Title: Practical Organ Building

Author: W. E. Dickson

Release date: May 28, 2020 [eBook #62257]

Most recently updated: October 18, 2024

Language: English

Credits: Produced by deaurider, Alan and the Online Distributed

Proofreading Team at https://www.pgdp.net (This file was

produced from images generously made available by The

Internet Archive)

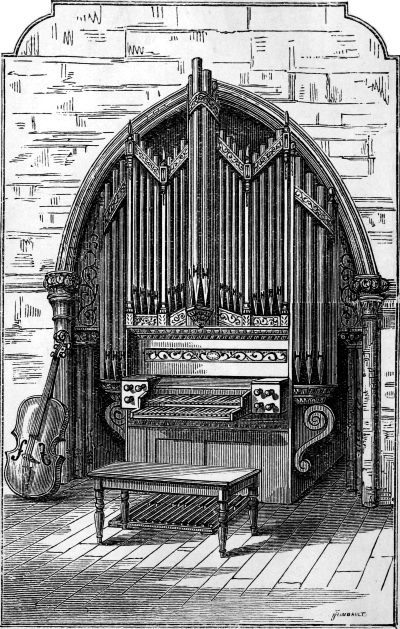

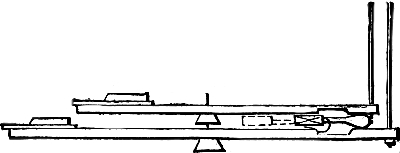

Frontispiece

By W. E. DICKSON, M.A.

PRECENTOR OF ELY CATHEDRAL

SECOND EDITION, REVISED, WITH ADDITIONS

LONDON

CROSBY LOCKWOOD AND CO.

7, STATIONERS' HALL COURT, LUDGATE HILL

1882

[All rights reserved]

LONDON:

PRINTED BY J. S. VIRTUE AND CO., LIMITED,

CITY ROAD.

PREFACE.

This little work is undertaken because it is believed that no treatise on the construction of organs, at once short, practical, and accessible by all classes of readers, is extant.

The bulky volume of Hopkins and Rimbault, worthy as it is of all commendation, and abounding with matter interesting to the musician, does not profess to enter into details essential to the workman. The same remark may be applied to sundry treatises in the form of articles contributed to Encyclopædias, or to periodicals of a popular kind. The writers of these articles, probably fully masters of the subject, cannot, from the very nature of the case, command the time, space, and amplitude of illustration absolutely necessary for the full elucidation of the mechanical processes involved in the construction of the most elaborate and ingenious of all musical instruments.

Readers of the French language, indeed, may find all that they require in a most admirable and exhaustive work, the "Facteur d'Orgues," by M. Hamel, forming one of the series of the[Pg vi] "Manuels-Roret," published in 1849 by Roret of Paris, in three volumes, with an atlas of plates. The author of this complete exposition of the organ-builder's art has taken for the foundation of his book the great work of Dom Bedos, a Benedictine monk, who printed in 1766-78, at Paris, two sumptuous folio volumes, with plates, which leave unnoticed nothing which was known or practised by the workmen of his period. The modern editor, however, who displays a most intimate knowledge of his subject, together with an enviable power of explaining it in all its minutest details, aided, as he is, by the most accurate of all European languages, has produced in his third volume a manual of the art of organ-building in recent times, which covers the whole field of investigation, and of which it is not too much to say that it can never be surpassed.

A somewhat indifferent translation of a German treatise on the "Organ and its Construction," by Herr Seidel, of Breslau, appeared some years ago. But this work, like the English publication first noticed, is not for the dwellers in workshops, but for organists, choir-masters, clergymen, and others entrusted with the care of existing organs, or likely to be concerned in the erection of new ones.

The writer has lately perused, with much pleasure and advantage, a tract of about forty pages on "Organ Voicing and Tuning," published for the author (evidently a practical operator). He can warmly recommend this unpretending introduction[Pg vii] to the highest branch of the art, so seldom mastered save by those who have had the advantage of early and assiduous practice under skilled guidance. But it deals, of course, with that highest branch only, and assumes previous knowledge of mechanical construction.

He himself, several years ago, contributed a short series of articles on the construction of small organs to a periodical publication now extinct. The letters which he received from working men, urging him to treat the subject in greater detail, furnished a striking proof of the extent to which the leisure hours of many artisans are devoted to the production of an organ in some one of its innumerable forms, from the toy with two or three stops to the complete instrument with as many rows of keys. Such inquirers will not be satisfied, he fears, by the narratives of "How we made our First Organ," and the like, in well-meant and otherwise well-written books for boys. The real difficulties of organ-building (and they are numerous) are simply evaded in some recent books of this kind, which convey the irresistible impression that their authors are not themselves handlers of the plane and chisel. The true workman knows full well that the very simplest of organs cannot be put together in a few weeks, out of school-hours, and side by side with other undertakings.

If the present work, in which the writer describes the results of his own experience, and lays[Pg viii] down no rules which he has not reduced to practice in his own workshop, should have the effect of deterring ingenious boys from attempting their "First Organ" until the possession of a large stock of patience, as well as the command of leisure, and of means moderately adequate for the purchase of good materials, are abundantly and unmistakably assured to them, the author, once a plodding and untiring boy-workman himself, will have reason to be satisfied that his efforts to explain a complicated and intricate structure have not been entirely fruitless.

PREFACE TO THE SECOND EDITION.

Since the publication of this work, the author has had reason to believe that some hints as to the design and erection of small organs in country churches may be acceptable to readers who occupy the position, not of constructors, but of purchasers. He trusts that the chapter now added, "On Village Church Organs," will be found to contain the desired information.

CONTENTS.

| CHAPTER I. | |

| PLANT AND MATERIALS. | |

| PAGE | |

| The Workshop—Tools—Lathe—Materials | 1 |

| CHAPTER II. | |

| THE STOPPED DIAPASON. | |

| Tablature, or Names of Notes—Lengths of Pipes—Parts of Stopped Pipe—The Scale—Two Methods of making Wooden Pipes—Some Varieties of Pipes—Old English Organs | 10 |

| CHAPTER III. | |

| THE SOUND-BOARD. | |

| Dimensions of Organs—Construction of Sound-board—Channels—Sliders—Plantations of Pipes—Bars—Bearers—Upper Boards—Rack-boards | 27 |

| CHAPTER IV. | |

| THE SOUND-BOARD.—(Continued.) | |

| Grooving—Boring Holes—Conducting-boards—Conveyances | 44 |

| CHAPTER V. | |

| THE WIND-CHEST. | |

| Running of Wind—Blacklead used—Pallets—Leather for Pallets—Springs—How to make them—Pull-downs—Drilling—Brass Plate—Front-board | 55 |

| CHAPTER VI. | |

| THE BELLOWS, TRUNKS, AND FRAME. | |

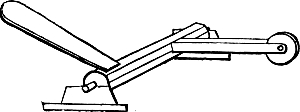

| Shape of Bellows—Valves or Clacks—Cummins's Improvements—Counter-balances—The Cuckoo-feeder—Hydraulic-power Engines—Trunks—The Frame—Its general Dimensions—Hollow Frame-work—Blowing Pedal—Blowing Lever | 72 |

| CHAPTER VII. | |

| PLANTATION OF PIPES. | |

| Pipe-feet—Rack-pins—Symmetry | [Pg x]90 |

| CHAPTER VIII. | |

| THE ACTION. | |

| Definitions—Back-fall—Bridge—Square—Sticker—Tracker—Tapped Wires—Cloths—Buttons—Rollers—Roller-boards—Principle of Organ-action—Fan-frame—Keys—Roller-frame—Double Sound-board Action—Thumping-board | 94 |

| CHAPTER IX. | |

| VOICING AND TUNING. | |

| Metal Pipes—Their Construction—Nicking—Voicing—The Wind-gauge—Defects in Pipes—Temperament—Regulation | 115 |

| CHAPTER X. | |

| THE DRAW-STOPS. | |

| Four Methods of drawing the Stops described—Levers—Bell-cranks—Trundles—Iron Trundles | 127 |

| CHAPTER XI. | |

| PEDALS. | |

| Their Compass—Dimensions—Springs—Dip—Connection with Key-board—Removable Pedal-board | 135 |

| CHAPTER XII. | |

| TWO-MANUAL ORGANS. | |

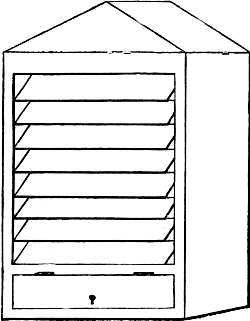

| Remarks on the Swell-organ—Organs with Great and Choir—Borrowing in Two-manual Organs—Chamber Organ by Schmidt—The Swell-box—Its Construction—The Swell-action—Reed-stops—Manual Couplers—Rising and Falling Bridges—Pedal Couplers—Old Method of Coupling—A Combination Manual—The Pedal Sub-bass of 16-feet Tone—Scale—Wind-valve for Pedal Chest—Violoncello Stop—Terzo Mano | 141 |

| CHAPTER XIII. | |

| VILLAGE CHURCH ORGANS. | |

| Principles of Construction—Suggestions for Designs—Objections noticed—Care of Old Organs | 165 |

ORGAN-BUILDING.

PLANT AND MATERIALS.

We shall assume at once, and at the very outset, that our reader has the fixed purpose of producing an organ which shall be creditable to its builder, a source of pleasure to its players and their hearers, and an ornament to the room or building in which it is erected: in short, that he remembers the excellent maxim, "whatever is worth doing at all, is worth doing well," and will not be content with rough workmanship, inferior materials, and inharmonious results.

Assuming this as the basis and principle of all our suggestions, we shall nevertheless bear in mind the necessity of adapting our rules to the conditions imposed by slender purses, and the imperfect appliances of humble workshops. Without attempting to quote the actual market prices of the wood, leather, and metal required, or of those important parts of the instrument which in most cases will be purchased ready-made, we shall endeavour to show[Pg 2] how economy may be consulted by obtaining all these gradually, as our work advances with that inevitably slow progress which attends all proceedings in which most haste is found to be worse speed.

We shall buy nothing which we can make for ourselves. The common sense of our readers may be trusted not to press the application of this rule to a reductio ad absurdum. As we shall certainly buy, and not make, our screws and nails, so in the course of the following pages we may possibly recommend the buying of certain parts of the work, in full remembrance of our rule. But even in these occasional instances we shall probably point out how expenditure may be saved by patient industry. We need not anticipate. Our readers will see for themselves what we mean as we go on.

Our task will be somewhat simplified if we suppose that an organ is desired for a room of moderate size. Such an instrument will commonly have one manual, or row of keys, with four or five stops, or sets of pipes. Pedals, with or without pipes of their own of deep bass quality, must be considered essential in every organ making any pretension to completeness, or intended to afford useful practice for learners. Taking this as a rough outline or sketch of probable plans, it will be easy to see hereafter how they may be indefinitely extended.

Our organ factory, then (with some such plan in our head), must be a roomy, well-lighted, perfectly dry workshop, furnished with a fire-place or stove[Pg 3] for the glue-pot, with drawers or cupboards for storing away skins of leather and other materials not in constant requirement, and with shelves on which pipes may be stowed without danger of rolling off. It must not be a mere shed or hovel in which we might mend the cart or the wheel-barrow, and it should not be far from our dwelling-house, if we are likely to work at our serious undertaking in the winter evenings.

The shop must be fitted with a full-sized bench in good condition, that is to say, with its top dressed truly, and not hacked by rough usage; and good workmanship will be much promoted if the usual appliances of such a bench are of the best kind and in complete order. True planing, so vitally essential in organ-building, cannot be done upon a crazy or worn-out bench. The bench should stand near a window, and it should be so placed that boards much longer than itself may be occasionally dressed upon it by temporary arrangements.

The tools required are chiefly those which are common to every joiner's shop; notably and of first importance the three planes, the jack, the jointer or trying plane, and the little smoothing plane. This last may now be bought in a very handy form, entirely of iron, and fitted with a clever adjustment by which the cutter can be set to any degree of fineness. This little plane (an American invention) is invaluable for many purposes involving extreme neatness and accuracy. The planes must at all times be kept in first-rate order, and any defect[Pg 4] which makes its appearance must be instantly rectified by a careful use of the oil stone. The latter, let us mention by the way, as we may have youthful and inexperienced readers, should be levelled occasionally by being rubbed on a flat slab with sand and water. The plane is emphatically the tool of the organ-builder, and no pains should be considered too great to be bestowed on the care of these beautiful tools, or on the attainment of dexterity in the use of them.

The usual saws, the ripping saw, the panel saw, the dovetail, the key-hole or pad saw, will be required; and we may take this opportunity of remarking that as the organ-builder must have a strong dash of the smith as well as of the joiner in his composition, his shop must have a stout vice fixed in a convenient part of it, and a few good files always available for brass or for iron. (The reader is doubtless aware that the same file must not be used for both these metals.) Drills for metal, some of them of small clockmaker's sizes with a bow and breast-plate for working them, will belong to this department, which will also include a screw-plate for tapping wires of various sizes from one-eighth of an inch downwards, and cutting pliers or nippers for dividing the wire.

The tool-chest must contain a thoroughly good brace and bits; and among the last should be some one of the various forms of adjustable centre-bits for cutting large circular holes of graduated dimensions up to 3 inches diameter.

In connection with this it may here be mentioned that most of the holes bored with the brace and bits (though not the huge holes just referred to), will be scorched or charred with a red-hot iron, in order to clear them of splinters, and allow a perfectly free passage for the air which will pass through them. A few pieces of iron rod, of sizes suitable for this purpose, will therefore be required. Many of these holes will be also countersunk, that is, rendered conical at their extremity, in order to receive the conical feet of the pipes which receive from these conduits their supply of wind. This countersunk portion is also scorched or charred, and two or three conical irons will be wanted for this purpose. But we have not yet come to this. When we are ready for these irons, we can have them made by any blacksmith, or we may have put aside some stout morsels of old iron from which we ourselves may contrive to fashion them.

An important question must next be asked.

Is a turning-lathe absolutely necessary as part of the plant of our factory? We must answer this. We should be sorry to deny that a small organ certainly can be and may be built without the aid of a lathe. We know that it has been done. But it is equally undeniable that the absence of a lathe, or of access to a lathe, will necessitate the purchase of certain parts (wooden pipe-feet for instance, and rack-pins), at an outlay which will bear an appreciable proportion to the first cost of[Pg 6] a simple and inexpensive machine. Pressed, then, to say if our workshop must include a lathe, we are bound to reply in the affirmative, explaining, in the same breath, that all the purposes of the young organ-builder will be answered by a lathe of humble character and trifling cost. We ourselves, during several years of early beginnings, used a small clockmaker's lathe by Fenn, of Newgate Street, just capable of admitting between its centres the little billet of wood ready for shaping as a pipe-foot, that is to say, about 7 inches in length, and from 2 inches down to half an inch in diameter. We still possess this little lathe, and still sometimes use it for small work. Some such simple lathe, or some lathe still simpler, being voted as necessary, the usual turning-chisels and gouges will of course accompany it, and we shall assume that our readers possess a sufficient acquaintance with the wood-turner's art to require no hints from us on the subject other than those which we shall give in regular course as we proceed. If they are fortunate enough to possess a superior lathe, with slide-rest and slow motion for turning iron and brass, they will find the machine most conducive to good and durable workmanship, and we shall not hesitate to point out, as we go on, how materially it will assist us in giving strength, firmness, and finish, to various parts of our work.

We have furnished, then, our workshop, or rather, let us say, we see it in our "mind's eye"[Pg 7] furnished as we should wish it to be. And now we may lay in our stock of wood.

Several boards of half-inch pine, perfectly dry and sound, without knots; these are of first necessity. Such boards are generally about 12 feet in length and from 12 to 15 or even 20 or more inches in breadth. If a little stock can be laid in of such boards when an opportunity occurs of obtaining exceptionally clean stuff, it will be well to have them by us. A board or two of three-quarters stuff, and a board of inch stuff, all sound and clean pine, must be provided.

And here we may pause for a moment.

We intend to begin our organ by making a set of wooden pipes. Hence we need not provide ourselves with more timber for the present than we shall need for this first operation. But as in our imaginary furnishing of the workshop, we included several or many things which belong rather to future than to immediate use, so we may here place the reader in a position to form some idea of the further expense to which he will be put for the purchase of timber for his proposed small organ of four or five stops. The pine boards just enumerated will give us our first set of pipes; but when these are ready, we shall require some rather costly wood for the sound-board. This should be Honduras mahogany, often called "Bay wood," and of three thicknesses, say, three-quarters stuff for the table of the sound-board;[1] a full inch, or, [Pg 8]still better, five-quarters, for the upper boards; and some very thin stuff, three-eighths or less, known as "coach-panel," for the sliders. The quantities, or number of square feet, of these mahogany boards will be determined by considerations discussed in a subsequent chapter. The wood must be carefully selected, for the grain of it is often tortuous and unkindly for the plane; it must be, like the pine, free from large knots, flaws, and cracks; and the completeness of its seasoning should be quite unquestionable and beyond the reach of suspicion.

[1] All these expressions will, of course, be explained hereafter.

It is not unreasonable to assume that the reader, who has contemplated for some time the building of an organ, has already by him some materials which he knows will be necessary; for instance, some boards of sound white deal for the framework, and perhaps for the bellows; and some scantlings of red deal, or pitch pine, or oak, or mahogany, or red cedar, for the blocks and stoppers of pipes. He will not need the aid of this book to be aware that old materials may sometimes be turned to excellent account in such a business as that upon which he is embarking. We have known the purchase (for a pound or two) of an old square pianoforte turn out a profitable investment. Its mahogany top was solid, not veneered; and the thin boards found in its interior dry as touch-wood, and perhaps one hundred years old, were made into pipes of charming sweetness.

The old organs before the days of mahogany were made chiefly of oak, often called "wainscot."[Pg 9] We ourselves have made much use of this durable and trustworthy material, which may be obtained in the convenient form known as "coopers' staves," being planks about 6 feet in length, as many inches in width, and 2 or 3 inches thick. They may be divided, at any saw-pit or saw-mill, into boards of the desired thinness, and they work pleasantly under thoroughly sharp tools.

And now we may set to work upon our set of wood pipes.

THE STOPPED DIAPASON.

Why do we begin by making a set of wooden pipes?

For two reasons. First, because they will afford a trial of patience, and involve a great deal of good joinery. Second, because until they are made, or, at any rate, until we know their precise dimensions, we cannot plot out with accuracy the very important sound-board, which is to carry them and the other pipes which are to follow. Either of these reasons is, to our mind, sufficient, apart from the other; and we strongly recommend the young beginner to set himself resolutely to the manufacture of the complete set of wooden pipes belonging to the commonest of all organ-stops, the Stopped Diapason, before taking any step in the direction of the machinery or apparatus which is to waken them into harmonious vibrations.

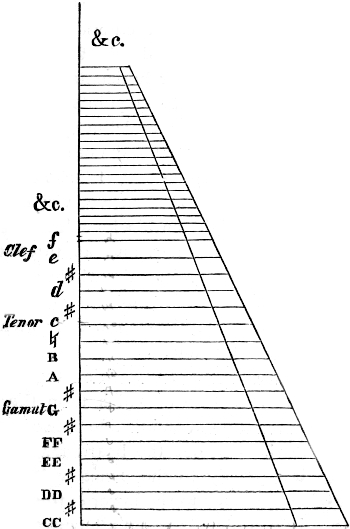

Our explanations will be much assisted here if we introduce a few definitions of terms in constant use. The pipes which we are about to make will give notes, when tuned, which are familiarly designated by certain names. Thus, the lowest[Pg 11] note on the manual or key-board of modern organs is called Double C (printed CC). The note one octave above this is Tenor C; the octave of Tenor C is Middle C; and above this, again, we have Treble C (often called Foot C) and C in Alto. Some of the other notes of the scale, in a similar way, have convenient names. Thus, the first F in the bass is Double F, or FF; the next F, the F of the Tenor octave, is often called Clef F, as the Bass, or F Clef, stands upon this line in music; its sharp is FF sharp; but then we come at once to a single G, and this note is often called Gamut G. The octave above this note is called Fiddle G, as it sounds the same note as the fourth string of the violin. The note B, we may add, throughout the organ, is understood to mean B flat; the semitone above this is indicated by the musical symbol the Natural (♮).

We have not quite done with this. There is another way of referring to pipes, and to complete sets of pipes, which is in familiar use, and is part of the mother-tongue of the organ-builder. We have said that Treble C is often called Foot C. This is because the ordinary open pipe of that note (speaking now quite inexactly, and without precision), is 1 foot in length. In a similar way, CC is 8-foot C, or the 8-foot note, because the open pipe is 8 feet in length, speaking roundly or roughly. Tenor C is 4-foot C; Middle C, 2-foot C.

It will be easily understood that these convenient designations are retained, even though the construc[Pg 12]tion of the pipes may render them strictly inapplicable. Thus, the lowest note of our first stop will still be 8-foot C, though, as we shall soon see, the stopping of the wooden tube enables us to reduce the actual length by one-half. Our CC will still be of 8-feet pitch, or tone, and by no means becomes a 4-foot C, because its actual measurement, when completed, will not exceed 4 feet in total length.

One step further. The theoretical length of the lowest note is not only used to designate that note and the pipes which belong to that note, but is extended to the designation of the whole set of pipes of which it is the lowest or longest. This whole set of pipes is called familiarly a Stop; thus we have at once the ready terms, 8-feet stops, 16-feet stops, 4-feet stops, 2-feet stops, &c.; and it will be understood that by an 8-feet stop, we mean a set of pipes yielding the common or ordinary pitch of the pianoforte, or of the human voice; while a 4-feet stop, when the very same keys are pressed down, will yield notes one octave higher than this ordinary or standard pitch; the 2-feet stop, notes two octaves higher; the 16-feet stop, notes one octave lower, or deeper. And if all these four stops are played at the same time, (tuning and other manipulations being now assumed), an effect will be produced highly agreeable to the ear, and vastly superior to that which would result from the mere multiplication of 8-feet stops only.

Our little organ of five stops, when completed,[Pg 13] will probably be described with correctness if it is said to contain two 8-feet stops, two 4-feet stops, and one 2-foot stop: a ready and conventional way of speaking, we repeat yet once more, since the instrument will contain no open pipe 8 feet in length, and since, of the 4-feet stops, one will be only of 4-feet tone, or pitch, while even the 2-feet stop, for reasons which will be abundantly made clear, may possibly have no 2-feet pipe.

Some pains have been taken to explain all this, because we have met with young workmen whose comprehension of such rudimentary matters was far from complete, and who were misled by the fanciful and wholly unimportant names engraved upon the knobs which govern the stops, e.g. "Flute," "Dulciana," &c. If we have any such young beginners among our present readers, they will see that the names are quite of secondary concern, and that the essential thing is to have a clear understanding of the pitch of each stop, as represented by the length of the pipe, actual or virtual, corresponding to the lowest note of the manual.

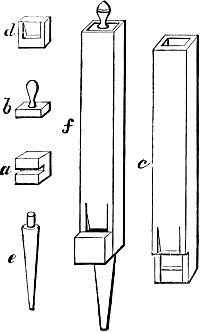

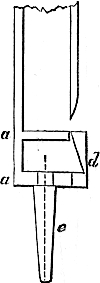

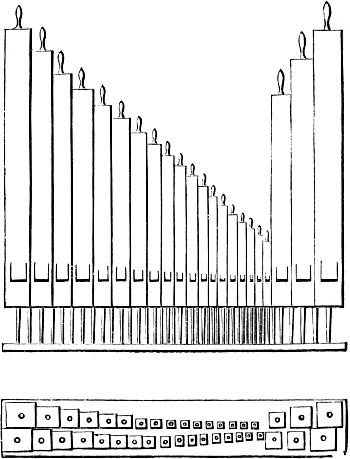

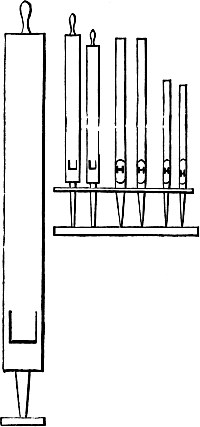

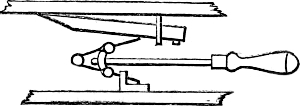

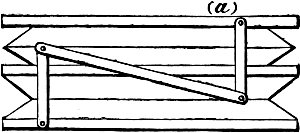

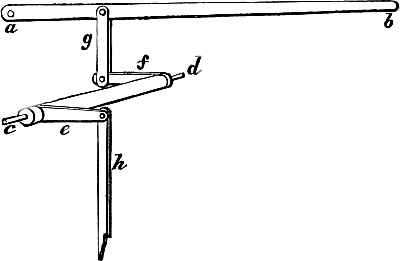

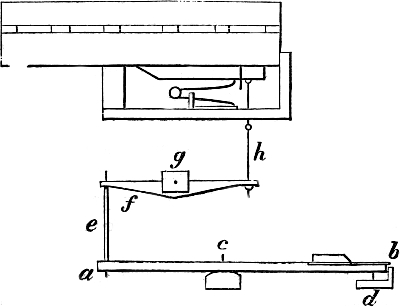

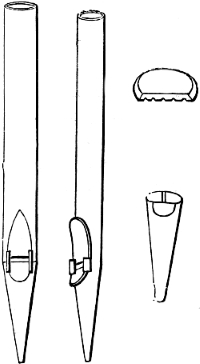

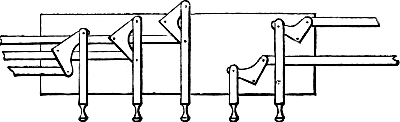

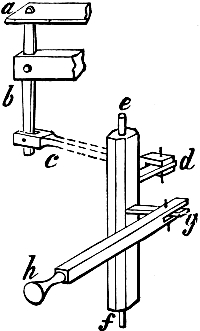

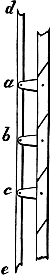

And now we proceed to our work. What we have to do is to make fifty-four pipes, extending from CC to F in alto, and of the form or sort known in England as Stopped Diapason. One of these pipes, let us suppose Tenor C, is shown in Fig. 1. a is a block of mahogany or oak, or of some other wood faced with mahogany or oak, and about 3 inches in length. It has a throat or deep depres[Pg 14]sion across it, formed by taking out the wood between two saw-cuts, or by boring adjacent holes with a centre-bit. b is a stopper, made of any wood, the exact size of the block, or a trifle less, to allow for a leather covering, and fashioned at top into a knob, or turned in the lathe, for convenient handling by the tuner. c is the pipe when put together by gluing three boards, namely, the back and the two sides, to the block, and one, namely the front board, to the edges of the sides. This fourth board is about 3 inches shorter than the others, and has a lip formed on its lower edge by bevelling the wood with a sharp chisel. d is a cap, 3 inches long, and as wide as the block with the side boards attached; it is hollowed in a wedge-shaped form as shown in the figure. e is a foot, turned in the lathe, bored from end to end, and 5 or 6 inches in length. f is the completed pipe, with the stopper inserted, the cap put on, and the foot in its place.

Fig. 1.

We have to make fifty-four such pipes, each of the dimensions proper for the production of its[Pg 15] own note, deep in the bass or shrill in the treble.

It is quite clear that we must not work by "rule of thumb," but understand well what we are about from the very first, if we do not wish to cut our wood to waste and cover ourselves with mortification.

Begin thus. Take a sheet of stout paper, and on it, with rule and compasses, draw a scale showing all the requisite measurements.

Here we must be a little arbitrary, and lay down the law without giving lengthy reasons for our ruling. Stopped pipes are half the length of open pipes yielding the same notes. Our CC pipe will therefore be 4 feet long. The four C's of the ascending scale are the halves of each other. Therefore Tenor C will be 2 feet, Middle C 1 foot, Treble C 6 inches, and C in alto 3 inches, in length. The word nearly, or about, must be understood as prefixed in every case to our measurements. Accordingly, the lengths of all the pipes in the stop will be easily obtained by drawing a vertical line 1 foot in length on the paper, and dividing it into twelve equal parts. At the bottom, write Tenor C, 2 feet; at the top, Middle C, 1 foot. Then the length of each of the eleven pipes intervening between these extremes will be at once obtained by easy measurement. By doubling these lengths we shall obtain those of the bass, or 8-feet octave. By halving them, those of the middle octave. By dividing them by four, we get those of the treble octave.

Note well that these rough and approximate lengths are speaking lengths of the wooden tubes, or, in other words, of the column of air within them, measured from the top of the block to the under side of the stopper. Hence, in cutting out the boards, the length of the block—about 3 inches, or less in small pipes—must be added to three of them, and an inch or more allowed to all four of them to give good room for the stopper.

But we are not yet in a position to cut out the boards.

It might be thought that as we get the lengths by the easy arithmetical process described above, so with equal ease shall we get the widths and depths of the blocks. The pipes are not square, but are deeper than they are wide, in the proportion of about 5 to 4. It might be thought that if the block of Tenor C be 2 inches wide and 2½ inches deep, then the block of Middle C will be 1 inch by 1¼ inches; the block of Foot C ½ inch by ⅝, and so on. This is not so. These treble pipes would be quite unreasonably small, and would give weak and thin sounds, while the bass octave, commencing with a block 4 inches by 5 inches, would be needlessly large for a chamber organ. Without wasting words upon a matter which is really very simple, let us say at once that we shall adopt for our Stopped Diapason a scale commencing with a CC block 3¼ inches wide and 4 inches deep, and that the block of Tenor C will be 2⅛ inches wide and 2⅝ deep. Thus the half of the width and depth[Pg 17] of the CC block will not be reached until the eighteenth note above it, instead of the thirteenth, and in the higher parts of the scale the diminution in the sizes of the blocks may be yet more gradual.

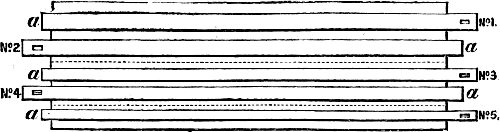

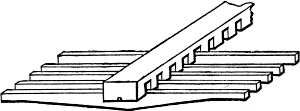

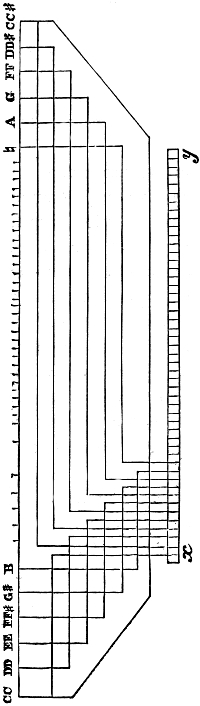

Fig. 2.

A glance at Fig. 2 will enable our readers to draw scales for themselves for the Stopped Diapason, and for other wooden stops which may follow it, from a few given data, and to suit cir[Pg 18]cumstances. A minute or Chinese accuracy is not requisite. The vertical line of any convenient length being drawn upon the paper, the width and depth of the CC block are measured off upon a horizontal line drawn at its lower extremity. Eighteen divisions being marked upon the vertical line, the half-width and half-depth of the CC block are measured upon another horizontal line drawn at the eighteenth mark. These points being joined by straight lines, and horizontal lines being drawn at each of the marks parallel to the others, we shall have the widths and depths of the blocks of all the pipes from CC to Clef F inclusive, viz. eighteen blocks. The next eighteen blocks will be sized in a precisely similar manner, and as three times eighteen is equal to fifty-four, the whole stop may be divided into three sections of eighteen pipes in each section, and it may be for our convenience to make one section at a time.

There are two methods of working together the block and the four boards which form the pipe. We will give them both, and decide between them.

First method. Cut out the board for the back, and dress it carefully to the exact width of the block. Glue the block to the lower extremity, and when the glue is dry dress up all perfectly flush. Cut out the side boards as wide as the depth of the block with the thickness of the back board added to it. Glue them to the sides of the block and to the edges of the backboard, obtaining a perfectly close joint by using wooden clamps and wedges[Pg 19] as in gluing up a violin, or by other obvious contrivances. When the glue is dry dress up the front edges flush with the block, and glue on the front board, which will be cut out as wide as the block together with the thicknesses of the side boards. The front board must overlap the upper edge of the block by about ⅛ inch or more. If all this is carefully done according to the rules of good joinery the result should be a neat and strong pipe, truly rectangular at its upper or open extremity. Brads or sprigs are not to be thought of in pipe-making, unless, indeed, in the very exceptional case of organs intended for tropical climates.

Second method. Cut out first the two side boards the width of the depth of the block, and glue them to it. Dress the edges flush with the block, and glue on at once the back and front boards, obtaining irreproachable joints as before, and taking infinite care that the upper extremities of the side boards do not approach each other. In making our smaller pipes (say from Middle C upwards), we are in the habit of straining whip-cord or stout hempen string round them, winding it first upon a loose pipe-foot or smooth tool-handle to avoid cutting the hands; and we ensure a correct aperture at the top by placing within it a thin slice cut from the block itself, or by introducing the stopper if it has been already prepared of the same size as the block. The notches made by the string upon the edges of the soft pine-wood[Pg 20] are easily removed when the finished pipe is dressed over with a fine plane.

We have no difficulty in giving our decision in favour of the second plan, which avoids the four tedious dryings of the glue, and which admits more readily of pressure being applied to the freshly glued joints. But in making open pipes, which have not to bear the driving-in of a stopper, there is much to recommend the first method.

This point being settled, we may cut out the side boards and prepare the blocks for one of our divisions, let us say the middle section, from Clef F sharp to the natural below Foot C. Blocks of this moderate size will be best made by taking a piece of wood of suitable character, long enough for six or more, and by dressing it down as each block is cut off, making careful and constant use of the gauge, the square, and the callipers. We like to form the throat with a centre-bit after the pipe is put together. The thirty-six boards will be glued to the eighteen blocks, and while the glue is drying we can prepare the backs and fronts. The bevelled lip of the latter will be left uncut until all the pipes have been glued up and dressed over, and the top edges nicely cleaned off and made true. But as there will be, doubtless, a most pardonable anxiety to hear the sound of one pipe, we will here explain that the height of the mouth of each pipe must be equal to one-third of its width; thus the mouth of the pipe measuring one inch and a half across the block (A in our scale) will[Pg 21] be ½ inch in height. In measuring the height of the mouths, a pair of proportional compasses with sliding centre, or common dividers set to thirds, fourths, and fifths, will be useful if not necessary. The slope of the bevel is not of great importance. Cut it with a sharp chisel, taking care not to injure the block, and leave the lower edge or lip rather blunt. A sharp and pointed knife may be employed in cutting the lip truly, guided by the square. The use of fine glass-paper is permissible here to smooth all these parts nicely.

The throat having been formed in the face of the block, about 1 inch from its lower end, bore the foot-hole in the bottom of the block clear into the throat, beginning with a small borer, and enlarging the hole cautiously, as rough and hasty proceedings might split the block at this point, especially in the case of small pipes.

Prepare the cap from a suitable bit of mahogany, oak, or other close-grained wood, and hollow out the back of it with a chisel as shown in d, Fig. 1. Form the flue or wind-way through which the air is to pass to the lip by filing away the edge left at the top of the wedge-shaped hollow, trying your work by placing the cap against the side of the pipe or any other flat surface. The flue must not be wider than 1⁄16 inch at Tenor C, and must be reduced as we ascend the scale until it will hardly admit a slip of thin paper. It will not be so much as ⅛ inch wide even at CC.

Perhaps the stopper has been already prepared[Pg 22] of the same size as the block, and has been formed into a knob at top, or turned in the lathe, or, in the case of the larger pipes, fitted with a turned handle glued into a hole bored for its reception. Dress off the angles of the stopper in order to allow room for the soft white leather with which it is covered to fold itself in the corners of the pipe. We generally rasp our stoppers, leaving them rough that the leather may cling to the stopper and not to the pipe. The leather cannot be too thin if it is soft, and if the stopper fits closely. Rub the interior of the top of the pipe with a bit of tallow-candle, and introduce the stopper cautiously. It should slide within the pipe at once easily and with accurate fit, and if your joinery has been good there should be no fear of splitting the pipe or of opening the joints.

The cap when finally fitted will have its upper edge about ⅛ inch below the upper edge of the block. On applying it in this position, holding it there with your fingers, or tying it on with string, and blowing gently into the foot-hole, you will have a pleasant fluty musical note. Probably a little chirp or whistle will be heard before the note comes on. The removal of this defect belongs to the important operation called voicing, of which we shall treat hereafter.

We have cut our boards from the half-inch pine, but as we rise in the scale much thinner stuff will be used. It is well to foresee this in laying in our materials. Red cedar, often used by cabinet[Pg 23]makers for the inside of drawers and wardrobes, makes very pretty pipes, holds the glue well, and has an agreeable odour in working. Harder woods, notably oak, were often used by the old builders. Pear-tree commends itself much in German workshops.

The four or five lowest pipes (CC to EE, or higher) should be of stouter stuff than half-inch, say five-eighths or even three-quarters. The caps of these large pipes will not be glued on but fixed with three screws, and we may modify a previous remark by admitting that in the case of these larger pipes the use of nails is legitimate.

Of the pipe-feet we shall speak when we come to the business of planning the rack-board with its holes for their reception.

We must not close this chapter without giving some further explanations on the subject of pipe-making.

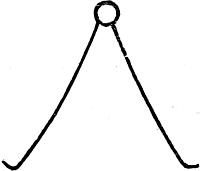

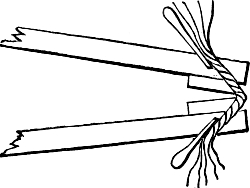

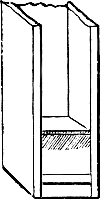

Large pipes, both open and stopped, may be advantageously made with languids instead of blocks. Fig. 3 shows the section of a pipe so made. The block is replaced by two pieces of suitable wood, a a, let into the side boards with plenty of glue. The glue should also be allowed to run freely into the angles and corners of the throat when the back board is fitted. Pipes made in this way are a little lighter than those with blocks.

Fig. 3.

The stoppers of the smaller pipes, say from Fiddle G or Middle C to top, are often bored with a hole passing clear through the wood and leather, and burnt smooth with an iron. After what has been said of the necessity of securing a good fit for the stopper, it might be thought that this hole would ruin the pipe. Curiously enough it is not so, but imparts a slight increase of fulness to the tone. The holes must not be large, ¼ inch at Middle C will be sufficient. Note well that pipes with perforated stoppers must be a trifle longer, say 1 inch in 12, than those completely closed. Thus the pipe for C sharp must be as long as the fully stopped C pipe.

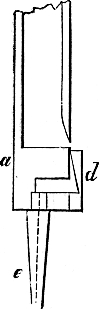

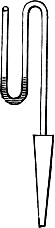

Wooden pipes are also made with inverted mouths, that is to say, the bevelled lip is formed on the inside instead of on the outside of the front board. In this case the bevel is cut and the mouth measured and formed before the pipe is put together, and the front board will be of the same length as the others, and will be glued like them to the block. The throat is cut through the board into the block, and the cap will project beyond the level of the board. All this is shown in Fig. 4.

Fig. 4.

We have a very charming Stopped Diapason made in this way, and with perforated stoppers, in one of our organs. It[Pg 25] is of red cedar from Middle C to top; the lower part is of pine and of the ordinary construction. The mouths are in the proportion of two-sevenths of the width of each pipe. Inverted mouths are well suited, also, to the Clarabella and Hohl Flöte, two kindred stops which sometimes take the place of the Stopped Diapason in its upper octaves. The pipes are open, and have a hollow penetrating tone; Middle C is 2 feet long, and its block may be of the same size as that of the same note in our scale, namely, about 1⅜ by 1¾. The mouth about 2⁄7 of the width. These open pipes are tuned by means of shades, which are pieces of pipe metal let into a saw-cut made in the top edge of the back board. The shade must be as wide as the pipe, and ½ inch longer than its depth. The pipe is flattened by bending the shade over the open top, sharpened by raising it.

The German stop, the Doppel-flöte, which has two mouths opposite to each other, and of course two caps for each pipe, is seldom or never heard in this country. A few pipes which we have made as experiments hardly seem to repay us for the additional trouble and labour.

Trouble and labour were of little account, apparently, in the old days of English organ-building two centuries ago, if we may judge from the really marvellous specimens of patient pipe-making in wood which have come down to us. We ourselves have seen and played organs of exquisite sweetness and beauty by old Bernhard Schmidt[Pg 26] (1660-1708), containing four or five stops in which every pipe was of oak, even up to the top note of a Fifteenth of 2 feet. Such an organ, built by Loosemore, 1664, the builder of the cathedral organ, is preserved, we believe, at Exeter. It has six stops, including a Twelfth, all made of wood. Modern life is too hasty and impetuous for such efforts. If any of our readers, however, should set themselves the task of making very small pipes in wood, we advise them to form the block and foot from one piece, and to follow the first method (see p. 18) in putting the minute contrivance together.

THE SOUND-BOARD.

We may fairly assume that no one will embark upon the very serious business of building an organ, and that probably no one will read this book, who has not sufficient previous knowledge of the subject to understand what is meant by the expressions sound-board, wind-chest, pallets, sliders.

It may be taken as certain, moreover, that the reader who takes up this book to assist him in the arduous work which he has undertaken, and in the hope (which we trust we shall not disappoint) of finding rules laid down in it which he can readily reduce to practice, has long ago decided upon the position which the projected organ is to occupy, and has measured with his eye, if not with his two-foot rule or tape, the breadth, depth, and height which can be fairly allowed to the finished instrument.

Great diversity of dimension and design is one of the peculiarities which distinguish organs from all other musical instruments. Our organ may be wide and shallow like a book-case, or it may be of[Pg 28] little greater width than its key-board, but deep like a wardrobe; it may be carried up nearly to the ceiling of a lofty apartment, or may be kept down to suit the low-browed rafters of a country farmhouse or a workman's cottage.

The site chosen for the organ may allow of convenient access to the back of it for tuning purposes; or it may compel us to arrange the interior so that the back may always remain in close contact with the wall. The projection of the keys, too, from the front, and therefore the position of the player when seated at the instrument, possibly in a small room; the place for the blowing-handle and for the person who works it, so that convenient space may be left for him to fulfil his irksome duty—these are matters of detail admitting of great variety of treatment.

There are cases in which it may be possible, and very advantageous, to separate the bellows from the organ which they supply, and to establish them in an adjoining room, or beneath the floor or platform on which the organ is placed.

All these considerations must receive full attention, and drawings or rough sketches sufficiently intelligible to the workman himself must be made in accordance with the decisions arrived at. Then, and not till then, we can launch ourselves upon the very serious business of designing and constructing the sound-board.

A serious business, we say, making a large demand upon our industry and perseverance, and[Pg 29] calling for adroit use of tools of several different characters.

To facilitate our own task in describing the process of constructing a sound-board, we shall divide this chapter into short sections, with intervening remarks.

1. The sound-board is a shallow box, divided internally into as many transverse grooves or channels as there are notes on the key-board. The pipes stand upon holes bored through the top of the box into these channels; and it is plain that if air is made to fill these channels, and to issue from these holes in a constant stream when we please, all the pipes which stand upon the holes will give their sounds according to their pitch and character.

Remark.—Thus if one channel, say the channel corresponding to Tenor C, have five holes bored into it through the top of the box, then five pipes standing upon those holes may be made to speak at once, or in chorus, by pressing down the one key on the manual.

2. It is plain that we must possess the power of opening and closing these holes in sets or classes at our pleasure, so that the air may be directed into those pipes which we desire to hear, while others are silent. The top of the box is therefore made double, or of two layers of wood; and between the two layers long strips of thin wood are introduced, lying lengthwise, that is to say, at right angles to the channels beneath or within.[Pg 30] The holes are bored down through all these three layers of wood forming the top of the box; and we see that by sliding the thin slip an inch or so to the right or left, we can cut off at once the current of air from the pipes standing on those holes, since the apertures in the three layers will then no longer coincide.

Remark.—All this is quite independent of, and preliminary to, the arrangements for admitting the supply of air to the channels themselves.

3. Having already made our Stopped Diapason pipes, let us range them on a table or floor, and consider well how they must be planted on a sound-board such as we are about to make for our organ, be it broad and shallow, or narrow and deep, be it low or lofty.

Remark.—No other stop will practically take up so much room on the sound-board as the Stopped Diapason; hence, if we plot the board with reference to it, all the other pipes will be easily worked in.

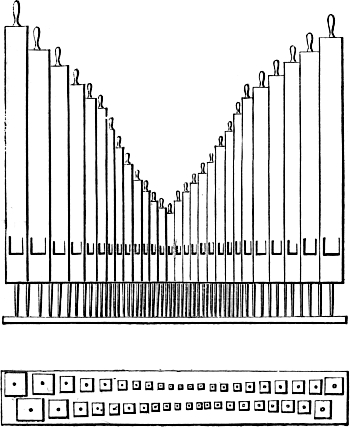

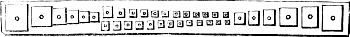

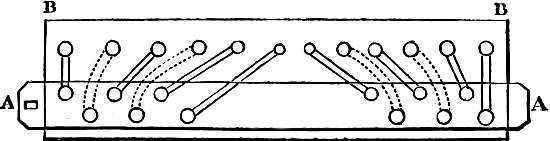

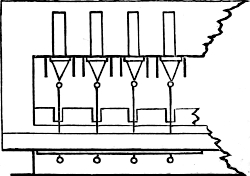

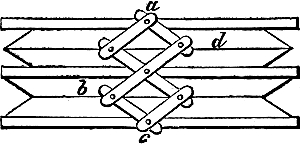

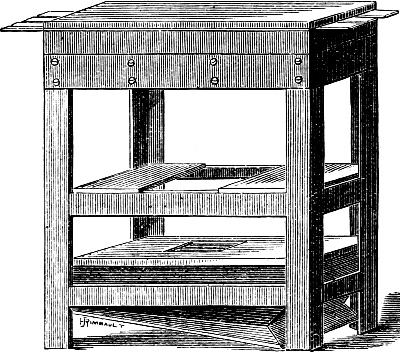

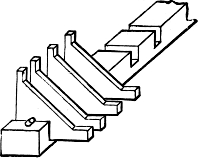

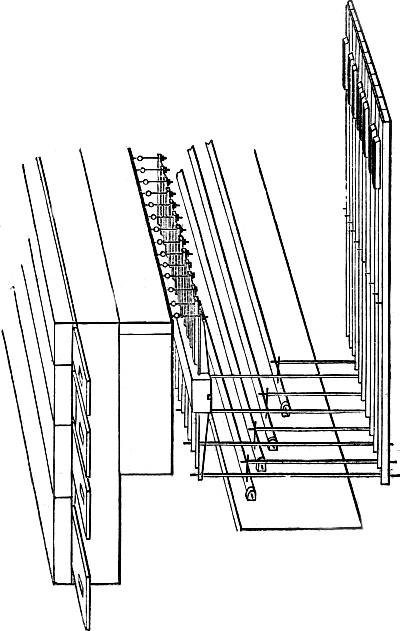

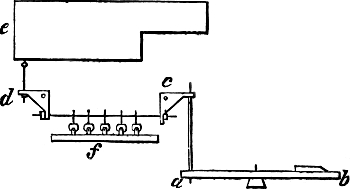

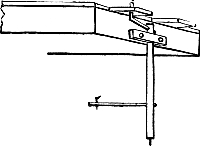

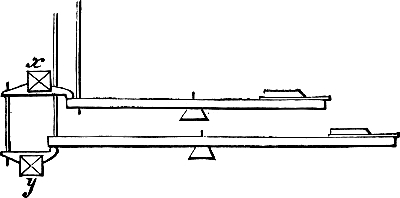

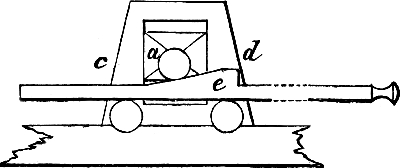

Fig. 5.

4. On the opposite page several different plantations of the Stopped Diapason are shown both in elevation and in plan. In Fig. 5 the pipes, planted in a double row throughout, are placed alternately to the right and to the left, meeting in the middle at the smallest pipe. The exact reverse of this plantation, namely, placing the largest pipes in the middle, and sloping down to the smallest pipes at each end, can be easily imagined, and it is unnecessary to figure it. It is clear that in both these [Pg 31]plantations the large pipes occupy a space, as regards depth, out of proportion to the space occupied by the upper part of the stop. Fig. 6 shows a very common plantation of pipes, which, as we shall see hereafter, allows us to simplify the internal mechanism or action. Fig. 7, in plan only, shows a mode of economising space as regards depth by planting the pipes of the lower octave in a single row, resuming the double row at Tenor C. This plantation would suit a wide and shallow organ. Figs. 8 and 9 show different methods of planting the large pipes in order to avoid a disproportionate [Pg 32]sacrifice of space on the board. It will be seen at a glance that they can be ranged behind the pipes of the tenor and treble octaves, or carried off to the right and left in rows standing at right angles to them. Fig. 10, in elevation only, shows how we may build an organ under the ceiling of a very low room, by planting the eight feet octave on a board[Pg 33] of its own at a lower level than that of the sound-board proper. And it is easy to conceive, without a figure, that this accessory board may be replaced by two boards, to right and left, resulting in a plan resembling that in Fig. 9, but giving a lower level to the tall pipes.

Fig. 6.

Fig. 7.

Fig. 8.

Fig. 9.

Remark.—We confess to a strong liking for these later plantations, which require some little careful mechanical adaptations, but result in a compact arrangement, admitting of enclosure in a case of graceful outline.

Fig. 10.

5. We have still some considerations requiring careful attention before we can map out our sound-board. The plantation of the pipes will be the chief guide to the planning of the channels, with the divisions or spaces between them; but it must not be forgotten that the boring of the holes for the supply of air must be done in regular lines within spaces or widths easily covered by the sliders. A[Pg 34] slider is seldom more than from 2 to 3 inches wide; there are good reasons why this width cannot conveniently be much exceeded. But the feet of the large pipes in the bass octave will be as much as 5 inches or more apart when the pipes are planted back to back, as in Figs. 5 and 6. Hence we must decide, before we begin to work, not only how the pipes are to stand on the board, but how they are to get their wind and be deprived of it by the action of a slider of the usual width. Perhaps we shall resolve to run two narrow sliders under the foot-holes of the whole stop, one for each of the two rows, controlling both sliders by a single knob or handle. By this method every pipe will stand on its wind, as the workmen say, that is, will be in direct and uninterrupted communication with the channel when the holes are open. Or possibly it may suit our plans better to run two sliders under the feet of the bass pipes, and a third between them, under the rest of the stop; all three, be it well understood, extending from end to end of the sound-board, but having holes only at the[Pg 35] proper places, and being blank elsewhere: these three sliders being governed by one knob, or by two, if the stop is to draw in halves (as it is called), that is, as a separate Bass and Treble. Or, once again, we may use a single slider for the whole stop, but carry the wind through grooves fashioned in the solid wood from the holes bored in the usual way to the points at which the pipes are planted. And, lastly, we may carry the wind from the holes to pipes planted in any position, and practically at any distance by tubes made of pipe-metal or other material.

Remark.—It need hardly be said that an examination of the interior of a well-built organ will be of great service to the beginner who is planning his first sound-board.

6. The dimensions, then, and character of the sound-board having been determined after full consideration of the site for the organ, and a drawing or sketch having been made for your own guidance, proceed thus:—Take a board of good clean bay-wood, ½, ⅝, or ¾ inch in thickness, and long enough and wide enough to form the "table" or top of your work; and dress this carefully until one of its surfaces is quite true and level. This dressed or levelled side is to be the lower or under side, and we are about to form upon it the grooves or channels of which it will ultimately form the roof. Next prepare a ruler or straight edge of any thin stuff, and on this, with compasses, rule, and square, guided by plenty of deliberate consideration, mark the size and place of each of the grooves, and of[Pg 36] the bar of wood which will divide each groove from its neighbour, from end to end. You will find, of course, and you were previously aware, that the widths of the grooves and the thickness of the bars will vary in proportion to their place in the scale. Let us say at once that ¾ inch will be ample width for the CC groove in our small organ; and let us advise that the smallest groove in the treble be about ¼ inch in width, and that the bars between these narrow grooves be at least ⅜ or ½ inch in thickness, in order to allow a good seat or margin for the pallets or valves which are to govern the admission of the wind. In the bass the bars will be very much thicker than this, or not, according to the plan which you have adopted. The part of your rule in which you will soon perceive that the chief danger of crowding your pipes will arise is the tenor octave. Refer carefully to your pipes, and be quite sure before you mark your ruler, that you are allowing room for Tenor C and its neighbours to stand clear of each other when they are planted on the completed board. Having satisfied yourself on these points, prepare your bars from sound pine-wood, planing them with care, and especially seeing that the edge of each bar is truly square with its sides. Two inches will be an ample width for each bar, in other words, an ample depth for each groove when completed. Their length will of course be equal to the width of the table, less an inch or so, according to the construction now to be described.

There are now two methods of proceeding. First method:—The table being turned over, with the dressed side uppermost, your ruler well in sight, with plenty of hot and fresh glue fix your first thick bar at or near either end of the table. We say, "or near either end," because you may like to leave room for a finishing cheek of mahogany when all the bars are put in. The second bar will be glued to the table in like manner, the proper distance from the first being secured by "filling-in pieces" of wood of the exact thickness, glued between the bars at their ends. This alternation of bars and fillings-in will be continued until all the grooves have been formed according to your ruler; the rough ends of the bars will then be dressed with a sharp plane, and neat cheeks of stout bay-wood will be glued on all the four sides of the divided box which you have thus built up. Second method:—Prepare the bay-wood cheeks first, and in the two long ones, using a fine saw and small chisel, cut grooves to receive the ends of the bars. Form a shallow box by gluing these bay-wood sides and ends to the table. The corners need not be dovetailed, but an equally close joint must be secured if dovetailing is omitted. Then introduce the bars, using an abundance of hot glue, and taking care that no bar fits so tightly between the cheeks as to risk bending. When all the bars are glued in, add more thin glue within each groove, placing the sound-board in a sloping position that the glue may run into the angles, and afterwards reversing[Pg 38] the board to the opposite slope, repeating the coating of thin glue.

Remark.—This unusual profusion of glue is to preclude the possibility of air making its way from one groove to the adjacent one bypassing between the edge of the bar and the table; and what is here said applies equally to both methods.

We ourselves prefer the second method to the first. M. Hamel, in his wonderfully accurate and minute treatise, describes a third, in which the fillings-in are avoided. Those to whom his book is accessible cannot fail to share the present writer's admiration of his marvellous industry, and of his great gift of clear and precise description of mechanical processes. Hopkins and Rimbault may also be consulted with much advantage.

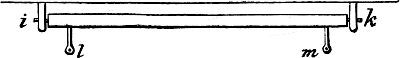

7. The work, thus glued up, must be left in a dry room for two or three days, until all is perfectly set and hard. Meanwhile the other pieces of which the completed sound-board will consist are being cut out and prepared. We shall want the upper boards, the sliders, and the slips of wood (false sliders the French builders call them, while in England they are termed bearers) which divide these from each other.

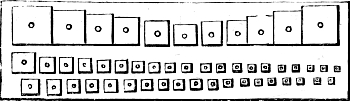

We may safely suppose that if the ordinary form of sound-board has been chosen—such, for instance, as that which is shown in Fig. 6—its size will be about 4 feet, or 6 inches more, in length. Its width will depend on the number of stops for which it is planned, and therefore of sliders which are to work[Pg 39] on the table; if we are to have five stops, about 15 inches may be taken as the probable width, but this may be less, or more, according to the class of stops selected, and the arrangement chosen for their bass pipes. To give accurate measurements in feet and inches for all the parts of the sound-board would only mislead our readers at this stage of our labours. We give general rules only: it must rest with the reader himself, as we have now abundantly reminded him, to decide on the shape of his sound-board and to make the plantation of his pipes, and the consequent arrangement of grooves and sliders conformable thereto.

Assuming, then, quite arbitrarily, and independently of all special considerations, that the sound-board is 4 feet long and 15 inches wide, we may cut out the upper boards from sound and clean bay-wood, 1¼ inch thick. Cut them 6 inches longer than the sound-board. And now as to width. As there are five stops, and five sliders for them, are we to understand that we shall have also five upper boards? To this we reply, by no means. Our stops, we assume, will be two of 8 feet, two of 4 feet, and one of 2 feet. For reasons which we shall soon give, we shall propose to have one upper board for each of these three divisions: that for the 8-feet stops being 7 inches wide, that for the 4 feet 5 inches, and for the 2 feet 3 inches. Under the 7-inch board there will be two sliders, each 2 inches in width; under the 5-inch, two sliders, each 1½ inch in width; and under the 3-inch, one[Pg 40] slider, 1¼ inch wide. The bearers will be thus:—The two outside bearers, that is, those which extend along the front and back margins of the sound-board, to be 1¼ inch in width; the second bearer (reckoning from the back) to be 1 inch; the third to be 1½ inch, because it will lie beneath the line of junction, or rather of division, between the two wider upper boards; the fourth bearer may be ½ inch only, being merely a separation between the next two sliders; the fifth may be 1¼ inch, falling as it does under a line of division; the sixth is similar to the first. It will thus be seen that we have—

| 2 | sliders, | 2 | inches | each | = | 4 | inches |

| 2 | " | 1½ | " | " | = | 3 | " |

| 1 | " | 1¼ | " | " | = | 1¼ | " |

| 3 | bearers, | 1¼ | " | " | = | 3¾ | " |

| 1 | " | 1½ | " | " | = | 1½ | " |

| 1 | " | 1 | " | " | = | 1 | " |

| 1 | " | ½ | " | " | = | ½ | " |

| — | |||||||

| Total width | = | 15 | inches. |

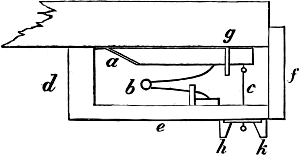

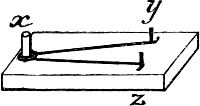

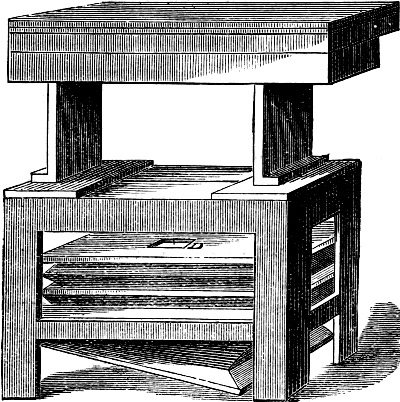

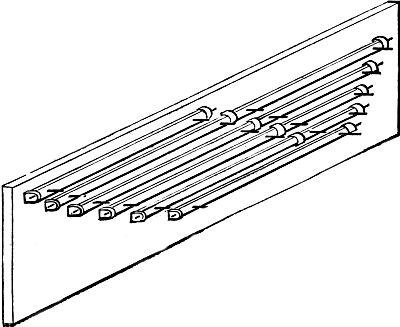

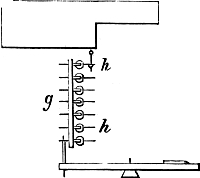

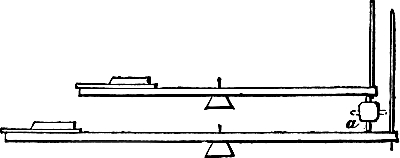

Remark.—All this is so important that we have shown the measurements drawn to scale in Fig. 11.

Cut out the sliders and bearers from perfectly clean sound bay-wood or red cedar boards, not more than ⅜ inch in thickness. Having turned your sound-board over, with the table uppermost, assemble all the pieces, and satisfy yourself that your measurements are correct, and that so far there is no error in your plans. See that all your planes are in first-rate order, and set yourself in earnest to bring to a perfectly level and true sur[Pg 41]face the table or top of the sound-board, and one side of the sliders and bearers. No pains must be spared to render the surface of the table absolutely true. Apply a "straight edge" rubbed with chalk, moving it in various directions, and use unwearied diligence in removing all inequalities detected by this means. Take care, too, that there is no "winding." In short, adopt all the means which the rules of good joinery give you for producing a surface faultlessly level. This done, arrange upon the table, with their planed sides downwards, your sliders and bearers, and pin them down upon it with very small brads, piercing through near their edges. In doing this have regard to the grain of the wood, as you are about to dress the upper surfaces. Sink the brads well out of the way of the plane with a punch, and bring the sliders and bearers to a true level as you did the table.

Scale, two-thirds of an inch to a foot.

Fig. 11.

Remark.—M. Hamel advises that in making the sound-board the table should be left 3 inches longer at each end than the actual box beneath, expressly to afford a bearing for the ends of the[Pg 42] sliders during this business of planing them. If this suggestion is not followed, the projecting ends of the sliders will require separate attention.

The three upper boards may now be brought down upon the finished sliders and bearers, and a couple of iron pins or dowels may be let into each of them and into the bearers and table beneath, near their extremities, for the purpose of confining them temporarily in the exact places which they are to occupy. Dress over now the upper sides of the three boards, which do not, however, require attention to absolute truth.

8. We cannot yet bore the holes for the pipes. Before we can do so we must prepare yet another board or boards of clean pine, ⅝ or ¾ inch thick, 4 feet 6 inches long, and 15 inches wide, for the rack boards through which the pipe-feet are to pass, and which are to maintain the pipes in an upright position. If you have two upper boards the division should occur between those of the 8-feet and 4-feet stops. Pin down your rack-board upon the upper boards with brads here and there near the edges.

Let us now consider for a moment. We have made our box of fifty-four transverse channels or grooves, and its top consists now of four layers of wood—namely, the table, the sliders, the upper boards, and the rack-boards. Through these four layers of wood, at the proper places, are to be bored holes of various sizes clear through into the channels; but it is plain that the holes in the rack[Pg 43]-boards will always be much larger than those in the three other layers, because the rack-boards are to be ultimately raised about 5 inches above the upper board on legs or pins, and will therefore receive the thick part of the conical pipe-feet, while the holes in the upper board will only receive their tip or small extremity. But the centres of the large holes in the rack-board must coincide accurately with the centres of the small holes beneath, and we shall therefore proceed to mark the exact spots where each of the holes will commence.

By the aid of your marked rule, trace a line on the front and back cheeks of the sound-board, showing the centre of each groove. From these points draw lines across the rack-boards. It is evident that all holes bored through the four layers of wood at any point in any of these lines must terminate in a channel. Draw lines at right angles to the last, showing the widths of the sliders and bearers; it will then be further evident that we cannot easily get wrong in boring the holes so that they may penetrate the sliders at the exact points intended. But the actual boring, with certain consequences or contingencies belonging thereto, must be reserved for the next chapter.

THE SOUND-BOARD.—(Continued.)

The time has come when we must decide what our five stops are to be, since the sizes and places of the holes must be in accordance with the quality and character of the pipes supplied by them.

The Stopped Diapason we have already made; and in our organ it will be the chief or foundation stop of 8-feet tone. We shall assume that the second stop in the 8-feet pitch will be a metal Dulciana, or small open Diapason. The 4-feet stops will doubtless be a Principal (or some equivalent) and a Flute. The 2-feet stop we will call simply Fifteenth for the moment. For convenience of reference we will number the stops thus:—

| 1. | Dulciana or open | } | 8 | feet pitch |

| 2. | Stopped Diapason | } | " | " |

| 3. | Principal | } | 4 | " |

| 4. | Flute | } | " | " |

| 5. | Fifteenth | 2 | " |

The pipes of No. 1, being the tallest in the organ, will be planted nearest to the back; all the others, occupying the successive sliders, will present a gradation of heights agreeable to the eye and convenient for the tuner.

No. 1, we say, is the tallest in the organ; but be it carefully observed that in our small instrument it will not be carried down to its lowest note CC, which would be 8 feet in speaking length; it will not descend lower than tenor C, 4 feet, and the last or lowest twelve notes or sounds will be obtained by using the corresponding pipes of the Stopped Diapason as a bass for both stops.

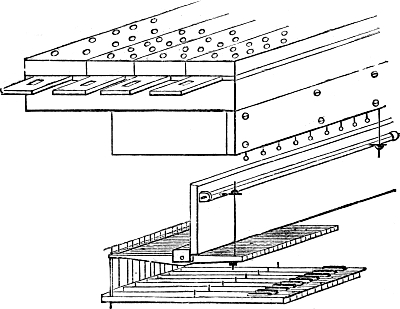

This will be done by "grooving;" and it will now be seen why, in cutting out the upper boards, we were careful to have a single board for the pipes of 8-feet pitch, and another single board for those of 4-feet pitch. For it is plain that by boring holes through the upper board, sliders, and table into any groove of the sound-board, and by connecting these holes together by means of another deep groove or score cut in the wood of the upper board, and then covered in with an air-tight covering, we obtain a secondary channel, supplied with air by either or both of the sliders at pleasure; and by boring one hole through the air-tight covering, and planting a pipe on that hole, that pipe will speak whenever a connection is made between the secondary channel on which it stands and the main channel or groove below, which is receiving air at the moment from the bellows.

Clearly, therefore, if we bore holes through the upper boards and sliders of Nos. 1 and 2 into the twelve grooves of the bass octave, and then connect these twelve pairs of holes by cutting upper grooves in the surface of the boards, covering them in by[Pg 46] thin boards of wood well glued down, we have then only to plant our twelve largest stopped pipes on twelve new holes bored in these thin boards last mentioned, and we have at once a bass common to both stops, and each of the two stops will be practically, and for ordinary purposes, complete down to the lowest note when its slider is drawn. When both sliders are drawn, the secondary groove will receive air from both holes in the upper board; but this will not have the effect of over-blowing the pipe, since the pressure or weight of the air remains the same, and since the pipe can only receive the quantity of air which is permitted to pass through the aperture in its foot.

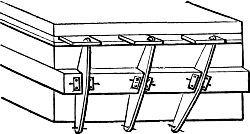

It will now be seen why we did not at once bore the holes, or rather mark their places, on the rack-board. Plainly, we must make these twelve grooves first, and cover them in. Then, replacing the rack-board as before, carefully mark on the latter the exact place of each bass pipe, as it will stand on any part of its secondary groove. Afterwards, with a bradawl or other sharp-pointed borer, prick quite through the rack-board at every one of the points which you have marked throughout its whole extent. At these points there will hereafter be circular holes of various sizes for the reception of the pipe-feet, but in the upper boards, sliders, and tables there will be smaller holes, adapted for conveying its stream of air to each pipe. Before removing the rack-board, decide upon the places where the rack-pins, or pillars[Pg 47] which will hold the rack-board up above the sound-board, are to be. Have plenty of these, say six or eight if you have a single rack-board, or five to each if you have two, in order to insure a firm plantation of the pipes, and bore holes for them with a centre-bit, say ⅝ diameter, through the rack-board and to the depth of 1 inch in the upper boards.

The rack-board now being put aside for the present, all the holes may be bored through the upper boards, sliders, and table with bits of various sizes. From what has been said above it will be seen that it is not the sizes of these holes, but of the apertures in the pipe-feet, which regulate the volumes of wind supplied to the pipes; but you will, of course, use bits proportioned to the pipes you have in view. The upper, or treble, holes must not let the little pipes slip into them, nor must the larger holes throttle or check the flow of the wind. In the bass the holes may be as large as the grooves will allow; and if these are narrow, or if there is secondary grooving or conducting, it will be well to cut the round hole at its interior aperture with a sharp chisel into a square or rectangular opening; or to bore two round holes and connect them by taking out the intervening wood. Afterwards, with iron rods of various sizes, heated to redness, scorch all the holes through the three thicknesses of wood, leaving a clear and smooth charred passage for the wind.

We have not yet done with grooving. This seems[Pg 48] to be the proper place for pointing out how the use of this system may further assist us in the arrangement of an organ.

Our bass pipes, we have said above, may be planted on holes cut in any part of the covering or roof of their respective secondary channels. It follows readily from this that the secondary groove or channel may be extended or prolonged for the express purpose of locating the pipes in situations convenient for them. Quite apart from any necessity which may exist for supplying a common bass to two or more sliders, we may evidently plant our larger pipes almost where and how we please by cutting grooves in the substance of the upper board, extending from the table beneath to the point where we wish the pipe to be. So long as the holes are of sufficient diameter and the grooves of ample dimensions, the wind will reach a pipe located at a distance even of 2 or 3 feet from its source of supply without any appreciable interval between the impact of the finger on the key and the production of the sound; and the grooves may be curved almost as we please, though sharp angles should be avoided.

Even if, in consequence of alterations of original plans or other circumstances, the upper boards should not be of sufficient thickness or size to admit of grooving, we may still avail ourselves of this convenient system by using an additional or supplementary upper board, which we will here call a conducting board, screwed down upon the main[Pg 49] upper board, and containing the grooves. To fix the exact places for the holes in the under side of the conducting board, corresponding with those in the table, spread a sheet of white paper over the upper board at the part where the conducting is to be, making the edges or corners of the paper coincide with those of the board, and rub the paper with the finger so as to take clear impressions of the holes; then transfer the paper to the under side of the conducting board, guided by the edges and corners as above, and prick out on this under side the centres of the circular impressions made on the paper. It is evident that when the conducting board is applied to the upper board, edges and corners coinciding as before, these punctured marks will be exactly over the wind holes in the table. The holes in the upper side of the conducting board will be marked as before from the rack-board, and grooves cut and roofed in with thin wood, as previously described.

Note further, that the grooving may be, if necessary, on both sides of the upper boards. All that is needful in such case is, that after the grooves on the under sides, next the sliders, are cut, the whole of the board, and not merely the grooved part of it, shall be covered or veneered with thin stuff. This must be dressed perfectly true, as in the case of the solid or ungrooved board, and all the holes will be bored through it. The upper sides will also have a neater appearance if the roofing of thin mahogany or cedar is carried over its entire surface. Upper[Pg 50] boards so treated are, in fact, compounded of three layers of wood, a central thick slab containing the grooves, and two coverings or veneers. The gluing on of these latter must, of course, be very sound and effectual in every part, or a running of wind might ensue—a most provoking and really fatal defect, incurable without complete reconstruction.

Short grooves may be made by boring holes with a centre-bit in the edges of the upper boards, and making the wind-hole beneath and the pipe-hole above communicate with this concealed tunnel. On plugging up the external aperture in the edge of the board, or on stopping a whole row of such apertures by gluing a band of leather, parchment, or thick paper over them, it is clear that the wind will pass to the pipes at pleasure. All such holes and channels must be scorched with hot irons. To the true joiner this may seem an unworkmanlike expedient, but it is necessary to prevent the weakening of the currents of air which would ensue from friction against rough surfaces, and to preclude the risk of carrying tiny chips and particles of wood into the pipes. If conducting boards are used, they should be faced with soft white leather on their under surfaces before they are screwed down in their places, unless, indeed, they are glued down immovably. The places for the screws, as well as for those which secure the whole upper board to the table, must be carefully determined with reference to the grooves.

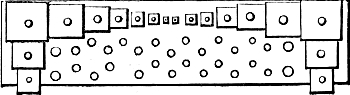

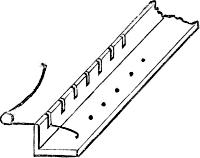

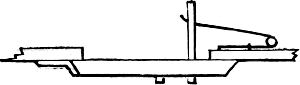

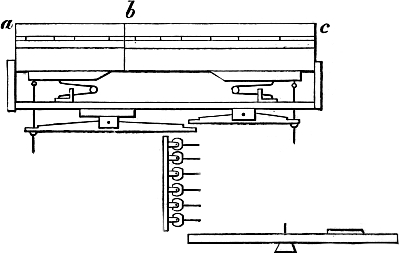

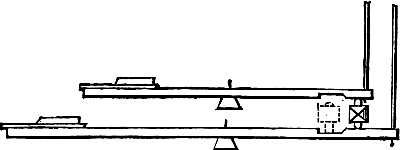

Fig. 12 is intended to show, in a rough way, how in an upper board BB grooves may conduct the wind from the holes in a slider AA to a row of pipe-holes near the margin of the board, resulting in an arrangement like that shown in Fig. 8. The dotted lines are meant to indicate grooves cut in the under side of the board. It is clear that these might be made to cross the others, so that different plantations of pipes might be obtained, as in Fig. 9.

Fig. 12.

Remark.—These figures, however, must be understood rather as illustrations of our meaning than as representations of actual work.

Conveyancing tubes are in constant use, not only as substitutes for grooving, but as ancillary to it. They are made of pipe-metal, and from about ⅝ inch in diameter to much larger sizes. To manage them neatly and well you should be adroit in the use of the soldering-iron. They are commonly smeared over with a composition which will not receive the melted solder; this composition is scraped off at the points where a junction is to be made at an angle, and with the usual copper tool, a little resin and tallow, the solder is applied. Much practice is needed to give mastery of this[Pg 52] process, apparently so easy; we have known instances in which it has been avoided altogether by covering the junctions of the conductors with white leather secured by thick flour paste. It is right, also, to add, that we have seen successful conveyances made of cartridge paper rolled upon wooden mandrels with paste. Any tin-plate worker in your town or village would make them of his own material or of zinc, and in an hour or two would solder all the junctions for you when you had planned your arrangement thoroughly.

Assuming, however, the use of the usual tubes, we may say that they are thus applied. Let us suppose that the large pipe shown in Fig. 10 is to be conducted off from the sound-board at the higher level to the plank on which it stands. Bore the hole in the upper board a trifle larger than the outside diameter of the tube. Glue a patch of white leather over the hole, and cut out the aperture in this leather somewhat smaller than the hole, leaving an excess of leather all round the hole of about 1/8 inch. Then, making the end of the tube a little conical, thrust it into the hole; it will carry in with it the surplus margin of the leather, which will form around it an air-tight joint or collar. A right angle may be allowed in the tube at this first commencement at the hole itself, but in its subsequent course sharp corners should be avoided. The pipe is planted on a hole bored to a sufficient depth in a plank; a second hole, suited to a conducting tube, is bored at any[Pg 53] convenient distance from this, and communication made between these two holes by a groove in the under side of the plank closed in with leather, parchment, thick paper, or wood; then the end of the tube is forced as before into the hole bored for it and provided with leather packing, and all is complete.

It is by these means that "speaking fronts" are arranged according to any design.

Remark.—If you have all your pipes, metal as well as wood, ready at hand, it might be well to pierce the rack-board and fit them in their places at this stage of the proceedings, because chips and dust are inseparable from the operation, and may be more troublesome and mischievous after the pallets are put in than now. Those readers who resolve on this course may turn, then, to the subsequent pages, in which they will find all the directions which are necessary for their guidance. For our own part, we prefer to continue in the next chapter our account of the mechanism of the sound-board.

We may further remark, that while the boring-tools are in use we may perhaps do wisely in piercing holes also for the screws which are to hold the upper boards down upon the sliders. If the planing has been perfectly true, about four pairs of screws should be enough for each upper board, and no extra screws should be required to force the boards into closer contact at any intermediate part. The screws should pass clear and[Pg 54] easily through the holes in the boards, and should bite well in the table beneath. The heads of the screws should be let down below the level of the upper surface of the boards by counter-sinking, and it is a useful practice to mark the places of these screws on the rack-board as well, and to bore corresponding holes in this latter, in order that if hereafter a slider should be pinched too tightly between the upper board and table, the end of a long screw-driver may be introduced to ease it by slackening the screws without disturbing the pipes.

But we shall have to return to this part of our subject.

THE WIND-CHEST.

The somewhat wearisome task of boring more than 250 holes in the sound-board being now assumed as accomplished, we may take the upper boards and sliders apart, and retouch the holes here and there, as required, with the hot iron. The apertures of the holes in the interior of the channels must be thus attended to, as the boring-bit may have occasionally torn the wood and left rough edges. Upon the faintest suspicion arising in your mind of any flaw or crack set up in any channel during the business of boring, smear over the whole interior of that channel anew with thin glue, letting it flow as before into the angles. A running of the wind from one channel to the next is, as we have said, the most provoking of all defects, and might compel us to pull the whole of the organ to pieces after it was set up.