Fig. 1.

Fig. 1.

The Project Gutenberg EBook of Outlines of Dairy Bacteriology, 8th edition, by

H. L. Russell

This eBook is for the use of anyone anywhere at no cost and with

almost no restrictions whatsoever. You may copy it, give it away or

re-use it under the terms of the Project Gutenberg License included

with this eBook or online at www.gutenberg.org

Title: Outlines of Dairy Bacteriology, 8th edition

A Concise Manual for the Use of Students in Dairying

Author: H. L. Russell

Release Date: January 11, 2009 [EBook #27778]

Language: English

Character set encoding: ISO-8859-1

*** START OF THIS PROJECT GUTENBERG EBOOK DAIRY BACTERIOLOGY, 8TH EDITION ***

Produced by Mark C. Orton, Linda McKeown, Josephine Paolucci

and the Online Distributed Proofreading Team at

https://www.pgdp.net.

EIGHTH EDITION

Thoroughly Revised

MADISON, WISCONSIN

H. L. RUSSELL

1907

Copyrighted 1905

BY

H. L. RUSSELL

STATE JOURNAL PRINTING COMPANY,

Printers And Stereotypers,

Madison, Wis.

Transcriber's note: Minor typos have been corrected.

Knowledge in dairying, like all other technical industries, has grown mainly out of experience. Many facts have been learned by observation, but the why of each is frequently shrouded in mystery.

Modern dairying is attempting to build its more accurate knowledge upon a broader and surer foundation, and in doing this is seeking to ascertain the cause of well-established processes. In this, bacteriology is playing an important rôle. Indeed, it may be safely predicted that future progress in dairying will, to a large extent, depend upon bacteriological research. As Fleischmann, the eminent German dairy scientist, says: "The gradual abolition of uncertainty surrounding dairy manufacture is the present important duty which lies before us, and its solution can only be effected by bacteriology."

It is therefore natural that the subject of Dairy Bacteriology has come to occupy an important place in the curriculum of almost every Dairy School. An exposition of its principles is now recognized as an integral part of dairy science, for modern dairy practice is rapidly adopting the methods that have been developed as the result of bacteriological study. The rapid development of the subject has necessitated a frequent revision of this work, and it is gratifying to the writer that the attempt which has been made to keep these Outlines abreast of bacteriological advance has been appreciated by students of dairying.

While the text is prepared more especially for the practical[Pg iv] dairy operator who wishes to understand the principles and reasons underlying his art, numerous references to original investigations have been added to aid the dairy investigator who wishes to work up the subject more thoroughly.

My acknowledgments are due to the following for the loan of illustrations: Wisconsin Agricultural Experiment Station; Creamery Package Mfg. Co., Chicago, Ill.; and A. H. Reid, Philadelphia, Pa.

Chapter I. Structure of the bacteria and conditions governing their development and distribution 1

Chapter II. Methods of studying bacteria 13

Chapter III. Contamination of milk 19

Chapter IV. Fermentations in milk and their treatment 62

Chapter V. Relation of disease-bacteria to milk 82

Diseases transmissible from animal to man through diseased milk 84

Diseases transmissible to man through infection of milk after withdrawal 94

Chapter VI. Preservation of milk for commercial purposes 102

Chapter VII. Bacteria and butter making 134

Bacterial defects in butter 156

Chapter VIII. Bacteria in cheese 160

Influence Of bacteria in normal cheese processes 160

Influence of bacteria in abnormal cheese processes 182

Before one can gain any intelligent conception of the manner in which bacteria affect dairying, it is first necessary to know something of the life history of these organisms in general, how they live, move and react toward their environment.

Nature of Bacteria. Toadstools, smuts, rusts and mildews are known to even the casual observer, because they are of evident size. Their plant-like nature can be more readily understood from their general structure and habits of life. The bacteria, however, are so small, that under ordinary conditions, they only become evident to our unaided senses by the by-products of their activity.

When Leeuwenhoek (pronounced Lave-en-hake) in 1675 first discovered these tiny, rapidly-moving organisms he thought they were animals. Indeed, under a microscope, many of them bear a close resemblance to those minute worms found in vinegar that are known as "vinegar-eels." The idea that they belonged to the animal kingdom continued to hold ground until after the middle of the nineteenth century; but with the improvement in microscopes, a more thorough study of these tiny structures was made possible, and their vegetable nature demonstrated. The bacteria as a class are separated from the fungi mainly by their method of growth; from the lower algae by the absence of chlorophyll, the green coloring matter of vegetable organisms.[Pg 2]

Structure of bacteria. So far as structure is concerned the bacteria stand on the lowest plane of vegetable life. The single individual is composed of but a single cell, the structure of which does not differ essentially from that of many of the higher types of plant life. It is composed of a protoplasmic body which is surrounded by a thin membrane that separates it from neighboring cells that are alike in form and size.

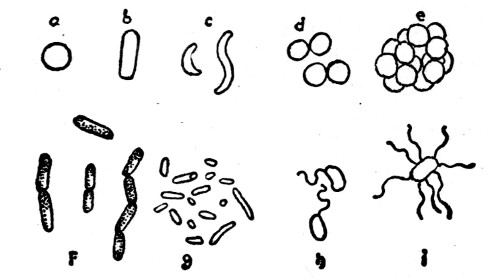

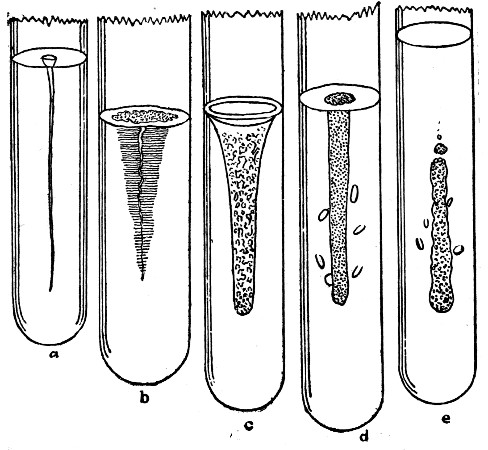

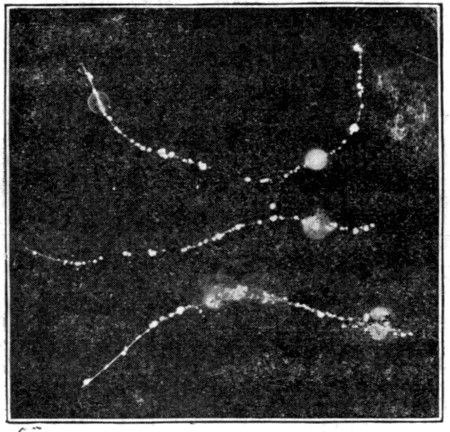

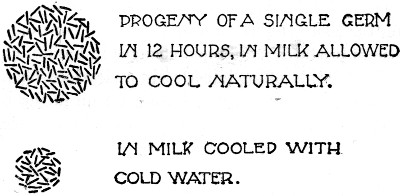

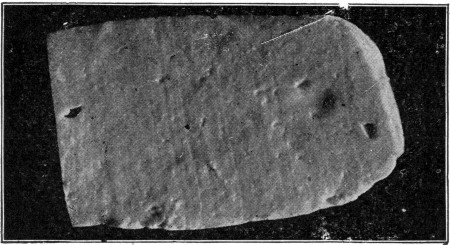

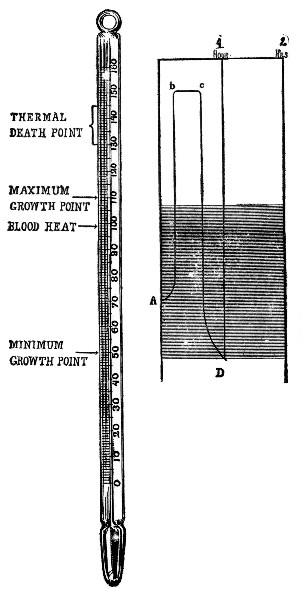

Form and size. When a plant is composed of a single cell but little difference in form is to be expected. While there are intermediate stages that grade insensibly into each other, the bacteria may be grouped into three main types, so far as form is concerned. These are spherical, elongated, and spiral, and to these different types are given the names, respectively, coccus, bacillus and spirillum (plural, cocci, bacilli, spirilla) (fig. 1). A ball, a short rod, and a corkscrew serve as convenient models to illustrate these different forms.

Fig. 1.

Fig. 1.

Different forms of bacteria. a, b, c, represent different types as to form: a, coccus, b, bacillus, c, spirillum; d, diplococcus or twin coccus; e, staphylococcus or cluster coccus; f and g, different forms of bacilli, g shows internal endospores within cell; h and i, bacilli with motile organs (cilia).

In size, the bacteria are the smallest organisms that are known to exist. Relatively there is considerable difference in[Pg 3] size between the different species, yet in absolute amount this is so slight as to require the highest powers of the microscope to detect it. As an average diameter, one thirty-thousandth of an inch may be taken. It is difficult to comprehend such minute measurements, but if a hundred individual germs could be placed side by side, their total thickness would not equal that of a single sheet of paper upon which this page is printed.

Manner of Growth. As the cell increases in size as a result of growth, it elongates in one direction, and finally a new cell wall is formed, dividing the so-called mother-cell into two, equal-sized daughter-cells. This process of cell division, known as fission, is continued until growth ceases and is especially characteristic of bacteria.

Cell Arrangement. If fission goes on in the same plane continually, it results in the formation of a cell-row. A coccus forming such a chain of cells is called strepto-coccus (chain-coccus). If only two cells cohere, it is called a diplo-coccus (twin-coccus). If the second cell division plane is formed at right angles to the first, a cell surface or tetrad is formed. If growth takes place in three dimensions of space, a cell mass or sarcina is produced. Frequently, these cell aggregates cohere so tenaciously that this arrangement is of value in distinguishing different species.

Spores. Some bacteria possess the property of forming spores within the mother cell (called endospores, fig. 1g) that are analogous in function to the seeds of higher plants and spores of fungi. By means of these structures which are endowed with greater powers of resistance than the vegetating cell, the organism is able to protect itself from the effect of an unfavorable environment. Many of the bacilli form endospores but the cocci do not. It is these[Pg 4] spore forms that make it so difficult to thoroughly sterilize milk.

Movement. Many bacteria are unable to move from place to place. They have, however, a vibrating movement known as the Brownian motion that is purely physical. Many other kinds are endowed with powers of locomotion. Motion is produced by means of fine thread-like processes of protoplasm known as cilia (sing. cilium) that are developed on the outer surface of the cell. By means of the rapid vibration of these organs, the cell is propelled through the medium. Nearly all cocci are immotile, while the bacilli may or may not be. These cilia are so delicate that it requires special treatment to demonstrate their presence.

Classification. In classifying or arranging the different members of any group of living objects, certain similarities and dissimilarities must be considered. These are usually those that pertain to the structure and form, as such are regarded as most constant. With the bacteria these differences are so slight that they alone do not suffice to distinguish distinctly one species from another. As far as these characters can be used, they are taken, but in addition, many characteristics of a physiological nature are added. The way that the organism grows in different kinds of cultures, the by-products produced in different media, and effect on the animal body when injected into the same are also used as data in distinguishing one species from another.

Conditions favoring bacterial growth. The bacteria, in common with all other living organisms are affected by external conditions, either favorably or unfavorably. Certain conditions must prevail before development can occur. Thus, the organism must be supplied with an adequate[Pg 5] and suitable food supply and with moisture. The temperature must also range between certain limits, and finally, the oxygen requirements of the organism must be considered.

Food supply. Most bacteria are capable of living on dead, inert, organic matter, such as meats, milk and vegetable material, in which case, they are known as saprophytes. In contradistinction to this class is a smaller group known as parasites, which derive their nourishment from the living tissues of animals or plants. The first group comprise by far the larger number of known organisms which are concerned for the most part in the decomposition of organic matter. The parasitic group includes those which are the cause of various communicable diseases. Between these two groups there is no sharp line of division, and in some cases, certain species possess the faculty of growing either as parasites or saprophytes, in which case they are known as facultative parasites or saprophytes.

The great majority of bacteria of interest in dairying belong to the saprophytic class; only those species capable of infecting milk through the development of disease in the animal are parasites in the strict sense of the term. Most disease-producing species, as diphtheria or typhoid fever, while parasitic in man lead a saprophytic method of life so far as their relation to milk is concerned.

Bacteria require for their growth, nitrogen, hydrogen, carbon, oxygen, together with a limited amount of mineral matter. The nitrogen and carbon are most available in the form of organic compounds, such as albuminous material. Carbon in the form of carbohydrates, as sugar or starch, is most readily attacked by bacteria.

Inasmuch as the bacteria are plant-cells, they must imbibe[Pg 6] their food from material in solution. They are capable of living on solid substances, but in such cases, the food elements must be rendered soluble, before they can be appropriated. If nutritive liquids are too highly concentrated, as in the case of syrups and condensed milk, bacteria cannot grow therein, although all the necessary ingredients may be present. Generally, bacteria prefer a neutral or slightly alkaline medium, rather than one of acid reaction; but there are numerous exceptions to this general rule, especially among the bacteria found in milk.

Temperature. Growth of bacteria can only occur within certain temperature limits, the extremes of which are designated as the minimum and maximum. Below and above these respective limits, life may be retained in the cell for a time, but actual cell-multiplication is stopped. Somewhere between these two cardinal temperature points, and generally nearer the maximum limit is the most favorable temperature for growth, known as the optimum. The temperature zone of most dairy bacteria in which growth occurs ranges from 40°-45° F. to somewhat above blood-heat, 105°-110° F., the optimum being from 80°-95° F. Many parasitic species, because of their adaptation to the bodies of warm-blooded animals, generally have a narrower range, and a higher optimum, usually approximating the blood heat (98°-99° F). The broader growth limits of bacteria in comparison with other kinds of life explain why these organisms are so widely distributed in nature.

Air supply. Most bacteria require as do the green plants and animal life, the free oxygen of the air for their respiration. These are called aerobic. Some species, however, and some yeasts as well possess the peculiar property of taking the oxygen which they need from organic compounds[Pg 7] such as sugar, etc., and are therefore able to live and grow under conditions where the atmospheric air is excluded. These are known as anaerobic. While some species grow strictly under one condition or the other, and hence are obligate aerobes or anaerobes, others possess the ability of growing under either condition and are known as facultative or optional forms. The great majority of milk bacteria are either obligate or facultative aerobes.

Rate of growth. The rate of bacterial development is naturally very much affected by external conditions, food supply and temperature exerting the most influence. In the neighborhood of the freezing point but little growth occurs. The rate increases with a rise in temperature until at the optimum point, which is generally near the blood heat or slightly below (90°-98° F.), a single cell will form two cells in 20 to 30 minutes. If temperature rises much above blood heat rate of growth is lessened and finally ceases. Under ideal conditions, rapidity of growth is astounding, but this initially rapid rate of development cannot be maintained indefinitely, for growth is soon limited by the accumulation of by-products of cell activity. Thus, milk sours rapidly at ordinary temperatures until the accumulation of acid checks its development.

Detrimental effect of external conditions. Environmental influences of a detrimental character are constantly at work on bacteria, tending to repress their development or destroy them. These act much more readily on the vegetating cell than on the more resistant spore. A thorough knowledge of the effect of these antagonistic forces is essential, for it is often by their means that undesirable bacteria may be killed out.[Pg 8]

Effect of cold. While it is true that chilling largely prevents fermentative action, and actual freezing stops all growth processes, still it does not follow that exposure to low temperatures will effectually destroy the vitality of bacteria, even in the vegetative condition. Numerous non-spore-bearing species remain alive in ice for a prolonged period, and recent experiments with liquid air show that even a temperature of -310° F. for hours does not effectually kill all exposed cells.

Effect of heat. High temperatures, on the other hand, will destroy any form of life, whether in the vegetative or latent stage. The temperature at which the vitality of the cell is lost is known as the thermal death point. This limit is not only dependent upon the nature of the organism, but varies with the time of exposure and the condition in which the heat is applied. In a moist atmosphere the penetrating power of heat is great; consequently cell-death occurs at a lower temperature than in a dry atmosphere. An increase in time of exposure lowers the temperature point at which death occurs.

For vegetating forms the thermal death point of most bacteria ranges from 130°-140° F. where the exposure is made for ten minutes which is the standard arbitrarily selected. In the spore stage resistance is greatly increased, some forms being able to withstand steam at 210°-212° F. from one to three hours. If dry heat is employed, 260°-300° F. for an hour is necessary to kill spores. Where steam is confined under pressure, a temperature of 230°-240° F. for 15-20 minutes suffices to kill all spores.

Drying. Spore-bearing bacteria like anthrax withstand drying with impunity; even tuberculous material, although not possessing spores retains its infectious properties for[Pg 9] many months. Most of the dairy bacteria do not produce spores, and yet in a dry condition, they retain their vitality unimpaired for considerable periods, if they are not subjected to other detrimental influences.

Light. Bright sunlight exerts on many species a powerful disinfecting action, a few hours being sufficient to destroy all cells that are reached by the sun's rays. Even diffused light has a similar effect, although naturally less marked. The active rays in this disinfecting action are those of the chemical or violet end of the spectrum, and not the heat or red rays.

Influence of chemical substances. A great many chemical substances exert a more or less powerful toxic action of various kinds of life. Many of these are of great service in destroying or holding bacterial growth in check. Those that are toxic and result in the death of the cell are known as disinfectants; those that merely inhibit, or retard growth are known as antiseptics. All disinfectants must of necessity be antiseptic in their action, but not all antiseptics are disinfectants even when used in strong doses. Disinfectants have no place in dairy work, except to destroy disease bacteria, or preserve milk for analytical purposes. Corrosive sublimate or potassium bichromate are most frequently used for these purposes. The so-called chemical preservatives used to "keep" milk depend for their effect on the inhibition of bacterial growth. With a substance so violently toxic as formaldehyde (known as formalin, freezene) antiseptic doses are likely to be exceeded. In this country most states prohibit the use of these substances in milk. Their only function in the dairy should be to check fermentative or putrefactive processes outside of milk and so keep the air free from taints.[Pg 10]

Products of growth. All bacteria in their development form certain more or less characteristic by-products. With most dairy bacteria, these products are formed from the decomposition of the medium in which the bacteria may happen to live. Such changes are known, collectively, as fermentations, and are characterised by the production of a large amount of by-products, as a result of the development of a relatively small amount of cell-life. The souring of milk, the formation of butyric acid, the making of vinegar from cider, are all examples of fermentative changes.

With many bacteria, especially those that affect proteid matter, foul-smelling gases are formed. These are known as putrefactive changes. All organic matter, under the action of various organisms, sooner or later undergoes decay, and in different stages of these processes, acids, alkalies, gases and numerous other products are formed. Many of these changes in organic matter occur only when such material is brought in direct contact with the living bacterial cell.

In other instances, soluble, non-vital ferments known as enzyms are produced by the living cell, which are able to act on organic matter, in a medium free from live cells, or under conditions where the activity of the cell is wholly suspended. These enzyms are not confined to bacteria but are found throughout the animal and plant world, especially in those processes that are concerned in digestion. Among the better known of these non-vital ferments are rennet, the milk-curdling enzym; diastase or ptyalin of the saliva, the starch-converting enzym; pepsin and trypsin, the digestive ferments of the animal body.

Enzyms of these types are frequently found among the bacteria and yeasts and it is by virtue of this characteristic[Pg 11] that these organisms are able to break down such enormous quantities of organic matter. Most of these enzyms react toward heat, cold and chemical poisons in a manner quite similar to the living cells. In one respect they are readily differentiated, and that is, that practically all of them are capable of producing their characteristic chemical transformations under anaesthetic conditions, as in a saturated ether or chloroform atmosphere.

Distribution of bacteria. As bacteria possess greater powers of resistance than most other forms of life, they are to be found more widely distributed than any other type. At the surface of the earth, where conditions permit of their growth, they are found everywhere, except in the healthy tissues of animals and plants. In the superficial soil layers, they exist in myriads, as here they have abundance of nourishment. At the depth of several feet however, they diminish rapidly in numbers, and in the deeper soil layers, from six to ten feet or more, they are not present, because of the unsuitable growth conditions.

The bacteria are found in the air because of their development in the soil below. They are unable to grow even in a moist atmosphere, but are so readily dislodged by wind currents that over land areas the lower strata of the air always contain them. They are more numerous in summer than in winter; city air contains larger numbers than country air. Wherever dried fecal matter is present, as in barns, the air contains many forms.

Water contains generally enough organic matter in solution, so that certain types of bacterial life find favorable growth conditions. Water in contact with the soil surface takes up many impurities, and is of necessity rich in microbes. As the rain water percolates into the soil, it loses[Pg 12] its germ content, so that the normal ground water, like the deeper soil layers, contains practically no bacterial life. Springs therefore are relatively deficient in germ life, except as they become infected with soil organisms, as the water issues from the soil. Water may serve to disseminate certain infectious diseases as typhoid fever and cholera among human beings, and a number of animal maladies.

While the inner tissues of healthy animals are free from bacteria, the natural passages as the respiratory and digestive tracts, being in more direct contact with the exterior, become more readily infected. This is particularly true with reference to the intestinal tract, for in the undigested residue, bacterial activity is at a maximum. The result is that fecal matter contains enormous numbers of organisms so that the possibility of pollution of any food medium such as milk with such material is sure to introduce elements that seriously affect the quality of the product.

Necessity of bacterial masses for study. The bacteria are so extremely small that it is impossible to study individual germs separately without the aid of first-class microscopes. For this reason, but little advance was made in the knowledge of these lower forms of plant life, until the introduction of culture methods, whereby a single organism could be cultivated and the progeny of this cell increased to such an extent in a short course of time, that they would be visible to the unaided eye.

This is done by growing the bacteria in masses on various kinds of food media that are prepared for the purpose, but inasmuch as bacteria are so universally distributed, it becomes an impossibility to cultivate any special form, unless the medium in which they are grown is first freed from all pre-existing forms of germ life. To accomplish this, it is necessary to subject the nutrient medium to some method of sterilization, such as heat or filtration, whereby all life is completely destroyed or eliminated. Such material after it has been rendered germ-free is kept in sterilized glass tubes and flasks, and is protected from infection by cotton stoppers.

Culture media. For culture media, many different substances are employed. In fact, bacteria will grow on almost any organic substance whether it is solid or fluid, provided the other essential conditions of growth are furnished. The food substances that are used for culture purposes are divided into two classes; solids and liquids.[Pg 14]

Solid media may be either permanently solid like potatoes, or they may retain their solid properties only at certain temperatures like gelatin or agar. The latter two are of utmost importance in bacteriological research, for their use, which was introduced by Koch, permits the separation of the different forms that may happen to be in any mixture. Gelatin is used advantageously because the majority of bacteria present wider differences due to growth upon this medium than upon any other. It remains solid at ordinary temperatures, becoming liquid at about 70° F. Agar, a gelatinous product derived from a Japanese sea-weed, has a much higher melting point, and can be successfully used, especially with those organisms whose optimum growth point is above the melting point of gelatin.

Besides these solid media, different liquid substances are extensively used, such as beef broth, milk, and infusions of various vegetable and animal tissues. Skim-milk is of especial value in studying the milk bacteria and may be used in its natural condition, or a few drops of litmus solution may be added in order to detect any change in its chemical reaction due to the bacteria.

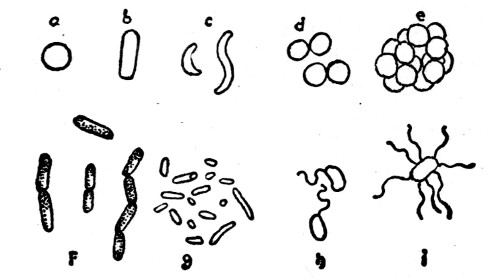

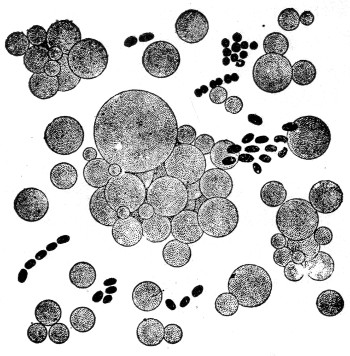

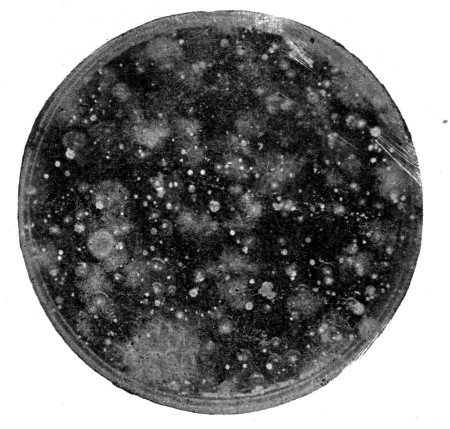

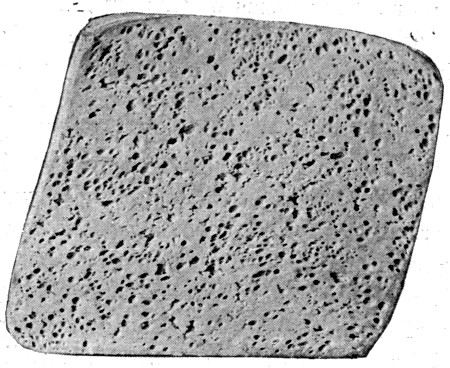

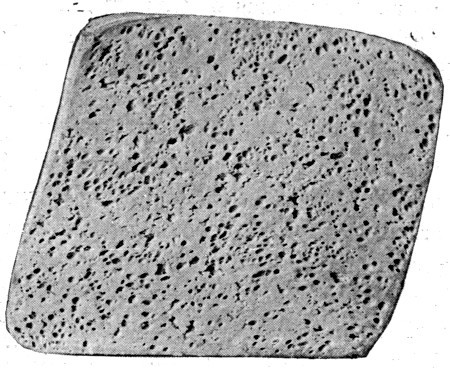

Fig. 2. A gelatin plate culture showing appearance of

different organisms in a sample of milk. Each mass represents a

bacterial growth (colony) derived from a single cell. Different forms

react differently toward the gelatin, some liquefying the same, others

growing in a restricted mass. a, represents a colony of the ordinary

bread mold; b, a liquefying bacterium; c, and d, solid forms.

Fig. 2. A gelatin plate culture showing appearance of

different organisms in a sample of milk. Each mass represents a

bacterial growth (colony) derived from a single cell. Different forms

react differently toward the gelatin, some liquefying the same, others

growing in a restricted mass. a, represents a colony of the ordinary

bread mold; b, a liquefying bacterium; c, and d, solid forms.

Methods of isolation. Suppose for instance one wishes to isolate the different varieties of bacteria found in milk. The method of procedure is as follows: Sterile gelatin in glass tubes is melted and cooled down so as to be barely warm. To this gelatin which is germ-free a drop of milk is added. The gelatin is then gently shaken so as to thoroughly distribute the milk particles, and poured out into a sterile flat glass dish and quickly covered. This is allowed to stand on a cool surface until the gelatin hardens. After the culture plate has been left for twenty-four to thirty-six[Pg 15] hours at the proper temperature, tiny spots will begin to appear on the surface, or in the depth of the culture medium. These patches are called colonies and are composed of an almost infinite number of individual germs, the result of the continued growth of a single organism that was in the drop of milk which was firmly held in place when the gelatin solidified. The number of these colonies represents approximately the number of germs that were present in the milk drop. If the plate is not too thickly sown with these germs, the colonies will continue to grow and increase in size, and as they do, minute differences will begin to appear. These differences may be in the color, the contour and the texture of the colony, or[Pg 16] the manner in which it acts toward gelatin. In order to make sure that the seeding in not too copious so as to interfere with continued study, an attenuation is usually made. This consists in taking a drop of the infected gelatin in the first tube, and transferring it to another tube of sterile media. Usually this operation is repeated again so that these culture plates are made with different amounts of seed with the expectation that in at least one plate the seeding will not be so thick as to prevent further study. For transferring the culture a loop made of platinum wire is used. By passing this through a gas flame, it can be sufficiently sterilized.

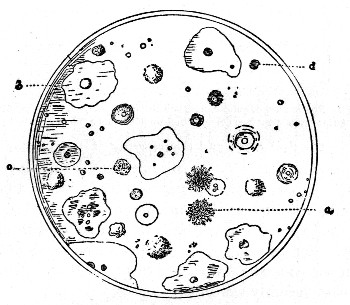

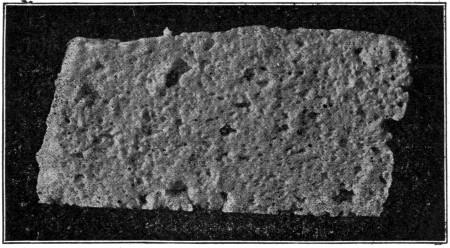

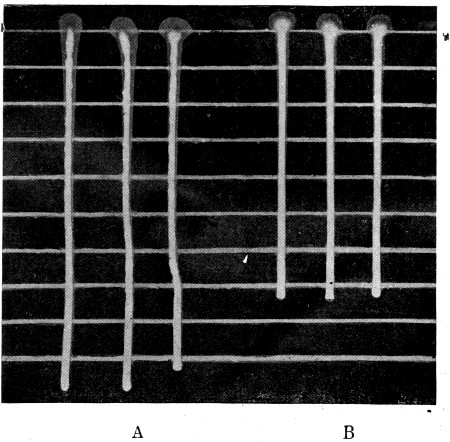

Fig. 3.

Fig. 3.

Profile view of gelatin plate culture; b, a liquefying form that dissolves the gelatin; c and d, surface colonies that do not liquefy the gelatin.

To further study the peculiarities of different germs, the separate colonies are transferred to other sterile tubes of culture material and thus pure cultures of the various germs are secured. These cultures then serve as a basis for continued study and must be planted and grown upon all the different kinds of media that are obtainable. In this way the slight variations in the growth of different forms are detected and the peculiar characteristics are determined, so that the student is able to recognize this form when he meets it again.

These culture methods are of essential importance in bacteriology, as it is the only way in which it is possible to secure a quantity of germs of the same kind.[Pg 17]

The microscope in bacterial investigation. In order to verify the purity of the cultures, the microscope is in constant demand throughout all the different stages of the isolating process. For this purpose, it is essential that the instrument used shall be one of strong magnifying powers (600-800 diameters), combined with sharp definition.

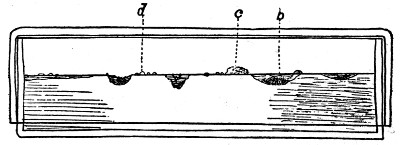

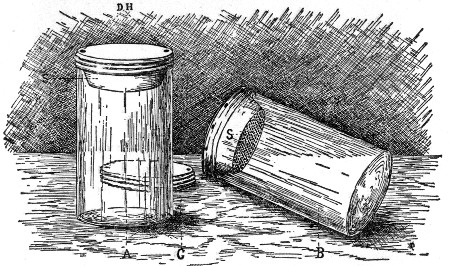

Fig. 4.

Fig. 4.

Pure cultures of different kinds of bacteria in gelatin tubes. a, growth slight in this medium; b, growth copious at and near surface. Fine parallel filaments growing out into medium liquefying at surface; c, a rapid liquefying form; d, a gas-producing form that grows equally well in lower part of tube as at surface (facultative anaerobe); e, an obligate anaerobe, that develops only in absence of air.

The microscopical examination of any germ is quite as[Pg 18] essential as the determination of culture characteristics; in fact, the two must go hand in hand. The examination reveals not only the form and size of the individual germs, but the manner in which they are united with each other, as well as any peculiarities of movement that they may possess.

In carrying out the microscopical part of the work, not only is the organism examined in a living condition, but preparations are made by using solutions of anilin dyes as staining agents. These are of great service in bringing out almost imperceptible differences. The art of staining has been carried to the highest degree of perfection in bacteriology, especially in the detection of germs that are found in diseased tissues in the animal or human body.

In studying the peculiarities of any special organism, not only is it necessary that these cultural and microscopical characters should be closely observed, but special experiments must be carried out along different lines, in order to determine any special properties that the germ may possess. Thus, the ability of any form to act as a fermentative organism can be tested by fermentation experiments; the property of causing disease, studied by the inoculation of pure cultures into animals. A great many different methods have been devised for the purpose of studying special characteristics of different bacteria, but a full description of these would necessarily be so lengthy that in a work of this character they must be omitted. For details of this nature consult standard reference books on bacteriological technique.

No more important lesson is to be learned than that which relates to the ways in which milk is contaminated with germ life of various kinds; for if these sources of infection are thoroughly recognized they can in large measure be prevented, and so the troubles which they engender overcome. Various organisms find in milk a congenial field for development. Yeasts and some fungi are capable of growth, but more particularly the bacteria.

Milk a suitable bacterial food. The readiness with which milk undergoes fermentative changes indicates that it is well adapted to nourish bacterial life. Not only does it contain all the necessary nutritive substances but they are diluted in proper proportions so as to render them available for bacterial as well as mammalian life.

Of the nitrogenous compounds, the albumen is in readily assimilable form. The casein, being insoluble, is not directly available, until it is acted upon by proteid-dissolving enzyms like trypsin which may be secreted by bacteria. The fat is relatively resistant to change, although a few forms are capable of decomposing it. Milk sugar, however, is an admirable food for many species, acids and sometimes gases being generally produced.

Condition when secreted. When examined under normal conditions milk always reveals bacterial life, yet in the secreting cells of the udder of a healthy cow germ life is not found. Only when the gland is diseased are bacteria[Pg 20] found in any abundance. In the passage of the milk from the secreting cells to the outside it receives its first infection, so that when drawn from the animal it generally contains a considerable number of organisms.

Fig. 5. Microscopic appearance of milk showing relative

size of fat globules and bacteria.

Fig. 5. Microscopic appearance of milk showing relative

size of fat globules and bacteria.

Contamination of milk. From this time until it is consumed in one form or another, it is continually subjected to contamination. The major part of this infection occurs while the milk is on the farm and the degree of care which is exercised while the product is in the hands of the milk producer is the determining factor in the course of bacterial changes involved. This of course does not exclude the possibility of contamination in the factory, but usually milk is so thoroughly seeded by the time it reaches the factory that the infection which occurs here plays a relatively minor rôle to that which happens earlier. The great majority of the organisms in milk are in no wise dangerous to health, but many species are capable of producing various fermentative changes that injure the quality of the product for butter or cheese. To be able to control abnormal changes of an undesirable character one must know the sources of infection which permit of the introduction of these unwelcome intruders.[Pg 21]

Sources of infection. The bacterial life that finds its way into milk while it is yet on the farm may be traced to several sources, which may be grouped under the following heads: unclean dairy utensils, fore milk, coat of animal, and general atmospheric surroundings. The relative importance of these various factors fluctuates in each individual instance.

Dairy utensils. Of first importance are the vessels that are used during milking, and also all storage cans and other dairy utensils that come in contact with the milk after it is drawn. By unclean utensils, actually visible dirt need not always be considered, although such material is often present in cracks and angles of pails and cans. Unless cleansed with especial care, these are apt to be filled with foul and decomposing material that suffices to seed thoroughly the milk. Tin utensils are best. Where made with joints, they should be well flushed with solder so as to be easily cleaned (see Fig. 6). In much of the cheaper tin ware on the market, the soldering of joints and seams is very imperfect, affording a place of refuge for bacteria and dirt.

Cans are often used when they are in a condition wholly unsuitable for sanitary handling of milk. When the tin coating becomes broken and the can is rusty, the quality of the milk is often profoundly affected. Olson[1] of the Wisconsin Station has shown that the action of rennet is greatly impaired where milk comes in contact with a rusty iron surface.

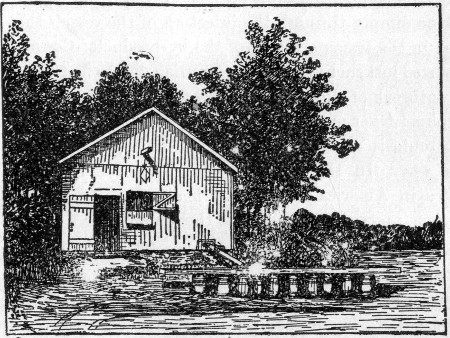

Fig. 6.

Fig. 6.

With the introduction of the form or hand separator a new milk utensil has been added to those previously in use and one which is very frequently not well cleaned. Where[Pg 22] water is run through the machine to rinse out the milk particles, gross bacterial contamination occurs and the use of the machine much increases the germ content of the milk. Every time the separator is used it should be taken apart and thoroughly cleaned and dried before reassembling.[2]

Use of milk-cans for transporting factory by-products. The general custom of using the milk-cans to carry back to the farm the factory by-products (skim-milk or whey) has much in it that is to be deprecated. These by-products are generally rich in bacterial life, more especially where the closest scrutiny is not given to the daily cleaning of the vats and tanks. Too frequently the cans are not cleaned immediately upon arrival at the farm, so that the conditions are favorable for rapid fermentation. Many of the taints that bother factories are directly traceable to such a cause. A few dirty patrons will thus seriously infect the whole supply. The responsibility for this defect should, however, not be laid entirely upon the shoulders of the producer. The factory operator should see that the refuse material does not accumulate in the waste vats from day to day and is not transformed into a more or less putrid mass. A dirty whey tank is not an especially good object lesson to the patron to keep his cans clean.

It is possible that abnormal fermentations or even contagious diseases may thus be disseminated.

Suppose there appears in a dairy an infectious milk trouble, such as bitter milk. This milk is taken to the factory and passes unnoticed into the general milk-supply. The skim-milk from the separator is of course infected with the germ, and if conditions favor its growth, the whole lot soon becomes tainted. If this waste product is returned to the different patrons in the same cans that are used for the fresh milk, the probabilities are strongly in[Pg 23] favor of some of the cans being contaminated and thus infecting the milk supply of the patrons. If the organism is endowed with spores so that it can withstand unfavorable conditions, this taint may be spread from patron to patron simply through the infection of the vessels that are used in the transportation of the by-products. Connell has reported just such a case in a Canadian cheese factory where an outbreak of slimy milk was traced to infected whey vats. Typhoid fever among people, foot and mouth disease and tuberculosis among stock are not infrequently spread in this way. In Denmark, portions of Germany and some states in America, compulsory heating of factory by-products is practiced to eliminate this danger.[3]

Pollution of cans from whey tanks. The danger is greater in cheese factories than in creameries, for whey usually represents a more advanced stage of fermentation than skim-milk. The higher temperature at which it is drawn facilitates more rapid bacterial growth, and the conditions under which it is stored in many factories contribute to the ease with which fermentative changes can go on in it. Often this by-product is stored in wooden cisterns or tanks, situated below ground, where it becomes impossible to clean them out thoroughly. A custom that is almost universally followed in the Swiss cheese factories, here in this country, as in Switzerland, is fully as reprehensible as any[Pg 24] dairy custom could well be. In Fig. 7 the arrangement in vogue for the disposal of the whey is shown. The hot whey is run out through the trough from the factory into the large trough that is placed over the row of barrels, as seen in the foreground. Each patron thus has allotted to him in his individual barrel his portion of the whey, which he is supposed to remove day by day. No attempt is made to clean out these receptacles, and the inevitable result is that they become filled with a foul, malodorous liquid, especially in summer. When such material is taken home in the same set of cans that is used to bring the fresh milk (twice a day as is the usual custom in Swiss factories), it is no wonder that this industry is seriously handicapped by "gassy" fermentations that injure materially the quality of the product. Not only is the above danger a very[Pg 25] considerable one, but the quality of the factory by-product for feeding purposes, whether it is skim-milk or whey, is impaired through the development of fermentative changes.

Fig. 7.

Fig. 7.

Swiss cheese factory (Wisconsin), showing careless way in which whey is handled. Each patron's share is placed in a barrel, from which it is removed by him. No attempt is made to cleanse these receptacles.

Improved methods of disposal of by-products. The difficulties which attend the distribution of these factory by-products have led to different methods of solution. One is to use another separate set of receptacles to carry back these products to the farm. This method has been tried, and while it is deemed impracticable by many to handle two sets of vessels, yet some of the most progressive factories report excellent results where this method is in use.

Large barrels could be used for this purpose to economize in wagon space.

Another method that has met with wider acceptance, especially in creameries, is the custom of pasteurizing or scalding the skim-milk immediately after it is separated, so that it is returned to the farmer in a hot condition. In factories where the whole milk is pasteurized, further treatment of the by-product is not necessary. In most factories steam, generally exhaust, is used directly in the milk, and experience has shown that such milk, without any cooling, will keep sweet for a considerable number of hours longer than the untreated product. It is noteworthy that the most advanced and progressive factories are the ones that appreciate the value of this work, and although it involves some time and expense, experience has shown the utility of the process in that a better grade of milk is furnished by the patrons of factories which follow this practice.[4] The exclusion of all danger of animal or human disease is also possible in this way.

Cleaning dairy utensils. The thorough cleaning of all dairy apparatus that in any way comes in contact with the milk is one of the most fundamental and important problems in dairying. All such apparatus should be so constructed as to permit of easy cleaning. Tinware, preferably of the pressed variety, gives the best surface for this purpose and is best suited for the handling of milk.

Milk vessels should never be allowed to become dry when dirty, for dried particles of milk residue are extremely difficult to remove. In cleaning dairy utensils they should first be rinsed in lukewarm instead of hot water, so as to remove organic matter without coagulating the milk. Then wash thoroughly in hot water, using a good washing powder. The best washing powders possess considerable disinfecting action.[5] Strong alkalies should not be used. After washing rinse thoroughly in clean hot water. If steam is available, as it always is in creameries, cans and pails should be turned over jet for a few moments. While a momentary exposure will not suffice to completely sterilize such a vessel, yet many bacteria are killed in even a short exposure, and the cans dry more thoroughly and quickly when heated by steam.

Not only should the greatest care be paid to the condition of the cans and milk-pails, but all dippers, strainers, and other utensils that come in contact with the milk must be kept equally clean. Cloth strainers, unless attended to, are objectionable, for the fine mesh of the cloth retains so much moisture that they become a veritable hot-bed of bacterial life, unless they are daily boiled or steamed.

The inability to thoroughly render vessels bacteria-free with the conveniences which are generally to be found on the farm has led in some cases to the custom of washing and sterilizing the milk cans at the factory.

Germ content of milk utensils. Naturally the number of bacteria found in different milk utensils after they have received their regular cleaning will be subject to great fluctuations; but, nevertheless, such determinations are of value as giving a scientific foundation for practical methods of improvement. The following studies may serve to indicate the relative importance of the utensils as a factor in milk contamination.

Two cans were taken, one of which had been cleaned in the ordinary way, while the other was sterilized by steaming. Before milking, the udder was thoroughly cleaned and special precautions taken to avoid raising of dust; the fore milk was rejected. Milk drawn into these two cans showed the following germ content:

| No. bacteria per cc. | Hours before souring. | |

| Steamed pail | 165 | 28-1/2 |

| Ordinary pail | 426 | 523 |

Harrison[6] has shown how great a variation is in the bacterial content in milk cans. The utensils were rinsed with 100 cc. of sterile water and numerical determinations of this rinsing water made. In poorly cleaned cans, the average germ content was 442,000; in cans washed in tepid water and then scalded—the best farm practice—54,000, and in cans carefully washed and then steamed for five minutes, 880.

Another method used by the writer is to wash the utensil with 100 cc. sterile wash water, using a sterile swab to remove dirt. Then repeat the process twice or more with fresh rinsing waters, making plate cultures from each. The following data were obtained from three such determinations:[Pg 28]

| No. bacteria in different washings. | |||

| I. | II. | III. | Total No. bacteria. |

| 7,800,000 | 1,450,000 | 49,000 | 9,299,000 |

| 283,000 | 43,400 | 35,000 | 361,400 |

| 1,685,000 | 105,000 | 61,400 | 1,851,400 |

Infection of milk in udder cavity. A frequently neglected but considerable factor of infection is that which is attributable to the bacteria which are present in the udder and which are removed in large numbers during the milking process. An examination of the fore milk, i. e., the first few streams from each teat, and that which is subsequently withdrawn, generally reveals a very much larger number of organisms in the fore milk.[7] Not infrequently will this part of the milk when drawn under as careful conditions as possible, contain several score thousand organisms per cc. If successive bacterial determinations are made at different periods of the milking, as shown in the following experiment, a marked diminution is to be noted after the first portion of the milk is removed:

| Fore milk. | 200th cc. | 2000th cc. | 4300th cc. | 6500th cc. | Strippings. | |

| Expt. 1 | 6,500 | 1,700 | 475 | 220 | 75 | 5 |

| Expt. 2 | 8,100 | 1,650 | 400 | 240 | 50 | 10 |

By some observers it has been claimed that it is possible to secure absolutely sterile milk in the strippings but this is rarely so. It is quite probable that such reported results are due to the fact that too small quantities of milk were used in the examinations and so erroneous conclusions were drawn. This marked diminution in numbers indicates that the larger proportion of the organisms found in[Pg 29] the fore milk are present in the lower portion of the udder and milk ducts. When consideration is given to the structure of the udder, it is readily apparent that infection will be greater here than above.

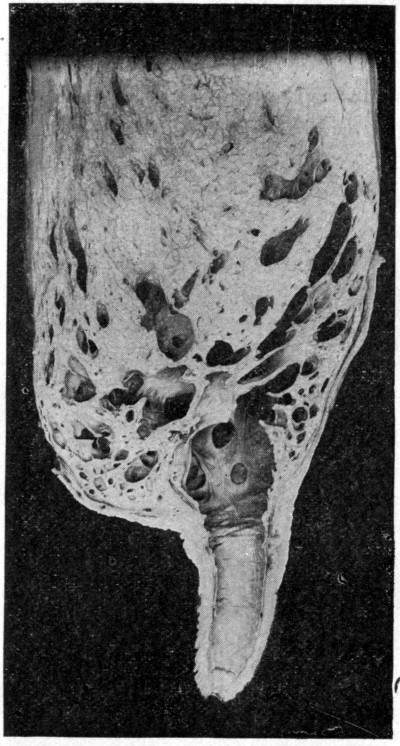

Fig. 8.

Fig. 8.

Sectional view of udder showing teat with milk duct connecting exterior with the milk cistern. Milk sinuses are mostly shown in cross section interspersed and below the secreting tissue (Moore and Ward).]

The udder is composed of secreting tissue (gland cells) held in place by fibrous connective tissue. Ramifying throughout this glandular structure are numerous channels (milk sinuses) that serve to convey the milk from the cells where it is produced into the milk cistern, a common receptacle just above the teats. This cavity is connected with the exterior through the milk duct in the teat, which is more or less tightly closed by the circular sphincter muscles, thus preventing the milk from flowing out. The mucous membranes of the milk duct and cistern are naturally moist. The habits of the animal render it impossible to prevent infection of the[Pg 30] external opening at the end of the teat and there is no mechanical reason why bacteria cannot readily find their way along the moist lining membrane for some distance. If organisms are adapted to this kind of an environment, ideal conditions exist for their multiplication, as moisture, warmth and suitable food supply are present. The question arises how far up into this organ is penetration possible? Within late years numerous observations have been made on the presence of organisms in the upper portion of the udder in contact with the secreting tissue.[8]

These investigations prove that bacteria are distributed throughout the whole of the udder, although numerically they are much less abundant in the region of the milk-secreting tissue than in the lower portion. Ward's conclusions are "that milk when secreted by the glands of a healthy udder is sterile. It may however, immediately become contaminated by the bacteria which are normally present in the smaller milk ducts of the udder."

Nature of bacteria in fore milk. Generally speaking the number of different species found in the fore milk is not large, and of those which do appear many occur at only occasional intervals. Moore[9] in the examination of 9 udders found 20 different forms, and of these only 3 species predominated, all of which proved to be micrococci. Streptococci have also been quite frequently reported. Freudenreich[10] found the most common types to be cocci, belonging to both the liquefying and non-liquefying class.

Peptonizing[11] and spore-bearing[12] species have also been reported as well as gas-producing[13] forms allied to the colon bacillus. Such findings are, however, due in all probability to accidental invasion. Most investigators report the absence of the distinctively lactic-acid group of organisms.[14]

Origin of bacteria in udder. There is no question but that many of the types of bacteria found in the udder gain access from the outside. Those belonging to the spore-bearing, digesting and intestinal types have such a favorable opportunity for introduction from outside and are so unlikely to have come directly from the body of the animal, that the external source of infection is much more probable. Whether this explanation answers the origin of the cocci that are so generally found in the upper portion of the udder is questionable. The statement is ordinarily made that the inner tissues of healthy organs are bacteria-free, but the studies of Ford[15] seem to indicate that 70 per cent. of such organs, removed under aseptic conditions from guinea pigs, rabbits, dogs and cats contained living organisms. Others have reported similar results in which cocci have been found[16] very similar to those occurring in the udder. These findings increase the probability that the origin of this type is from the blood. The persistence[Pg 32] of certain species in the udder for months as noted by Ward indicates possibility of growth of some forms at least. Stocking[17] has shown where cows are not milked clean that the germ content of succeeding milkings is greatly increased.

Artificial introduction of bacteria into udder. If bacteria are capable of actually developing in the udder proper, it ought to be possible to easily demonstrate this by the artificial introduction of cultures. In a number of cases[18] such experiments have been made with various saprophytic forms, such as B. prodigiosus, lactic acid bacilli and others. In no case has it appeared evident that actual growth has occurred, although the introduced organism has been demonstrated in diminishing numbers for 5-6 days. Even the common lactic acid germ and a yellow liquefying coccus isolated from the fore milk failed to persist for more than a few days when thus artificially introduced. This failure to colonize is indeed curious and needs explanation. Is it due to unsuitable environmental conditions or attributable to the germicidal influence of the milk?

Various body fluids are known to possess the property of destroying bacteria and it is claimed by Fokker[19] that this same property was found in freshly drawn milk. This peculiarity has also been investigated by Freudenreich,[20] and Hunziker[21] who find a similar property.

No material increase in germ content takes place in milk for several hours when chilled to 40°-70° F.; on the other[Pg 33] hand an actual, but usually not a marked decrease is observed for about 6 hours. This phenomenon varies with the milk of different cows. Nothing is known as to the cause of this apparent germicidal action. The question is yet by no means satisfactorily settled, although the facts on which the hypothesis is based are not in controversy. If such a peculiarity belongs to milk, it is not at all improbable that it may serve to keep down the germ content in the udder. Freudenreich[22] found that udders which were not examined for some time after death showed abundant growth, which fact he attributed to the loss of this germicidal property.

The infection of the whole milk can be materially reduced by rejecting the fore milk, but it is questionable whether such rejection is worth while, except in the case of "sanitary" dairies where milk is produced with as low a germ content as possible. The intrinsic loss in butter fat in the fore milk is inconsiderable as the first few streams contain only about one-fifth the normal fat content.

Infection of milk after withdrawal from animal. The germ content of the milk, when it is being drawn from the animal is immediately increased upon contact with the atmosphere. These organisms are derived from the surrounding air and the utensils in which the milk is received and stored. The number of organisms which find their way into the milk depends largely upon the character of the surroundings. Bacteria are so intimately associated with dirt, dust and filth of all kinds that wherever the latter are found, the former are sure to be present in abundance.

The most important factors in the infection of the milk after withdrawal are the pollution which is directly traceable[Pg 34] to the animal herself and the condition of the milk utensils. Fortunately both of these sources of contamination are capable of being greatly minimized by more careful methods of handling.

Infection directly from the cow. It is a popular belief that the organisms found in milk are derived from the feed and water which the cow consumes, the same passing directly from the intestinal tract to the milk by the way of the blood circulation. Such a view has no foundation in fact as bacteria absorbed into the circulation are practically all destroyed in the tissues by the action of the body fluids and cells.[23] While organisms cannot pass readily from the intestine to the udder, yet this must not be interpreted as indicating that no attention should be given to the bacterial character of the material consumed. The water supply given should be pure and wholesome and no decomposed or spoiled food should be used.

The infection traceable directly to the cow is modified materially by the conditions under which the animal is kept and the character of the feed consumed. The nature of the fecal matter is in part dependent upon the character of the food. The more nitrogenous rations with which animals are now fed leads to the production of softer fecal discharges which is more likely to soil the coat of the animal unless care is taken. The same is true with animals kept on pasture in comparison with those fed dry fodder.

Stall-fed animals, however, are more likely to have their flanks fouled, unless special attention is paid to the removal of the manure. All dairy stalls should be provided[Pg 35] with a manure drop which should be cleaned as frequently as circumstances will permit.

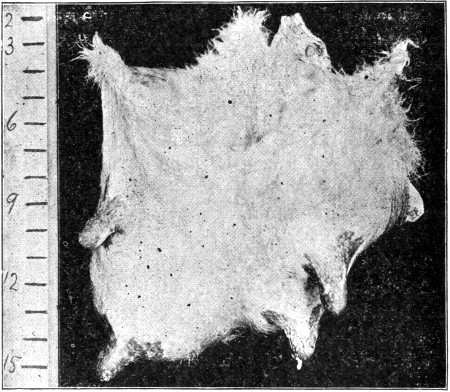

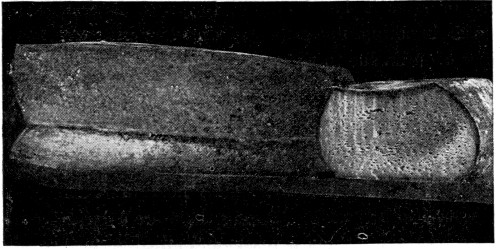

Fig. 9.

Fig. 9.

Showing the bacterial contamination arising from hair. These hairs were allowed to fall on a sterile gelatin surface. The adherent bacteria developed readily in this medium, and the number of bacteria thus introduced into the milk from these hairs can be estimated by the number of developing colonies.]

The animal herself contributes materially to the quota of germ life finding its way into the milk through the dislodgment of dust and filth particles adhering to its hairy coat. The nature of this coat is such as to favor the retention of these particles. Unless care is taken the flanks and udder become polluted with fecal matter, which upon drying is displaced with every movement of the animal. Every hair or dirt particle so dislodged and finding its way into the milk-pail adds its quota of organisms to the liquid. This can be readily demonstrated by placing cow's hairs collected with care on the moist surface of gelatin culture plates. Almost invariably, bacteria will be found in considerable numbers adhering to such hairs as is indicated in Fig. 9. Dirt particles are even richer in germ life. Not only is there the dislodgment of hairs, epithelial scales and masses of dirt and filth, but during[Pg 36] the milking process, as at all other times, every motion of the animal is accompanied by a shower of invisible particles more or less teeming with bacterial life.

The amount of actual impurities found in milk is often considerable and when it is remembered that about one-half of fresh manure dissolves in milk,[24] and thus does not appear as sediment, the presence of this undissolved residue bespeaks filthy conditions as to milking. From actual tests made, it is computed that the city of Berlin, Germany consumes about 300 pounds of such dirt and filth daily. Renk has laid down the following rule with reference to this insoluble dirt: If a sample of milk shows any evidence of impurity settling on a transparent bottom within two hours, it should be regarded as too dirty for use.

While the number of organisms here introduced is at all times large, the character of the species is of even greater import. Derived primarily from dirt and fecal matter, it is no wonder that such forms are able to produce very undesirable fermentative changes.

Influence of milker. The condition of the milker is not to be ignored in determining all possible factors of infection, for when clothed in the dust-laden garments that have been worn all day, a favorable opportunity for direct contamination is possible. The filthy practice of wetting the hands with milk just before milking is to be condemned. The milker's hands should be washed immediately before milking in clean water and dried. A pinch of vaseline on hands is sometimes used to obtain a firmer grasp and prevents the ready dislodgment of scales.[25] It must also be[Pg 37] borne in mind that the milker may spread disease through the milk. In typhoid fever and diphtheria, the germs often remain in the system for weeks and thus make infection possible. Stocking[26] has shown that the individual milker exerts a potent influence on the total germ content of milk, even where the procedure is quite the same. In sanitary dairies milkers are usually clad in white duck suits.

Milking by machinery. Several mechanical devices have been invented for milking, some of which have been tested bacteriologically as to their efficiency. Harrison[27] has examined the "Thistle" machine but found a much higher germ content than with hand-drawn milk. The recent introduction of the Burrel-Lawrence-Kennedy machine has led to numerous tests in which very satisfactory results have been obtained. If the rubber parts of the milker are thoroughly cleaned and kept in lime water solution, they remain nearly sterile. When milk is properly handled, the germ content may be greatly reduced.

Reduction in dirt and adherent bacteria. No factor of contamination is so susceptible of improvement as that which relates to the reduction in filth and dirt which gains access during and immediately subsequent to the milking. The care which is taken to keep the coat of the animal clean by grooming lessens very much the grosser portion of such contamination, but with a dry, hairy coat, fine scales and dust particles must of necessity be dislodged.[28] Ordinarily the patron thinks all evidence of such dirt is removed if the milk is strained, but this process only lessens the difficulty; it does not overcome it. Various methods are in use, the effectiveness of which is subject to[Pg 38] considerable variation. Some of these look to the elimination of the bacteria after they are once introduced into the milk; others to the prevention of infection in the first place.

1. Straining the milk. Most of the visible, solid particles of filth, such as hairs, dirt particles, etc., can be removed by simple straining, the time-honored process of purification. As ordinarily carried out, this process often contributes to instead of diminishing the germ life in milk. The strainer cloths unless washed and thoroughly sterilized by boiling harbor multitudes of organisms from day to day and may thus actually add to the organisms present. Various methods have been suggested for this simple process, but the most practical and efficient strainer is that made of fine wire gauze to which is added 3-4 layers of cheese cloth, the whole to set over the storage milk can.

2. Filtration. In Europe especially, the system of cleaning milk by filtration through sand, gravel and other substances has been quite extensively used. These filters are built in sections and the milk passes from below upward. The filtering substance is washed in hot water immediately after use and then steamed and finally baked. While it is possible to remove the solid impurities in this way, the germ content cannot be greatly reduced.[29] Cellulose filters have also been suggested[30] as an improvement over the sand filters. Methods of filtration of this character have not been used under commercial conditions here in this country.

3. Clarification in separator. Within recent years the custom has grown of clarifying milk or removing the visible[Pg 39] dirt by passing the milk through a centrifugal separator the cream and skim milk being remixed after separation. This process naturally removes the solid impurities as dirt, hairs, epithelial scales and cells, also some of the casein, making what is known as centrifuge slime. This conglomerate mass is incomparably rich in germ life and the natural inference would be that the bacterial content of the milk would be greatly reduced by this procedure. Eckles and Barnes[31] noted a reduction of 37 to 56 per cent. of the bacteria but others have failed to observe such reductions.[32] This condition is explained by the more thorough breaking up of the bacterial masses in the process, thus apparently not reducing them in numbers.

It is somewhat surprising that in spite of the elimination of much organic matter and bacteria, such clarified milk sours as rapidly as the untreated product.[33]

The mechanical shock of separation ruptures the clusters of fat globules and so delays creaming and also lessens the consistency of cream derived from such milk. This practical disadvantage together with the increased expense of the operation and the failure to materially enhance the keeping quality of the product outweigh the advantage which might come from removal of solid impurities which can be largely accomplished on the farm by efficient straining.

4. Washing the udder. If a surface is moist, bacteria adherent to it cannot be dislodged by ordinary movements. Thus the air over snow-covered mountains or oceans is[Pg 40] relatively devoid of germ life. The method of moistening the udder is applied with success to the hairy coat of the animal thus subserving the double purpose of cleaning the animal and preventing in large measure the continual dislodgment of dust particles. After these parts have been well carded to remove loose hairs and dirt particles, the skin should be thoroughly moistened with clean water and then wiped. It has been urged that this procedure lessens the yield of milk but Eckles[34] concludes from experiments that when the animal becomes accustomed to this treatment, no noticeable change in amount of milk or butter-fat is produced.

The effectiveness of this method in reducing the actual amount of dirt and filth introduced into the milk as well as the great diminution in germ life is shown by the instructive experiments of Fraser[35] who found that the actual amount of dirt dislodged from udders of apparently clean animals during the milking process was three and one-half times as much as when the cow's udders were washed. From udders visibly polluted one ounce of such filth was removed in 275 pounds of milk, while from cows whose udders had been washed, the same amount of dirt was distributed through 24,030 pounds.

Fraser observed as a result of 420 examinations that the average germ content of 4-inch culture dishes under clean but unwashed udders was 578, while under washed animals it was reduced to 192. From numerous tests made in the writer's laboratory, it is evident that the germ content of the milk in the pail is increased from 20,000-40,000 bacteria per minute during the milking period. By far the[Pg 41] larger part of this pollution can be easily prevented by cleaning and dampening the udder.

5. Diminishing exposed surface of pail. The entrance of organisms into the milk can be greatly reduced by lessening the area of the milk pail directly exposed to the dust shower. A number of so-called sanitary or hygienic milk pails have been devised for this purpose. In one case the pail is smaller at the top than bottom, but in most of them the common form is kept and the exposed area is lessened by means of a cover, the milk being received through a narrower opening. In some cases, strainers are also interposed so as to remove more effectually the coarse particles. It is necessary to have these covers and strainers constructed in such a way so they can be easily removed and cleaned.

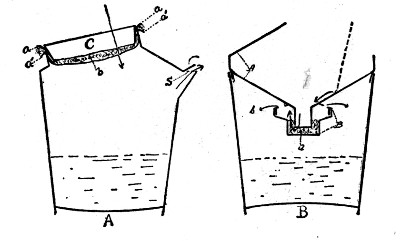

Fig. 10. Sanitary milk pails designed to diminish the

introduction of hairs, scales, dirt, etc., into milk.

Fig. 10. Sanitary milk pails designed to diminish the

introduction of hairs, scales, dirt, etc., into milk.

Stocking tested one of these pails (A, Fig. 10) and found that 63 per cent of the dirt and 29 per cent. of the bacteria were prevented from passing into the milk. Eckles examined one in which the germ content was found to be[Pg 42] 3200 per cc. as against 43200 per cc. in a common open pail. This milk did not sour until it was 64 hours old in the first case while in the latter it curdled in 43 hours.

Air in barn. The atmosphere of the barn where the milking is done may frequently contribute considerable infection. Germ life is incapable of development in the air, but in a dried condition, organisms may retain their vitality for long periods. Anything which contributes to the production of dust in the stable and aids in the stirring up of the same increases the number of organisms to be found in the air (Fig. 11). Thus, the feeding of dry fodder and the bedding of animals with straw adds greatly to the germ life floating in the air. Dust may vary much in its germ content depending upon its origin. Fraser found the[Pg 43] dust from corn meal to contain only about one-sixth to one-eighth as much germ life as that from hay or bran.[36] In time most of these dust particles settle to the floor, but where the herd is kept in the barn, the constant movement of the animals keeps these particles more or less in motion. Much can be done by forethought to lessen the germ content of stables. Feeding dry feed should not be done until after milking.[37] In some of the better sanitary dairies, it is customary to have a special milking room that is arranged with special reference to the elimination of all dust. In this way this source of infection may be quite obviated as the air of a clean, still room is relatively free from bacteria, especially if the floor is moistened. It has often been noted that the milk of stall-fed animals does not keep as well as that milked out of doors, a condition in part attributable to the lessened contamination.

Fig. 11.

Fig. 11.

Effect of contaminated air. The number of spots indicate the colonies that have developed from the bacteria which fell in 30 seconds on the surface of the gelatin plate (3 inches in diameter). This exposure was made at time the cows were fed.

Relative importance of different sources of infection. It is impossible to measure accurately the influence of the different sources of infection as these are continually subject to modification in each and every case. As a general rule, however, where milk is drawn and handled without any special care, the utensils and the animal contribute the larger proportion of dirt and bacteria that find their way into milk. Where the manner of milking and handling is designed to exclude the largest number of organisms possible, the bacteria appearing in the fore milk make up the major portion remaining. By putting into practice the various suggestions that have been made with reference to diminishing the bacterial content of milk, it is possible to greatly reduce the number of organisms found therein, and at the same time materially improve the keeping[Pg 44] quality of the milk. Backhaus[38] estimates that the germ life in milk can be easily reduced to one-two thousandth of its original number by using care in milking. He reports a series of experiments covering two years in which milk was secured that averaged less than 10,000 bacteria per cc., while that secured under ordinary conditions averaged over 500,000.

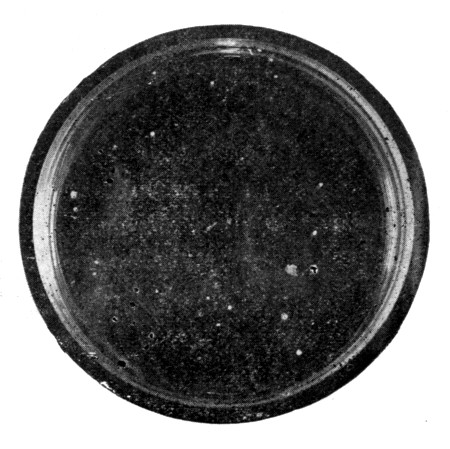

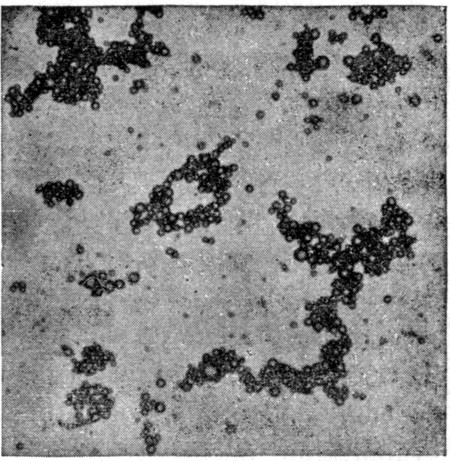

Fig. 12.

Fig. 12.

Bacterial content of milk handled in ordinary way. Each spot represents a colony growing on gelatin plate. Compare with Fig. 13, where same quantity of milk is used in making culture. Over 15,000 bacteria per cc. in this milk.

Fig. 13 gives an illustration as to what care in milking will do in the way of eliminating bacteria. Fig. 12 shows a gelatin plate seeded with the same quantity of milk that was used in making the culture indicated by Fig. 13. The first plate was inoculated with milk drawn under good conditions, the germ content of which was found to be[Pg 45] 15,500 bacteria per cc., while the sample secured under as nearly aseptic conditions as possible (Fig. 13) contained only 330 organisms in the same volume.

Fig. 13.

Fig. 13.

Bacterial content of milk drawn with care. Diminished germ content is shown by smaller number of colonies (330 bacteria per cc.). Compare this culture with that shown in Fig. 12.

"Sanitary" or "certified" milk. Within recent years there has been more or less generally introduced into many cities, the custom of supplying high grade milk that has been handled in a way so as to diminish its germ content as much as possible. Milk of this character is frequently known as "sanitary," "hygienic" or "certified," the last term being used in connection with a certification from veterinary authorities or boards of health as to the freedom of animals from contagious disease. Frequently a numerical bacterial standard is exacted as a pre-requisite[Pg 46] to the recommendation of the board of examining physicians. Thus, the Pediatric Society of Philadelphia requires all children's milk that receives its recommendation to have not more than 10,000 bacteria per cc. Such a standard has its value in the scrupulous cleanliness that must prevail in order to secure these results. This in itself is practically a guarantee of the absence of those bacteria liable to produce trouble in children. The number of organisms found in such milks is surprisingly low when compared with ordinary milk. Naturally, there is considerable fluctuation from day to day, and occasionally the germ content is increased to a high figure without any apparent reason. The average results though, show a greatly reduced number of organisms. De Schweinitz[39] found in a Washington dairy in 113 examinations extending throughout a year, an average of 6,485 bacteria per cc. The daily analyses made of the Walker-Gordon supply sold in Philadelphia for an entire year, showed that the milk almost always contained less than 5,000 bacteria per cc. and on 120 days out of the year the germ content was 1,000 organisms per cc. or less.

From a practical point of view, the improvement in quality of sanitary milk, in comparison with the ordinary product is seen in the enhanced keeping quality. During the Paris Exposition in 1900, milk and cream from several such dairies in the United States were shipped to Paris, arriving in good condition after 15 to 18 days transit. When milk has been handled in such a way, it is evident that it is much better suited to serve as a food supply than where it has undergone the fermentative changes incident to the development of myriads of organisms.[Pg 47]

Application of foregoing precautions to all milk producers. Milk is so susceptible to bacterial changes that it is necessary to protect it from invasion, if its original purity is to be maintained, and yet, from a practical point of view, the use to which it is destined has much to do with the care necessary to take in handling. The effect of the bacterial contamination of milk depends largely upon the way in which the product is used. To the milk-man engaged in the distribution of milk for direct consumption, all bacterial life is more or less of a detriment, while to the butter-maker and cheese-maker some forms are a direct necessity. It is unnecessary and impracticable to require the same degree of care in handling milk destined to be worked up into factory products as is done, for instance, in sanitary milk supplies, but this fact should not be interpreted to mean that the care of milk for factories is a matter of small consequence. In fact no more important dairy problem exists, and the purer and better the quality of the raw material the better the product will be. Particularly is this true with reference to cheese-making.

Dairymen have learned many lessons in the severe school of experience, but it is earnestly to be hoped that future conditions will not be summed up in the words of the eminent German dairy scientist, Prof. Fleischmann, when he says that "all the results of scientific investigation which have found such great practical application in the treatment of disease, in disinfection, and in the preservation of various products, are almost entirely ignored in milking."

Growth of bacteria in milk. Milk is so well suited as a medium for the development of germ life that it might be[Pg 48] expected that all microörganisms would develop rapidly therein, and yet, as a matter of fact, growth does not begin at once, even though the milk may be richly seeded. At ordinary temperatures, such as 70° F., no appreciable increase is to be noted for a period of 6-9 hours; at lower temperatures (54° F.) this period is prolonged to 30-40 hours or even longer. After this period has elapsed, active growth begins and continues more or less rapidly until after curdling.

The cause of this suspended development is attributed to the germicidal properties inherent to the milk.[40]

Milk is of course seeded with a considerable variety of organisms at first. The liquefying and inert species are the most abundant, the distinctively lactic acid class occurring sparsely, if at all. As milk increases in age, germ growth begins to occur. More or less development of all types go on, but soon the lactic species gain the ascendency, owing to their being better suited to this environment; they soon outstrip all other species, with the result that normal curdling generally supervenes. The growth of this type is largely conditioned by the presence of the milk sugar. If the sugar is removed from milk by dialysis, the liquid undergoes putrefactive changes due to the fact that the putrefactive bacteria are able to grow if no acid is produced.

Relation of temperature to growth. When growth does once begin in milk, the temperature at which it is stored exerts the most profound effect on the rate of development. When milk is not artificially cooled, it retains its heat for some hours, and consequently the conditions become very[Pg 49] favorable for the rapid multiplication of the contained organisms, as is shown in following results obtained by Freudenreich[41]:

| 77° F. | 95° F. | ||||

| 5 | hrs. | after | milking | 10,000 | 30,000 |

| 8 | " | " | " | 25,000 | 12,000,000 |

| 12 | " | " | " | 46,000 | 35,280,000 |

| 26 | " | " | " | 5,700,000 | 50,000,000 |

Fig. 14. Effect of cooling milk on the growth of

bacteria.

Fig. 14. Effect of cooling milk on the growth of

bacteria.

Conn[42] is inclined to regard temperature of more significance in determining the keeping quality than the original infection of the milk itself. Milk which curdled in 18 hours at 98° F., did not curdle in 48 hours at 70°, and often did not change in two weeks, if the temperature was kept at 50° F.

Where kept for a considerable period at this low temperature, the milk becomes filled with bacteria of the undesirable putrefactive type, the lactic group being unable to form acid in any appreciable amounts. Running well[Pg 50] water can be used for cooling, if it is possible to secure it at a temperature of 48°-50° F. The use of ice, of course, gives better results, and in summer is greatly to be desired. The influence of these lowered temperatures makes it possible to ship milk long distances[43] by rail for city supplies, if the temperature is kept low during transit.