Title: Canning, Freezing, Storing Garden Produce

Creator: United States. Department of Agriculture

Release date: July 24, 2019 [eBook #59977]

Language: English

Credits: Produced by Stephen Hutcheson and the Online Distributed

Proofreading Team at http://www.pgdp.net

United States Department of Agriculture

Agriculture Information Bulletin 410

296This is a reprint of Part 4 from the 1977 Yearbook of Agriculture, Gardening for Food and Fun. The Yearbook may be purchased at government bookstores or ordered from the Superintendent of Documents, U.S. Government Printing Office, Washington, D.C. 20402. Original page numbers from the entire book are used in this reprint.

Issued in December 1977

by Edmund A. Zottola and Isabel D. Wolf[1]

The telephone rings in a county Extension office. A harried voice says, “My garden is growing more than my family can eat, what shall I do with it? How can I keep it from spoiling?”

How many times during the gardening season is this scenario repeated in an Extension office? Too often to count! The answers to these questions are readily available in the many bulletins, folders, and leaflets on food preservation available from county, State, and Federal Extension agencies. The publications tell how to preserve food safely and wholesomely, but do little else to explain why directions must be followed precisely. Let’s take a look at the whys.

To understand food preservation, first consider the sources. Home garden food comes from plants: sources of raw food are living, biological entities, continuing to metabolize after they are harvested. Plants also provide a source of food for micro-organisms which can grow on or in them, spoiling food before it can be eaten. The primary objective of food preservation is to prevent food spoilage by preserving food until it can be used by people.

Historically, food preservation and processing assured a food supply and prevented starvation. This is probably the major reason why food is processed today in many developing countries. In the United States, however, affluence and a plentiful food supply now influence the reasons for food preservation. Today, Americans live many miles from rural areas where food is produced. Consequently, food must be preserved to assure the nonfarm population an adequate supply.

Our people want a food supply that is safe, high in quality and appearance, adequate nutritionally, and reasonably priced. Many consumers try to obtain these food attributes by returning to the “old ways” of growing and preserving food themselves.

To understand food preservation, let’s look at five causes of food spoilage or deterioration (four are biological, the fifth physical or mechanical):

(1) The primary cause of food spoilage in the United States is microbiological. Micro-organisms are small living organisms such as yeast, molds, or bacteria. They are the chief causes of microbial spoilage.

Related to microbiological spoilage of food and also a concern in food preservation is microbiological food-borne disease. There are two types. Salmonellosis is an example of a food infection where food may not support growth of the micro-organisms but merely serves to transfer it from the source to the human host. In the second type, the micro-organism grows in the food and produces a poison or toxin which when eaten, causes illness symptoms. Staphylococcal food poisoning is the most common of the second type in the US.

Severity of the major types of food-borne disease in the United States varies from the finality of botulism to the mild discomforts of Clostridium perfringens food poisoning. Food preservation techniques, followed precisely, prevent food-borne disease.

(2) The second cause of food spoilage is vermin such as rodents, rats, mice and insects that attack the food and eat or contaminate it before humans can use it. These vermin ruin millions of pounds of food each year.

WHAT ELSE CAN WE DO WITH TOMATOES?!!

(3) Have you noticed how an apple, left at room temperature, eventually gets soft, wrinkles, and dries out? This spoilage is called senescence: an aging process caused by continued respiration of the apple, eventually making it useless as food. Other foods also spoil this way.

(4) Related to senescence is chemical deterioration of food. The development of rancid flavor in high fat-containing foods is a chemical reaction which brings about an undesirable change. Loss of color or bleaching and loss of vitamins, while food is stored, are chemical deteriorations that can be controlled with proper preservation methods.

Both senescence and chemical deterioration are conveyed by organic compounds called enzymes. These enzymes are produced by all living organisms and their function is to speed up or cause the metabolic reaction necessary for the organism’s continued existence. The enzymes will continue to act after the plant is harvested, and bring about deterioration of the food unless controlled or destroyed. Preservation methods have been developed to control or destroy these organic catalysts.

(5) The last cause of food spoilage concerns food handling. Physical or mechanical damage to the food causes bruising, crushing, cutting, and wilting or water loss. These mechanical defects, besides detracting from the food’s appearance, allow easier entry of micro-organisms, insects, and other vermin to cause spoilage and aging.

Food preservation processes have been developed to slow down, prevent, or stop completely these processes of food spoilage.

An inherent part of food preservation is the package containing the food before or after processing.

Packaging provides a convenient method of handling food, prevents contamination during and after processing, bars vermin infestation, supplies a container for storage, and is a necessary part of preservation. An example would be a mason jar with proper seal for pickling.

What are the major methods available for home preservation of food? How are they carried out? Why do they prevent spoilage, food-borne disease, and give desired attributes of safety, quality, appearance, nutrition, and economy? The economics of food preservation will be developed in a subsequent chapter. Let’s explore the following available methods for home preservation of food:

The major method used for home preservation of food is temperature control. This includes canning with a pressure canner or a boiling water bath, blanching food before freezing, refrigerating food, and freezing it. Micro-organisms which cause disease and food spoilage are sensitive to environment temperature variations. By increasing the food’s temperature, micro-organisms are destroyed. When the temperature is decreased, their growth is inhibited.

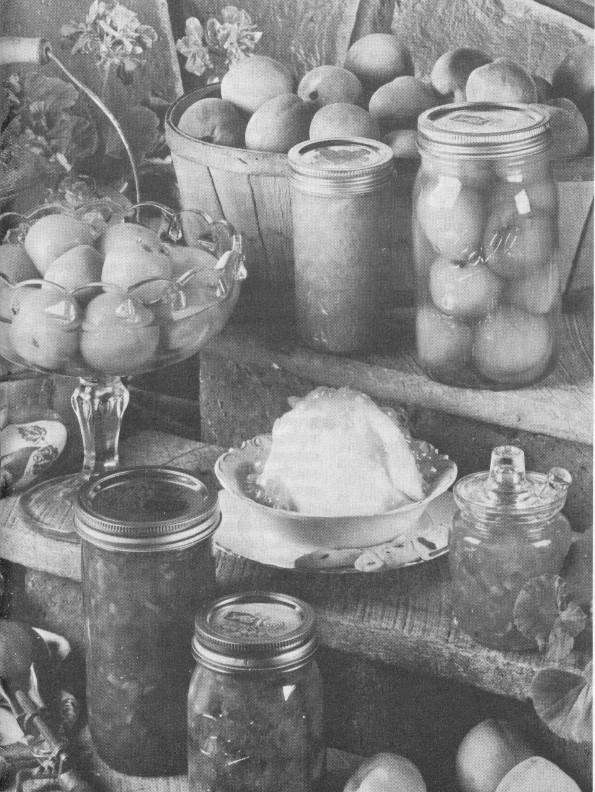

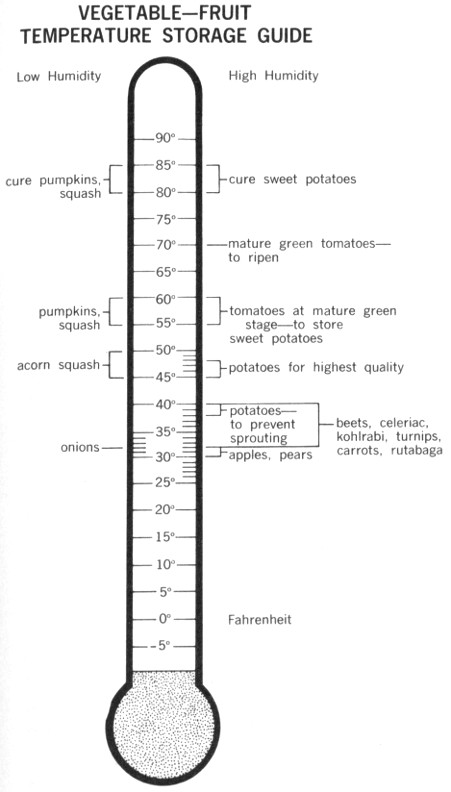

Let’s look at the temperature scale 300 illustration and see how temperature affects micro-organisms. To prevent growth of micro-organisms in food and subsequent microbial spoilage, food must be kept out of the temperature range that allows growth. This is most commonly achieved by refrigerating or freezing. Refrigeration slows down or stops microbial spoilage. Freezing stops it completely.

EFFECT OF TEMPERATURE ON MICRO-ORGANISMS

| Degrees Fahrenheit | |

|---|---|

| 225 | spore-forming bacteria killed |

| 220-250 | proper canning temperatures (low acid foods) |

| 212 | water boils; pressure canner needed to obtain temperatures above boiling |

| 170-210 | non-spore-forming bacteria, yeasts, and molds killed |

| 120-140 | some bacteria can grow |

| 98.6 | body temperature |

| 70-80 | room temperatures may fall in this range |

| 60-120 | DANGER ZONE most bacteria, including food-poisoning types, grow rapidly over this temperature range |

| 32 | water freezes |

| 30-60 | cold-tolerant bacteria, yeasts and molds grow |

| 0 | no microbial growth |

Enzymatic activity, while slowed down by freezing, is not stopped in many vegetables and these enzymes must be destroyed by blanching the vegetables before freezing to prevent enzymatic deterioration. Successful preservation by freezing must deactivate any enzymes that might be in the food as well as rapidly lower the food temperature to below freezing to stop microbial activity.

Freezer burn, a common problem with frozen foods, comes from improper packaging. Food moisture is lost in freezer burn, which results in undesirable flavor and texture changes. Freezer burn can be controlled by proper packaging, proper storing temperature, and avoiding long-term storage.

Refrigeration or storage above freezing, but below room temperature, preserves food for days and sometimes weeks. Refrigerated storage slows down activities of enzymes in the food and reduces metabolism of the contaminating micro-organisms.

Preservation of food by reduced temperature, refrigeration, or freezing is achieved because enzyme activity and microbial deterioration are slowed down or stopped.

Increasing the temperature of food to achieve preservation also results in destruction of the micro-organisms that produce spoilage and disease. Time and temperature regulate this preservation. Theoretically, since food will be stored at temperatures which will allow most microbes to grow, the ideal heat treatment needed to preserve the food would be one that completely sterilizes the food, that is, kills all attendant micro-organisms. To achieve complete sterilization, for example, every particle of food in a jar must reach the required temperature and be held there long enough to destroy all micro-organisms.

The time required for heat to penetrate to the center of the food in a container (the slowest heating point) is extremely important. Heat is transferred through food in containers by two mechanisms: conduction and convection. The mechanism involved depends on the consistency and amount of liquid in the food. The heat penetration rate is also influenced by size of the container, type of heating medium (wet steam vs. dry air), ratio 301 of solid to liquid, kind and size of solid material in container, amount of fat, and amount of salt and sugar.

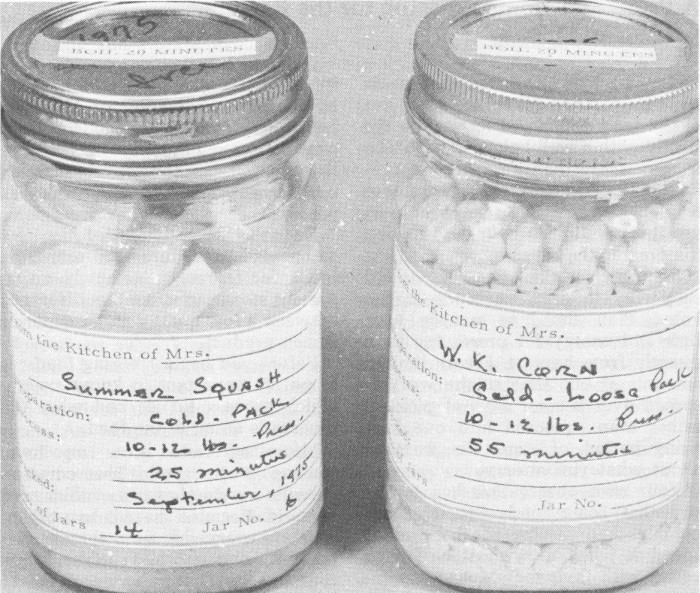

For example, pumpkin or squash can be home canned in two forms: strained or cubed. University of Minnesota research has shown that the time required for the center of a pint jar of strained squash (which heats by conduction) to reach sterilization temperature is three to four times as long as for a pint jar of cubed squash (which heats by convection). The same is true of creamed corn (heats by conduction) and whole kernel corn (heats by convection).

Methods and recipes recommended by Extension agencies take into account all of these factors and must be followed precisely to assure a safe and wholesome product.

Why is it necessary to heat-process pint jars of string beans at 240° F for 20 minutes in a pressure canner when tomatoes can be successfully heat-processed in a boiling water bath? This brings up the second method of preserving food at home, controlling the food’s acid content. This method is most commonly used in combination with heat processing.

Most foods contain naturally occurring organic acids. Some foods contain more of these acids and are called acid or high acid foods. These organic acids have the ability to limit, inhibit, or prevent the growth of many of the micro-organisms producing spoilage and disease. The degree of inhibition is related to the amount of acid present.

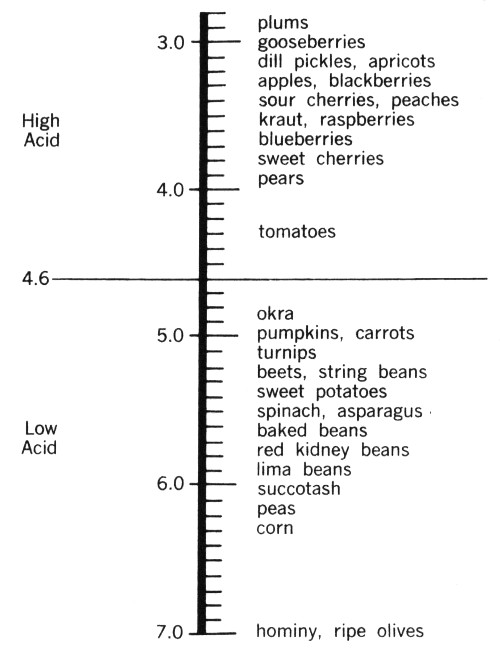

A method used for measuring acid content is called pH. A measure of pH is a determination of the hydrogen ion concentration which reflects the amount of acid or alkali present in the system. A scale from 0 to 14 is used. A pH of 7 is considered neutral, above 7 alkaline, below 7 acidic. Very few foods have a pH above 7.

The classification of foods in the acid range below 7 is extremely important. Above pH 4.6 most of the spoilage type micro-organisms can grow, as well as the dreaded Clostridium botulinum (see discussion following on botulism). In foods with a pH greater than 4.6, it is necessary to heat-process the food at temperatures above boiling to obtain the desired level of sterility.

There are some types of bacteria that produce entities called endospores or spores which are extremely resistant to environmental stresses. They are a means of assuring survival in bacteria, although not themselves a reproductive mechanism. One growing or vegetative cell will produce one spore, which under proper growth conditions will germinate and produce one cell. This one cell continues to grow and can produce millions of bacterial cells. Destruction of the resistant spore necessitates the use of temperatures above that of boiling water (212° F).

BOTULISM. One of the most notorious of the spore-forming bacteria is Clostridium botulinum. When growing in food this bacteria can produce a deadly poison which causes botulism, a deadly illness. The mortality rate is 56 percent. This bacteria and its spore are present in soil throughout the world and as a result contaminates most of the food we eat. But the spore only germinates and grows where there is suitable food, no air, and a pH above 4.6. These conditions exist in canned low acid foods.

To assure botulism-free home-canned foods, it is absolutely essential that low-acid foods be canned in a pressure canner at temperatures above 212° F. The poison produced by this bacteria is one of the most potent poisons known to humans. It has been estimated that 1 cup (8 ounces) is sufficient to kill all the humans on earth. It is not something to take chances about. All home canning procedures recommended by Federal and State Extension agencies 302 are adequate to destroy this dreaded spore-forming bacteria.

pH VALUE OF VARIOUS FOODS

| High Acid | |

|---|---|

| 2.9 | plums |

| 3.0 | gooseberries |

| 3.2 | dill pickles, apricots |

| 3.3 | apples, blackberries |

| 3.4 | sour cherries, peaches |

| 3.5 | kraut, raspberries |

| 3.7 | blueberries |

| 3.8 | sweet cherries |

| 3.9 | pears |

| 4.3 | tomatoes |

| 4.6 | ———— |

| Low Acid | |

| 4.8 | okra |

| 5.0 | pumpkins, carrots |

| 5.1 | turnips |

| 5.2 | beets, string beans |

| 5.4 | sweet potatoes |

| 5.5 | spinach, asparagus |

| 5.6 | baked beans |

| 5.7 | red kidney beans |

| 5.9 | lima beans |

| 6.0 | succotash |

| 6.2 | peas |

| 6.3 | corn |

| 7.0 | hominy, ripe olives |

Commercial canneries, which are regulated by the Food and Drug Administration, use similar processes to assure safe canned foods. In the past 50 years, 75 percent of the reported cases of botulism in the United States have been caused by home-canned food while less than 10 percent have been caused by commercially canned food. If proper home-canning procedures are followed, botulism from this source could virtually be eliminated as a cause of death in the US.

On the lower side of pH 4.6, acid content of the food will prevent growth of Clostridium botulinum and most of the other spore-forming bacteria. Thus, these foods can be preserved by using a lower heat treatment. The most common types of spoilage micro-organisms associated with acid foods are yeasts and molds. These organisms are acid-tolerant and can grow in an acid environment. They are killed at a lower temperature than spore-forming bacteria. Acid foods only need a heat treatment in a boiling water bath for a specified time to destroy the microbes present.

Preservation of food by controlling the acid content can be achieved in two ways. One is to naturally ferment the food—turning cabbage into sauerkraut. The other is to add an organic acid to the food to reduce the pH—adding vinegar to cucumbers to make pickles. Some foods such as berries and fruits naturally contain enough organic acids so their pH is below 4.6, and preservation of these foods requires only a boiling water bath heat treatment or freezing.

In a natural fermentation, lactic acid bacteria convert fermentable carbohydrates in the food to lactic acid. In this way the pH is reduced and most bacterial growth inhibited. When cabbage is fermented to sauerkraut, the cabbage’s pH is reduced from pH 6.8 during the fermentation to less than 3.5. Cucumbers can also be fermented to pickles by a similar process; however, most pickles are made by direct acidification of the cucumbers.

Direct acidification, that is, adding vinegar which contains 4 to 5 percent acetic acid, is the most common method of making cucumber pickles in the United States. It is easier, quicker, and foolproof. Often the natural fermentation will go astray. Other undesirable microbes may grow, bringing unwanted changes in the food: spoiling rather than preserving. Other foods made by fermentation include wine.

Regardless of the method used to control the pH of food, to successfully preserve food by this method it is absolutely essential to heat-process or freeze to prevent spoilage by yeasts and molds. An example of spoilage in cucumber pickles not heat-treated after acidification is the development of cloudiness and bubbling. This 303 common spoilage is caused by microbes that would be destroyed by heat processing.

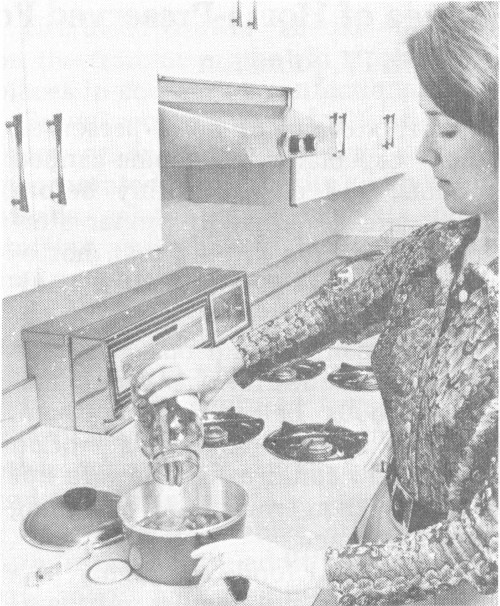

Control of the moisture content of food is one of the oldest preservation methods. Removal of water from the food prevents growth of most microbes and slows down enzymatic deterioration.

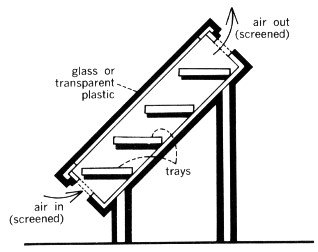

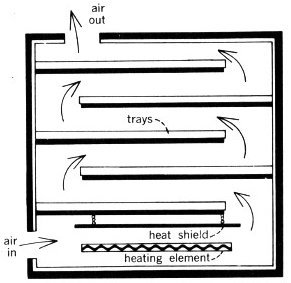

Water removal from food can have several forms. The oldest and most primitive method for removing water is sun drying, which requires long hot days with low humidity to dry food evenly and quickly. Over-drying and uneven drying will result in nutrient destruction, microbial growth, and other undesirable changes. Drying of food in the home can be done and a later chapter tells how.

Water activity or availability of water in foods can also be controlled by adding compounds to the food which tie up the water chemically, making it unavailable for use in an enzymatic reaction or for use by the micro-organisms. The two most common home ingredients used in this way are sugar and salt. In making fruit preserves, the high sugar content ties up the water and helps prevent growth of many micro-organisms.

Methods used for preserving food in the home are combinations of the basic techniques discussed here. Make certain the recipe you follow is from a reliable source. Follow it precisely and be assured of a safe and wholesome food supply.

by Gerald D. Kuhn and Louise W. Hamilton[2]

All methods of preserving food will alter, if not lower, the quality of fresh fruits and vegetables, but these changes can be minimized. For practical understanding of how to minimize quality changes you need to know something about: (1) natural differences in raw food, (2) natural causes of quality deterioration, and (3) how various food handling, preparation, packaging and storage techniques and conditions affect quality retention.

Because of insufficient research information on home preserved foods, some research findings of commercially processed food have been used to foster an increased awareness of factors affecting the quality of home preserved food.

Natural differences in quality and nutrient content in raw food often exceed losses caused by preserving food. Extreme variations (tenfold or more) in vitamin A and C content have been found in some fruits and vegetables. These natural differences are known to be caused singly or collectively by differences between varieties, climate changes between seasons in the same region, and between regions in the same year. They are also influenced by some cultural practices, and maturity of crops at harvest.

Because of color, texture and especially flavor qualities, some varieties are more suited for canning; others are more suitable for freezing. Few varieties possess the all-purpose criteria needed to preserve them as either high-quality canned or frozen products.

There is no single, ideal maturity for harvesting or preserving fruits and vegetables. Obviously, the quality of canned or frozen products made from any maturity other than ideal for that specific commodity lacks the ultimate potential of satisfaction for eating.

Three natural causes account for most quality changes in freshly harvested fruits and vegetables—respiration, enzymes and oxygen. Their effects generally increase with the time between harvest and preservation, and at higher temperatures.

Freshly harvested fruits and vegetables are living organisms. They are sustained by cellular reactions known as “respiration,” in which native enzymes use oxygen and components in food and give off heat, water and carbon dioxide. The energy needed to sustain respiration is obtained from a storehouse of natural components in food. As a result, natural flavors and vitamins are diminished, sugars and sometimes acids decrease, and texture may soften. The speed of respiration and the onset of its effects differs among various fruits and vegetables, and is generally lowered by refrigerator temperatures.

Besides enzymes relating to respiration, fruits and vegetables sometimes contain other cellular enzymes associated with reducing food quality. These enzymes act with oxygen to cause rapid discoloration of bruised, peeled and sliced tissue; oxidation of flavors, and excessive softening.

The roles of oxygen in respiration and other enzyme reactions have been noted. Oxygen may react still another way to lower food quality: autoxidation, where sensitive flavor, color and vitamin components are altered by oxygen. This causes fading of colors, off-flavors and, reduced vitamin retention. 305 These reactions occur quickly during canning and drying of foods, and also account for slow changes during storage of preserved food.

Because of the effects of respiration, other enzymes, autoxidation, and desiccation (loss of water), the raw product temperature and the time between harvest and preservation are of utmost importance to preserving high-quality fruits and vegetables.

Ideal handling conditions vary with the product. Small berry and stone fruits, asparagus, green beans, beets, broccoli, corn and leafy greens, to name a few, should be preserved the same day of harvest, for highest quality. Apples, peaches, pears, plums and tomatoes, if harvested at firm maturity, should be ripened a few days before preserving them. Other fruits and vegetables may be stored from a week to months before preservation without significantly lowering their quality.

From a nutritional standpoint, if after harvest the handling and preservation of these crops are carefully planned and implemented, quality of the preserved products can be equal to food prepared from fresh market fruits and vegetables.

Fruits and vegetables are recognized as significant sources of vitamins A, the B family, C, minerals, and fiber.

Vitamin A, pro-carotene, is heat-stable and insoluble in water but is subject to a minor loss caused by autoxidation. Therefore, losses in home preserved foods are insignificant.

Of the water-soluble vitamins, ascorbic acid (C) and thiamin (B₁) are subject to serious loss upon heating foods. Riboflavin (B₂) is subject to loss when raw or preserved foods are exposed to light.

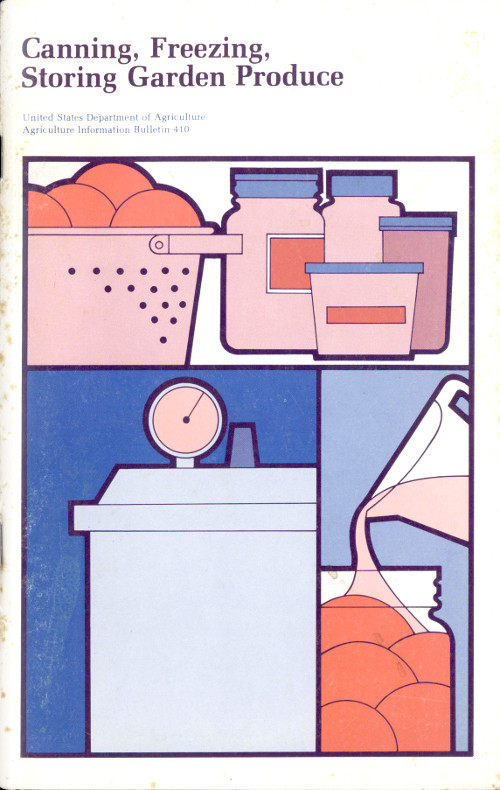

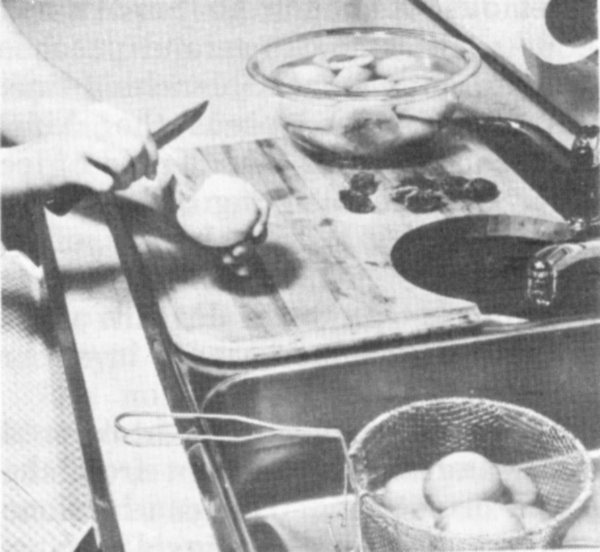

Removing the skins from peaches before canning.

Significant losses of water-soluble vitamins and minerals occur when food contacts water, such as in washing, blanching, cooking or canning foods. As would be expected, losses due to leaching of water-soluble vitamins and minerals rise with increased cut or exposed food surface areas, repeated exposures to water, and more time in water, especially when heated.

The effects on fiber in preserved food is much the same as in fresh cooked foods.

Home canned foods should have a bright color, characteristic texture, pleasant flavor and contain nutrients naturally present. When all steps of scientifically based canning directions are carefully followed, color, texture and flavor will be optimum. These observable signs of quality are also an index to nutrient retention of that canned food.

Proper pretreatment of the fruit or vegetable being canned is essential for top quality. This includes using only good, wholesome food at peak eating quality. Any trace of moldy or otherwise spoiled food should be completely removed. All food must be washed thoroughly.

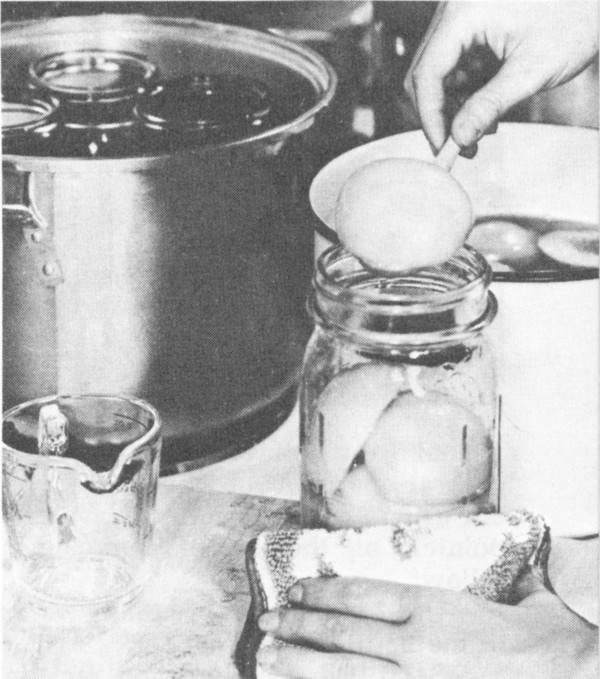

Removal of skins from thin-skinned foods such as tomatoes and peaches is important. A short blanching time in boiling water loosens the skins, and a short cooling time in cold or ice water stops the cooking of the food. Because water leaches out vitamins, dilutes color and flavor, and results in a mushy product, do not allow foods to soak unnecessarily in either hot or cold water.

Air is an enemy of light-colored foods, and should be kept from the peeled or cut food. This can be done with a commercial antioxidant (ascorbic acid), lemon juice, or a simple solution of two tablespoons each of vinegar and salt per gallon of water. Peel or cut food directly into such a solution for maximum protection from air. When enough food for a canner load is prepared, drain and rinse the food for best flavor.

The packing method used is one of the most important factors in quality canned products. Foods that are heated before being put in jars have better quality than foods packed raw in jars. Heating destroys enzymes and removes much of the air from food tissues.

Enzymes must be destroyed quickly for top-quality food. Removal of air not only shrinks the food, but leads to better color, flavor and nutrient retention, and too, fruits are less likely to float. Hot packed jars also have higher vacuums, thus less oxidation can take place.

Tomatoes and tomato juice are less likely to separate if tomatoes are cut and heated at once. Cutting activates enzymes in tomatoes which then change the pectins in the tomatoes and causes separation. Heating right after cutting inactivates the enzymes and minimizes separation.

Sugar, salt and vinegar play important roles in quality canned foods. While sugar is not needed to safely can fruits, it contributes to better color, flavor and texture. Likewise, vegetables may be safely canned without salt, but when salt is used, better flavor results. Salt is essential for slow process pickles; vinegar is needed for quick process pickles. Canning or pickling salt should always be used. Iodized salt will inhibit proper fermentation and react with the starch in some foods, causing them to turn pink or blue.

Sugar concentration in sirups is important to appearance of the fruit. With a light sirup, fruits are less likely to float than with a heavier sirup. And with a light sirup, fewer calories are added. Then too, the cost is less than with a medium or heavy sirup.

Using the proper amount of headspace pays off in quality products. Adequate headspace is needed so food has enough room for expansion during heat sterilization.

Generally, more headspace is needed for foods heat-sterilized in a pressure canner than those in a boiling water canner, because of increased expansion of foods at the higher temperature.

With too little headspace, liquid is more likely to cook out of the jars during heat sterilization. This increases the danger of seal failure due to food particles that may be trapped at the interface of the sealing surface. With too much headspace, air remaining in the jar can cause darkening of the food, oxidized flavor, and lower vitamin retention, especially in food at the top of the jar.

Pressure canning low-acid foods is receiving increased emphasis today, mainly based on the greater safety of this technique. The method also offers an additional advantage that is little known to home canners—improved quality and nutrient retention.

Generally an 18° F (10° C) rise in canner temperatures increases the 307 destruction of bacteria tenfold. At the same time, chemical changes that affect color, flavor, texture and nutrients of the food are only doubled.

This means that for every 18° F (10° C) increase in canning temperature, bacteria are destroyed five times faster than are vitamins, flavor, color and texture. Accordingly, in contrast to boiling water canning, heat sterilizing in a pressure canner at 240° F (116° C) (10 p.s.i.) destroys bacteria about 17 times faster than chemical changes are effected, accounting for better nutrient and quality retention of pressure canned low-acid foods.

Be cautious about interpreting this as an advantage in pressure sterilizing acid foods. This technique can increase quality and nutrient losses because of the total time the jars of food will be near or above boiling water temperature.

For example, with tomatoes it takes about 5 minutes until steam begins to escape, 10 minutes to exhaust the air, about 5 minutes to build up pressure, 5 minutes for heat sterilizing at 240° F (116° C) and 30 to 45 minutes cooling before opening the canner. That adds up to about 55 to 80 minutes at temperatures near or above 212° F (100° C), as compared to the recommended 35 minutes for heat sterilizing in a boiling water canner. Assuming the average product temperature is elevated above 212° F (100° C) about half of this total time, the loss in quality could be at least doubled.

Properly managed heat sterilization has a great deal to do with the quality of canned food. If the temperature is too high or the time of sterilization too long, the result is a product with poor color, soft texture, and less flavor. Tomatoes canned in the pressure canner are an example.

After heat sterilization, a quality canned food will have liquid covering the solid food in the jar. The lid must allow air, but not liquid, to escape during heat sterilization. A low liquid level in the jar may indicate the lid did not function properly, pressure was allowed to fluctuate in the pressure canner, or the canner wasn’t cooled completely before opening, or raw pack was used. Foods not covered with liquid will have poorer quality.

Jars must be air-cooled naturally after heat sterilization to maintain quality as well as for safety. Delayed cooling in tightly enclosed areas, such as cardboard cartons, will decrease quality of the product.

Storage conditions are vital to quality of canned foods. If stored in a light, rather than a dark place, light-sensitive colors will darken gradually. Some colors, such as carotenoids in tomatoes and carrots will gradually fade with prolonged storage.

Storage temperatures between 40 to 50° F (4.5° to 10° C), if the spot is dry, are best for quality retention. Quality losses are increased when canned foods are stored at higher temperatures. For example, about a third of the vitamin C is lost if foods are stored a year at temperatures of 80° F (26° C) or higher.

Storage temperatures between 50° to 70° F (10° to 21° C) are acceptable.

Properly canned and stored foods should be safe to eat for more than two years. However, for top quality, it is best to can only the amount to be used in one year.

Top quality home canned foods have rich, jewel-like colors, characteristic of the food canned. Colors are those of well-prepared foods ready to be served, rather than fresh uncooked foods or over-cooked foods. Light-colored foods should retain their color with no signs of darkening at tops of jars. Fruits should look neither under-ripe and hard, nor over-ripe and mushy. Vegetables ought to look young and tender, rather than 308 old and starchy. Vegetables and fruits should be free of stems, cores, seeds, or pieces of skin, and be of uniform size, shape and color.

Freezing, like canning, does not improve food quality. Top quality fresh fruits and vegetables are essential for premium frozen products. Quality factors include a suitable variety for freezing, optimum maturity, and freshness of the product. Even with high quality, fresh produce, it is imperative to freeze foods on the day when they are at their peak of maturity or ripeness for eating fresh.

Selection, sorting and trimming of produce and the quality control steps as related to color, flavor, and nutrient retention described for canning high quality fruits and vegetables apply equally to preservation by freezing. However, most vegetables must be blanched before packaging and freezing to prevent slow but accumulating effects of enzyme activity and autoxidation. These effects, if not prevented, will cause discoloration, oxidized flavors (sometimes described as tasting grassy or hay-like), and increased loss of vitamins, especially A and C. Proper blanching recommendations are contained in the USDA Home and Garden Bulletin No. 10, Home Freezing of Fruits and Vegetables.

The quality of packaging materials used is reflected in overall quality of the frozen product. Packaging materials must be moisture-vapor-proof. This means there is no transfer of liquids or vapors from the inside to the outside, or from the outside to the inside of the frozen packages.

In addition, fruits and vegetables must be packaged in containers with as little air inside as possible. Air left inside will oxidize the food, causing deterioration of color, flavor and nutrients.

Proper sealing is essential for packaging quality frozen foods. If the seal itself is not moisture-vapor-proof, it becomes the weakest part of the package and poorer quality results.

Adequate labeling helps assure that each package of food is used while at top quality. Packages kept too long will be of poor quality. Even with the finest produce and use of the best preparation and packaging procedures, retention of quality in frozen food is affected by how quickly food is frozen, the temperature of food stored in the freezer, and how long it is frozen before eating.

For top quality, avoid freezing per day, more than two pounds of fresh packaged food per cubic foot capacity of your home freezer. Food packages to be frozen should be spread one package deep over the bottom or other areas designated by your freezer manufacturer. The freezer should be regulated to a uniform temperature between 0° F (-18° C) and minus 5° F (-21° C). A freezer temperature fluctuation of more than 5° F should be avoided if possible. Freezing too slowly, temperatures above 0° F, and temperature fluctuations in freezers increase the ice crystal size in frozen food, lower the quality and shorten the shelf life of food. Frozen foods should be used according to the guidelines in the 1974 Yearbook of Agriculture, Shoppers Guide.

Quality frozen fruits and vegetables should have the natural color, texture and flavor of the individual food. There should be a minimum of ice crystals inside the package and no sign of freezer burn.

Frozen foods should be higher in ascorbic acid and thiamin than canned foods. Vitamin C, including that leached into the juices, approaches 90 percent of the value of raw fruits.

Quality fruits and vegetables can 309 be sun-dried or dried inside using an oven or a food dehydrator. As with other methods of preservation, quality of the final product will depend greatly on quality of the fresh food being dried. Drying does not improve the quality of any food.

A top quality dried product reflects suitable pre-treatment before drying, and adequate drying under proper conditions. Also, appropriate storage after drying is vital to keep moisture from re-entering the dried product.

Fruits may be dried more easily than vegetables, because of their high sugar content and since not as much moisture must be removed to get a quality product. When properly dried, fruits should be leathery and pliable, and have a color characteristic of the fruit. Excessive darkening indicates a less desirable, poorer quality product.

Vegetables must be dried until they are brittle. The color should be characteristic of the vegetable and not excessively dark.

To sum up, nutrient content of foods depends on natural differences, control of deterioration, and handling techniques of food preparation as well as preservation. Therefore, overall nutrient content of a specific fruit or vegetable, whether fresh or preserved, may be about the same.

Top quality, garden fresh foods, served in season, provide the greatest satisfaction when served fresh as table-ready food. Individual preferences for market fresh, frozen canned, or dried food will differ. Since nutrient content is nearly the same, the choice is up to the consumer. Even more important is the choice of vegetables and fruits for a good diet.

Food editors of Farm Journal, How to Dry Fruits and Vegetables at Home, Countryside Press and Doubleday & Company (Dolphin Books), 1975. $2.95.

Hamilton, Louise W., Kuhn, Gerald D., Rugh, Karen A., with the food editors of Farm Journal, Home Canning—The Last Word, Countryside Press and Doubleday & Company (Dolphin Books), 1976. $2.95.

US. Department of Agriculture, Home Canning of Fruits and Vegetables, H&G Bul. No. 8, on sale by Superintendent of Documents, U.S. Government Printing Office, Washington, D.C. 20402. 45¢.

U.S. Department of Agriculture, Home Freezing of Fruits and Vegetables, H&G Bul. No. 10, on sale by Superintendent of Documents, U.S. Government Printing Office, Washington, D.C. 20402. 75¢.

by Ruth N. Klippstein[3]

Back-to-basics may turn out to be the theme song of the 1970’s as some of the simple activities of the past are rediscovered and practiced. Do-it-yourself is in. Nowhere is the trend more apparent than in the area of home production and preservation of the family food supply. Ten years ago no one would have dreamed the lowly canning jar lid would be the subject of Federal hearings. No one would have believed that an estimated one in four U.S. families would be raising and preserving a portion of their food supply.

What motivates people to return to home food production and preservation? Are their expectations realistic? How extensive is their gardening? Will they continue a second year? Do they preserve any of their crop? These were among the questions posed by Stuhlmiller, How and Stone of Cornell University in 1975 to a group of gardeners in five upstate New York counties.

When asked whether they gardened to save money, to have better quality food or just for a hobby or recreation, three-fourths of the 2,800 who replied hoped to save money, 54 percent considered gardening a hobby, while only 46 percent gardened for fresher food. Most said they preserved at least some of the food they grew.

If this study is indicative of the country as a whole, it is important to realistically assess whether home food production and preservation can save substantial amounts of money and whether the satisfaction gained warrants the cost of time and energy expended.

The actual costs of home food preservation, for example, should be considered. The cost of home grown food should be compared to the cost of similar food purchased for preservation in quantities at local farms or markets. The quality of the home preserved items should be realistically analyzed against readily available commercially preserved food.

There is no such thing as free food. Someone, somewhere, has to pay for it in time, energy, know-how, and at least some outlay of dollars. Home production in amounts needed for food preservation requires a longtime commitment of family resources. Beginners should realize that realistic goals and reasonable skills in the field and kitchen are essential to make home preservation pay off.

There are no general statistics citing the average dollar-cost needed to grow a given amount of fresh produce in a home garden. Conditions between individual gardens, weather, soil type, skill of operator, and geographic areas vary too much for valid comparisons.

Extension specialists at Michigan State University, however, have computed the actual cost of raising tomatoes under home gardening conditions in East Lansing, Mich. They found it costs 12¢ to grow the amount of tomatoes (2½ to 3 pounds) needed for one quart, canned. A similar cost analysis for green beans showed that beans cost 30¢ for the amount needed for a quart. Only the expendable cost—seed, fertilizer, pesticides and water—was considered.

Adding the expense for needed tools, hoses and other capital items raised the cost another 33¢ a quart if the cost were absorbed in one season or 2¢ if amortized over a 20-year 311 period. Unfortunately, the first-year gardener will find that the outlay for tools must be spent the first year so that return for the investment requires a commitment to gardening over many years.

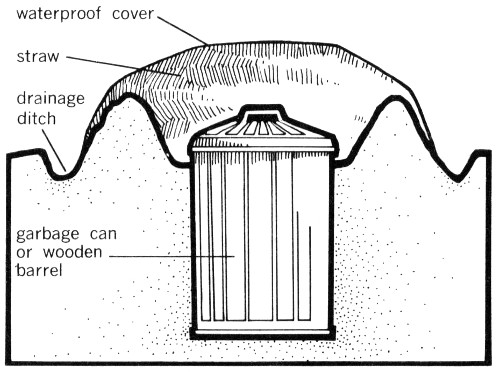

Additional expenses are necessary if the bounty is to be preserved at home. Equipment for preserving tomatoes is minimal but equipment for canning vegetables and for freezing may be costly. Homemakers needing to invest in canners, a pressure canner, and home freezer will find that the dollar cost per package of food preserved during the first years of preservation may be higher than the cost of comparable food at the corner supermarket.

The costs of canning peaches, tomatoes and green beans in upstate New York were calculated by the author in 1975 and updated for price changes in 1976 using a number of different cost variables. She found that those who canned tomatoes could realize substantial savings, while the cost of purchasing peaches and preserving them at home approximated the cost of the commercially canned peach.

Determinations of the true cost of frozen food must consider the initial cost of the freezer plus the cost of operation and repair. Containers, plastic bags and boxes, or foil are additional costs.

Evelyn Johnson in her Outlook Talk of 1975 quoted staff at Virginia Polytechnic Institute and Cornell University as reporting a cost of 20¢ to 24¢ per pound of food frozen just for the convenience of freezing and storing food at home. Add to this the price of the food being frozen for the correct cost of home-preserved frozen food.

Freezing is probably the most satisfactory method of home food preservation, the most versatile and the easiest to do. But for all except the very best managers who use the freezer intensively, the home freezer is more a convenience than a money saver.

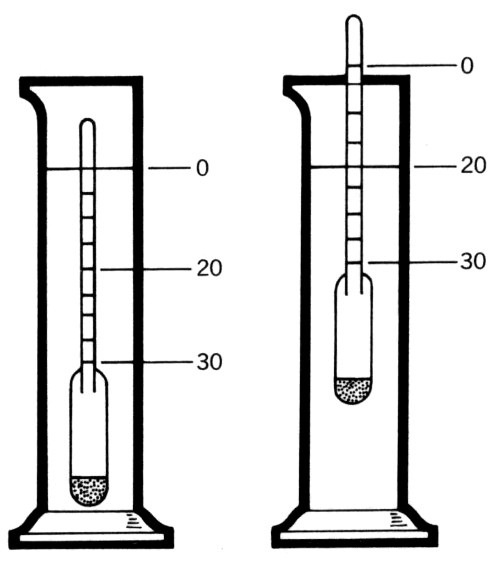

Needed equipment for home canning. Left, water bath canner, and right, pressure canner.

Raising a garden takes time over a significant number of months. As a hobby for table use, gardening can be a real pleasure. Skillful persons with the right tools and know-how can handle a garden of the size needed for home food preservation with a few hours of work a week, once the plants are well established. Novices can expect to spend a significantly greater amount of time per week during the four or five month growing season in northern areas and even more in areas with longer growing seasons.

The author, an experienced gardener, kept records of the hours spent cultivating and harvesting a 20 by 40-foot garden, planted primarily for fresh consumption. Only three foods—tomatoes, green beans and cucumbers—were raised in amounts sufficient for a limited amount of home preservation. Over 40 person-hours were required. The actual grocery store value of the garden food consumed by the family of three was $45. Food given as gifts and preserved raised the dollar value to $75.

Gardening often helps stretch cash income, but the dollar return is low for hours of effort. And poor weather may cause crop failures and small 312 yields, regardless of effort. Food preservation also is time-consuming.

Satisfactions. Why garden or preserve food at home? Most gardeners will cite a number of reasons:

—The best of good fresh food with no unknown additives or ingredients

—Healthy exercise

—Family pleasure working together toward a goal

—The joy of giving

—The challenge of growing a seed into edible food

—Prestige

| Energy | |||||

|---|---|---|---|---|---|

| Method | Time | Fuel | Human effort | Dollar cost from kitchen to table | Quality satisfaction |

| Freezing | Minimal low | High | Low | Very high | Very high |

| Canning | Moderate | Moderate | High | Moderate | Moderate to high |

| Drying | High | Moderate to high | Moderate | Moderate to high | High (specialty items) |

| Low, if only method available | |||||

| Pickling | High | Low | Moderate | []Depends upon type chosen | High |

| Storage (Unprocessed) | Low to moderate | Low | Moderate (Checking/culling) | Low | Moderate to high |

There is no one right answer to the question, “Does it pay to raise and preserve my own food?” It depends upon your personal goals. You may not save a significant number of dollars. You will work hard. And you probably will experience one of the most exciting activities possible—raising at least some of the food your family uses.

“We grew it” are heady words which bring people back to home food production and preservation year after year.

by Frances Reasonover[4]

Canning is probably the most economical and practical method of preserving food at home. Among other things it is a way to save food that otherwise might be wasted.

Cost of home canning depends on the kinds and sources of food canned as well as the processing methods, containers, and equipment used. Other cost factors—labor, energy, water and added ingredients—make exact cost figures impossible to apply generally, but studies are reporting averages that show canning to be economical.

The wise homemaker will can only the amount to be used within a year. Food held longer will be safe to eat if it has a good seal and no signs of spoilage, but there may be nutrient or quality loss, especially if stored at temperatures above 70° F.

As a beginner canner you need to know something about micro-organisms, including yeasts, molds and bacteria, on the food, in water, air and soil, as causes of spoilage in foods. Knowing about these minute forms of life, which are so abundant everywhere, will help make the work safer as well as more interesting.

In addition to the action of these minute organisms, the spoiling of fruits and vegetables is hastened by natural changes in color, flavor and texture of the food. These changes result from the action of enzymes or micro-organisms found in nature which break down and decompose foodstuffs.

Bacteria are the most serious foes to combat in canning because they are more difficult to kill by heat than either molds or yeasts.

Acid in canned food is expressed as pH value. Foods having a pH of 4.5 or lower are called high-acid foods and those with a value of 4.6 or higher are termed low-acid foods.

Since few bacteria thrive in acids, their destruction is less difficult in fruits than in vegetables (with the exception of tomatoes).

Botulism is a deadly poison caused by a toxin from the growth of spores (seeds) of the bacteria, Clostridium botulinum. These spores will produce a deadly toxin in low-acid foods in the absence of air (oxygen) inside a sealed jar. Therefore, the spores must be destroyed by processing under pressure at 240° F. The length of time has been determined by scientists for each individual food.

Clostridium botulinum will not grow in foods with a pH of 4.5 or lower, so high-acid foods may be processed safely in boiling water at 212° F.

Yeasts, mold and non-spore forming bacteria are readily controlled by processing at 212° F.

Most canning equipment and supplies may be purchased at hardware stores, housewares departments, and from mail order companies. Jars and lids are available in many retail stores.

Select standard canning jars made of tempered glass that can withstand high temperatures. The manufacturer’s name or symbol in glass will identify the product. With careful handling, jars last an average of about 10 years. Avoid using antique jars because there can be hair-line cracks not visible to the eye, causing jars to break.

Use canning jars in sizes suitable for the product canned and your family’s needs. Canning jars generally are sold in half-pint, pint and quart sizes with wide and narrow mouths. Large-mouth jars are convenient for packing such foods as whole tomatoes and peach halves. Quart jars are convenient for vegetables and fruits where your family has four or more members.

Examine the sealing edge of jars for nicks, cracks, or sharp edges that would prevent a seal. Discard any with these imperfections.

One-trip jars from purchased canned foods should not be used because they generally are not tempered to withstand the high heat required for home canning, and may break when subjected to the heat. Tops of these jars may not fit standard canning lids, thus preventing a good seal.

Home canning equipment.

Closures—jar lids and rings come with new canning jars. The sealing compound of lids recommended for one use only will not hold a seal effectively after the first use.

Select lids appropriate for the jars being used. You may find the two-piece units (flat lid with sealing composition and ring), one-piece lids, or flats with separate gaskets made of metal or plastic. Always follow the instructions for pretreatment as indicated on the box or container by the manufacturer. If no name is indicated on the lid, use a black wax marking pencil or crayon and mark the identity on each lid. If there are problems, contact the manufacturer whose name and address is on the box or container.

Screw ring bands may be reused if kept clean and dry in a protective container with a tight-fitting lid. Never use bands with rust, or pried up or bent edges.

If you have extra lids, store them protected in a dry, cool place.

One-piece zinc caps lined with white porcelain, with rubber rings, may be used. The caps may be reused if they have not cracked, spread or bent at the edges and are clean, like new. The rubber rings are effective only once because they tend to dry and deteriorate with age, often become porous, and sometimes crack.

If you have jars with bail wire clamps, sometimes called “lightning”-type jars, be sure they are not in the “antique” class. Lids for these jars are all glass, and rubber rings are used between the jar and lid for sealing. A wire clamp holds the lid in place during processing; after processing, the short spring wire of the clamp is snapped down to complete the seal.

A boiling water bath canner is needed for processing high-acid foods, such as fruits, tomatoes, tomato and fruit juice, and pickles.

Water bath canners in several sizes are available on the market. The container must be deep enough for a rack 315 to hold the jars off the bottom of the canner. The depth allows water to be over the jars of food by at least 1 to 2 inches. Keep 1 to 2 inches of space above the water to allow for boiling; this prevents water from boiling over.

The canner must have a tight-fitting lid. Or you can use a large kettle with a tight-fitting lid, and a wooden or wire rack to hold jars off the bottom. There should be free circulation of water to every part of the surface of the jar and lid.

If you are going to buy a water bath canner, check the height, and the lid to be sure it is tight-fitting. The rack preferably should have dividers so jars will not touch each other or fall against the sides of the canner or each other during processing.

A steam pressure canner is absolutely essential in canning low-acid foods, such as vegetables, and insures the destruction of spoilage micro-organisms.

Ten pounds pressure is used for processing food in standard canning jars at sea level. This pressure corresponds to 240° F.

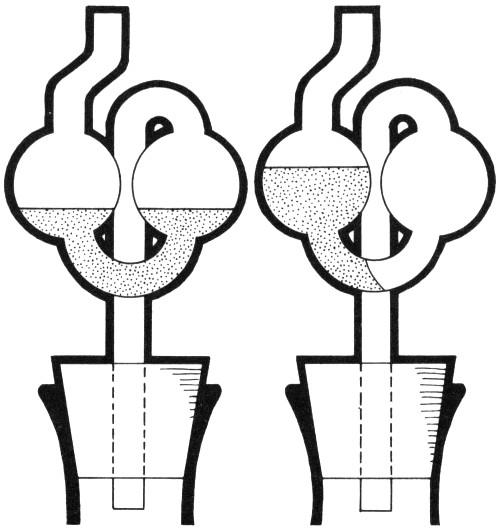

The steam pressure canner is made of heavy metal that withstands high pressure developed by steam. It consists of a kettle with a tight-fitting lid equipped with an accurate weight or dial gage to register the pounds of pressure in the canner. The lid must lock or seal to prevent escape of steam.

The canner must have a safety valve, petcock or steam vent that can be opened or closed to permit exhausting (venting), and a pressure gage. It must have a rack to hold jars at least ½ inch from the bottom of the canner.

A dial gage indicates pressure on a numbered instrument.

A weighted gage has no dial, but automatically limits pressure with weights preset for 5, 10, and 15 pounds pressure.

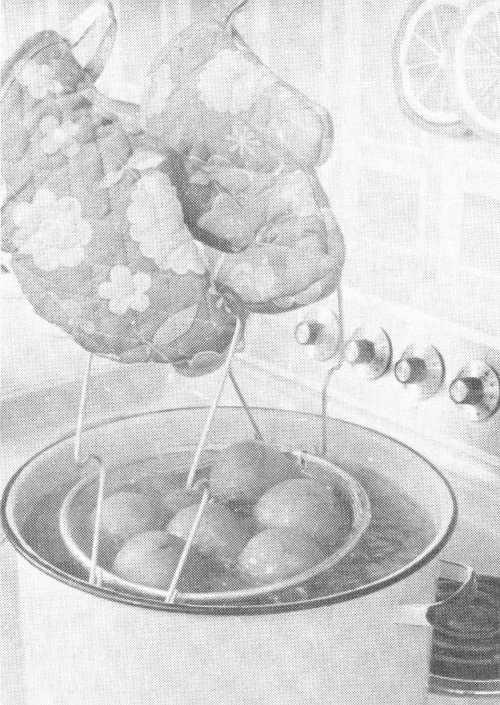

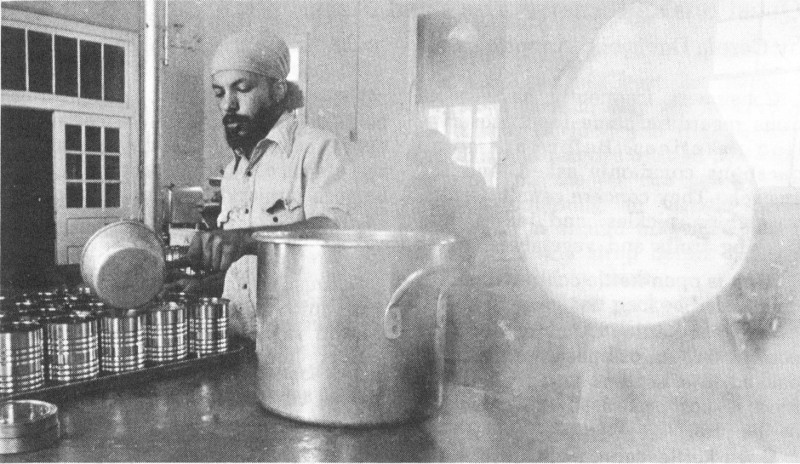

Scalding tomatoes in a blancher.

The pressure is adjusted for high altitude. For information on canning at altitudes above sea level, see the later chapter by Carole Davis.

To insure the canner’s proper working condition, check the dial gage for accuracy each year—or if a canner or lid has been roughly handled or dropped, the dial gage glass broken, or any parts are rusty. The manufacturer or your county Extension office can give information on testing availability. Study and follow the manufacturer’s directions for using your pressure canner.

Run through the process of operating the pressure canner on your range in a trial run before you get into the canning season, to be sure everything is working properly. Make a note of the dial setting of the range if you use an electric range for holding pressure steady.

Trying to use a pressure canner obtained from garage, rummage, or auction sales or handed down to you from someone’s attic may prove dangerous. 316 You may not have any idea as to the care, handling, or storage of the canner. A manufacturer manual on care, use and replaceable parts usually is not available. Old-old canners did not have complete information—manufacturer’s name, address or model number—on the appliance.

General kitchen equipment is helpful in any needed washing, peeling, coring and slicing in the preparation of fruits and vegetables. Examples are, a vegetable brush for cleaning vegetables, a blancher or wire basket for scalding fruits and vegetables such as tomatoes and peaches to loosen skins for peeling, and a colander for washing delicate fruits such as berries.

A food mill is handy for making purees and straining fruits for making juices, and a strainer for straining juice. A long handled fork or plastic spatula aids in fitting and packing food and removing air bubbles. A wide-mouth funnel is very convenient for filling jars, and a jar lifter helps you avoid burns in handling hot jars. Use an automatic timer to time processing accurately.

The number of pints of preserved food you will get from a given quantity of fresh food depends on the quality, variety, and maturity of the fruit or vegetable; on the size of the pieces, and on the packing method used.

Selection of good sound fruits and vegetables is of paramount importance. The quality of canned fruits and vegetables will be no better than quality of the raw food used. For best flavor retention, preserve only those vegetables that are young, tender, and freshly gathered.

All steps, from beginning to end, of any lot of canning should be carried through as rapidly as possible. A good slogan is “two hours from harvest to container”.

Work fast with small amounts of food at a time, especially vegetables with high starch content such as corn and peas which lose quality rapidly. Any delay will result in loss of flavor and nutritive value.

Sorting and grading should be done very carefully, according to size and degree of maturity and ripeness.

Use only uniformly well-ripened products. Discard all defective products and use together those of the same size.

Dirt in seeds, bits of food, or sirup contains bacteria that is hardest to kill, and encourages yeasts and molds to grow on the outer surfaces. Wash fruits and vegetables thoroughly before canning.

Scalding, peeling and coring—some fruits, such as peaches and tomatoes, are scalded in order to peel them smoothly.

Follow up-to-date recommendations, available in U.S. Department of Agriculture or Extension publications, for detailed procedures in preparing fruits and vegetables for canning.

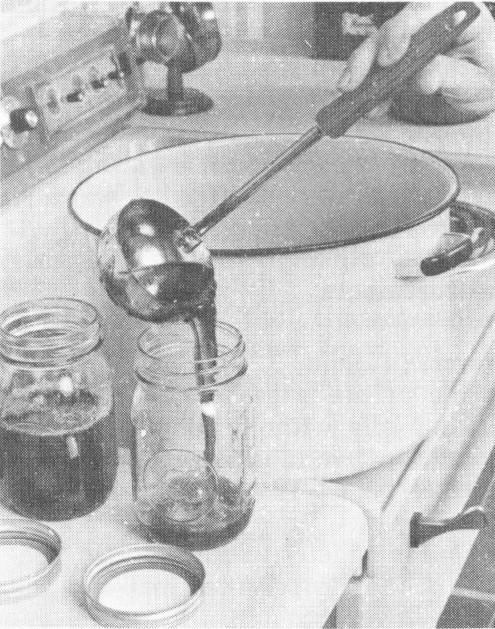

You can pack food hot or raw in jars. Hot-packed food is heated thoroughly before it is packed into jars. Raw-packed food is placed raw in jars. Watery and soft foods such as tomatoes are pressed gently to make their own juice.

Air, a poor conductor of heat, should be removed from the jar. Remove air bubbles by gently moving the blade of a plastic spatula or plastic knife around the jar—being careful that the food is not broken. Add more boiling liquid if necessary to get a proper fill.

When filling jars, you will find the jar-filling funnel easy to manage. This makes it possible to avoid spills of seeds, bits of food, or sirup that could prevent sealing. But even when using a funnel you still need to wipe the jar rim.

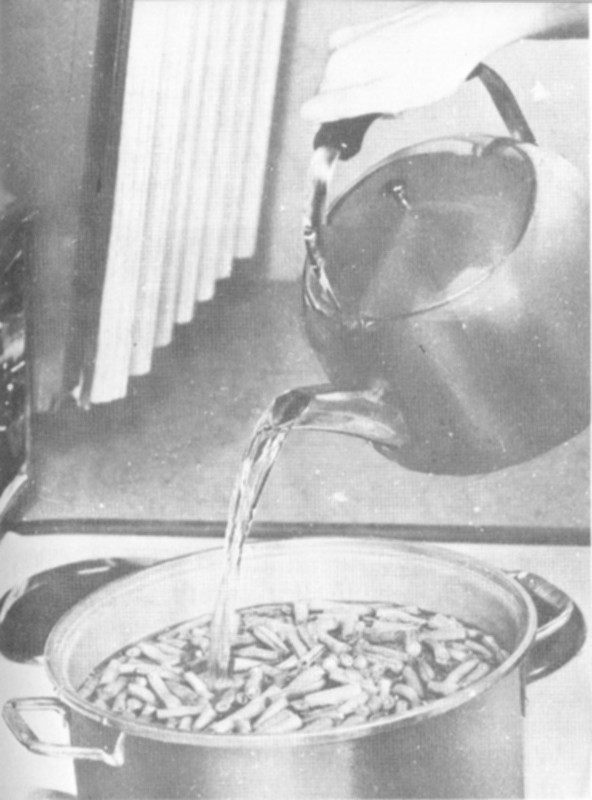

Heating beans thoroughly before placing them in jars. Here, cut beans are covered with water to be followed by five minutes of boiling.

Prepare the lids and sealing of jar according to the manufacturer’s directions. When using a flat metal lid, place the composition side on the rim of the jar. Add the ring band and screw it down until firm, but not hard enough to cut through the sealing compound. The lid will have enough “give” to let air escape during processing. This is called venting and means heating to remove air from jars.

When using porcelain-lined zinc caps, fit the wet rubber ring on the jar shoulder, but do not stretch it more than necessary. Screw the cap firmly and turn it back ¼ inch.

Use a jar lifter or tongs and place the filled jars on the rack in the canner. Fill and place jars in the canner one at a time to keep jars as hot as possible while filling the canner.

Before you begin preparing the food, fill the water bath canner half full of hot water. This permits water to heat while you prepare the food. Put a large kettle or teakettle of water on to boil. The water should be boiling when hot-pack food is put into the canner.

Place raw-pack jars in water that is hot (180° to 190° F), just below boiling. Then bring it to a boil after adding jars.

As the rack of jars is lowered into the water, the water level will rise. If more water is needed to have the jars completely covered by 2 inches of water, add boiling water.

Prepare only enough jars of food at one time to fill the canner. Work rapidly, allowing as little time as possible between filling and closing the jars and getting them into the canner.

Start counting processing time as soon as the water in the canner reaches a gently rolling boil. Put the lid on the canner. Set your timer or clock and make a written note of starting time and final time. Keep the water boiling all during the processing period. If water boils down, add boiling water sufficient to keep it at the required height. When pouring water, avoid letting it hit tops of the jars.

Process for the recommended length of time. Do not cut processing time.

Follow the manufacturer’s directions for operation of your pressure canner before, during and following processing. Supplement these directions with information in U.S. Department of Agriculture or Extension publications.

Count processing time as soon as the pressure reaches 10 pounds or the proper pressure adjusted for altitude. Be sure to hold pressure steady.

At end of the processing time, remove the canner from the heat. Allow the canner to cool until the gage registers zero to avoid breakage of jars and loss of liquid from jars. After a minute or two, open the petcock 318 gradually and remove the cover. If a weighted gage is used, nudge the weight slightly. If no steam escapes, pressure is down. Tilt the far side of the lid upward so steam escapes away from your hands and face. Because food in the jars may be boiling vigorously, leave jars in the canner about five minutes and then remove them.

When you remove hot jars from the canner, use a jar lifter, or protect your hands with cooking mits, pot holders or canvas gloves. Set the jars upright to cool on a rack, such as a cake rack, or a bread or cutting board, with double layers of dry cloth or newspapers beneath the jars. If jars are placed on a cold surface or wet cloth, the difference in temperatures may cause the glass to crack.

Avoid placing jars in a draft, but leave two or three inches between them so air can circulate freely. Avoid further tightening of lids that have sealing compound, since this usually breaks the seal—unless the lid manufacturer states it is safe to tighten.

If your processing temperature was not held steady and liquid boiled out in processing, do not open the jar to add more. Leave the sealed jar just as it is.

Do not cover jars because this slows down cooling and food continues to cook. If you have an air conditioning vent that will direct cold air on jars, cover the vent during this canning session.

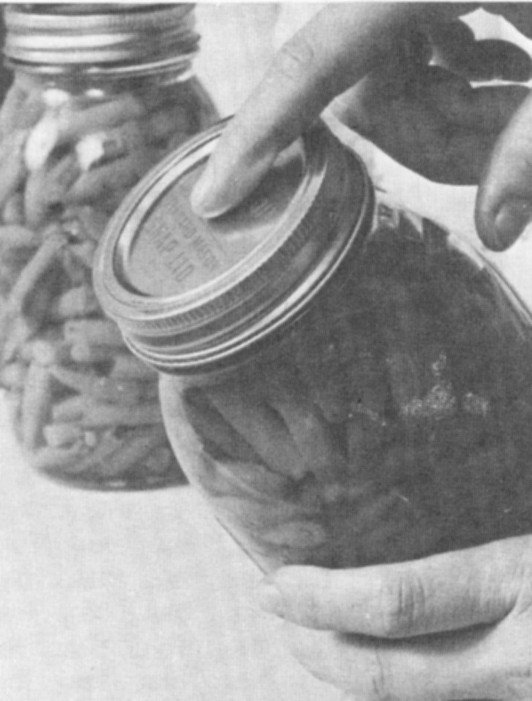

After 12 hours, check the seals. The vacuum may cause a loud snap of the two-piece vacuum seal while it cools, which is an indicator of an airtight seal. If the center of the lid holds down when pressed and the lid does not move, it is sealed.

Tap the center of the lid with a spoon—a clear, ringing sound indicates a good seal; a thudding sound indicates the possibility of an imperfect seal.

If there is a sealing failure, you will need to reprocess the jars. Remove the lid, heat the food and liquid, fill a clean jar and use a new lid. Process the full length of time. If only a few jars did not seal, you may elect to refrigerate and use the food within a day or two or freeze it.

Once the jar is sealed, allow it to set until cold. Then remove the screw ring band, wash and store in a dry place for reuse. For safety make a routine check of canned foods each month.

Write name of product and date canned on a gummed label or the lid of each jar with a felt tip pen. Keep a record of food canned, date, number of quarts or pints, and a place for you to check them off as you use them. This can be your guide for next year’s preservation plan. Use food preserved for the current year, readying a storage place for next season’s garden produce.

Canned foods stored in a dry, dark, cool temperature (70° F or below) will retain good eating quality for a year. Home canned foods stored in a warm place near direct sunlight, hot pipes, above a range or refrigerator, or in kitchen cabinets may lose some eating quality within a few weeks. Dampness may corrode lids and cause leakage so that the food spoils.

The main cause of spoilage in canned foods is improper processing. Bulging jar lids, or a leak, may mean gas is present and the food spoiled.

Before opening home canned foods, wash jars and lids and carefully inspect the jars. Bacteria, yeasts and molds should have been destroyed if the food was properly processed.

When you open the container, look for such danger signs as spurting, cloudy or frothy liquid, an “off” odor, deterioration, or slimy texture. A foamy or murky appearance and patches of mold are visible signs of 319 spoilage. That ordinary looking mold on home-canned food may indicate the presence of a much more deadly problem: botulism.

ALWAYS label home-canned foods.

Destroy food if any of these signs are obvious; discard out of reach of humans and animals.

The odor in good jars of food should be pleasant and characteristic of the product. Do not use food which looks or smells bad, or if there is any doubt as to its safety.

All low-acid, home-canned food should be boiled 10 to 20 minutes to insure destruction of botulism-causing toxin for added safety. Heating denatures the toxin so that it does not react with the body. Never taste home canned food before cooking it.

Successful results largely depend upon the accuracy with which up-to-date directions are followed.

Safety is best assured when you exercise special care as you prepare and pack food into canning jars, fitting jars with properly pretreated lids, and heating jars of food to a high enough temperature for a sufficient length of time to kill micro-organisms that cause spoilage.

by Charlotte M. Dunn[5]

Every homemaker knows that meals must be planned to get the most out of the food dollar and to provide the family with a well-balanced diet. The freezer, more than any other household appliance, can help secure these results. The more you learn how to use it in relation to your own family, the greater the returns.

Freezing is a quick, convenient and easy way to preserve foods in the home. Plan ahead to manage your time and energy for preserving food directly from harvest. Freeze limited amounts at one time so the work is spread over several days of picking, rather than squeezed into one long tiring period of time. Be practical about what you attempt.

Your own observation has taught you that some foods “spoil” more quickly than others, so the rate of speed at which they must be frozen varies with their individual temperaments. A good rule for home freezing is: two hours from garden or orchard to container, and the faster the better!

Most food that is highly perishable at normal temperatures can be quick frozen. Even delicate fruits and vegetables can be frozen, with only a few exceptions such as tomatoes (stewed tomatoes can be frozen) and those vegetables that lose crispness such as radishes, celery, cucumbers and salad greens.

Decide what you will freeze on the basis of availability of foods, family needs and taste, freezer space, cost of freezer storage, and availability of alternate methods of storage.

It is essential to start with high quality raw material. As garden foods mature, process without delay. Quality of the frozen food will be only as good as the quality of the food before freezing. Freeze foods at their peak of eating quality to preserve flavor, texture, and appearance as near those of the fresh product as possible.

Do not ignore details of the recommended procedures for preparing foods for freezing. Seemingly unimportant steps can make the difference between a low quality and a superior frozen product.

Before you begin freezing foods at home it’s important to know exactly which process to use and what the process is doing to the food.

Micro-organisms grow on food, causing it to spoil. The common growths are simple yeasts, molds, and bacteria. Because these micro-organisms are everywhere—in the air, water, soil and on all surfaces they contact—they naturally occur on all foods. Storing and preserving foods properly controls or inhibits the growth of micro-organisms, thus maintaining both quality and safety of the food.

Cleanliness and sanitary methods are as important in handling foods for freezing as in preparing them for immediate use.

All foods contain chemical substances called enzymes. They are essential to life, and continue their chemical activity after the fruits and vegetables mature or are harvested.

If allowed to work after a food reaches its peak of maturity, enzymes destroy the food’s physical properties, thus changing its color, flavor and texture.

When perishable food is not preserved by one of the recommended ways, enzymes within the cells of the food continue to live and cause spoilage.

Freezing and storage even at very low temperatures will not inactivate any of the common enzymes. At 0° F, the recommended temperature for storing frozen foods, enzymes are not inactivated but only slowed down. In two to three months they will produce off-odors and bad taste. This temperature only checks the growth and reproduction of destructive bacteria. The faster a food is properly prepared frozen, the sooner both enzymes and bacteria are rendered harmless.

Just about every kind of food you or I will freeze contains moisture or water, and the process of freezing food involves the freezing point of water. As temperature of the surrounding air goes below the freezing point of water, the water progressively crystallizes out in the form of pure ice. Size of the crystals which form is determined by the span of time during which freezing takes place. When the temperature is lowered slowly, the crystals expand considerably. If the freezing is sharp and sudden, the crystals retain approximately the same size as the original water molecules.

In case you have doubts about how well a food will freeze, test it before freezing large quantities. To test, freeze three or four packages and sample the food a couple of weeks later. This will show the effect of freezing but not the effect of storage. Some varieties of the same kind of food freeze well, others do not.

Much of the success you have with your home freezer will depend on how you prepare, package, wrap and seal foods. Protecting frozen food is as important as freezing food of high quality.

You will need general kitchen utensils plus a steel, aluminum or enamel kettle large enough to hold at least one gallon of boiling water, with a tight fitting cover. Use a mesh basket, a strainer, or large squares of cheesecloth to hold one pound of vegetables in the boiling water.

Steaming of cut, sliced or green leafy vegetables is recommended and will preserve more nutrients than water does.

You will need a container to hold ice water for quick chilling of vegetables to stop cooking action. Drain thoroughly in a colander and turn out on absorbent towels.

It is false economy to skimp on wrappings and containers. They should protect the food from cold air, which is dry, so as to retain the moisture in foods and prevent freeze burn and dehydration. Select them according to the use they will be put to.

Most freezer containers on the market today are easy to seal, waterproof, and give satisfactory results. Rigid plastic containers, bags, and jars with wide tops are favorites.

Moisture- and vapor-resistant wraps, which are exceptionally effective at excluding oxygen, include heavyweight aluminum foil, coated and laminated papers, polyethylene films, saran, and polyester films. They should be strong and pliable so the wrap will adhere readily to irregularly shaped objects, and eliminate as much air as possible to avoid frost accumulation inside. Careful wrapping is of no avail if the package breaks. It should be easily sealed, either by heatsealing or freezer tape.

Freezer bags are available, and freeze-and-cook bags that withstand temperatures from below 0° F. to above the boiling point. The freeze-and-cook bags are suitable for freezing and reheating food. Points to consider include the size convenient for your use and the cost.

Materials not moisture-proof and vapor-proof, and thus not suitable for packaging foods to be frozen, are ordinary waxed papers, cartons from ice cream or milk, and plastic cartons 322 from cottage cheese or gelatin products because they crack easily.

Compare price, durability, shape and reusability in selecting containers, keeping in mind their convenience and the economical use of freezer space.

Retaining the vitamins and other nutrients depends on how fruits and vegetables are handled before freezing, on storage temperature in the freezer, and on how you cook them. Always follow up-to-date recommendations available from the U.S. Department of Agriculture or county Extension office.

Select foods of top quality. A freezer is not magic—it does not improve food. Its function is to preserve quality and food values and to prevent spoilage.

Choose vegetables and fruits suitable for freezing, and the best varieties for freezing. Because growing conditions and varieties vary greatly across the country, check with your county Extension office to find out which varieties are best for freezing.

Freeze fruits and vegetables when they are at their best for table use. If possible, freeze those that are ripened on the tree, vine or bush. Fruits should be ripe but firm.

Enzymatic changes continue after harvest, lowering quality and nutritive value. If stored at too warm temperatures, fruits can lose vitamin C, turn brown, lose flavor and color, and toughen.

Don’t delay in harvesting vegetables since asparagus, corn, peas, snap beans, and lima beans all deteriorate rapidly in the garden after reaching their peak.

Observe cleanliness while you work, to avoid contaminating foods.

Prepare vegetables for freezing by blanching them in boiling water for recommended times. County Extension offices will have information on specific times for various foods.

Blanching vegetables is absolutely necessary to inactivate enzymes that cause undesirable changes in flavor and texture. This brief heat treatment reduces the number of micro-organisms on the food, enhances the green color in vegetables such as peas, broccoli and spinach, and displaces air trapped in the tissues.

Pack food in containers as solidly as possible to avoid air pockets, leaving the necessary head space for expansion. Press out as much air as possible, with your hands or by using a freezer pump. Then seal the plastic bags by twisting the open end, folding it over. Freezer rubber bands, twist-seals, or freezer tape are satisfactory for sealing bags.

Label packages clearly and carefully with name of product, date when frozen, number of servings or poundage, and any information that will help you. Special pens are made for marking frozen food products. Or you can use a wax pencil or crayon.

Speed is important in preparing food and getting it into the freezer, so as to maintain quality. Put only the amount of unfrozen foods into the freezer at one time that will sharp freeze within 24 hours.

Allow at least one inch between packages of unfrozen food in the freezer for circulation of cold air. Leave packages in freezing position for 24 hours before stacking them close together.

Uniform freezing temperature and keeping frozen products at 0° F or lower will maintain quality. Different foods have varying storage periods, so keep your frozen food inventory changing.

Use a freezer thermometer in your freezer. Check your freezer door and wall plug daily to avoid any catastrophe.

A freezer can pay wonderful dividends with considerable thought and planning by the homemaker.

by Nadine Fortna Tope[6]

Use of a pressure canner for preserving low-acid foods is not new. Pressure canners for home canning were first marketed in the early 1900’s. In 1917, the U. S. Department of Agriculture announced that use of a pressure canner at 10 pounds pressure (240° F) was the only safe method for canning vegetables. Today’s recommendations are essentially the same.

A temperature of 240° F or 10 pounds pressure at sea level is needed to kill spoilage organisms in a reasonable time, especially the spores of Clostridium botulinum. These spores, if not killed, can produce the most deadly toxin known to man.

The commercial canning industry stringently follows safe canning practices. Their safety record is excellent. A Complete Course in Canning by Lopez (1975) says that since 1925 four deaths have been reported from the consumption of more than 800 billion cans of commercially processed foods. The record for home canning is much worse—450 deaths in a fraction of the number of cans. Unsafe practices were probably used in preserving the deadly home-canned food.

Methods like open kettle, oven, and boiling water bath canning for low-acid foods are not sufficient to kill Clostridium botulinum spores. Educators talk to many people even today who still use unsafe practices because “that’s the way my mother always did it”, or because they are unfamiliar with pressure canners.

In this chapter, the need for safe pressure canning procedures will be discussed along with the rationale for using care in preparing low-acid foods for canning.

Acidity of a particular food is the most important factor in determining which canning method should be used—pressure or boiling water bath.

Acidity is measured and stated much the same way we express length or weight. Acidity (pH) refers to acid strength, not the amount of acid present.

For example, citric acid, an acid found in oranges, grapefruit, and other citrus fruits, is a weak acid compared to hydrochloric acid, a very strong acid. The measure used to express acid strength is pH. The pH scale runs from 1 to 14 with 7 as the neutral point. Substances with pH below 7 are called acidic, while those above 7 are called basic or alkaline foods. The lower the pH, the more acid the food.

Acidity or pH of a food affects the length of time it must be processed at a particular temperature to make it safe. The more acid the food (the lower the pH), the shorter the time required for processing.

Almost all foods are acid in nature. Hominy is an example of a food that is neutral or slightly alkaline.

Foods are further categorized as high acid or low acid because the C. botulinum spore will not grow at pH levels of 4.6 or below. High acid foods (pH 4.6 or below) include tomatoes and all fruits except figs. (See chart).

Those with a pH above 4.6 are the low-acid foods. All vegetables except tomatoes and those that have been pickled or fermented are low-acid.

Safe processing times have been established at 240° F for low-acid home canned products, since at this temperature the processing times are reasonably short and texture of the 324 resulting product remains good. The heat-resistant C. botulinum spore has been known to survive many hours of boiling at 212°. Once food reaches 240°, the spore is killed when held for the recommended number of minutes.

Holding of produce to be canned for long periods in warm summer temperatures gives bacteria ample time to multiply into vast numbers, thus increasing the chances of spoilage.

For example, one cell can multiply into a billion cells in just 15 hours of holding under favorable conditions.

Salt and spices added to low-acid canned products in amounts recommended do not appreciably alter processing time. Salt may slightly lower the heat resistance of some micro-organisms but not enough to present a problem if omitted for dietary reasons.

Fats and oils, if added, may reduce the rate of destruction of bacterial spores. Spores of C. botulinum have been known to survive beyond all reasonable expectation when heated in oil suspensions. Thus, adding oil or fat to a product being canned could be dangerous and is not recommended.

The type, consistency, and piece size of food and how it is packed in the jars are important factors which affect processing time. In preparing jars of food for the pressure canner, follow directions carefully. Do not use jars larger than the directions specify.

Determining the safe processing time for a food product involves two important steps.