake and clearance of front tools | 254 | ||

| Influence of the height of a tool upon its clearance and keenness | 255 | ||

| Tools with side rake in various directions | 256 | ||

| The effect of side rake | 256 | ||

| The angle of clearance in lathe tools | 257 | ||

| Variation of clearance from different rates of feed and diameters of work | 257 | ||

| Round-nosed tools | 258 | ||

| Utmost Duty of cutting tools | 258 | ||

| Judging the quantity of the tool from the shape of its cutting | 259 | ||

| Square-nosed tools | 260 | ||

| The height of lathe tools | 260 | ||

| Side tools for lathe work | 261 | ||

| Cutting-off or grooving tools | 262 | ||

| Facing tools or knife tools | 262 | ||

| Spring tools | 263 | ||

| Brass Work, front tools for | 264 | ||

| Side tools for | 264 | ||

| Threading tools | 264 | ||

| Internal threading tools | 264 | ||

| The length of threading tools | 265 | ||

| The level of threading tools | 265 | ||

| Gauges for threading tools | 266 | ||

| Setting threading tools | 266 | ||

| Circular threading tools | 267 | ||

| Threading tool holders | 267 | ||

| Chasers | 268 | ||

| Chaser holders | 268 | ||

| Setting chasers | 268 | ||

| Square Threads, clearance of tools for | 269 | ||

| Diameter at the roots of threads | 269 | ||

| Cutting coarse pitch square threads | 269 | ||

| Dies for finishing square threads | 269 | ||

| Tool Holders for outside work | 270 | ||

| For circular cutters | 272 | ||

| Swiveled | 273 | ||

| Combined tool holders and cutting-off tools | 273 | ||

| Power Required to drive cutting tools | 273 | ||

| CHAPTER XI. | |||

| DRILLING AND BORING IN THE LATHE. | |||

| The Twist Drill | 274 | ||

| Twist drill holders | 274 | ||

| The diametral clearance of twist drills | 274 | ||

| The front rake of twist drills | 275 | ||

| The variable clearance on twist drills as usually ground | 275 | ||

| Demonstration of the common error in grinding twist drills | 276 | ||

| The effects of improper grinding upon twist drills | 276 | ||

| Table of speeds and feeds for twist drills | 277 | ||

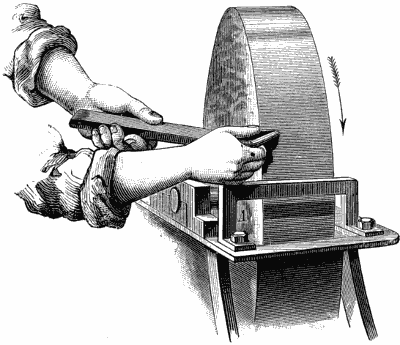

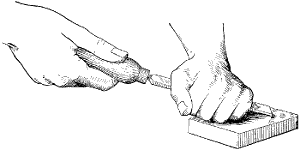

| Grinding twist drills by hand | 279 | ||

| Twist drills for wood work | 279 | ||

| Tailstock Chucks for drilled work | 279 | ||

| Flat Drills for lathe work | 280 | ||

| Holders for lathe work | 281 | ||

| Half-round bit or pod auger | 281 | ||

| With front rake for wrought iron or steel | 281 | ||

| With adjustable cutter | 281 | ||

| For very true work | 281 | ||

| Chucking Reamer | 281 | ||

| The number of teeth for reamers | 282 | ||

| Spacing the teeth of reamers | 282 | ||

| Spiral teeth for reamers | 282 | ||

| Grinding the teeth of reamers | 282 | ||

| Various positions of emery-wheel in grinding reamers | 282 | ||

| Chucking reamers for true work | 283 | ||

| Shell reamers | 283 | ||

| Arbor for shell reamers | 283 | ||

| Rose-bit or rose reamers | 283 | ||

| Shell rose reamers | 284 | ||

| Adjustable reamers | 284 | ||

| Stepped reamers for taper work | 285 | ||

| Half-round reamers | 285 | ||

| Reamers for rifle barrels | 285 | ||

| Boring Tools for lathe work | 285 | ||

| Countersinks | 285 | ||

| Shapes of lathe boring tools | 285 | ||

| Boring tools for brass work | 286 | ||

| The spring of boring tools | 286 | ||

| Boring tools for small work | 287 | ||

| Boring tool holders | 287 | ||

| Boring Devices for Lathes | 288 | ||

| Boring Heads | 288 | ||

| Boring Bars | 289 | ||

| Boring bar cutters | 289 | ||

| Three versus four cutters for boring bars | 290 | ||

| Boring bars with fixed heads | 290 | ||

| With sliding heads | 290 | ||

| Bar cutters, the shapes of | 291 | ||

| Boring head with nut feed | 291 | ||

| Boring bars for taper work, various forms of | 292 | ||

| Boring double-coned work | 293 | ||

| Boring bar, centres for | 293 | ||

| Cutting Speeds and feeds for wrought iron | 294 | ||

| Examples of speeds taken from practice | 295 | ||

| CHAPTER XII. | |||

| EXAMPLES IN LATHE WORK. | |||

| Technical Terms used in the work | 296 | ||

| Lathe Centres | 296 | ||

| Devices for truing | 297 | ||

| Tools for testing the truth of, for fine work | 298 | ||

| Shapes of, for light and heavy work | 299 | ||

| Centre Drilling, attachment for lathes | 300 | ||

| The error induced by straightening work after | 300 | ||

| Machine | 300 | ||

| Combined centre-drill and countersink | 300 | ||

| Countersink with adjustable drill | 300 | ||

| Centring square | 300 | ||

| Centre-punch | 300 | ||

| Centre-punch guide | 301 | ||

| Centring work with the scribing block | 301 | ||

| Finding the centre of very rough work | 301 | ||

| Centre-drill chuck | 302 | ||

| The proper form of countersink for lathe work | 302 | ||

| Countersinks for lathe work | 302 | ||

| Various forms of square centres | 303 | ||

| The advantage of the square centre for countersinking | 303 | ||

| Novel form of countersink for hardened work | 303 | ||

| Chucks for centre-drilling and countersinking | 303 | ||

| Recentring turned work | 304 | ||

| Straightening Work. Straightening machine for bar iron | 304 | ||

| Hand device for straightening lathe work | 305 | ||

| Chuck for straightening wire | 305 | ||

| Cutting Rods into small pieces of exact length, tools for | 305 | ||

| Roughing cuts, the change of shape of work that occurs from removing the surface by | 306 | ||

| Feeds for | 306 | ||

| Rates of feed for | 307 | ||

| Finishing Work, the position of the tool for | 307 | ||

| Finishing cast-iron with water | 307 | ||

| Specks in finished cast-iron work | 307 | ||

| Scrapers for finishing cast-iron work | 307 | ||

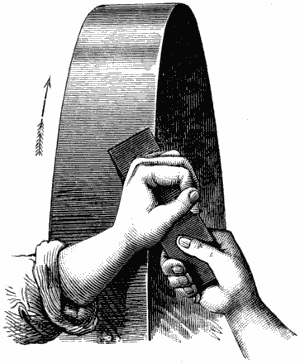

| Method of polishing lathe work | 308 | ||

| Filing lathe work | 308 | ||

| The use of emery paper on lathe work | 308 | ||

| The direction of tool feed in finishing long work | 309 | ||

| Forms of laps for finishing gauges or other cylindrical lathe work | 310 | ||

| Forms of laps for finishing internal work | 311 | ||

| Grinding and polishing clamps for lathe work | 311 | ||

| Burnishing lathe work | 311 | ||

| Taper Work, turning | 312 | ||

| The wear of the centres of | 312 | ||

| Setting over the tailstock to turn | 312 | ||

| Gauge for setting over | 313 | ||

| Fitting | 313 | ||

| Grinding | 313 | ||

| The order of procedure in turning | 313 | ||

| The influence of the height of the tool in producing true | 314 | ||

| Special Forms. Curved work | 314, 315 | ||

| Standard gauges for taper work | 316 | ||

| Methods of turning an eccentric | 317 | ||

| Turning a cylinder cover | 318 | ||

| Turning pulleys | 318 | ||

| Chucking device for pulleys | 318 | ||

| Cutting Screws in the lathe | 319 | ||

| The arrangement of the change gears | 319 | ||

| The intermediate wheels | 319 | ||

| The compounded gears | 320 | ||

| Finding the change wheels to cut a given thread | 320 | ||

| Finding the change wheels for a lathe whose gears are compounded | 321 | ||

| Finding the change gears for cutting fractional pitches | 321 | ||

| To find what pitch of thread the wheels already on the lathe will cut | 322 | ||

| Cutting left-hand threads | 322 | ||

| Cutting double threads | 322 | ||

| Cutting screws whose pitches are given in the terms of the metric system | 322 | ||

| Cutting threads on taper work | 323 | ||

| Errors in cutting threads on taper work | 324 | ||

| CHAPTER XIII.[I-xii] | |||

| EXAMPLES IN LATHE WORK (Continued). | |||

| Ball Turning with tubular saw | 325 | ||

| With a single tooth on the end of a revolving tube | 325 | ||

| With a removable tool on an arbor | 325 | ||

| Tool holder with worm feed | 325 | ||

| By hand | 325 | ||

| Cams, cutting in the lathe | 326 | ||

| Improved method of originating cams in the lathe | 326 | ||

| Motions for turning cams in the lathe | 326, 327 | ||

| Application of cam motions to special work | 327 | ||

| Cam chuck for irregular work | 328 | ||

| Milling or knurling tool | 328 | ||

| Improved forms of | 328 | ||

| Winding Spiral Springs in the lathe | 329 | ||

| Hand Turning | 330 | ||

| The heel tool | 330 | ||

| The graver and its applications | 330, 331 | ||

| Hand side tools | 331 | ||

| Hand round-nosed tools for iron | 331 | ||

| Hand finishing tool | 331 | ||

| Hand Tools, for roughing out brass work | 332 | ||

| Various forms and applications of scrapers | 332, 333 | ||

| Clockmakers’ hand tool for special or standard work | 334 | ||

| Screw cutting with hand tools | 334 | ||

| Outside and inside chasers | 334 | ||

| Hobs and their uses | 335 | ||

| The application of chasers, and errors that may arise from the position in which they are presented to the work | 336 | ||

| Errors commonly made in cutting up inside chasers | 337 | ||

| V-tool for starting outside threads | 337 | ||

| Starting outside threads | 338 | ||

| Cutting taper threads | 338 | ||

| Wood turning hand tools | 338 | ||

| The gauge and how to use it | 338 | ||

| The chisel and its use | 339 | ||

| The skew chisel and how to use it | 339 | ||

| Wood turners’ boring tools for lathe work | 340 | ||

| CHAPTER XIV. | |||

| MEASURING MACHINES, TOOLS AND DEVICES. | |||

| Standards of Measurements, in various countries | 341 | ||

| Use of, by sight and by the sense of feeling | 341 | ||

| Variations in standard gauges | 341 | ||

| The necessity for accurate standards | 341 | ||

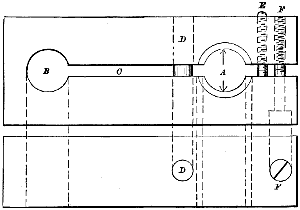

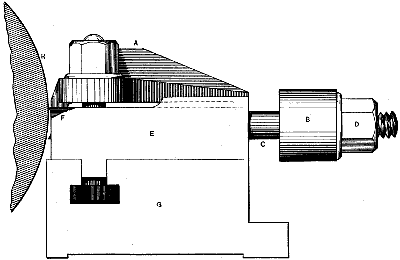

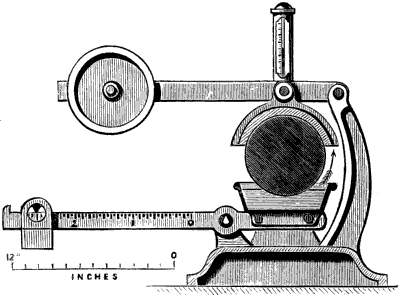

| The Rogers Bond standard measuring machine | 342 | ||

| Details of construction of | 343, 344 | ||

| The principle of construction of | 344 | ||

| The methods of using | 345 | ||

| The Whitworth measuring machine | 345 | ||

| The Betts Machine Company’s measuring machine | 346 | ||

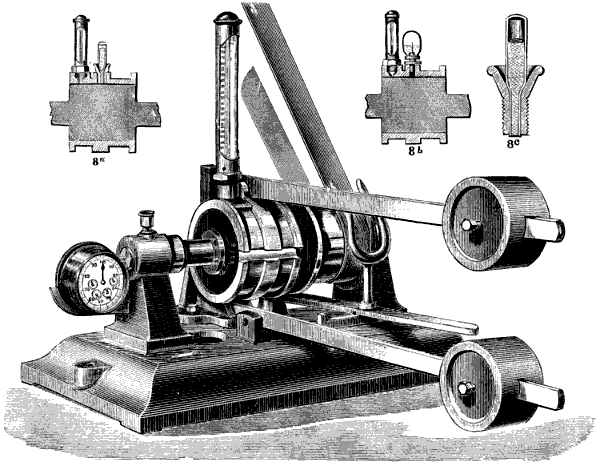

| Professor Sweet’s measuring machine | 347 | ||

| Measuring machine for sheet metal | 348 | ||

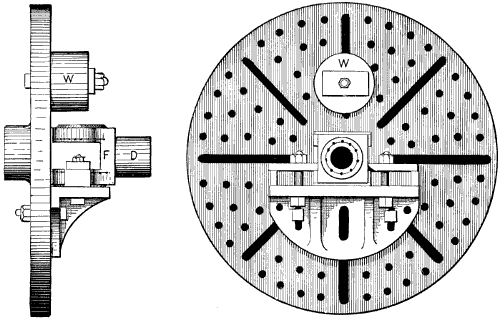

| Circle, division of the | 348 | ||

| Troughton’s method of dividing the circle | 348, 349 | ||

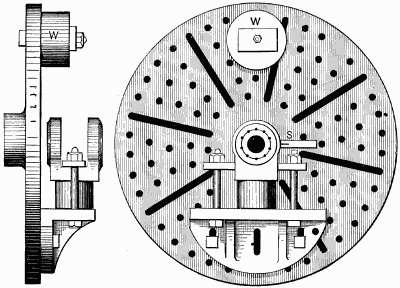

| Ramsden’s dividing engine | 349 | ||

| The construction of | 350, 351 | ||

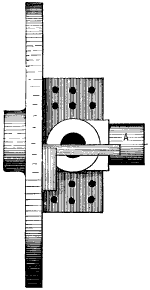

| Pratt and Whitney’s dividing device | 352 | ||

| Practical application of | 353 | ||

| Index wheel, method of originating, by R. Hoe & Co. | 353 | ||

| Application of the index wheel (Hoe & Co.’s system) | 353 | ||

| Classification of the measuring tools used by workmen | 354 | ||

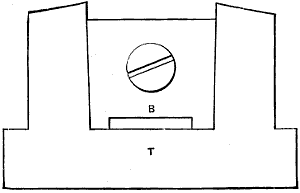

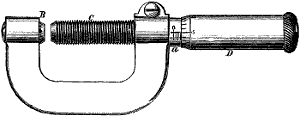

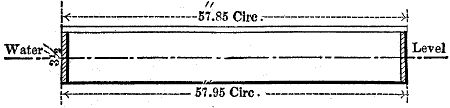

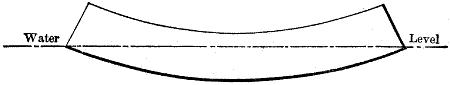

| Micrometer Caliper and its principle of construction | 354, 355 | ||

| Gauges. Standard plug and collar gauges | 356 | ||

| Methods of comparing standard plug and collar gauges | 356 | ||

| The effects of variations of temperature upon standard gauges | 356 | ||

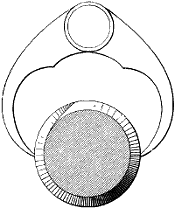

| Plug and collar gauges for taper work | 357 | ||

| The Baldwin standards for taper bolts | 359 | ||

| Workmen’s gauges for lathe work | 359 | ||

| Calipers, outside, the various forms of | 360 | ||

| Inside calipers | 360 | ||

| Calipers with locking devices | 360 | ||

| Spring calipers | 360 | ||

| The methods of holding and using | 361, 362 | ||

| Keyway calipers | 363 | ||

| The advantages of calipers | 363 | ||

| Fitting. The four kinds of fit in machine work | 363 | ||

| The influence of the diameter of the work in limiting the application of standard gauges | 363 | ||

| The wear of tools and its influence upon the application of the standard gauge system | 364 | ||

| The influence of the smoothness of the surface upon the allowance to be made for drilling or hydraulic fits | 365 | ||

| Examples of allowance for hydraulic fits | 365 | ||

| Parallel holes and taper plugs for hydraulic fits | 365 | ||

| Fitting. Practicable methods of testing the fit of axle brasses forced in by hydraulic pressure | 366 | ||

| Shrinkage or contraction fits | 366 | ||

| Allowances for | 366 | ||

| Gauge for | 367 | ||

| The shrinkage system at the Royal Gun Factory at Woolwich | 367 | ||

| Experiments by Thomas Wrightson upon the shrinkage of iron under repeated heatings and coolings | 368 to 374 | ||

| Shrinking work, to refit it | 374, 375 | ||

| CHAPTER XV. | |||

| MEASURING TOOLS. | |||

| End Measurements of large lathe work | 376 | ||

| Template gauges for | 376 | ||

| Trammels or Trains | 377 | ||

| Adjustable gauges for | 377 | ||

| Compasses—Dividers | 377 | ||

| Compass calipers | 378 | ||

| Key Seating rule | 378 | ||

| Surface Gauge | 378 | ||

| Pattern makers’ pipe gauge | 379 | ||

| Squares. The try square | 379 | ||

| The T square | 379 | ||

| Various methods of testing squares | 379, 380 | ||

| Bevel squares | 380 | ||

| Bevel Protractors | 380 | ||

| Hexagon Gauge | 381 | ||

| Straight Edge and its applications | 381, 382 | ||

| Winding strips and their application | 382 | ||

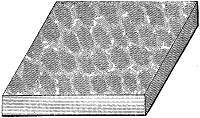

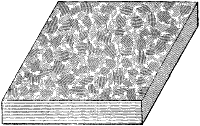

| Surface Plate or planimeter | 383 | ||

| Templates for curves | 384 | ||

| Wire Gauges, notch | 384 | ||

| Standard gauges for wire, &c. | 384, 386 | ||

| Gauge for music wire | 386 | ||

| Brown and Sharpe wire gauge | 387 | ||

| Birmingham wire gauge for rolled shell silver and gold | 387 | ||

| Sheet iron gauge, Russian | 387 | ||

| Galvanized iron | 387 | ||

| Belgian sheet zinc | 387 | ||

| American sheet zinc | 387 | ||

| Rifle Bore gauge | 387 | ||

| Strength of Wire, Kirkaldy’s experiments | 387, 388 | ||

| CHAPTER XVI. | |||

| SHAPING AND PLANING MACHINES. | |||

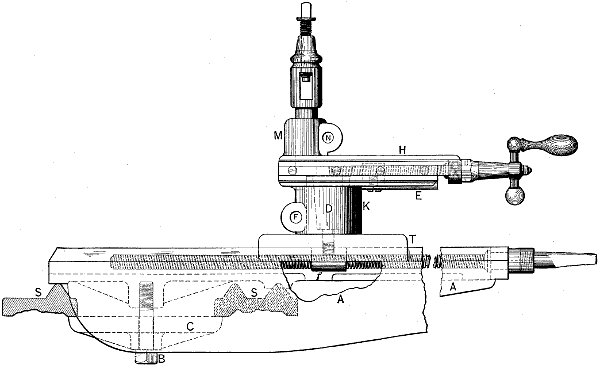

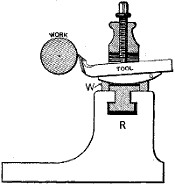

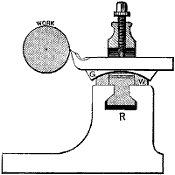

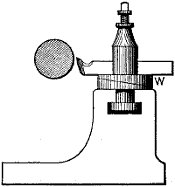

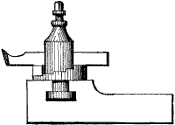

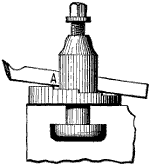

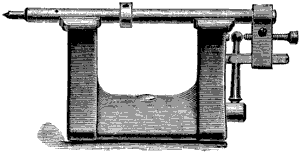

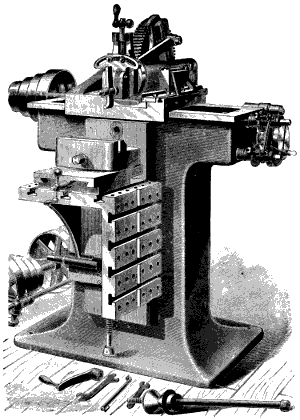

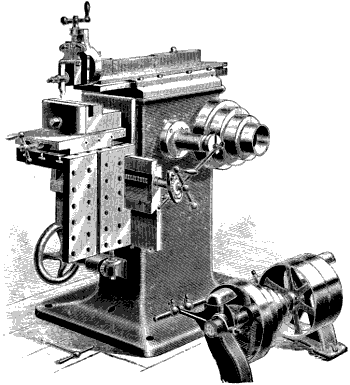

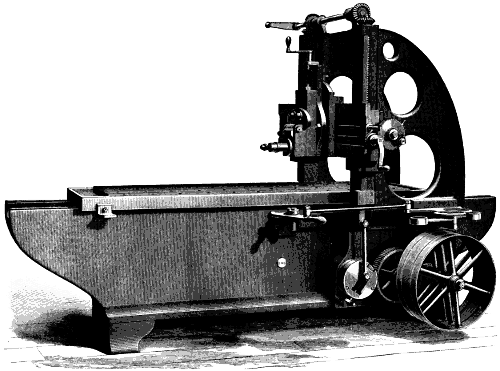

| General description of a shaping machine | 389 | ||

| Construction of swivel head | 389 | ||

| Slide | 390 | ||

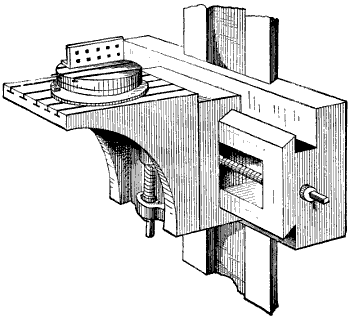

| Vice chuck | 390 | ||

| Feed motion | 390 | ||

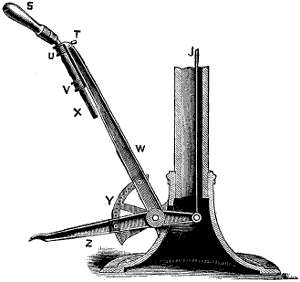

| Hand shaping machine | 392 | ||

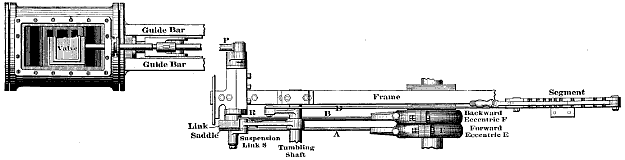

| Quick Return Motion, Whitworth’s | 392 | ||

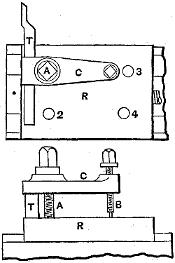

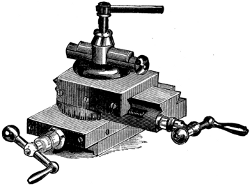

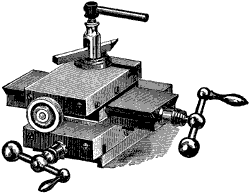

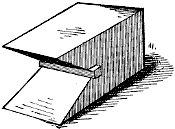

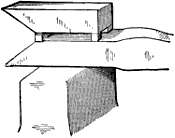

| Vice Chucks, the principles of construction of plain, for planing machine | 392 | ||

| The proper methods of chucking work in | 393 | ||

| Holding taper work in | 394 | ||

| Various forms of | 394 | ||

| Swiveling | 395 | ||

| Rapid motion | 396 | ||

| For vice work | 396 | ||

| Centres for shaping machines | 397 | ||

| Traveling Head in shaping machine | 397 | ||

| Planer Shapers or shaping machines, having a tappet motion for reversing the direction of motion | 398, 399 | ||

| Quick Return Motion shaping machines, link | 399 | ||

| The Whitworth | 400 | ||

| Comparisons of the link motion and Whitworth | 401 | ||

| Simple Crank, investigating the motion of | 401 | ||

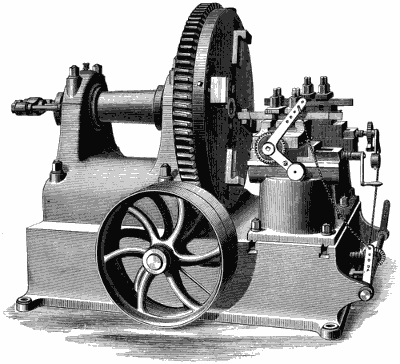

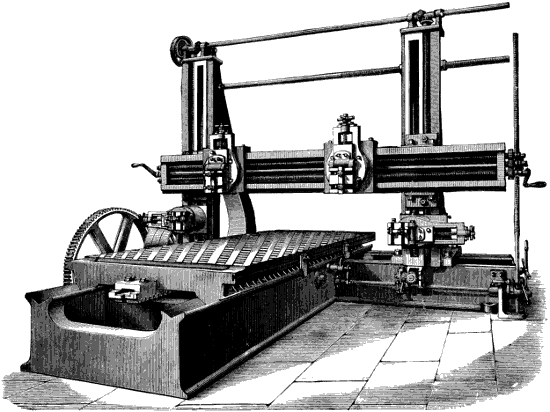

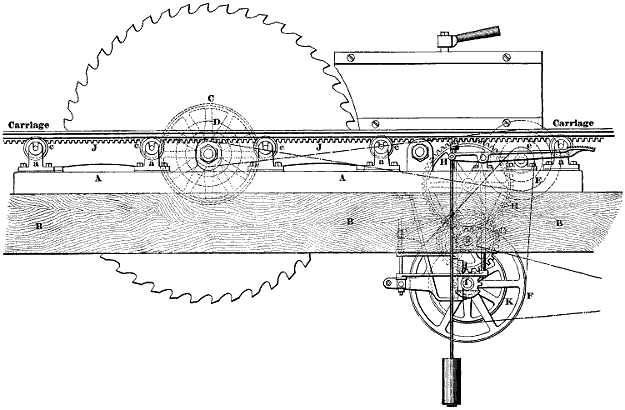

| Planing Machines, or planer | 402 | ||

| The various motions of | 402, 403 | ||

| The table driving gear | 404 | ||

| Planing machine with double heads | 404 | ||

| Rotary planing machine | 405 | ||

| CHAPTER XVII. | |||

| PLANING MACHINERY. | |||

| The Sellers planing machine | 406 | ||

| The belt shifting mechanism | 406, 407 | ||

| The automatic feed motions | 408 | ||

| Sliding Head | 408 | ||

| Cross Bar | 409 | ||

| Slides of Planers, the various forms of construction of | 410 | ||

| [I-xiii]Wear of the Slides of planer heads, various methods of taking up the | 410 | ||

| Swivel Heads | 411 | ||

| Tool Aprons | 411 | ||

| Swivel Tool-holding devices for planers | 411 | ||

| Planer Heads, graduations of | 412 | ||

| Safety devices for | 413 | ||

| Feed motions for | 414 | ||

| V-guideways for | 414 | ||

| Flat guideways for | 415 | ||

| Oiling devices for | 415 | ||

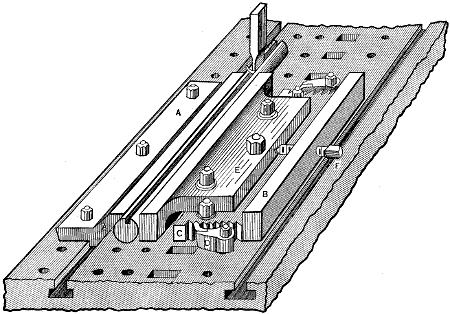

| Planing Machine Tables | 415 | ||

| Slots and holes in planing machine tables | 416 | ||

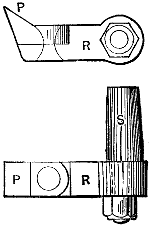

| Forms of bolts for planer tables | 417 | ||

| Supplementary tables for planer tables | 417 | ||

| Angle plates for planer tables | 418 | ||

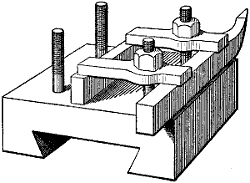

| Chucking devices for planer tables | 418 | ||

| Planer Centres | 418 | ||

| Planer Chucks | 419 | ||

| For spiral grooved work | 419 | ||

| For curved work | 420 | ||

| Chucking machine beds on planer tables | 420 | ||

| For large planing machines | 422 | ||

| Chucking the halves of large pulleys on a planer | 423 | ||

| Gauges for planing V-guideways in machine beds | 421 | ||

| Planing guideways in machine beds | 422 | ||

| Gauge for planer tools | 424 | ||

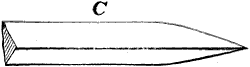

| Planer Tools, the shapes of | 424 | ||

| For coarse finishing feeds | 424 | ||

| The clearance of | 424 | ||

| For slotted work | 424 | ||

| Planer Tool Holder, with tool post | 425 | ||

| Various applications of | 425 | ||

| Simple and advantageous form of | 426 | ||

| Examples of application of | 426 | ||

| CHAPTER XVIII. | |||

| DRILLING MACHINES. | |||

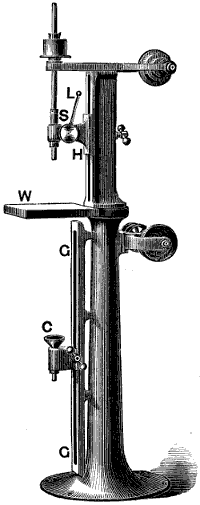

| Drilling Machines. General description of a power drilling machine | 428 | ||

| Lever feed | 428 | ||

| With automatic and quick return feed motions | 428 | ||

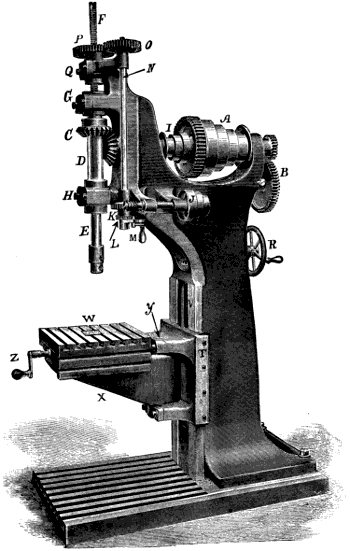

| Improved, with simple belt and uniform motion, two series of rates of automatic feed, and guide for boring bar | 429, 430 | ||

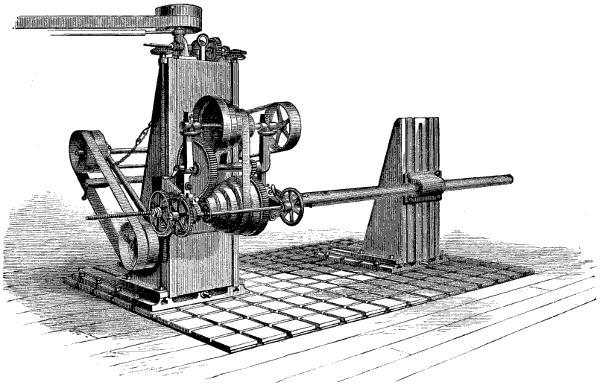

| Radial | 430, 431 | ||

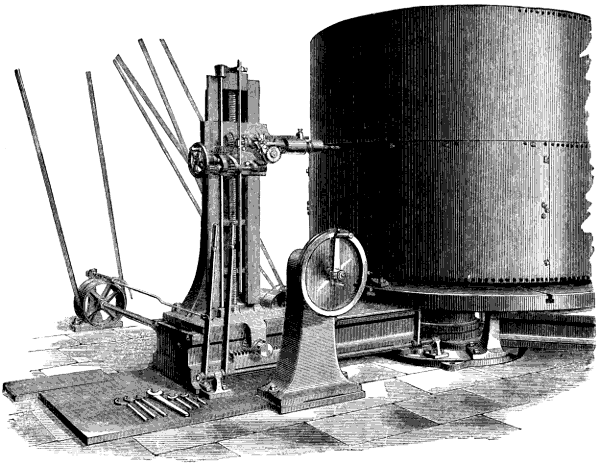

| For boiler shells | 436 | ||

| Cotter or keyway | 438 | ||

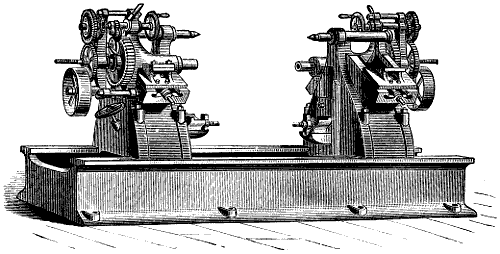

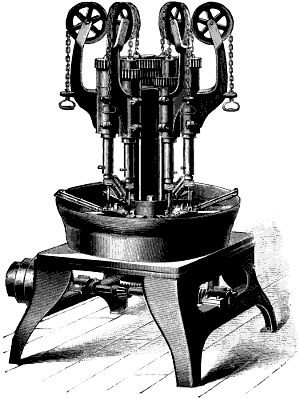

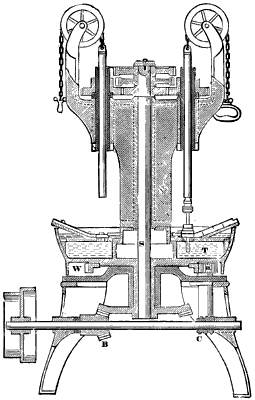

| Drilling Machine, three-spindle | 434 | ||

| Four-spindle | 434 | ||

| Drilling and Boring machine | 431 | ||

| Feed motion of | 432 | ||

| Combined Drilling Machine and lathe | 433 | ||

| Boring Machine, horizontal | 433 | ||

| For car wheels | 438 | ||

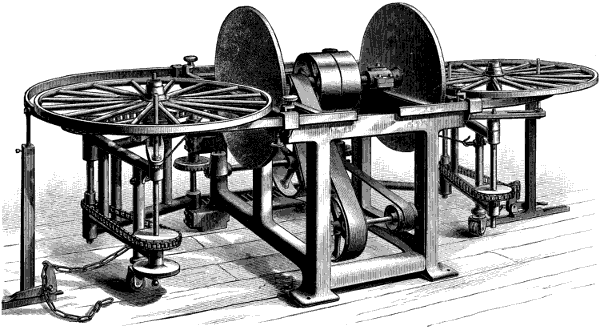

| For pulleys | 438 | ||

| Quartering Machine | 434 | ||

| Drilling and Turning Machine for boiler makers | 435 | ||

| Feed motions of | 436 | ||

| CHAPTER XIX. | |||

| DRILLS AND CUTTERS FOR DRILLING MACHINES. | |||

| Jigs or Fixtures for drilling machines | 439 | ||

| Limits of error in | 439 | ||

| Examples of, for simple work, as for links, &c. | 440 | ||

| Considerations in designing | 440 | ||

| For drilling engine cylinders | 440 to 441 | ||

| For cutting out steam ports | 441 | ||

| Drills and Cutters for drilling machines | 442 | ||

| Table of sizes of twist drills, and their shanks | 442 | ||

| Flat drills for drilling machines | 442 | ||

| Errors in grinding flat drills | 443 | ||

| The tit-drill | 443 | ||

| The lip drill | 443 | ||

| Cotter or keyway drills | 446 | ||

| Drilling holes true to location with flat drills | 444 | ||

| Drilling hard metal | 444 | ||

| Table of sizes of tapping holes | 445 | ||

| Drill Shanks and sockets | 445 | ||

| Improved form of drill shank | 446 | ||

| Square shanked drills and their disadvantages | 446 | ||

| Drill Chucks | 446 | ||

| Stocks and Cutters for drilling machines | 447 | ||

| Tube plate cutters | 448 | ||

| Stocks and Cutters. Adjustable stock and cutter | 448 | ||

| Facing tool with reamer pin | 449 | ||

| Counterbores for drilling machines | 449 | ||

| Drill and counterbore for wood work | 449 | ||

| Facing and countersink cutters | 449 | ||

| Device for drilling square holes | 450 | ||

| Device for drilling taper holes in a drilling machine | 451 | ||

| CHAPTER XX. | |||

| HAND-DRILLING AND BORING TOOLS, AND DEVICES. | |||

| The Brad-awl | 452 | ||

| Bits. The gimlet bit | 452 | ||

| The German bit | 452 | ||

| The nail bit | 452 | ||

| The spoon bit | 452 | ||

| The nose bit | 453 | ||

| The auger bit | 453 | ||

| Cook’s auger bit | 453 | ||

| Principles governing the shapes of the cutting edges of auger bits | 453 | ||

| Auger bit for boring end grain wood | 453 | ||

| The centre bit | 454 | ||

| The expanding bit | 454 | ||

| Drills. Drill for stone | 454 | ||

| The fiddle drill | 455 | ||

| The fiddle drill with feeding device | 455 | ||

| Drill with cord and spring motion | 455 | ||

| Drill stock with spiral grooves | 455 | ||

| Drill brace | 455 | ||

| Drill brace with ratchet motion | 456 | ||

| Universal joint for drill brace | 456 | ||

| Drill brace with multiplying gear and ratchet motion | 456 | ||

| Breast drill with double gear | 456 | ||

| Drilling levers for blacksmiths | 457 | ||

| Drill cranks | 457 | ||

| Ratchet brace | 457 | ||

| Flexible shaft for driving drills | 458 | ||

| Drilling device for lock work | 459 | ||

| Hand drilling machine | 459 | ||

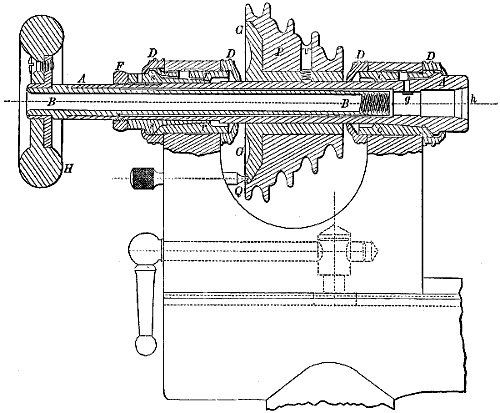

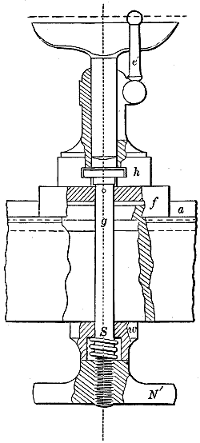

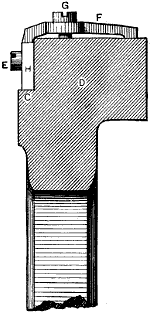

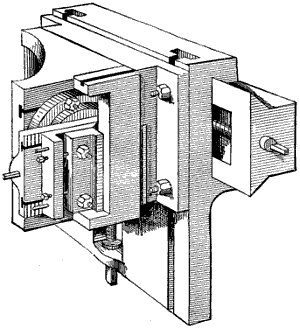

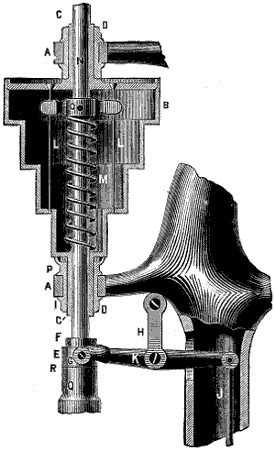

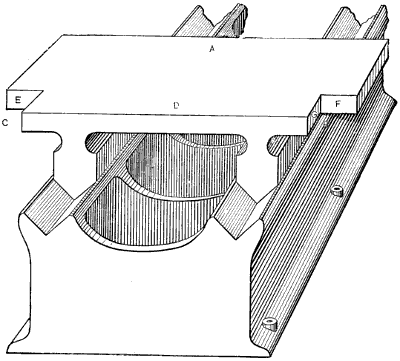

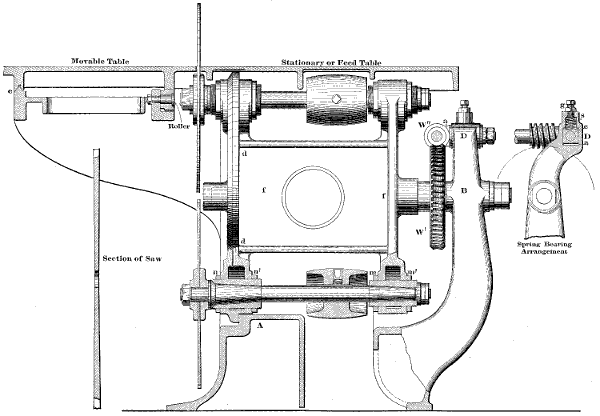

| Slotting Machine | 459 | ||

| Sectional view of | 460 | ||

| Tool holders | 460, 461 | ||

| Tools | 461, 462 | ||

| CHAPTER XXI. | |||

| THREAD-CUTTING MACHINERY AND BROACHING PRESS. | |||

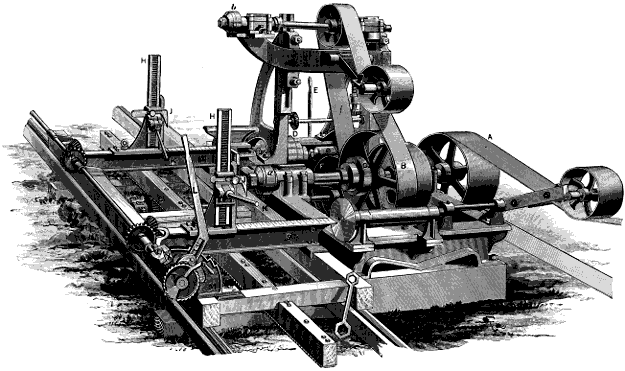

| Pipe Threading, die stock for, by hand | 463 | ||

| Die stock for, by power | 463 | ||

| Pipe threading machines, general construction of | 463 | ||

| Bolt Threading hand machine | 464 | ||

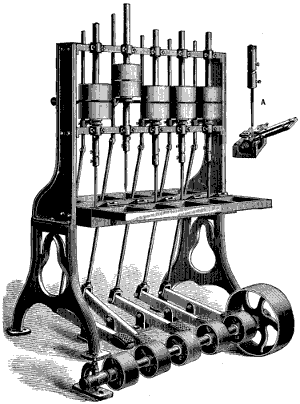

| With revolving head | 465 | ||

| Power threading machine | 465 | ||

| With automatic stop motion | 466 | ||

| Construction of the head | 466 | ||

| Construction of the chasers | 466 | ||

| Bolt threading machine with back gear | 467 | ||

| Single rapid bolt threading machine | 467 | ||

| Double rapid bolt threading machine | 467 | ||

| Construction of the heads of the rapid machines | 468 | ||

| Bolt threading machinery, the Acme | 468 | ||

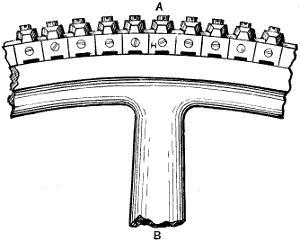

| Construction of the head of | 468 to 470 | ||

| Capacity of | 470 | ||

| Cutting Edges for taps, the number of | 471 | ||

| Examples when three and when four cutting edges are used, and the results upon bolts that are not round | 471, 472 | ||

| Demonstration that four cutting edges are correct for bar iron | 472 | ||

| Positions of Dies, or chasers in the heads of bolt cutting machine | 473 | ||

| Dies, methods of hobbing, to avoid undue friction | 473 | ||

| The construction of, for bolt threading machines | 473 | ||

| Method of avoiding friction in thread cutting | 474 | ||

| Hob for threading | 474 | ||

| Cutting speeds for threading | 474 | ||

| Nut Tapping machine | 475 | ||

| Automatic socket for | 475 | ||

| Rotary | 475 | ||

| Three-spindle | 475 | ||

| Pipe Threading Machine | 475 to 477 | ||

| Tapping Machine for steam pipe fittings | 478 | ||

| Broaching Press | 478 | ||

| Principles of broaching | 478 | ||

| Examples in the construction of broaches | 479 | ||

| Facing | |||

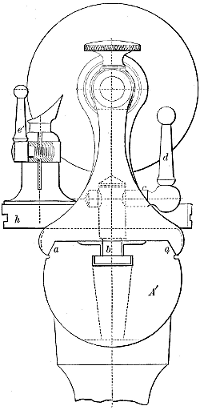

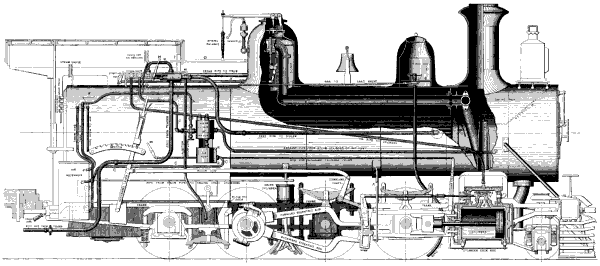

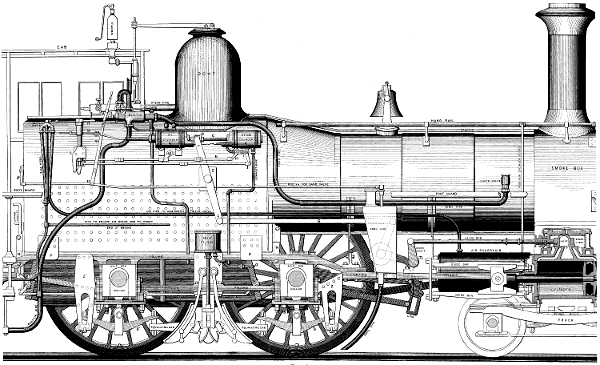

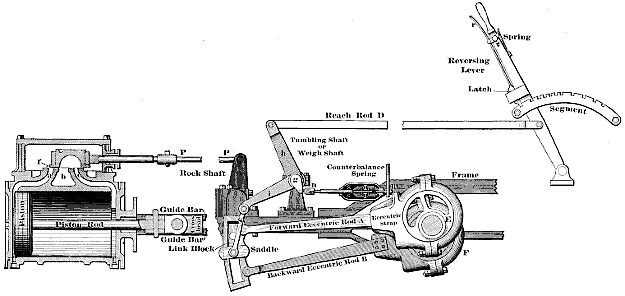

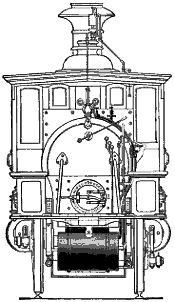

| Frontispiece. | MODERN LOCOMOTIVE ENGINE. | Title Page | |

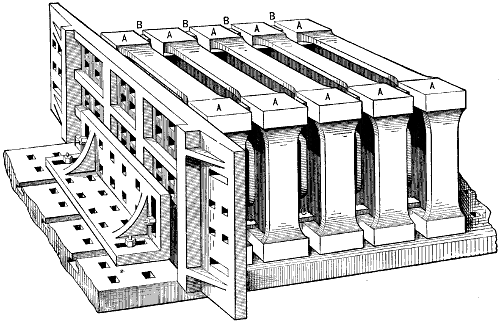

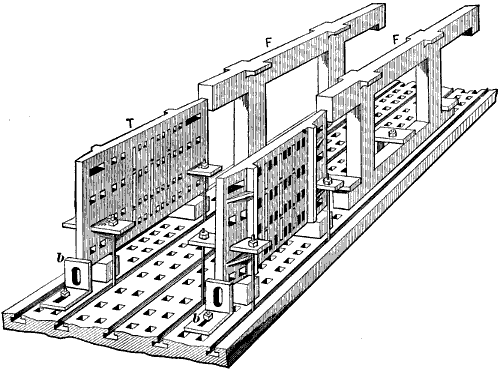

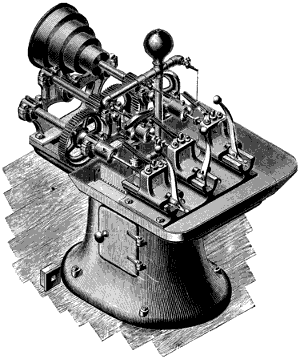

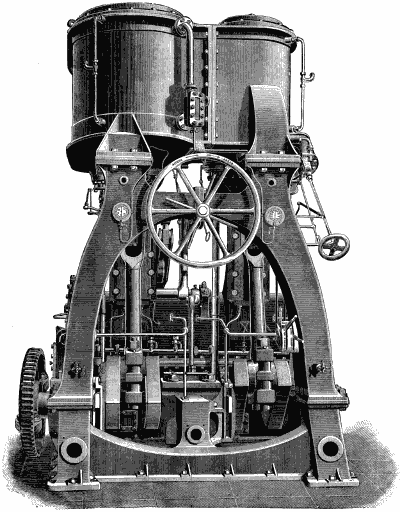

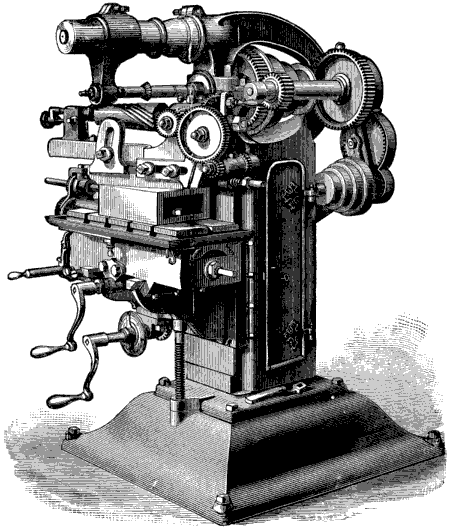

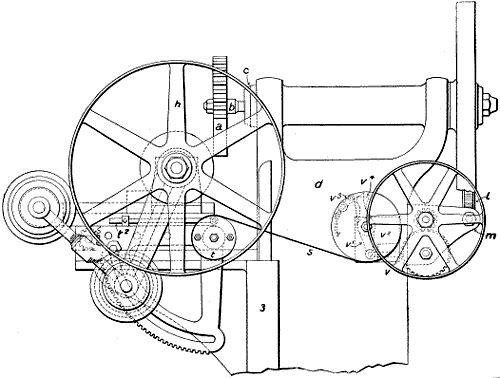

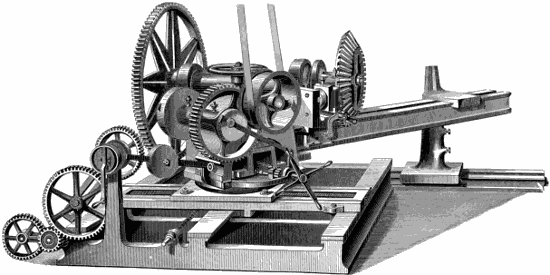

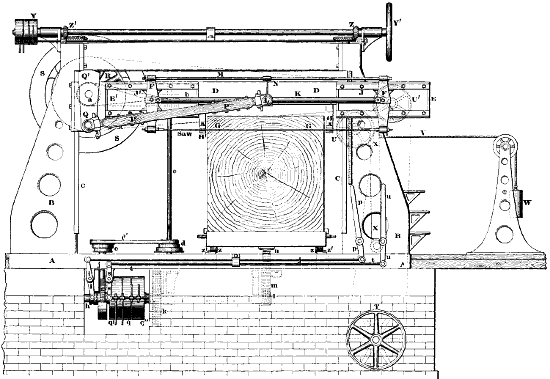

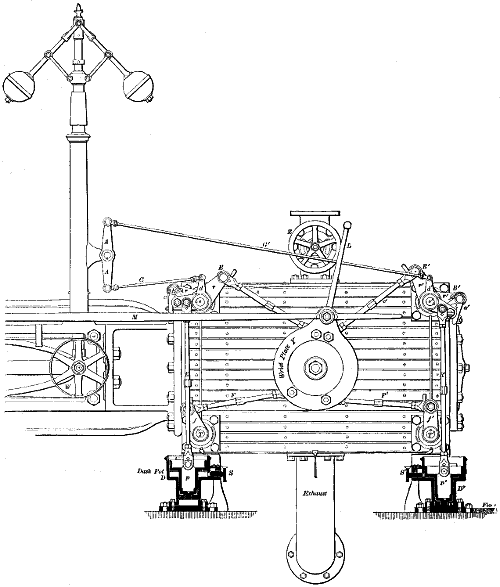

| Plate | I. | TEMPLATE-CUTTING MACHINES FOR GEAR TEETH. | 34 |

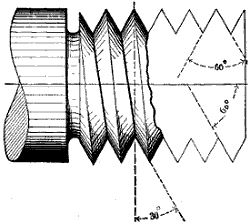

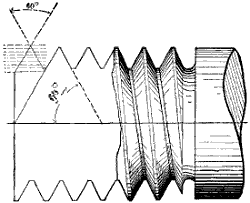

| „ | II. | FORMS OF SCREW THREADS. | 85 |

| „ | III. | MEASURING AND GAUGING SCREW THREADS. | 93 |

| „ | IV. | END-ADJUSTMENT AND LOCKING DEVICES. | 120 |

| „ | V. | EXAMPLES IN LATHE CONSTRUCTION. | 148 |

| „ | VI. | CHUCKING LATHES. | 150 |

| „ | VII. | TOOL-HOLDING AND ADJUSTING APPLIANCES. | 174 |

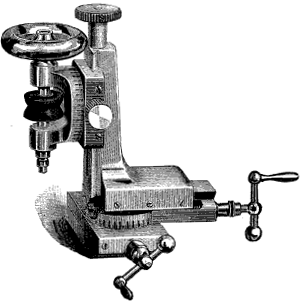

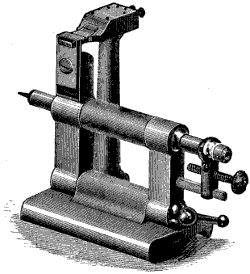

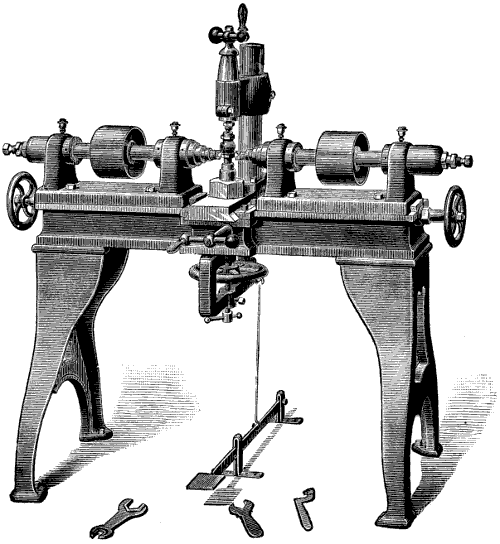

| „ | VIII. | WATCHMAKER’S LATHE. | 188 |

| „ | IX. | DETAILS OF WATCHMAKER’S LATHE. | 188 |

| „ | X. | EXAMPLES OF SCREW MACHINES. | 200 |

| „ | XI. | ROLL-TURNING LATHE. | 215 |

| „ | XII. | EXAMPLES IN ANGLE-PLATE CHUCKING. | 252 |

| „ | XIII. | METHODS OF BALL-TURNING. | 325 |

| „ | XIV. | STANDARD MEASURING MACHINES. | 341 |

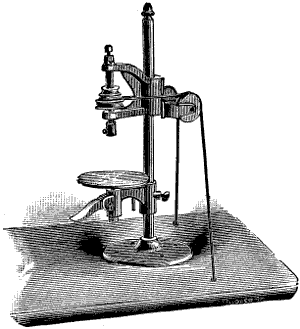

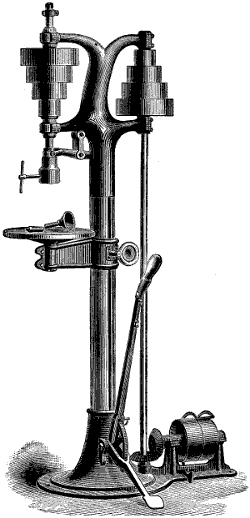

| „ | XV. | DIVIDING ENGINE AND MICROMETER. | 354 |

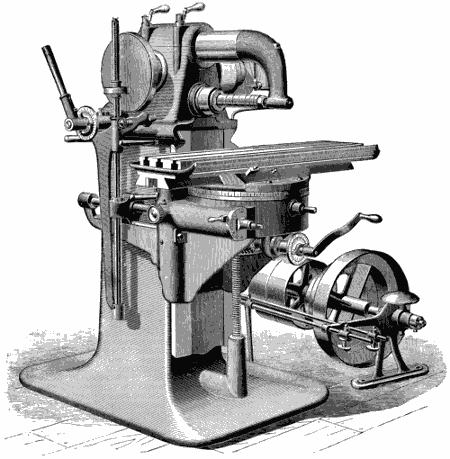

| „ | XVI. | SHAPING MACHINES AND TABLE-SWIVELING DEVICES. | 398 |

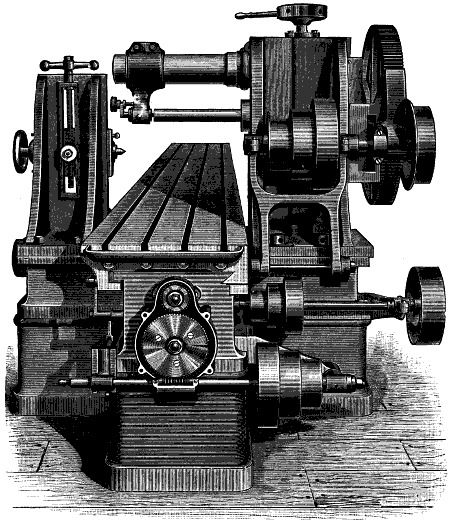

| „ | XVII. | EXAMPLES OF PLANING MACHINES. | 404 |

| „ | XVIII. | EXAMPLES IN PLANING WORK. | 422 |

| „ | XIX. | LIGHT DRILLING MACHINES. | 428 |

| „ | XX. | HEAVY DRILLING MACHINES. | 430 |

| „ | XXI. | EXAMPLES IN BORING MACHINERY. | 434 |

| „ | XXII. | BOILER-DRILLING MACHINERY. | 436 |

| „ | XXIII. | NUT-TAPPING MACHINERY. | 475 |

A wheel that is provided with teeth to mesh, engage, or gear with similar teeth upon another wheel, so that the motion of one may be imparted to the other, is called, in general terms, a gear-wheel.

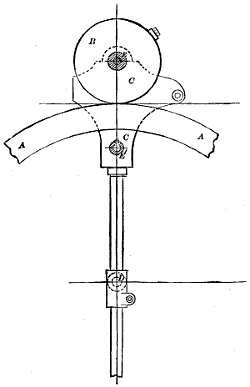

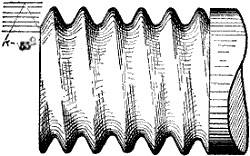

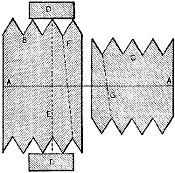

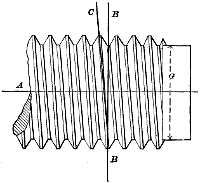

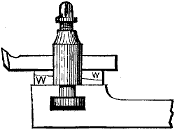

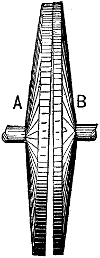

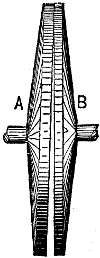

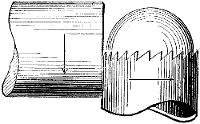

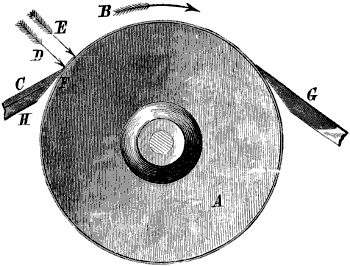

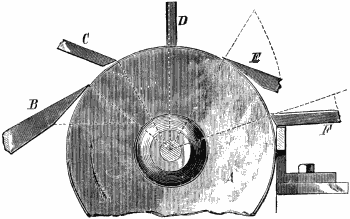

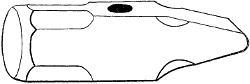

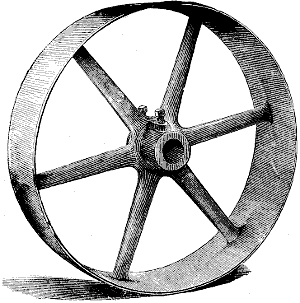

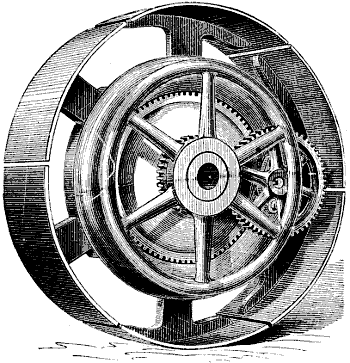

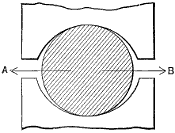

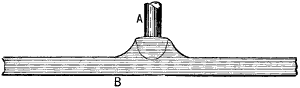

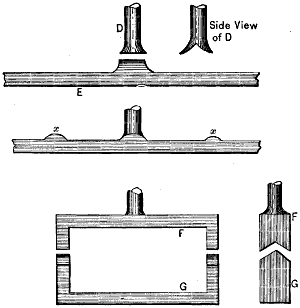

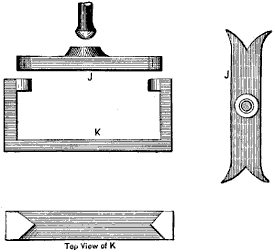

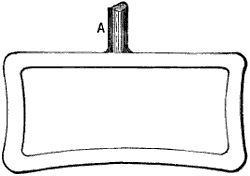

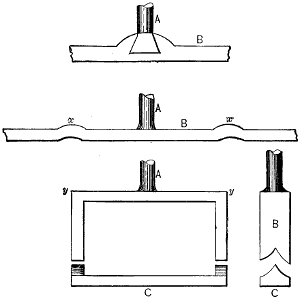

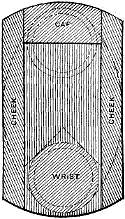

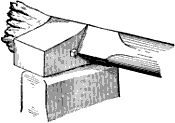

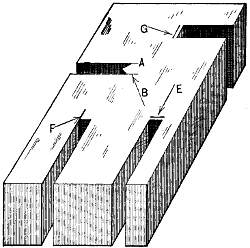

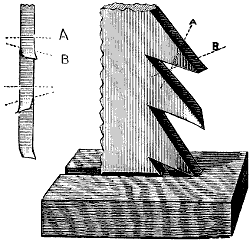

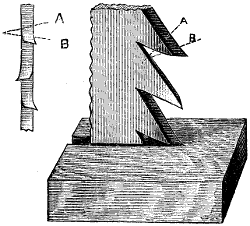

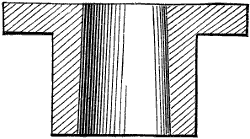

When the teeth are arranged to be parallel to the wheel-axis, as in Fig. 1, the wheel is termed a spur-wheel. In the figure, a represents the axial line or axis of the wheel or of its shaft, to which the teeth are parallel while spaced equidistant around the rim, or face, as it is termed, of the wheel.

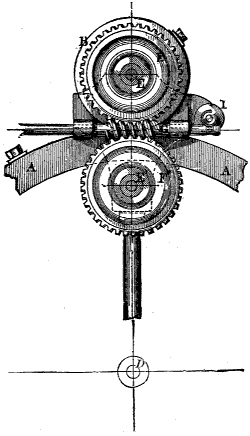

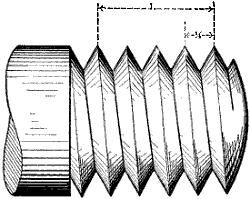

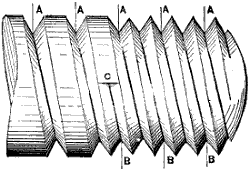

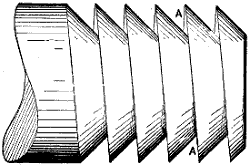

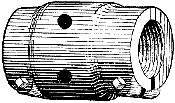

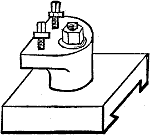

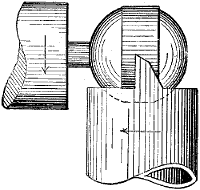

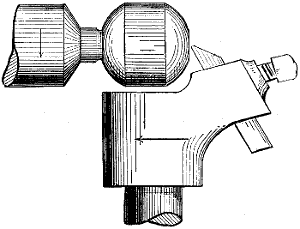

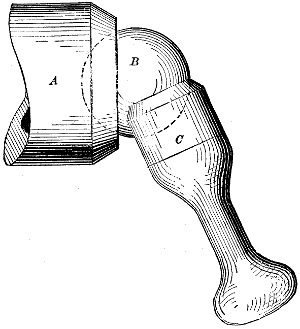

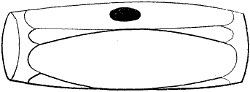

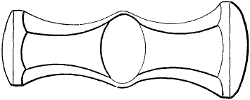

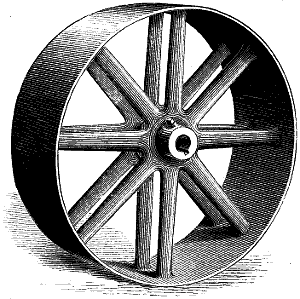

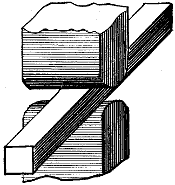

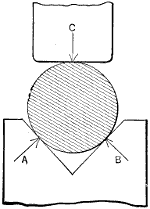

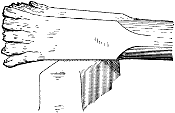

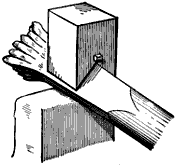

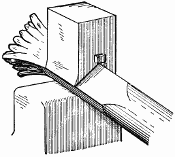

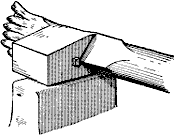

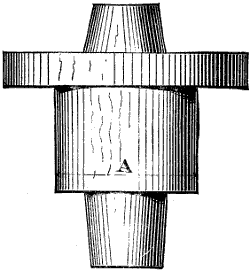

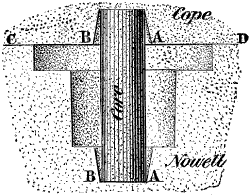

When the wheel has its teeth arranged at an angle to the shaft, as in Fig. 2, it is termed a bevel-wheel, or bevel gear; but when this angle is one of 45°, as in Fig. 3, as it must be if the pair of wheels are of the same diameter, so as to make the revolutions of their shafts equal, then the wheel is called a mitre-wheel. When the teeth are arranged upon the radial or side face of the wheel, as in Fig. 4, it is termed a crown-wheel. The smallest wheel of a pair, or of a train or set of gear-wheels, is termed the pinion; and when the teeth are composed of rungs, as in Fig. 5, it is termed a lantern, trundle, or wallower; and each cylindrical piece serving as a tooth is termed a stave, spindle, or round, and by some a leaf.

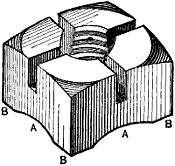

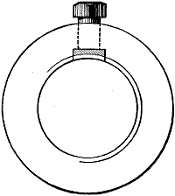

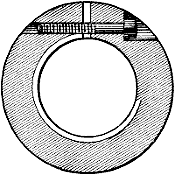

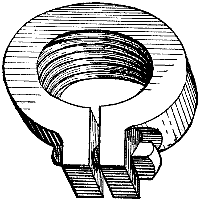

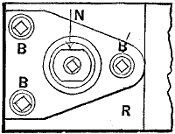

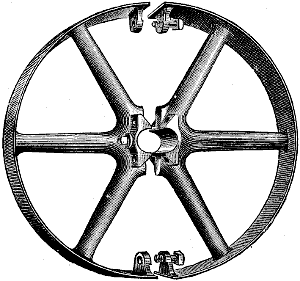

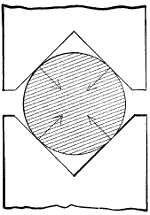

An annular or internal gear-wheel is one in which the faces of the teeth are within and the flanks without, or outside the pitch-circle, as in Fig. 6; hence the pinion p operates within the wheel.

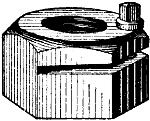

When the teeth of a wheel are inserted in mortises or slots provided in the wheel-rim, it is termed a mortised-wheel, or a cogged-wheel, and the teeth are termed cogs.

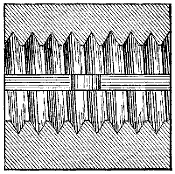

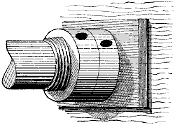

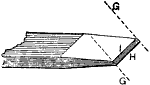

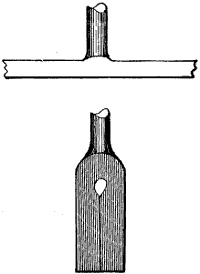

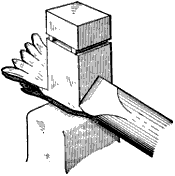

When the teeth are arranged along a plane surface or straight line, as in Fig. 7, the toothed plane is termed a rack, and the wheel is termed a pinion.

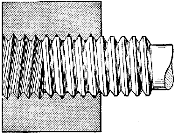

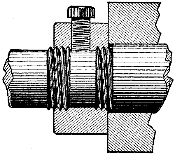

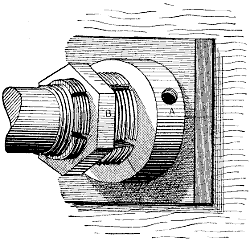

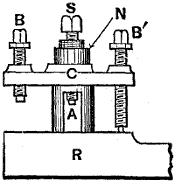

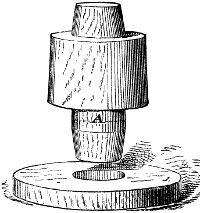

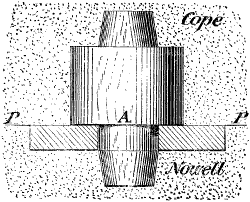

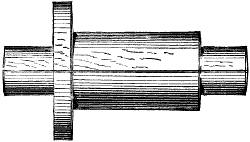

A wheel that is driven by a revolving screw, or worm as it is termed, is called a worm-wheel, the arrangement of a worm and worm-wheel being shown in Fig. 8. The screw or worm is sometimes also called an endless screw, because its action upon the wheel does not come to an end as it does when it is revolved in one continuous direction and actuates a nut. So also, since the worm is tangent to the wheel, the arrangement is sometimes called a wheel and tangent screw.

The diameter of a gear-wheel is always taken at the pitch circle, unless otherwise specially stated as “diameter over all,” “diameter of addendum,” or “diameter at root of teeth,” &c., &c.

When the teeth of wheels engage to the proper distance, which is when the pitch circles meet, they are said to be in gear, or geared together. It is obvious that if two wheels are to be geared together their teeth must be the same distance apart, or the same pitch, as it is called.

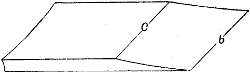

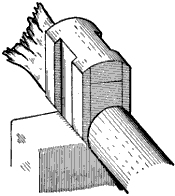

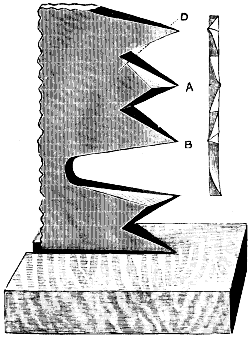

The designations of the various parts or surfaces of a tooth of a gear-wheel are represented in Fig. 9, in which the surface a is the face of the tooth, while the dimension f is the width of face of the wheel, when its size is referred to. b is the flank or distance from the pitch line to the root of the tooth, and c the[I-2] point. h is the space, or the distance from the side of one tooth to the nearest side of the next tooth, the width of space being measured on the pitch circle p p. e is the depth of the tooth, and g its thickness, the latter also being measured on the pitch circle p p. When spoken of with reference to a tooth, p p is called the pitch line, but when the whole wheel is referred to it becomes the pitch circle.

The points c and the surface h are true to the wheel axis.

The teeth are designated for measurement by the pitch; the height or depth above and below pitch line; and the thickness.

The pitch, however, may be measured in two ways, to wit, around the pitch circle a, in Fig. 10, which is called the arc or circular pitch, and across b, which is termed the chord pitch.

In proportion as the diameter of a wheel (having a given pitch) is increased, or as the pitch of the teeth is made finer (on a wheel of a given diameter) the arc and chord pitches more nearly coincide in length. In the practical operations of marking out the teeth, however, the arc pitch is not necessarily referred to, for if the diameter of the pitch circle be made correct for the required number of teeth having the necessary arc pitch, and the wheel be accurately divided off into the requisite number of divisions with compasses set to the chord pitch, or by means of an index plate, then the arc pitch must necessarily be correct, although not referred to, save in determining the diameter of the wheel at the pitch circle.

The difference between the width of a space and the thickness of the tooth (both being measured on the pitch circle or pitch line) is termed the clearance or side clearance, which is necessary to prevent the teeth of one wheel from becoming locked in the spaces of the other. The amount of clearance is, when the teeth are cut to shape in a machine, made just sufficient to prevent contact on one side of the teeth when they are in proper gear (the pitch circles meeting in the line of centres). But when the teeth are cast upon the wheel the clearance is increased to allow for the slight inequalities of tooth shape that is incidental to casting them. The amount of clearance given is varied to suit the method employed to mould the wheels, as will be explained hereafter.

The line of centres is an imaginary line from the centre or axis of one wheel to the axis of the other when the two are in gear; hence each tooth is most deeply engaged, in the space of the other wheel, when it is on the line of centres.

There are three methods of designating the sizes of gear-wheels. First, by their diameters at the pitch circle or pitch diameter and the number of teeth they contain; second, by the number of teeth in the wheel and the pitch of the teeth; and third, by a system known as diametral pitch.

The first is objectionable because it involves a calculation to find the pitch of the teeth; furthermore, if this calculation be made by dividing the circumference of the pitch circle by the number of teeth in the wheel, the result gives the arc pitch, which cannot be measured correctly by a lineal measuring rule, especially if the wheel be a small one having but few teeth, or of coarse pitch, as, in that case, the arc pitch very sensibly differs from the chord pitch, and a second calculation may become necessary to find the chord pitch from the arc pitch.

The second method (the number and pitch of the teeth) possesses the disadvantage that it is necessary to state whether the pitch is the arc or the chord pitch.

If the arc pitch is given it is difficult to measure as before, while if the chord pitch is given it possesses the disadvantage that the diameters of the wheels will not be exactly proportional to the numbers of teeth in the respective wheels. For instance, a wheel with 20 teeth of 2 inch chord pitch is not exactly half the diameter of one of 40 teeth and 2 inch chord pitch.

To find the chord pitch of a wheel take 180 (= half the degrees in a circle) and divide it by the number of teeth in the wheel. In a table of natural sines find the sine for the number so found, which multiply by 2, and then by the radius of the wheel in inches.

Example.—What is the chord pitch of a wheel having 12 teeth and a diameter (at pitch circle) of 8 inches? Here 180 ÷ 12 = 15;[I-3] (sine of 15 is .25881). Then .25881 × 2 = .51762 × 4 (= radius of wheel) = 2.07048 inches = chord pitch.

| Degrees. | Sine. | Degrees. | Sine. | Degrees. | Sine. |

| 1 | .01745 | 16 | .27563 | 31 | .51503 |

| 2 | .03489 | 17 | .29237 | 32 | .52991 |

| 3 | .05233 | 18 | .30901 | 33 | .54463 |

| 4 | .06975 | 19 | .32556 | 34 | .55919 |

| 5 | .08715 | 20 | .34202 | 35 | .57357 |

| 6 | .10452 | 21 | .35836 | 36 | .58778 |

| 7 | .12186 | 22 | .37460 | 37 | .60181 |

| 8 | .13917 | 23 | .39073 | 38 | .61566 |

| 9 | .15643 | 24 | .40673 | 39 | .62932 |

| 10 | .17364 | 25 | .42261 | 40 | .64278 |

| 11 | .19080 | 26 | .43837 | 41 | .65605 |

| 12 | .20791 | 27 | .45399 | 42 | .66913 |

| 13 | .22495 | 28 | .46947 | 43 | .68199 |

| 14 | .24192 | 29 | .48480 | 44 | .69465 |

| 15 | .25881 | 30 | .50000 | 45 | .70710 |

The principle upon which diametral pitch is based is as follows:—

The diameter of the wheel at the pitch circle is supposed to be divided into as many equal parts or divisions as there are teeth in the wheel, and the length of one of these parts is the diametral pitch. The relationship which the diametral bears to the arc pitch is the same as the diameter to the circumference, hence a diametral pitch which measures 1 inch will accord with an arc pitch of 3.1416; and it becomes evident that, for all arc pitches of less than 3.1416 inches, the corresponding diametral pitch must be expressed in fractions of an inch, as 1⁄2, 1⁄3, 1⁄4, and so on, increasing the denominator until the fraction becomes so small that an arc with which it accords is too fine to be of practical service. The numerators of these fractions being 1, in each case, they are in practice discarded, the denominators only being used, so that, instead of saying diametral pitches of 1⁄2, 1⁄3, or 1⁄4, we say diametral pitches of 2, 3, or 4, meaning that there are 2, 3, or 4 teeth on the wheel for every inch in the diameter of the pitch circle.

Suppose now we are given a diametral pitch of 2. To obtain the corresponding arc pitch we divide 3.1416 (the relation of the circumference to the diameter) by 2 (the diametral pitch), and 3.1416 ÷ 2 = 1.57 = the arc pitch in inches and decimal parts of an inch. The reason of this is plain, because, an arc pitch of 3.1416 inches being represented by a diametral pitch of 1, a diametral pitch of 1⁄2 (or 2 as it is called) will be one half of 3.1416. The advantage of discarding the numerator is, then, that we avoid the use of fractions and are readily enabled to find any arc pitch from a given diametral pitch.

Examples.—Given a 5 diametral pitch; what is the arc pitch? First (using the full fraction 1⁄5) we have 1⁄5 × 3.1416 = .628 = the arc pitch. Second (discarding the numerator), we have 3.1416 ÷ 5 = .628 = arc pitch. If we are given an arc pitch to find a corresponding diametral pitch we again simply divide 3.1416 by the given arc pitch.

Example.—What is the diametral pitch of a wheel whose arc pitch is 11⁄2 inches? Here 3.1416 ÷ 1.5 = 2.09 = diametral pitch. The reason of this is also plain, for since the arc pitch is to the diametral pitch as the circumference is to the diameter we have: as 3.1416 is to 1, so is 1.5 to the required diametral pitch; then 3.1416 × 1 ÷ 1.5 = 2.09 = the required diametral pitch.

To find the number of teeth contained in a wheel when the diameter and diametral pitch is given, multiply the diameter in inches by the diametral pitch. The product is the answer. Thus, how many teeth in a wheel 36 inches diameter and of 3 diametral pitch? Here 36 × 3 = 108 = the number of teeth sought. Or, per contra, a wheel of 36 inches diameter has 108 teeth. What is the diametral pitch? 108 ÷ 36 = 3 = the diametral pitch. Thus it will be seen that, for determining the relative sizes of wheels, this system is excellent from its simplicity. It also possesses the advantage that, by adding two parts of the diametral pitch to the pitch diameter, the outside diameter of the wheel or the diameter of the addendum is obtained. For instance, a wheel containing 30 teeth of 10 pitch would be 3 inches diameter on the pitch circle and 32⁄10 outside or total diameter.

Again, a wheel having 40 teeth of 8 diametral pitch would have a pitch circle diameter of 5 inches, because 40 ÷ 8 = 5, and its full diameter would be 51⁄4 inches, because the diametral pitch is 1⁄8, and this multiplied by 2 gives 1⁄4, which added to the pitch circle diameter of 5 inches makes 51⁄4 inches, which is therefore the diameter of the addendum, or, in other words, the full diameter of the wheel.

Suppose now that a pair of wheels require to have pitch circles of 5 and 8 inches diameter respectively, and that the arc pitch requires to be, say, as near as may be 4⁄10 inch; to find a suitable pitch and the number of teeth by the diametral pitch system we proceed as follows:

In the following table are given various arc pitches, and the corresponding diametral pitch.

| Diametral Pitch. | Arc Pitch. | Arc Pitch. | Diametral Pitch. | ||||

| Inch. | |||||||

| 2 | 1 | .57 | 1 | .75 | 1 | .79 | |

| 2 | .25 | 1 | .39 | 1 | .5 | 2 | .09 |

| 2 | .5 | 1 | .25 | 1 | .4375 | 2 | .18 |

| 2 | .75 | 1 | .14 | 1 | .375 | 2 | .28 |

| 3 | 1 | .04 | 1 | .3125 | 2 | .39 | |

| 3 | .5 | .890 | 1 | .25 | 2 | .51 | |

| 4 | .785 | 1 | .1875 | 2 | .65 | ||

| 5 | .628 | 1 | .125 | 2 | .79 | ||

| 6 | .523 | 1 | .0625 | 2 | .96 | ||

| 7 | .448 | 1 | .0000 | 3 | .14 | ||

| 8 | .392 | 0 | .9375 | 3 | .35 | ||

| 9 | .350 | 0 | .875 | 3 | .59 | ||

| 10 | .314 | 0 | .8125 | 3 | .86 | ||

| 11 | .280 | 0 | .75 | 4 | .19 | ||

| 12 | .261 | 0 | .6875 | 4 | .57 | ||

| 14 | .224 | 0 | .625 | 5 | .03 | ||

| 16 | .196 | 0 | .5625 | 5 | .58 | ||

| 18 | .174 | 0 | .5 | 6 | .28 | ||

| 20 | .157 | 0 | .4375 | 7 | .18 | ||

| 22 | .143 | 0 | .375 | 8 | .38 | ||

| 24 | .130 | 0 | .3125 | 10 | .00 | ||

| 26 | .120 | 0 | .25 | 12 | .56 | ||

From this table we find that the nearest diametral pitch that will correspond to an arc pitch of 4⁄10 inch is a diametral pitch of 8, which equals an arc pitch of .392, hence we multiply the pitch circles (5 and 8,) by 8, and obtain 40 and 64 as the number of teeth, the arc pitch being .392 of an inch. To find the number of teeth and pitch by the arc pitch and circumference of the pitch circle, we should require to find the circumference of the pitch circle, and divide this by the nearest arc pitch that would divide the circumference without leaving a remainder, which would entail more calculating than by the diametral pitch system.

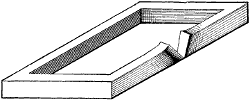

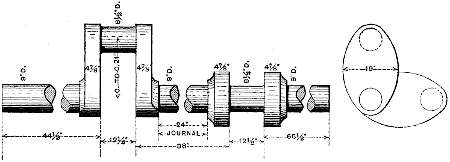

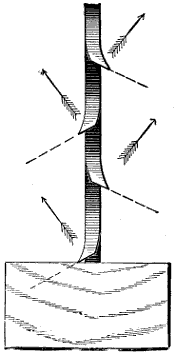

The designation of pitch by the diametral pitch system is, however, not applied in practice to coarse pitches, nor to gears in which the teeth are cast upon the wheels, pattern makers generally preferring to make the pitch to some measurement that accords with the divisions of the ordinary measuring rule.

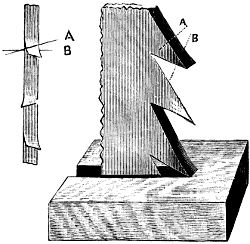

Of two gear-wheels that which impels the other is termed the driver, and that which receives motion from the other is termed the driven wheel or follower; hence in a single pair of wheels in gear together, one is the driver and the other the driven wheel or follower. But if there are three wheels in gear together, the middle one will be the follower when spoken of with reference to the first or prime mover, and the driver, when mentioned with reference to the third wheel, which will be a follower. A series of more than two wheels in gear together is termed a train of wheels or of gearing. When the wheels in a train are in gear continuously, so that each wheel, save the first and last, both receives and imparts motion, it is a simple train, the first wheel being the driver, and the last the follower, the others being termed intermediate wheels. Each of these intermediates is a follower with reference to the wheel that drives it, and a driver to the one that it drives. But the velocity of all the wheels in the train is the same in fact per second (or in a given space of time), although the revolutions in[I-4] that space of time may vary; hence a simple train of wheels transmits motion without influencing its velocity. To alter the velocity (which is always taken at a point on the pitch circle) the gearing must be compounded, as in Fig. 11, in which a, b, c, e are four wheels in gear, b and c being compounded, that is, so held together on the shaft d that both make an equal number of revolutions in a given time. Hence the velocity of c will be less than that of b in proportion as the diameter, circumference, radius, or number of teeth in c, varies from the diameter, radius, circumference, or number of teeth (all the wheels being supposed to have teeth of the same pitch) in b, although the rotations of b and c are equal. It is most convenient, and therefore usual, to take the number of teeth, but if the teeth on c (and therefore those on e also) were of different pitch from those on b, the radius or diameters of the wheels must be taken instead of the pitch, when the velocities of the various wheels are to be computed. It is obvious that the compounded pair of wheels will diminish the velocity when the driver of the compounded pair (as c in the figure) is of less radius than the follower b, and conversely that the velocity will be increased when the driver is of greater radius than the follower of the compound pair.