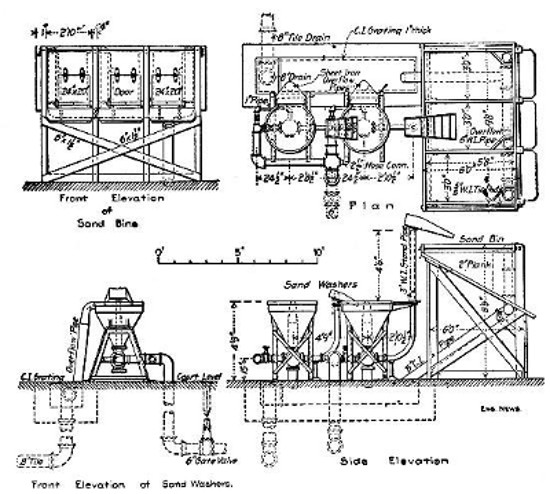

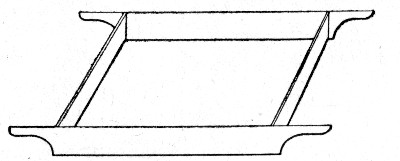

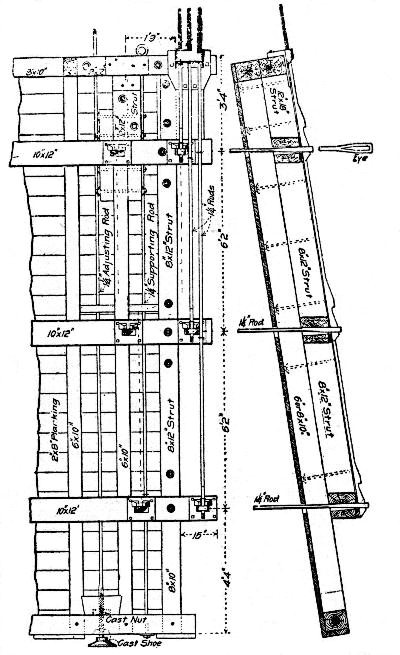

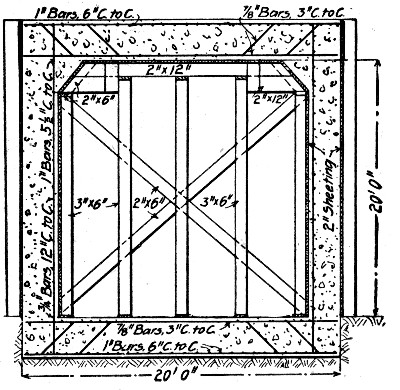

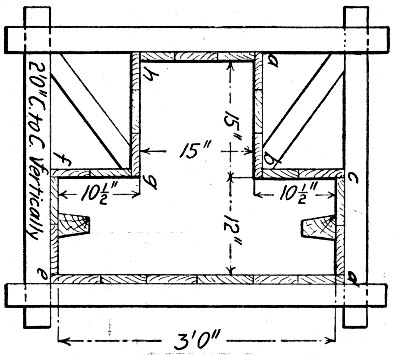

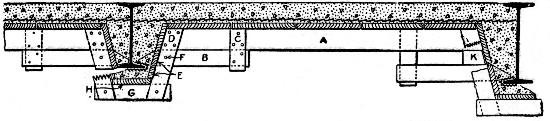

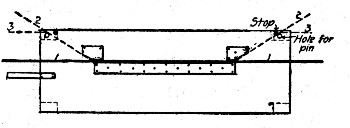

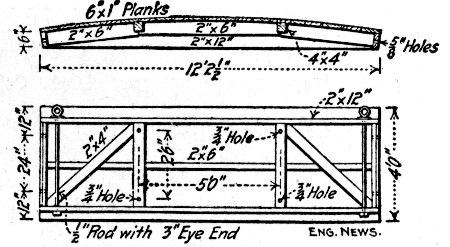

Fig. 1.—Plan and Elevation of Two-Hopper Ejector Sand

Washing Plant.

Fig. 1.—Plan and Elevation of Two-Hopper Ejector Sand

Washing Plant.

The Project Gutenberg EBook of Concrete Construction, by

Halbert P. Gillette and Charles S. Hill

This eBook is for the use of anyone anywhere at no cost and with

almost no restrictions whatsoever. You may copy it, give it away or

re-use it under the terms of the Project Gutenberg License included

with this eBook or online at www.gutenberg.org

Title: Concrete Construction

Methods and Costs

Author: Halbert P. Gillette

Charles S. Hill

Release Date: March 16, 2008 [EBook #24855]

Language: English

Character set encoding: ISO-8859-1

*** START OF THIS PROJECT GUTENBERG EBOOK CONCRETE CONSTRUCTION ***

Produced by Brian Sogard, Josephine Paolucci and the Online

Distributed Proofreading Team at http://www.pgdp.net.

Copyright. 1908

BY

The Myron C. Clark Publishing Co.

How best to perform construction work and what it will cost for materials, labor, plant and general expenses are matters of vital interest to engineers and contractors. This book is a treatise on the methods and cost of concrete construction. No attempt has been made to present the subject of cement testing which is already covered by Mr. W. Purves Taylor's excellent book, nor to discuss the physical properties of cements and concrete, as they are discussed by Falk and by Sabin, nor to consider reinforced concrete design as do Turneaure and Maurer or Buel and Hill, nor to present a general treatise on cements, mortars and concrete construction like that of Reid or of Taylor and Thompson. On the contrary, the authors have handled the subject of concrete construction solely from the viewpoint of the builder of concrete structures. By doing this they have been able to crowd a great amount of detailed information on methods and costs of concrete construction into a volume of moderate size.

Though the special information contained in the book is of most particular assistance to the contractor or engineer engaged in the actual work of making and placing concrete, it is believed that it will also prove highly useful to the designing engineer and to the architect. It seems plain that no designer of concrete structures can be a really good designer without having a profound knowledge of methods of construction and of detailed costs. This book, it is believed, gives these methods and cost data in greater number and more thoroughly analyzed than they can be found elsewhere in engineering literature.

The costs and other facts contained in the book have been collected from a multitude of sources, from the engineering journals, from the transactions of the engineering societies, from Government Reports and from the personal records of the authors and of other engineers and contractors. It is but fair to say that the great bulk of the matter contained in the book,[Pg iv] though portions of it have appeared previously in other forms in the authors' contributions to the technical press, was collected and worked up originally by the authors. Where this has not been the case the original data have been added to and re-analyzed by the authors. Under these circumstances it has been impracticable to give specific credit in the pages of the book to every source from which the authors have drawn aid. They wish here to acknowledge, therefore, the help secured from many engineers and contractors, from the volumes of Engineering News, Engineering Record and Engineering-Contracting, and from the Transactions of the American Society of Civil Engineers and the proceedings and papers of various other civil engineering societies and organizations of concrete workers. The work done by these journals and societies in gathering and publishing information on concrete construction is of great and enduring value and deserves full acknowledgment.

In answer to any possible inquiry as to the relative parts of the work done by the two authors in preparing this book, they will answer that it has been truly the labor of both in every part.

H. P. G.

C. S. H.

Chicago, Ill., April 15, 1908.

PAGE

CHAPTER I.—METHODS AND COST OF SELECTING AND PREPARING

MATERIALS FOR CONCRETE. 1

Cement: Portland Cement—Natural Cement—Slag Cement—Size and Weight of

Barrels of Cement—Specifications and Testing. Sand: Properties of Good

Sand—Cost of Sand—Washing Sand; Washing with Hose; Washing with Sand

Ejectors; Washing with Tank Washers. Aggregates: Broken

Stone—Gravel—Slag and Cinders—Balanced Aggregate—Size of

Aggregate—Cost of Aggregate—Screened and Crusher Run Stone for

Concrete—Quarrying and Crushing Stone—Screening and Washing Gravel.

CHAPTER II.—THEORY AND PRACTICE OF PROPORTIONING CONCRETE. 25

Voids: Voids in Sand; Effect of Mixture—Effect of Size of Grains—Voids

in Broken Stone and Gravel; Effect of Method of Loading; Test

Determinations; Specific Gravity; Effect of Hauling—Theory of the

Quantity of Cement in Mortar; Tables of Quantities in Mortar—Tables of

Quantities in Concrete—Percentage of Water in Concrete—Methods of

Measuring and Weighing; Automatic Measuring Devices.

CHAPTER III.—METHODS AND COSTS OF MAKING AND PLACING

CONCRETE BY HAND. 45

Loading into Stock Piles—Loading from Stock Piles—Transporting

Materials to Mixing Boards—Mixing—Loading and Hauling Mixed

Concrete—Dumping, Spreading and Ramming—Cost of

Superintendence—Summary of Costs.

CHAPTER IV.—METHODS AND COST OF MAKING AND PLACING

CONCRETE BY MACHINE. 61

Introduction—Conveying and Hoisting Devices—Unloading with Grab

Buckets—Inclines—Trestle and Car Plants—Cableways—Belt

Conveyors—Chutes—Methods of Charging Mixers—Charging by Gravity from

Overhead Bins; Charging with Wheelbarrows; Charging with Cars; Charging

by Shoveling; Charging with Derricks—Types of Mixers; Batch Mixers;

Chicago Improved Cube Tilting Mixer, Ransome Non-Tilting Mixer, Smith

Tilting Mixer; Continuous Mixers; Eureka Automatic Feed Mixer; Gravity

Mixers; Gilbreth Trough Mixer, Hains Gravity Mixer—Output of

Mixers—Mixer Efficiency.

CHAPTER V.—METHODS AND COST OF DEPOSITING CONCRETE

UNDER WATER AND OF SUBAQUEOUS GROUTING. 86

Introduction—Depositing in Closed Buckets; O'Rourke Bucket; Cyclopean

Bucket; Steubner Bucket—Depositing in Bags—Depositing Through a

Tremie; Charlestown Bridge; Arch Bridge Piers, France; Nussdorf Lock,

Vienna—Grouting Submerged Stone; Tests of H. F. White; Hermitage

Breakwater.

CHAPTER VI.—METHODS AND COST OF MAKING AND USING RUBBLE

AND ASPHALTIC CONCRETE. 98

Introduction—Rubble Concrete: Chattahoochee River Dam; Barossa

Dam, South Australia; other Rubble Concrete Dams, Boonton Dam,

Spier Falls Dam, Hemet Dam, Small Reservoir Dam, Boyd's Corner

Dam; Abutment for Railway Bridge; English Data, Tharsis & Calamas

Ry., Bridge Piers, Nova Scotia—Asphalt Concrete; Slope Paving for

Earth Dam; Base for Mill Floor.

CHAPTER VII.—METHODS AND COST OF LAYING CONCRETE IN

FREEZING WEATHER. 112

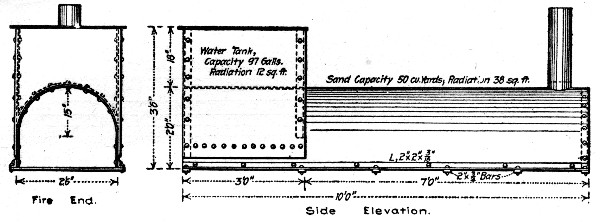

[Pg vi]Introduction—Lowering the Freezing Point of the Mixing Water; Common

Salt (Sodium Chloride):—Freezing Temperature Chart—Heating Concrete

Materials; Portable Heaters; Heating in Stationary Bins; Other Examples

of Heating Methods, Power Plant, Billings, Mont., Wachusett Dam,

Huronian Power Co. Dam, Arch Bridge, Piano, Ill., Chicago, Burlington &

Quincy R. R. Work, Heating in Water Tank—Covering and Housing the Work;

Method of Housing in Dam, Chaudiere Falls, Quebec; Method of Housing in

Building Work.

CHAPTER VIII.—METHODS AND COST OF FINISHING CONCRETE

SURFACES 124

Imperfectly Made Forms—Imperfect Mixing and

Placing—Efflorescence—Spaded and Troweled Finishes—Plaster and Stucco

Finish—Mortar and Cement Facing—Special Facing Mixtures for Minimizing

Form Marks—Washes—Finishing by Scrubbing and Washing—Finishing by

Etching with Acid—Tooling Concrete Surfaces—Gravel or Pebble Surface

Finish—Colored Facing.

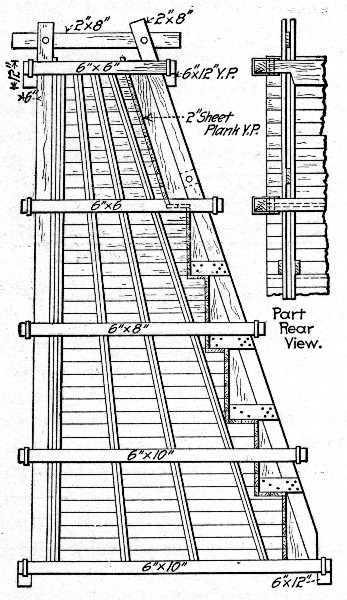

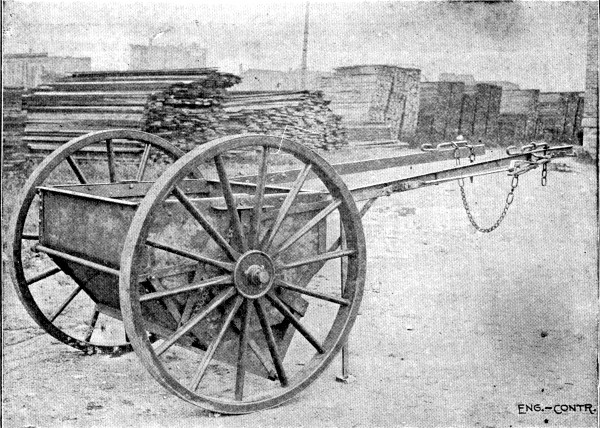

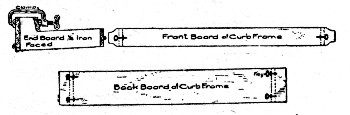

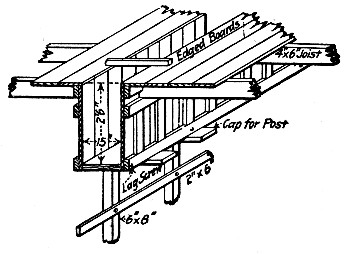

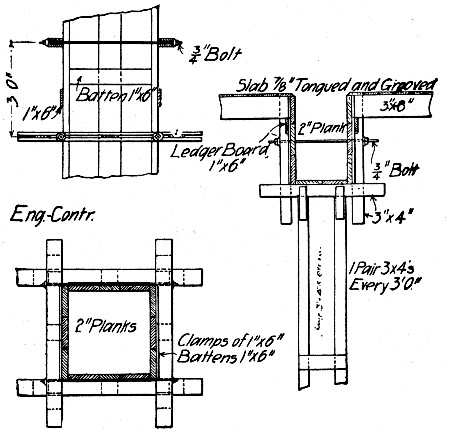

CHAPTER IX.—METHODS AND COST OF FORM CONSTRUCTION 136

Introduction—Effect of Design on Form Work—Kind of Lumber—Finish and

Dimensions of Lumber—Computation of Forms—Design and

Construction—Unit Construction of Forms—Lubrication of

Forms—Falsework and Bracing—Time for and Method of Removing

Forms—Estimating and Cost of Form Work.

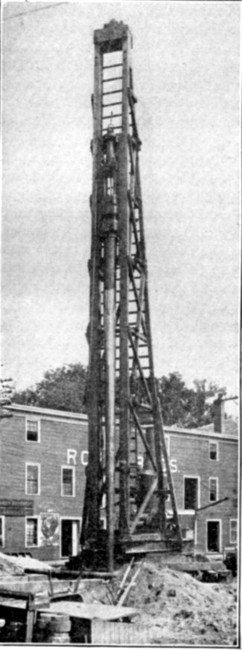

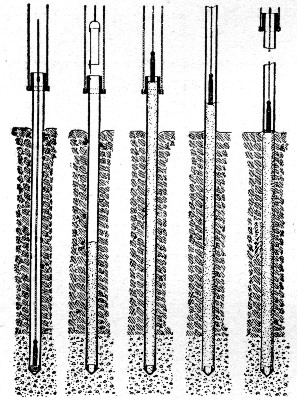

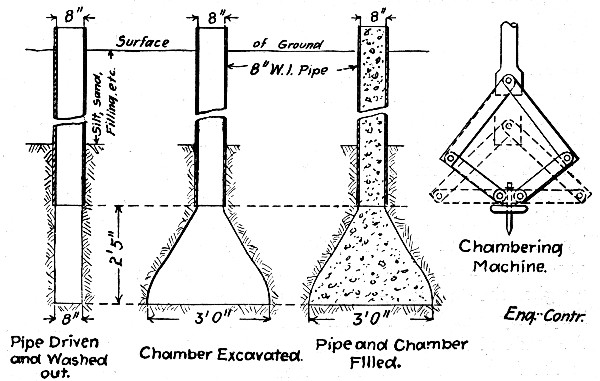

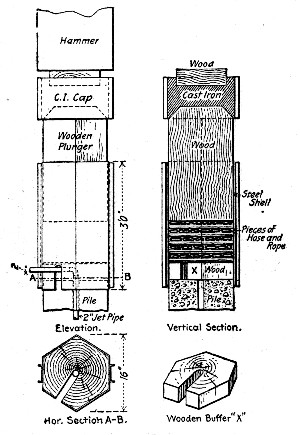

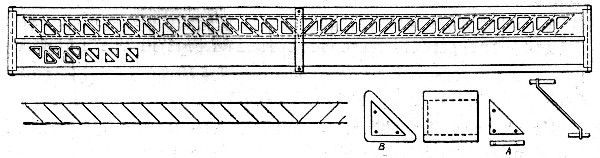

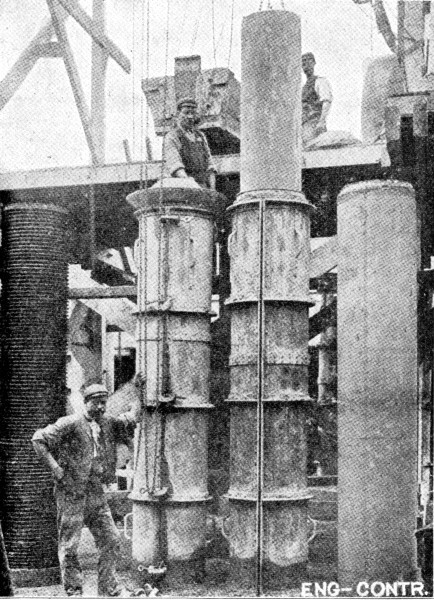

CHAPTER X.—METHODS AND COST OF CONCRETE PILE AND PIER

CONSTRUCTION 151

Introduction—Molding Piles in Place; Method of Constructing Raymond

Piles; Method of Constructing Simplex Piles; Method of Constructing

Piles with Enlarged Footings; Method of Constructing Piles

by the Compressol System; Method of Constructing Piers in Caissons—Molding

Piles for Driving—Driving Molded Piles: Method and Cost

of Molding and Jetting Piles for an Ocean Pier; Method of Molding

and Jetting Square Piles for a Building Foundation; Method of Molding

and Jetting Corrugated Piles for a Building Foundation; Method of

Molding and Driving Round Piles; Molding and Driving Square Piles

for a Building Foundation; Method of Molding and Driving Octagonal

Piles—Method and Cost of Making Reinforced Piles by Rolling.

CHAPTER XI.—METHODS AND COST OF HEAVY CONCRETE WORK

IN FORTIFICATIONS, LOCKS, DAMS, BREAKWATERS AND

PIERS 184

Introduction—Fortification Work: Gun Emplacement, Staten Island, N. Y.,

Mortar Battery Platform, Tampa Bay, Fla., Emplacement for Battery, Tampa

Bay, Fla.; U. S. Fortification Work—Lock Walls, Cascades Canal—Locks,

Coosa River, Alabama—Lock Walls, Illinois & Mississippi Canal—Hand

Mixing and Placing Canal Lock Foundations—Breakwater at Marquette,

Mich.—Breakwater, Buffalo, N. Y.—Breakwater, Port Colborne,

Ontario—Concrete Block Pier, Superior Entry, Wisconsin—Dam, Richmond,

Ind.—Dam at McCall Ferry, Pa.—Dam at Chaudiere Falls, Quebec.

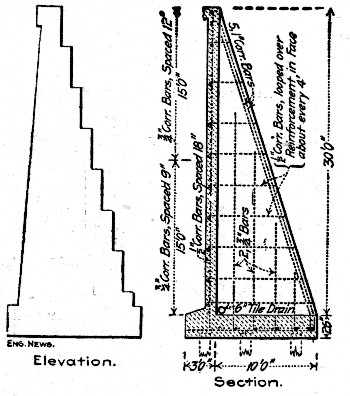

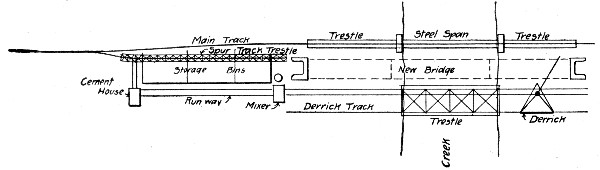

CHAPTER XII.—METHODS AND COST OF CONSTRUCTING BRIDGE

PIERS AND ABUTMENTS 230

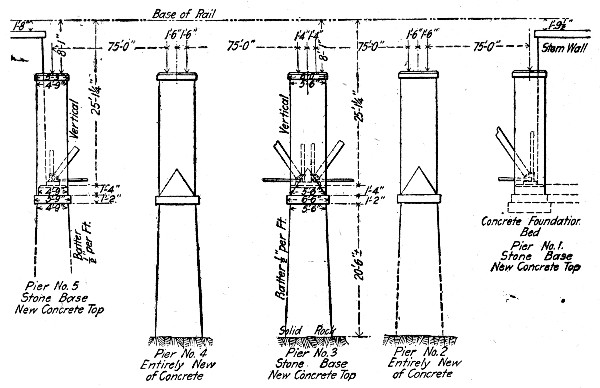

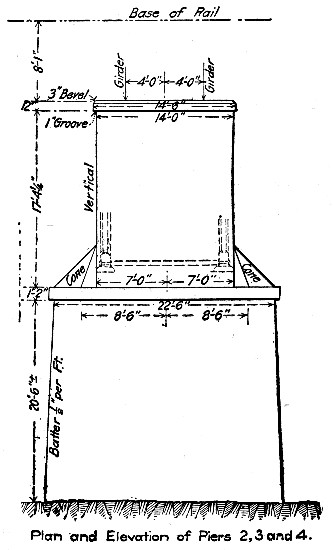

Introduction—Rectangular Pier for a Railway Bridge—Backing for

Bridge Piers and Abutments—Pneumatic Caissons, Williamsburg Bridge—Filling

Pier Cylinders—Piers, Calf Killer River Bridge—Constructing

21 Bridge Piers—Permanent Way Structures, Kansas City Outer Belt

& Electric Ry.—Plate Girder Bridge Abutments—Abutments and Piers,>

Lonesome Valley Viaduct—Hand Mixing and Wheelbarrow Work for

Bridge Piers.

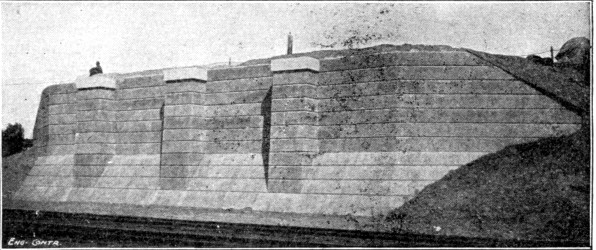

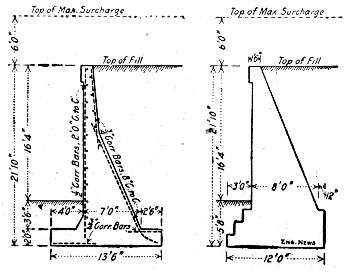

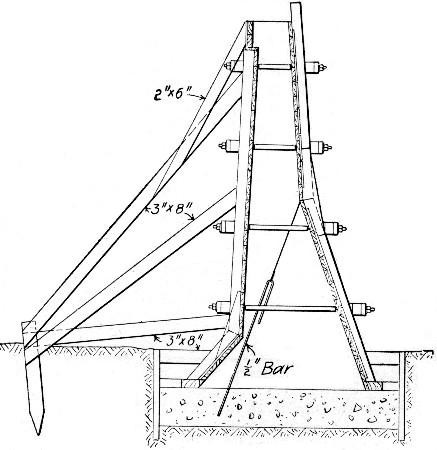

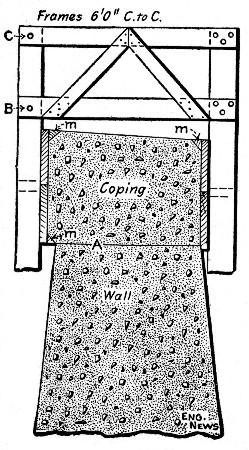

CHAPTER XIII.—METHODS AND COST OF CONSTRUCTING RETAINING

WALLS 259

Introduction—Comparative Economy of Plain and Reinforced Concrete

[Pg vii]Walls—Form Construction—Mixing and Placing Concrete—Walls in

Trench—Chicago Drainage Canal—Grand Central Terminal, New

York, N. Y.—Wall for Railway Yard—Footing for Rubble Stone Retaining

Walls—Track Elevation, Allegheny, Pa.

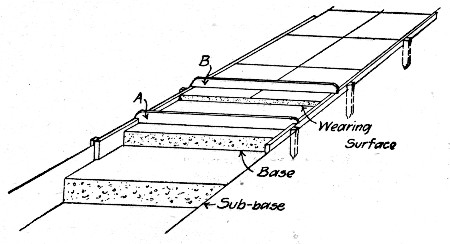

CHAPTER XIV.—METHODS AND COST OF CONSTRUCTING CONCRETE

FOUNDATIONS FOR PAVEMENT 288

Introduction—Mixtures Employed—Distribution of Stock Piles—Hints on

Hand Mixing—Methods of Machine Mixing—Foundation for Stone Block

Pavement, New York, N. Y.—Foundation for Pavement, New Orleans,

La.—Foundation for Pavement, Toronto, Canada—Miscellaneous Examples of

Pavement Foundation Work—Foundation for Brick Pavement, Champaign,

Ill.—Foundation Construction using Continuous Mixers.—Foundation

Construction for Street Railway Track Using Continuous

Mixers—Foundation Construction Using Batch Mixers and Wagon

Haulage—Foundation Construction Using a Traction Mixer—Foundation

Construction Using a Continuous Mixer—Foundation Construction Using a

Portable Batch Mixer.

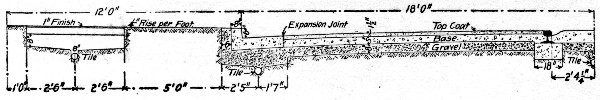

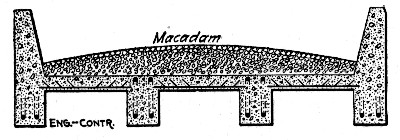

CHAPTER XV.—METHODS AND COST OF CONSTRUCTING SIDEWALKS,

PAVEMENTS, AND CURB AND GUTTER 307

Introduction—Cement Sidewalks: General Method of Construction—Bonding

of Wearing Surface and Base—Protection of Work from Sun and

Frost—Cause and Prevention of Cracks—Cost of Cement Walks; Toronto,

Ont.; Quincy, Mass.; San Francisco, Cal.; Cost in Iowa. Concrete

Pavement: Windsor, Ontario—Richmond, Ind. Concrete Curb and Gutter:

Form Construction—Concrete Mixtures and Concreting—Cost of Curb and

Gutter: Ottawa, Canada; Champaign, Ill.

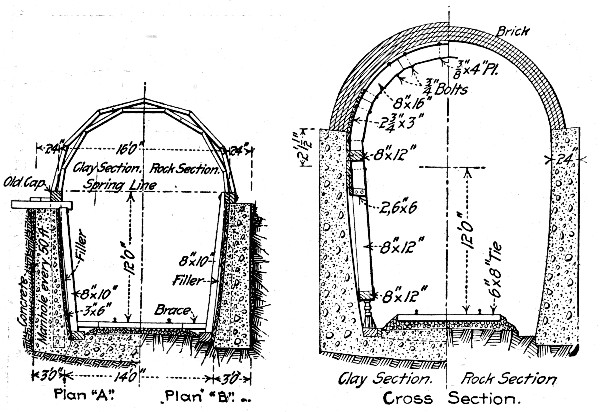

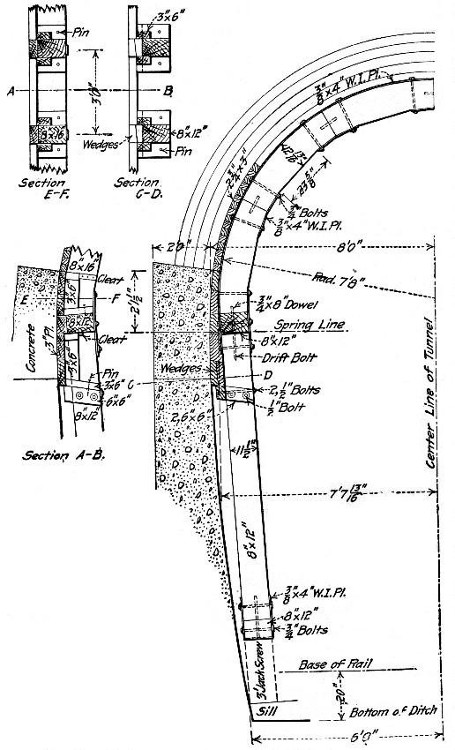

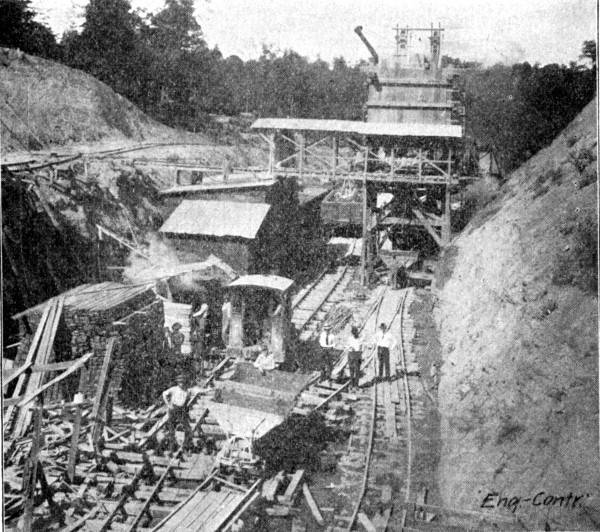

CHAPTER XVI.—METHODS AND COST OF LINING TUNNELS AND

SUBWAYS 328

Introduction—Capitol Hill Tunnel, Pennsylvania R. R., Washington, D.

C.—Constructing Side Walls in Relining Mullan Tunnel—Lining a Short

Tunnel, Peekskill, N. Y.—Cascade Tunnel Great Northern Ry.—Relining

Hodges Pass Tunnel, Oregon Short Line Ry.—Lining a 4,000-ft.

Tunnel—Method of Mixing and Placing Concrete for a Tunnel

Lining—Gunnison Tunnel—New York Rapid Transit Subway—Traveling Forms

for Lining New York Rapid Transit Railway Tunnels—Subway Lining, Long

Island R. R., Brooklyn, N. Y.

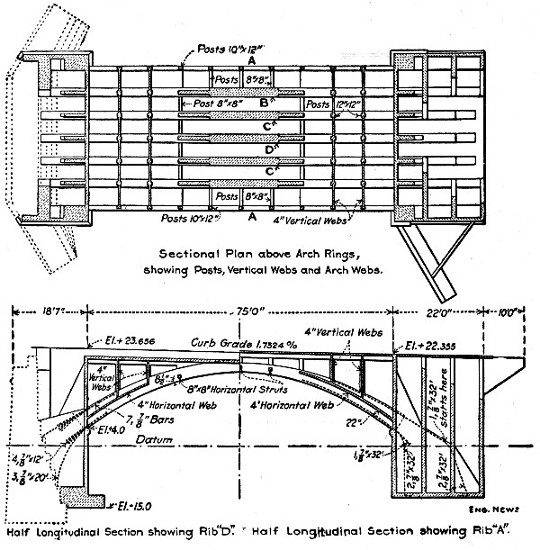

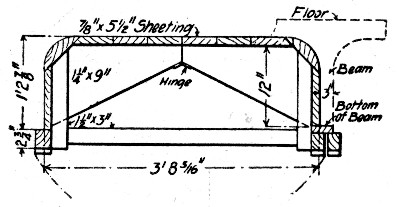

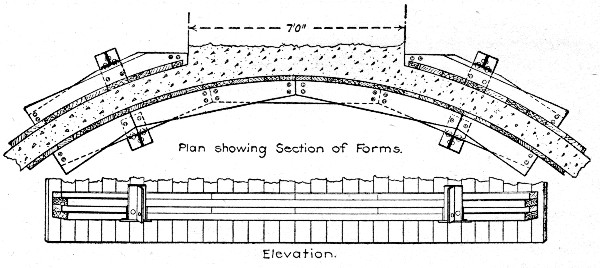

CHAPTER XVII.—METHODS AND COST OF CONSTRUCTING ARCH

AND GIRDER BRIDGES 363

Introduction—Centers—Mixing and Transporting Concrete; Cableway

Plants; Car Plant for 4-Span Arch Bridge; Hoist and Car Plant for

21-Span Arch Viaduct; Traveling Derrick Plant for 4-Span Arch

Bridge—Concrete Highway Bridges Green County, Iowa—Highway Girder

Bridges—Molding Slabs for Girder Bridges—Connecticut Ave. Bridge,

Washington, D. C—Arch Bridges, Elkhart, Ind.—Arch Bridge, Plainwell,

Mich.—Five Span Arch Bridge—Arch Bridge, Grand Rapids, Mich.

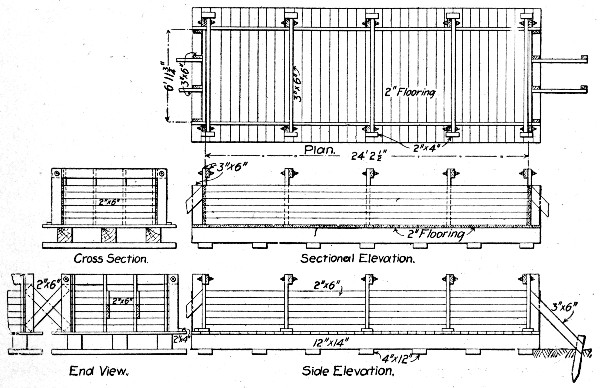

CHAPTER XVIII.—METHODS AND COST OF CULVERT CONSTRUCTION 414

Introduction—Box Culvert Construction, C., B. & Q. R. R.—Arch Culvert

Costs, N. C. & St. L. Ry.; 18-ft. Arch Culvert; Six Arch Culverts 6 to

16-ft. Span; 14¾-ft. Arch Culvert—Culverts for New Construction,

Wabash Ry.—Small Arch Culvert Costs, Pennsylvania R. R.—26-ft. Span

Arch Culvert—12-ft. Culvert, Kalamazoo, Mich.—Method and Cost of

Molding Culvert Pipe.

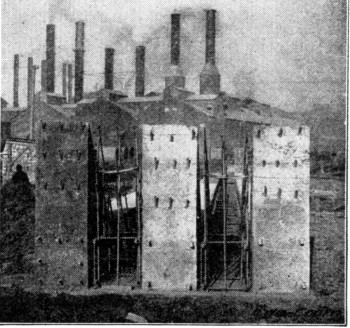

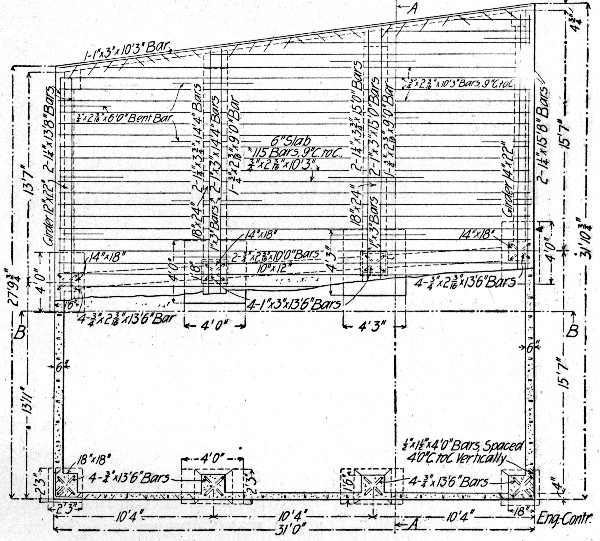

CHAPTER XIX.—METHODS AND COST OF REINFORCED CONCRETE

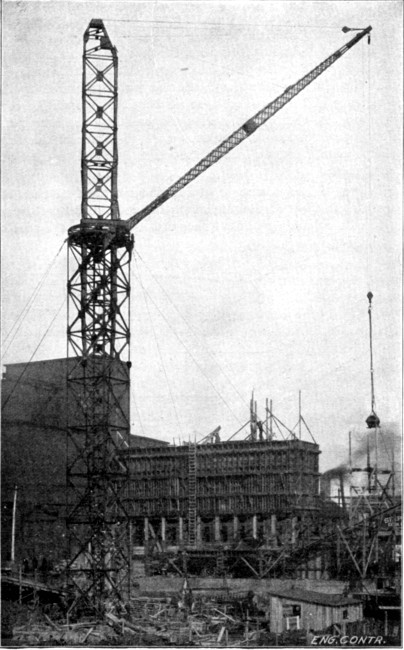

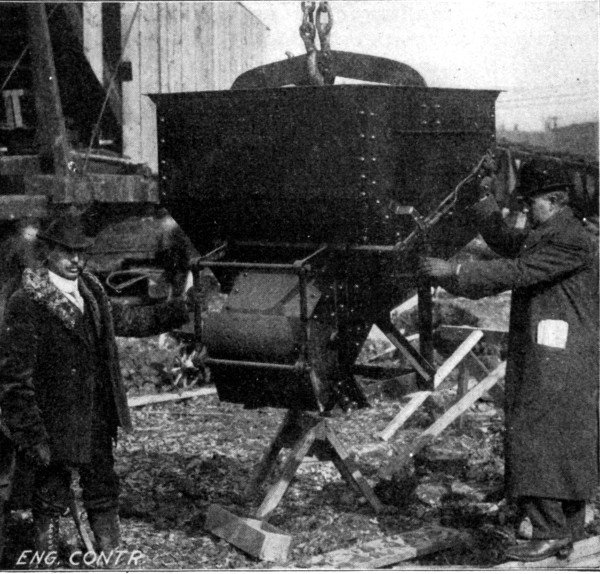

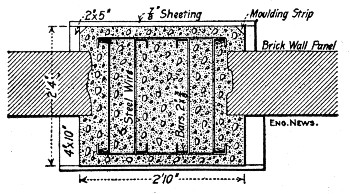

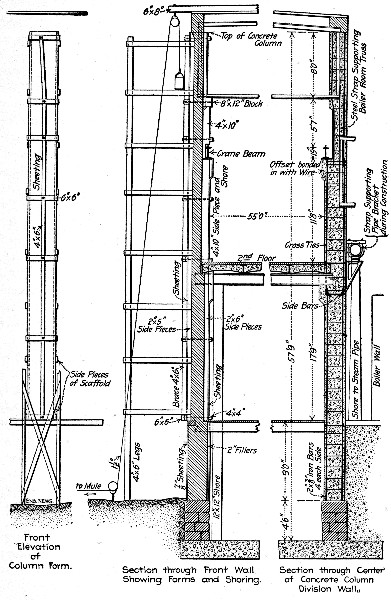

BUILDING CONSTRUCTION 433

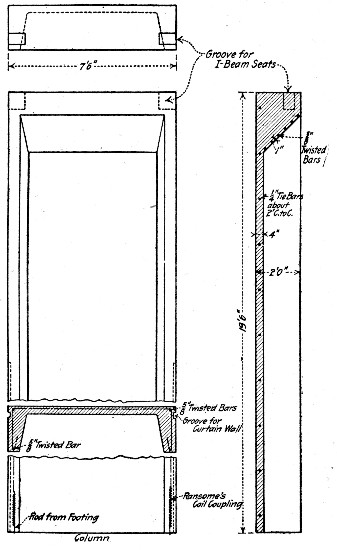

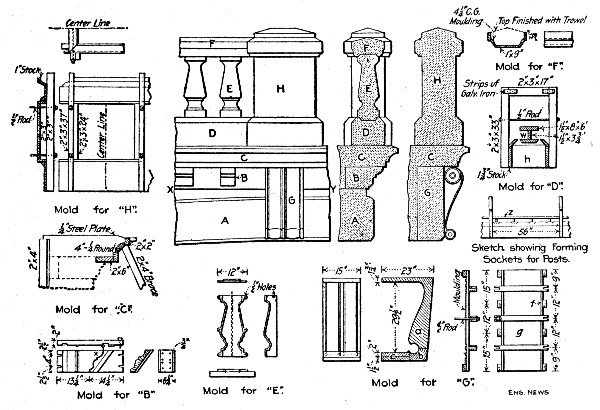

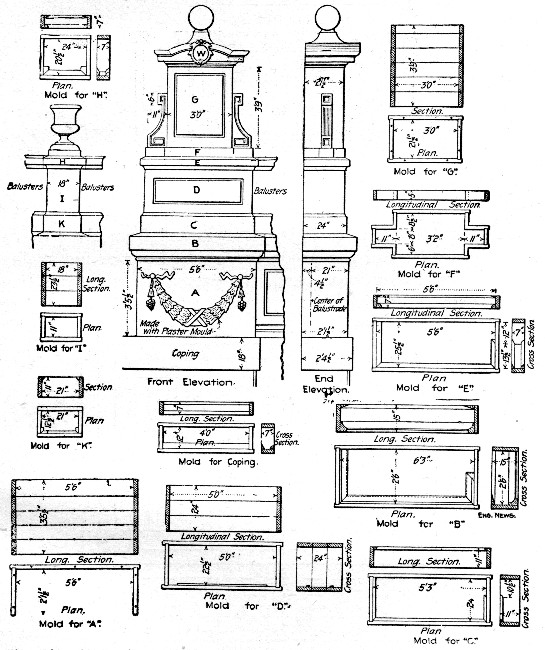

Introduction—Construction, Erection and Removal of Forms: Column Forms;

Rectangular Columns; Polygonal Columns; Circular Columns; Ornamental

Columns—Slab and Girder Forms; Slab and I-Beam Floors; Concrete Slab

and Girder Floors—Wall Forms—Erecting Forms—Removing Forms,

[Pg viii]Fabrication and Placing Reinforcement; Fabrication; Placing—Mixing,

Transporting and Placing Concrete: Mixing; Transporting; Bucket Hoists;

Platform Hoists; Derricks—Placing and Ramming—Constructing Wall

Columns for a Brick Building—Floor and Column Construction for a

Six-Story Building—Wall and Roof Construction for One-Story Car

Barn—Constructing Wall Columns for a One-Story Machine

Shop—Constructing One-Story Walls with Movable Forms and Gallows

Frames—Floor and Roof Construction for Four-Story Garage.

CHAPTER XX.—METHOD AND COST OF BUILDING CONSTRUCTION

OF SEPARATELY MOLDED MEMBERS 515

Introduction—Column, Girder and Slab Construction: Warehouses,

Brooklyn, N. Y.; Factory, Reading, Pa.; Kilnhouse, New Village, N.

J.—Hollow Block Wall Construction: Factory Buildings, Grand Rapids,

Mich.; Residence, Quogue, N. Y., Two-Story Building, Albuquerque, N.

Mex.; General Cost Data.

CHAPTER XXI.—METHODS AND COST OF AQUEDUCT AND SEWER

CONSTRUCTION 532

Introduction—Forms and Centers—Concreting—Reinforced Conduit, Salt

River Irrigation Works, Arizona—Conduit, Torresdale Filters,

Philadelphia, Pa.—Conduit, Jersey City Water Supply, Twin Tube Water

Conduit at Newark, N. J.—66-in. Circular Sewer, South Bend, Ind.—Sewer

Invert Haverhill, Mass.—29-ft. Sewer, St. Louis, Mo.—Sewer,

Middlesborough, Ky.—Intercepting Sewer, Cleveland, Ohio—Reinforced

Concrete Sewer, Wilmington, Del.—Sewer with Monolithic Invert and Block

Arch—Cost of Block Manholes—Cement Pipe Constructed in Place—Pipe

Sewer, St. Joseph, Mo.—Cost of Molding Small Cement Pipe—Molded Pipe

Water Main, Swansea, England.

CHAPTER XXII.—METHODS AND COST OF CONSTRUCTING RESERVOIRS

AND TANKS 588

Introduction—Small Covered Reservoir—500,000 Gallon Covered Reservoir,

Ft. Meade, So. Dak.—Circular Reservoir, Bloomington, Ill.—Standpipe at

Attleborough, Mass.—Gas Holder Tank, Des Moines, Iowa—Gas Holder Tank,

New York City—Lining a Reservoir, Quincy, Mass.—Relining a Reservoir,

Chelsea, Mass.—Lining Jerome Park Reservoir—Reservoir Floor, Canton,

Ill.—Reservoir Floor, Pittsburg, Pa.—Constructing a Silo—Grained Arch

Reservoir Roof—Grain Elevator Bins.

CHAPTER XXIII.—METHODS AND COST OF CONSTRUCTING ORNAMENTAL

WORK 636

Introduction—Separately Molded Ornaments: Wooden Molds; Iron Molds;

Sand Molding; Plaster Molds—Ornaments Molded in Place: Big Muddy

Bridge; Forest Park Bridge; Miscellaneous Structures.

CHAPTER XXIV.—MISCELLANEOUS METHODS AND COSTS 653

Introduction—Drilling and Blasting Concrete—Bench Monuments, Chicago,

III.—Pole Base—Mile Post—Bonding New Concrete to Old—Dimensions and

Capacities of Mixers—Data for Estimating Weight of Steel in Reinforced

Concrete; Computing Weight from Percentage of Volume; Weights and

Dimensions of Plain and Special Reinforcing Metals—Recipes for Coloring

Mortars.

CHAPTER XXV.—METHODS AND COST OF WATERPROOFING CONCRETE

STRUCTURES 667

Impervious Concrete Mixtures—Star Stetten Cement—Medusa Waterproofing

Compound—Novoid Waterproofing Compound—Impermeable Coatings and

Washes: Bituminous Coatings; Szerelmey Stone Liquid Wash; Sylvester

Wash; Sylvester Mortars; Hydrolithic Coating; Cement Mortar Coatings;

Oil and Paraffine Washes—Impermeable Diaphragms; Long Island R. R.

Subway; New York Rapid Transit Subway.

Concrete is an artificial stone produced by mixing cement mortar with broken stone, gravel, broken slag, cinders or other similar fragmentary materials. The component parts are therefore hydraulic cement, sand and the broken stone or other coarse material commonly designated as the aggregate.

At least a score of varieties of hydraulic cement are listed in the classifications of cement technologists. The constructing engineer and contractor recognize only three varieties: Portland cement, natural cement and slag or puzzolan cement. All concrete used in engineering work is made of either Portland, natural or slag cement, and the great bulk of all concrete is made of Portland cement. Only these three varieties of cement are, therefore, considered here and they only in their aspects having relation to the economics of construction work. For a full discussion of the chemical and physical properties of hydraulic cements and for the methods of determining these properties by tests, the reader is referred to "Practical Cement Testing," by W. Purves Taylor.

PORTLAND CEMENT.—Portland cement is the best of the hydraulic cements. Being made from a rigidly controlled artificial mixture of lime, silica and alumina the product of the best mills is a remarkably strong, uniform and stable material. It is suitable for all classes of concrete work and is the only variety of hydraulic cement allowable for reinforced concrete or for plain concrete having to endure hard[Pg 2] wear or to be used where strength, density and durability of high degree are demanded.

NATURAL CEMENT.—Natural cement differs from Portland cement in degree only. It is made by calcining and grinding a limestone rock containing naturally enough clayey matter (silica and alumina) to make a cement that will harden under water. Owing to the imperfection and irregularity of the natural rock mixture, natural cement is weaker and less uniform than Portland cement. Natural cement concrete is suitable for work in which great unit strength or uniformity of quality is not essential. It is never used for reinforced work.

SLAG CEMENT.—Slag cement has a strength approaching very closely that of Portland cement, but as it will not stand exposure to the air slag cement concrete is suitable for use only under water. Slag cement is made by grinding together slaked lime and granulated blast furnace slag.

SIZE AND WEIGHT OF BARRELS OF CEMENT.—The commercial unit of measurement of cement is the barrel; the unit of shipment is the bag. A barrel of Portland cement contains 380 lbs. of cement, and the barrel itself weighs 20 lbs.; there are four bags (cloth or paper sacks) of cement to the barrel, and the regulation cloth sack weighs 1½ lbs. The size of cement barrels varies, due to the differences in weight of cement and to differences in compacting the cement into the barrel. A light burned Portland cement weighs 100 lbs. per struck bushel; a heavy burned Portland cement weighs 118 to 125 lbs. per struck bushel. The number of cubic feet of packed Portland cement in a barrel ranges from 3 to 3½. Natural cements are lighter than Portland cement. A barrel of Louisville, Akron, Utica or other Western natural cement contains 265 lbs. of cement and weighs 15 lbs. itself; a barrel of Rosendale or other Eastern cement contains 300 lbs. of cement and the barrel itself weighs 20 lbs. There are 3¾ cu. ft. in a barrel of Louisville cement. Usually there are three bags to a barrel of natural cement.

As stated above, the usual shipping unit for cement is the bag, but cement is often bought in barrels or, for large works, in bulk. When bought in cloth bags, a charge is made of[Pg 3] 10 cts. each for the bags, but on return of the bags a credit of 8 to 10 cts. each is allowed. Cement bought in barrels costs 10 cts. more per barrel than in bulk, and cement ordered in paper bags costs 5 cts. more per barrel than in bulk. Cement is usually bought in cloth sacks which are returned, but to get the advantage of this method of purchase the user must have an accurate system for preserving, checking up and shipping the bags.

Where any considerable amount of cement is to be used the contractor will find that it will pay to erect a small bag house or to close off a room at the mixing plant. Provide the enclosure with a locked door and with a small window into which the bags are required to be thrown as fast as emptied. One trustworthy man is given the key and the task of counting up the empty bags each day to see that they check with the bags of cement used. The following rule for packing and shipping is given by Gilbreth.[A]

[A] "Field System," Frank B. Gilbreth. Myron C. Clark Publishing Co., New York and Chicago.

"Pack cement bags laid flat, one on top of the other, in piles of 50. They can then be counted easily. Freight must be prepaid when cement bags are returned and bills of lading must be obtained in duplicate or credit cannot be obtained on shipment."

The volumes given above are for cement compacted in the barrel. When the cement is emptied and shoveled into boxes it measures from 20 to 30 per cent more than when packed in the barrel. The following table compiled from tests made for the Boston Transit Commission, Mr. Howard Carson, Chief Engineer, in 1896, shows the variation in volume of cement measured loose and packed in barrels:

| Brand | Vol. Barrel cu. ft. | Vol. Packed cu. ft. | Vol. Loose cu. ft. | Per cent Increase in bulk |

| Portland. | ||||

| Giant | 3.5 | 3.35 | 4.17 | 25 |

| Atlas | 3.45 | 3.21 | 3.75 | 18 |

| Saylors | 3.25 | 3.15 | 4.05 | 30 |

| Alsen | 3.22 | 3.16 | 4.19 | 33 |

| Dyckerhoff | 3.12 | 3.03 | 4.00 | 33 |

Mr. Clarence M. Foster is authority for the statement that[Pg 4] Utica cement barrels measure 16¼ ins. across at the heads, 19½ ins. across the bilge, and 25¾ ins. in length under heads, and contain 3.77 cu. ft. When 265 lbs. of Utica natural hydraulic cement are packed in a barrel it fills it within 2½ ins. of the top and occupies 3.45 cu. ft., and this is therefore the volume of a barrel of Utica hydraulic cement packed tight.

In comparative tests made of the weights and volumes of various brands of cements at Chicago in 1903, the following figures were secured:

| Vol. per bbl., cu. ft. | Weight per bbl., lbs. | Weight per cu. ft. | ||

| Brand. | Loose. | Gross. | Net. | Loose, lbs. |

| Dyckerhoff | 4.47 | 395 | 369.5 | 83 |

| Atlas | 4.45 | 401 | 381 | 85.5 |

| Alpha | 4.37 | 400.5 | 381 | 86.5 |

| Puzzolan | 4.84 | 375 | 353.5 | 73.5 |

| Steel | 4.96 | 345 | 322.5 | 67.5 |

| Hilton | 4.64 | 393 | 370.5 | 79.5 |

SPECIFICATIONS AND TESTING—The great bulk of cement used in construction work is bought on specification. The various government bureaus, state and city works departments, railway companies, and most public service corporations have their own specifications. Standard specifications are also put forward by several of the national engineering societies, and one of these or the personal specification of the engineer is used for individual works. Buying cement to specification necessitates testing to determine that the material purchased meets the specified requirements. For a complete discussion of the methods of conducting such tests the reader is referred to "Practical Cement Testing" by W. Purves Taylor.

According to this authority a field testing laboratory will cost for equipment $250 to $350. Such a laboratory can be operated by two or three men at a salary charge of from $100 to $200 per month. Two men will test on an average four samples per day and each additional man will test four more samples. The cost of testing will range from $3 to $5 per sample, which is roughly equivalent to 3 cts. per barrel of[Pg 5] cement, or from 3 to 5 cts. per cubic yard of concrete. These figures are for field laboratory work reasonably well conducted under ordinarily favorable conditions. In large laboratories the cost per sample will run somewhat lower.

Sand constitutes from ⅓ to ½ of the volume of concrete; when a large amount of concrete is to be made a contractor cannot, therefore, afford to guess at his source of sand supply. A long haul over poor roads can easily make the sand cost more than the stone per cubic yard of concrete.

PROPERTIES OF GOOD SAND.—Engineers commonly specify that sand for concrete shall be clean and sharp, and silicious in character. Neither sharpness nor excessive cleanliness is worth seeking after if it involves much expense. Tests show conclusively that sand with rounded grains makes quite as strong a mortar, other things being equal, as does sand with angular grains. The admixture with sand of a considerable percentage of loam or clay is also not the unmixed evil it has been supposed to be. Myron S. Falk records[B] a number of elaborate experiments on this point. These experiments demonstrate conclusively that loam and clay in sand to the amount of 10 to 15 per cent. result in no material reduction in the strength of mortars made with this sand as compared with mortars made with the same sand after washing. There can be no doubt but that for much concrete work the expense entailed in washing sand is an unnecessary one.

[B] "Cements, Mortars and Concretes" By Myron S. Falk. Myron C. Clark Publishing Co., Chicago, Ill.

The only substitute for natural sand for concrete, that need be considered practically, is pulverized stone, either the dust and fine screenings produced in crushing rock or an artificial sand made by reducing suitable rocks to powder. As a conclusion from the records of numerous tests, M. S. Falk says: "It may be concluded that rock screenings may be substituted for sand, either in mortar or concrete, without any loss of strength resulting. This is important commercially, for it precludes the necessity of screening the dust from crushed rock and avoids, at the same time, the cost of procuring a natural sand to take its place."[Pg 6]

The principal danger in using stone dust is failure to secure the proper balance of different size grains. This is also an important matter in the choice of natural sands. Sand composed of a mixture of grains ranging from fine to coarse gives uniformly stronger mortars than does sand with grains of nearly one size, and as between a coarse and a fine sand of one size of grains the coarse sand gives the stronger mortar. Further data on the effect of size of grains on the utility of sand for concrete are given in Chapter II, in the section on Voids in Sand, and for those who wish to study in detail, the test data on this and the other matters referred to here, the authors recommend "Cements, Mortars and Concretes; Their Physical Properties," by Myron S. Falk.

COST OF SAND.—A very common price for sand in cities is $1 per cu. yd., delivered at the work. It may be noted here that as sand is often sold by the load instead of the cubic yard, it is wise to have a written agreement defining the size of a load. Where the contractor gets his sand from the pit its cost will be the cost of excavating and loading at the pit, the cost of hauling in wagons, the cost of freight and rehandling it if necessary, and the cost of washing, added together.

An energetic man working under a good foreman will load 20 cu. yds. of sand into wagons per 10-hour day; with a poor foreman or when laborers are scarce, it is not safe to count on more than 15 cu. yds. per day. With wages at $1.50 per day this will make the cost of loading 10 cts. per cubic yard. The cost of hauling will include the cost of lost team time and dumping, which will average about 5 cts. per cubic yard. With 1 cu. yd. loads, wages of team 35 cts. per hour, and speed of travel 2½ miles per hour, the cost of hauling proper is ½ ct. per 100 ft., or 27 cts. per mile. Assuming a mile haul, the cost of sand delivered based on the above figures will be 10 cts. + 5 cts. + ½ ct. per 100 ft. = 15 + 27 cts. = 42 cts. per cu. yd. Freight rates can always be secured and it is usually safe to estimate the weight on a basis of 2,700 lbs. per cubic yard. For a full discussion of the cost of excavating sand and other earths the reader is referred to "Earth Excavation and Embankments; Methods and Cost," by Halbert P. Gillette and Daniel J. Hauer.[Pg 7]

METHODS AND COST OF WASHING SAND.—When the available sand carries considerable percentages of loam or clay and the specifications require that clean sand shall be used, washing is necessary. The best and cheapest method of performing this task will depend upon the local conditions and the amount of sand to be washed.

Washing With Hose.—When the quantity of sand to be washed does not exceed 15 to 30 cu. yds. per day the simplest method, perhaps, is to use a hose. Build a wooden tank or box, 8 ft. wide and 15 ft. long, the bottom having a slope of 8 ins. in the 15 ft. The sides should be about 8 ins. high at the lower end and rise gradually to 3 ft. in height at the upper end. Close the lower end of the tank with a board gate about 6 ins. in height and sliding in grooves so that it can be removed. Dump about 3 cu. yds. of sand into the upper end of the tank and play a ¾-in. hose stream of water on it, the hose man standing at the lower end of the tank. The water and sand flow down the inclined bottom of the tank where the sand remains and the dirt flows over the gate and off with the water. It takes about an hour to wash a 3-cu. yd. batch, and by building a pair of tanks so that the hose man can shift from one to the other, washing can proceed continuously and one man will wash 30 cu. yds. per 10-hour day at a cost, with wages at $1.50, of 5 cts. per cubic yard. The sand, of course, has to be shoveled from the tank and this will cost about 10 cts. per cubic yard, making 15 cts. per cubic yard for washing and shoveling, and to this must be added any extra hauling and, if the water is pumped, the cost of pumping which may amount to 10 cts. per cubic yard for coal and wages. Altogether a cost of from 15 to 30 cts. per cubic yard may be figured for washing sand with a hose.

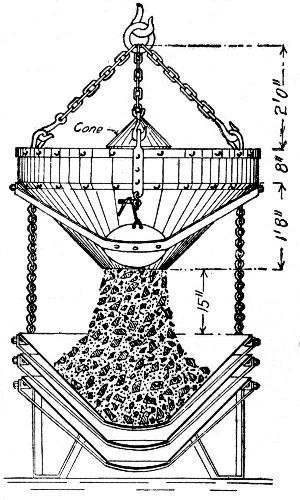

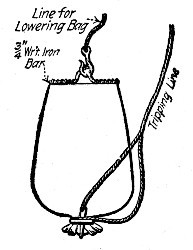

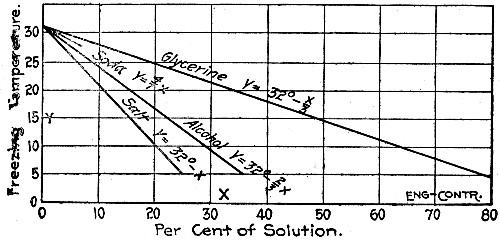

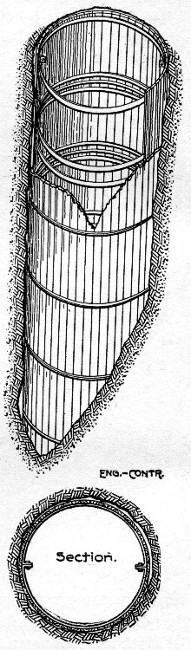

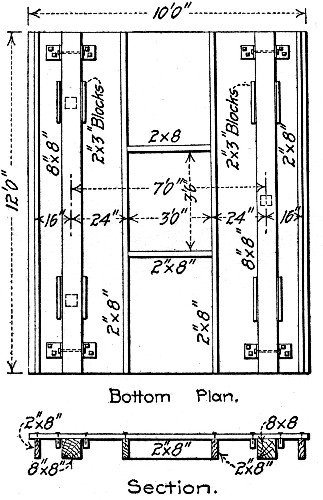

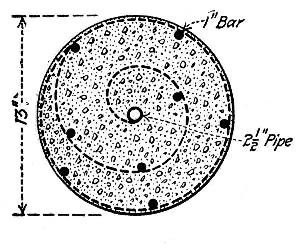

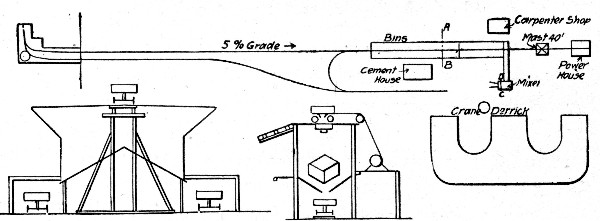

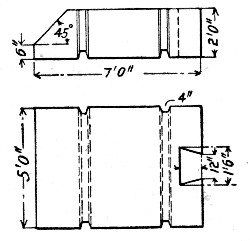

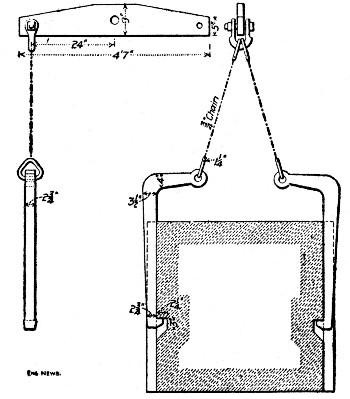

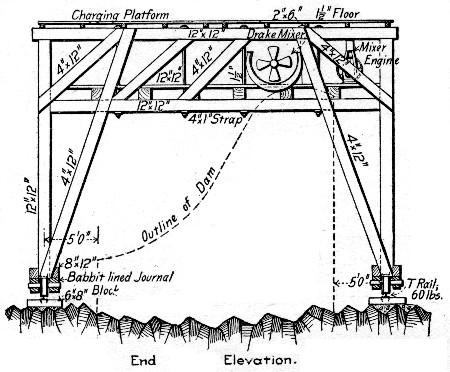

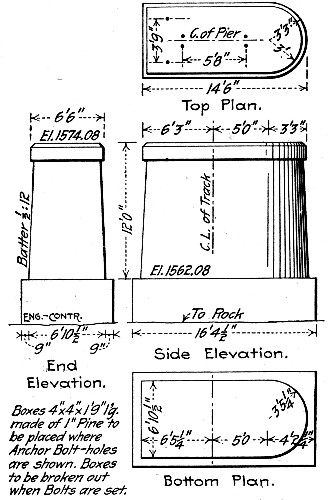

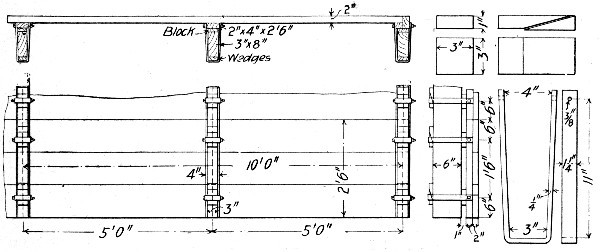

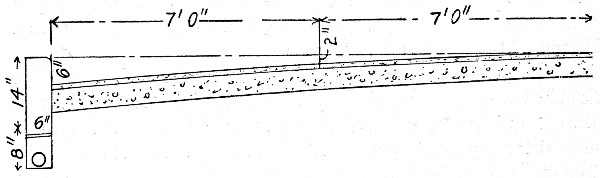

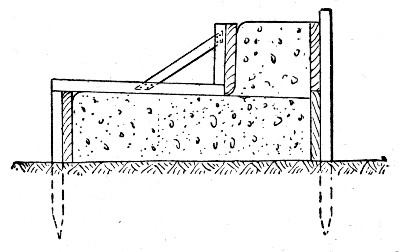

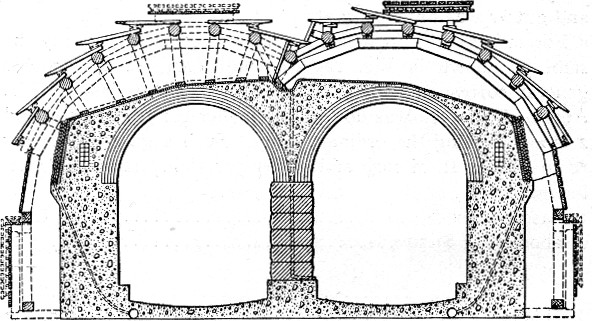

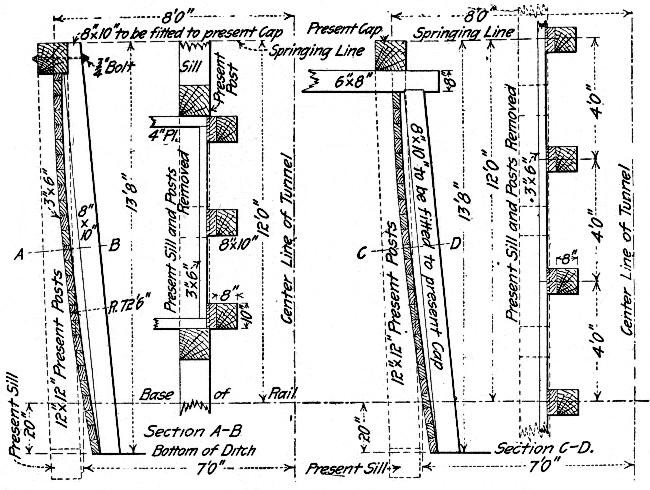

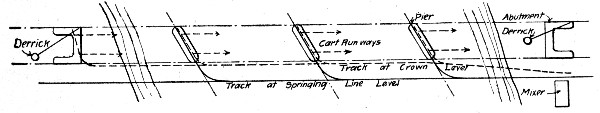

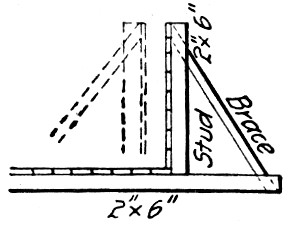

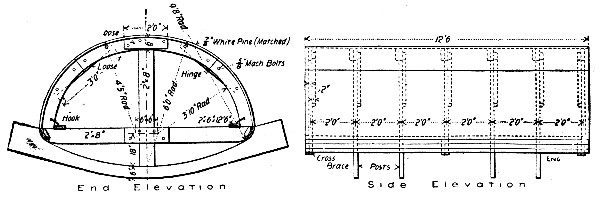

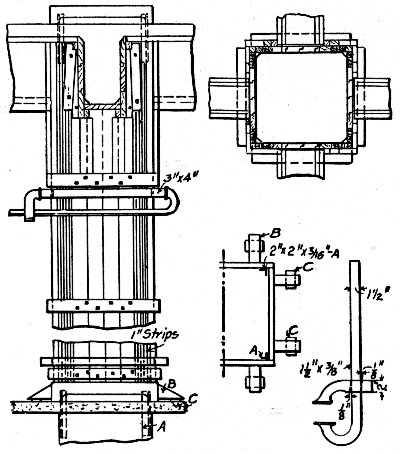

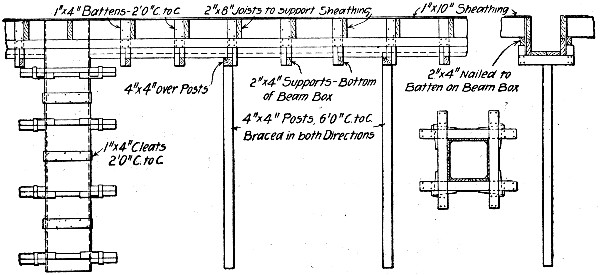

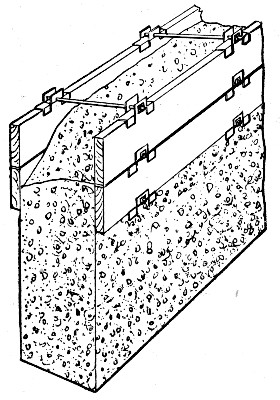

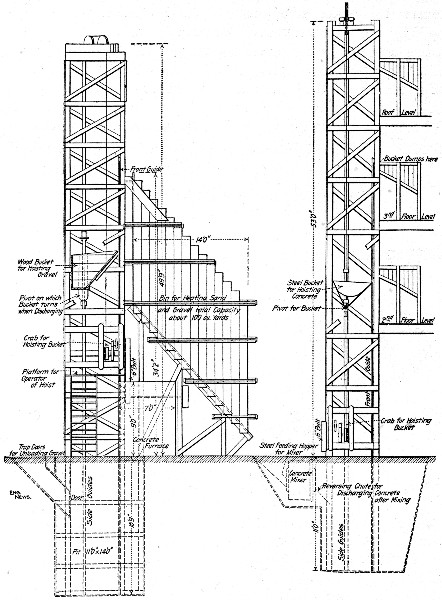

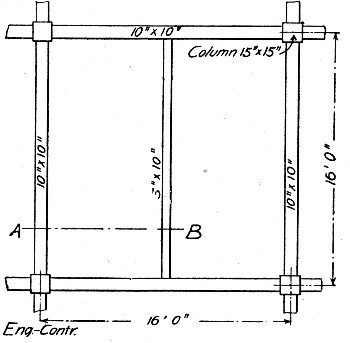

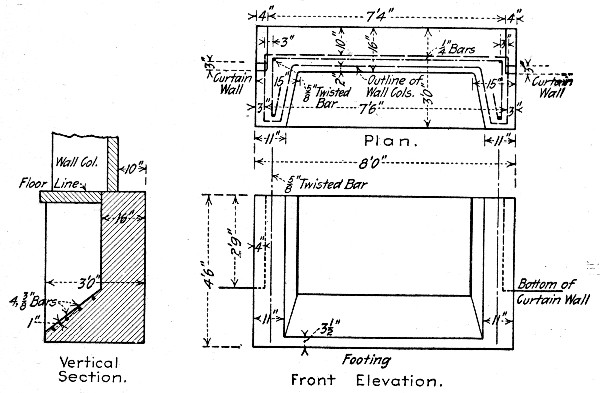

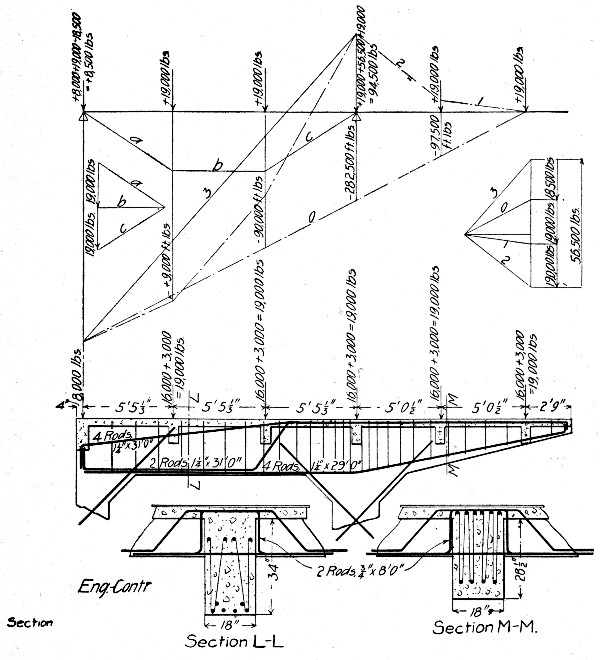

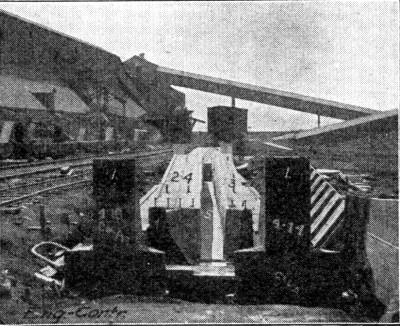

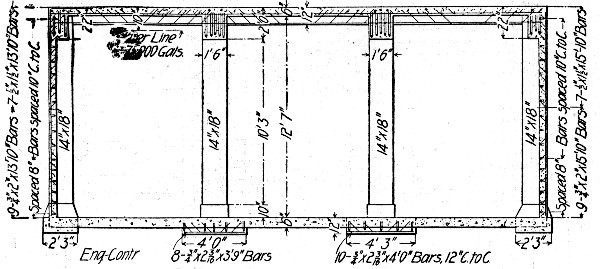

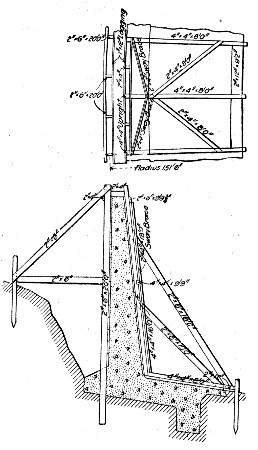

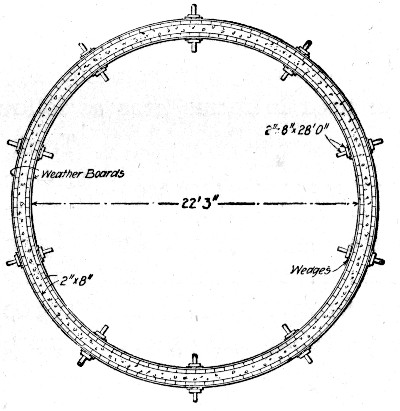

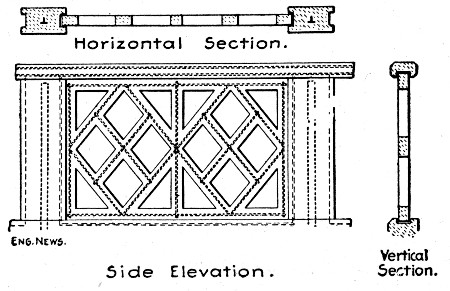

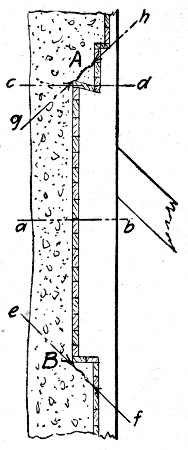

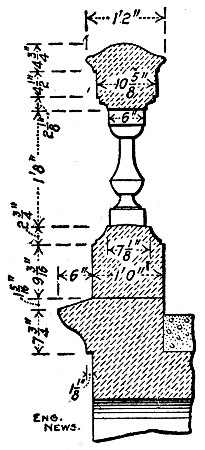

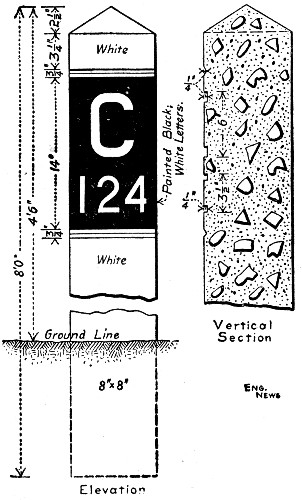

Fig. 1.—Plan and Elevation of Two-Hopper Ejector Sand

Washing Plant.

Fig. 1.—Plan and Elevation of Two-Hopper Ejector Sand

Washing Plant.

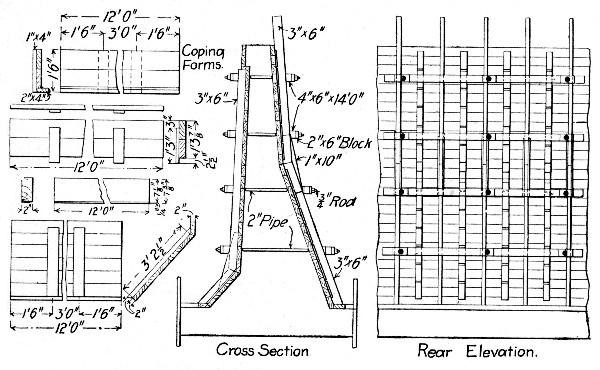

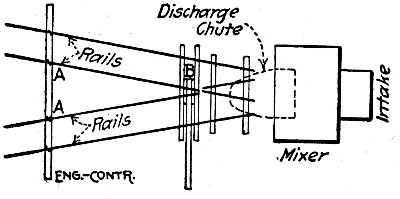

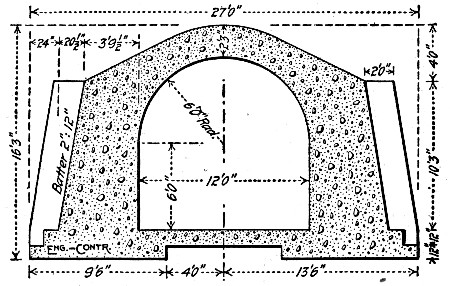

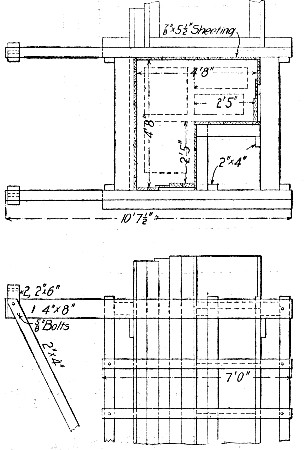

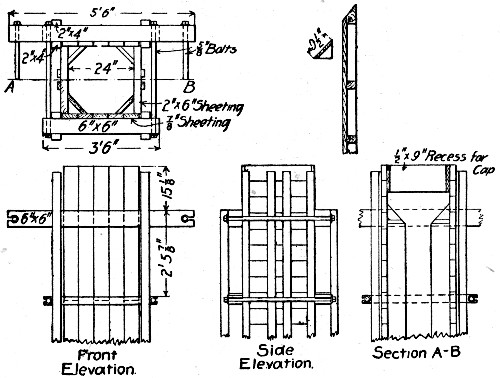

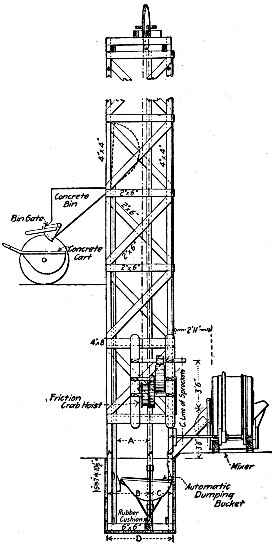

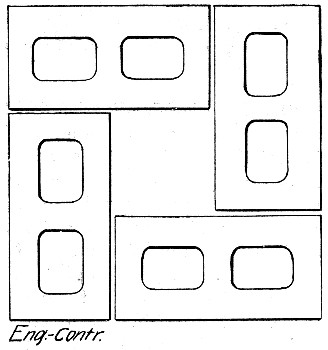

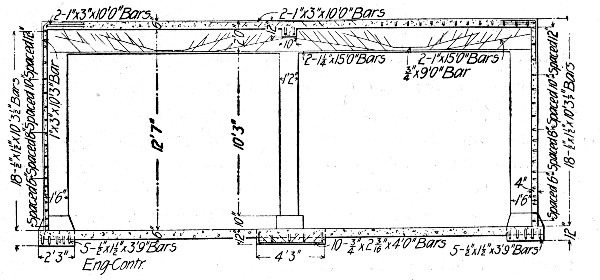

Fig. 2.—Plan and Elevation of Four-Hopper Ejector Sand

Washing-Plant.

Fig. 2.—Plan and Elevation of Four-Hopper Ejector Sand

Washing-Plant.

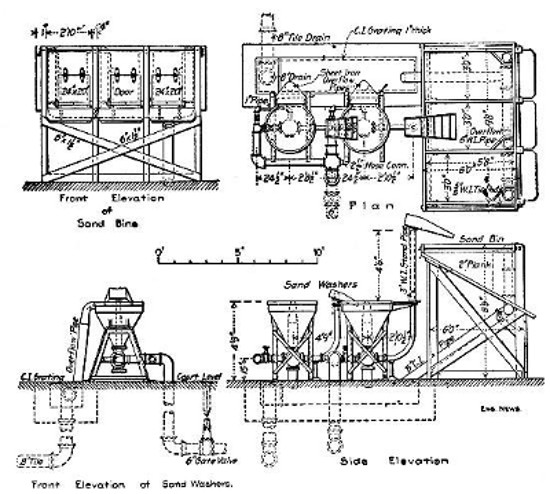

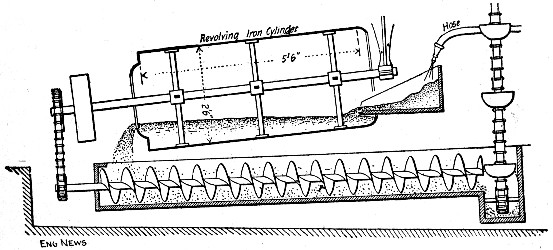

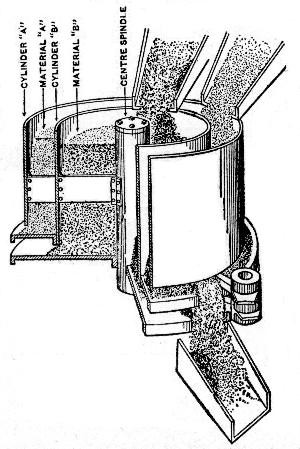

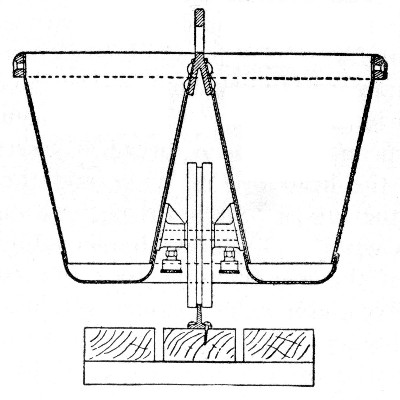

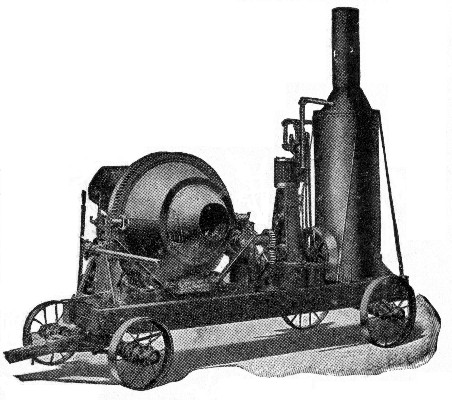

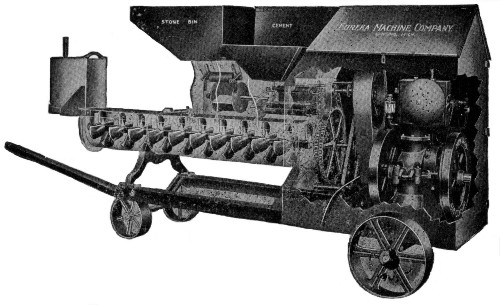

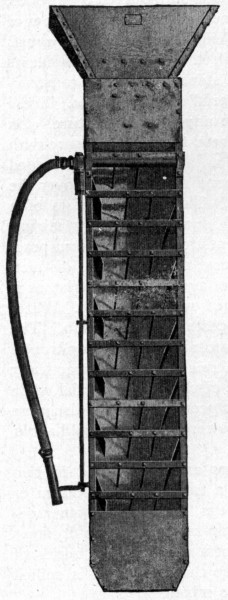

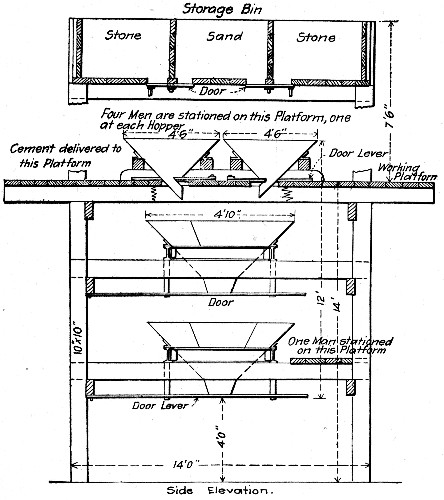

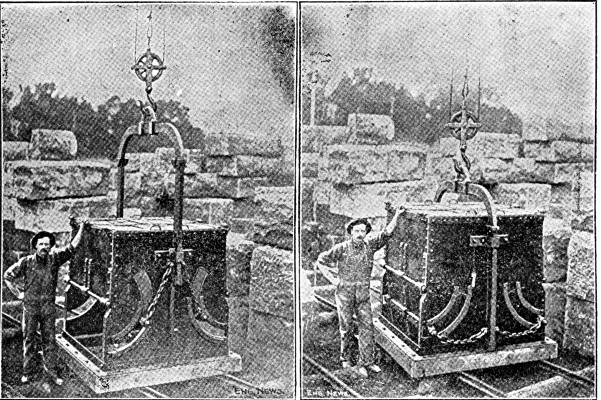

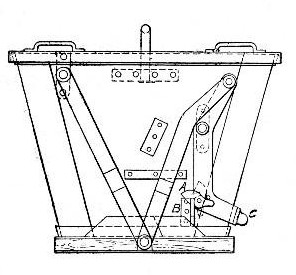

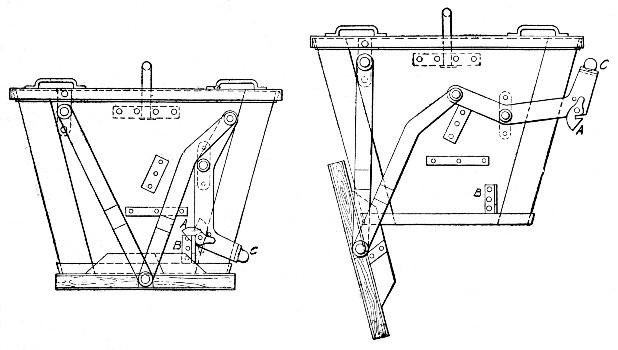

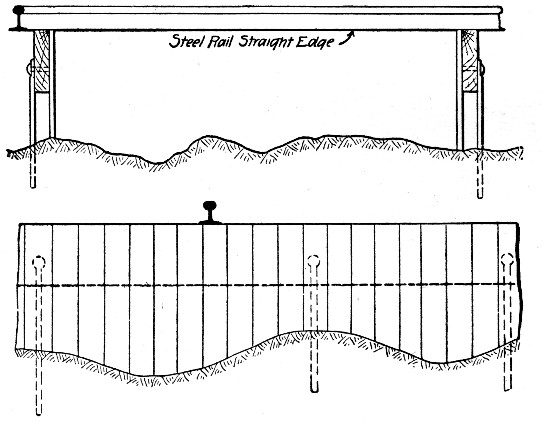

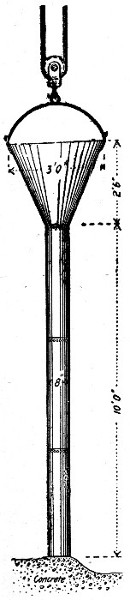

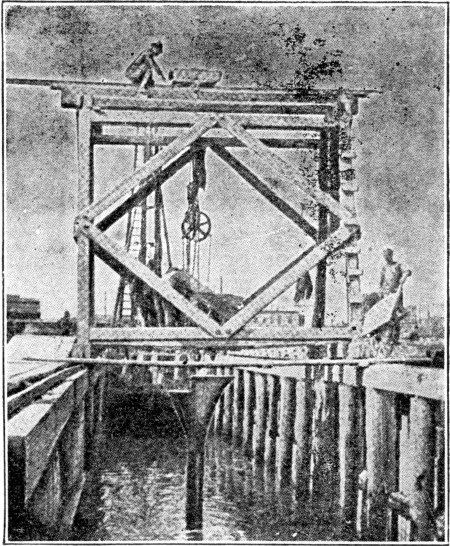

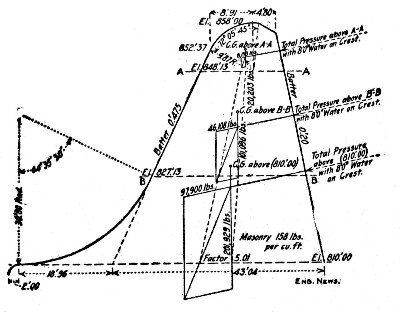

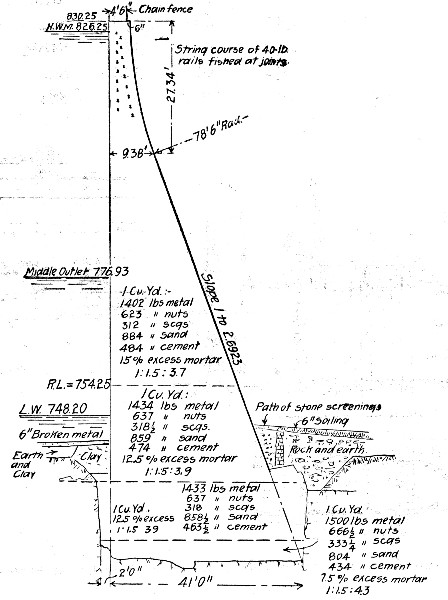

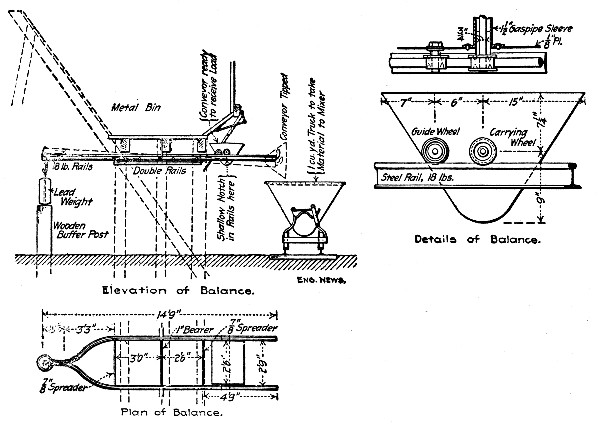

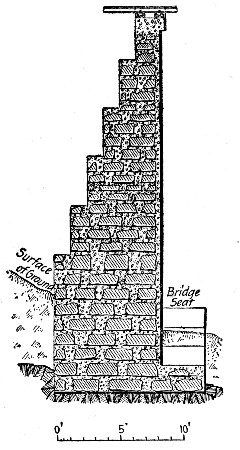

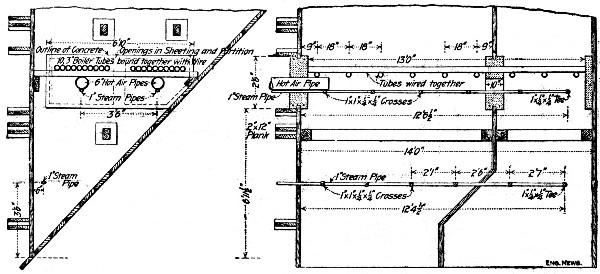

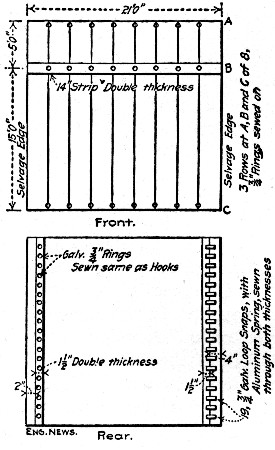

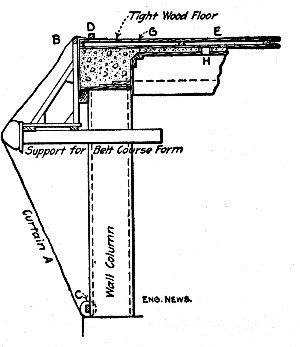

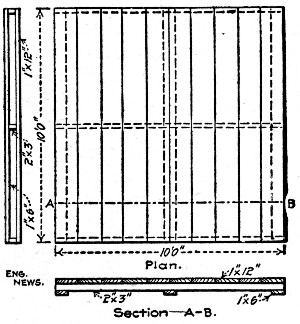

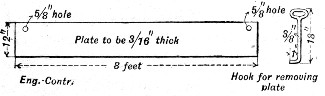

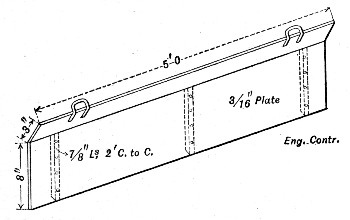

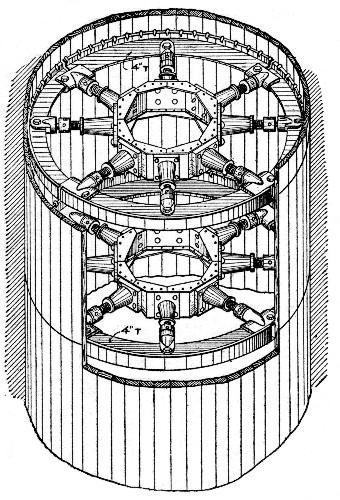

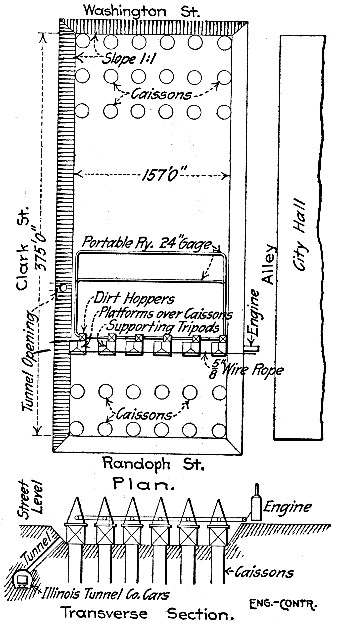

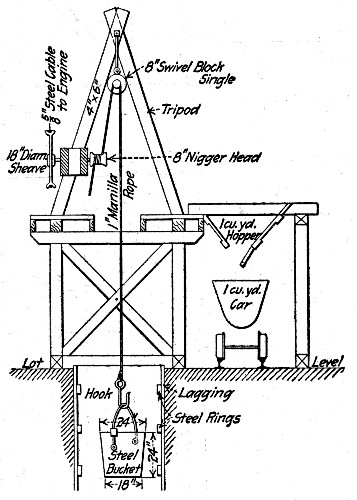

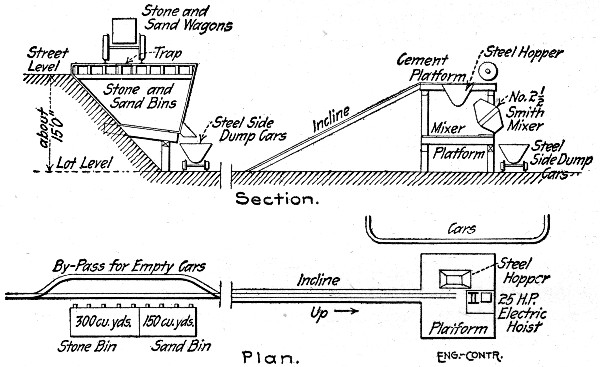

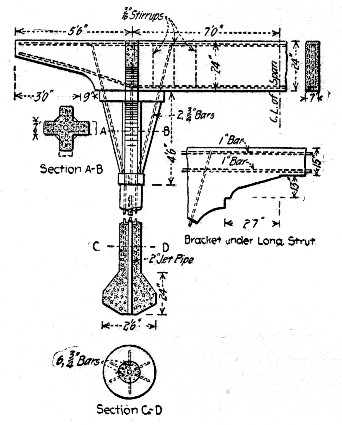

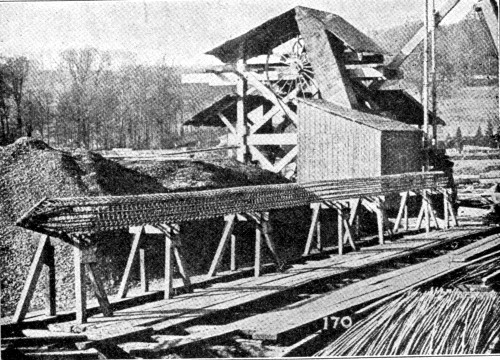

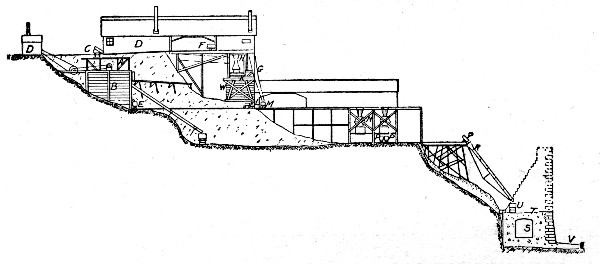

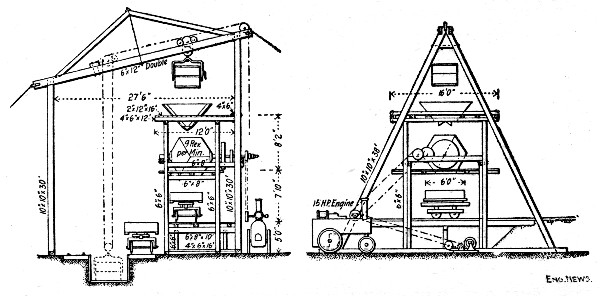

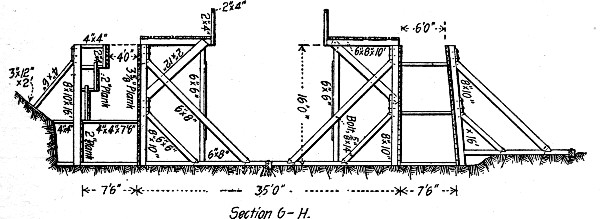

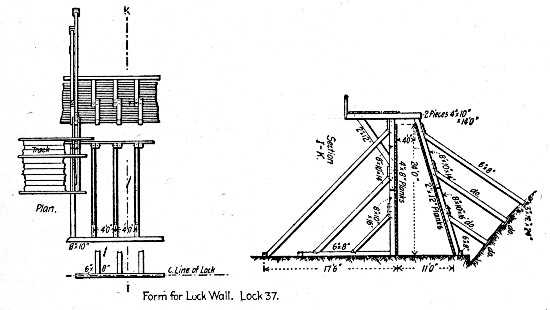

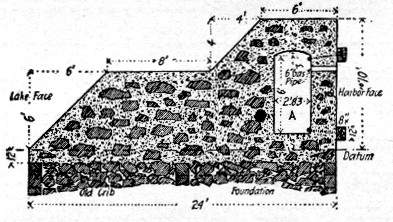

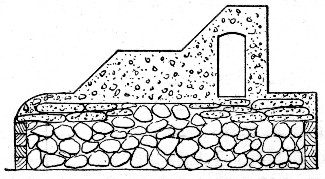

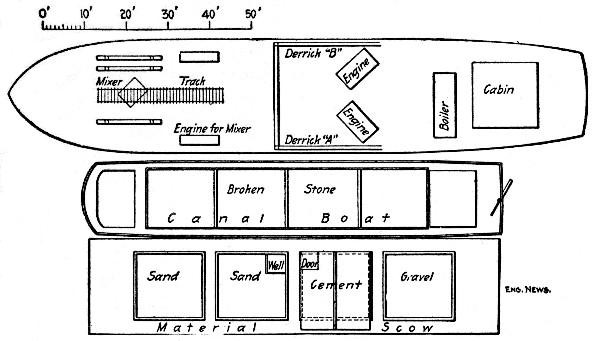

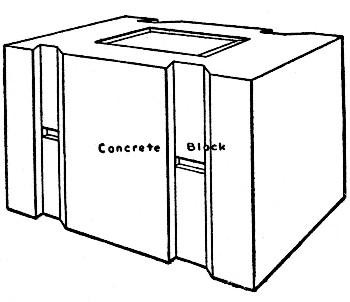

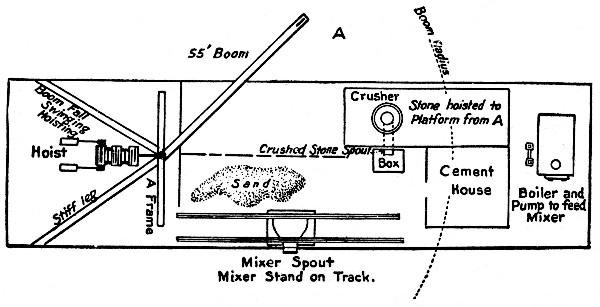

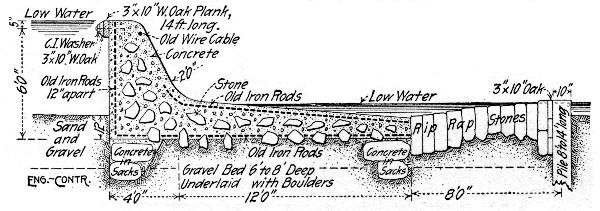

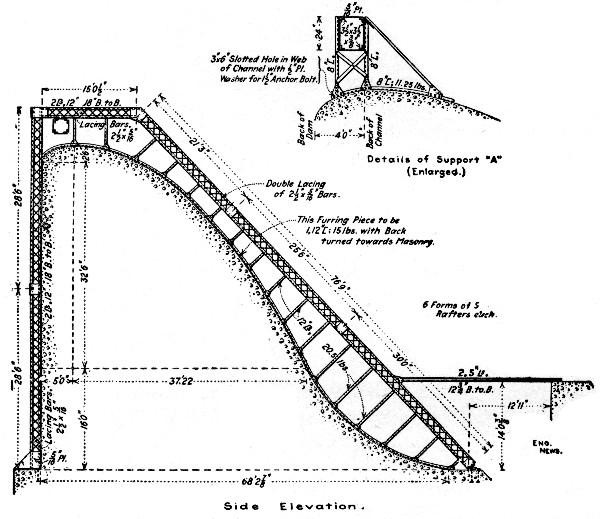

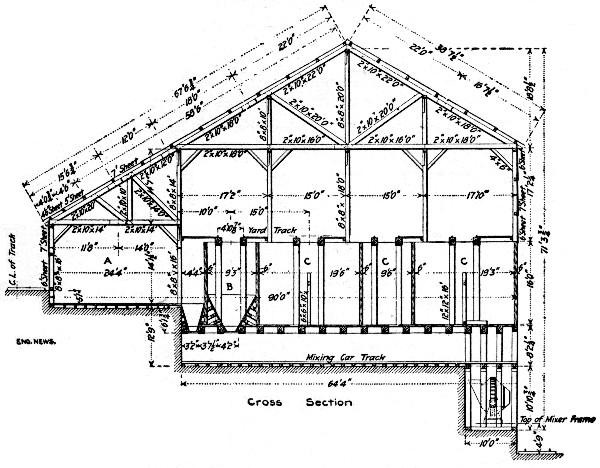

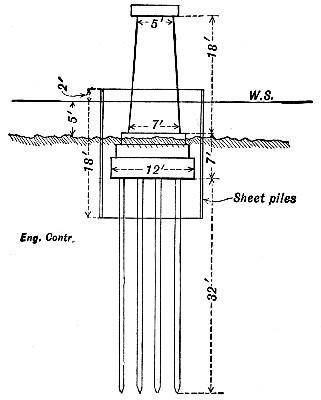

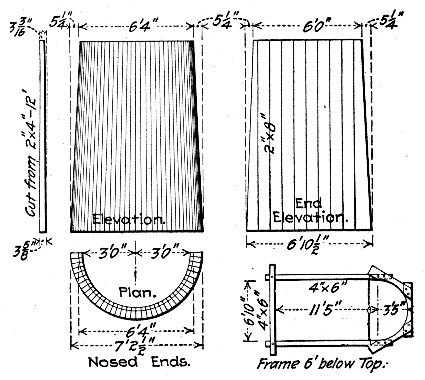

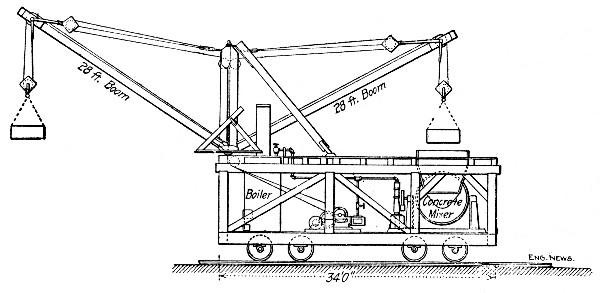

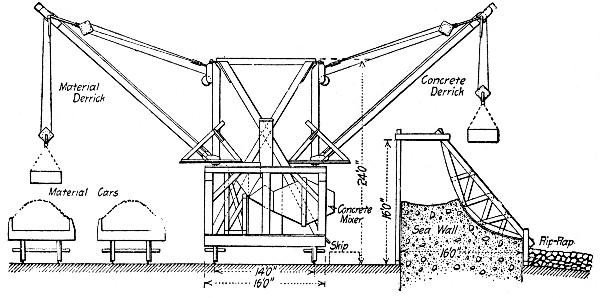

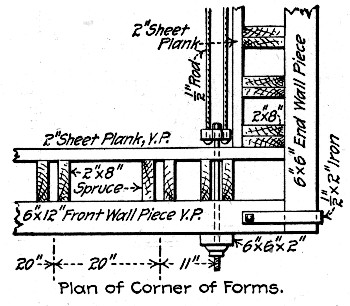

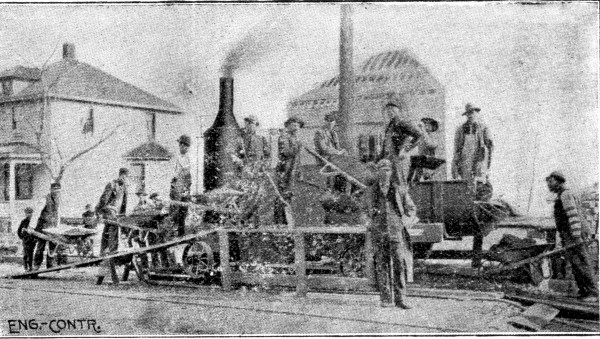

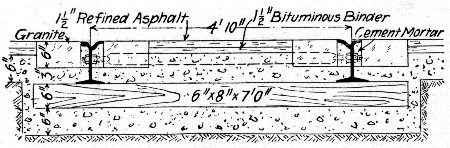

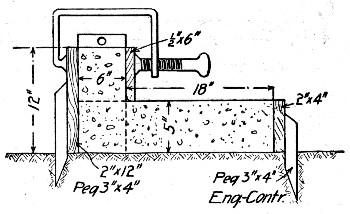

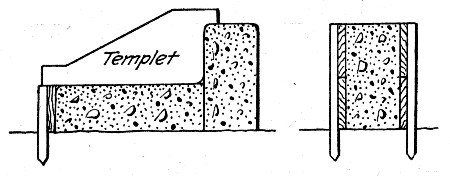

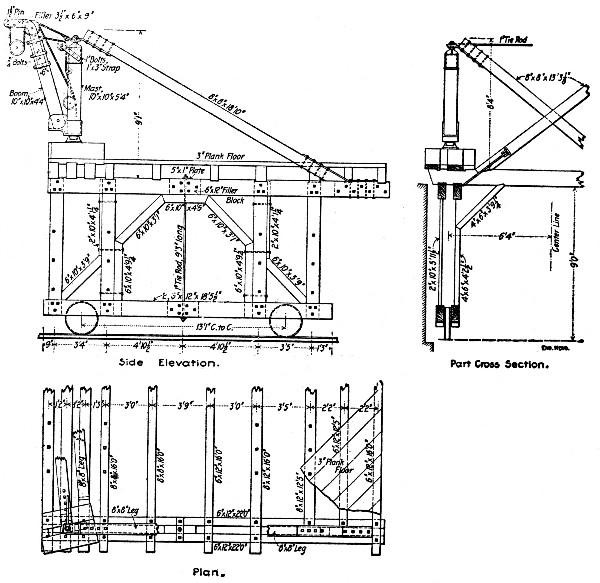

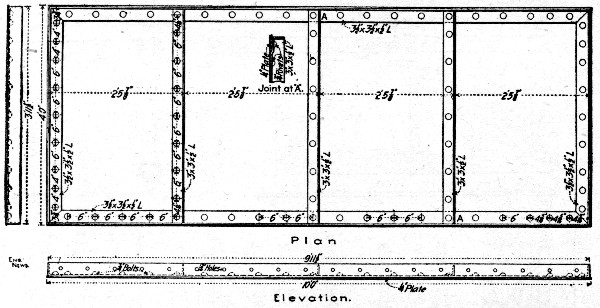

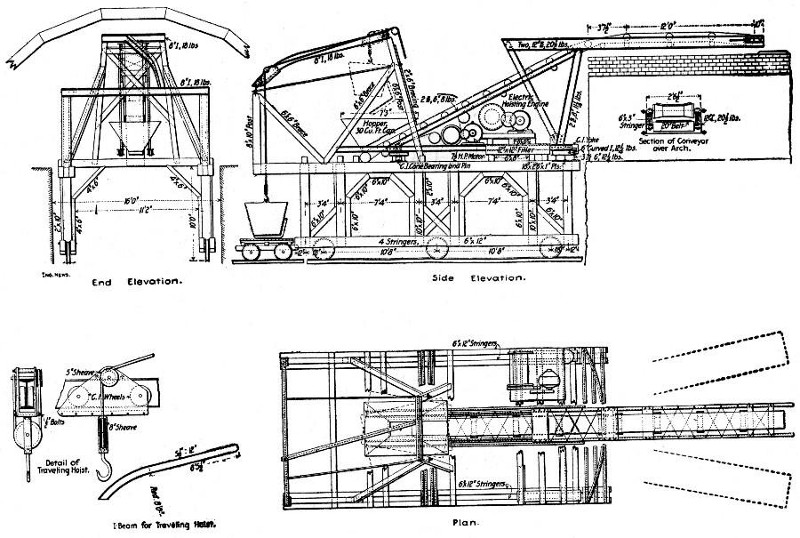

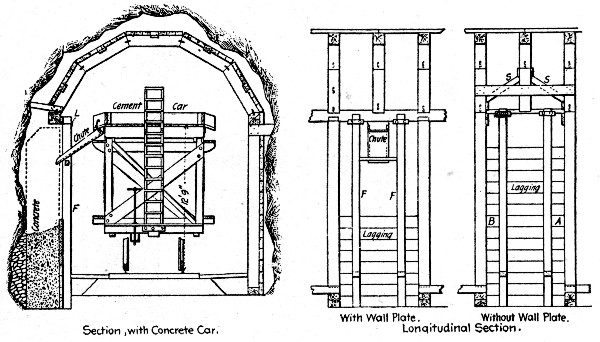

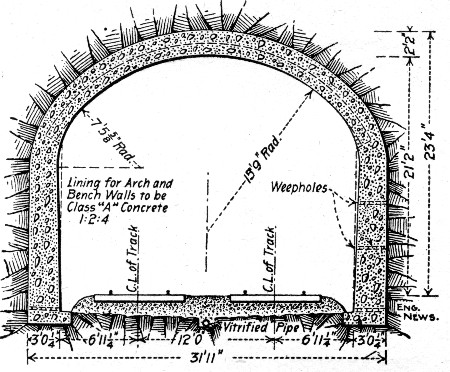

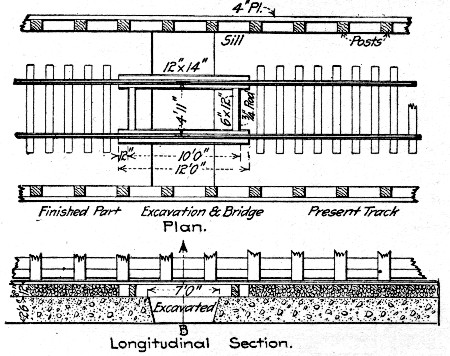

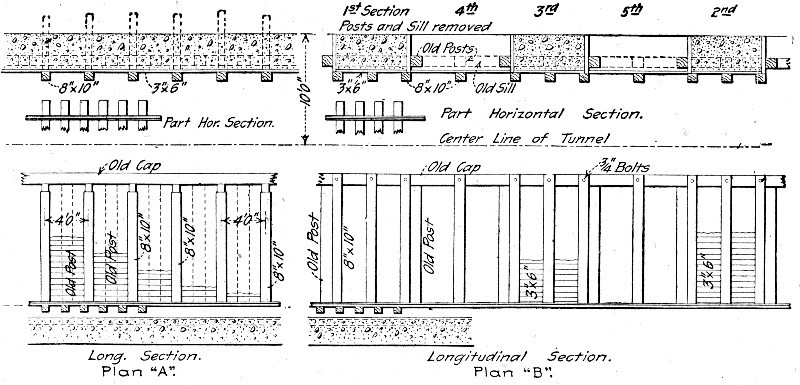

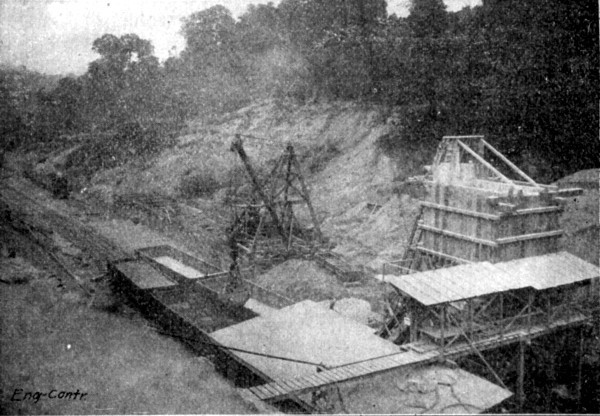

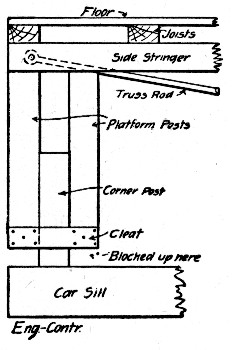

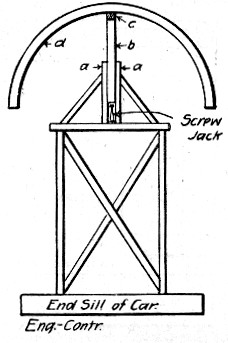

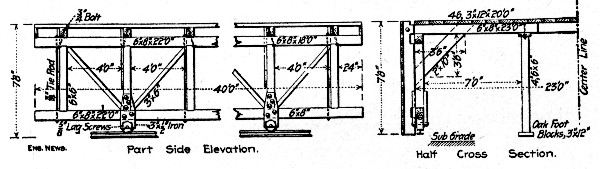

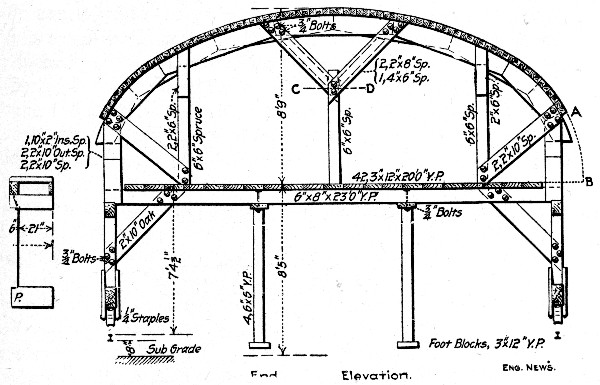

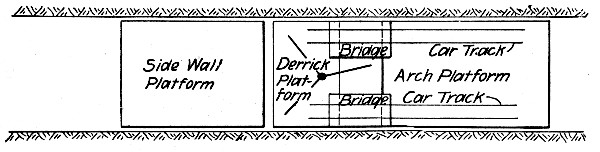

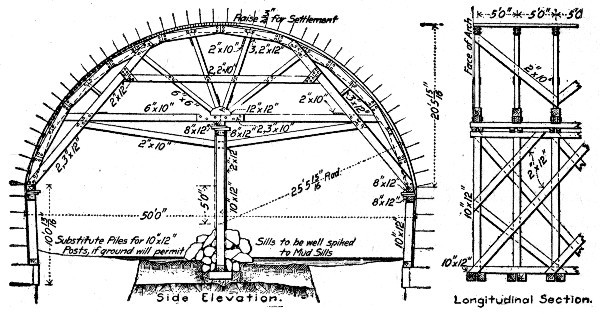

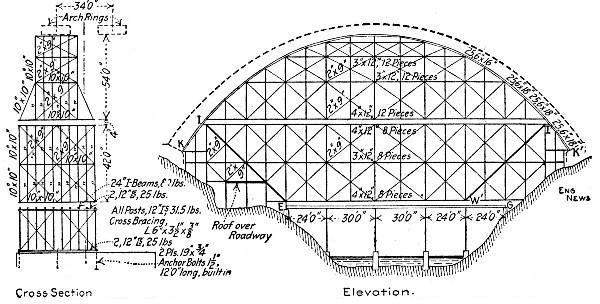

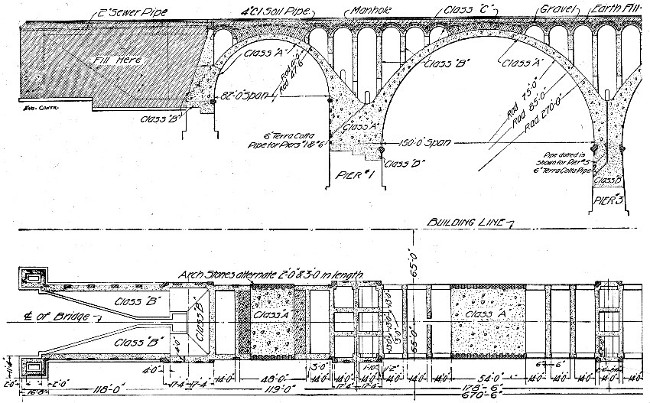

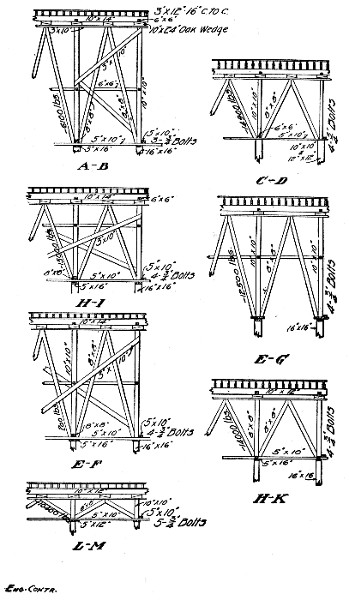

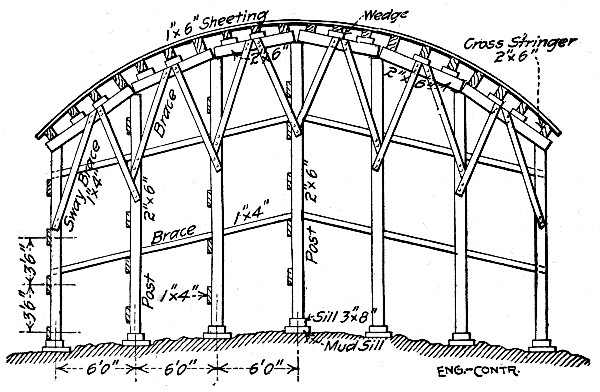

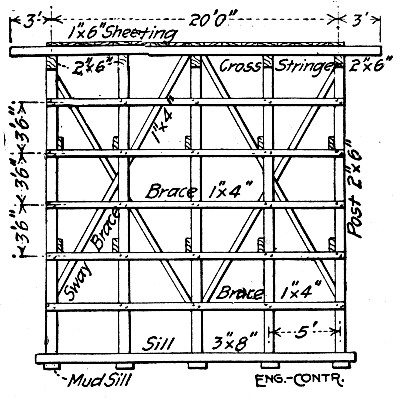

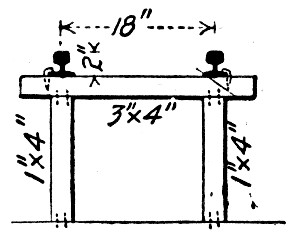

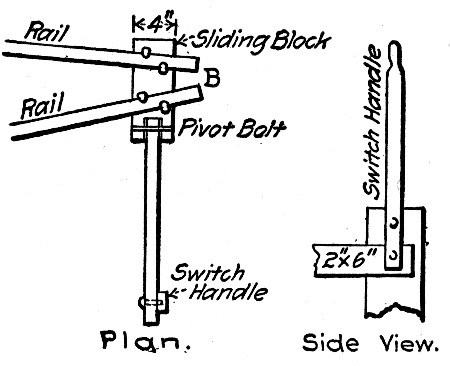

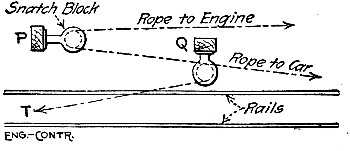

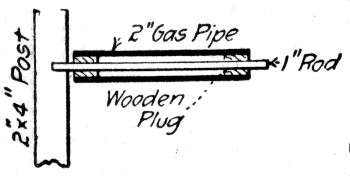

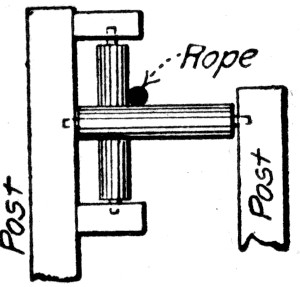

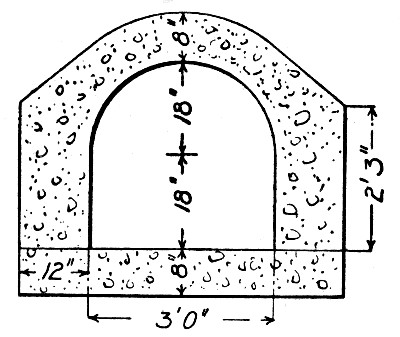

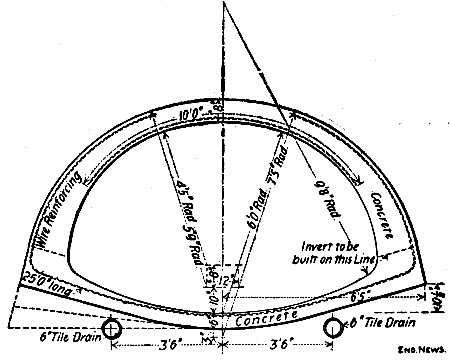

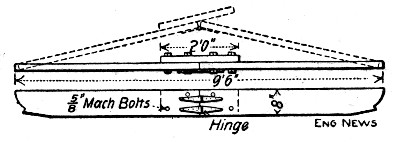

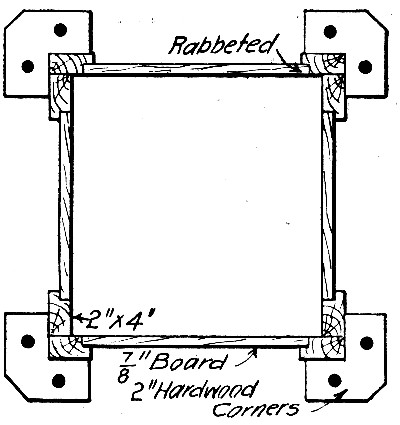

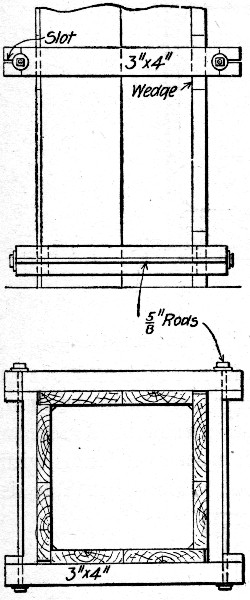

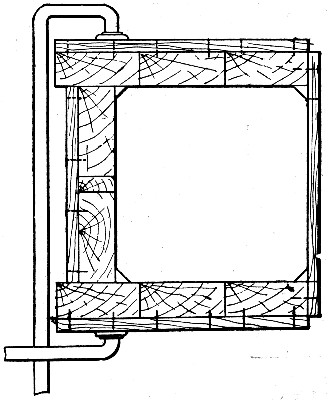

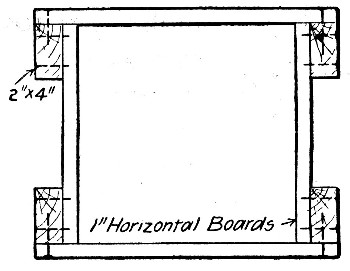

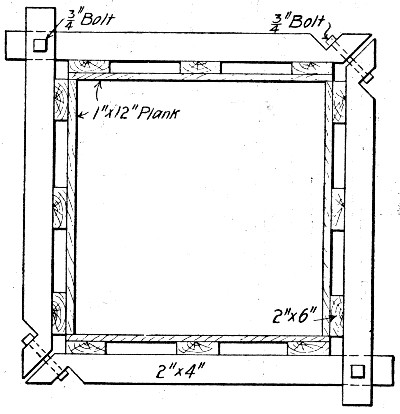

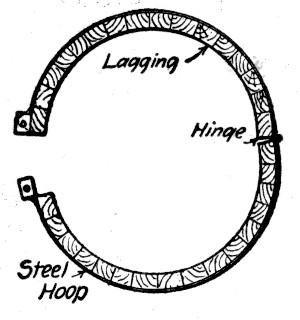

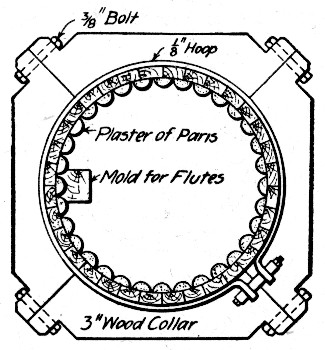

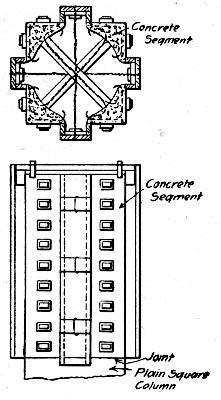

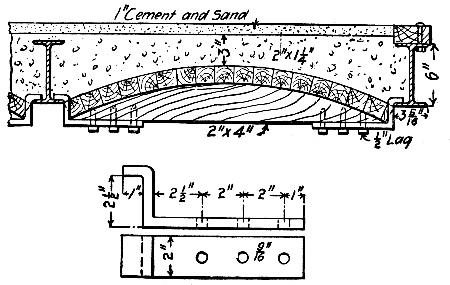

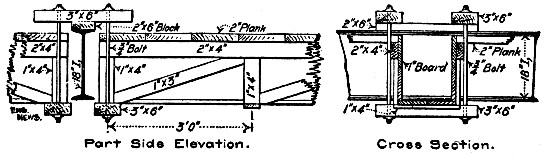

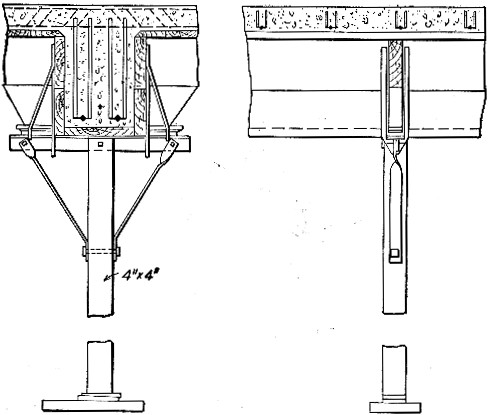

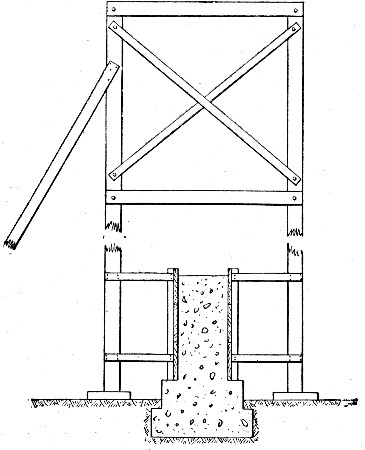

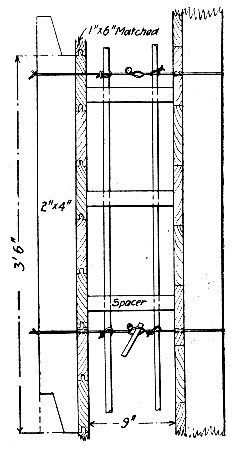

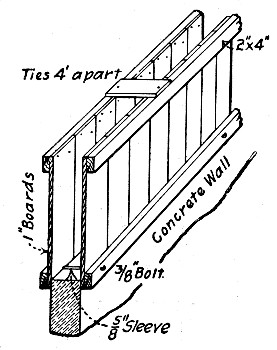

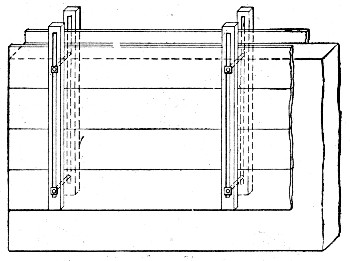

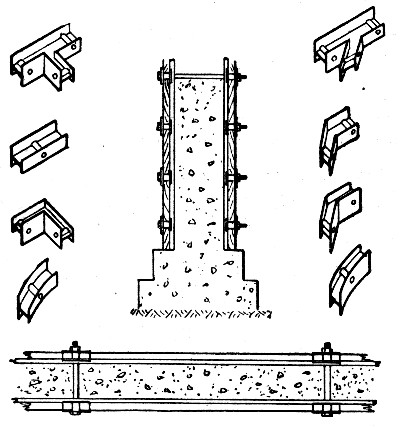

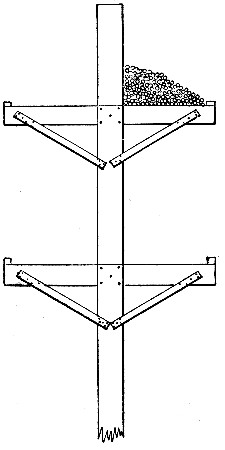

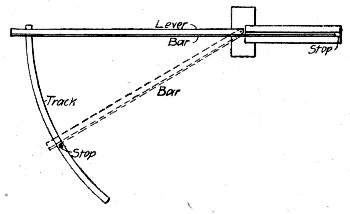

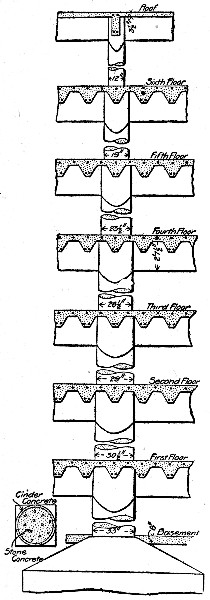

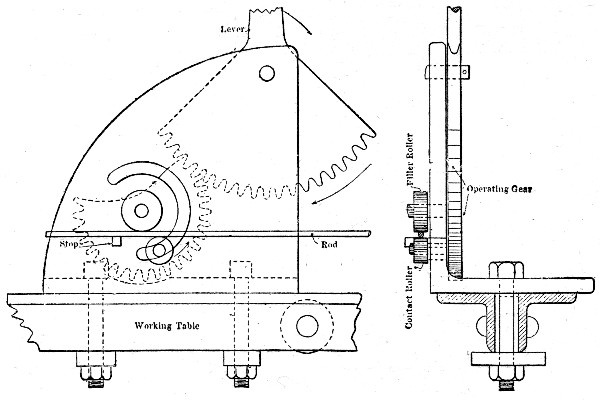

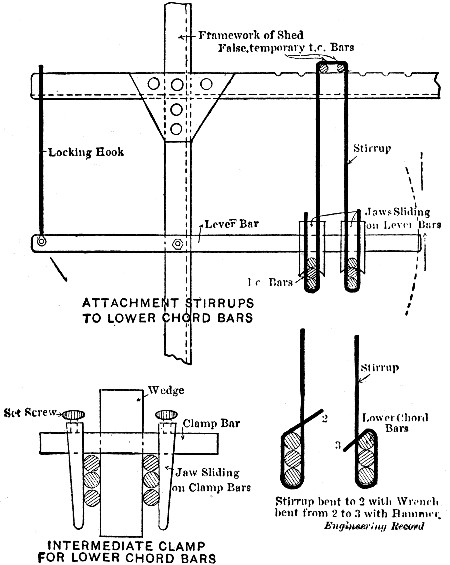

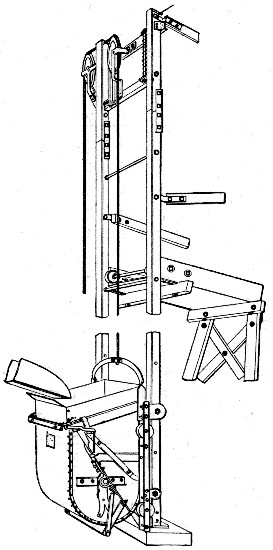

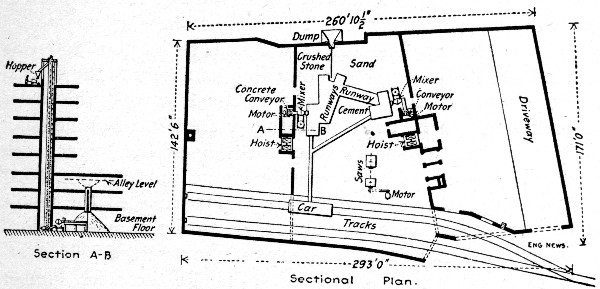

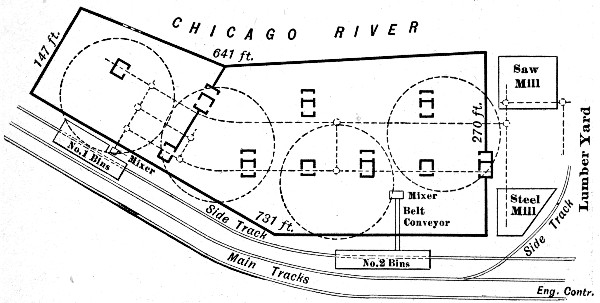

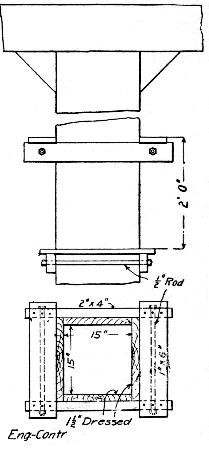

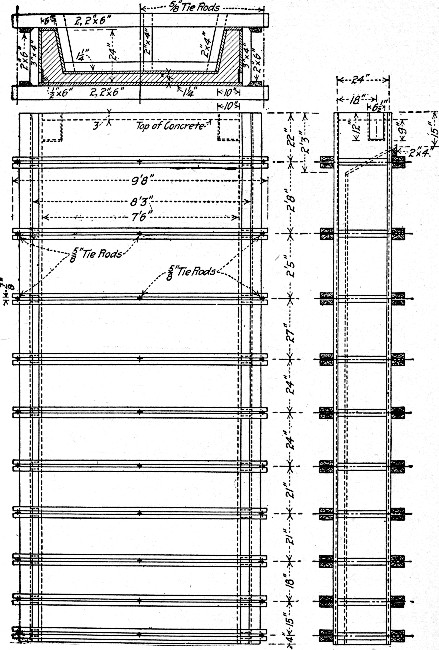

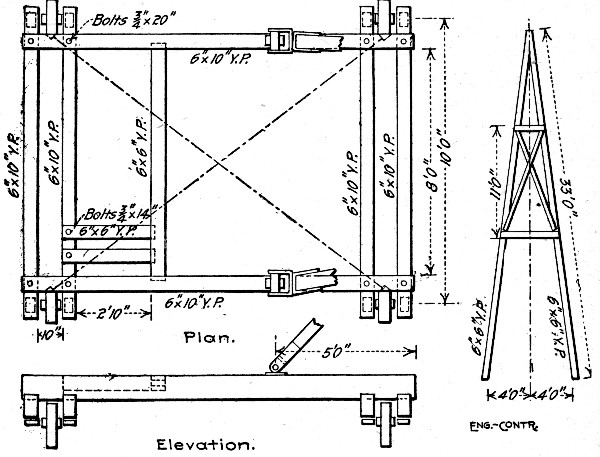

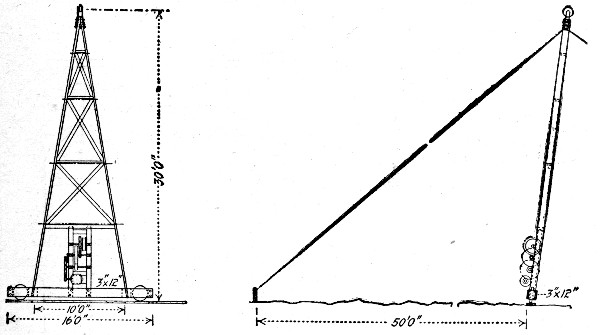

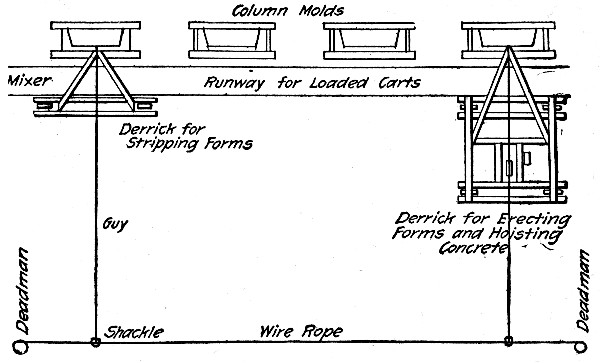

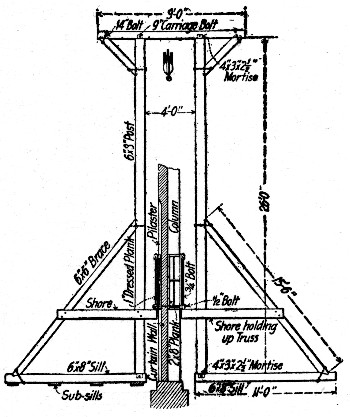

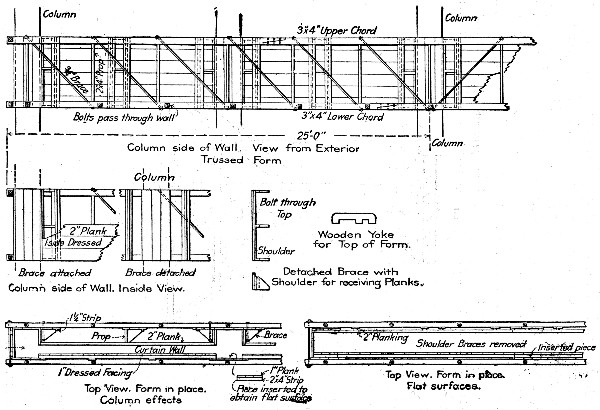

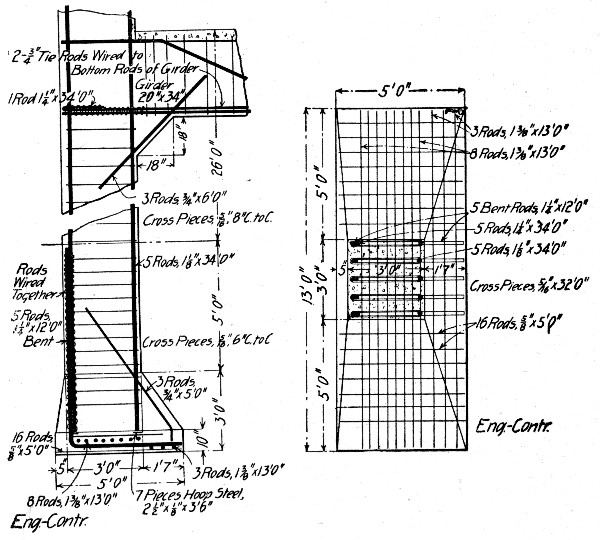

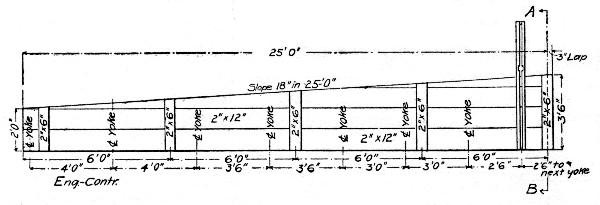

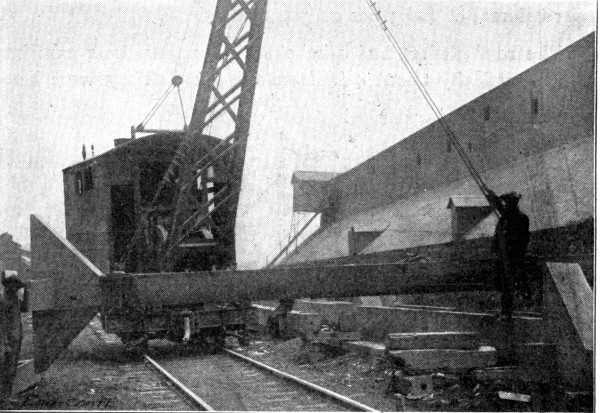

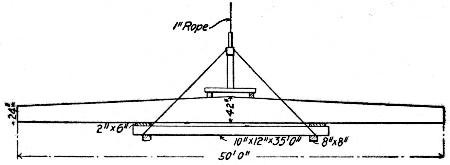

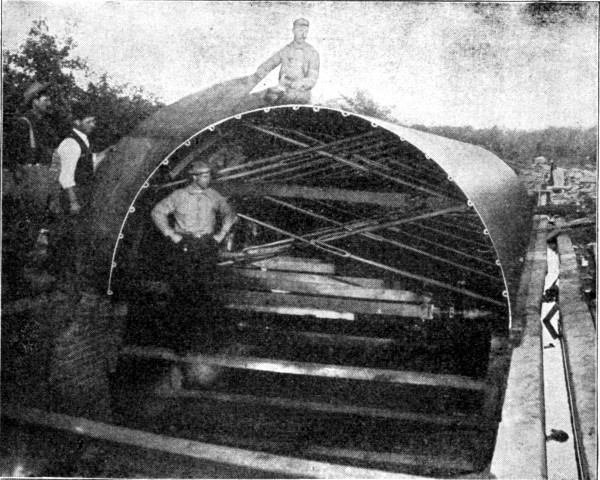

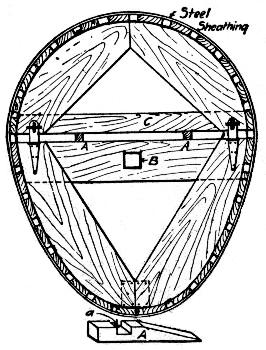

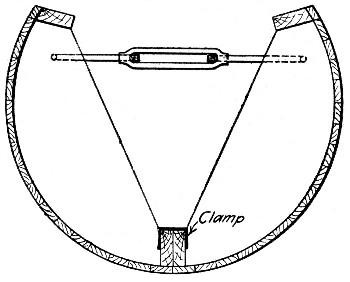

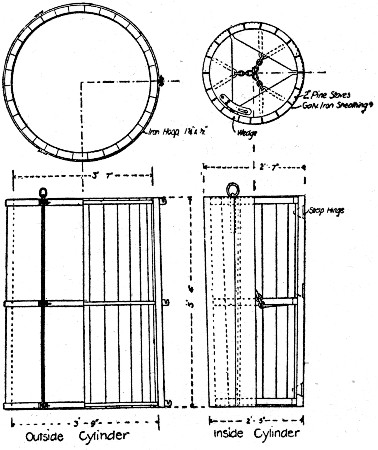

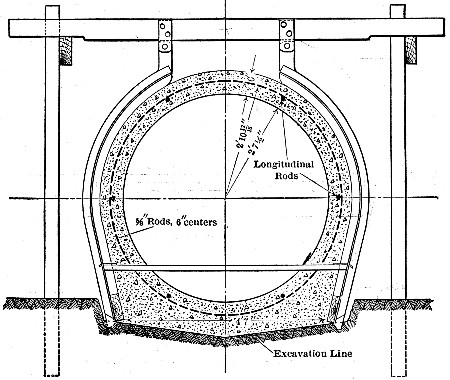

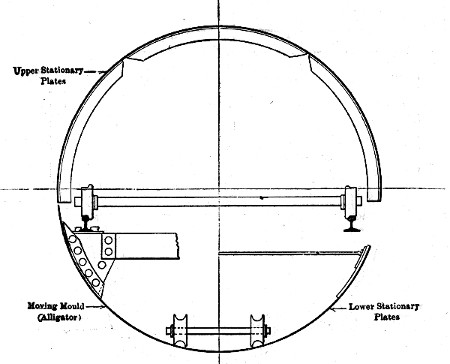

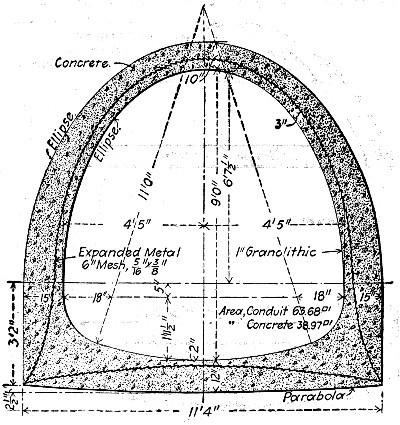

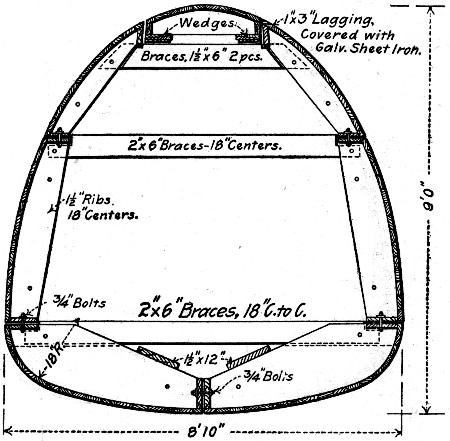

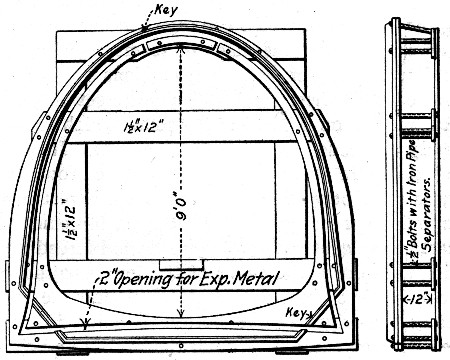

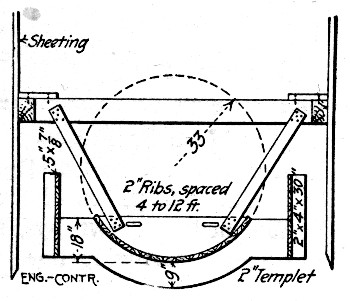

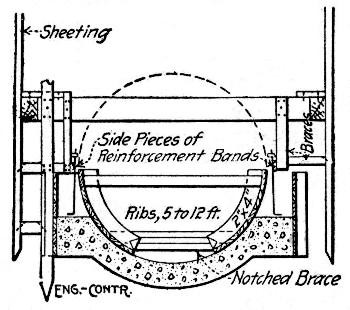

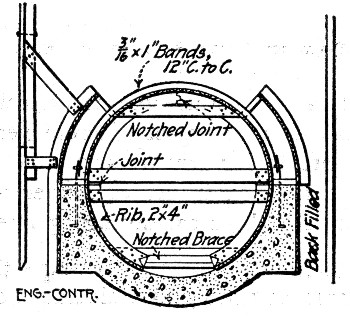

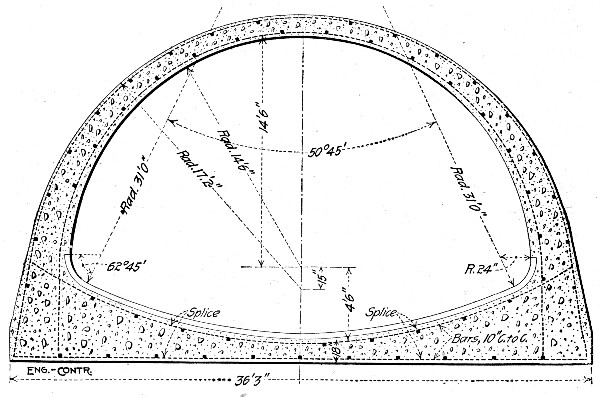

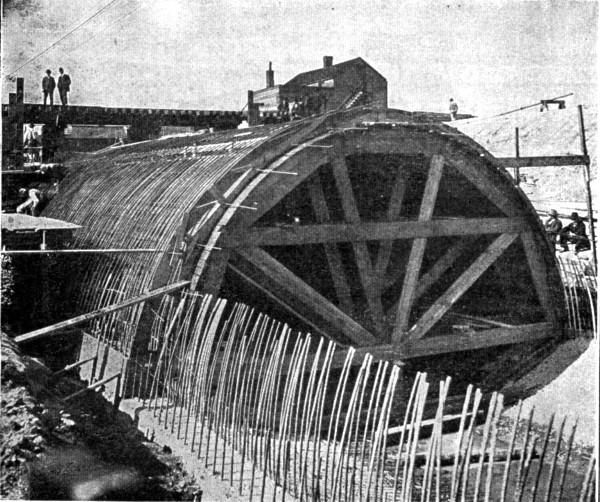

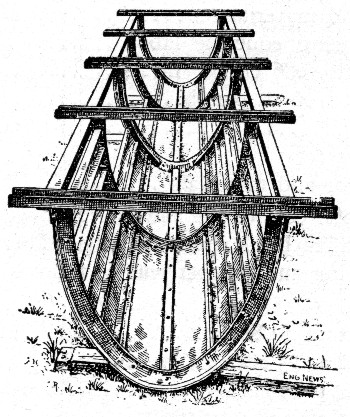

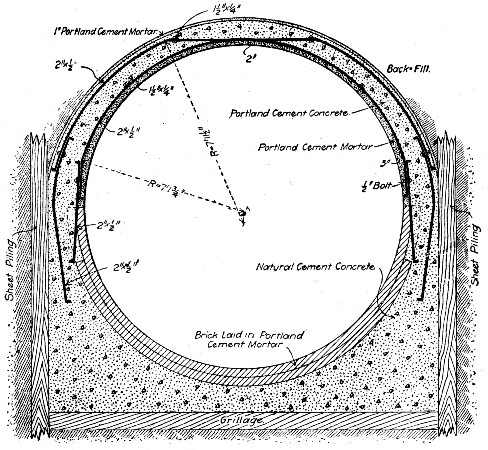

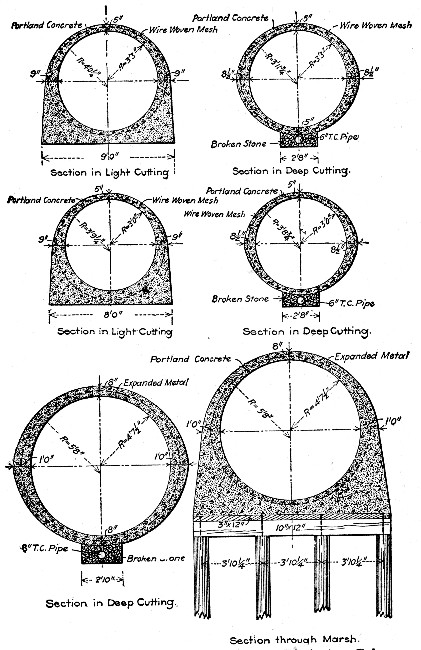

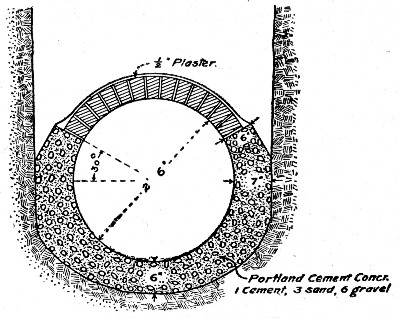

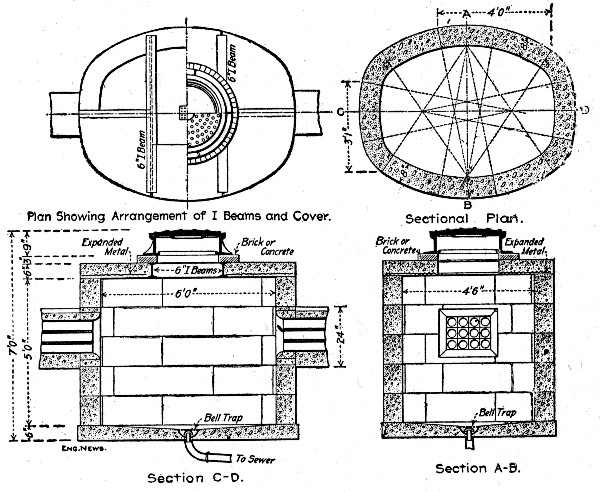

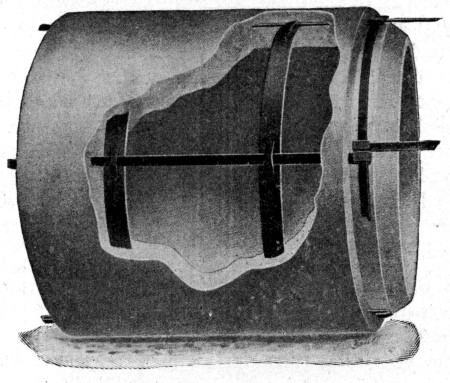

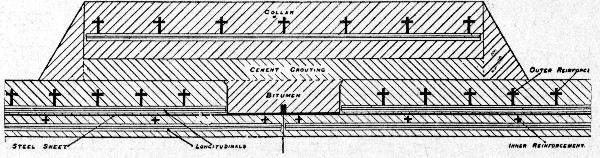

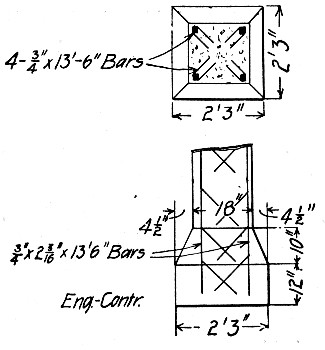

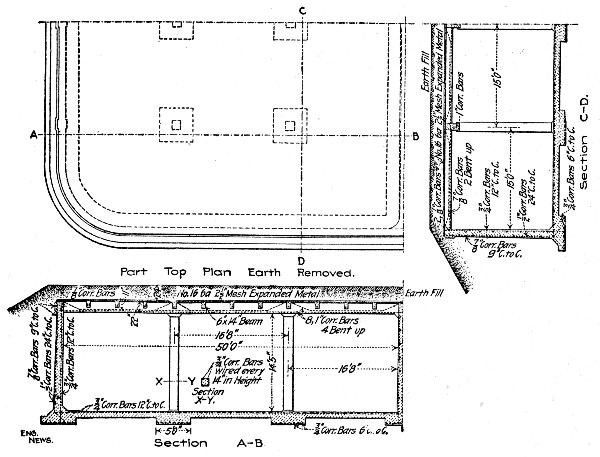

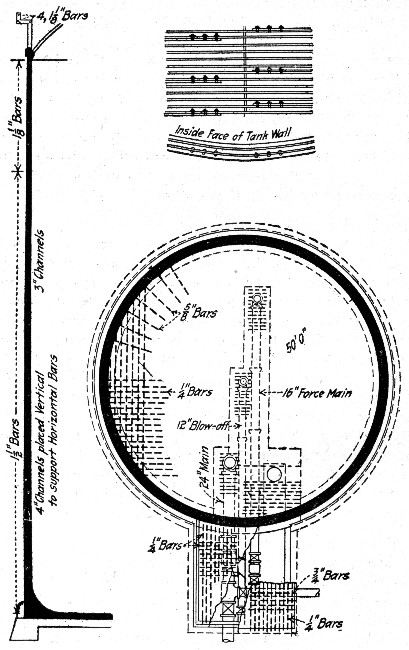

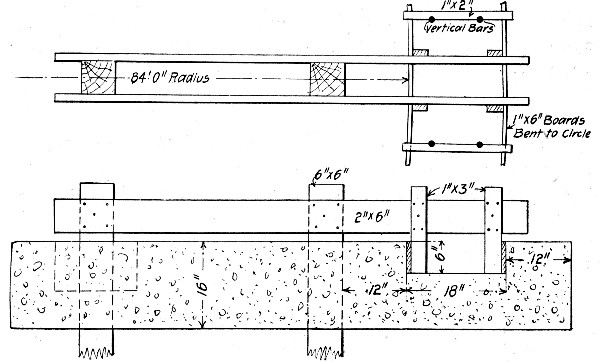

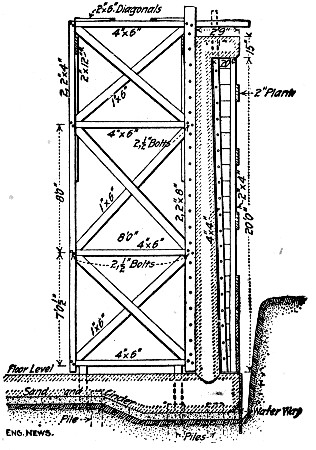

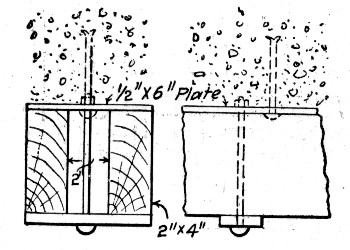

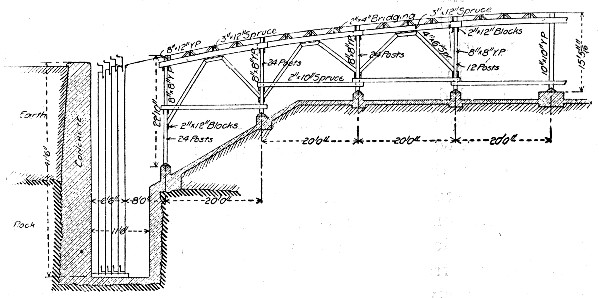

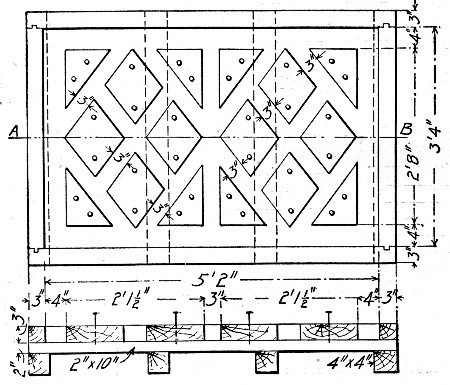

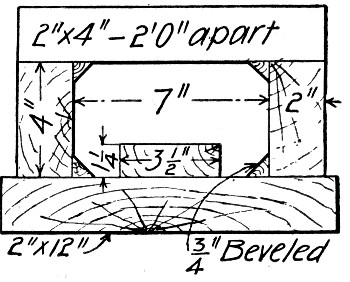

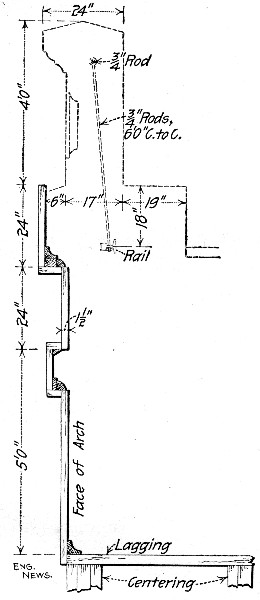

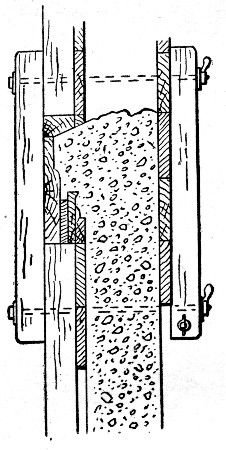

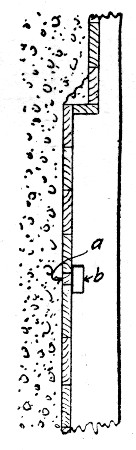

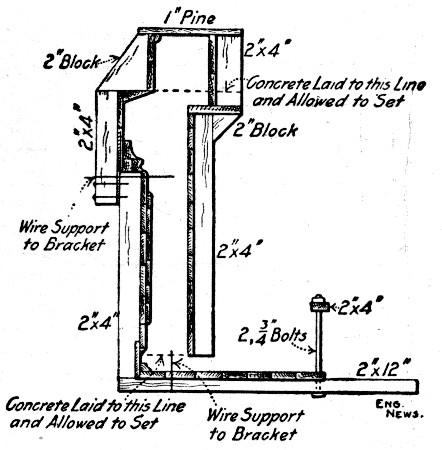

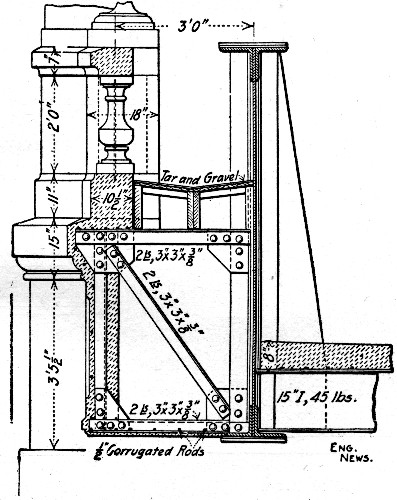

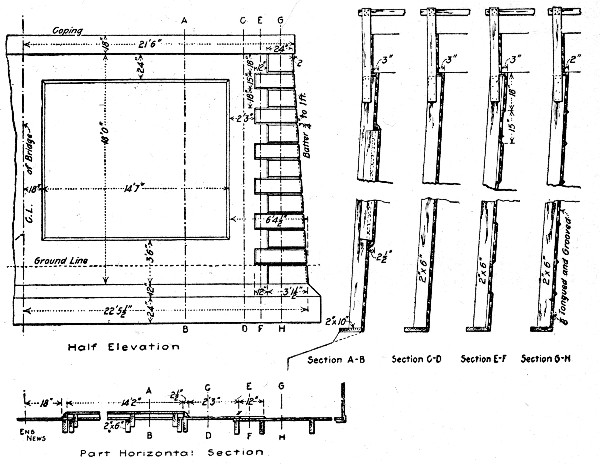

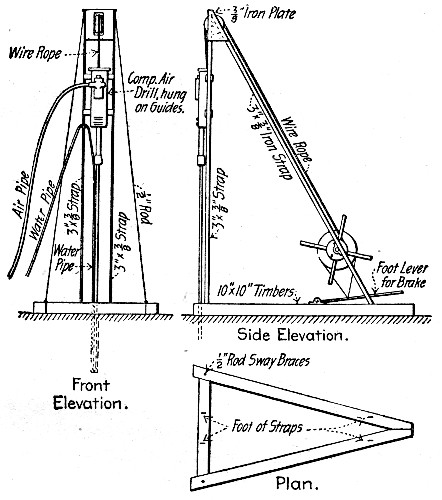

Washing With Sand Ejectors.—When large quantities of sand are to be washed use may be made of the sand ejector system, commonly employed in washing filter sand at large water filtration plants; water under pressure is required. In this system the dirty sand is delivered into a conical or pyramidal hopper, from the bottom of which it is drawn by an ejector and delivered mixed with water into a second similar hopper; here the water and dirt overflow the top of the hopper,[Pg 8] while the sand settles and is again ejected into a third hopper or to the stock pile or bins. The system may consist of anywhere from two to six hoppers. Figure 1 shows a two-hopper lay-out and Fig. 2 shows a four-hopper lay-out. In[Pg 9] the first plant the washed sand is delivered into bins so arranged, as will be seen, that the bins are virtually a third washing hopper. The clean sand is chuted from these bins directly into cars or wagons. In the second plant the clean sand is ejected into a trough which leads it into buckets handled by a derrick. The details of one of the washing hoppers for the plant shown by Fig. 1 are illustrated by Fig. 3.

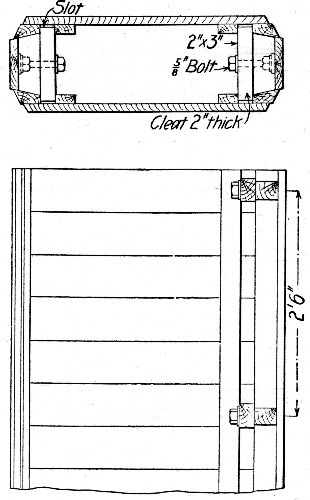

Fig. 3.—Details of Washing Hopper and Ejector for Plant

Shown by Fig. 1.

Fig. 3.—Details of Washing Hopper and Ejector for Plant

Shown by Fig. 1.

At filter plants the dirty sand is delivered mixed with water to the first hopper by means of ejectors stationed in the filters and discharging through pipes to the washers. When, as would usually be the case in contract work, the sand is delivered comparatively dry to the first hopper, this hopper must be provided with a sprinkler pipe to wet the sand. In studying the ejector washing plants illustrated it should be borne in mind that for concrete work they would not need to be of such permanent construction as for filter plants, the washers would be mounted on timber frames, underground piping would be done away with, etc.; at best, however, such plants are expensive and will be warranted only when the amount of sand to be washed is large.

The usual assumption of water-works engineers is that the volume of water required for washing filter sand is 15 times the volume of the sand washed. At the Albany, N. Y., filters the sand passes through five ejectors at the rate of 3 to 5 cu.[Pg 10] yds. per hour and takes 4,000 gallons of water per cubic yard. One man shovels sand into the washer and two take it away. Based on an output of 32 cu. yds. in 10 hours, Mr. Allen Hazen estimates the cost of washing as follows:

| 3 men, at $2 per day | $6.00 |

| 110,000 gallons of water, at $0.05 | 5.50 |

| ——— | |

| Total, 32 cu. yds., at 36 cts. | $11.50 |

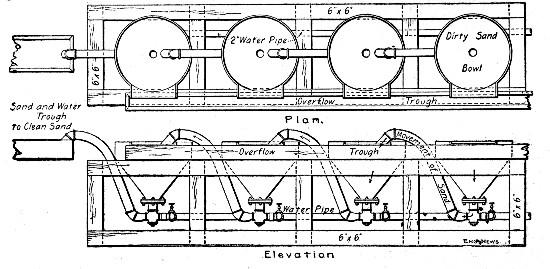

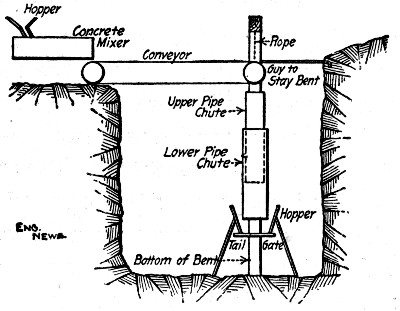

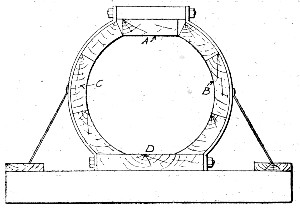

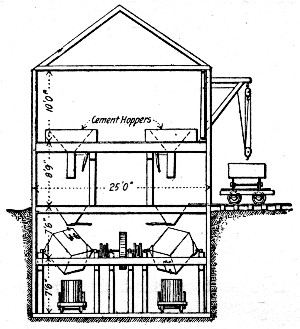

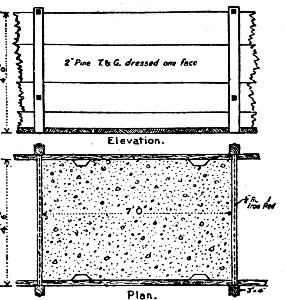

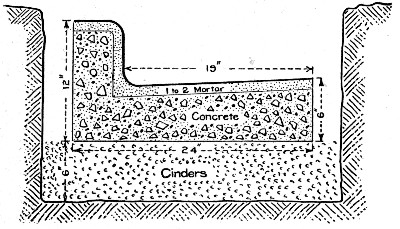

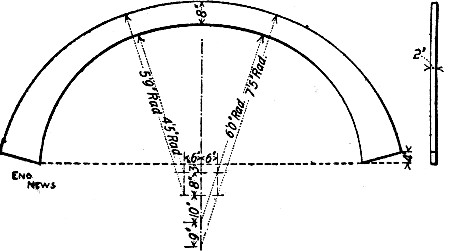

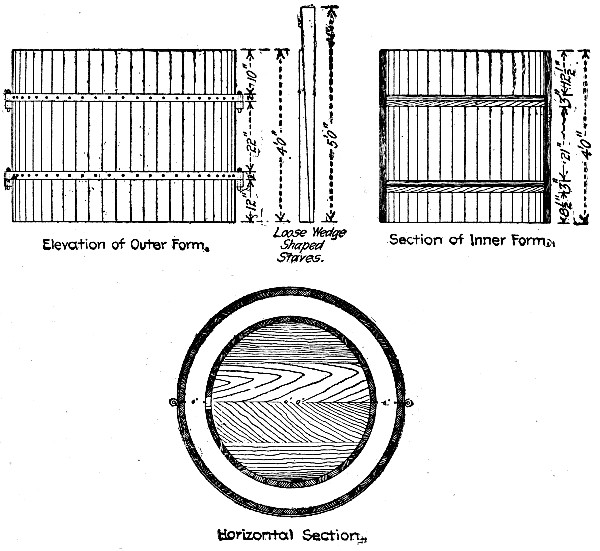

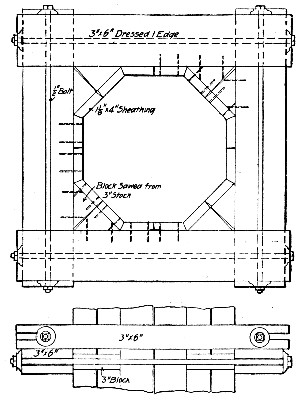

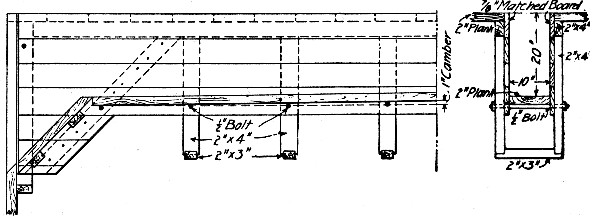

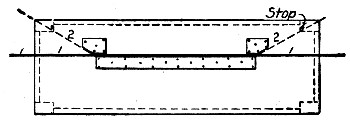

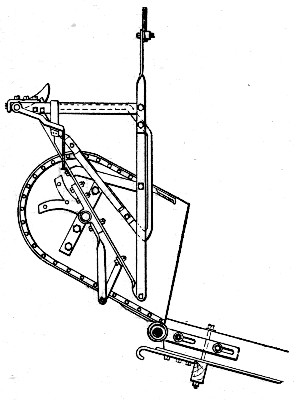

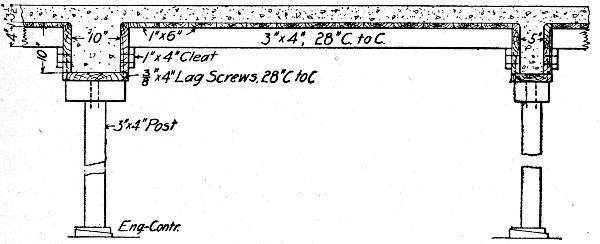

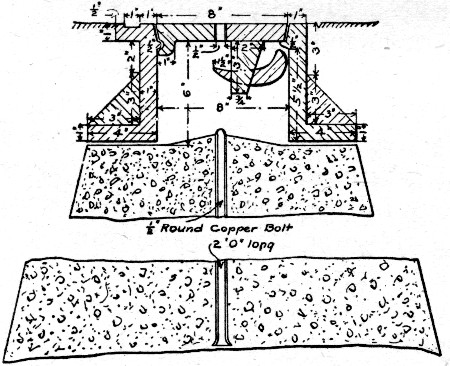

Washing With Tank Washers.—Figure 4 shows a sand washer used in constructing a concrete lock at Springdale, Pa., in the United States government improvement work on the Allegheny river. The device consisted of a circular tank 9 ft. in diameter and 7 ft. high, provided with a sloping false bottom perforated with 1-in. holes, through which water was forced as indicated. A 7½×5×6-in. pump with a 3-in. discharge pipe was used to force water into the tank, and the rotating paddles were operated by a 7 h.p. engine. This apparatus washed a batch of 14 cu. yds. in from 1 to 2 hours at a cost of 7 cts. per cubic yard. The sand contained much fine coal and silt. The above data are given by Mr. W. H. Roper.

Fig. 4.—Details of Tank Washer Used at Springdale, Pa.

Fig. 4.—Details of Tank Washer Used at Springdale, Pa.

Fig. 5.—Details of Tank Washer Used at Yonkers, N. Y.

Fig. 5.—Details of Tank Washer Used at Yonkers, N. Y.

Fig. 6.—Details of Rotating Tank Sand Washer Used at

Hudson, N. Y.

Fig. 6.—Details of Rotating Tank Sand Washer Used at

Hudson, N. Y.

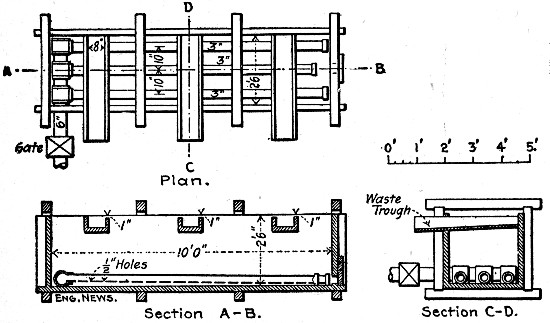

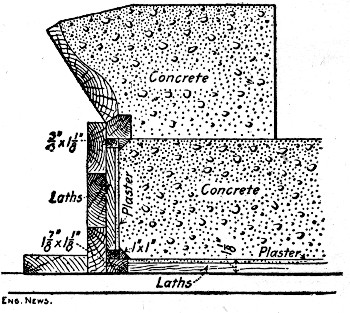

Another form of tank washer, designed by Mr. Allen Hazen, for washing bank sand at Yonkers, N. Y., is shown by Fig. 5. This apparatus consisted of a 10×2½×2½ ft. wooden box, with a 6-in. pipe entering one end at the bottom and there[Pg 11] branching into three 3-in. pipes, extending along the bottom and capped at the ends. The undersides of the 3-in. pipes were pierced with ½-in. holes 6 ins. apart, through which water under pressure was discharged into the box. Sand was shoveled into the box at one end and the upward currents of water raised the fine and dirty particles until they escaped through the waste troughs. When the box became filled with sand a sliding door at one end was opened and the batch discharged. The operation was continuous as long as sand was shoveled into the box; by manipulating the door the sand could be made to run out with a very small percentage of[Pg 12] water. Sand containing 7 per cent of dirt was thus washed so that it contained only 0.6 per cent dirt. The washer handled 200 cu. yds. of sand in 10 hours. The above data are given by F. H. Stephenson.

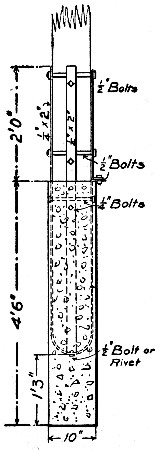

A somewhat more elaborate form of tank washer than either of those described is shown by Fig. 6. This apparatus was used by Mr. Geo. A. Soper for washing filter sand at Hudson, N. Y. The dirty sand was shoveled into a sort of hopper, from which it was fed by a hose stream into an inclined cylinder, along which it traveled and was discharged into a wooden trough provided with a screw conveyor and closed at both ends. The water overflowing the sides of the trough carried away the dirt and the clean sand was delivered by the screw to the bucket elevator which hoisted it to a platform, from which it was taken by barrows to the stock pile. A 4-h.p. engine with a 5-h.p. boiler operated the cylinder, screw, elevator and pump. Four men operated the washer and handled 32 cu. yds. of sand per day; with wages at $1.50 the cost of washing was 20 cts. per cubic yard.

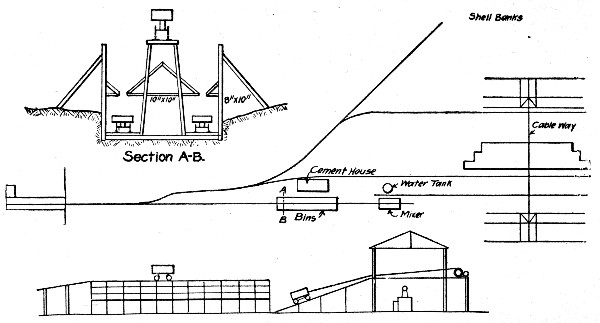

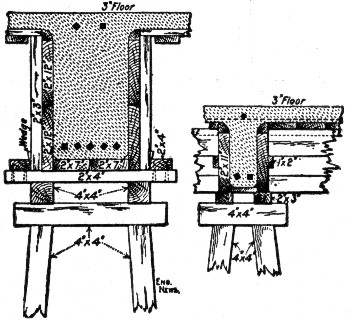

Fig. 7.—Arrangement of Sand Washing Plant at Lynchburg,

Va.

Fig. 7.—Arrangement of Sand Washing Plant at Lynchburg,

Va.

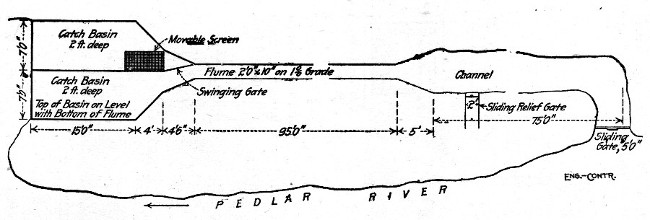

In constructing a concrete block dam at Lynchburg, Va., sand containing from 15 to 30 per cent. of loam, clay and[Pg 13] vegetable matter was washed to a cleanliness of 2 to 5 per cent of such matter by the device shown by Fig. 7. A small creek was diverted, as shown, into a wooden flume terminating in two sand tanks; by means of the swinging gate the flow was passed through either tank as desired. The sand was hauled by wagon and shoveled into the upper end of the flume; the current carried it down into one of the tanks washing the dirt loose and carrying it off with the overflow over the end of the tank while the sand settled in the tank. When one tank was full the flow was diverted into the other tank and the sand in the first tank was shoveled out, loaded into wagons, and hauled to the stock pile. As built this washer handled about 30 cu. yds. of sand per 10-hour day, but the tanks were built too small for the flume, which could readily handle 75 cu. yds. per day with no larger working force. This force consisted of three men at $1.50 per day, making the cost, for a 30 cu. yd. output, 15 cts. per cu. yd. for washing.

None of the figures given above includes the cost of handling the sand to and from the washer. When this involves much extra loading and hauling, it amounts to a considerable expense, and in any plan for washing sand the contractor should figure, with exceeding care, the extra handling due to the necessity of washing.

The aggregates commonly used in making concrete are broken or crushed stone, gravel, slag and cinders. Slag and cinders make a concrete that weighs considerably less than stone or gravel mixtures, and being the products of combustion are commonly supposed to make a specially fire resisting concrete; their use is, therefore, confined very closely to fireproof building work and, in fact, to floor construction for such buildings. Slag and cinder concretes are for this reason given minor consideration in this volume.

BROKEN STONE.—Stone produced by crushing any of the harder and tougher varieties of rock is suitable for concrete. Perhaps the best stone is produced by crushing trap rock. Crushed trap besides being hard and tough is angular and has an excellent fracture surface for holding cement; it also withstands heat better than most stone. Next to[Pg 14] trap the hard, tough, crystalline limestones make perhaps the best all around concrete material; cement adheres to limestone better than to any other rock. Limestone, however, calcines when subjected to fire and is, therefore, objected to by many engineers for building construction. The harder and denser sandstones, mica-schists, granites and syanites make good stone for concrete and occasionally shale and slate may be used.

GRAVEL.—Gravel makes one of the best possible aggregates for concrete. The conditions under which gravel is produced by nature make it reasonably certain that only the tougher and harder rocks enter into its composition; the rounded shapes of the component particles permit gravel to be more closely tamped than broken stone and give less danger of voids from bridging; the mixture is also generally a fairly well balanced composition of fine and coarse particles. The surfaces of the particles being generally smooth give perhaps a poorer bond with the cement than most broken stone. In the matter of strength the most recent tests show that there is very little choice between gravel and broken stone concrete.

SLAG AND CINDERS.—The slag used for concrete aggregate is iron blast furnace slag crushed to proper size. Cinders for aggregate are steam boiler cinders; they are best with the fine ashes screened out and should not contain more than 15 per cent. of unburned coal.

BALANCED AGGREGATE.—With the aggregate, as with the sand for concrete, the best results, other things being equal, will be secured by using a well-balanced mixture of coarse and fine particles. Usually the product of a rock crusher is fairly well balanced except for the very fine material. There is nearly always a deficiency of this, which, as explained in a succeeding section, has to be supplied by adding sand. Usually, also, the engineer accepts the crusher product coarser than screenings as being well enough balanced for concrete work, but this is not always the case. Engineers occasionally demand an artificial mixture of varying proportions of different size stones and may even go so far as to require gravel to be screened and reproportioned. This[Pg 15] artificial grading of the aggregate adds to the cost of the concrete in some proportion which must be determined for each individual case.

SIZE OF AGGREGATE.—The size of aggregate to be used depends upon the massiveness of the structure, its purpose, and whether or not it is reinforced. It is seldom that aggregate larger than will pass a 3-in. ring is used and this only in very massive work. The more usual size is 2½ ins. For reinforced concrete 1¼ ins. is about the maximum size allowed and in building work 1-in. aggregate is most commonly used. Same constructors use no aggregate larger than ¾ in. in reinforced building work, and others require that for that portion of the concrete coming directly in contact with the reinforcement the aggregate shall not exceed ¼ to ½ in. The great bulk of concrete work is done with aggregate smaller than 2 ins., and as a general thing where the massiveness of the structure will allow of much larger sizes it will be more economic to use rubble concrete. (See Chapter VI.)

COST OF AGGREGATE.—The locality in which the work is done determines the cost of the aggregate. Concerns producing broken stone or screened and washed gravel for concrete are to be found within shipping distance in most sections of the country so that these materials may be purchased in any amount desired. The cost will then be the market price of the material f. o. b. cars at plant plus the freight rates and the cost of unloading and haulage to the stock piles. If the contractor uses a local stone or gravel the aggregate cost will be, for stone the costs of quarrying and crushing and transportation, and, for gravel, the cost of excavation, screening, washing and transportation.

SCREENED OR CRUSHER-RUN STONE FOR CONCRETE.—Formerly engineers almost universally demanded that broken stone for concrete should have all the finer particles screened out. This practice has been modified to some considerable extent in recent years by using all the crusher product both coarse and fine, or, as it is commonly expressed, by using run-of-crusher stone. The comparative merits of screened and crusher-run stone for concrete work are questions[Pg 16] of comparative economy and convenience. The fine stone dust and chips produced in crushing stone are not, as was once thought, deleterious; they simply take the place of so much of the sand which would, were the stone screened, be required to balance the sand and stone mixture. It is seldom that the proportion of chips and dust produced in crushing stone is large enough to replace the sand constituent entirely; some sand has nearly always to be added to run-of-crusher stone and it is in determining the amount of this addition that uncertainty lies. The proportions of dust and chips in crushed stone vary with the kind of stone and with the kind of crusher used. Furthermore, when run-of-crusher stone is chuted from the crusher into a bin or pile the screenings and the coarse stones segregate. Examination of a crusher-run stone pile will show a cone-shaped heart of fine material enclosed by a shell of coarser stone, consequently when this pile of stone is taken from to make concrete a uniform mixture of fine and coarse particles is not secured, the material taken from the outside of the pile will be mostly coarse and that from the inside mostly fine. This segregation combined with the natural variation in the crusher product makes the task of adding sand and producing a balanced sand and stone mixture one of extreme uncertainty and some difficulty unless considerable expenditure is made in testing and reproportioning. When the product of the crusher is screened the task of proportioning the sand to the stone is a straightforward operation, and the screened out chips and dust can be used as a portion of the sand if desired. The only saving, then, in using crusher-run stone direct is the very small one of not having to screen out the fine material. The conclusion must be that the economy of unscreened stone for concrete is a very doubtful quantity, and that the risk of irregularity in unscreened stone mixtures is a serious one. The engineer's specifications will generally determine for the contractor whether he is to use screened or crusher-run stone, but these same specifications will not guarantee the regularity of the resulting concrete mixture; this will be the contractor's burden and if the engineer's inspection is rigid and the crusher-run product runs uneven for the reasons given above it will[Pg 17] be a burden of considerable expense. The contractor will do well to know his product or to know his man before bidding less or even as little on crusher-run as on screened stone concrete.

COST OF QUARRYING AND CRUSHING STONE.—The following examples of the cost of quarrying and crushing stone are fairly representative of the conditions which would prevail on ordinary contract work. In quarrying and crushing New Jersey trap rock with gyratory crushers the following was the cost of producing 200 cu. yds. per day:

| Per day. | Per cu. yd. | |

| 3 drillers at $2.75 | $ 8.25 | $0.041 |

| 3 helpers at $1.75 | 5.25 | 0.026 |

| 10 men barring out and sledging | 15.00 | 0.075 |

| 14 men loading carts | 21.00 | 0.105 |

| 4 cart horses | 6.00 | 0.030 |

| 2 cart drivers | 3.00 | 0.015 |

| 2 men dumping carts and feeding crusher | 3.00 | 0.015 |

| 1 fireman for drill boiler | 2.50 | 0.013 |

| 1 engineman for crusher | 3.00 | 0.015 |

| 1 blacksmith | 3.00 | 0.015 |

| 1 blacksmith helper | 2.00 | 0.010 |

| 1 foreman | 5.00 | 0.025 |

| 2 tons coal at $3.50 | 7.00 | 0.035 |

| 150 lbs. 40% dynamite at 15 cts. | 22.50 | 0.113 |

| ——— | ——— | |

| Total | $106.50 | $0.533 |

The quarry face worked was 12 to 18 ft., and the stone was crushed to 2-in. size. Owing to the seamy character of the rock it was broken by blasting into comparatively small pieces requiring very little sledging. The stone was loaded into one-horse dump carts, the driver taking one cart to the crusher while the other was being loaded. The haul was 100 ft. The carts were dumped into an inclined chute leading to a No. 5 Gates crusher. The stone was elevated by a bucket elevator and screened. All stone larger than 2 ins. was returned through a chute to a No. 3 Gates crusher for[Pg 18] recrushing. The cost given above does not include interest, depreciation, and repairs; these items would add about $8 to $10 more per day or 4 to 5 cts. per cubic yard.

In quarrying limestone, where the face of the quarry was only 5 to 6 ft. high, and where the amount of stripping was small, one steam drill was used. This drill received its steam from the same boiler that supplied the crusher engine. The drill averaged 60 ft. of hole drilled per 10-hr. day, but was poorly handled and frequently laid off for repairs. The cost of quarrying and crushing was as follows:

| 1 driller | $ 2.50 |

| 1 helper | 1.50 |

| 1 man stripping | 1.50 |

| 4 men quarrying | 6.00 |

| 1 blacksmith | 2.50 |

| ⅛ ton coal at $3 | 1.00 |

| Repairs to drill | .60 |

| Hose, drill steel and interest on plant | .90 |

| 24 lbs. dynamite | 3.60 |

| ——— | |

| Total | $20.10 |

| 1 engineman | $ 2.50 |

| 2 men feeding crusher | 3.50 |

| 6 men wheeling | 9.00 |

| 1 bin man | 1.50 |

| 1 general foreman | 3.00 |

| ⅓ ton coal at $3 | 1.00 |

| 1 gallon oil | .25 |

| Repairs to crusher | 1.00 |

| Repairs to engine and boiler | 1.00 |

| Interest on plant | 1.00 |

| ——— | |

| Total | $23.75 |

| Per day. | Per. cu. yd. | |

| Quarrying | $20.10 | $0.37 |

| Crushing | 23.75 | 0.39 |

| ——— | —— | |

| Total for 60 cu. yds. | $43.85 | $0.76 |

The "4 men quarrying" barred out and sledged the stone to sizes that would enter a 9×16-in. jaw crusher. The "6 men wheeling" delivered the stone in wheelbarrows to the crusher platform, the run plank being never longer than 150 ft. Two men fed the stone into the crusher, and a bin-man helped load the wagons from the bin, and kept tally of the loads. The stone was measured loose in the wagons, and it was found that the average load was 1½ cu. yds., weighing 2,400 lbs. per cu. yd. There were 40 wagon loads, or 60 cu. yds.[Pg 19] crushed per 10-hr. day, although on some days as high as 75 cu. yds. were crushed. The stone was screened through a rotary screen, 9 ft. long, having three sizes of openings, ½-in., 1¼-in. and 2¼-in. The output was 16% of the smallest size, 24% of the middle size, and 60% of the large size. All tailings over 2½ ins. in size were recrushed.

It will be noticed that the interest on the plant is quite an important item. This is due to the fact that, year in and year out, a quarrying and crushing plant seldom averages more than 100 days actually worked per year, and the total charge for interest must be distributed over these 100 days, and not over 300 days as is so commonly and erroneously done. The cost of stripping the earth off the rock is often considerably in excess of the above given cost, and each case must be estimated separately. Quarry rental or royalty is usually not in excess of 5 cts. per cu. yd., and frequently much less. The dynamite used was 40%, and the cost of electric exploders is included in the cost given. Where a higher quarry face is used the cost of drilling and the cost of explosives per cu. yd. is less. Exclusive of quarry rent and heavy stripping costs, a contractor should be able to quarry and crush limestone or sandstone for not more than 75 cts. per cu. yd., or 62 cts. per ton of 2,000 lbs., wages and conditions being as above given.

The labor cost of erecting bins and installing a 9×16 jaw crusher, elevator, etc., averages about $75, including hauling the plant two or three miles, and dismantling the plant when work is finished.

The following is a record of the cost of crushing stone and cobbles on four jobs at Newton, Mass., in 1891. On jobs A and B the stone was quarried and crushed; on jobs C and D cobblestones were crushed. A 9×15-in. Farrel-Marsondon crusher was used, stone being fed in by two laborers. A rotary screen having ½, 1 and 2½-in. openings delivered the stone into bins having four compartments, the last receiving the "tailings" which had failed to pass through the screen. The broken stone was measured in carts as they left the bin, but several cart loads were weighed, giving the following weights per cubic foot of broken stone:[Pg 20]

| —————Size.——————— | ||||

| ½-in. | 1-in. | 2½-ins. | Tailings. | |

| lbs. | lbs. | lbs. | lbs. | |

| Greenish trap rock, "A" | 95.8 | 84.3 | 88.3 | 91.0 |

| Conglomerate, "B" | 101.0 | 87.7 | 94.4 | .... |

| Cobblestones, "C" and "D" | 102.5 | 98.0 | 99.6 | .... |

A one-horse cart held 26 to 28 cu. ft. (average 1 cu. yd.) of broken stone; a two-horse cart, 40 to 42 cu. ft., at the crusher.

| ——————————Job.—————— | ||||

| A. | B. | C. | D. | |

| Hours run | 412 | 144 | 101 | 198 |

| Short tons per hour | 9.0 | 11.2 | 15.7 | 12.1 |

| Cu. yds. per hour | 7.7 | 8.9 | 11.8 | 9.0 |

| Per cent of tailings | 31.8 | 29.3 | 17.5 | 20.5 |

| Per cent of 2½-in. stone | 51.3 | 51.9 | 57.0 | 55.1 |

| Per cent of 1-in. stone | 10.2 | .... | .... | .... |

| Per cent of ½-in. stone or dust | 6.7 | 18.8 | 25.5 | 23.4 |

| ——————————Job.—————— | ||||

| A. | B. | C. | D. | |

| Explosives, coal for drill and repairs | $0.084 | $0.018 | .... | .... |

| Labor steam drilling | 0.092 | .... | .... | .... |

| Labor hand drilling | .... | 0.249 | .... | .... |

| Sharpening tools | 0.069 | 0.023 | .... | .... |

| Sledging stone for crusher | 0.279 | 0.420 | .... | .... |

| Loading carts | 0.098 | 0.127 | .... | $0.144 |

| Carting to crusher | 0.072 | 0.062 | $0.314 | 0.098 |

| Feeding crusher | 0.053 | 0.053 | 0.033 | 0.065 |

| Engineer of crusher | 0.031 | 0.038 | 0.029 | 0.036 |

| Coal for crusher | 0.079 | 0.050 | 0.047 | 0.044 |

| Repairs to crusher | 0.041 | .... | .... | 0.011 |

| Moving portable crusher | .... | 0.023 | .... | 0.019 |

| Watchman ($1.75 a day) | .... | 0.053 | 0.022 | 0.030 |

| ——— | ——— | ——— | ——— | |

| Total cost per cu. yd. | $0.898 | $1.116 | $0.445 | $0.447 |

| Total cost per short ton | 0.745 | 0.885 | 0.330 | 0.372 |

Note.—"A" was trap rock; "B" was conglomerate rock; "C" and "D" were trap and granite cobblestones. Common laborers on jobs "A" and "D" were paid $1.75 per 9-hr. day; on jobs "B" and "C," $1.50 per 9-hr. day; two-horse cart and driver, $5 per day; blacksmith, $2.50; engineer on crusher, $2 on job "A," $2.25 on "B," $2.00 on "C," $2.50 on "D"; steam driller received $3, and helper $1.75 a day; foreman, $3 a day. Coal was $5.25 per short ton. Forcite powder, 11⅓ cts. per lb.

For a full discussion of quarrying and crushing methods and costs and for descriptions of crushing machinery and plants the reader is referred to "Rock Excavation; Methods and Cost," by Halbert P. Gillette.

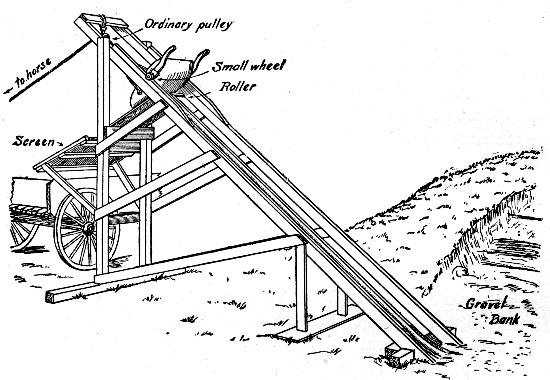

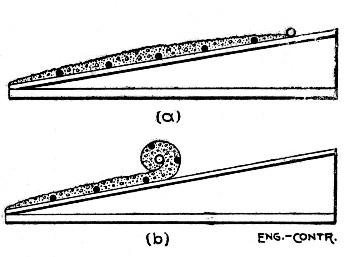

SCREENING AND WASHING GRAVEL.—Handwork is resorted to in screening gravel only when the amount to be screened is small and when it is simply required to separate the fine sand without sorting the coarser material into sizes. The gravel is shoveled against a portable inclined screen through which the sand drops while the pebbles slide down and accumulate at the bottom. The cost of screening by hand is the cost of shoveling the gravel against the screen divided by the number of cubic yards of saved material. In screening gravel for sand the richer the gravel is in fine material the cheaper will be the cost per cubic yard for screening; on the contrary in screening gravel for the pebbles the less sand there is in the gravel the cheaper will be the cost per cubic yard for screening. The cost of shoveling divided by the number of cubic yards shoveled is the cost of screening only when both the sand and the coarser material are saved. Tests made in the pit will enable the contractor to estimate how many cubic yards of gravel must be shoveled to get a cubic yard of sand or pebbles. An energetic man will shovel about 25 cu. yds. of gravel against a screen per 10-hour day and keep the screened material cleared away, providing no carrying is necessary.

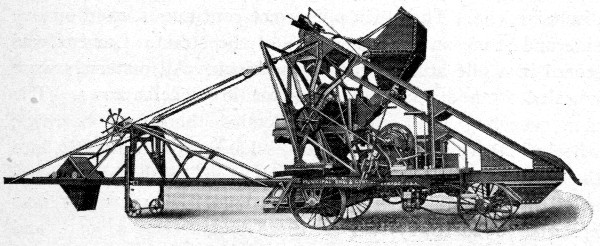

A mechanical arrangement capable of handling a considerably larger yardage of material is shown by Fig. 8. Two men and a team are required. The team is attached to the scraper by means of the rope passing through the pulley at the top of the incline. The scraper is loaded in the usual manner, hauled up the incline until its wheels are stopped by blocks and then the team is backed up to slacken the rope and permit the scraper to tip and dump its load. The trip holding the scraper while dumping is operated from the ground. The[Pg 22] scraper load falls onto an inclined screen which takes out the sand and delivers the pebbles into the wagon. By erecting bins to catch the sand and pebbles this same arrangement could be made continuous in operation.

Fig. 8.—Device for Excavating and Screening Gravel and

Loading Wagons.

Fig. 8.—Device for Excavating and Screening Gravel and

Loading Wagons.

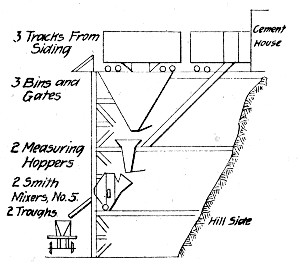

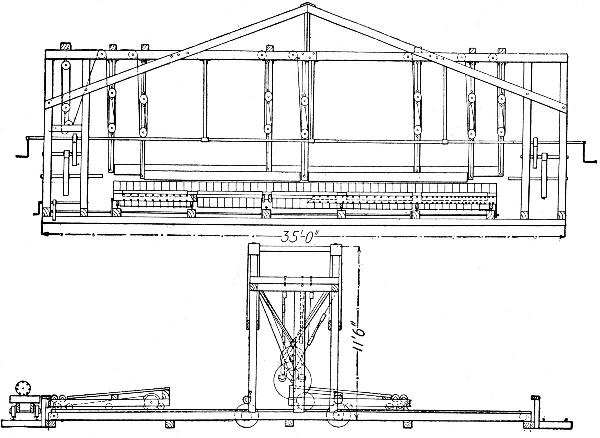

Fig. 9.—Gravel Washing Plant of 120 to 130 Cu. Yds., Per

Hour Capacity.

Fig. 9.—Gravel Washing Plant of 120 to 130 Cu. Yds., Per

Hour Capacity.

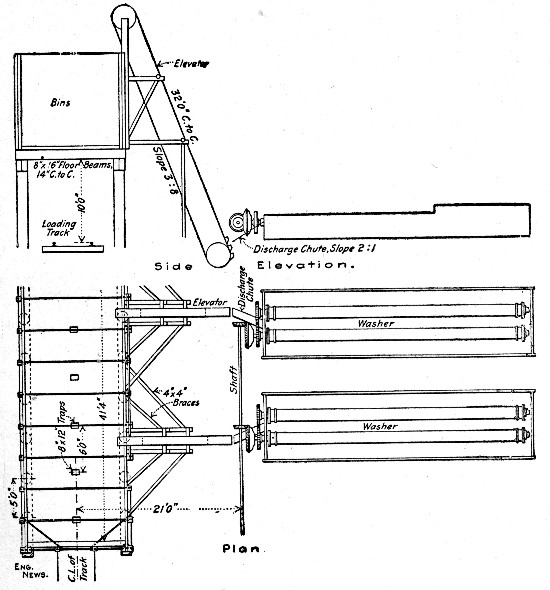

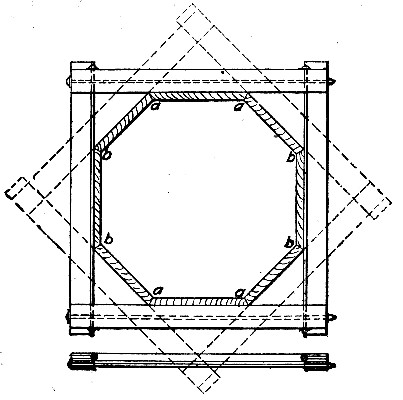

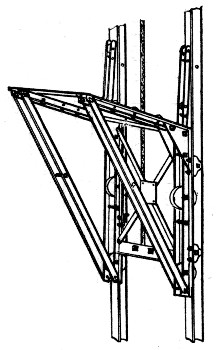

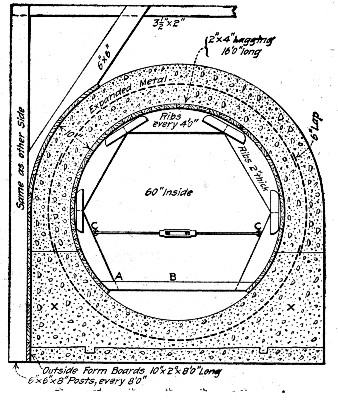

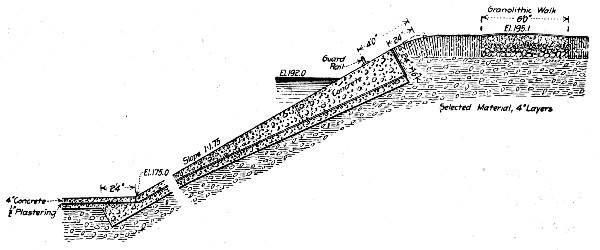

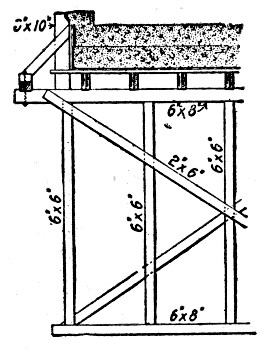

In commercial gravel mining, the gravel is usually sorted into several sizes and generally it is washed as well as screened. Where the pebbles run into larger sizes a crushing plant is also usually installed to reduce the large stones. Works producing several hundred cubic yards of screened and washed gravel per day require a plant of larger size and greater cost than even a very large piece of concrete work will warrant, so that only general mention will be made here of such plants. The commercial sizes of gravel are usually 2-in., 1-in., ½-in. and ¼-in., down to sand. No very detailed costs of producing gravel by these commercial plants are available. At the plant of the Lake Shore & Michigan Southern Ry., where gravel is screened and washed for ballast, the gravel is passed over a 2-in., a ¾-in., a ¼-in. and a ⅛-in. screen in turn and the fine sand is saved. About 2,000 tons are handled per day; the washed gravel, 2-in. to ⅛-in. sizes, represents from 40 to 65 per cent. of the raw gravel and costs from 23 to 30 cts. per cu. yd., for excavation, screening and[Pg 23] washing. The drawings of Fig. 9 show a gravel washing plant having a capacity of 120 to 130 cu. yds. per hour, operated by the Stewart-Peck Sand Co., of Kansas City, Mo. Where washing alone is necessary a plant of one or two washer units like those here shown could be installed without excessive cost by a contractor at any point where water is available. Each washer unit consists of two hexagonal troughs 18 ins. in diameter and 18 ft. long. A shaft carrying blades set spirally is rotated in each trough to agitate the gravel and force it along; each trough also has a fall of 6 ins. toward its receiving end. The two troughs are inclosed in a tank or box and above and between them is a 5-in. pipe having[Pg 24] ¾-in. holes 3 ins. apart so arranged that the streams are directed into the troughs. The water and dirt pass off at the lower end of the troughs while the gravel is fed by the screws into a chute discharging into a bucket elevator, which in turn feeds into a storage bin. The gravel to be washed runs from 2 ins. to ⅛-in. in size; it is excavated by steam shovel and loaded into 1½ cu. yd. dump cars, three of which are hauled by a mule to the washers, where the load is dumped into the troughs. The plant having a capacity of 120 to 130 cu. yds. per hour cost $25,000, including pump and an 8-in. pipe line a mile long. A 100-hp. engine operates the plant, and 20 men are needed for all purposes. This plant produces washed gravel at a profit for 40 cts. per cu. yd.

American engineers proportion concrete mixtures by measure, thus a 1-3-5 concrete is one composed of 1 volume of cement, 3 volumes of sand and 5 volumes of aggregate. In Continental Europe concrete is commonly proportioned by weight and there have been prominent advocates of this practice among American engineers. It is not evident how such a change in prevailing American practice would be of practical advantage. Aside from the fact that it is seldom convenient to weigh the ingredients of each batch, sand, stone and gravel are by no means constant in specific gravity, so that the greater exactness of proportioning by weight is not apparent. In this volume only incidental attention is given to gravimetric methods of proportioning concrete.

VOIDS.—Both the sand and the aggregates employed for concrete contain voids. The amount of this void space depends upon a number of conditions. As the task of proportioning concrete consists in so proportioning the several materials that all void spaces are filled with finer material the conditions influencing the proportion of voids in sand and aggregates must be known.

Voids in Sand.—The two conditions exerting the greatest influence on the proportion of voids in sand are the presence of moisture and the size of the grains of which the sand is composed.[Pg 26]

| Per cent of water in sand | 0 | 0.5 | 1 | 2 | 3 | 5 | 10 |

| Lbs. | Lbs. | Lbs. | Lbs. | Lbs. | Lbs. | Lbs. | |

| Weight per cu. yd. of fine sand and water | 3,457 | 2,206 | 2,085 | 2,044 | 2,037 | 2,035 | 2,133 |

| Weight per cu. yd. of coarse sand and water | 2,551 | 2,466 | 2,380 | 2,122 | 2,058 | 2,070 | 2,200 |

The volume of sand is greatly affected by the presence of varying percentages of moisture in the sand. A dry loose sand that has 45 per cent. voids if mixed with 5 per cent. by weight of water will swell, unless tamped, to such an extent that its voids may be 57 per cent. The same sand if saturated with water until it becomes a thin paste may show only 37½ per cent. voids after the sand has settled. Table I shows the results of tests made by Feret, the French experimenter. Two kinds of sand were used, a very fine sand and a coarse sand. They were measured in a box that held 2 cu. ft. and was 8 ins. deep, the sand being shoveled into the box but not tamped or shaken. After measuring and weighing the dry sand 0.5 per cent. by weight of water was added and the sand was mixed and shoveled back into the box again and then weighed. These operations were repeated with varying percentages of water up to 10 per cent. It will be noted that the weight of mixed water and sand is given; to ascertain the exact weight of dry sand in any mixture, divide the weight given in the table by 100 per cent. plus the given tabular per cent.; thus the weight of dry, fine sand in a 5 per cent. mixture is 2,035 ÷ 1.5 = 1,98 lbs. per cu. yd. The voids in the dry sand were 45 per cent. and in the sand with 5 per cent. moisture they were 56.7 per cent. Pouring water onto loose, dry sand compacts it. By mixing fine sand and water to a thin paste and allowing it to settle, it was found that the sand occupied 11 per cent. less space than when measured dry. The voids in fine sand, having a specific gravity of 2.65, were determined by measurement in a quart measure and found to be as follows:

| Sand not packed, per cent. voids | 44½ |

| Sand shaken to refusal, per cent. voids | 35 |

| Sand saturated with water, per cent. voids | 37½ |

Another series of tests made by Mr. H. P. Boardman, using Chicago sand having 34 to 40 per cent. voids, showed the following results:

| Water added, per cent. | 2 | 4 | 6 | 8 | 10 |

| Resulting per cent. increase | 17.6 | 22 | 19.5 | 16.6 | 15.6 |

Mr. Wm. B. Fuller found by tests that a dry sand, having[Pg 27] 34 per cent. voids, shrunk 9.6 per cent. in volume upon thorough tamping until it had 27 per cent. voids. The same sand moistened with 6 per cent. water and loose had 44 per cent. voids, which was reduced to 31 per cent. by ramming. The same sand saturated with water had 33 per cent. voids and by thorough ramming its volume was reduced 8½ per cent. until the sand had only 26¼ per cent. voids. Further experiments might be quoted and will be found recorded in several general treatises on concrete, but these are enough to demonstrate conclusively that any theory of the quantity of cement in mortar to be correct must take into account the effect of moisture on the voids in sand.

The effect of the size and the shape of the component grains on the amount of voids in sand is considerable. Feret's experiments are conclusive on these points, and they alone will be followed here. Taking for convenience three sizes of sand Feret mixed them in all the varying proportions possible with a total of 10 parts; there were 66 mixtures. The sizes used were: Large (L), sand composed of grains passing a sieve of 5 meshes per linear inch and retained on a sieve of 15 meshes per linear inch; medium (M), sand passing a sieve of 15 meshes and retained on a sieve of 50 meshes per linear inch, and fine (F), sand passing a 50-mesh sieve. With a dry sand whose grains have a specific gravity of 2.65, the weight of a cubic yard of either the fine, or the medium, or the large size, was 2,190 lbs., which is equivalent to 51 per cent. voids. The greatest weight of mixture, 2,840 lbs. per cu. yd., was an L6M0F4 mixture, that is, one composed of six parts large, no parts medium and 4 parts fine; this mixture was the densest of the 66 mixtures made, having 36 per cent. voids. It will be noted that the common opinion that the densest mixture is obtained by a mixture of gradually increasing sizes of grains is incorrect; there must be enough difference in the size of the grains to provide voids so large that the smaller grains will enter them and not wedge the larger grains apart. Turning now to the shape of the grains, the tests showed that rounded grains give less voids than angular grains. Using sand having a [Pg 28]composition of L5M3F2 Feret got the following results:

| —Per cent. Voids— | ||

| Kind of Grains. | Shaken. | Unshaken. |

| Natural sand, rounded grains | 25.6 | 35.9 |

| Crushed quartzite, angular grains | 27.4 | 42.1 |

| Crushed shells, flat grains | 31.8 | 44.3 |

| Residue of quartzite, flat grains | 34.6 | 47.5 |

The sand was shaken until no further settlement occurred. It is plain from these data on the effect of size and shape of grains on voids why it is that discrepancies exist in the published data on voids in dry sand. An idea of the wide variation in the granulometric composition of different sands is given by Table II. Table III shows the voids as determined for sands from different localities in the United States.

| Held by a Sieve. | A | B | C | E |

| No. 10 | 35.3% | |||

| No. 20 | 32.1 | 12.8% | 4.2% | 11% |

| No. 30 | 14.6 | 49.0 | 12.5 | 14 |

| No. 40 | ... | ... | 44.4 | ... |

| No. 50 | 9.6 | 29.3 | ... | 53 |

| No. 100 | 4.9 | 5.7 | ... | ... |

| No. 200 | 2.0 | 2.3 | ... | ... |

| —— | —— | —— | —— | |

| Voids | 33% | 39% | 41.7% | 31% |

Note.—A, is a "fine gravel" (containing 8% clay) used at Philadelphia. B, Delaware River sand. C, St. Mary's River sand. D, Green River, Ky., sand, "clean and sharp."

| Locality. | Authority. | Percent Voids. | Remarks. |

| Ohio River | W. M. Hall | 31 | Washed |

| Sandusky, O. | C. E. Sherman | 40 | Lake |

| Franklin Co., O. | C. E. Sherman | 40 | Bank |

| Sandusky Bay, O. | S. B. Newberry | 32.3 | ...... |

| St. Louis, Mo. | H. H. Henby | 34.3 | Miss. River |

| Sault Ste. Marie | H. von Schon | 41.7 | River |

| Chicago, Ill. | H. P. Broadman | 34 to 40 | ...... |

| Philadelphia, Pa | 39 | Del. River | |

| Mass. Coast | 31 to 34 | ...... | |

| Boston, Mass | Geo. Kimball | 33 | Clean |

| Cow Bay, L. I. | Myron S. Falk | 40½ | ...... |

| Little Falls, N. J. | W. B. Fuller | 45.6 | ...... |

| Canton, Ill. | G. W. Chandler | 30 | Clean |

Voids in Broken Stone and Gravel.—The percentage of voids in broken stone varies with the nature of the stone: whether it is broken by hand or by crushers; with the kind of crusher used, and upon whether it is screened or crusher-run[Pg 29] product. The voids in broken stone seldom exceed 52 per cent. even when the fragments are of uniform size and the stone is shoveled loose into the measuring box. The following records of actual determinations of voids in broken stone cover a sufficiently wide range of conditions to show about the limits of variation.

The following are results of tests made by Mr. A. N. Johnson, State Engineer of Illinois, to determine the variation in voids in crushed stone due to variation in size and to method of loading into the measuring box. The percentage of voids was determined by weighing the amount of water added to fill the box:

| Size. | Method of Loading. | Per cent. of Voids. |

| 3 in. | 20-ft. drop | 41.8 |

| 3 in. | 15-ft drop | 46.8 |

| 3 in. | 15-ft. drop | 47.2 |

| 3 in. | Shovels | 48.7 |

| 1½ in. | 20-ft. drop | 42.5 |

| 1½ in. | 15-ft. drop | 46.8 |

| 1½ in. | 15-ft. drop | 46.8 |

| 1½ in. | Shovels | 50.5 |

| ¾ in. | 20-ft. drop | 39.4 |

| ¾ in. | 15-ft. drop | 42.7 |

| ¾ in. | 15-ft. drop | 41.5 |

| ¾ in. | 15-ft. drop | 41.8 |

| ¾ in. | Shovels | 45.2 |

| ¾ in. | Shovels | 44.6 |

| ⅜ in. | Shovels | 41.0 |

| ⅜ in. | Shovels | 40.6 |

| ⅜ in. | Shovels | 41.0 |

The table shows clearly the effect on voids of compacting the stone by dropping it; it also shows for the ¾-in. and the ⅜-in. stone loaded by shovels how uniformly the percentages of voids run for stone of one size only. Dropping the stone 20 ft. reduced the voids some 12 to 15 per cent. as compared with shoveling.[Pg 30]

| Authority. | Percent Voids. | Remarks. |

| Sabin | 49.0 | Limestone, crusher run after screening out ⅛-in. and under. |

| " | 44.0 | Limsetone (1 part screenings mixed with 6 parts broken stone). |

| Wm. M. Black | 46.5 | Screened and washed, 2-ins. and under. |

| J. J. R. Croes | 47.5 | Gneiss, after screening out ¼-in. and under. |

| S. B. Newberry | 47.0 | Chiefly about egg size. |

| H. P. Broadman | 39 to 42 | Chicago limestone, crusher run. |

| " | 48 to 52 | " " screened into sizes. |

| Wm. M. Hall | 48.0 | Green River limestone, 2½-ins. and smaller dust screened out. |

| " | 50.0 | Hudson River trap, 2½-ins. and smaller, dust screened out. |

| Wm. B. Fuller | 47.6 | New Jersey trap, crusher run, 1/6 to 2.1 in. |

| Geo. A. Kimball | 49.5 | Roxbury conglomerate, ½ to 2½ ins. |

| Myron S. Falk | 48.0 | Limestone, ½ to 3 ins. |

| W. H. Henby | 43.0 | " 2-in size. |

| " | 46.0 | " 1½-in size |

| Feret | 53.4 | Stone, 1.6 to 2.4 ins. |

| " | 51.7 | " 0.8 to 1.6 in. |

| " | 52.1 | " 0.4 to 0.8 in. |

| A. W. Dow | 45.3 | Bluestone, 89% being 1½ to 2½ ins. |

| " | 45.3 | " 90% being 1/6 to 1½ in. |

| Taylor and Thompson | 54.5 | Trap, hard, 1 to 2½ ins. |

| " | 54.5 | " " ½ to 1 in. |

| " | 45.0 | " " 0 to 2½ in. |

| " | 51.2 | " soft, ¾ to 2 ins. |

| G. W. Chandler | 40.0 | Canton, Ill. |

| Emile Low | 39.0 | Buffalo limestone, crusher run, dust in. |

| C. M. Saville | 46.0 | Crushed cobblestone, screened into sizes. |

| ———Per cent Voids in——— | |||||

| Passing a ring of | 2.4" | 1.6" | 0.8" | Round | Broken |

| Held by a ring | 1.6" | 0.8" | 0.4" | Pebbles. | Stone. |

| Parts | 1 | 0 | 0 | 40.0 | 53.4 |

| " | 0 | 1 | 0 | 38.8 | 51.7 |

| " | 0 | 0 | 1 | 41.7 | 52.1 |

| " | 1 | 1 | 0 | 35.8 | 50.5 |

| " | 1 | 0 | 1 | 35.6 | 47.1 |

| " | 0 | 1 | 1 | 37.9 | 40.5 |

| " | 1 | 1 | 1 | 35.5 | 47.8 |

| " | 4 | 1 | 1 | 34.5 | 49.2 |

| " | 1 | 4 | 1 | 36.6 | 49.4 |

| " | 1 | 1 | 4 | 38.1 | 48.6 |

| " | 8 | 0 | 2 | 34.1 | .... |

Table IV gives the voids in broken stone as determined by various engineers; it requires no explanation. Table V, taken from Feret's tests, shows the effect of changes in granulometric composition on the amount of voids in both broken stone and gravel. Considering the column giving voids in stone it is to be noted first how nearly equal the voids are for stone of uniform size whatever that size be. As was the case with sand a mixture of coarse and fine particles gives the fewest voids; for stone an L1M0F1 mixture and for gravel an L8M0F2 mixture. Tamping reduces the voids in broken stone. Mr. Geo. W. Rafter gives the voids in clean, hand-broken limestone passing a 2½-in. ring as 43 per cent. after being lightly shaken and 37½ per cent. after being rammed. Generally speaking heavy ramming will reduce the voids in loose stone about 20 per cent.

It is rare that gravel has less than 30 per cent. or more than 45 per cent. voids. If the pebbles vary considerably in size so that the small fit in between the large, the voids may be as low as 30 per cent. but if the pebbles are tolerably uniform in size the voids will approach 45 per cent. Table V shows the effect of granulometric composition on the voids in gravel as determined by Feret. Mr. H. Von Schon gives the following granulometric analysis of a gravel having 34.1 per cent. voids:

| Retained on 1-in. ring, per cent. | 10.70 |

| Retained on ⅜-in. ring, per cent. | 23.65 |

| Retained on No. 4 sieve, per cent. | 8.70 |

| Retained on No. 10 sieve, per cent. | 17.14 |

| Retained on No. 20 sieve, per cent. | 21.76 |

| Retained on No. 30 sieve, per cent. | 6.49 |

| Retained on No. 40 sieve, per cent. | 5.96 |

| Passed a No. 40 sieve, per cent. | 5.59 |

| Passed a 1½-in ring, per cent. | 100.00 |

As mixtures of broken stone and gravel are often used the following determinations of voids in such mixtures are given. The following determinations were made by Mr. Wm. M. Hall for mixtures of blue limestone and Ohio River washed gravel:[Pg 32]

| Per cent. Stone. | Per cent. Gravel. | Per cent. Voids in Mix | |

| 100 | with | 0 | 48 |

| 80 | " | 20 | 44 |

| 70 | " | 30 | 41 |

| 60 | " | 40 | 38½ |

| 50 | " | 50 | 36 |

| 0 | " | 100 | 35 |

The dust was screened from the stone all of which passed a 2½-in. ring; the gravel all passed a 1½-in. screen. Using the same sizes of gravel and Hudson River trap rock, the results were:

| Per cent. Trap. | Per cent. Gravel. | Per cent. Voids in Mix. | |

| 100 | with | 0 | 50 |

| 60 | " | 40 | 38½ |

| 50 | " | 50 | 36 |

| 0 | " | 100 | 35 |

The weight of a cubic foot of loose gravel or stone is not an accurate index of the percentage of voids unless the specific gravity is known. Pure quartz weighs 165 lbs., per cu. ft., hence broken quartz having 40 per cent. voids weighs 165 × .60 = 99 lbs. per cu. ft. Few gravels are entirely quartz, and many contain stone having a greater specific gravity like some traps or a less specific gravity like some shales and sandstone. Tables VI and VII give the specific gravities of common stones and minerals and Table VIII gives the weights corresponding to different percentages of voids for different specific gravities.

| Trap, | Boston, Mass. | 2.78 |

| " | Duluth, Minn. | 2.8 to 3.0 |

| " | Jersey City, N. J. | 3.03 |

| " | Staten Island, N. Y. | 2.86 |

| Gneiss, | Madison Ave., N. Y. | 2.92 |

| Granite, | New London, Conn. | 2.66 |

| " | Greenwich, Conn. | 2.84 |

| " | Vinalhaven, Me. | 2.66 |

| " | Quincy, Mass. | 2.66 |

| " | Barre, Vt. | 2.65 |

| Limestone, | Joliet, Ill. | 2.56 |

| " | Quincy, Ill. | 2.51 to 2.57 |

| Limestone, (oolitic) | Bedford, Ind. | 2.25 to 2.45 |

| " | Marquette, Mich. | 2.34 |

| " | Glens Falls, N.Y. | 2.70 |

| " | Lake Champlain, N. Y. | 2.75 |

| Sandstone, | Portland, Conn. | 2.64 |

| " | Haverstraw, N. Y. | 2.13 |

| " | Medina, N. Y. | 2.41 |

| " | Potsdam, N. Y. | 2.60 |

| " | (grit) Berea, O. | 2.12 |

| Apatite | 2.92-3.25 |

| Basalt | 3.01 |

| Calcite, CaCO3 | 2.5-2.73 |

| Cassiterite, SnO2 | 6.4-7.1 |

| Cerrusite, PbCO3 | 6.46-6.48 |

| Chalcopyrite, CuFeS2 | 4.1-4.3 |

| Coal, anthracite | 1.3-1.84 |

| Coal, bituminous | 1.2-1.5 |

| Diabase | 2.6-3.03 |

| Diorite | 2.92 |

| Dolomite, CaMg (CO3)² | 2.8-2.9 |

| Felspar | 2.44-2.78 |

| Felsite | 2.65 |

| Galena, Pbs | 7.25-7.77 |

| Garnet | 3.15-4.31 |

| Gneiss | 2.62-2.92 |

| Granite | 2.55-2.86 |

| Gypsum | 2.3-3.28 |

| Halite (salt) NaCl | 2.1-2.56 |

| Hematite, Fe2O3 | 4.5-5.3 |

| Hornblende | 3.05-3.47 |

| Limonite, Fe3O4 (OH)6 | 3.6-4.0 |

| Limestone | 2.35-2.87 |

| Magnetite, Fe3O4 | 4.9-5.2 |

| Marble | 2.08-2.85 |

| Mica | 2.75-3.1 |

| Mica Schist | 2.5-2.9 |

| Olivine | 3.33-3.5 |

| Porphyry | 2.5-2.6 |

| Pyrite, FeS2 | 4.83-5.2 |

| Quartz, SiO2 | 2.5-2.8 |

| Quartzite | 2.6-2.7 |

| Sandstone | 2.0-2.78 |

| " Medina | 2.4 |

| " Ohio | 2.2 |

| " Slaty | 1.82 |

| Shale | 2.4-2.8 |

| Slate | 2.5-2.8 |

| Sphalerite, ZnS | 3.9-4.2 |

| Stibnite, Sb2S3 | 4.5-4.6 |

| Syenite | 2.27-2.65 |

| Talc | 2.56-2.8 |

| Trap | 2.6-3.0 |

| Weight in Lbs. per cu. yd. when Voids are | |||||||

| Specific Gravity. | Weight in Lbs. per cu. ft. | Weight in Lbs. per cu. yd. | 30% | 35% | 40% | 45% | 50% |

| 1.0 | 62.355 | 1,684 | 1,178 | 1,094 | 1,010 | 926 | 842 |

| 2.0 | 124.7 | 3,367 | 2,357 | 2,187 | 2,020 | 1,852 | 1,684 |

| 2.1 | 130.9 | 3,536 | 2,475 | 2,298 | 2,121 | 1,945 | 1,768 |

| 2.2 | 137.2 | 3,704 | 2,593 | 2,408 | 2,222 | 2,037 | 1,852 |

| 2.3 | 143.4 | 3,872 | 2,711 | 2,517 | 2,323 | 2,130 | 1,936 |

| 2.4 | 149.7 | 4,041 | 2,828 | 2,626 | 2,424 | 2,222 | 2,020 |