Title: Kinematics of Mechanisms from the Time of Watt

Author: Eugene S. Ferguson

Release date: October 31, 2008 [eBook #27106]

Language: English

Credits: Produced by Chris Curnow, Viv, Joseph Cooper and the Online

Distributed Proofreading Team at http://www.pgdp.net

Eugene S. Ferguson

| JAMES WATT, KINEMATIC SYNTHESIST | 187 |

| TO DRAW A STRAIGHT LINE | 199 |

| SCHOLARS AND MACHINES | 209 |

| MECHANICIANS AND MECHANISMS | 216 |

| MECHANISMS IN AMERICA, 1875-1955 | 223 |

| ADDITIONAL REFERENCES | 229 |

In an inventive tour de force that seldom, if ever, has been equalled for its brilliance and far-reaching consequences, James Watt radically altered the steam engine not only by adding a separate condenser but by creating a whole new family of linkages. His approach was largely empirical, as we use the word today.

This study suggests that, despite the glamor of today's sophisticated methods of calculation, a highly developed intuitive sense, reinforced by a knowledge of the past, is still indispensable to the design of successful mechanisms.

THE AUTHOR: Eugene S. Ferguson, formerly curator of mechanical and civil engineering in the United States National Museum, Smithsonian Institution, is now professor of mechanical engineering at Iowa State University of Science and Technology.

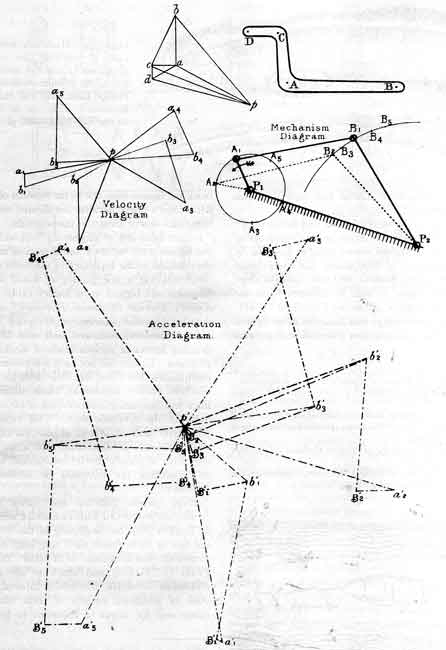

In engineering schools today, a student is introduced to the kinematics of mechanisms by means of a course of kinematic analysis, which is concerned with principles underlying the motions occurring in mechanisms. These principles are demonstrated by a study of mechanisms already in existence, such as the linkage of a retractable landing gear, computing mechanisms, mechanisms used in an automobile, and the like. A systematic, if not rigorous, approach to the design of gears and cams also is usually presented in such a course. Until recently, however, no serious attempt was made to apply the principles developed in kinematic analysis to the more complex problem of kinematic synthesis of linkages. By kinematic synthesis is meant the designing of a linkage to produce a given series of motions for a particular purpose.

That a rational—numerical or geometrical—approach to kinematic synthesis is possible is a relatively recent idea, not yet fully accepted; but it is this idea that is responsible for the intense scholarly interest in the kinematics of mechanisms that has occurred in this country within the last 10 years.

This scholarly activity has resulted in the rediscovery of many earlier works on the subject, and nearly all the scholars now working in this field have acknowledged in one way or another their debt to those who arrived on the scene at an earlier time than they. There have been occasional reviews of the sequence and nature of developments, but the emphasis naturally has been upon the recent past. It seems to me that there is something to be gained in looking beyond our own generation, or even beyond the time of Franz Reuleaux (1829-1905), who is generally credited with originating many of our modern concepts of mechanism analysis and design, and to inquire into the ideas that made possible Reuleaux's contributions.

Take to Kinematics. It will repay you. It is

more fecund than geometry; it adds a fourth dimension to

space.

—Chebyshev to Sylvester, 1873

While no pretense of completeness is made, I have tried in this paper to trace the high points in the development of kinematic analysis and synthesis, both in academic circles and in the workshop, noting where possible the influence of one upon the other. If I have devoted more space to particular people and episodes than is warranted by their contributions to the modern treatment of the subject, it is because I have found that the history of kinematics of mechanisms, like the history of any other branch of engineering, is more interesting and more plausible if it is recognized that its evolutionary development is the result of human activity. This history was wrought by people like us, no less intelligent and no less subject than we are to environment, to a subjective way of looking at things, and to a heritage of ideas and beliefs.

I have selected the period from the time of Watt because modern mechanisms originated with him, and I have emphasized the first century of the period because by 1885 many of the ideas of modern kinematics of mechanisms were well developed. Linkages are discussed, to the virtual exclusion of gears and cams, because much of the scholarly work in kinematic synthesis is presently directed toward the design of linkages and because linkages provide a convenient thread for a narrative that would have become unnecessarily complex if detailed treatment of gears and cams had been included. I have brought the narrative down to the present by tracing kinematics as taught in American engineering schools, closing with brief mention of the scholarly activity in kinematics in this country since 1950. An annotated list of additional references is appended as an encouragement to further work in the history of the subject.

James Watt (1736-1819), improver of the steam engine, was a highly gifted designer of mechanisms, although his background included no formal study of mechanisms. Indeed, the study of mechanisms, without immediate regard to the machines in which they were used, was not introduced until after Watt's important work had been completed, while the actual design of mechanisms had been going on for several centuries before the time of Watt.

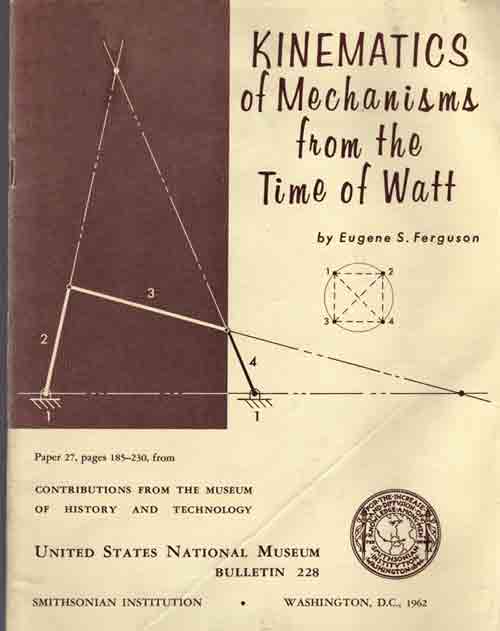

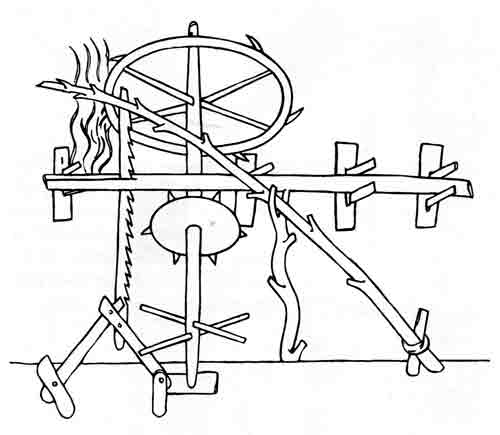

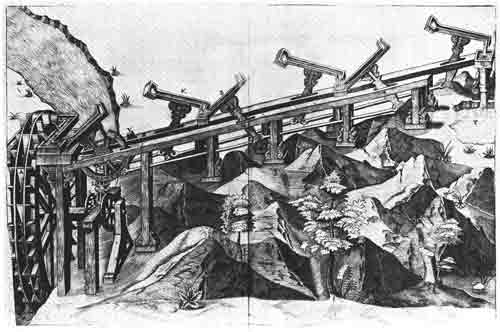

Mechanisms that employed screws, cams, and gears were certainly in use by the beginning of the Christian era. While I am not aware of unequivocal evidence of the existence of four-bar linkages before the 16th century, their widespread application by that time indicates that they probably originated much earlier. A tantalizing 13th-century sketch of an up-and-down sawmill (fig. 1) suggests, but does not prove, that the four-bar linkage was then in use. Leonardo da Vinci (1452-1519) delineated, if he did not build, a crank and slider mechanism, also for a sawmill (fig. 2). In the 16th century may be found the conversion of rotary to reciprocating motion (strictly speaking, an oscillation through a small arc of a large circle) and vice versa by use of linkages of rigid members (figs. 3 and 4), although the conversion of rotary to reciprocating motion was at that time more frequently accomplished by cams and intermittent gearing. Nevertheless, the idea of linkages was a firmly established part of the repertory of the machine builder before 1600. In fact one might have wondered in 1588, when Agostino Ramelli published his book on machines,[1] whether linkages had not indeed reached their ultimate stage of development. To illustrate my point, I have selected the plate of Ramelli that most appeals to me (fig. 5), although the book exhibits more than 200 other machines of comparable complexity and ingenuity.

[1] Agostino Ramelli, Le Diverse et Artificiose Machine, Paris, 1588.

Figure 1.—Up-and-down sawmill of the 13th century. The guide mechanism at lower left, attached to the saw blade, appears to be a 4-bar linkage. After Robert Willis, trans. and ed., Facsimile of the Sketch-Book of Wilars de Honecort (London, 1859, pl. 43).

Figure 2.—Slider-crank mechanism of Leonardo da Vinci (1452-1519), redrawn from his manuscript notebooks. A frame saw is depicted at the lower end of the guides. From Theodor Beck, Beiträge zur Geschichte des Maschinenbaues (Berlin, 1899, p. 323).

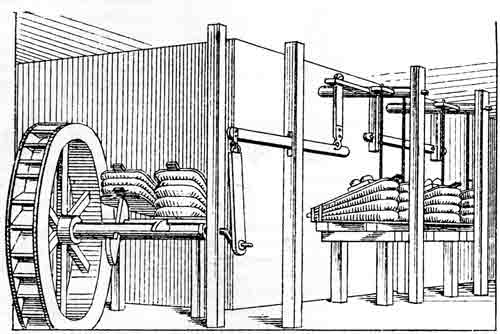

Figure 3.—Blowing engine by Vanuccio Biringuccio, about 1540, showing conversion of motion of the waterwheel shaft from rotation to oscillation. From Theodor Beck, Beiträge zur Geschichte des Maschinenbaues (Berlin, 1899. p. 120).

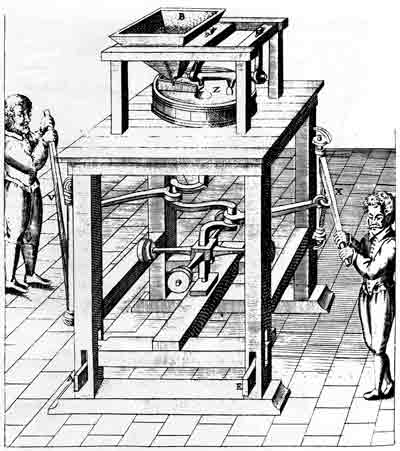

Figure 4.—Grain mill, 1588, showing conversion of motion of the operating bars from oscillation to rotation. Note the fly-weights, predecessors of the flywheel. From Agostino Ramelli, Le Diverse et Artificiose Machine (Paris, 1588, pl. opposite p. 199).

Figure 5.—Machine for raising water. Such a machine was built in Spain during the 16th century and was operated for some 80 years. From Agostino Ramelli, Le Diverse et Artificiose Machine (Paris, 1588, p. 199).

There was a vast difference, both in conception and execution, between the linkages of Ramelli and those of James Watt some 200 years later. Watt was responsible for initiating profound changes in mechanical technology, but it should be recognized that the mechanic arts had, through centuries of slow development, reached the stage where his genius could flourish. The knowledge and ability to provide the materials and tools necessary for Watt's researches were at hand, and through the optimism and patient encouragement of his partner, Matthew Boulton, they were placed at his disposal.

Watt's genius was nowhere more evident than in his synthesis of linkages. An essential ingredient in the success of Watt's linkages, however, was his partner's appreciation of the entirely new order of refinement that they called for. Matthew Boulton, who had been a successful manufacturer of buttons and metal novelties long before his partnership with Watt was formed, had recognized at once the need for care in the building of Watt's steam engine. On February 7, 1769, he had written Watt:[2] "I presumed that your engine would require money, very accurate workmanship and extensive correspondence to make it turn out to the best advantage and that the best means of keeping up the reputation and doing the invention justice would be to keep the executive part of it out of the hands of the multitude of empirical engineers, who from ignorance, want of experience and want of necessary convenience, would be very liable to produce bad and inaccurate workmanship; all of which deficiencies would affect the reputation of the invention." Boulton expected to build the engines in his shop "with as great a difference of accuracy as there is between the blacksmith and the mathematical instrument maker." The Soho Works of Boulton and Watt, in Birmingham, England, solved for Watt the problem of producing "in great" (that is, in sizes large enough to be useful in steam engines) the mechanisms that he devised.[3]

[2] Henry W. Dickinson, James Watt, Craftsman & Engineer, Cambridge, Cambridge University Press, 1936, pp. 52-53.

[3] James P. Muirhead, The Origin and Progress of the Mechanical Inventions of James Watt, London, 1854, vol. 1, pp. 56, 64. This work, in three volumes, contains letters, other documents, and plates of patent specification drawings.

The contributions of Boulton and Watt to practical mechanics "in great" cannot be overestimated. There were in the 18th century instrument makers and makers of timekeepers who had produced astonishingly accurate work, but such work comprised relatively small items, all being within the scope of a bench lathe, hand tools, and superb handwork. The rapid advancement of machine tools, which greatly expanded the scope of the machine-building art, began during the Boulton and Watt partnership (1775-1800).

In April 1775 the skirmish at Concord between American colonists and British redcoats marked the beginning of a war that was to determine for the future the course of political events in the Western Hemisphere.

Another event of April 1775 occurring in Birmingham now appears to have been one that marked the beginning of a new era of technological advance. It was near the end of this month that Boulton, at the Soho Works, wrote to his partner and commented upon receiving the cast iron steam engine cylinder that had been finished in John Wilkinson's boring mill:

... it seems tolerably true, but is an inch

thick and weighs about

10 cwt. Its diameter is about as much above 18

inches as the tin

one was under, and therefore it is become

necessary to add a brass

hoop to the piston, which is made almost two

inches broad.[4]

[4] Ibid., vol. 2, p. 84.

This cylinder indeed marked the turning point in the discouragingly long development of the Watt steam engine, which for 10 years had occupied nearly all of Watt's thoughts and all the time he could spare from the requirements of earning a living. Although there were many trials ahead for the firm of Boulton and Watt in further developing and perfecting the steam engine, the crucial problem of leakage of steam past the piston in the cylinder had now been solved by Wilkinson's new boring mill, which was the first large machine tool capable of boring a cylinder both round and straight.

The boring mill is pertinent to the development of linkages "in great," being the first of a new class of machine tools that over the next 50 or 60 years came to include nearly all of the basic types of heavy chip-removing tools that are in use today. The development of tools was accelerated by the inherent accuracy required of the linkages that were originated by Watt. Once it had been demonstrated that a large and complex machine, such as the steam engine, could be built accurately enough so that its operation would be relatively free of trouble, many outstanding minds became engaged in the development of machines and tools. It is interesting, however, to see how Watt and others grappled with the solutions of problems that resulted from the advance of the steam engine.

During the 1770's the demand for continuous, dependable power applied to a rotating shaft was becoming insistent, and much of Boulton's and Watt's effort was directed toward meeting this demand. Mills of all kinds used water or horses to turn "wheel-work," but, while these sources of power were adequate for small operations, the quantity of water available was often limited, and the use of enormous horse-whims was frequently impracticable.

The only type of steam engine then in existence was the Newcomen beam engine, which had been introduced in 1712 by Thomas Newcomen, also an Englishman. This type of engine was widely used, mostly for pumping water out of mines but occasionally for pumping water into a reservoir to supply a waterwheel. It was arranged with a vertical steam cylinder located beneath one end of a large pivoted working beam and a vertical plunger-type pump beneath the other end. Heavy, flat chains were secured to a sector at each end of the working beam and to the engine and pump piston rods in such a way that the rods were always tangent to a circle whose center was at the beam pivot. The weight of the reciprocating pump parts pulled the pump end of the beam down; the atmosphere, acting on the open top of the piston in the steam cylinder, caused the engine end of the beam to be pulled down when the steam beneath the piston was condensed. The chains would of course transmit force from piston to beam only in tension.

It is now obvious that a connecting rod, a crank, and a sufficiently heavy flywheel might have been used in a conventional Newcomen engine in order to supply power to a rotating shaft, but contemporary evidence makes it clear that this solution was by no means obvious to Watt nor to his contemporaries.

At the time of his first engine patent, in 1769, Watt had devised a "steam wheel," or rotary engine, that used liquid mercury in the lower part of a toroidal chamber to provide a boundary for steam spaces successively formed by flap gates within the chamber. The practical difficulties of construction finally ruled out this solution to the problem of a rotating power source, but not until after Boulton and Watt had spent considerable effort and money on it.[5]

[5] Henry W. Dickinson and Rhys Jenkins, James Watt and the Steam Engine, Oxford, Clarendon Press, 1927, pp. 146-148, pls. 14, 31. This work presents a full and knowledgeable discussion, based on primary material, of the development of Watt's many contributions to mechanical technology. It is ably summarized in Dickinson, op. cit. (footnote 2).

In 1777 a speaker before the Royal Society in London observed that in order to obtain rotary output from a reciprocating steam engine, a crank "naturally occurs in theory," but that in fact the crank is impractical because of the irregular rate of going of the engine and its variable length of stroke. He said that on the first variation of length of stroke the machine would be "either broken to pieces, or turned back."[6] John Smeaton, in the front rank of English steam engineers of his time, was asked in 1781 by His Majesty's Victualling-Office for his opinion as to whether a steam-powered grain mill ought to be driven by a crank or by a waterwheel supplied by a pump. Smeaton's conclusion was that the crank was quite unsuited to a machine in which regularity of operation was a factor. "I apprehend," he wrote, "that no motion communicated from the reciprocating beam of a fire engine can ever act perfectly equal and steady in producing a circular motion, like the regular efflux of water in turning a waterwheel." He recommended, incidentally, that a Boulton and Watt steam engine be used to pump water to supply the waterwheel.[7] Smeaton had thought of a flywheel, but he reasoned that a flywheel large enough to smooth out the halting, jerky operation of the steam engines that he had observed would be more of an encumbrance than a pump, reservoir, and waterwheel.[8]

[6] John Farey, A Treatise on the Steam Engine, London, 1827, pp. 408-409.

[7] Reports of the Late John Smeaton, F.R.S., London, 1812, vol. 2, pp. 378-380.

[8] Farey, op. cit. (footnote 6), p. 409.

The simplicity of the eventual solution of the problem was not clear to Watt at this time. He was not, as tradition has it, blocked merely by the existence of a patent for a simple crank and thus forced to invent some other device as a substitute.

Matthew Wasbrough, of Bristol, the engineer commonly credited with the crank patent, made no mention of a crank in his patent specification, but rather intended to make use of "racks with teeth," or "one or more pullies, wheels, segments of wheels, to which are fastened rotchets and clicks or palls...." He did, however, propose to "add a fly or flys, in order to render the motion more regular and uniform." Unfortunately for us, he submitted no drawings with his patent specification.[9]

[9] British Patent 1213, March 10, 1779.

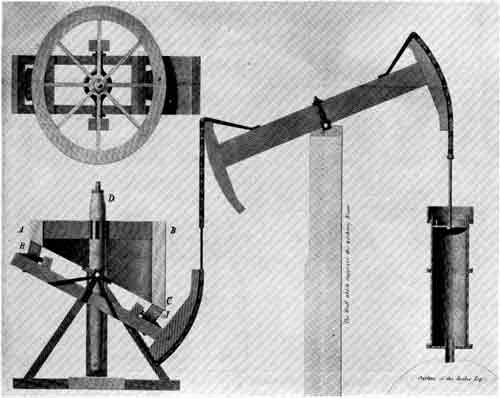

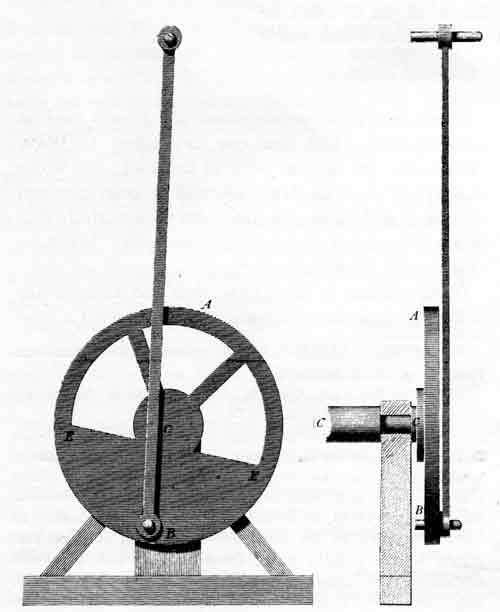

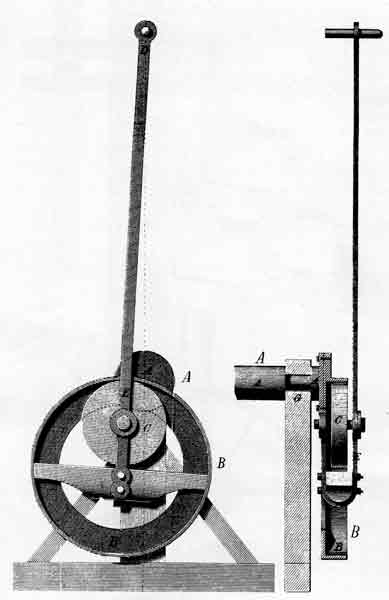

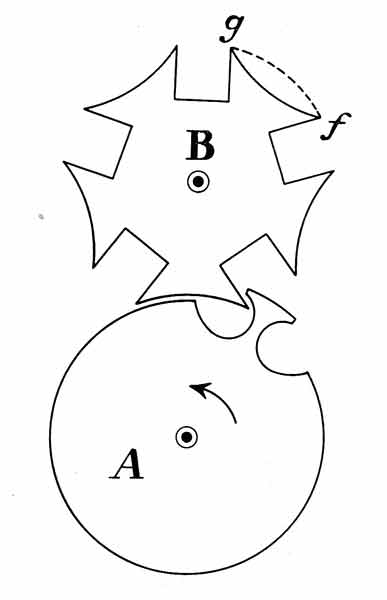

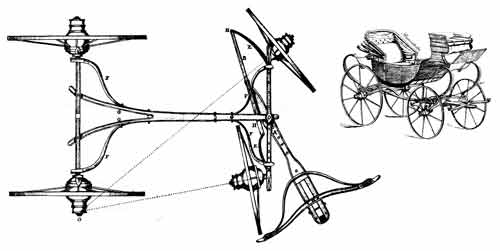

James Pickard, of Birmingham, like Boulton, a buttonmaker, in 1780 patented a counterweighted crank device (fig. 6) that was expected to remove the objection to a crank, which operated with changing leverage and thus irregular power. In figure 6, the counterweighted wheel, revolving twice for each revolution of the crank (A), would allow the counterweight to descend while the crank passed the dead-center position and would be raised while the crank had maximum leverage. No mention of a flywheel was made in this patent.[10]

[10] British Patent 1263, August 23, 1780.

Figure 6.—One of the steam engine "Crank Patents" that hindered James Watt's progress. This patent, granted to James Pickard in 1780, claimed only the arrangement of counterweights, not the crank. The crank pin to which the connecting rod was attached is at Aa. From British Patent 1263, August 23, 1780.

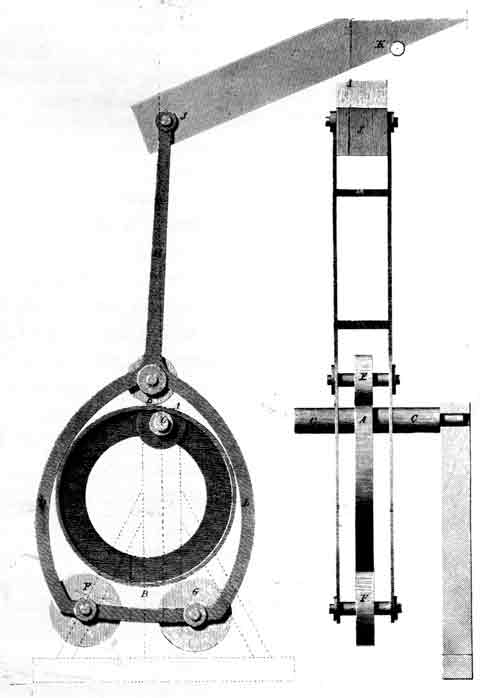

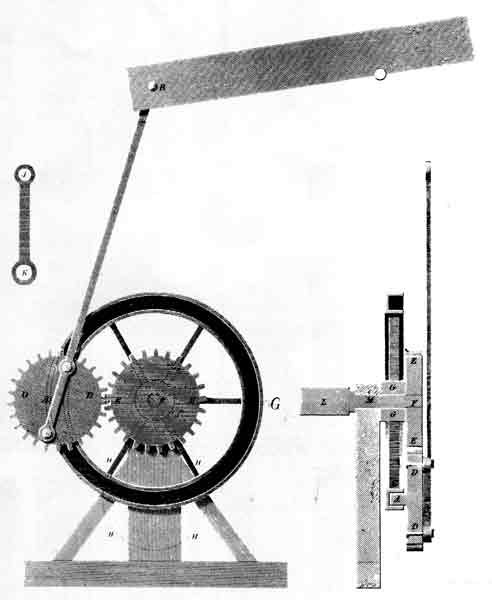

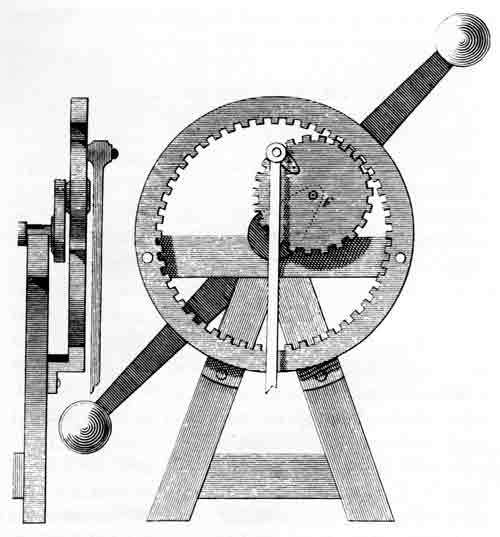

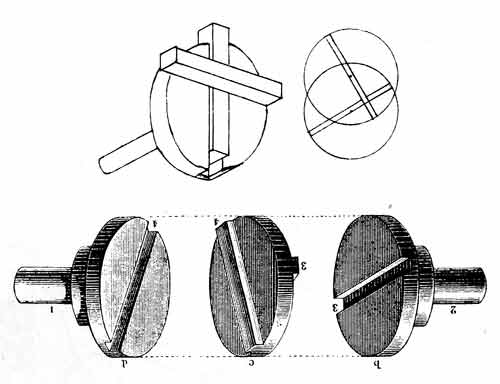

Wasbrough, finding that his "rotchets and clicks" did not serve, actually used, in 1780, a crank with a flywheel. Watt was aware of this, but he remained unconvinced of the superiority of the crank over other devices and did not immediately appreciate the regulating ability of a flywheel.[11] In April 1781 Watt wrote to Boulton, who was then out of town: "I know from experiment that the other contrivance, which you saw me try, performs at least as well, and has in fact many advantages over the crank."[12] The "other contrivance" probably was his swash wheel which he built and which appeared on his next important patent specification (fig. 7a). Also in this patent were four other devices, one of which was easily recognizable as a crank, and two of which were eccentrics (fig. 7a, b). The fourth device was the well-known sun-and-planet gearing (fig. 7e).[13] In spite of the similarity of the simple crank to the several variations devised by Watt, this patent drew no fire from Wasbrough or Pickard, perhaps because no reasonable person would contend that the crank itself was a patentable feature, or perhaps because the similarity was not at that time so obvious. However, Watt steered clear of directly discernible application of cranks because he preferred to avoid a suit that might overthrow his or other patents. For example, if the Wasbrough and Pickard patents had been voided, they would have become public property; and Watt feared that they might "get into the hands of men more ingenious," who would give Boulton and Watt more competition than Wasbrough and Pickard.[14]

[11] Dickinson and Jenkins, op. cit. (footnote 5), pp. 150, 154.

[12] Ibid., p. 154.

[13] William Murdock, at this time a Boulton and Watt erector, may have suggested this arrangement. Ibid., p. 56.

[14] Muirhead, op. cit. (footnote 3), vol. 3, note on p. 39.

Figure 7.—James Watt's five alternative devices for the conversion of reciprocating motion to rotary motion in a steam engine. (British Patent 1306, October 25, 1781). From James P. Muirhead, The Origin and Progress of the Mechanical Inventions of James Watt (London, 1854, vol. 3, pls. 3-5, 7).

(a) "Inclined wheel." The vertical shaft at D is rotated by action of wheels H and J on cam, or swash plate, ABC. Boulton and Watt tried this device but discarded it.

(b) Counterweighted crank wheel.

(c) "Eccentric wheel" with external yoke hung from working beam. The wheel pivots at C.

(d) "Eccentric wheel" with internal driving wheel hung from working beam. Wheel B is pivoted at center of shaft A.

(e) Sun-and-planet gearing. This is the idea actually employed in Boulton and Watt engines. As the optional link JK held the gearwheel centers always equidistant, the annular guide G was not used.

The sun-and-planet arrangement, with gears of equal size, was adopted by Watt for nearly all the rotative engines that he built during the term of the "crank patents." This arrangement had the advantage of turning the flywheel through two revolutions during a single cycle of operation of the piston, thus requiring a flywheel only one-fourth the size of the flywheel needed if a simple crank were used. The optional link (JK of fig. 7e) was used in the engines as built.

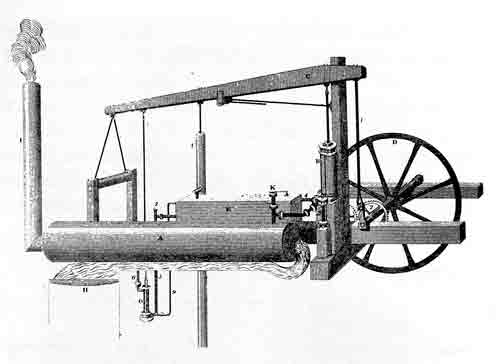

From the first, the rotative engines were made double-acting—that is, work was done by steam alternately in each end of the cylinder. The double-acting engine, unlike the single-acting pumping engine, required a piston rod that would push as well as pull. It was in the solution of this problem that Watt's originality and sure judgment were most clearly demonstrated.

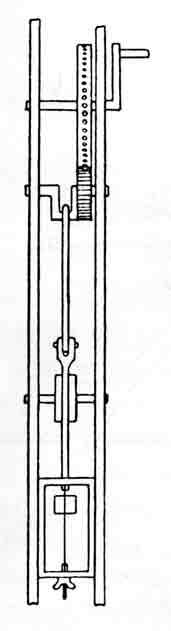

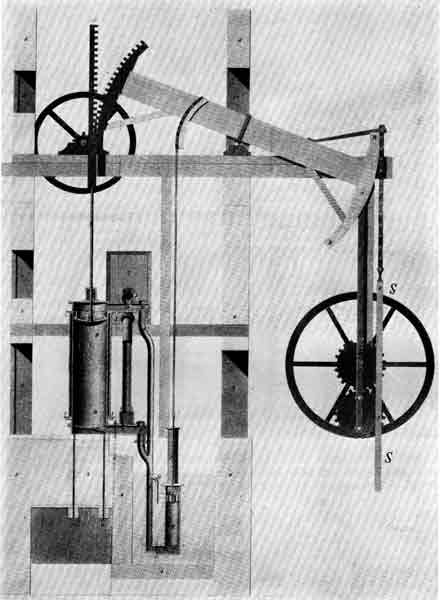

A rack and sector arrangement (fig. 8) was used on some engines. The first one, according to Watt, "has broke out several teeth of the rack, but works steady."[15] A little later he told a correspondent that his double-acting engine "acts so powerfully that it has broken all its tackling repeatedly. We have now tamed it, however."[16]

[15] James Watt, March 31, 1783, quoted in Dickinson and Jenkins, op. cit. (footnote 5), p. 140.

[16] Watt to De Luc, April 26, 1783, quoted in Muirhead, op. cit. (footnote 3), vol. 2, p. 174.

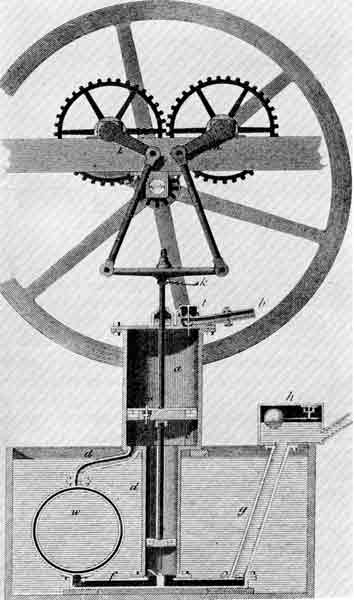

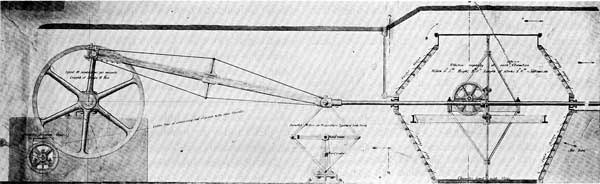

Figure 8.—Watt engine of 1782 (British Patent 1321, March 12, 1782) showing the rack and sector used to guide the upper end of the piston rod and to transmit force from piston to working beam. This engine, with a 30-inch cylinder and an 8-foot stroke, was arranged for pumping. Pump rod SS is hung from sector of the working beam. From James P. Muirhead, The Origin and Progress of the Mechanical Inventions of James Watt (London, 1854, vol. 3, pl. 15).

It was about a year later that the straight-line linkage[17] was thought out. "I have started a new hare," Watt wrote to his partner. "I have got a glimpse of a method of causing the piston-rod to move up and down perpendicularly, by only fixing it to a piece of iron upon the beam, without chains, or perpendicular guides, or untowardly frictions, arch-heads, or other pieces of clumsiness.... I have only tried it in a slight model yet, so cannot build upon it, though I think it a very probable thing to succeed, and one of the most ingenious simple pieces of mechanism I have contrived...."[18]

[17] Watt's was a four-bar linkage. All four-bar straight-line linkages that have no sliding pairs trace only an approximately straight line. The exact straight-line linkage in a single plane was not known until 1864 (see p. 204). In 1853 Pierre-Frédéric Sarrus (1798-1861), a French professor of mathematics at Strasbourg, devised an accordion-like spatial linkage that traced a true straight line. Described but not illustrated (Académie des Sciences, Paris, Comptes rendus, 1853, vol. 36, pp. 1036-1038, 1125), the mechanism was forgotten and twice reinvented; finally, the original invention was rediscovered by an English writer in 1905. For chronology, see Florian Cajori, A History of Mathematics, ed. 2, New York, 1919, p. 301.

[18] Muirhead, op. cit. (footnote 3), vol. 2, pp. 191-192.

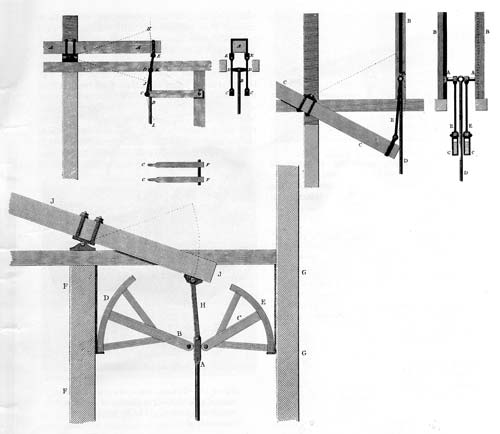

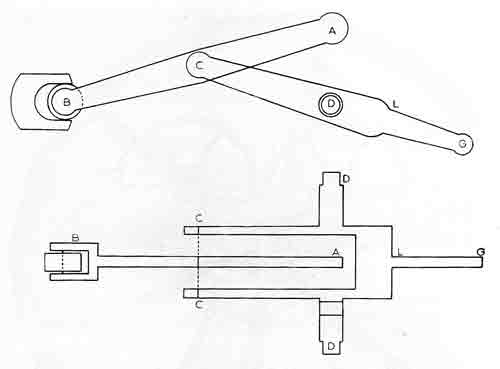

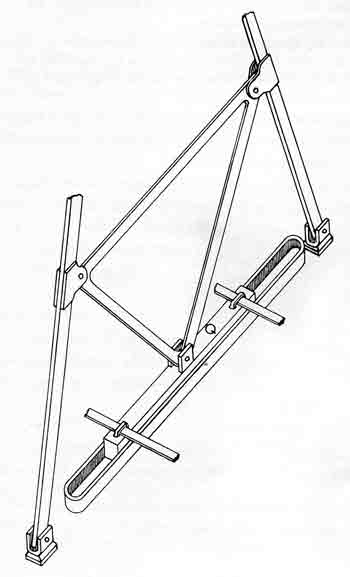

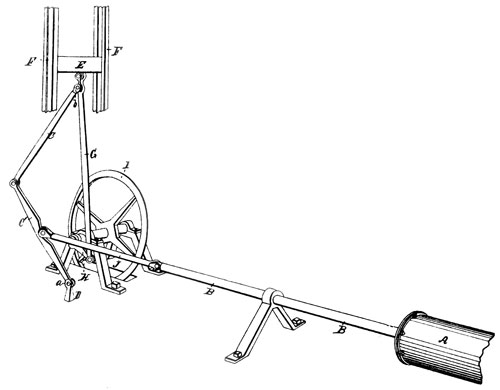

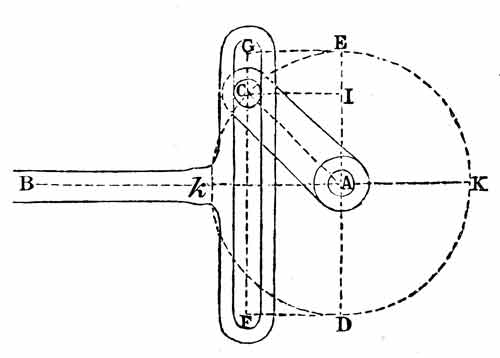

Watt's marvelously simple straight-line linkage was incorporated into a large beam engine almost immediately, and the usually pessimistic and reserved inventor was close to a state of elation when he told Boulton that the "new central perpendicular motion answers beyond expectation, and does not make the shadow of a noise."[19] This linkage, which was included in an extensive patent of 1784, and two alternative devices are illustrated here (fig. 9). One of the alternatives is a guided crosshead (fig. 9, top right).

[19] Ibid., p. 202.

Figure 9.—Watt's mechanisms for guiding the upper end of the piston rod of a double-acting engine (British Patent 1432, April 28, 1784). Top left, straight-line linkage; top right, crosshead and guide arrangement; lower left, piston rod A is guided by sectors D and E, suspended by flexible cords. From James P. Muirhead, The Origin and Progress of the Mechanical Inventions of James Watt (London, 1854, vol. 3, pls. 21, 22).

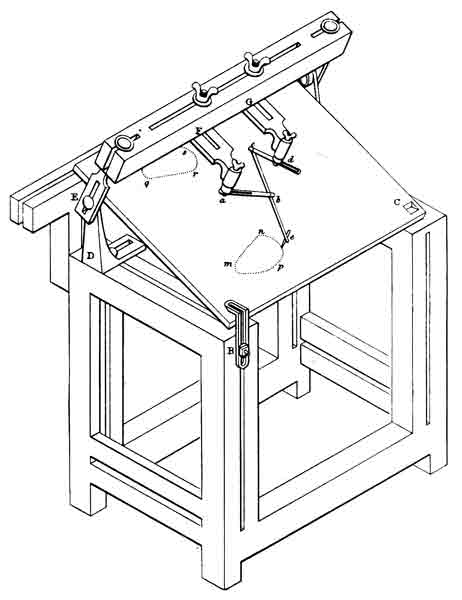

Brilliant as was the conception of this linkage, it was followed up by a synthesis that is very little short of incredible. In order to make the linkage attached to the beam of his engines more compact, Watt had plumbed his experience for ideas; his experience had yielded up the work done much earlier on a drafting machine that made use of a pantograph.[20] Watt combined his straight-line linkage with a pantograph, one link becoming a member of the pantograph.

[20] "It has only one fault," he had told a friend on December 24, 1773, after describing the drafting machine to him, "which is, that it will not do, because it describes conic sections instead of straight lines." Ibid., p. 71.

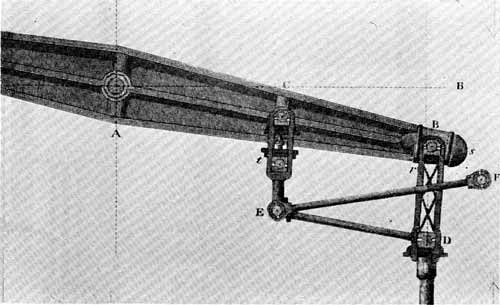

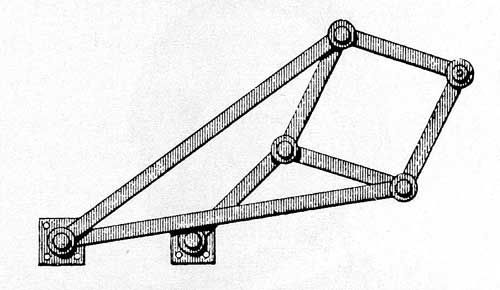

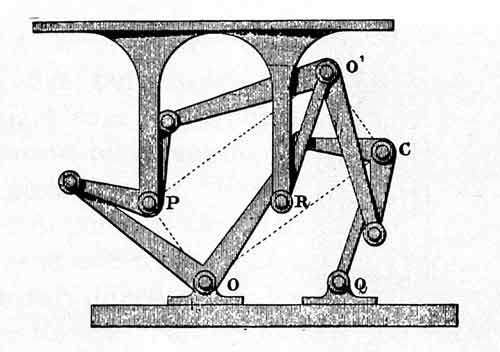

The length of each oscillating link of the straight-line linkage was thus reduced to one-fourth instead of one-half the beam length, and the entire mechanism could be constructed so that it would not extend beyond the end of the working beam. This arrangement soon came to be known as Watt's "parallel motion" (fig. 10).[21] Years later Watt told his son: "Though I am not over anxious after fame, yet I am more proud of the parallel motion than of any other mechanical invention I have ever made."[22]

[21] Throughout the 19th century the term "parallel motion" was used indiscriminately to refer to any straight-line linkage. I have not discovered the origin of the term. Watt did not use it in his patent specification, and I have not found it in his writings or elsewhere before 1808 (see footnote 22). The Cyclopaedia (Abraham Rees, ed., London, 1819, vol. 26) defined parallel motion as "a term used among practical mechanics to denote the rectilinear motion of a piston-rod, &c. in the direction of its length; and contrivances, by which such alternate rectilinear motions are converted into continuous rotatory ones, or vice versa...." Robert Willis in his Principles of Mechanism (London, 1841, p. 399) described parallel motion as "a term somewhat awkwardly applied to a combination of jointed rods, the purpose of which is to cause a point to describe a straight line...." A. B. Kempe in How to Draw a Straight Line (London, 1877, p. 49) wrote: "I have been more than once asked to get rid of the objectionable term 'parallel motion.' I do not know how it came to be employed, and it certainly does not express what is intended. The expression, however, has now become crystallised, and I for one cannot undertake to find a solvent."

[22] Muirhead, op. cit. (footnote 3), vol. 3, note on p. 89.

Figure 10.—Watt's "parallel motion." Engine's working beam is pivoted at A. Pivot F is attached to the engine frame. From Dyonysius Lardner, The Steam Engine (Philadelphia, 1852), pl. 5 (American ed. 5 from London ed. 5).

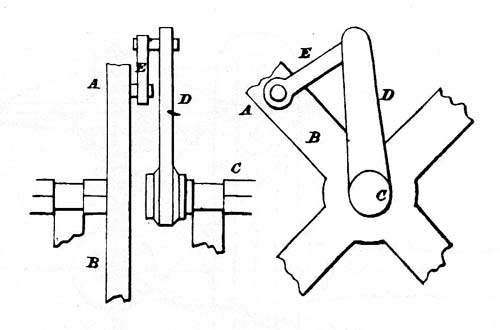

The Watt four-bar linkage was employed 75 years after its inception by the American Charles B. Richards when, in 1861, he designed his first high-speed engine indicator (fig. 11). Introduced into England the following year, the Richards Indicator was an immediate success, and many thousands were sold over the next 20 or 30 years.[23]

[23] Charles T. Porter, Engineering Reminiscences, New York, 1908, pp. 58-59, 90.

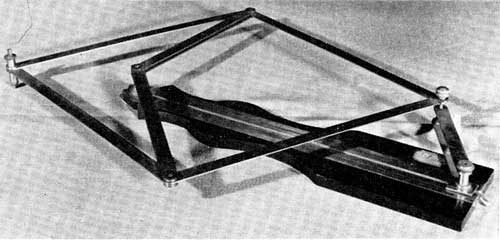

Figure 11.—Richards high-speed engine indicator of 1861, showing application of the Watt straight-line linkage. (USNM 307515; Smithsonian photo 46570).

In considering the order of synthetic ability required to design the straight-line linkage and to combine it with a pantograph, it should be kept in mind that this was the first one of a long line of such mechanisms.[24] Once the idea was abroad, it was only to be expected that many variations and alternative solutions should appear. One wonders, however, what direction the subsequent work would have taken if Watt had not so clearly pointed the way.

[24] At least one earlier straight-line linkage, an arrangement later ascribed to Richard Roberts, had been depicted before Watt's patent (Pierre Patte, Mémoirs sur les objets les plus importants de l'architecture, Paris, 1769, p. 229 and pl. 11). However, this linkage (reproduced here in figure 18) had no detectable influence on Watt or on subsequent practice.

In 1827 John Farey, in his exhaustive study of the steam engine, wrote perhaps the best contemporary view of Watt's work. Farey as a young man had several times talked with the aging Watt, and he had reflected upon the nature of the intellect that had caused Watt to be recognized as a genius, even within his own lifetime. In attempting to explain Watt's genius, Farey set down some observations that are pertinent not only to kinematic synthesis but to the currently fashionable term "creativity."

In Farey's opinion Watt's inventive faculty was far superior to that of any of his contemporaries; but his many and various ideas would have been of little use if he had not possessed a very high order of judgment, that "faculty of distinguishing between ideas; decomposing compound ideas into more simple elements; arranging them into classes, and comparing them together...."

Farey was of the opinion that while a mind like Watt's could produce brilliant new ideas, still the "common stock of ideas which are current amongst communities and professions, will generally prove to be of a better quality than the average of those new ideas, which can be produced by any individual from the operation of his own mind, without assistance from others." Farey concluded with the observation that "the most useful additions to that common stock, usually proceed from the individuals who are well acquainted with the whole series."[25]

[25] Farey, op. cit. (footnote 6), pp. 651, 652.

During most of the century after James Watt had produced his parallel motion, the problem of devising a linkage, one point of which would describe a straight line, was one that tickled the fancies of mathematicians, of ingenious mechanics, and of gentlemanly dabblers in ideas. The quest for a straight-line mechanism more accurate than that of Watt far outlasted the pressing practical need for such a device. Large metal planing machines were well known by 1830, and by midcentury crossheads and crosshead guides were used on both sides of the Atlantic in engines with and without working beams.

By 1819 John Farey had observed quite accurately that, in England at least, many other schemes had been tried and found wanting and that "no methods have been found so good as the original engine; and we accordingly find, that all the most established and experienced manufacturers make engines which are not altered in any great feature from Mr. Watt's original engine...."[26]

[26] In Rees, op. cit. (footnote 21), vol. 34 ("Steam Engine"). John Farey was the writer of this article (see Farey, op. cit., p. vi).

Two mechanisms for producing a straight line were introduced before the Boulton and Watt monopoly ended in 1800. Perhaps the first was by Edmund Cartwright (1743-1823), who is said to have had the original idea for a power loom. This geared device (fig. 12), was characterized patronizingly by a contemporary American editor as possessing "as much merit as can possibly be attributed to a gentleman engaged in the pursuit of mechanical studies for his own amusement."[27] Only a few small engines were made under the patent.[28]

[27] Emporium of Arts and Sciences, December 1813, new ser., vol. 2, no. 1, p. 81.

[28] Farey, op. cit. (footnote 6), p. 666.

Figure 12.—Cartwright's geared straight-line mechanism of about 1800. From Abraham Rees, The Cyclopaedia (London, 1819, "Steam Engine," pl. 5).

The properties of a hypocycloid were recognized by James White, an English engineer, in his geared design which employed a pivot located on the pitch circle of a spur gear revolving inside an internal gear. The diameter of the pitch circle of the spur gear was one-half that of the internal gear, with the result that the pivot, to which the piston rod was connected, traced out a diameter of the large pitch circle (fig. 13). White in 1801 received from Napoleon Bonaparte a medal for this invention when it was exhibited at an industrial exposition in Paris.[29] Some steam engines employing White's mechanism were built, but without conspicuous commercial success. White himself rather agreed that while his invention was "allowed to possess curious properties, and to be a pretty thing, opinions do not all concur in declaring it, essentially and generally, a good thing."[30]

[29] H. W. Dickinson, "James White and His 'New Century of Inventions,'" Transactions of the Newcomen Society, 1949-1951, vol. 27, pp. 175-179.

[30] James White, A New Century of Inventions, Manchester, 1822, pp. 30-31, 338. A hypocycloidal engine used in Stourbridge, England, is in the Henry Ford Museum.

Figure 13.—James White's hypocycloidal straight-line mechanism, about 1800. The fly-weights (at the ends of the diagonal arm) functioned as a flywheel. From James White, A New Century of Inventions (Manchester, 1822, pl. 7).

The first of the non-Watt four-bar linkages appeared shortly after 1800. The origin of the grasshopper beam motion is somewhat obscure, although it came to be associated with the name of Oliver Evans, the American pioneer in the employment of high-pressure steam. A similar idea, employing an isosceles linkage, was patented in 1803 by William Freemantle, an English watchmaker (fig. 14).[31] This is the linkage that was attributed much later to John Scott Russell (1808-1882), the prominent naval architect.[32] An inconclusive hint that Evans had devised his straight-line linkage by 1805 appeared in a plate illustrating his Abortion of the Young Steam Engineer's Guide (Philadelphia, 1805), and it was certainly used on his Columbian engine (fig. 15), which was built before 1813. The Freemantle linkage, in modified form, appeared in Rees's Cyclopaedia of 1819 (fig. 16), but it is doubtful whether even this would have been readily recognized as identical with the Evans linkage, because the connecting rod was at the opposite end of the working beam from the piston rod, in accordance with established usage, while in the Evans linkage the crank and connecting rod were at the same end of the beam. It is possible that Evans got his idea from an earlier English periodical, but concrete evidence is lacking.

[31] British Patent 2741, November 17, 1803.

[32] William J. M. Rankine, Manual of Machinery and Millwork, ed. 6, London, 1887, p. 275.

Figure 14.—Freemantle straight-line linkage, later called the Scott Russell linkage. From British Patent 2741, November 17, 1803.

Figure 15.—Oliver Evans' "Columbian" engine, 1813, showing the Evans, or "grasshopper," straight-line linkage. From Emporium of Arts and Sciences (new ser., vol. 2, no. 3, April 1814, pl. opposite p. 380).

Figure 16.—Modified Freemantle linkage, 1819, which is kinematically the same as the Evans linkage. Pivots D and E are attached to engine frame. From Abraham Rees, The Cyclopaedia (London, 1819, "Parallel Motions," pl. 3).

If the idea did in fact originate with Evans, it is strange that he did not mention it in his patent claims, or in the descriptions that he published of his engines.[33] The practical advantage of the Evans linkage, utilizing as it could a much lighter working beam than the Watt or Freemantle engines, would not escape Oliver Evans, and he was not a man of excessive modesty where his own inventions were concerned.

[33] Greville and Dorothy Bathe, Oliver Evans, Philadelphia, 1935, pp. 88, 196, and passim.

Another four-bar straight-line linkage that became well known was attributed to Richard Roberts of Manchester (1789-1864), who around 1820 had built one of the first metal planing machines, which machines helped make the quest for straight-line linkages largely academic. I have not discovered what occasioned the introduction of the Roberts linkage, but it dated from before 1841. Although Roberts patented many complex textile machines, an inspection of all of his patent drawings has failed to provide proof that he was the inventor of the Roberts linkage.[34] The fact that the same linkage is shown in an engraving of 1769 (fig. 18) further confuses the issue.[35]

[34] Robert Willis (op. cit. [footnote 2] p. 411) credited Richard Roberts with the linkage. Roberts' 15 British patent drawings exhibit complex applications of cams, levers, guided rods, cords, and so forth, but no straight-line mechanism. In his patent no. 6258 of April 13, 1832, for a steam engine and locomotive carriage, Roberts used Watt's "parallel motion" on a beam driven by a vertical cylinder.

[35] This engraving appeared as plate 11 in Pierre Patte's 1769 work (op. cit. footnote 24). Patte stated that the machine depicted in his plate 11 was invented by M. de Voglie and was actually used in 1756.

Figure 17.—Straight-line linkage (before 1841) attributed to Richard Roberts by Robert Willis. From A. B. Kempe, How to Draw a Straight Line (London, 1877, p. 10).

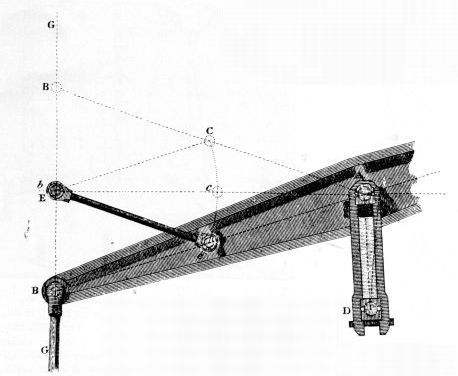

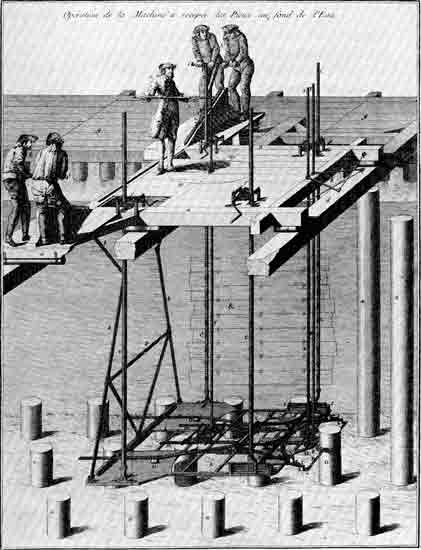

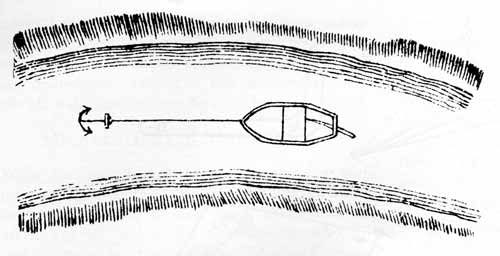

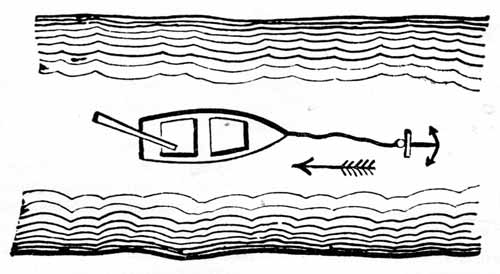

Figure 18.—Machine for sawing off pilings under water, about 1760, designed by De Voglie. The Roberts linkage operates the bar (Q in detailed sketch on left) at the rear of the machine below the operators. The significance of the linkage apparently was not generally recognized. A similar machine depicted in Diderot's Encyclopédie, published several years later, did not employ the straight-line linkage. From Pierre Patte, Memoirs sur les objets plus importants de l'architecture (Paris, 1769, pl. 11).

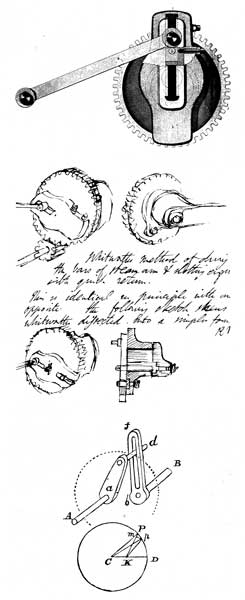

The appearance in 1864 of Peaucellier's exact straight-line linkage went nearly unnoticed. A decade later, when news of its invention crossed the Channel to England, this linkage excited a flurry of interest, and variations of it occupied mathematical minds for several years. For at least 10 years before and 20 years after the final solution of the problem, Professor Chebyshev,[36] a noted mathematician of the University of St. Petersburg, was interested in the matter. Judging by his published works and his reputation abroad, Chebyshev's interest amounted to an obsession.

[36] This is the Library of Congress spelling

Pafnutïĭ L'vovich Chebyshev was born in 1821, near Moscow, and entered the University of Moscow in 1837. In 1853, after visiting France and England and observing carefully the progress of applied mechanics in those countries, he read his first paper on approximate straight-line linkages, and over the next 30 years he attacked the problem with new vigor at least a dozen times. He found that the two principal straight-line linkages then in use were Watt's and Evans'. Chebyshev noted the departure of these linkages from a straight line and calculated the deviation as of the fifth degree, or about 0.0008 inch per inch of beam length. He proposed a modification of the Watt linkage to refine its accuracy but found that he would have to more than double the length of the working beam. Chebyshev concluded ruefully that his modification would "present great practical difficulties."[37]

[37] Oeuvres de P. L. Tchebychef, 2 vols., St. Petersburg, 1899-1907, vol. 1, p. 538; vol. 2, pp. 57, 85.

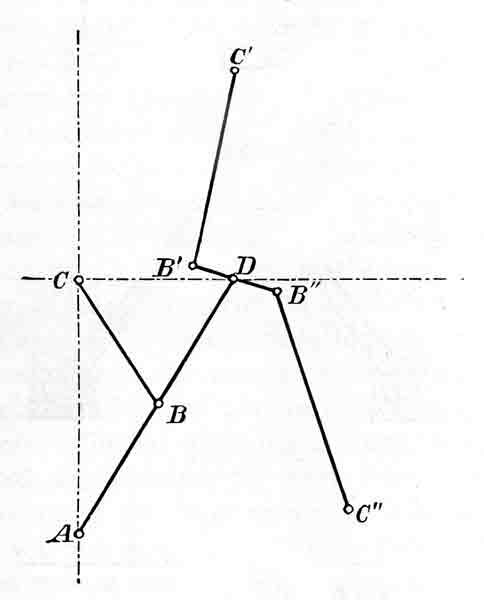

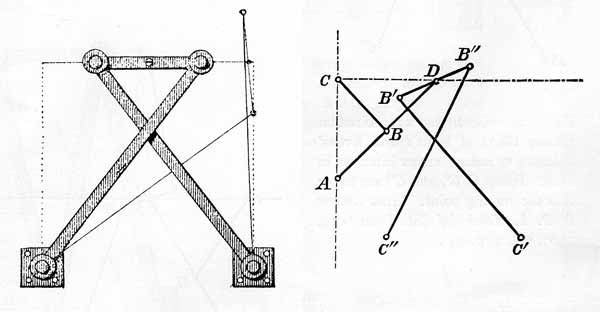

At length an idea occurred to Chebyshev that would enable him to approach if not quite attain a true straight line. If one mechanism was good, he reasoned, two would be better, et cetera, ad infinitum. The idea was simply to combine, or compound, four-link approximate linkages, arranging them in such a way that the errors would be successively reduced. Contemplating first a combination of the Watt and Evans linkages (fig. 19), Chebyshev recognized that if point D of the Watt linkage followed nearly a straight line, point A of the Evans linkage would depart even less from a straight line. He calculated the deviation in this case as of the 11th degree. He then replaced Watt's linkage by one that is usually called the Chebyshev straight-line mechanism (fig. 20), with the result that precision was increased to the 13th degree.[38] The steam engine that he displayed at the Vienna Exhibition in 1873 employed this linkage—the Chebyshev mechanism compounded with the Evans, or approximate isosceles, linkage. An English visitor to the exhibition commented that "the motion is of little or no practical use, for we can scarcely imagine circumstances under which it would be more advantageous to use such a complicated system of levers, with so many joints to be lubricated and so many pins to wear, than a solid guide of some kind; but at the same time the arrangement is very ingenious and in this respect reflects great credit on its designer."[39]

[38] Ibid., vol. 2, pp. 93, 94.

[39] Engineering, October 3, 1873, vol. 16, p. 284.

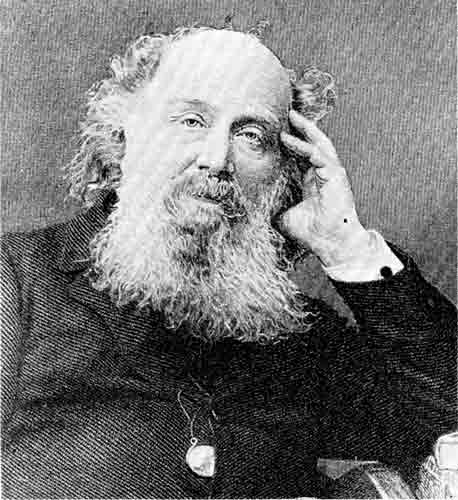

Figure 19.—Pafnutïĭ L'vovich Chebyshev (1821-1894), Russian mathematician active in analysis and synthesis of straight-line mechanisms. From Ouvres de P. L. Tchebychef (St. Petersburg, 1907, vol. 2, frontispiece).

Figure 20.—Chebyshev's combination (about 1867) of Watt's and Evans' linkages to reduce errors inherent in each. Points C, C', and C" are fixed; A is the tracing point. From Oeuvres de P. L. Tchebychef (St. Petersburg, 1907, vol. 2, p. 93).

Figure 21.—Left: Chebyshev straight-line linkage, 1867; from A. B. Kempe, How to Draw a Straight Line (London, 1877, p. 11). Right: Chebyshev-Evans combination, 1867; from Oeuvres de P. L. Tchebychef (St. Petersburg, 1907, vol. 2, p. 94). Points C, C', and C" are fixed. A is the tracing point.

There is a persistent rumor that Professor Chebyshev sought to demonstrate the impossibility of constructing any linkage, regardless of the number of links, that would generate a straight line; but I have found only a dubious statement in the Grande Encyclopédie[40] of the late 19th century and a report of a conversation with the Russian by an Englishman, James Sylvester, to the effect that Chebyshev had "succeeded in proving the nonexistence of a five-bar link-work capable of producing a perfect parallel motion...."[41] Regardless of what tradition may have to say about what Chebyshev said, it is of course well known that Captain Peaucellier was the man who finally synthesized the exact straight-line mechanism that bears his name.

[40] La Grande Encyclopédie, Paris, 1886 ("Peaucellier").

[41] James Sylvester, "Recent Discoveries in Mechanical Conversion of Motion," Notices of the Proceedings of the Royal Institution of Great Britain, 1873-1875, vol. 7, p. 181. The fixed link was not counted by Sylvester; in modern parlance this would be a six-link mechanism.

Figure 22.—Peaucellier exact straight-line linkage, 1873. From A. B. Kempe, How to Draw a Straight Line (London, 1877, p. 12).

Figure 23.—Model of the Peaucellier "Compas Composé," deposited in Conservatoire National des Arts et Métiers, Paris, 1875. Photo courtesy of the Conservatoire.

Figure 24.—James Joseph Sylvester (1814-1897), mathematician and lecturer on straight-line linkages. From Proceedings of the Royal Society of London (1898, vol. 63, opposite p. 161).

Charles-Nicolas Peaucellier, a graduate of the Ecole Polytechnique and a captain in the French corps of engineers, was 32 years old in 1864 when he wrote a short letter to the editor of Nouvelles Annales de mathématiques (ser. 2, vol. 3, pp. 414-415) in Paris. He called attention to what he termed "compound compasses," a class of linkages that included Watt's parallel motion, the pantograph, and the polar planimeter. He proposed to design linkages to describe a straight line, a circle of any radius no matter how large, and conic sections, and he indicated in his letter that he had arrived at a solution.

This letter stirred no pens in reply, and during the next 10 years the problem merely led to the filling of a few academic pages by Peaucellier and Amédée Mannheim (1831-1906), also a graduate of Ecole Polytechnique, a professor of mathematics, and the designer of the Mannheim slide rule. Finally, in 1873, Captain Peaucellier gave his solution to the readers of the Nouvelles Annales. His reasoning, which has a distinct flavor of discovery by hindsight, was that since a linkage generates a curve that can be expressed algebraically, it must follow that any algebraic curve can be generated by a suitable linkage—it was only necessary to find the suitable linkage. He then gave a neat geometric proof, suggested by Mannheim, for his straight-line "compound compass."[42]

[42] Charles-Nicholas Peaucellier, "Note sur une question de geométrie de compas," Nouvelles Annales de mathématiques, 1873, ser. 2, vol. 12, pp. 71-78. A sketch of Mannheim's work is in Florian Cajori, A History of the Logarithmic Slide Rule, New York, about 1910, reprinted in String Figures and Other Monographs, New York, Chelsea Publishing Company, 1960.

On a Friday evening in January 1874 Albemarle Street in London was filled with carriages, each maneuvering to unload its charge of gentlemen and their ladies at the door of the venerable hall of the Royal Institution. Amidst a "mighty rustling of silks," the elegant crowd made its way to the auditorium for one of the famous weekly lectures. The speaker on this occasion was James Joseph Sylvester, a small intense man with an enormous head, sometime professor of mathematics at the University of Virginia, in America, and more recently at the Royal Military Academy in Woolwich. He spoke from the same rostrum that had been occupied by Davy, Faraday, Tyndall, Maxwell, and many other notable scientists. Professor Sylvester's subject was "Recent Discoveries in Mechanical Conversion of Motion."[43]

[43] Sylvester, op. cit. (footnote 41), pp. 179-198. It appears from a comment in this lecture that Sylvester was responsible for the word "linkage." According to Sylvester, a linkage consists of an even number of links, a "link-work" of an odd number. Since the fixed member was not considered as a link by Sylvester, this distinction became utterly confusing when Reuleaux's work was published in 1876. Although "link" was used by Watt in a patent specification, it is not probable that he ever used the term "link-work"—at any rate, my search for his use of it has been fruitless. "Link work" is used by Willis (op. cit. footnote 21), but the term most likely did not originate with him. I have not found the word "linkage" used earlier than Sylvester.

Remarking upon the popular appeal of most of the lectures, a contemporary observer noted that while many listeners might prefer to hear Professor Tyndall expound on the acoustic opacity of the atmosphere, "those of a higher and drier turn of mind experience ineffable delight when Professor Sylvester holds forth on the conversion of circular into parallel motion."[44]

[44] Bernard H. Becker, Scientific London, London, 1874, pp. 45, 50, 51.

Sylvester's aim was to bring the Peaucellier linkage to the notice of the English-speaking world, as it had been brought to his attention by Chebyshev—during a recent visit of the Russian to England—and to give his listeners some insight into the vastness of the field that he saw opened by the discovery of the French soldier.[45]

[45] Sylvester, op. cit. (footnote 41), p. 183; Nature, November 13, 1873, vol. 9, p. 33.

"The perfect parallel motion of Peaucellier looks so simple," he observed, "and moves so easily that people who see it at work almost universally express astonishment that it waited so long to be discovered." But that was not his reaction at all. The more one reflects upon the problem, Sylvester continued, he "wonders the more that it was ever found out, and can see no reason why it should have been discovered for a hundred years to come. Viewed a priori there was nothing to lead up to it. It bears not the remotest analogy (except in the fact of a double centring) to Watt's parallel motion or any of its progeny."[46]

[46] Sylvester, op. cit. (footnote 41), p. 181.

It must be pointed out, parenthetically at least, that James Watt had not only had to solve the problem as best he could, but that he had no inkling, so far as experience was concerned, that a solvable problem existed.

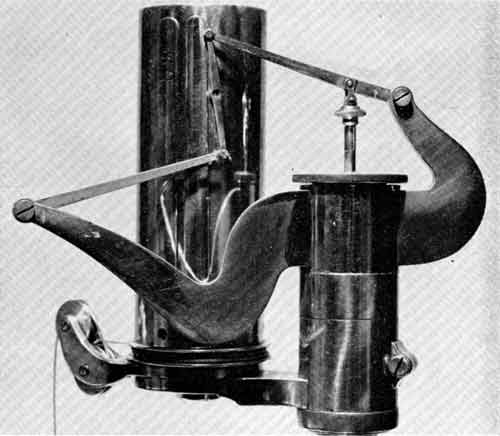

Sylvester interrupted his panegyric long enough to enumerate some of the practical results of the Peaucellier linkage. He said that Mr. Penrose, the eminent architect and surveyor to St. Paul's Cathedral, had "put up a house-pump worked by a negative Peaucellier cell, to the great wonderment of the plumber employed, who could hardly believe his senses when he saw the sling attached to the piston-rod moving in a true vertical line, instead of wobbling as usual from side to side." Sylvester could see no reason "why the perfect parallel motion should not be employed with equal advantage in the construction of ordinary water-closets." The linkage was to be employed by "a gentleman of fortune" in a marine engine for his yacht, and there was talk of using it to guide a piston rod "in certain machinery connected with some new apparatus for the ventilation and filtration of the air of the Houses of Parliament." In due course, Mr. Prim, "engineer to the Houses," was pleased to show his adaptation of the Peaucellier linkage to his new blowing engines, which proved to be exceptionally quiet in their operation (fig. 25).[47] A bit on the ludicrous side, also, was Sylvester's 78-bar linkage that traced a straight line along the line connecting the two fixed centers of the linkage.[48]

[47] Ibid., pp. 182, 183, 188, 193.

[48] Kempe, op. cit. (footnote 21), p. 17.

Figure 25.—Mr. Prim's blowing engine used for ventilating the House of Commons, 1877. The crosshead of the reciprocating air pump is guided by a Peaucillier linkage shown at the center. The slate-lined air cylinders had rubber-flap inlet and exhaust valves and a piston whose periphery was formed by two rows of brush bristles. Prim's machine was driven by a steam engine. Photograph by Science Museum, London.

Before dismissing with a smile the quaint ideas of our Victorian forbears, however, it is well to ask, 88 years later, whether some rather elaborate work reported recently on the synthesis of straight-line mechanisms is more to the point, when the principal objective appears to be the moving of an indicator on a "pleasing, expanded" (i.e., squashed flat) radio dial.[49]

[49] Machine Design, December 1954, vol. 26, p. 210.

But Professor Sylvester was more interested, really, in the mathematical possibilities of the Peaucellier linkage, as no doubt our modern investigators are. Through a compounding of Peaucellier mechanisms, he had already devised square-root and cube-root extractors, an angle trisector, and a quadratic-binomial root extractor, and he could see no limits to the computing abilities of linkages as yet undiscovered.[50]

[50] Sylvester, op. cit. (footnote 41), p. 191.

Sylvester recalled fondly, in a footnote to his lecture, his experience with a little mechanical model of the Peaucellier linkage at an earlier dinner meeting of the Philosophical Club of the Royal Society. The Peaucellier model had been greeted by the members with lively expressions of admiration "when it was brought in with the dessert, to be seen by them after dinner, as is the laudable custom among members of that eminent body in making known to each other the latest scientific novelties." And Sylvester would never forget the reaction of his brilliant friend Sir William Thomson (later Lord Kelvin) upon being handed the same model in the Athenaeum Club. After Sir William had operated it for a time, Sylvester reached for the model, but he was rebuffed by the exclamation "No! I have not had nearly enough of it—it is the most beautiful thing I have ever seen in my life."[51]

[51] Ibid., p. 183.

The aftermath of Professor Sylvester's performance at the Royal Institution was considerable excitement amongst a limited company of interested mathematicians. Many alternatives to the Peaucellier straight-line linkage were suggested by several writers of papers for learned journals.[52]

[52] For a summary of developments and references, see Kempe, op. cit. (footnote 21), pp. 49-51. Two of Hart's six-link exact straight-line linkages referred to by Kempe are illustrated in Henry M. Cundy and A. P. Rollett, Mathematical Models, Oxford, Oxford University Press, 1952, pp. 204-205. Peaucellier's linkage was of eight links.

In the summer of 1876, after Sylvester had departed from England to take up his post as professor of mathematics in the new Johns Hopkins University in Baltimore, Alfred Bray Kempe, a young barrister who pursued mathematics as a hobby, delivered at London's South Kensington Museum a lecture with the provocative title "How to Draw a Straight Line."[53]

[53] Kempe, op. cit. (footnote 21), p. 26.

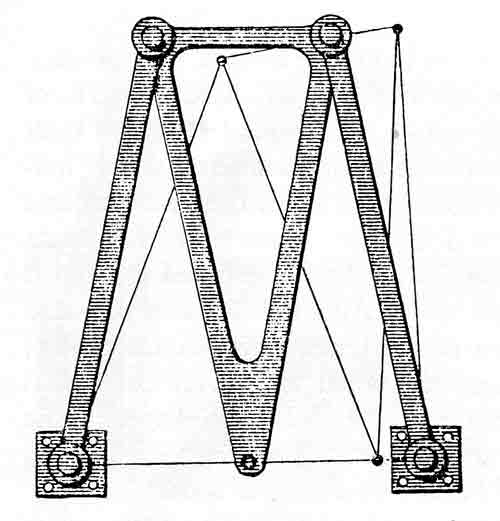

In order to justify the Peaucellier linkage, Kempe belabored the point that a perfect circle could be generated by means of a pivoted bar and a pencil, while the generation of a straight line was most difficult if not impossible until Captain Peaucellier came along. A straight line could be drawn along a straight edge; but how was one to determine whether the straight edge was straight? He did not weaken his argument by suggesting the obvious possibility of using a piece of string. Kempe had collaborated with Sylvester in pursuing the latter's first thoughts on the subject, and one result, that to my mind exemplifies the general direction of their thinking, was the Sylvester-Kempe "parallel motion" (fig. 26).

Figure 26.—Sylvester-Kempe translating linkage, 1877. The upper and lower plates remain parallel and equidistant. From A. B. Kempe, How to Draw a Straight Line (London, 1877, p. 37).

Figure 27.—Gaspard Monge (1746-1818), professor of mathematics at the Ecole Polytechnique from 1794 and founder of the academic discipline of machine kinematics, From Livre du Centenaire, 1794-1894, Ecole Polytechnique (Paris, 1895, vol. 1, frontispiece).

Enthusiastic as Kempe was, however, he injected an apologetic note in his lecture. "That these results are valuable cannot I think be doubted," he said, "though it may well be that their great beauty has led some to attribute to them an importance which they do not really possess...." He went on to say that 50 years earlier, before the great improvements in the production of true plane surfaces, the straight-line mechanisms would have been more important than in 1876, but he added that "linkages have not at present, I think, been sufficiently put before the mechanician to enable us to say what value should really be set upon them."[54]

[54] Ibid.,, pp. 6-7. I have not pursued the matter of cognate linkages (the Watt and Evans linkages are cognates) because the Roberts-Chebyshev theorem escaped my earlier search, as it had apparently escaped most others until 1958. See R. S. Hartenberg and J. Denavit, "The Fecund Four-Bar," Transactions of the Fifth Conference on Mechanisms, Cleveland, Penton Publishing Company, 1958, pp. 194-206, reprinted in Machine Design, April 16, 1959, vol. 31, pp. 149-152. See also A. E. R. de Jonge, "The Correlation of Hinged Four-Bar Straight-Line Motion Devices by Means of the Roberts Theorem and a New Proof of the Latter," Annals of the New York Academy of Sciences, March 18, 1960, vol. 84, art. 3, pp. 75-145 (published separately).

It was during this same summer of 1876, at the Loan Exhibition of Scientific Apparatus in the South Kensington Museum, that the work of Franz Reuleaux, which was to have an important and lasting influence on kinematics everywhere, was first introduced to English engineers. Some 300 beautifully constructed teaching aids, known as the Berlin kinematic models, were loaned to the exhibition by the Royal Industrial School in Berlin, of which Reuleaux was the director. These models were used by Prof. Alexander B. W. Kennedy of University College, London, to help explain Reuleaux's new and revolutionary theory of machines.[55]

[55] Alexander B. W. Kennedy, "The Berlin Kinematic Models," Engineering, September 15, 1876, vol. 22, pp. 239-240.

When, in 1829, André-Marie Ampère (1775-1836) was called upon to prepare a course in theoretical and experimental physics for the Collège de France, he first set about determining the limits of the field of physics. This exercise suggested to his wide-ranging intellect not only the definition of physics but the classification of all human knowledge. He prepared his scheme of classification, tried it out on his physics students, found it incomplete, returned to his study, and produced finally a two-volume work wherein the province of kinematics was first marked out for all to see and consider.[56] Only a few lines could be devoted to so specialized a branch as kinematics, but Ampère managed to capture the central idea of the subject.

[56] André-Marie Ampère, Essai sur la philosophie des sciences, une exposition analytique d'une classification naturelle de toutes les connaissances humaines, 2 vols., Paris, 1838 (for origin of the project, see vol. 1, pp. v, xv).

Cinématique (from the Greek word for movement) was, according to Ampère, the science "in which movements are considered in themselves [independent of the forces which produce them], as we observe them in solid bodies all about us, and especially in the assemblages called machines."[57] Kinematics, as the study soon came to be known in English,[58] was one of the two branches of elementary mechanics, the other being statics.

[57] Ibid., vol. 1, pp. 51-52.

[58] Willis (op. cit. footnote 21) adopted the word "kinematics," and this Anglicization subsequently became the standard term for this branch of mechanics.

In his definition of kinematics, Ampère stated what the faculty of mathematics at the Ecole Polytechnique, in Paris, had been groping toward since the school's opening some 40 years earlier. The study of mechanisms as an intellectual discipline most certainly had its origin on the left bank of the Seine, in this school spawned, as suggested by one French historian,[[59] by the great Encyclopédie of Diderot and d'Alembert.

[59] G. Pinet, Histoire de l'Ecole Polytechnique, Paris, 1887, pp. viii-ix. In their forthcoming book on kinematic synthesis, R. S. Hartenberg and J. Denavit will trace the germinal ideas of Jacob Leupold and Leonhard Euler of the 18th century.

Because the Ecole Polytechnique had such a far-reaching influence upon the point of view from which mechanisms were contemplated by scholars for nearly a century after the time of Watt, and by compilers of dictionaries of mechanical movements for an even longer time, it is well to look for a moment at the early work that was done there. If one is interested in origins, it might be profitable for him to investigate the military school in the ancient town of Mézières, about 150 miles northeast of Paris. It was here that Lazare Carnot, one of the principal founders of the Ecole Polytechnique, in 1783 published his essay on machines,[60] which was concerned, among other things, with showing the impossibility of "perpetual motion"; and it was from Mézières that Gaspard Monge and Jean Hachette[61] came to Paris to work out the system of mechanism classification that has come to be associated with the names of Lanz and Bétancourt.

[60] Lazare N. M. Carnot, Essai sur les machines en général, Mézières, 1783 (later published as Principes fondamentaux de l'equilibre et du mouvement, Paris, 1803).

[61] Biographical notices of Monge and Hachette appear in Encyclopaedia Britannica, ed. 11. See also L'Ecole Polytechnique, Livre du Centenaire, Paris, 1895, vol. 1, p. 11ff.

Gaspard Monge (1746-1818), who while a draftsman at Mézières originated the methods of descriptive geometry, came to the Ecole Polytechnique as professor of mathematics upon its founding in 1794, the second year of the French Republic. According to Jean Nicolas Pierre Hachette (1769-1834), who was junior to Monge in the department of descriptive geometry, Monge planned to give a two-months' course devoted to the elements of machines. Having barely gotten his department under way, however, Monge became involved in Napoleon's ambitious scientific mission to Egypt and, taking leave of his family and his students, embarked for the distant shores.

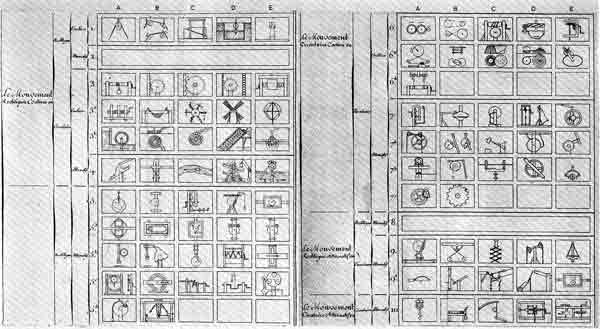

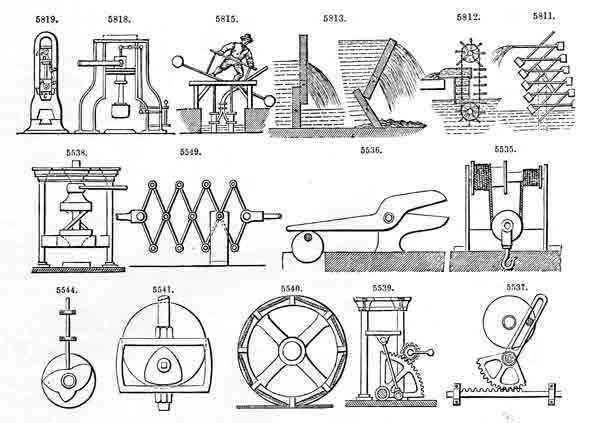

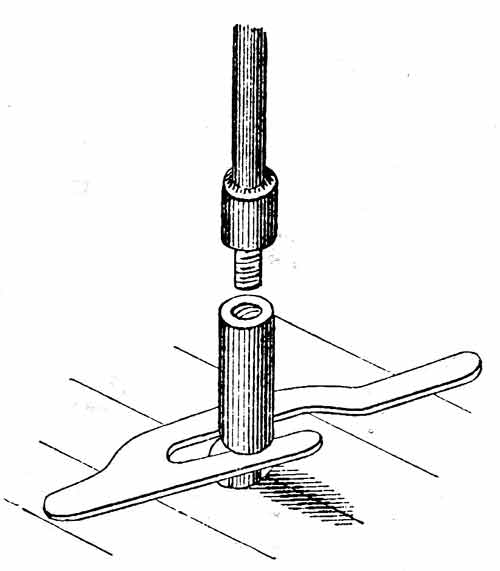

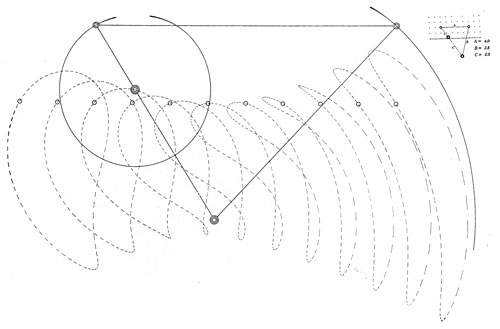

"Being left in charge," wrote Hachette, "I prepared the course of which Monge had given only the first idea, and I pursued the study of machines in order to analyze and classify them, and to relate geometrical and mechanical principles to their construction." Changes of curriculum delayed introduction of the course until 1806, and not until 1811 was his textbook ready, but the outline of his ideas was presented to his classes in chart form (fig. 28). This chart was the first of the widely popular synoptical tables of mechanical movements.[62]

[62] Jean N. P. Hachette, Traité élémentaire des machines, Paris, 1811, p. v.

Figure 28.—Hachette's synoptic chart of elementary mechanisms, 1808. This was the first of many charts of mechanical movements that enjoyed wide popularity for over 100 years.

From Jean N. P. Hachette, Traité Élémentaire des Machines (Paris, 1811, pl. 1).

Hachette classified all mechanisms by considering the conversion of one motion into another. His elementary motions were continuous circular, alternating circular, continuous rectilinear, and alternating rectilinear. Combining one motion with another—for example, a treadle and crank converted alternating circular to continuous circular motion—he devised a system that supplied a frame of reference for the study of mechanisms. In the U.S. Military Academy at West Point, Hachette's treatise, in the original French, was used as a textbook in 1824, and perhaps earlier.[63]

[63] This work was among the books sent back by Sylvanus Thayer when he visited France in 1816 to observe the education of the French army cadets. Thayer's visit resulted in his adopting the philosophy of the Ecole Polytechnique in his reorganization of the U.S. Military Academy and, incidentally, in his inclusion of Hachette's course in the Academy's curriculum (U.S. Congress, American State Papers, Washington, 1832-1861, Class v, Military Affairs, vol. 2, p. 661: Sidney Forman, West Point, New York, 1950, pp. 36-60). There is a collection of miscellaneous papers (indexed under Sylvanus Thayer and William McRee, U.S. National Archives, RG 77, Office, Chief of Engineers, Boxes 1 and 6) pertaining to the U.S. Military Academy of this period, but I found no mention of kinematics in this collection.

Lanz and Bétancourt, scholars from Spain at the Ecole Polytechnique, plugged some of the gaps in Hachette's system by adding continuous and alternating curvilinear motion, which doubled the number of combinations to be treated, but the advance of their work over that of Hachette was one of degree rather than of kind.[64]

[64] Phillipe Louis Lanz and Augustin de Bétancourt, Essai sur la composition des machines, Paris, 1808. Hachette's chart and an outline of his elementary course on machines is bound with the Princeton University Library copy of the Lanz and Bétancourt work. This copy probably represents the first textbook of kinematics. Bétancourt was born in 1760 in Teneriffe, attended the military school in Madrid, and became inspector-general of Spanish roads and canals. He was in England before 1789, learning how to build Watt engines, and he introduced the engines to Paris in 1790 (see Farey, op. cit.,, p. 655). He entered Russian service in 1808 and died in St. Petersburg in 1826 (J. C. Poggendorff, Biographisches-literarisches Handwörterbuch für Mathematik ..., Leipzig, 1863, vol. 1.

Figure 29.—Robert Willis (1800-1875), Jacksonian Professor, Cambridge University, and author of Principles of Mechanism, one of the landmark books in the development of kinematics of mechanisms. Photo courtesy Gonville and Caius College, Cambridge University.

Giuseppe Antonio Borgnis, an Italian "engineer and member of many academies" and professor of mechanics at the University of Pavia in Italy, in his monumental, nine-volume Traité complet de méchanique appliquée aux arts, caused a bifurcation of the structure built upon Hachette's foundation of classification when he introduced six orders of machine elements and subdivided these into classes and species. His six orders were récepteurs (receivers of motion from the prime mover), communicateurs, modificateurs (modifiers of velocity), supports (e.g., bearings), regulateurs (e.g., governors), and operateurs, which produced the final effect.[65]

[65] Giuseppe Antonio Borgnis, Théorie de la mécanique usuelle in Traité complet de mécanique appliquée aux arts, Paris, 1818, vol. 1, pp. xiv-xvi.

The brilliant Gaspard-Gustave de Coriolis (1792-1843)—remembered mainly for a paper of a dozen pages explaining the nature of the acceleration that bears his name[66]—was another graduate of the Ecole Polytechnique who wrote on the subject of machines. His book,[67] published in 1829, was provoked by his recognition that the designer of machines needed more knowledge than his undergraduate work at the Ecole Polytechnique was likely to give him. Although he embraced a part of Borgnis' approach, adopting récepteurs, communicateurs, and operateurs, Coriolis indicated by the title of his book that he was more concerned with forces than with relative displacements. However, the attractively simple three-element scheme of Coriolis became well fixed in French thinking.[68]

[66] Gaspard-Gustave de Coriolis, "Memoire sur les equations du mouvement relatif des systèmes de corps," Journal de l'Ecole Polytechnique, 1835, vol. 15, pp. 142-154.

[67] Gaspard-Gustave de Coriolis, De Calcul de l'effet des machines, Paris, 1829. In this book Coriolis proposed the now generally accepted equation, work = force × distance (pp. iii, 2).

[68] The renowned Jean Victor Poncelet lent weight to this scheme. (See Franz Reuleaux, Theoretische Kinematik: Grundzüge einer Theorie des Maschinenwesens, Braunschweig, 1875, translated by Alexander B. W. Kennedy as The Kinematics of Machinery: Outlines of a Theory of Machines, London, 1876, pp. 11, 487. I have used the Kennedy translation in the Reuleaux references throughout the present work.)

Michel Chasles (1793-1880), another graduate of the Ecole Polytechnique, contributed some incisive ideas in his papers on instant centers[69] published during the 1830's, but their tremendous importance in kinematic analysis was not recognized until much later.

[69] The instant center was probably first recognized by Jean Bernoulli (1667-1748) in his "De Centro Spontaneo Rotationis" (Johannis Bernoulli ... Opera Omnia ..., Lausanne, 1742, vol. 4, p. 265ff.).

Figure 30.—Franz Reuleaux (1829-1905). His Theoretische Kinematik, published in 1875, provided the basis for modern kinematic analysis. Photo courtesy Deutsches Museum, Munich.

Acting upon Ampère's clear exposition of the province of kinematics and excluding, as Ampère had done, the consideration of forces, an Englishman, Robert Willis, made the next giant stride forward in the analysis of mechanisms. Willis was 37 years old in 1837 when he was appointed professor of natural and experimental philosophy at Cambridge. In the same year Professor Willis—a man of prodigious energy and industry and an authority on archeology and architectural history as well as mechanisms—read his important paper "On the Teeth of Wheels" before the Institution of Civil Engineers[[70] and commenced at Cambridge his lectures on kinematics of mechanisms that culminated in his 1841 book Principles of Mechanism.[71]

[70] Robert Willis, "On the Teeth of Wheels," Transactions of the Institution of Civil Engineers of London, 1838, vol. 2, pp. 89-112.

[71] Willis, op. cit. (footnote 21). Through the kindness of its owner (Mr. Warren G. Ogden of North Andover, Massachusetts), I have had access to Willis' own copy of his 1841 edition of Principles of Mechanism. The book is interleaved, and it contains notes made by Willis from time to time until at least 1870, when the second edition was issued. Corrections, emendations, notations of some of his sources (for example, the De Voglie linkage mentioned in footnote 35 above), notes to himself to "examine the general case" and "examine the modern forms" of straight-line devices are interspersed with references to authors that had borrowed from his work without acknowledgment. Of one author Willis writes an indignant "He ignores my work."

It seemed clear to Willis that the problem of devising a mechanism for a given purpose ought to be attacked systematically, perhaps mathematically, in order to determine "all the forms and arrangements that are applicable to the desired purpose," from which the designer might select the simplest or most suitable combination. "At present," he wrote, "questions of this kind can only be solved by that species of intuition which long familiarity with a subject usually confers upon experienced persons, but which they are totally unable to communicate to others."

In analyzing the process by which a machine was designed, Willis observed: "When the mind of a mechanician is occupied with the contrivance of a machine, he must wait until, in the midst of his meditations, some happy combination presents itself to his mind which may answer his purpose." He ventured the opinion that at this stage of the design process "the motions of the machine are the principal subject of contemplation, rather than the forces applied to it, or the work it has to do." Therefore he was prepared to adopt without reservation Ampère's view of kinematics, and, if possible, to make the science useful to engineers by stating principles that could be applied without having to fit the problem at hand into the framework of the systems of classification and description that had gone before. He appraised the "celebrated system" of Lanz and Bétancourt as "a merely popular arrangement, notwithstanding the apparently scientific simplicity of the scheme." He rejected this scheme because "no attempt is made to subject the motions to calculation, or to reduce these laws to general formulas, for which indeed the system is totally unfitted."

Borgnis had done a better job, Willis thought, in actually describing machinery, with his "orders" based upon the functions of machine elements or mechanisms within the machine, but again there was no means suggested by which the kinematics of mechanisms could be systematically investigated.

Although Willis commenced his treatise with yet another "synoptical table of the elementary combinations of pure mechanism," his view shifted quickly from description to analysis. He was consistent in his pursuit of analytical methods for "pure mechanism," eschewing any excursions into the realm of forces and absolute velocities. He grasped the important concept of relative displacements of machine elements, and based his treatment upon "the proportions and relations between the velocities and directions of the pieces, and not upon their actual and separate motions."[72]

[72] Ibid., pp. iv, x-xii, xxi, 15.

That he did not succeed in developing the "formulas" that would enable the student to determine "all the forms and arrangements that are applicable to the desired purpose"—that he did not present a rational approach to synthesis—is not to be wondered at. Well over a century later we still are nibbling at the fringes of the problem. Willis did, nonetheless, give the thoughtful reader a glimpse of the most powerful tool for kinematic synthesis that has yet been devised; namely, kinematic analysis, in which the argument is confined to the relative displacements of points on links of a mechanism, and through which the designer may grasp the nature of the means at his disposal for the solution of any particular problem.

As remarked by Reuleaux a generation later, there was much in Professor Willis's book that was wrong, but it was an original, thoughtful work that departed in spirit if not always in method from its predecessors. Principles of Mechanism was a prominent landmark along the road to a rational discipline of machine-kinematics.

A phenomenal engineer of the 19th century was the Scottish professor of civil engineering at the University of Glasgow, William John MacQuorn Rankine. Although he was at the University for only 17 years—he died at the age of 52, in 1872—he turned out during that time four thick manuals on such diverse subjects as civil engineering, ship-building, thermodynamics, and machinery and mill-work, in addition to literally hundreds of papers, articles, and notes for scientific journals and the technical press. Endowed with apparently boundless energy, he found time from his studies to command a battalion of rifle volunteers and to compose and sing comic and patriotic songs. His manuals, often used as textbooks, were widely circulated and went through many editions. Rankine's work had a profound effect upon the practice of engineering by setting out principles in a form that could be grasped by people who were dismayed by the treatment usually found in the learned journals.

When Rankine's book titled A Manual of Machinery and Millwork was published in 1869 it was accurately characterized by a reviewer as "dealing with the principles of machinery and millworks, and as such it is entirely distinct from [other works on the same subject] which treat more of the practical applications of such principles than of the principles themselves."[73]

[73] Engineering, London, August 13, 1869, vol. 8, p. 111.

Rankine borrowed what appeared useful from Willis' Principles of Mechanism and from other sources. His treatment of kinematics was not as closely reasoned as the later treatises of Reuleaux and Kennedy, which will be considered below. Rankine did, however, for the first time show the utility of instant centers in velocity analysis, although he made use only of the instant centers involving the fixed link of a linkage. Like others before him, he considered the fixed link of a mechanism as something quite different from the movable links, and he did not perceive the possibilities opened up by determining the instant center of two movable links.

Many other books dealing with mechanisms were published during the middle third of the century, but none of them had a discernible influence upon the advance of kinematical ideas.[74] The center of inquiry had by the 1860's shifted from France to Germany. Only by scattered individuals in England, Italy, and France was there any impatience with the well-established, general understanding of the machine-building art.

[74] Several such books are referred to by Reuleaux, op. cit. (footnote 68), pp. 12-16.

In Germany, on the other hand, there was a surge of industrial activity that attracted some very able men to the problems of how machines ought to be built. Among the first of these was Ferdinand Redtenbacher (1809-1863), professor of mechanical engineering in the polytechnic school in Karlsruhe, not far from Heidelberg. Redtenbacher, although he despaired of the possibility of finding a "true system on which to base the study of mechanisms," was nevertheless a factor in the development of such a system. He had young Franz Reuleaux in his classes for two years, from 1850. During that time the older man's commanding presence, his ability as a lecturer, and his infectious impatience with the existing order influenced Reuleaux to follow the scholar's trail that led him to eminence as an authority of the first rank.[75]

[75] See Carl Weihe, "Franz Reuleaux und die Grundlagen seiner Kinematik," Deutsches Museum, Munich, Abhandlung und Berichte, 1942, p. 2; Friedrich Klemm, Technik: Eine Geschichte ihrer Probleme, Freiburg and Munich, Verlag Karl Alber, 1954, translated by Dorothea W. Singer as A History of Western Technology, New York, Charles Scribner's Sons, 1959, p. 317.

Before he was 25 years old Franz Reuleaux published, in collaboration with a classmate, a textbook whose translated title would be Constructive Lessons for the Machine Shop.[76] His several years in the workshop, before and after coming under Redtenbacher's influence, gave his works a practical flavor, simple and direct. According to one observer, Reuleaux's book exhibited "a recognition of the claims of practice such as Englishmen do not generally associate with the writings of a German scientific professor."[77]

[76] See Weihe, op. cit. (footnote 75), p. 3; Hans Zopke, "Professor Franz Reuleaux," Cassier's Magazine, December 1896, vol. 11, pp. 133-139; Transactions of the American Society of Mechanical Engineers, 1904-1905, vol. 26, pp. 813-817.

[77] Engineering, London, September 8, 1876, vol. 22, p. 197.