Title: Inside Illinois: Mineral Resources

Creator: Illinois State Geological Survey

Release date: September 16, 2021 [eBook #66317]

Most recently updated: October 18, 2024

Language: English

Credits: Stephen Hutcheson and the Online Distributed Proofreading Team at https://www.pgdp.net

Educational Series 9

Illinois State Geological Survey

STATE of ILLINOIS

DEPARTMENT of

REGISTRATION and EDUCATION

1965

ILLINOIS STATE GEOLOGICAL SURVEY

John C. Frye, Chief

URBANA, ILLINOIS

Printed by Authority of State of Illinois, Ch. 127, IRS, Par. 58.25.

Although Illinois has been nicknamed the “Prairie State,” many parts of it are hilly and scenic. The idea of large areas of the state being nothing more than broad, flat prairies has come about because the major highways have been built to take advantage of the comparatively low, gently rolling landscape rather than the rougher more scenic areas.

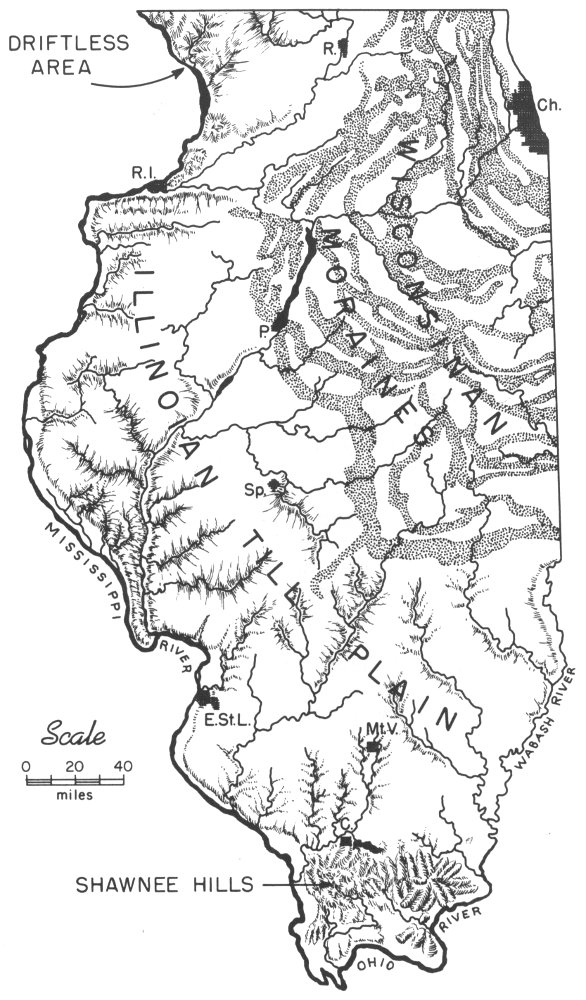

Physiography is the study of the creation and gradual change of land surface forms (the landscape). Thus, the land surface as we see it today in each of the physiographic provinces (fig. 1) has had a particular history of development.

Illinois is about 385 miles long from north to south and about 218 miles wide. It has an area of 55,947 square miles. The average elevation of the state is about 600 feet above sea level. Charles Mound, however, in the northern part of Jo Daviess County in extreme northwestern Illinois, has an elevation of 1,241 feet above sea level and is the highest point in the state.

Cheap water transportation is available to Illinois industry through Lake Michigan, the Illinois Waterway, and the Mississippi, Ohio, and Wabash Rivers. These major rivers of Illinois collect the surface drainage of the state from a network of about 500 streams.

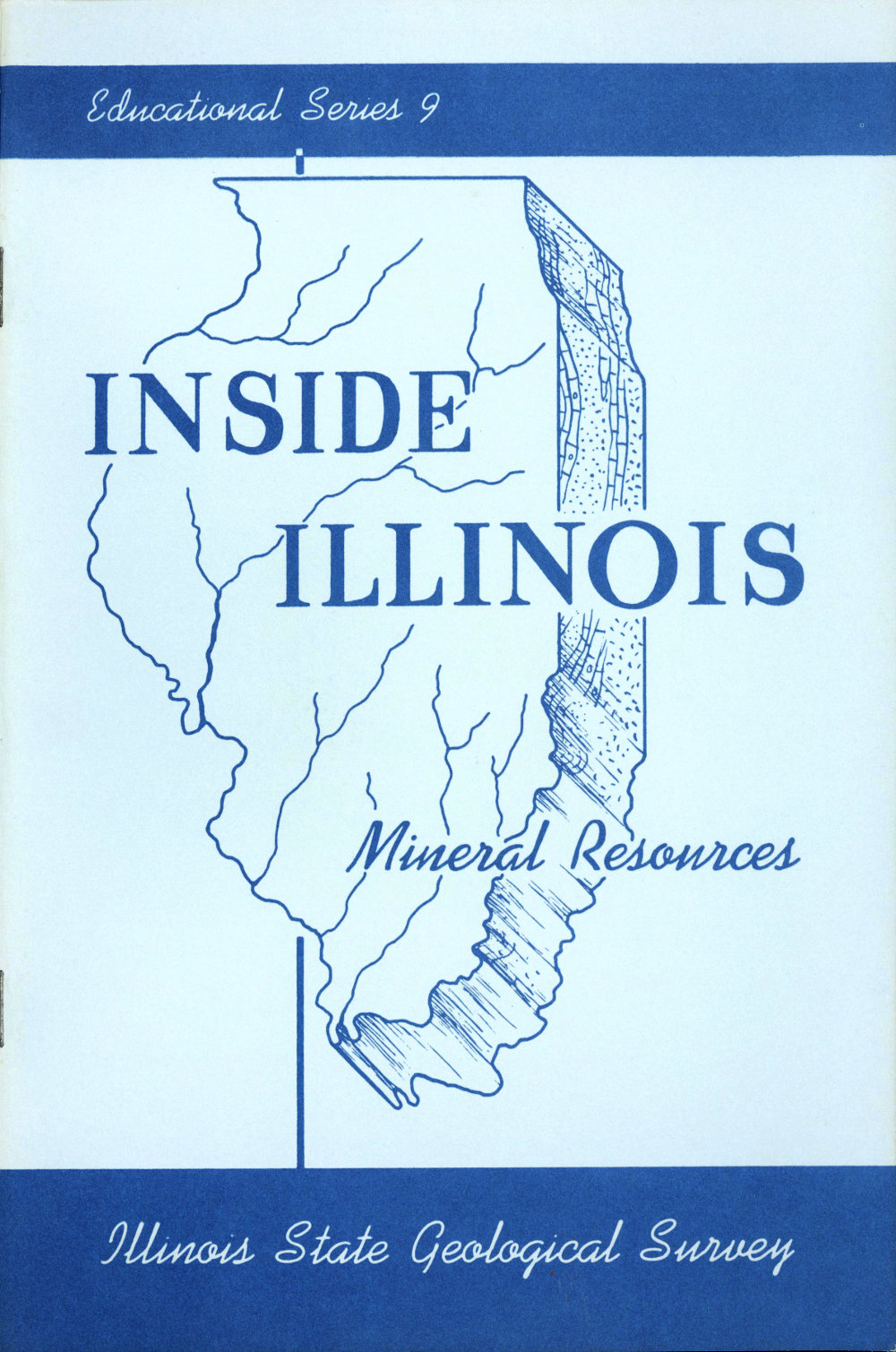

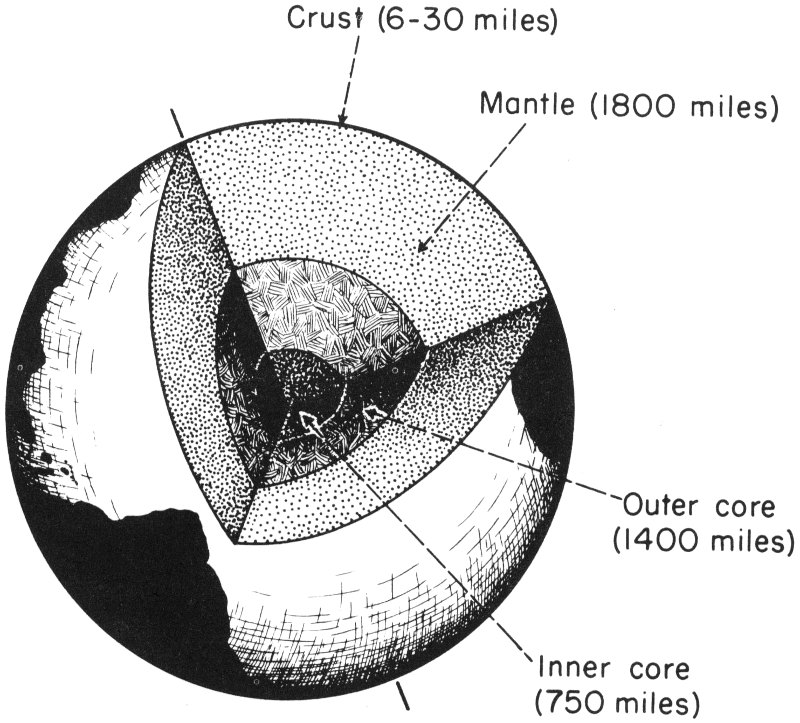

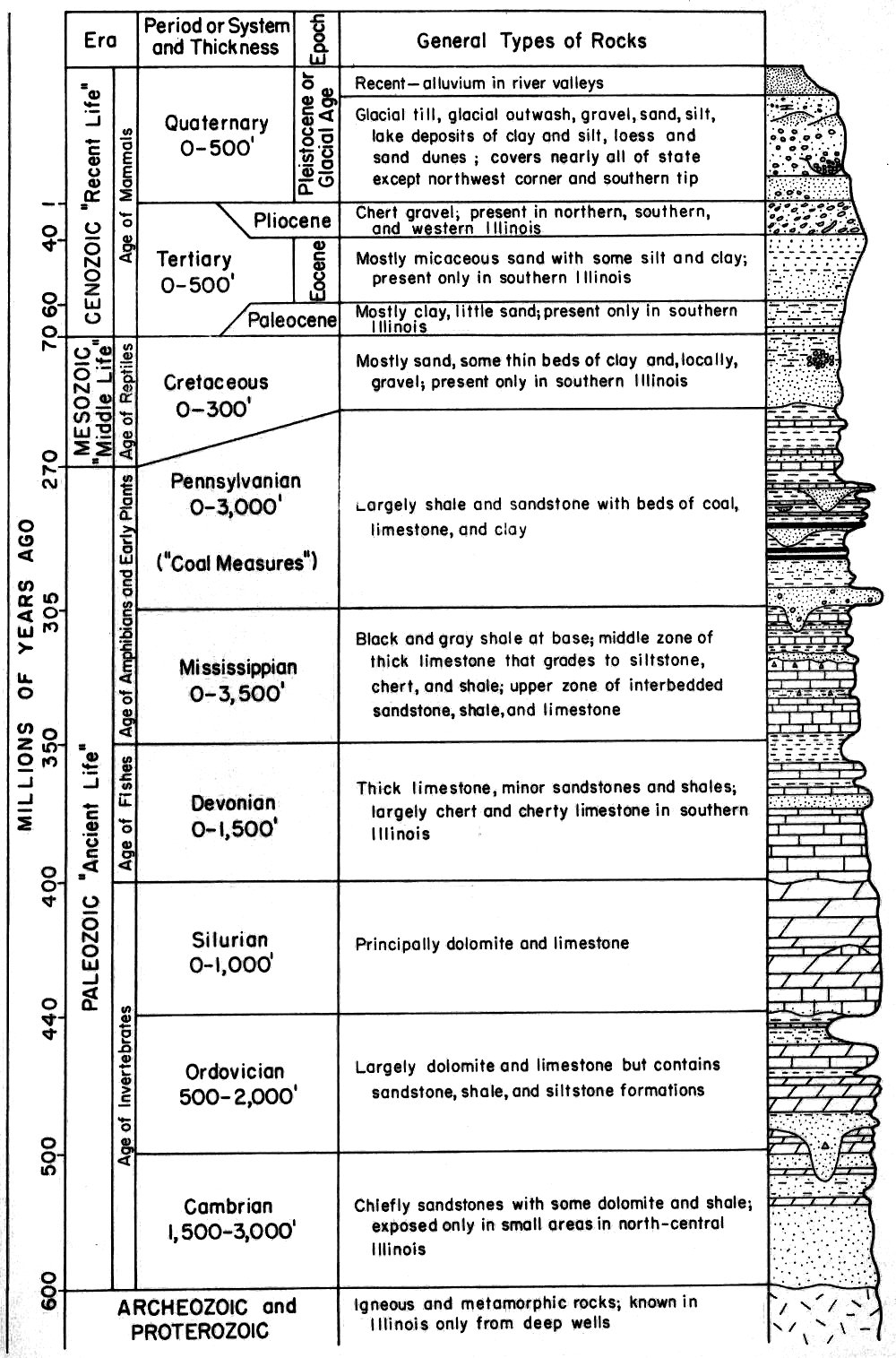

The earth is made of a large number of different rocks and minerals (limestone, sandstone, shale, coal, iron, granite, and many others). These materials are divided into three zones: core, mantle, and crust (fig. 2).

Figure 1—Physiographic provinces of Illinois.

Figure 2—The earth with a segment removed to show supposed internal zones.

The core is the innermost zone of the earth. It is mainly iron with some nickel and cobalt. The inner core probably is solid, but the outer core may consist of the same elements in a molten form. The core is the most dense (heaviest) of the three zones.

The mantle, which surrounds the core, is a rigid zone of materials rich in iron and magnesium. These materials are not as dense as those found in the core.

The crust, the top part of which includes the ground we walk on, is the hard, outer surface layer of the earth. Although the 4 crust is about 6 to 30 miles deep, the scale (size) of figure 2 allows it to be drawn only as the thin outer line. The rocks and minerals that we are all acquainted with are found in the crust. These rocks are not as dense and do not have as high an iron content as do the rocks of the mantle and the core.

The earth’s crust under Illinois is made of: sedimentary rocks deposited by water, wind, or glaciers (limestone, sandstone, shale, glacial drift); igneous, or melted rocks (granite, gabbro); and metamorphic, or altered sedimentary and igneous rocks (quartzite, gneiss). These various types of rocks have a relatively thin covering of broken or weathered material called mantle rock and soil.

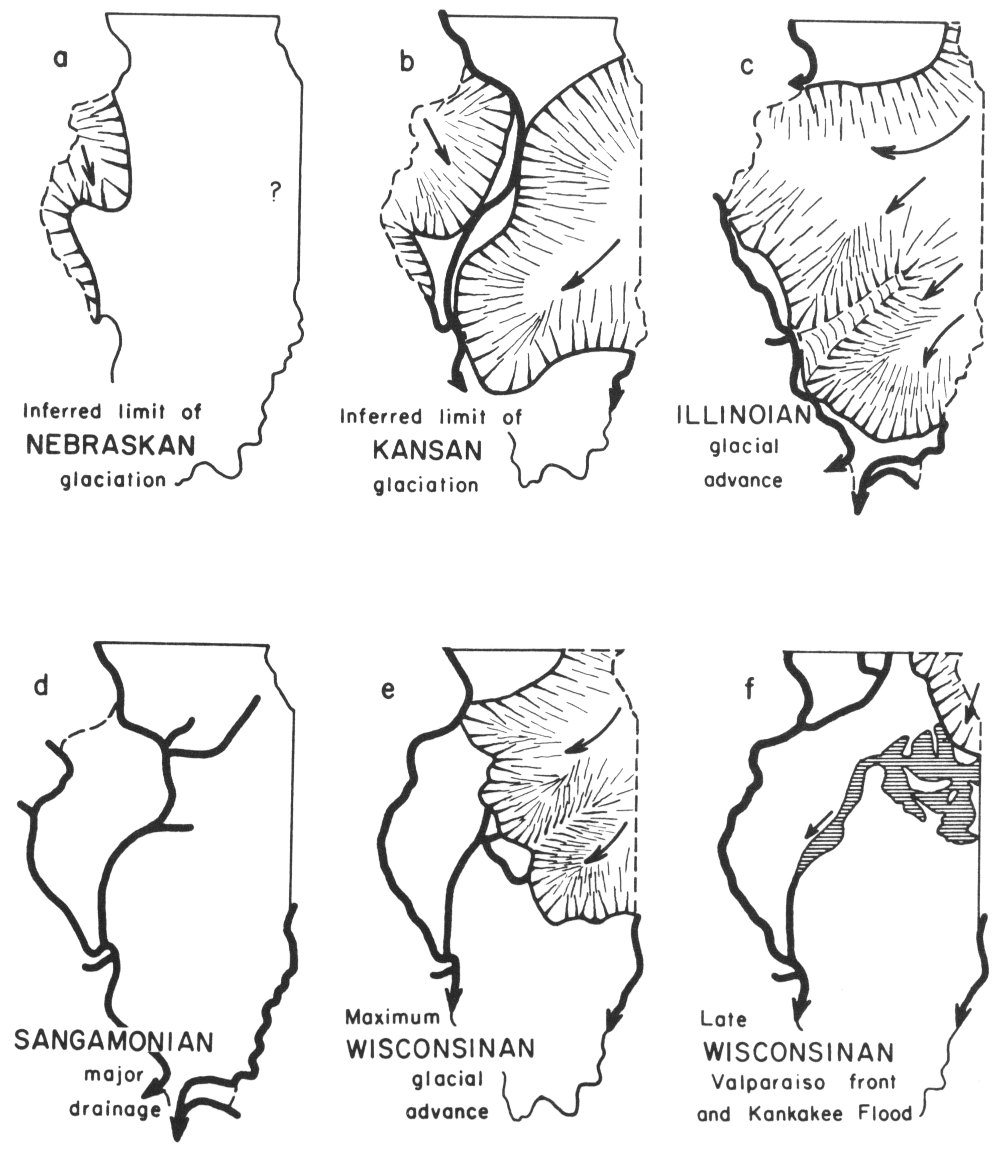

The ground surface over most of Illinois was formed during the ice age (Quaternary Period) which lasted from about one million years ago up to nearly 5,000 years ago. As much as 90 percent of the state was covered by one of several sheets of glacial ice (fig. 3). The glaciers smoothed down and covered much of the old, rocky, hilly land surface and filled old valleys with loose, unconsolidated deposits.

In Canada vast thicknesses of snow and ice accumulated until the weight of the ice finally caused it to flow slowly outward, mainly to the south (fig. 4). Rocks and surface materials of all types were picked up and carried by the glaciers for great distances before being deposited. Pieces of granite, quartzite, and native copper among the many local rocks and minerals are found in glacial deposits and indicate that at least part of these deposits came from the Great Lakes Region. The materials deposited range from clay-size minerals to large boulders.

Figure 3—Extent of the main glacial advances which began with the Nebraskan (a—the oldest) and ended with the late Wisconsinan (f—the youngest). Diagram “d” shows the major stream development during the time between the Illinoian and the earliest Wisconsinan glaciers. The heavy lines on the diagrams indicate major stream valleys that were present during these times.

Figure 4—Limits of ice age glaciers.

Weathering and bacterial decay action have modified many of the loose, unconsolidated surface materials into soils. The present soils of Illinois are fertile partly because they have minerals and trace elements (minute amounts of elements such as copper, zinc, manganese) brought in by the glaciers from adjacent parts of the country. The youngest and most fertile soils occur in the northeastern part of the state and along the Illinois and Mississippi River valleys. These young soils are more fertile because the glacial deposits and loess (wind-blown silt) upon which they have developed are younger and fresher. The minerals and trace elements in these deposits have not been dissolved out to the extent that they have in the older glacial deposits and soils in other parts of the state.

Figure 5—Woolly mammoth (after C. R. Knight).

Scattered mammoth (fig. 5) and mastodon remains have been found in glacial deposits at various localities in the state. Peat, which is an accumulation of partially decomposed plant materials, has been found, especially in the northern part of the state. It is marketed as an organic soil conditioner.

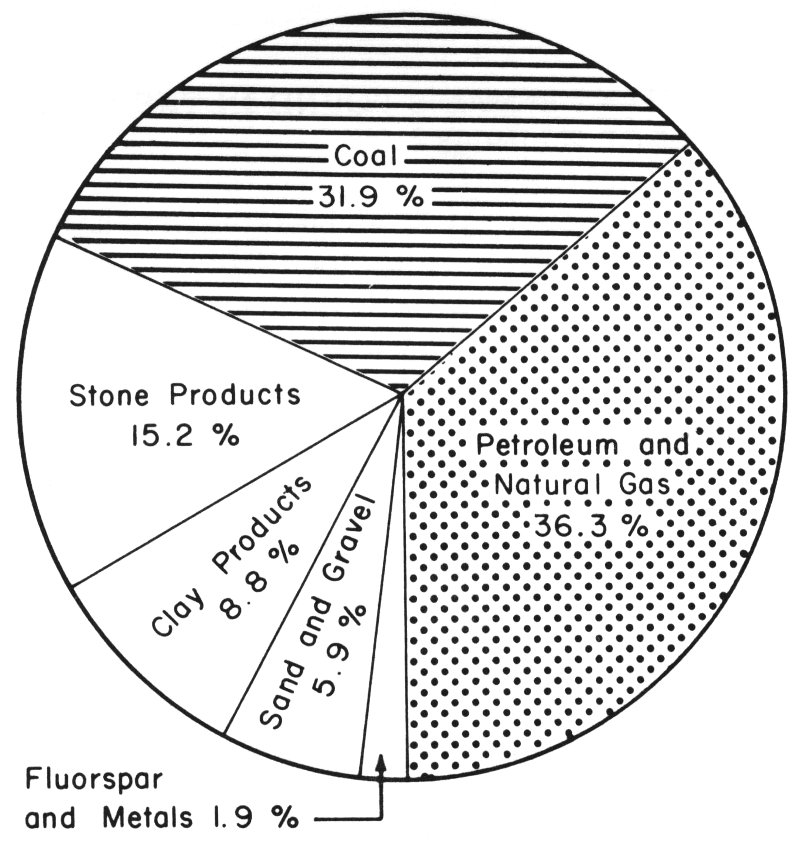

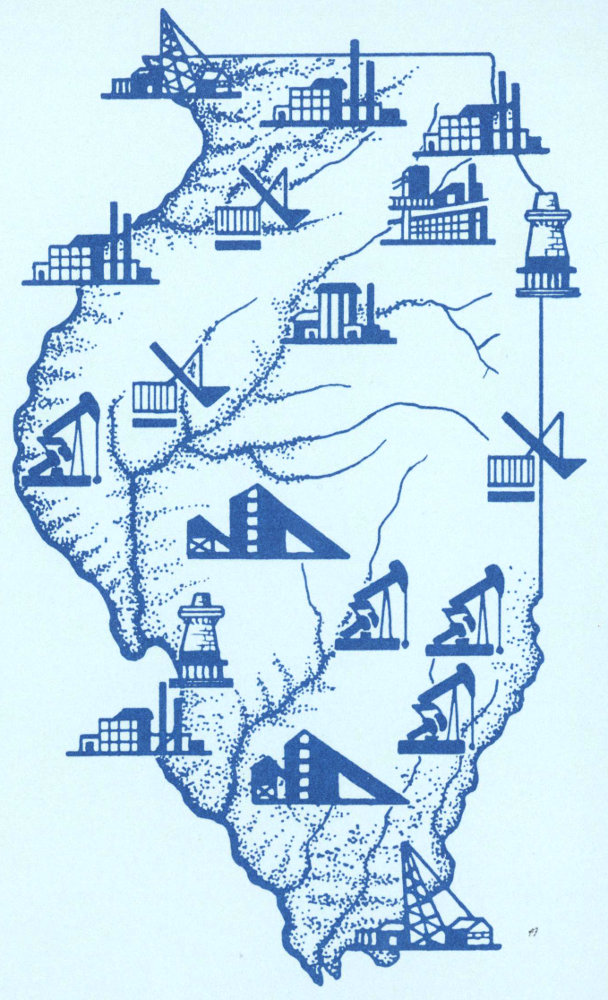

In 1963, Illinois mineral production totaled approximately $615,000,000. This placed the state first as a mineral producer in the Upper Mississippi Valley and eighth in the nation.

Coal and petroleum, two of the world’s most important mineral resources, are produced in Illinois. Iron ore, another mineral of extreme importance, is brought into the steel mills of the Chicago and East St. Louis areas from deposits in Minnesota and Missouri. Some ore from foreign countries is also processed in these mills.

A great variety of mineral commodities are produced in Illinois. In the order of their 1963 value (fig. 6) they are (1) crude oil and natural gas, (2) coal, (3) clay products, (4) crushed stone and cement, (5) common sand and gravel, (6) special sands, (7) fluorspar, and (8) metals—zinc and lead.

In 1963, 99 of the 102 counties of Illinois reported mineral production of one kind or another.

Figure 6—Percentage diagram of Illinois mineral production value for 1963.

In 1963, approximately 27,000 people worked in mines, quarries, oil fields, and direct processing operations such as cement and clay products plants and oil refineries. Many other persons were employed in transporting the materials and in plants and general offices.

The farmers of the state are among those receiving direct and indirect benefits from Illinois minerals. In 1963, more than 4,800,000 tons of agstone (crushed limestone and dolomite) were spread on Illinois fields to reduce acidity, maintain soil fertility, and improve crop production. Other stone and stone products are used in constructing farm buildings and facilities and in the maintenance of farm-to-market roads. In addition, petroleum products and coal provide energy to power the laborsaving devices that enable the farmer to increase his production and scale of operations.

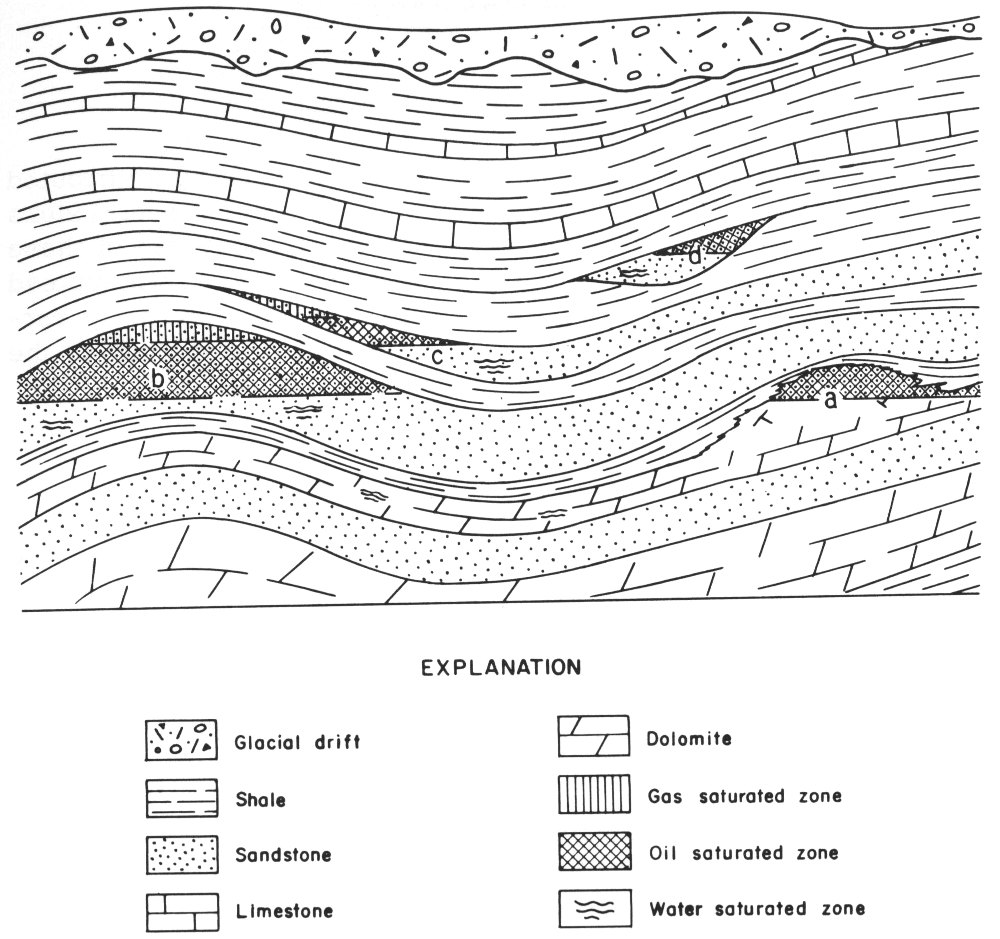

Petroleum is a dark, oily fluid that is irregularly distributed in sedimentary rocks throughout the world. There are several ideas about the origin of petroleum. The most widely accepted of these is that billions of plants and animals lived and died in widespread seas and their remains decomposed and released fluid, fatty particles. These were distilled into “hydrocarbons” (a mixture of the elements hydrogen and carbon, such as gas and oil).

The hydrocarbons, or oil and gas droplets, were buried by countless tons of sediments that accumulated on ancient sea bottoms. As these sediments hardened into sedimentary rocks, the hydrocarbons were squeezed into whatever empty spaces were available in the rocks. As the layers of sedimentary rocks later became folded and broken, oil and gas droplets and salt water moved upward through any interconnecting open spaces. Some droplets escaped to the surface as “seeps,” but many were trapped when they came up against a nonporous barrier. Gas, being lighter than either oil or water, was trapped at the top, and oil was stopped in the middle, above the salt water. An accumulation of this kind is termed a “pool” or a “field.”

Conditions under which oil is found in Illinois (fig. 7) are as follows: (a) coral reefs, (b) anticlines (upfolds or arches of rock layers), (c) “pinching” or “lensing” out of dipping, overlapping porous rock layers, and (d) buried sandstone-filled ancient stream channels.

No. Oil and gas accumulate in the pores (openings) between silt and sand grains and in small openings in limestone and dolomite.

Figure 7—Places where oil is found in Illinois: (a) coral reefs, (b) anticlines, (c) pinch-outs, and (d) channel sandstones.

Although prospect (test) drilling is still the only way to prove the presence or absence of commercial quantities of oil beneath the surface, careful study by a geologist of all available information may indicate the most favorable places for testing. Since oil 11 and gas migrate to the highest parts of the porous rock zones, the geologist tries to find these high places even though they may be several hundred feet underground. Sometimes dipping rocks can be seen in outcrops, and several geophysical methods have been used to indicate where such high places may occur underground. At other times, high places are found by studying with a microscope samples of rocks collected from wells already drilled in the surrounding area. The geologist notes the type and order of the formations which have been drilled. Many holes have been drilled based on such information.

Whether or not the test drilling is successful as a producing well, small samples of cuttings of the rock being drilled are collected and saved to be studied at a later time. Various instruments are also put down into the hole to record temperatures, pressures, electrical properties, and other characteristics of the rocks. This type of information, when carefully plotted on maps, serves to locate new areas for test drilling.

There is no way to tell before a hole is drilled whether or not oil will be found, how much oil is present, or what will be the best way to get it to the surface. Where subsurface pressures are great enough, oil may flow to the surface.

Generally speaking, about one-third of the oil actually present in the rocks can be pumped before the well becomes uneconomical to operate. This is called primary production. Oil operators have learned that by pumping water or gas down some wells into the oil-bearing formation, another third of the oil may be forced out through neighboring wells. This is called secondary production. Experiments that use steam or that burn some of the oil underground in an oil-bearing formation are attempts to recover the remaining third. These methods using heat are often referred to as tertiary production methods.

Illinois’ largest well, near Centralia, flowed 12,000 barrels of oil in a 24-hour period. Most Illinois oil wells, however, 12 have to be pumped, and the majority of them are now producing 10 barrels or less a day. The deepest producing well, 5,354 feet, was drilled in 1960 in Wayne County, near Fairfield. In the same year the deepest oil test was drilled to a depth of 8,616 feet and was stopped in granite. This test is located in Fayette County near Beecher City and has its oil production from a zone over 4,000 feet above the bottom of the hole.

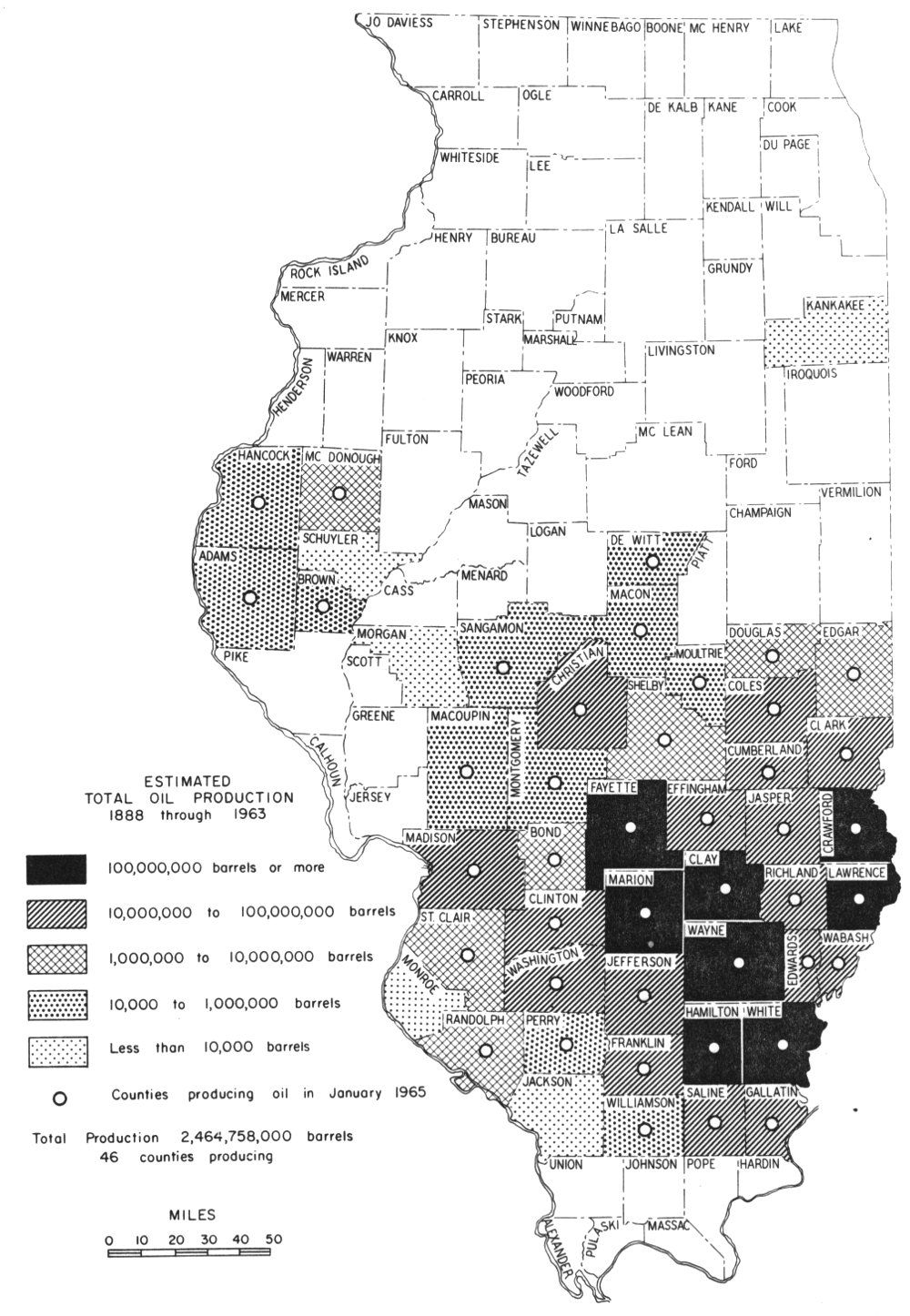

In 1963, about 75 million barrels of oil, 2.7 percent of the nation’s total, were produced in Illinois (fig. 8). This oil is valued at over $221,000,000.

In 1940, our state had its highest yield of oil when 147,647,000 barrels were produced. Although production figures remained fairly high for some time, they have declined in the past few years. Since no new large oil discoveries have been made recently, Illinois’ total known oil reserves are decreasing yearly. In 1963, Illinois ranked eighth among the oil-producing states, with 420 oil fields consisting of 30,149 wells.

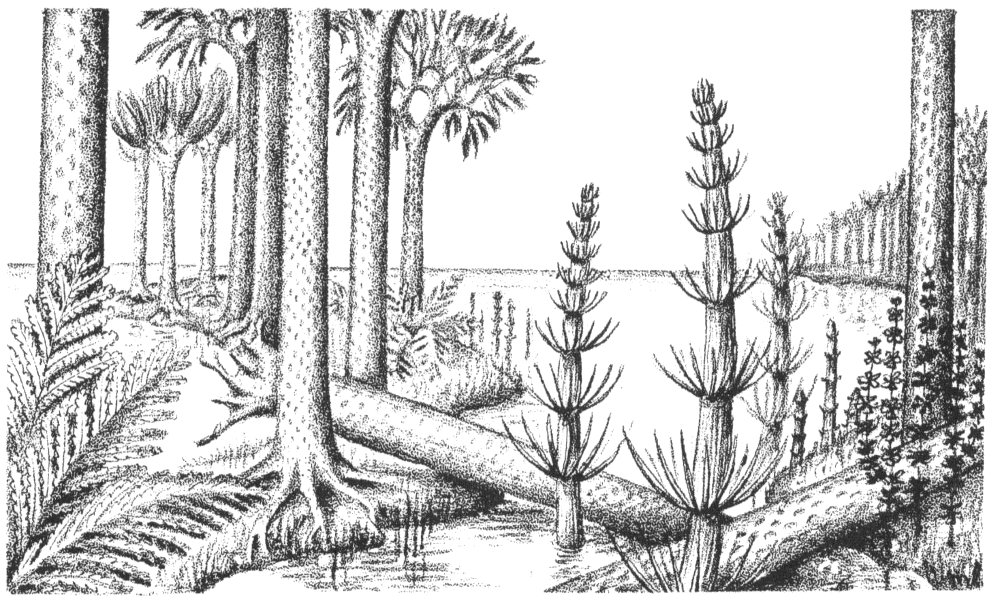

Coal is a combustible rock that was formed by the accumulation and partial decay of vegetation. When coal was forming millions of years ago, most of the state was a low coastal plain bordered on the west and southwest by a shallow sea. A large variety of plants grew in great swamps which covered this coastal plain (fig. 9). When the plants died, they accumulated in the swamps to form thick masses of peat that were eventually covered by shallow seas and buried beneath mud and sand. Periodically, the region was above sea level, new swamps developed, new peat deposits accumulated, and more sediments were laid down. This process occurred repeatedly until over 3,000 feet of sediments had been deposited. Then the sediments were slowly compacted and hardened so that sandstones, shales, limestones, and coals were formed.

Figure 8—Estimated total oil production by counties from 1888 through 1963.

Figure 9—Reconstruction of coal-forming swamp.

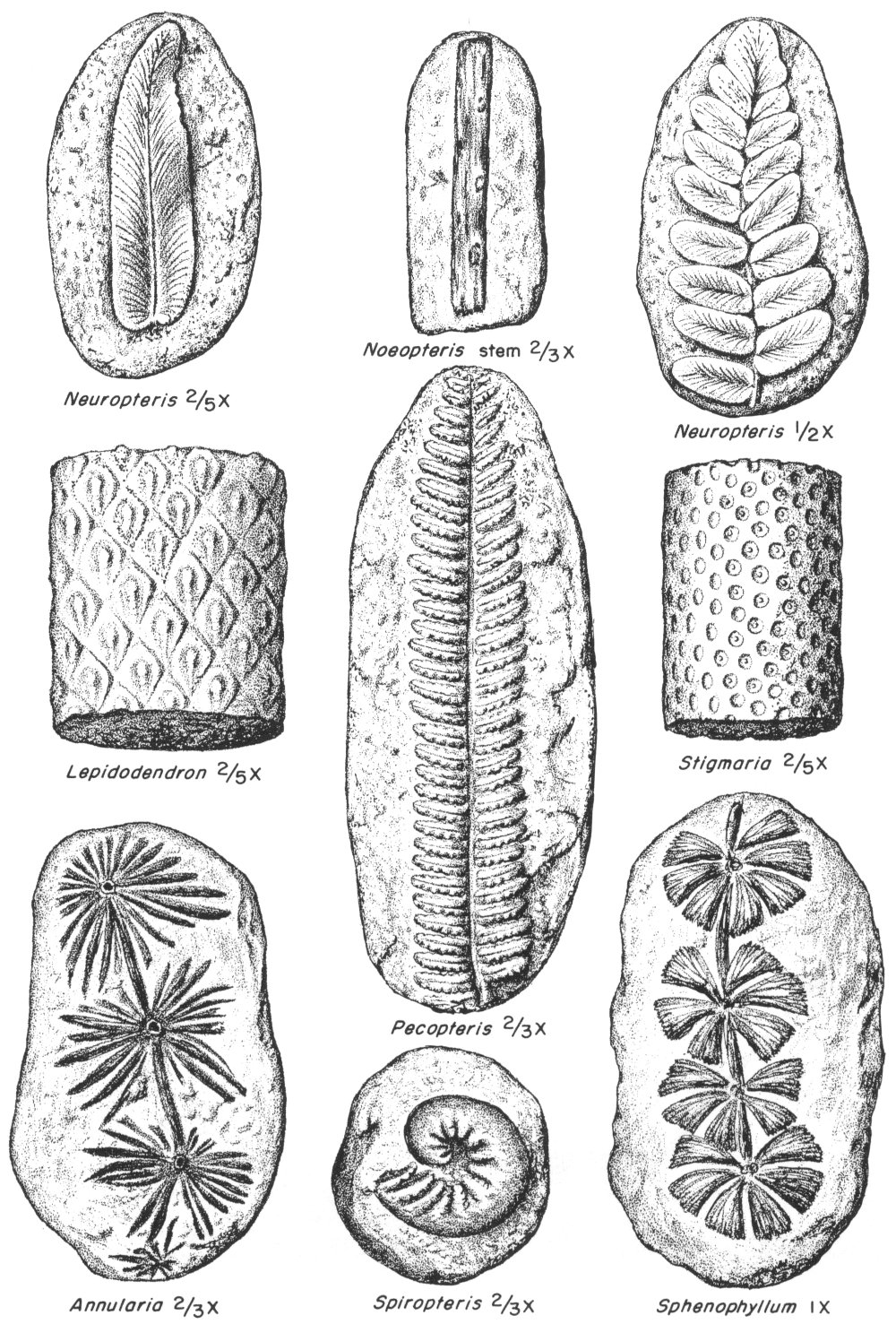

Although plant impressions or fossilized wood can be seen in coal, they are more common in shales and sandstones associated with the coal. Often roots can be seen in the clay that lies just under the coal, and in some places stumps of trees from the coal swamp forest are preserved in the sediments adjacent to the coal (fig. 10). When pieces of coal are examined with a microscope, carbonized plant remains can be seen.

There are at least 40 different coal seams in Illinois, but most are relatively thin. Seven coal seams have been mined extensively, and all together 20 or more have been mined.

Figure 10—Some root, stem, and leaf fossils found in Illinois coal-bearing rocks.

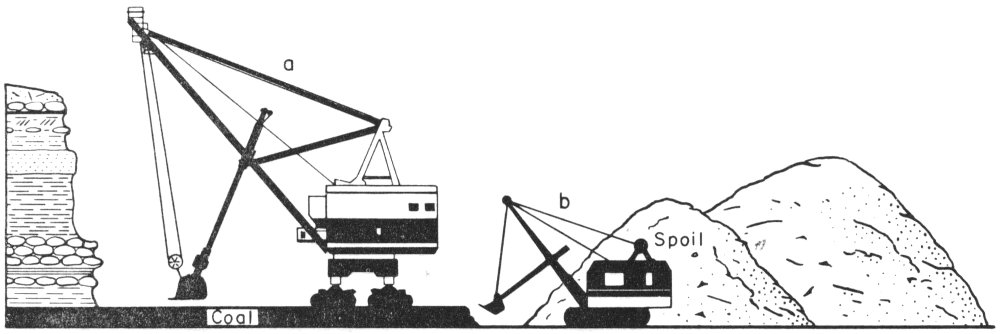

In Illinois there are two main ways of mining coal: strip (open-cut) and underground. Strip or open-cut mines (fig. 11) usually operate where the coal is at very shallow depths, although such mining is done as much as 100 feet deep or more in some places. Many old underground mines produced coal from seams that were less than 100 feet deep because they did not have the large machinery for strip mining when these mines were started. An abandoned mine, 1,004 feet deep, near Assumption is the deepest underground coal mine in the state. Coal is now being mined at depths somewhat over 800 feet in Jefferson County.

Illinois ranks fourth in production of coal in the United States. It is exceeded only by West Virginia, Kentucky, and Pennsylvania. Some of the largest and most efficient mines in the country are operated in Illinois. Underground mines in Illinois have the highest rate of tons mined per man each day in the country, and this rate is increasing. Increased mining efficiency has made it possible to hold the price of coal low enough so that it can successfully compete against other fuels for many uses.

Figure 11—Diagram of strip mine showing: (a) stripping shovel, and (b) coal-loading shovel.

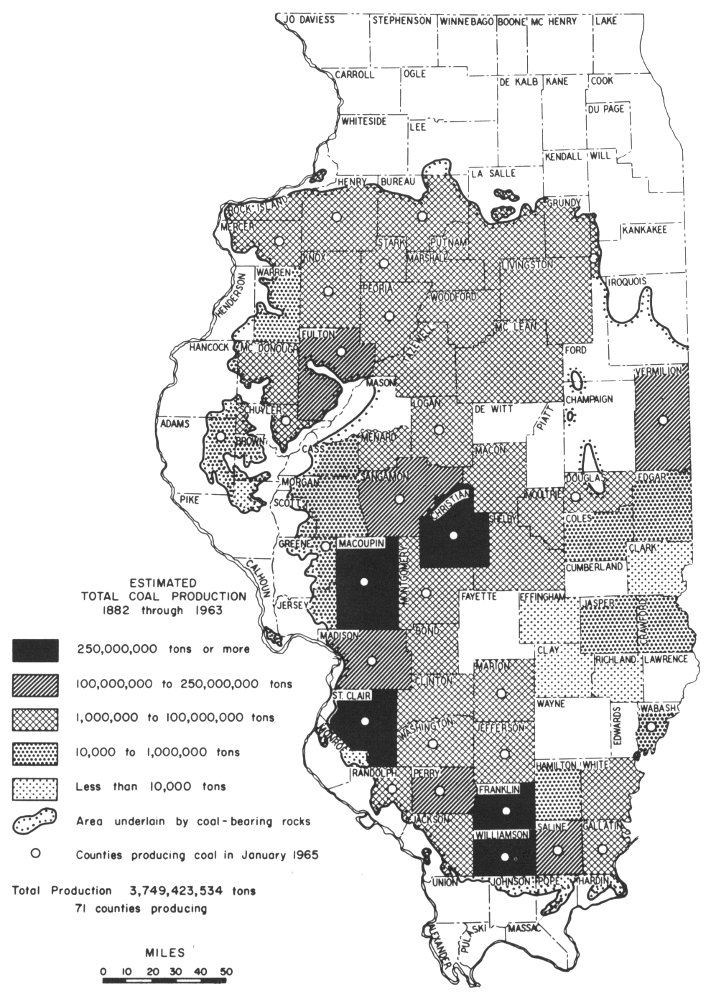

In the last 10 years, an average of about 46 million tons of coal has been mined each year (fig. 12). In 1963, approximately 51.6 million tons were produced, which were valued at about $196,000,000 at the mine. Since 1961, strip mines have produced over half of the coal mined in Illinois.

It will take well over 1,000 years at the present rate of mining in Illinois to exhaust our coal reserves. An estimated 140 billion tons of coal in seams of minable thickness remain in the ground in our state; these are the largest known reserves of bituminous coal of any state in the United States.

Electric power generation consumes the greater part of the annual coal production in Illinois. Coal is also used for home and commercial heating, for production of coke, and for manufacturing various chemical compounds from coal tar. Products derived from coal tar include drugs and medicines, plastics, synthetic fibres, perfumes, flavorings, dyes, synthetic rubbers, explosives, specialized oils, solvents, wood preservatives, tarlike paving and roofing materials, and some gas. The gas is both produced and utilized in the coke industry.

Coke is a material produced by burning coal in the absence of air so that most of the gases and water are driven off without consuming the solid portion. The resulting solid coke is a strong, porous, combustible substance.

The structure and nature of coke make it a valuable fuel for blast furnace use in the production of steel. In the past, most of the coal used in the manufacture of coke has come from areas of higher quality coal outside of our state. However, at present, over 1,000,000 tons of Illinois coal are mined annually for the production of metallurgical coke.

Figure 12—Estimated total coal production by counties from 1882 through 1963.

Limestone and dolomite are the most abundant rocks quarried in Illinois. Small amounts of marble, limestone, and sandstone for building stone are also produced. In addition, some glacial boulders and cobbles are used for rock gardens and in home construction. The crushed limestone industry is Illinois’ most important rock products industry.

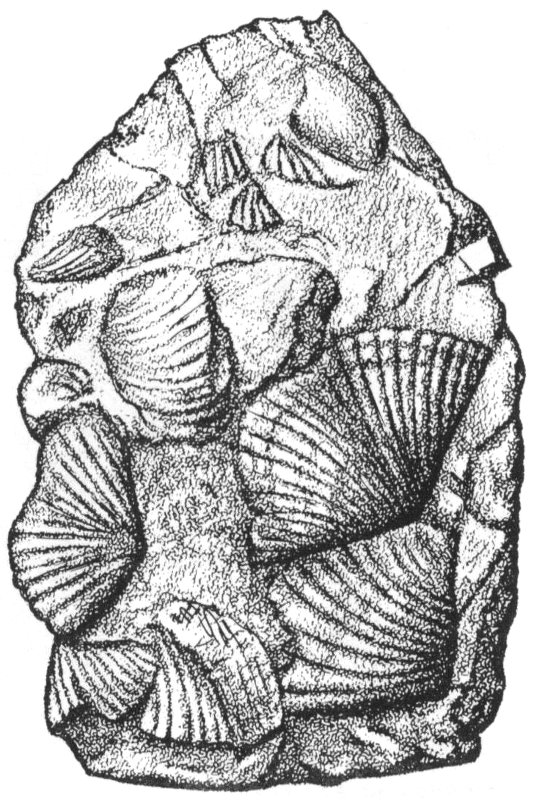

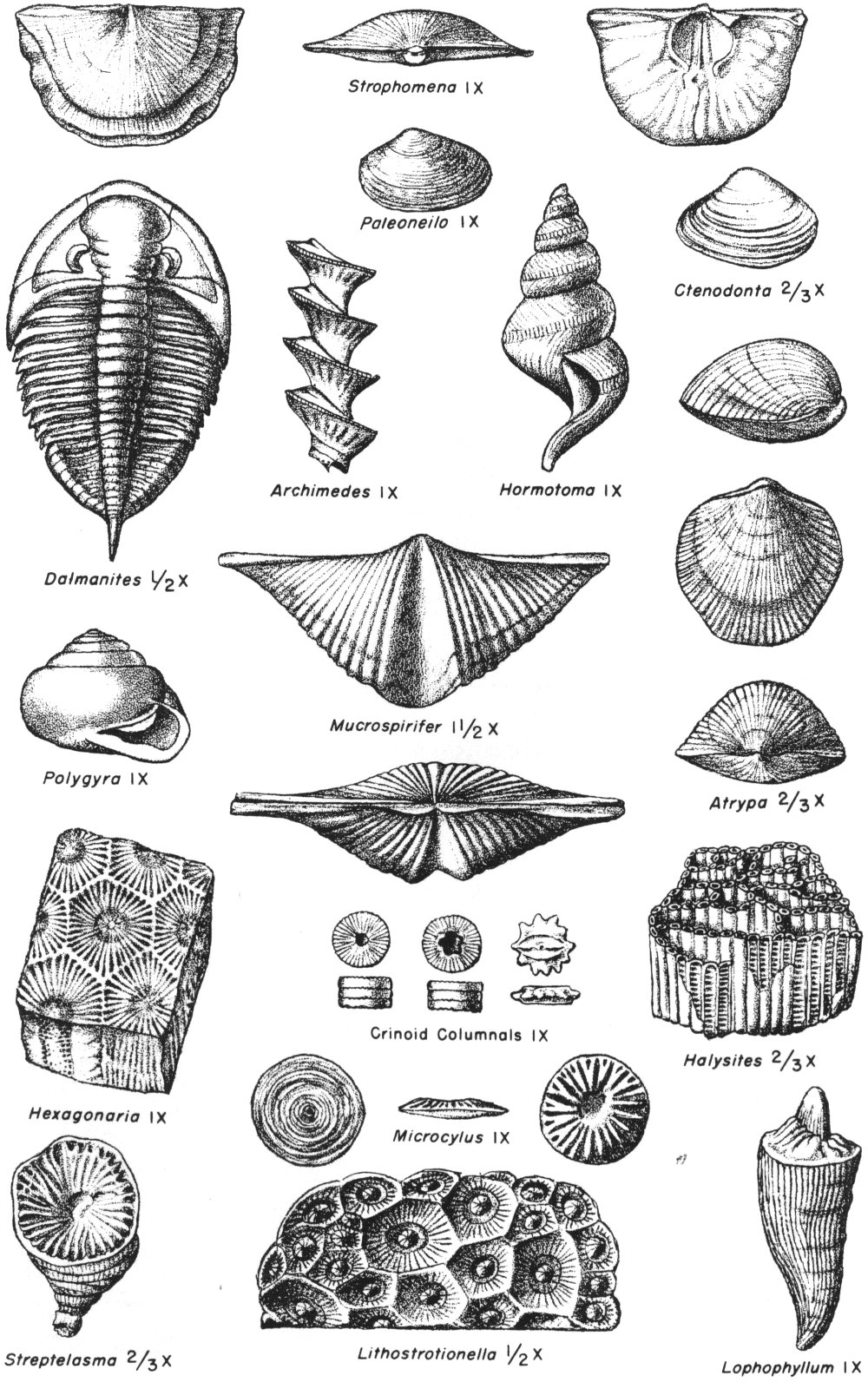

Limestone is a sedimentary rock that consists chiefly of calcite, which is composed of calcium, carbon, and oxygen. Dolomite is a variety of limestone that contains considerable magnesium in addition to the other elements. Limestones were deposited on the floors of ancient seas that repeatedly covered most parts of Illinois. Shelled creatures, corals, and coral reefs helped build up the thick limestone deposits (figs. 13 and 14).

Figure 13—Piece of limestone largely made up of fossil brachiopod shells.

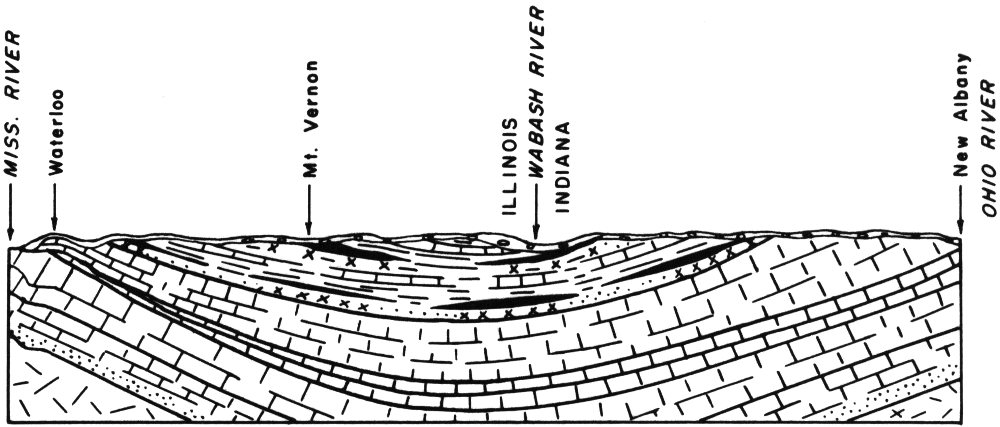

Limestone and dolomite quarries are located along the southern, western, and northern margins of the state where the thick deposits of these rocks crop out at the surface. Although bedrock was deposited in horizontal layers, it has since been downfolded into the Illinois Basin whose center is in southeastern Illinois. Thus, the thick limestones and dolomites that are quarried along the margins of the state are too deeply buried to be quarried in the central part of this basin (fig. 15).

Figure 14—Fossils commonly found in Illinois rocks.

Figure 15—Diagrammatic cross section of the Illinois Basin.

Yes. In the area underlain by the basin, stone quarries are operated in younger, thinner rock strata of Pennsylvanian age. These strata also overlie the thick limestones and dolomites quarried along the margins of the state. The quarries located within the basin area produce stone for agricultural limestone, roads, and other purposes.

Millions of tons of stone are crushed annually to produce aggregate for use in making concrete roads and buildings, for road surfacing, and for agricultural limestone. Agstone is applied to farmlands to neutralize soil acidity, improve soil structure, add calcium and magnesium, and promote conditions favorable for the utilization of soil materials by plants. Large quantities of limestone are used in making lime and cement. There are three cement plants 22 in northern Illinois—two at LaSalle and one at Dixon—and one in southern Illinois, at Joppa.

Small amounts of stone are used for making alkalies and glass, for railroad ballast, for building stone, for dusting coal mines to prevent coal dust explosions, and for ingredients in mineral feeds for livestock.

A production of about 36 million tons of stone in 1963 was valued at almost $48,000,000. The cement made from Illinois limestone in the same year was valued at $32,000,000.

Weathering or alteration of some rocks produces clay which is a very fine-grained, unconsolidated rock. Clay is made up of a group of minerals, of which illite, montmorillonite, kaolinite, and chlorite are the most abundant.

Clay deposits in Illinois consist of Quaternary clays, which were deposited by glaciers, lakes, and winds; and of fireclay, shale, kaolin, and “fuller’s earth,” all of which are bedrock deposits. Quaternary clay, fireclay, and shale resources occur widely in very large quantities; “fuller’s earth” and kaolin deposits are small in relation to other clay resources.

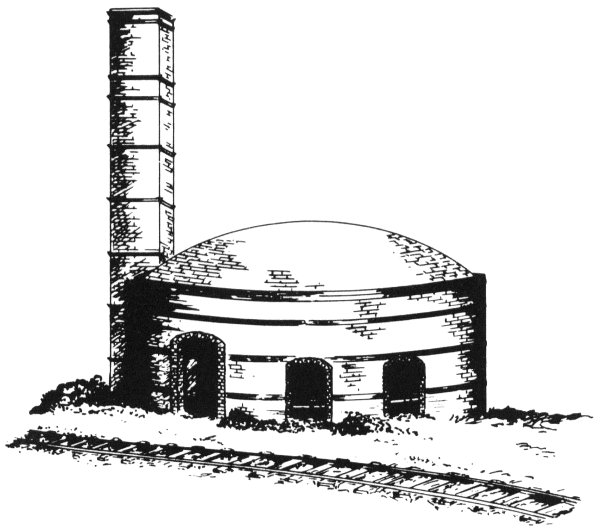

Surface clay, shale, and fireclay are used in the manufacture of structural clay products, such as brick, drain tile, and hollow block (fig. 16). Fireclay is used for a bonding agent in molding sand, for the making of stoneware vessels, for a plaster on the walls of industrial furnaces, and for making 23 refractory brick. Refractory brick must be able to withstand very high temperatures and is used to line industrial furnaces, boilers, kilns, and ladles for molten steel.

Shale and clay are ground up and mixed with limestone in the manufacture of cement. Crucibles, refractories, china, and porcelain are made from kaolin. “Fuller’s earth” is used as a sweeping compound and as an animal litter.

Figure 16—Typical Illinois bee-hive kiln.

About $53,900,000 worth of clay products were manufactured in Illinois in 1963.

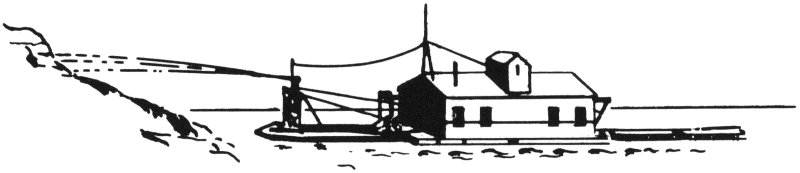

Glacial deposits of sand and gravel are the chief source of these materials in Illinois, but chert or flint gravels that are older than the glacial deposits are known and utilized locally in western and extreme southern Illinois. Sands of recent origin are dredged from deposits in the larger rivers and streams (fig. 17), and commercial silica sand is produced from sandstone bedrock.

Figure 17—Dredge equipment used in producing sand and gravel.

Production of common sand and gravel totaled 27,115,000 tons at a value of $24,800,000 in 1963.

Although natural sands are aggregations of many kinds of small rock and mineral fragments, silica sand consists almost entirely of fine grains of a single mineral, quartz. The principal sources of Illinois silica sand are in LaSalle (Ottawa, Utica, Wedron, and Troy Grove areas) and Ogle (Oregon area) Counties.

Silica sand, produced in northern Illinois, is famous for its high purity, and is widely used in making glass. More than two-thirds of the raw material in common glass is silica sand.

Quantities of silica sand are used as molding sand, because it can withstand the high temperatures produced in casting steel and other metals. It also is used for grinding and smoothing plate glass, for sand blasting, and for fracturing sand used to increase the production of oil wells. Some silica sand is ground to a fine powder and utilized as an ingredient in scouring compounds, paint fillers, pottery, glazes, and enamels.

A specially sized sand is produced from the St. Peter Sandstone Formation (Ordovician in age) that is used in testing the strength of cements and as a laboratory standard in various kinds of tests.

Illinois is a major producer of silica sand, having produced 2,900,000 tons in 1963. The silica sand and ground silica produced in the same year was valued at $11,400,000.

Tripoli, also known as amorphous silica, is mined in Alexander County in southern Illinois. It is prepared for market by being ground to a fine powder. It consists of tiny particles of quartz.

Tripoli is used as “white rouge” in optical lens polishing, as a paint filler, as a fine abrasive, in the ceramic industry, and for many other purposes.

Fluorspar, or fluorite, is a glassy mineral that is commonly gray, white, or colorless, but may be green, blue, purple, yellow, or black. It is composed of calcium and fluorine. Fluorite is not a gem because it is too fragile and soft. Mineral collectors seek it because it is attractive and because some varieties have the ability to glow under invisible ultraviolet light (hence the term “fluorescence”).

Fluorspar produced in the United States comes chiefly from a small area in Illinois and Kentucky where it has been mined since 1842. Illinois produced about 66 percent of the nation’s total in 1963. The state’s production amounted to more than 132,000 tons, valued at about $6,547,000. The crude ore is extracted from nearly horizontal bedded deposits and from nearly vertical veins in mines up to 800 feet deep in Pope and Hardin Counties. Finished fluorspar is produced from the crude ore by separating and concentrating methods.

In the separation of fluorspar from the other materials with which it naturally occurs, a process is used that involves grinding the spar to a very fine powder. The powdered spar has a number of uses, but to suit it for use as a flux (a substance which promotes fusion) it is made into pellets by the use of a binder.

Fluorspar is used extensively as a flux in the steel industry, but over 50 percent of the spar produced in Illinois in 1963 was consumed in the manufacture of hydrofluoric acid. A large portion of this acid production is used in the aluminum industry. Hydrofluoric acid is also employed in the preparation of many fluorine compounds, particularly those used in the production of fluorocarbons (refrigerants, plastics, aerosols), insecticides, and high-energy fuels for rockets and missiles. The fluorocarbons utilize about 40 percent of the hydrofluoric acid production.

The mineral galena is the principal ore of lead. Galena is gray in color, very heavy, has a bright metallic luster, and breaks into cubes along steplike cleavage surfaces (fig. 18). It is composed of lead and sulfur.

The chief ore of zinc is the mineral sphalerite. It may be brown, yellow, or black. Sphalerite is a combination of zinc and sulfur, has a resinous luster, and is not as heavy as galena.

Although the lead deposits of extreme northwestern Illinois (now Jo Daviess County) were reported by the French explorers 27 in 1658 and are said to have been worked by the Indians, the influx of white settlers in the early 1800’s marked the beginning of an extensive mining industry, which was an important factor in the early development of that part of the state. The town of Galena takes its name from the mineral galena, which was the principal ore mined.

Figure 18—Galena cubes.

In 1845, the Upper Mississippi Valley produced 60 percent of all lead mined in the United States, which then ranked first in world lead production. Until about 1860, the zinc ore was considered useless, but today its total value is several times that of lead.

Lead mining began in southern Illinois in 1842. Lead and zinc production in this area is a by-product of fluorspar mining.

In 1963, Illinois produced 20,377 tons of zinc valued at about $4,677,500 and 2,901 tons of lead worth about $626,600.

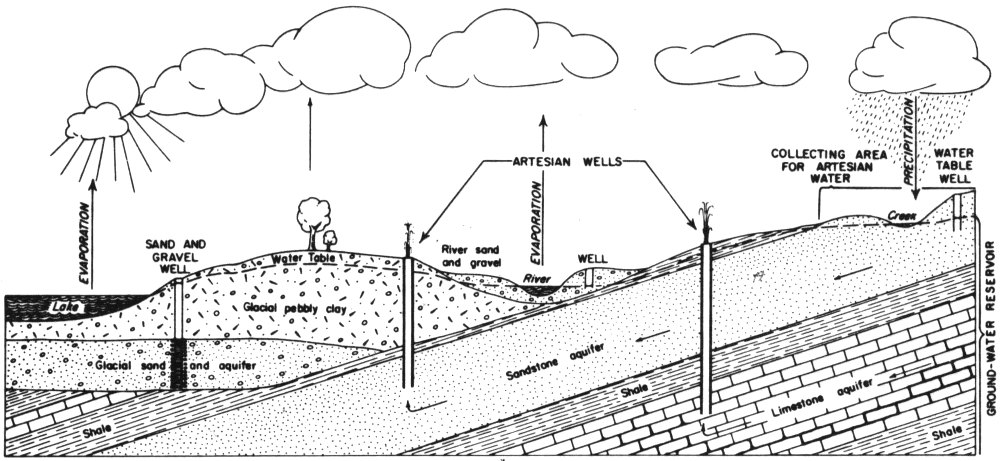

Ground water is water that fills all openings in earth materials in the zone of permanent saturation. The top of the zone of saturation is called the water table. The source of ground water is precipitation (rain and snow) that seeps into the soil and percolates downward. Below the water table, ground water moves slowly toward places of discharge such as springs, lakes, rivers, marshes, and wells. Water falls to the ground, moves through the rocks, returns to the surface, and finally gets back to the atmosphere by evaporation and from plants (fig. 19). This cycle is continuously repeated.

Ground water is most readily obtained from saturated rocks that have fairly large openings between grains (such as sand, gravel, and sandstone) or have interconnected cracks or channels (such as limestones). Rocks that contain ground water and that will yield it to wells are called aquifers. Sand and gravel beds are widely used aquifers in Illinois.

Figure 19—Source, movement, and occurrence of ground water. Arrows in aquifers show direction of flow of water.

No. There are a few large springs that flow from rocks along river bluffs in Illinois, but most ground water occurs in tiny openings within the rocks. Ground water reservoirs may be regarded as similar to sponges rather than as underground lakes or rivers.

The water table rises and falls seasonally and from year to year, depending upon the amount of precipitation. Sometimes the water table may fall below the bottom of the well or below the pump. Sometimes overpumping the well or pumping too many wells in a small area lowers the water table sufficiently to check the yield of the well.

An artesian well is one in which pressure forces water to rise in the well above the level where it was found. In some artesian wells water flows out at the surface. Conditions for artesian wells are illustrated in figure 19. The shale above the sandstone and limestone aquifers in the figure is “tight” and does not permit water to escape upward to the level at which it enters the aquifers in the intake areas. The water is under natural pressure. When a well is drilled through the shale and into the aquifers, water rises, seeking its own level. Most of the deep wells in northern Illinois are artesian wells, though few of them flow at the surface anymore.

This is generally true. However, in much of the southern two-thirds of Illinois the deeper waters are quite salty. Therefore, only the upper few hundred feet of rocks are worth exploring for water. In the northern third of Illinois, where the deepest water wells are located, fresh water extends in some places to more than 2,000 feet.

The most effective way of locating a ground water supply is by using knowledge of the geology and ground water conditions—gained partly from study of existing well records—to determine the most favorable areas and depths to drill to.

An additional tool that has been used successfully in Illinois is the electrical earth resistivity survey. The resistivity survey attempts to locate buried sand and gravel layers that commonly are sources of ground water. Test drilling is recommended at sites that appear to be underlain by sand and gravel.

There is no known method that will positively “find” ground water without drilling.

Geology and allied sciences are being called upon increasingly to aid in more intelligent and efficient discovery and utilization of mineral wealth. Our national life and welfare are more and more dependent upon the further discovery and proper use of the earth’s natural resources. Illinois is widely recognized by scientists, industrialists, and educators as being outstanding in its promotion of research and industrial development.

The occurrence and distribution of rock and mineral deposits in Illinois are studied by the State Geological Survey Division of the Department of Registration and Education (fig. 20). In seeking new information concerning the state’s natural mineral resources, physical and chemical studies of useful rocks, minerals, and mineral products are made. Techniques and methods are developed and experiments are conducted to find and prepare Illinois’ mineral substances for use.

The results of the Survey’s field and laboratory findings are published and made available to all citizens upon request. 31 Much information that has not been published is in the open files of the Geological Survey where it may be examined by the public. Members of the Survey’s scientific and technical staff answer requests for information received by letter, telegram, telephone, or personal interview.

Since the main ideas of geology are easy to understand and greatly increase one’s enjoyment and appreciation of the world in which we live, the Geological Survey publishes popular and educational booklets designed for the use of Illinois teachers and students. The Survey also distributes a labeled collection of rocks and minerals for class use in Illinois schools. Six geological science field trips are conducted each year throughout various sections of the state for teachers and interested laymen. Members of the Survey staff give illustrated lectures to organized groups about the geology and mineral resources of the state.

Figure 20—Geological Survey offices are located in the Natural Resources Building, Urbana, Illinois.

All of the Survey’s publications are distributed free to schools and teachers. Only topographic maps and certain base maps, which are prepared and printed by the U.S. Geological Survey in Washington, are sold at nominal prices.

| Era | General Types of Rocks | |||

|---|---|---|---|---|

| Period or System and Thickness | ||||

| Epoch | ||||

| CENOZOIC “Recent Life” | ||||

| Age of Mammals | ||||

| Quaternary 0-500′ | ||||

| Pleistocene or Glacial Age | ||||

| Recent—alluvium in river valleys | ||||

| Glacial till, glacial outwash, gravel, sand, silt lake deposits of clay and silt, loess and sand dunes; covers nearly all of state except northwest corner and southern tip | ||||

| Tertiary 0-500′ | ||||

| Pliocene | Chert gravel; present in northern, southern, and western Illinois | |||

| Eocene | Mostly micaceous sand with some silt and clay; present only in southern Illinois | |||

| Paleocene | Mostly clay, little sand; present only in southern Illinois | |||

| MESOZOIC “Middle Life” | ||||

| Age of Reptiles | ||||

| Cretaceous 0-300′ | Mostly sand, some thin beds of clay and, locally, gravel; present only in southern Illinois | |||

| PALEOZOIC “Ancient Life” | ||||

| Age of Amphibians and Early Plants | ||||

| Pennsylvanian 0-3,000′ (“Coal Measures”) | Largely shale and sandstone with beds of coal, limestone, and clay | |||

| Mississippian 0-3,500′ | Black and gray shale at base; middle zone of thick limestone that grades to siltstone, chert, and shale; upper zone of interbedded sandstone, shale and limestone | |||

| Age of Fishes | ||||

| Devonian 0-1,500′ | Thick limestone, minor sandstones and shales; largely chert and cherty limestone in southern Illinois | |||

| Age of Invertebrates | ||||

| Silurian 0-1,000′ | Principally dolomite and limestone | |||

| Ordovician 500-2,000′ | Largely dolomite and limestone but contains sandstone, shale, and siltstone formations | |||

| Cambrian 1,500-3,000′ | Chiefly sandstones with some dolomite and shale; exposed only in small areas in north-central Illinois | |||

| ARCHEOZOIC and PROTEROZOIC | ||||

| Igneous and metamorphic rocks; known in Illinois only from deep wells | ||||

Illinois State Geological Survey

Educational Series 9