The subject of Physiological Chemistry, or Biochemistry, is enlarging its borders to such an extent at the present time that no single text-book upon the subject, without being cumbrous, can adequately deal with it as a whole, so as to give both a general and a detailed account of its present position. It is, moreover, difficult, in the case of the larger text-books, to keep abreast of so rapidly growing a science by means of new editions, and such volumes are therefore issued when much of their contents has become obsolete.

For this reason, an attempt is being made to place this branch of science in a more accessible position by issuing a series of monographs upon the various chapters of the subject, each independent of and yet dependent upon the others, so that from time to time, as new material and the demand therefor necessitate, a new edition of each monograph can be issued without reissuing the whole series. In this way, both the expenses of publication and the expense to the purchaser will be diminished, and by a moderate outlay it will be possible to obtain a full account of any particular subject as nearly current as possible.

The editors of these monographs have kept two objects in view: firstly, that each author should be himself working at the subject with which he deals; and, secondly, that a Bibliography, as complete as possible, should be included, in order to avoid cross references, which are apt to be wrongly cited, and in order that each monograph may yield full and independent information of the work which has been done upon the subject.

It has been decided as a general scheme that the volumes first issued shall deal with the pure chemistry of physiological products and with certain general aspects of the subject. Subsequent monographs will be devoted to such questions as the chemistry of special tissues and particular aspects of metabolism. So the series, if continued, will proceed from physiological chemistry to what may be now more properly termed chemical physiology. This will depend upon the success which the first series achieves, and upon the divisions of the subject which may be of interest at the time.

THE NATURE OF ENZYME ACTION. By W. M. Bayliss, D.Sc., F.R.S. Third Edition. 5s. net.

THE CHEMICAL CONSTITUTION OF THE PROTEINS. By R. H. A. Plimmer, D.Sc. Part I.—Analysis. Second Edition, Revised and Enlarged. 5s. 6d. net. Part II.—Synthesis, etc. Second Edition, Revised and Enlarged. 3s. 6d. net.

THE GENERAL CHARACTERS OF THE PROTEINS. By S. B. Schryver, Ph.D., D.Sc. 2s. 6d. net.

THE VEGETABLE PROTEINS. By Thomas B. Osborne, Ph.D. 3s. 6d. net.

THE SIMPLE CARBOHYDRATES AND THE GLUCOSIDES. By E. Frankland Armstrong, D.Sc., Ph.D. Second Edition, Revised and Enlarged. 5s. net.

THE FATS. By J. B. Leathes, F.R.S., M.A., M.B., F.R.C.S. 4s. net.

ALCOHOLIC FERMENTATION. By A. Harden, Ph.D., D.Sc., F.R.S. Second Edition. 4s. net.

THE PHYSIOLOGY OF PROTEIN METABOLISM. By E. P. Cathcart, M.D., D.Sc. 4s. 6d. net.

SOIL CONDITIONS AND PLANT GROWTH. By E. J. Russell, D.Sc. 5s. net.

OXIDATIONS AND REDUCTIONS IN THE ANIMAL BODY. By H. D. Dakin, D.Sc., F.I.C. 4s. net.

THE SIMPLER NATURAL BASES. By G. Barger, M.A., D.Sc. 6s. net.

NUCLEIC ACIDS. THEIR CHEMICAL PROPERTIES AND PHYSIOLOGICAL CONDUCT. By Walter Jones, Ph.D. 3s. 6d. net.

THE DEVELOPMENT AND PRESENT POSITION OF BIOLOGICAL CHEMISTRY. By F. Gowland Hopkins, M.A., M.B., D.Sc., F.R.S.

THE POLYSACCHARIDES. By Arthur R. Ling, F.I.C.

COLLOIDS. By W. B. Hardy, M.A., F.R.S.

RESPIRATORY EXCHANGE IN ANIMALS. By A. Krogh, Ph.D.

PROTAMINES AND HISTONES. By A. Kossel, Ph.D.

LECITHIN AND ALLIED SUBSTANCES. By H. Maclean, M.D., D.Sc.

THE ORNAMENTAL PLANT PIGMENTS. By A. G. Perkin, F.R.S.

CHLOROPHYLL AND HAEMOGLOBIN. By.H. J. Page, B.Sc.

ORGANIC COMPOUNDS OF ARSENIC AND ANTIMONY. By Gilbert T. Morgan, D.Sc., F.I.C.

LONGMANS, GREEN AND CO.,

LONDON, NEW YORK, BOMBAY, CALCUTTA, AND MADRAS.

The following chapters are based on courses of lectures delivered at the London University and the Royal Institution during 1909–1910. In them an account is given of the work done on alcoholic fermentation since Buchner's epoch-making discovery of zymase, only in so far as it appears to throw light on the nature of that phenomenon. Many interesting subjects, therefore, have perforce been left untouched, among them the problem of the formation of zymase in the cell, and the vexed question of the relation of alcoholic fermentation to the metabolic processes of the higher plants and animals.

My thanks are due to the Council of the Royal Society, and to the Publishers of the "Journal of Physiology" for permission to make use of blocks (Figs. 2, 4 and 7) which have appeared in their publications.

In the New Edition no change has been made in the scope of the work. The rapid progress of the subject has, however, rendered necessary many additions to the text and a considerable increase in the bibliography.

May,1914.

| CHAPTER | PAGE | |

|---|---|---|

| I. | Historical Introduction | 1 |

| II. | Zymase and its Properties | 18 |

| III. | The Function of Phosphates in Alcoholic Fermentation | 41 |

| IV. | The Co-Enzyme of Yeast-Juice | 59 |

| V. | Action of Some Inhibiting and Accelerating Agents on the Enzymes of Yeast-Juice | 70 |

| VI. | Carboxylase | 81 |

| VII. | The By-Products of Alcoholic Fermentation | 85 |

| VIII. | The Chemical Changes involved in Fermentation | 96 |

| IX. | The Mechanism of Fermentation | 119 |

| Bibliography | 136 | |

| Index | 155 | |

The problem of alcoholic fermentation, of the origin and nature of that mysterious and apparently spontaneous change which converted the insipid juice of the grape into stimulating wine, seems to have exerted a fascination over the minds of natural philosophers from the very earliest times. No date can be assigned to the first observation of the phenomena of the process. History finds man in the possession of alcoholic liquors, and in the earliest chemical writings we find fermentation, as a familiar natural process, invoked to explain and illustrate the changes with which the science of those early days was concerned. Throughout the period of alchemy fermentation plays an important part; it is, in fact, scarcely too much to say that the language of the alchemists and many of their ideas were founded on the phenomena of fermentation. The subtle change in properties permeating the whole mass of material, the frothing of the fermenting liquid, rendering evident the vigour of the action, seemed to them the very emblems of the mysterious process by which the long sought for philosopher's stone was to convert the baser metals into gold. As chemical science emerged from the mists of alchemy, definite ideas about the nature of alcoholic fermentation and of putrefaction began to be formed. Fermentation was distinguished from other chemical changes in which gases were evolved, such as the action of acids on alkali carbonates (Sylvius de le Boë, 1659); the gas evolved was examined and termed gas vinorum, and was distinguished from the alcohol with which it had at first been confused (van Helmont, 1648); afterwards it was found that like the gas from potashes it was soluble in water (Wren, 1664). The gaseous product of fermentation and putrefaction was identified by MacBride, in 1764, with the fixed air of Black, whilst Cavendish in 1766 showed that fixed air alone was evolved in alcoholic fermentation and that a mixture of this with inflammable air was produced by putrefaction. In the meantime it had been recognised that only sweet liquors could be fermented ("Ubi notandum, nihil fermentare quod non sit dulce," Becher, 1682), and finally Cavendish [p002] [1776] determined the proportion of fixed air obtainable from sugar by fermentation and found it to be 57 per cent. It gradually became recognised that fermentation might yield either spirituous or acid liquors, whilst putrefaction was thought to be an action of the same kind as fermentation, differing mainly in the character of the products (Becher).

As regards the nature of the process very confused ideas at first prevailed, but in the time of the phlogistic chemists a definite theory of fermentation was proposed, first by Willis (1659) and afterwards by Stahl [1697], the fundamental idea of which survived the overthrow of the phlogistic system by Lavoisier and formed the foundation of the views of Liebig. To explain the spontaneous origin of fermentation and its propagation from one liquid to another, they supposed that the process consisted in a violent internal motion of the particles of the fermenting substance, set up by an aqueous liquid, whereby the combination of the essential constituents of this material was loosened and new particles formed, some of which were thrust out of the liquid (the carbon dioxide) and others retained in it (the alcohol).

Stahl specifically states that a body in such a state of internal disquietude can very readily communicate the disturbance to another, which is itself at rest but is capable of undergoing a similar change, so that a putrefying or fermenting liquid can set another liquid in putrefaction or fermentation.

Taking account of the gradual accumulation of fact and theory we find at the time of Lavoisier, from which the modern aspect of the problem dates, that Stahl's theoretical views were generally accepted. Alcoholic fermentation was known to require the presence of sugar and was thought to lead to the production of carbon dioxide, acetic acid, and alcohol.

The composition of organic compounds was at that time not understood, and it was Lavoisier who established the fact that they consisted of carbon, hydrogen, and oxygen, and who made systematic analyses of the substances concerned in fermentation (1784–1789). Lavoisier [1789] applied the results of these analyses to the study of alcoholic fermentation, and by employing the principle which he regarded as the foundation of experimental chemistry, "that there is the same quantity of matter before and after the operation," he drew up an equation between the quantities of carbon, hydrogen, and oxygen in the original sugar and in the resulting substances, alcohol, carbon dioxide, and acetic acid, showing that the products contained the whole matter of the sugar, and thus for the first time giving a clear view of the chemical [p003] change which occurs in fermentation. The conclusion to which he came was, we now know, very nearly accurate, but the research must be regarded as one of those remarkable instances in which the genius of the investigator triumphs over experimental deficiencies, for the analytical numbers employed contained grave errors, and it was only by a fortunate compensation of these that a result so near the truth was attained.

Lavoisier's equation or balance sheet was as follows:—

| Carbon. | Hydrogen. | Oxygen. | |

|---|---|---|---|

| 95·9 pounds of sugar (cane sugar) consist of | 26·8 | 7·7 | 61·4 |

| These yield:— | |||

| 57·7 pounds of alcohol containing | 16·7 | 9·6 | 31·4 |

| 35·3 pounds of carbon dioxide containing | 9·9 | — | 25·4 |

| 2·5 pounds of acetic acid containing | 0·6 | 0·2 | 1·7 |

| ――― | ――― | ――― | |

| Total contained in products | 27·2 | 9·8 | 58·5 |

The true composition of the sugar used was carbon 40·4, hydrogen 6·1, oxygen 49·4.

Lavoisier expressed no view as to the agency by which fermentation was brought about, but came to a very definite and characteristic conclusion as to the chemical nature of the change. The sugar, which he regarded in harmony with his general views as an oxide, was split into two parts, one of which was oxidised at the expense of the other to form carbonic acid, whilst the other was deoxygenised in favour of the former to produce the combustible substance alcohol, "so that if it were possible to recombine these two substances, alcohol and carbonic acid, sugar would result".

From this point commences the modern study of the problem. Provided by the genius of Lavoisier with the assurance that the hitherto mysterious process of fermentation was to be ranked along with familiar chemical changes, and that it proceeded in harmony with the same quantitative laws as these simpler reactions, chemists were stimulated in their desire to penetrate further into the mysteries of the phenomenon, and the importance and interest of the problem attracted many workers.

So important indeed did the matter appear to Lavoisier's countrymen that in the year 8 of the French Republic (1800) a prize—consisting of a gold medal, the value of which, expressed in terms of the newly introduced metric system, was that of one kilogram of gold—was offered by the Institute for the best answer to the question: "What are the characteristics by which animal and vegetable substances which act as ferments can be distinguished from those which they are capable of fermenting?" [p004]

This valuable prize was again offered in 1802 but was never awarded, as the fund from which it was to be drawn was sequestrated from the Institute in 1804. The first response to this stimulating offer was an important memoir by citizen Thenard [1803], which provided many of the facts upon which Liebig subsequently based his views. Thenard combats the prevailing idea, first expressed by Fabroni (1787–1799), that fermentation is caused by the action of gluten derived from grain on starch and sugar, but is himself uncertain as to the actual nature of the ferment. He points out that all fermenting liquids deposit a material resembling brewer's yeast, and he shows that this contains nitrogen, much of which is evolved as ammonia on distillation. His most important result is, however, that when yeast is used to ferment pure sugar, it undergoes a gradual change and is finally left as a white mass, much reduced in weight, which contains no nitrogen and is without action on sugar. Thenard, moreover, it is interesting to note, differs from Lavoisier, inasmuch as he ascribes the origin of some of the carbonic acid to the carbon of the ferment, an opinion which was still held in various degrees by many investigators (see Seguin, quoted by Thenard).

Thenard's memoir was followed by a communication of fundamental importance from Gay-Lussac [1810]. A process for preserving food had been introduced by Appert, which consisted in placing the material in bottles, closing these very carefully and exposing them to the temperature of boiling water for some time. Gay-Lussac was struck by the fact that when such a bottle was opened fermentation or putrefaction set in rapidly. Analysis of the air left in such a sealed bottle showed that all the oxygen had been absorbed, and these facts led to the view that fermentation was set up by the action of oxygen on the fermentable material. Experiment appeared to confirm this in the most striking way. A bottle of preserved grape-juice was opened over mercury and part of its contents passed through the mercury into a bell-jar containing air, the remainder into a similar vessel free from air. In the presence of air fermentation set in at once, in the absence of air no fermentation whatever occurred. This connection between fermentation and the presence of air was established by numerous experiments and appeared incontestable. Fermentation, it was found, could be checked by boiling even after the addition of oxygen, and hence food could be preserved in free contact with the air, provided only that it was raised to the temperature of boiling water at short intervals of time. Gay-Lussac's opinion was that the ferment was formed by the action of the oxygen on the [p005] liquid, and that the product of this action was altered by heat and rendered incapable of producing fermentation, as was also brewer's yeast, which, however, he regarded, on account of its insolubility, as different from the soluble ferment which initiated the change in the limpid grape-juice. Colin, on the other hand [1825], recognised that alcoholic fermentation by whatever substance it was started, resulted in the formation of an insoluble deposit more active than the original substance, and he suggested that this deposit might possibly in every case be of the same nature.

So far no suspicion appears to have arisen in the minds of those who had occupied themselves with the study of fermentation that this change differed in any essential manner from many other reactions familiar to chemists. The origin and properties of the ferment were indeed remarkable and involved in obscurity, but the uncertainty regarding this substance was no greater than that surrounding many, if not all, compounds of animal and vegetable origin. Although, however, the purely chemical view as to the nature of yeast was generally recognised and adopted, isolated observations were not wanting which tended to show that yeast might be something more than a mere chemical reagent. As early as 1680 in letters to the Royal Society Leeuwenhoek described the microscopic appearance of yeast of various origins as that of small, round, or oval particles, but no further progress seems to have been made in this direction for nearly a century and a half, when we find that Desmazières [1826] examined the film formed on beer, figured the elongated cells of which it was composed, and described it under the name of Mycoderma Cerevisiæ. He, however, regarded it rather as of animal than of vegetable origin, and does not appear to have connected the presence of these cells with the process of fermentation.

Upon this long period during which yeast was regarded merely as a chemical compound there followed, as has so frequently occurred in similar cases, a sudden outburst of discovery. No less than three observers hit almost simultaneously upon the secret of fermentation and declared that yeast was a living organism.

First among these in strict order of time was Cagniard-Latour [1838], who made a number of communications to the Academy and to the Société Philomatique in 1835–6, the contents of which were collected in a paper presented to the Academy of Sciences on 12 June, 1837, and published in 1838. The observations upon which this memoir was based were almost exclusively microscopical. Yeast was recognised as consisting of spherical particles, which were capable of [p006] reproduction by budding but incapable of motion, and it was therefore regarded as a living organism probably belonging to the vegetable kingdom. Alcoholic fermentation was observed to depend on the presence of living yeast cells, and was attributed to some effect of their vegetative life (quelque effet de leur végétation). It was also noticed that yeast was not deprived of its fermenting power by exposure to the temperature of solid carbonic acid, a sample of which was supplied to Cagniard-Latour by Thilorier, who had only recently prepared it for the first time.

Theodor Schwann [1837], whose researches were quite independent of those of Cagniard-Latour, approached the problem from an entirely different point of view. During the year 1836 Franz Schulze [1836] published a research on the subject of spontaneous generation, in which he proved that when a solution containing animal or vegetable matter was boiled, no putrefaction set in provided that all air which was allowed to have access to the liquid was previously passed through strong sulphuric acid. Schwann performed a very similar experiment by which he showed that this same result, the absence of putrefaction, was attained by heating all air which came into contact with the boiled liquid. Wishing to show that other processes in which air took part were not affected by the air being heated, he made experiments with fermenting liquids and found, contrary to his expectation, that a liquid capable of undergoing vinous fermentation and containing yeast did not undergo this change after it had been boiled, provided that, as in the case of his previous experiments, only air which had been heated was allowed to come into contact with it.

Schwann's experiments on the prevention of putrefaction were unexceptionable and quite decisive. The analogous experiments dealing with alcoholic fermentation were not quite so satisfactory. Yeast was added to a solution of cane sugar, the flask containing the mixture placed in boiling water for ten minutes, and then inverted over mercury. About one-third of the liquid was then displaced by air and the flasks corked and kept inverted at air temperature. In two flasks the air introduced was ordinary atmospheric air, and in these flasks fermentation set in after about four to six weeks. Into the other two flasks air which had been heated was led, and in these no fermentation occurred. As described, the experiment is quite satisfactory, but Schwann found on repetition that the results were irregular. Sometimes all the flasks showed fermentation, sometimes none of them. This was correctly ascribed to the experimental difficulties, but none [p007] the less served as a point of attack for hostile and damaging criticism at the hands of Berzelius (p. 8).

The origin of putrefaction was definitely attributed by Schwann to the presence of living germs in the air, and the similarity of the result obtained with yeast suggested the idea that alcoholic fermentation was also brought about by a living organism, a conception which was at once confirmed by a microscopical examination of a fermenting liquid. The phenomena observed under the microscope were similar to those noted by Cagniard-Latour, and in accordance with these observations alcoholic fermentation was attributed to the development of a living organism, the fermentative function of which was found to be destroyed by potassium arsenite and not by extract of Nux vomica, so that the organism was regarded rather as of vegetable than of animal nature. This plant received the name of "Zuckerpilz" or sugar fungus (which has been perpetuated in the generic term Saccharomyces). Alcoholic fermentation was explained as "the decomposition brought about by this sugar fungus removing from the sugar and a nitrogenous substance the materials necessary for its growth and nourishment, whilst the remaining elements of these compounds, which were not taken up by the plant, combined chiefly to form alcohol".

Kützing's memoir, the third of the trio [1837], also dates from 1837, and his opinions, like those of Cagniard-Latour, are founded on microscopical observations. He recognises yeast as a vegetable organism and accurately describes its appearance. Alcoholic fermentation depends on the formation of yeast, which is produced when the necessary elements and the proper conditions are present and then propagates itself. The action on the liquid thus increases and the constituents not required to form the organism combine to form unorganised substances, the carbonic acid and alcohol. "It is obvious," says Kützing, in a passage which roused the sarcasm of Berzelius, "that chemists must now strike yeast off the roll of chemical compounds, since it is not a compound but an organised body, an organism."

These three papers, which were published almost simultaneously, were received at first with incredulity. Berzelius, at that time the arbiter and dictator of the chemical world, reviewed them all in his "Jahresbericht" for 1839 [1839] with impartial scorn. The microscopical evidence was denied all value, and yeast was no more to be regarded as an organism than was a precipitate of alumina. Schwann's experiment (p. 6) was criticised on the ground that the fermenting power of the added yeast had been only partially destroyed in the [p008] flasks in which fermentation ensued, completely in those which remained unchanged, the admission of heated or unheated air being indifferent, a criticism to some extent justified by Schwann's statement, already quoted, of the uncertain result of the experiment.

Berzelius himself regarded fermentation as being brought about by the yeast by virtue of that catalytic force, which he had supposed to intervene in so many reactions, both between substances of mineral and of animal and vegetable origin [1836], and which enabled "bodies, by their mere presence, and not by their affinity, to arouse affinities ordinarily quiescent at the temperature of the experiment, so that the elements of a compound body arrange themselves in some different way, by which a greater degree of electro-chemical neutralisation is attained".

To the scorn of Berzelius was soon added the sarcasm of Wöhler and Liebig [1839, 1839]. Stimulated in part by the publications of the three authors already mentioned, and in part by the report of Turpin [1838], who at the request of the Academy of Sciences had satisfied himself by observation of the accuracy of Cagniard-Latour's conclusions, Wöhler prepared an elaborate skit on the subject, which he sent to Liebig, to whom it appealed so strongly that he added some touches of his own and published it in the "Annalen," following immediately upon a translation of Turpin's paper. Yeast was here described with a considerable degree of anatomical realism as consisting of eggs which developed into minute animals, shaped like a distilling apparatus, by which the sugar was taken in as food and digested into carbonic acid and alcohol, which were separately excreted, the whole process being easily followed under the miscroscope.

Close upon this pleasantry followed a serious and important communication from Liebig [1839], in which the nature of fermentation, putrefaction, and decay was exhaustively discussed. Liebig did not admit that these phenomena were caused by living organisms, nor did he attribute them like Berzelius to the catalytic action of a substance which itself survived the reaction unchanged. As regards alcoholic fermentation, Liebig's chief arguments may be briefly summarised. As the result of alcoholic fermentation, the whole of the carbon of the sugar reappears in the alcohol and carbon dioxide formed. This change is brought about by a body termed the ferment, which is formed as the result of a change set up by the access of air to plant juices containing sugar, and which contains all the nitrogen of the nitrogenous constituents of the juice. This ferment is a substance remarkably susceptible of change, which undergoes an uninterrupted and progressive metamorphosis, of [p009] the nature of putrefaction or decay, and produces the fermentation of the sugar as a consequence of the transformation which it is itself undergoing.

The decomposition of the sugar is therefore due to a condition of instability transferred to it from the unstable and changing ferment, and only continues so long as the decomposition of the ferment proceeds. This communication of instability from one substance undergoing chemical change to another is the basis of Liebig's conception, and is illustrated by a number of chemical analogies, one of which will suffice to explain his meaning. Platinum is itself incapable of decomposing nitric acid and dissolving in it; silver, on the other hand, possesses this power. When platinum is alloyed with silver, the whole mass dissolves in nitric acid, the power possessed by the silver being transferred to the platinum. In like manner the condition of active decomposition of the ferment is transferred to the sugar, which by itself is quite stable. The central idea is that of Stahl (p. 2) which was thus reintroduced into scientific thought.

In a pure sugar solution the decomposition of the ferment soon comes to an end and fermentation then ceases. In beer wort or vegetable juices, on the other hand, more ferment is continually formed in the manner already described from the nitrogenous constituents of the juice, and hence the sugar is completely fermented away and unexhausted ferment left behind. Liebig's views were reiterated in his celebrated "Chemische Briefe," and became the generally accepted doctrine of chemists. There seems little doubt that both Berzelius and Liebig in their scornful rejection of the results of Cagniard-Latour, Schwann and Kützing, were influenced, perhaps almost unconsciously, by a desire to avoid seeing an important chemical change relegated to the domain of that vital force from beneath the sway of which a large part of organic chemistry had just been rescued by Wöhler's brilliant synthetical production of urea and by the less recognised synthesis of alcohol by Hennell (see on this point Ahrens [1902]). A strong body of evidence, however, gradually accumulated in favour of the vegetable nature of yeast, so that it may be said that by 1848 a powerful minority adhered to the views of Cagniard-Latour, Schwann, and Kützing [see Schrohe, 1904, p. 218, and compare Buchner, 1904]. Among these must be included Berzelius [1848], who had so forcibly repudiated the idea only ten years before, whereas Liebig in the 1851 edition of his letters does not mention the fact that yeast is a living organism (Letter XV).

The recognition of the vegetable nature of yeast, however, by no [p010] means disproved Liebig's view of the nature of the change by which sugar was converted into carbon dioxide and alcohol, as was carefully pointed out by Schlossberger [1844] in a research on the nature of yeast, carried out in Liebig's laboratory but without decisive results.

Mitscherlich was also convinced of the vegetable character of yeast, and showed [1841] that when yeast was placed in a glass tube closed by parchment and plunged into sugar solution, the sugar entered the glass tube and was there fermented, but was not fermented outside the tube. He regarded this as a proof that fermentation only occurred at the surface of the yeast cells, and explained the process by contact action in the sense of the catalytic action of Berzelius, rather than by Liebig's transference of molecular instability. Similar results were obtained with an animal membrane by Helmholtz [1843], who also expressed his conviction that yeast was a vegetable organism.

In 1854 Schröder and von Dusch [1854, 1859, 1861] strongly reinforced the evidence in favour of this view by succeeding in preventing the putrefaction and fermentation of many boiled organic liquids by the simple process of filtering all air which had access to them through cotton-wool. These experiments, which were continued until 1861, led to the conclusion that the spontaneous alcoholic fermentation of liquids was due to living germs carried by the air, and that when the air was passed through the cotton-wool these germs were held back.

At the middle of the nineteenth century opinions with regard to alcoholic fermentation, notwithstanding all that had been done, were still divided. On the one hand Liebig's theory of fermentation was widely held and taught. Gerhardt, for example, as late as 1856 in the article on fermentation in his treatise on organic chemistry [1856], gives entire support to Liebig's views, and his treatment of the matter affords an interesting glimpse of the arguments which were then held to be decisive. The grounds on which he rejects the conclusions of Schwann and the other investigators who shared the belief in the vegetable nature of yeast are that, although in some cases animal and vegetable matter and infusions can be preserved from change by the methods described by these authors, in others they cannot, a striking case being that of milk, which even after being boiled becomes sour even in filtered air, and this without showing any trace of living organisms. The action of heat, sulphuric acid, and filtration on the air is to remove, or destroy, not living organisms but particles of decomposing matter, that is to say, ferments which would add their activity to that of the oxygen of the air. Moreover, many ferments, as for example diastase, act without [p011] producing any insoluble deposit whatever which can be regarded as an organism.

"Evidemment," he concludes, "la théorie de M. Liebig explique seule tous les phénomènes de la manière la plus complète et la plus logique; c'est à elle que tous les bons esprits ne peuvent manquer de se rallier."

On the other hand it was held by many to have been shown that Liebig's view of the origin of yeast by the action of the air on a vegetable infusion was erroneous, and that fermentation only arose when the air transferred to the liquid an active agent which could be removed from it by sulphuric acid (Schulze), by heat (Schwann), and by cotton-wool (Schröder and von Dusch). Accompanying alcoholic fermentation there was a development of a living organism, the yeast, and fermentation was believed, without any very strict proof, to be a phenomenon due to the life and vegetation of this organism. This doctrine seems indeed [Schrohe, 1904] to have been widely taught in Germany from 1840–56, and to have established itself in the practice of the fermentation industries.

In 1857 commenced the classical researches of Pasteur which finally decided the question as to the origin and functions of yeast and led him to the conclusion that "alcoholic fermentation is an act correlated with the life and organisation of the yeast cells, not with the death or putrefaction of the cells, any more than it is a phenomenon of contact, in which case the transformation of sugar would be accomplished in presence of the ferment without yielding up to it or taking from it anything" [1860]. It is impossible here to enter in detail into Pasteur's experiments on this subject, or indeed to do more than indicate the general lines of his investigation. His starting-point was the lactic acid fermentation.

The organism to which this change was due had hitherto escaped detection, and as we have seen the spontaneous lactic fermentation of milk was one of the phenomena adduced by Gerhardt (p. 10) in favour of Liebig's views. Pasteur [1857] discovered the lactic acid producing organism and convinced himself that it was in fact a living organism and the active cause of the production of lactic acid. One of the chief buttresses of Liebig's theory was thus removed, and Pasteur next proceeded to apply the same method and reasoning to alcoholic fermentation. Liebig's theory of the origin of yeast by the action of the oxygen of the air on the nitrogenous matter of the fermentable liquid was conclusively and strikingly disproved by the brilliant device of producing a crop of yeast in a liquid medium containing only comparatively [p012] simple substances of known composition—sugar, ammonium tartrate and mineral phosphate. Here there was obviously present in the original medium no matter which could be put into a state of putrefaction by contact with oxygen and extend its instability to the sugar. Any such material must first be formed by the vital processes of the yeast. In the next place Pasteur showed by careful analyses and estimations that, whenever fermentation occurred, growth and multiplication of yeast accompanied the phenomenon. The sugar, he proved, was not completely decomposed into carbon dioxide and alcohol, as had been assumed by Liebig (p. 8). A balance-sheet of materials and products was constructed which showed that the alcohol and carbon dioxide formed amounted only to about 95 per cent. of the invert sugar fermented, the difference being made up by glycerol, succinic acid, cellulose, and other substances [1860, p. 347]. In every case of fermentation, even when a paste of yeast was added to a solution of pure cane sugar in water, the yeast was found by quantitative measurements to have taken something from the sugar. This "something" was indeterminate in character, but, including the whole of the extractives which had passed from the yeast cells into the surrounding liquid, it amounted to as much as 1·63 per cent. of the weight of the sugar fermented [1860, p. 344].

Pasteur was therefore led to consider fermentation as a physiological process accompanying the life of the yeast. His conclusions were couched in unmistakable words: "The chemical act of fermentation is essentially a phenomenon correlative with a vital act, commencing and ceasing with the latter. I am of opinion that alcoholic fermentation never occurs without simultaneous organisation, development, multiplication of cells, or the continued life of cells already formed. The results expressed in this memoir seem to me to be completely opposed to the opinions of Liebig and Berzelius. If I am asked in what consists the chemical act whereby the sugar is decomposed and what is its real cause, I reply that I am completely ignorant of it.

"Ought we to say that the yeast feeds on sugar and excretes alcohol and carbonic acid? Or should we rather maintain that yeast in its development produces some substance of the nature of a pepsin, which acts upon the sugar and then disappears, for no such substance is found in fermented liquids? I have nothing to reply to these hypotheses. I neither admit them nor reject them, and wish only to restrain myself from going beyond the facts. And the facts tell me simply that all true fermentations are correlative with physiological phenomena."

Liebig felt to the full the weight of Pasteur's criticisms; his reply [p013] was long delayed [1870], and, according to his biographer, Volhard [1909], caused him much anxiety. In it he admits the vegetable nature of yeast, but does not regard Pasteur's conclusion as in any way a solution of the problem of the nature of alcoholic fermentation. Pasteur's "physiological act" is for Liebig the very phenomenon which requires explanation, and which he still maintains can be explained by his original theory of communicated instability. On some of Pasteur's results, notably the very important one of the cultivation of yeast in a synthetic medium, he casts grave doubt, whilst he explains the production of glycerol and succinic acid as due to independent reactions. The phenomenon of fermentation is still for him one which accompanies the decomposition of the constituents of the cell, rather than their building up by vegetative growth. "When the fungus ceases to grow, the bond which holds together the constituents of the cell contents is relaxed, and it is the motion which is thus set up in them which is the means by which the yeast cells are enabled to bring about a displacement or decomposition of the elements of sugar or other organic molecules." Pasteur replied in a brief and unanswerable note [1872]. All his attention was concentrated on the one question of the production of yeast in a synthetic medium, which he recognised as fundamental. The validity of this experiment he emphatically reaffirmed, and finally undertook, from materials supplied by Liebig himself, to produce as much yeast as could be reasonably desired. This challenge was never taken up, and this communication formed the last word of the controversy. Pasteur had at this time firmly established his thesis, no fermentation without life, both for alcoholic fermentation and for those other fermentations which are produced by bacteria, and had put upon a sound and permanent basis the conclusions drawn by Schulze, Cagniard-Latour, Schwann, and Kützing from their early experiments. It became generally recognised that putrefaction and other fermentative changes were due to specific organisms, which produced them in the exercise of their vital functions.

Pasteur subsequently [1875] came to the conclusion that fermentation was the result of life without oxygen, the cells being able, in the absence of free oxygen, to avail themselves of the energy liberated by the decomposition of substances containing combined oxygen. This view, which did not involve any alteration of Pasteur's original thesis but was an attempt to explain the physiological origin and function of fermentation, gave rise to a prolonged controversy, which cannot be further discussed in these pages. [p014]

Nevertheless, Liebig's desire to penetrate more deeply into the nature of the process of fermentation remained in many minds, and numerous endeavours were made to obtain further insight into the problem. In spite of an entire lack of direct experimental proof, the conception that alcoholic fermentation was due to the chemical action of some substance elaborated by the cell and not directly to the vital processes of the cell as a whole found strenuous supporters even among those who were convinced of the vegetable character of yeast. As early as 1833 diastase, discovered still earlier by Kirchhoff and Dubrunfaut, had been extracted by means of water from germinating barley and precipitated by alcohol as a white powder, the solution of which was capable of converting starch into sugar, but lost this power when heated [Payen and Persoz, 1833]. Basing his ideas in part upon the behaviour of this substance, Moritz Traube [1858] enunciated in the clearest possible manner the theory that all fermentations produced by living organisms are caused by ferments, which are definite chemical substances produced in the cells of the organism. He regarded these substances as being closely related to the proteins and considered that their function was to transfer the oxygen and hydrogen of water to different parts of the molecule of the fermentable substance and thus bring about that apparent intramolecular oxidation and reduction which is so characteristic of fermentative change and had arrested the attention of Lavoisier and, long after him, of Liebig.

Traube's main thesis, that fermentation is caused by definite ferments or enzymes, attracted much attention, and received fresh support from the separation of invertase in 1860 from an extract of yeast by Berthelot, and from the advocacy and authority of this great countryman of Pasteur, who definitely expressed his opinion that insoluble ferments existed which could not be separated from the tissues of the organism, and further, that the organism could not itself be regarded as the ferment, but only as the producer of the ferment [1857, 1860]. Hoppe-Seyler [1876] also supported the enzyme theory of fermentation, but differed in some respects from Traube as to the exact function of the ferment [see Traube, 1877; Hoppe-Seyler, 1877].

Direct experimental evidence was, however, still wanting, and Pasteur's reiterated assertion [1875] that all fermentation phenomena were manifestations of the life of the organism remained uncontroverted by experience.

Numerous and repeated direct experimental attacks had been made [p015] from time to time upon the problem of the existence of a fermentation enzyme, but all had yielded negative or unreliable results.

As early as 1846 a bold attempt had been made by Lüdersdorff [1846] to ascertain whether fermentation was or was not bound up with the life of the yeast by grinding yeast and examining the ground mass. A single gram of yeast was thoroughly ground, the process lasting for an hour, and the product was tested with sugar solution. Not a single bubble of gas was evolved. A similar result was obtained in a repetition of the experiment by Schmidt in Liebig's laboratory [1847], the grinding being continued in this case for six hours, but the natural conclusion that living yeast was essential for fermentation was not accepted, on the ground that during the lengthy process of trituration in contact with air the yeast had become altered and now no longer possessed the power of producing alcoholic fermentation, but instead had acquired that of changing sugar into lactic acid [see Gerhardt, 1856, p. 545].

Similar experiments made in 1871 by Marie von Manasseïn [1872, 1897], in which yeast was ground for six to fifteen hours with powdered rock crystal, yielded products which fermented sugar, but they contained unbroken yeast cells, so that the results obtained could not be considered decisive [Buchner and Rapp, 1898, 1], although Frau von Manasseïn herself drew from them and from others in which sugar solution was treated with heated yeast, but not under aseptic conditions, the conclusion that living yeast cells were not necessary for fermentation.

Quite unsuccessful were also the attempts made to accomplish the separation of fermentation from the living cell by Adolf Mayer [1879, p. 66], and, as we learn from Roux, by Pasteur himself, grinding, freezing, and plasmolysing the cells, having in his hands proved alike in vain. Extraction by glycerol or water, a method by which many enzymes can be obtained in solution, gave no better results [Nägeli and Loew, 1878], and the enzyme theory of alcoholic fermentation appeared quite unjustified by experiment.

Having convinced himself of this, Nägeli [1879] suggested a new explanation of the facts based on molecular-physical grounds. According to this view, which unites in itself some of the conceptions of Liebig, Pasteur, and Traube, fermentation is the transference of a state of motion from the molecules, atomic groups, and atoms of the compounds constituting the living plasma of the cell to the fermentable material, whereby the equilibrium existing in the molecules of the latter is disturbed and decomposition ensues [1879, p. 29]. [p016]

This somewhat complex idea, whilst including, as did Liebig's theory, Stahl's fundamental conception of a transmission of a state of motion, satisfies Pasteur's contention that fermentation cannot occur without life, and at the same time explains the specific action of different organisms by differences in the constitution of their cell contents. The really essential part of Nägeli's theory consisted in the limitation of the power of transference of molecular motion to the living plasma, by which the failure of all attempts to separate the power of fermentation from the living cell was explained. This was the special phenomenon which required explanation; to account for this the theory was devised, and when this was experimentally disproved, the theory lost all significance.

For nearly twenty years no further progress was made, and then in 1897 the question which had aroused so much discussion and conjecture, and had given rise to so much experimental work, was finally answered by Eduard Buchner, who succeeded in preparing from yeast a liquid which, in the complete absence of cells, was capable of effecting the resolution of sugar into carbon dioxide and alcohol [1897, 1].

In the light of this discovery the contribution to the truth made by each of the great protagonists in the prolonged discussion on the problem of alcoholic fermentation can be discerned with some degree of clearness. Liebig's main contention that fermentation was essentially a chemical act was correct, although his explanation of the nature of this act was inaccurate. Pasteur, in so far as he considered the act of fermentation as indissolubly connected with the life of the organism, was shown to be in error, but the function of the organism has only been restricted by a single stage, the active enzyme of alcoholic fermentation has so far only been observed as the product of the living cell. Nearest of all to the truth was Traube, who in 1858 enunciated the theorem, which was only proved for alcoholic fermentation in 1897, that all fermentations produced by living organisms are due to ferments secreted by the cells.

Buchner's discovery of zymase has introduced a new experimental method by means of which the problem of alcoholic fermentation can be attacked, and the result has been that since 1897 a considerable amount of information has been gained with regard to the nature and conditions of action of the enzymes of the yeast cell. It has been found that the machinery of fermentation is much more complex than had been surmised. The enzyme zymase, which is essential for fermentation, cannot of itself bring about the alcoholic fermentation of sugar, but is dependent on the presence of a second substance, termed, for [p017] want of a more reasonable name, the co-enzyme. The chemical nature and function of this mysterious coadjutor are still unknown, but as it withstands the temperature of boiling water and is dialysable, it is probably more simple in constitution than the enzyme. This, however, is not all; for the decomposition of sugar a phosphate is also indispensable. It appears that in yeast-juice, and therefore also most probably in the yeast cell, the phosphorus present takes an active part in fermentation and goes through a remarkable cycle of changes. The breakdown of sugar into alcohol and carbon dioxide is accompanied by the formation of a complex hexosephosphate, and the phosphate is split off from this compound and thus again rendered available for action by means of a special enzyme, termed hexosephosphatase. In addition to this complex of ferments, the cell also possesses special enzymes by which the zymase and the co-enzyme can be destroyed, and, further, at least one substance, known as an anti-enzyme, which directly checks this destructive action. It seems probable, moreover, that the decomposition of the sugar molecule takes place in stages, although much doubt yet exists as to the nature of these.

At the present moment the subject remains one of the most interesting in the whole field of biological chemistry, the limited degree of insight which has already been gained into the marvellous complexity of the cell lending additional zest to the attempt to penetrate the darkness which shrouds the still hidden mysteries.

The history of Buchner's discovery is of great interest [Gruber, 1908; Hahn, 1908]. As early as 1893 Hans and Eduard Buchner found that the cells of even the smallest micro-organism could be broken by being ground with sand [Buchner, E. and H., and Hahn, 1903, p. 20], and in 1896 the same process was applied by these two investigators to yeast, with the object of obtaining a preparation for therapeutic purposes. Difficulties arose in the separation of the cell contents from the ground-up mixture of cell membranes, unbroken cells, and sand, but these were overcome by carrying out the suggestion of Martin Hahn (at that time assistant to Hans Buchner) that kieselguhr should be added and the liquid squeezed out by means of a hydraulic press [Buchner, E. and H., and Hahn, 1903, p. 58]. The yeast-juice thus obtained was, in the first instance, employed for animal experiments, but underwent change very rapidly. The ordinary antiseptics were found to be unsuitable, and hence sugar was added as a preservative, and it was the marked action of the juice upon this added cane sugar that drew Eduard Buchner's attention to the fact that fermentation was proceeding in the absence of yeast-cells.

As in the case of so many discoveries, the new phenomenon was brought to light, apparently by chance, as the result of an investigation directed to quite other ends, but fortunately fell under the eye of an observer possessed of the genius which enabled him to realise its importance and give to it the true interpretation.

In his first papers [1897, 1, 2; 1898], Buchner established the following facts: (1) yeast-juice free from cells is capable of producing the alcoholic fermentation of glucose, fructose, cane sugar, and maltose; (2) the fermenting power of the juice is neither destroyed by the addition of chloroform, benzene, or sodium arsenite [Hans Buchner, 1897], by filtration through a Berkefeld filter, by evaporation to dryness at 30° to 35°, nor by precipitation with alcohol; (3) the fermenting power is completely destroyed when the liquid is heated to 50°. [p019]

From these facts he drew the conclusion "that the production of alcoholic fermentation does not require so complicated an apparatus as the yeast cell, and that the fermentative power of yeast-juice is due to the presence of a dissolved substance". To this active substance he gave the name of zymase.

Buchner's discovery was not received without some hesitation. A number of investigators prepared yeast-juice, but failed to obtain an active product [Will, 1897; Delbrück, 1897; Martin and Chapman, 1898; Reynolds Green, 1897; Lintner, 1899]. A more accurate knowledge of the necessary conditions and of the properties of yeast-juice, however, led to more successful results [Will, 1898; Reynolds Green, 1898; Lange, 1898], and it was soon established that, given suitable yeast, an active preparation could be readily procured by Buchner's method. Criticism was then directed to the effect of the admitted presence of a certain number of micro-organisms in yeast-juice [Stavenhagen, 1897], but Buchner [Buchner and Rapp, 1897] was able to show by experiments in the presence of antiseptics and with juice filtered through a Chamberland candle that the fermentation was not due to living organisms of any kind.

The most weighty criticism of Buchner's conclusion consisted in an attempt to show that the properties of yeast-juice might be due to the presence, suspended in it, of fragments of living protoplasm, which, although severed from their original surroundings in the cell, might retain for some time the power of producing alcoholic fermentation. This, it will be seen, was an endeavour to extend Nägeli's theory to include in it the newly discovered fact.

In favour of this view were adduced the similarity between the effects of many antiseptics on living yeast and on the juice, the ephemeral nature of the fermenting agent present in the juice, the effect of dilution with water, and the phenomenon of autofermentation which is exhibited by the juice in the absence of added sugar [Abeles, 1898; v. Kupffer, 1897; v. Voit, 1897; Wehmer, 1898; Neumeister, 1897; Macfadyen, Morris, and Rowland, 1900; Bokorny, 1906; Fischer, 1903; Beijerinck, 1897, 1900; Wroblewski, 1899, 1901].

A brief general description of the actual properties of yeast-juice and of the phenomena of fermentation by its means is sufficient to show the great improbability of this view.

The juice prepared by Buchner's method forms a somewhat viscous opalescent brownish-yellow liquid, which is usually faintly acid in reaction [compare Ahrens, 1900] and almost optically inactive. It has a specific gravity of 1·03 to 1·06, contains 8·5 to 14 per cent. [p020] of dissolved solids, and leaves an ash amounting to 1·4 to 2 per cent. About 0·7 to 1·7 per cent. of nitrogen is present, nearly all in the form of protein, which coagulates to a thick white mass when the juice is heated.

A powerful digestive enzyme of the type of trypsin is also present, so that when the juice is preserved its albumin undergoes digestion at a rate which depends on the temperature [Hahn, 1898; Geret and Hahn, 1898, 1, 2; 1900; Buchner, E. and H., and Hahn, 1903, pp. 287–340], and is converted into a mixture of bases and amino-acids. After about six days at 37°, or 10 to 14 days at the ordinary temperature, the digestion is so complete that no coagulation occurs when the juice is boiled. As this proteoclastic enzyme, like the alcoholic enzyme, cannot be extracted from the living cells, it is termed yeast endotrypsin or endotryptase. Fresh yeast-juice produces a slow fermentation of sugar, which lasts for forty-eight to ninety-six hours at 25° to 30°, about a week at the ordinary temperature, and then ceases, owing, not to exhaustion of the sugar, but to the disappearance of the fermenting agent. When the juice is preserved or incubated in the absence of a fermentable sugar this disappearance occurs considerably sooner, so that even after standing for a single day at room temperature, or two days at 0°, no fermentation may occur when sugar is added. The reason for this behaviour has not been definitely ascertained. As will be seen later on (p. 64) the phenomenon is a complex one, but the disappearance of the enzyme was originally ascribed by Buchner to the digestive action upon it of the endotrypsin of the juice [1897, 2], and no better explanation has yet been found. Confirmation of this view is afforded by the fact that the addition of a tryptic enzyme of animal origin greatly hastens the disappearance of the alcoholic enzyme [Buchner, E. and H., and Hahn, 1903, p. 126], and that some substances which hinder the tryptic action favour fermentation [Harden, 1903]. The amount of fermentation produced is almost unaffected by the presence of such antiseptics as chloroform or toluene, although some others, such as arsenites and fluorides, decrease it when added in comparatively high concentrations, and it is only slightly diminished by dilution with three or four volumes of sugar solution, somewhat more considerably by dilution with water. When it is filtered through a Chamberland filter the first portions of the filtrate are capable of bringing about fermentation, but the fermenting power diminishes in the succeeding portions and finally disappears. The juice can be spun in a centrifugal machine without being in any way altered, and no separation into more or less active layers takes place under these conditions. [p021]

The amorphous powder obtained by drying the precipitate produced when the juice is added to a mixture of alcohol and ether is also capable of producing fermentation, and the process of precipitation may be repeated without seriously diminishing the fermenting power of the product.

These facts clearly show that the various phenomena adduced by the supporters of the theory of protoplasmic fragments are quite consistent with the presence of a dissolved enzyme as the active agent of the juice, and at the same time that the properties demanded of the living fragments of protoplasm to which fermentation is ascribed are such as cannot be reconciled with our knowledge of living matter. If living protoplasm is the cause of alcoholic fermentation by yeast-juice, a new conception of life will be necessary; the properties of the postulated fragments of protoplasm must be so different from those which the protoplasm of the living cell possesses as to deprive the theory of all real value [Buchner, 1900, 2; Buchner, E. and H., and Hahn, 1903, p. 33].

Further and very convincing evidence against the protoplasm theory is afforded by the behaviour of yeast towards various desiccating agents. When yeast is dried at the ordinary temperature it retains its vitality for a considerable period. If, however, the dried yeast be heated for six hours at 100° it loses the power of growth and reproduction but still retains that of fermenting sugar, and when ground with sand, kieselguhr and 10 per cent. glycerol solution yields an active juice [Buchner, 1897, 2; 1900, 1]. Preparations (known as zymin) obtained by treating yeast with a mixture of alcohol and ether [Albert, 1900, 1901, 1], or with acetone and ether [Albert, Buchner, and Rapp, 1902], show precisely similar properties (p. 38). The proof in this case has been carried a step further, for the active juice obtained by grinding such acetone-yeast, when precipitated with alcohol and ether, yields an amorphous powder, still capable of fermenting sugar.

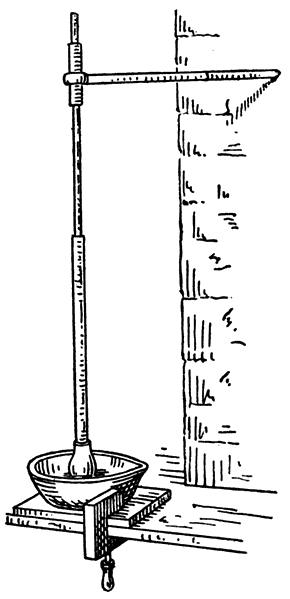

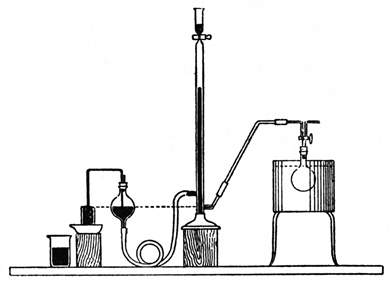

Buchner's process for the preparation of active yeast-juice is characterised by extreme simplicity. The yeast employed, which should be fresh brewery yeast, is washed two or three times by being suspended in a large amount of water and allowed to settle in deep vessels. It is then collected on a filter cloth, wrapped in a press cloth, and submitted to a pressure of about 50 kilos, per sq. cm. for five minutes. The resulting friable mass contains about 70 per cent. of water and is free from adhering wort. The washed yeast is then [p022] mixed with an equal weight of silver sand and 0·2 to 0·3 parts of kieselguhr, care being taken that this is free from acid. The correct amount of kieselguhr to be added can only be ascertained by experience, and varies with different samples of yeast. The dry powder thus obtained is brought in portions of 300 to 400 grams into a large porcelain mortar and ground by hand by means of a porcelain pestle fastened to a long iron rod which passes through a ring fixed in the wall (Fig. 1). The mortar used by Buchner has a diameter of 40 cm. and the pestle and rod together weigh 8 kilos.

As the grinding proceeds the light-coloured powder gradually darkens and becomes brown, and the mass becomes moist and adheres to the pestle, until finally, after two to three minutes' grinding, it takes the consistency of dough, at which stage the process is stopped. The mass is next enveloped in a press cloth and submitted to a pressure of 90 kilos, per sq. cm. in a hydraulic hand press, the pressure being very gradually raised in order to avoid rupture of the cloth. The cloth required for 1000 grams of yeast measures 60 by 75 cm. and is previously soaked in water and then submitted to a pressure of 50 kilos, per sq. cm., retaining about 35 to 40 c.c. of water.

The juice runs from the press on to a folded filter paper, to remove kieselguhr and yeast cells, and passes into a vessel standing in ice water.

The yield of juice obtained by Buchner in an operation of this kind from 1 kilo. of yeast amounts to 320 to 460 c.c. It may be increased by re-grinding the press cake and again submitting it to pressure, and then amounts on the average to 450 to 500 c.c.

Since the cell membranes constitute about 20 per cent. of the weight of the dry yeast, this yield corresponds to more than 60 per cent. of the total cell contents of the yeast. It has been computed by Will [quoted by Buchner, E. and H., and Hahn, 1903, p. 66] that [p023] only about 20 per cent. of the cells are left unaltered by one grinding and pressing, and only 4 per cent. after a repetition of the process, at least 57 per cent. of the cells being actually ruptured by the double process, and the remainder to some extent altered. It seems probable from these figures that a certain amount of the juice may be derived from the unbroken cells, and Will expressly states that many unbroken cells have lost their vacuoles.

If the yeast be submitted to a process of regeneration, which consists in exposure to a well-aerated solution of sugar and mineral salts until fermentation is complete, the juice subsequently obtained [p024] is more active than that yielded by the original yeast [Albert, 1899, 1].

A modified method of grinding yeast was introduced by Macfadyen, Morris, and Rowland [1900], who placed a mixture of yeast and sand in a jacketed and cooled vessel, in which a spindle carrying brass flanges was rapidly rotated [Rowland, 1901]. One kilo. of yeast ground in this way for 3·5 hours yielded 350 c.c. of juice.

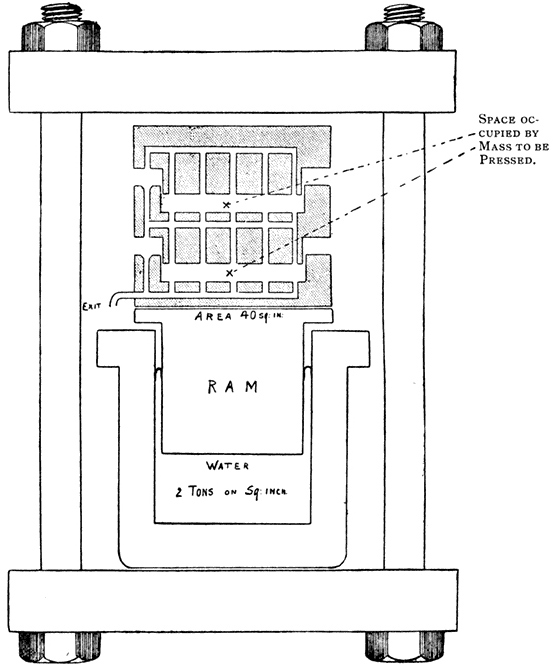

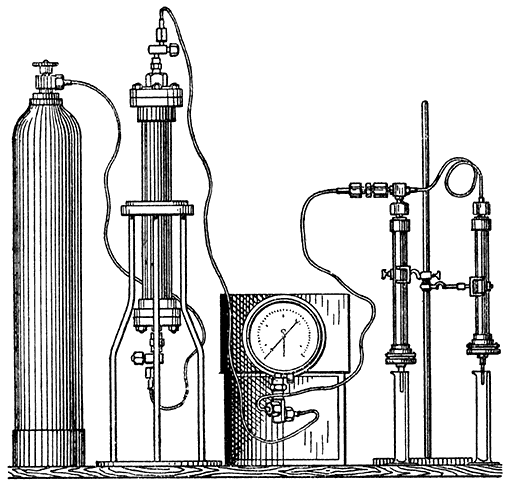

This grinding process was at first adopted by Harden and Young in their experiments but was afterwards abandoned in favour of Buchner's hand-grinding process, as it was found liable to yield juices of low fermenting power, probably on account of inefficient cooling during the grinding process. A slight modification of Buchner's process has, however, been introduced, the hand-ground mass being mixed with a further quantity of kieselguhr until a nearly dry powder is formed, and the mass packed between two layers of chain cloth in steel filter plates and pressed out in a hydraulic press at about 2 tons to the square inch (300 kilos. per sq. cm.). The press and plates are shown in section in Fig. 2. It has also been found convenient to remove yeast cells and kieselguhr from the freshly pressed juice by centrifugalisation instead of by filtration through paper, and to wash the yeast before grinding by means of a filter-press.

Working with English top yeasts Harden and Young have found the yield of juice extremely variable, the general rule being that the amount of juice obtainable from freshly skimmed yeast is smaller than that yielded by the same yeast after standing for a day or two after being skimmed. The yield for 1000 grams of pressed brewer's yeast varies from 150 to 375 c.c., and is on the average about 250 c.c.

Very fresh yeast occasionally presents the peculiar phenomenon that scarcely any juice can be expressed from the ground mass, although the latter does not differ in appearance or consistency from a mass which gives a good yield.

A valuable addition to the methods of obtaining an active solution of zymase was made in 1911 by Lebedeff [1911, 2; 1912, 2; see also 1911, 3, 7, and 1912, 1]. This investigator had been in the habit of grinding dried yeast with water for preparing samples of yeast-juice of uniform character and observed that when the dried yeast was digested with sugar solution and the mixture heated, coagulation [p025] took place throughout the whole liquid, the proteins of the yeast having passed out of the cells. Further examination revealed the interesting fact that dried yeast readily yielded an active extract when macerated in water for some time. The quality of the resulting "maceration extract" depends on a considerable number of factors, the chief of which are: (1) the temperature of drying of the yeast; (2) the temperature of maceration; (3) the duration of maceration; and (4) the nature of the yeast, as well as, of course, the amount of water added in maceration.

In general the yeast should be dried at 25°–30° and then macerated with 3 parts of water for 2 hours at 35°.

The temperature of maceration may as a rule be varied, without detriment to the product provided that the time of maceration is also suitably altered; thus with dried Munich yeast, maceration for 4·5 hours at 25° is about as effective as 2 hours at 35°, whereas treatment for a shorter time at 25° or a longer time at 35° produces in general a less efficacious extract. Yeast dried at a lower temperature than 25° tends to yield an extract poor in co-enzyme (p. 59) and hence of low fermenting power, this being especially marked at air temperature.

The subsequent treatment of the yeast during maceration may, however, be of great influence in such cases. Thus a yeast dried at 15° gave by maceration at 25° for 4·5 hours a weak extract (yielding with excess of sugar 0·33g. CO2), whereas when macerated at 35° for 2 hours it yielded a normal extract (1·36g. CO2).

The nature of the yeast is of paramount importance. Thus while Munich (bottom) yeast usually gives a good result, a top yeast from a Paris brewery was found to yield extracts containing neither zymase nor its co-enzyme in whatever way the preparation was conducted. The existence of such yeasts is of great interest, and it was probably due to the unfortunate selection of such a yeast for his experiments that Pasteur was unable to prepare active fermenting extracts and therefore failed to anticipate Buchner by more than 30 years (see p. 15). The English top yeasts as a rule give poor results [see Dixon and Atkins, 1913] and sometimes yield totally inactive maceration extract. It is not understood why the enzyme passes out of the cell during the process of maceration and the whole method gives rise to a number of extremely interesting problems.

Method.—A suitable yeast is washed by decantation, filtered through a cloth, lightly pressed by means of a hand press, and then passed through a sieve of 5mm. mesh, spread out in a layer 1–1·5cm. thick and left at 25°–35° for two days. Fifty grams of the dried yeast is [p026] thoroughly and carefully mixed with 150 c.c. of water in a basin by means of a spatula and the whole digested for two hours at 35°. The mass often froths considerably. It is then filtered through ordinary folded filter paper, preferably in two portions, and collected in a vessel cooled by ice. The separation may also be effected by centrifuging or pressing out the mass, and the maceration may be conveniently conducted in a flask immersed in the water of a thermostat. It is not advisable to macerate more than 50 grams in one operation. Under these conditions 25–30 c.c. of extract are obtained after 20 minutes' filtration, 70–80 c.c. in twelve hours. Dried Munich yeast can be bought from Messrs. Schroder of Munich and serves as a convenient source of the extract.[1]

This extract closely resembles in properties the juice obtained by grinding the same yeast, but it is usually more active and contains more inorganic phosphate (see p. 46).

Attempts to prepare active extracts from undried yeast in an analogous manner have so far not been very successful. Thus Rinckleben [1911] found that plasmolysis by glycerol (8 per cent.) or sodium phosphate (5 per cent.) sometimes yielded an active juice and sometimes a juice which contained enzyme but no co-enzyme, but more often an inactive juice incapable of activation (p. 64) [see also Kayser, 1911].

Giglioli [1911] by the addition of chloroform also obtained an active liquid. It appears in fact as though almost any method of plasmolysing the yeast cell may yield a certain proportion of zymase in the exudate.

An ingenious process has been devised by Dixon and Atkins [1913] who applied the method of freezing in liquid air which they had found efficacious for obtaining the sap from various plant organs. They thus succeeded in obtaining from yeast, derived from Guinness' brewery in Dublin, liquids capable of fermenting sugar and of about the same efficacy as the maceration extracts prepared by Lebedeff's method from the same yeast. The results were, however, in both cases very low, the maximum total production of CO2 by 25 c.c. of liquid from excess of sugar being 32·5 c.c. (air temperature) or about 0·06g. Munich yeast on the other hand yields, either by maceration or grinding, a liquid giving as much as 1·5–2g. of CO2 per 25 c.c., whilst [p027] English yeast-juice prepared by grinding often gives as much as 0·5–0·7g. of CO2.

No direct comparison with the juice prepared by grinding was made by Dixon and Atkins, but it may be concluded from their results that the best method of obtaining an active preparation from the top yeasts used in this country is that of grinding. Maceration, freezing and plasmolysis alike yield poor results. With Munich yeast on the other hand the maceration process yields excellent results, whilst the liquid air process has not so far been tried.

In order to estimate the amount of carbon dioxide evolved in a given time and the total amount evolved by the action of yeast-juice on sugar, Buchner adopted an extremely simple method, which consisted in carrying out the fermentation in an Erlenmeyer flask provided with a small wash-bottle, which contained sulphuric acid and was closed by a Bunsen valve, and ascertaining the loss of weight during the experiment. Corrections are necessary for the carbon dioxide present in the original juice and retained in the liquid at the close of the experiment and for that present in the air space of the apparatus, but it was found that for most purposes these could be neglected. In cases in which greater accuracy was desired, the carbon dioxide was displaced by air before the weighings were made. A typical experiment of this kind, without displacement of carbon dioxide, is the following:—

| March 22, 1899, Berlin bottom yeast V. 20 c.c. juice + 8 grams cane sugar + 0·2 c.c. toluene as antiseptic at 16°. Grams of carbon dioxide after | ||||

|---|---|---|---|---|

| 24 | 48 | 72 | 96 hours. | |

| 0·40 | 0·64 | 0·99 | 1·11 | |

The total weight of carbon dioxide evolved under these conditions is termed the fermenting power of the juice (Buchner).

A more accurate method [Macfadyen, Morris, and Rowland, 1900] consists in passing the carbon dioxide into caustic soda solution and estimating it by titration. The yeast-juice, sugar, and antiseptic are placed in an Erlenmeyer flask provided with a straight glass tube, through which air can be passed over the surface of the liquid, and a conducting tube leading into a second flask which contains 50 c.c. of 10 per cent. caustic soda solution and is connected with the air by a guard tube containing soda lime. The juice can be freed from carbon dioxide by agitation in a current of air before the flask is connected to [p028] that containing the caustic soda solution, and at the end of the period of incubation air is passed through the apparatus, the liquid being boiled out if great accuracy is required. The absorption flask is then disconnected and the amount of absorbed carbon dioxide estimated by titration. This is carried out by making up the contents of the flask to 200 c.c., taking out an aliquot portion, rendering this exactly neutral to phenophthalein by the addition first of normal and finally of decinormal acid, adding methyl orange and titrating with decinormal acid to exact neutrality. Each c.c. of decinormal acid used in this last titration represents 0·0044 gram of carbon dioxide in the quantity of solution titrated.

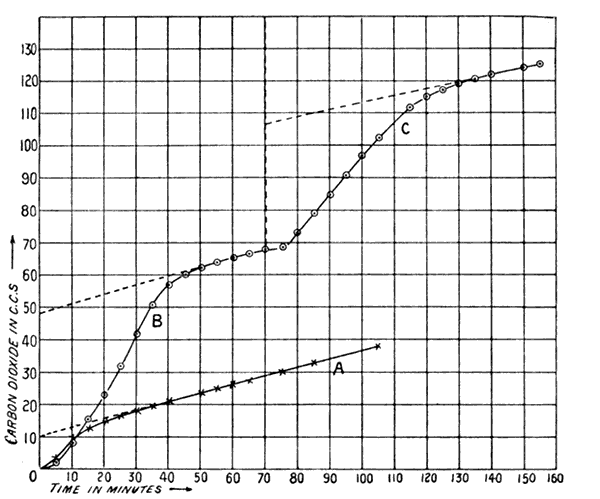

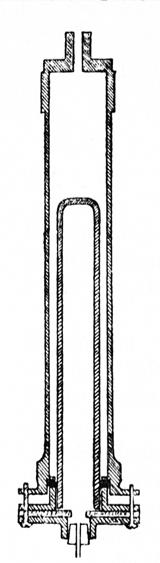

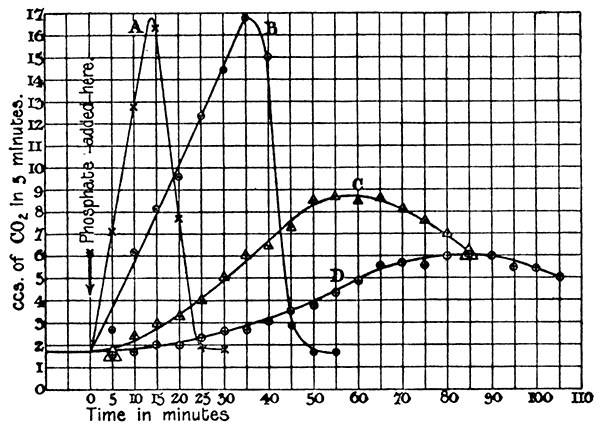

These methods are only suitable for observations at considerable intervals of time. For the continuous observation of the course of fermentation Harden, Thompson and Young [1910] connect the fermentation flask with a Schiff's azotometer filled with mercury and measure the volume of gas evolved, the liquid having been previously saturated with carbon dioxide (Fig. 3). The level of the mercury in the reservoir is kept constant by a syphon overflow, as shown in the figure, or, according to a modification introduced by S. G. Paine, by a specially constructed bottle provided with two tubulures near the bottom. This ensures that no change in the pressure in the flask occurs, and the volume of gas observed is reduced to normal pressure by means of a table. Before making a reading it is necessary to shake the fermenting mixture thoroughly, as the albuminous liquid very readily becomes greatly supersaturated with carbon dioxide, so much so in fact that very little gas is evolved in the intervals between the shakings. The exact procedure in making an observation consists in shaking the flask [p029] thoroughly, replacing in the thermostat, allowing to remain for one minute, and then reading the level of the mercury in the azotometer. After the required time, say five minutes, has elapsed from the time at which the flask was first shaken, it is again removed from the bath, shaken as before, replaced, allowed to remain for one minute and the reading then taken. In this way readings can be conveniently made at intervals of three or five minutes or even less, and much more detailed information obtained about the course of the reaction than is possible by means of observations made at intervals of several hours.

Another form of volumetric apparatus, designed by Walton [1904], has been used by Lebedeff [1909].

An apparatus on a different principle has been designed by Slator [1906] for use with living yeast, but is equally applicable to yeast-juice, and a very similar form has been more recently employed by Iwanoff [1909, 2]. In this apparatus the change of pressure produced by the evolution of carbon dioxide is measured at constant volume, and comparative rates of evolution can be obtained with considerable accuracy, although the method has the disadvantage that the absolute volume of gas evolved is not measured. The apparatus consists of a bottle or flask connected with a mercury manometer. The fermenting mixture is placed in the bottle along with glass beads to facilitate agitation, the pressure is reduced to a small amount by the water-pump, and the rise of pressure is then observed at intervals, this being proportional to the volume of gas produced. As in the preceding case, the liquid must be well shaken before a reading is made.

Yeast-juice brings about a slow fermentation of those sugars which are fermented by the yeast from which it is prepared as well as of dextrin, and of starch and glycogen, which are not fermented by living yeast.

Both in rate of fermentation and in the total fermentation produced, yeast-juice stands far behind the equivalent amount of living yeast. Taking 25 c.c. of yeast-juice to be equivalent to at least 36 grams of pressed yeast containing 70 per cent. of moisture, it is found that whereas the yeast-juice (from English top yeast) gives with glucose a maximum rate of fermentation of about 3 c.c. in five minutes, the living yeast ferments the sugar at the rate of about 126 c.c. in the same time, or [p030] about forty times as quickly. The total carbon dioxide obtainable from the yeast-juice, moreover, corresponds to the fermentation of only 2 to 3 grams of sugar, whilst the living yeast will readily ferment a much larger quantity, although the exact limit in this respect has not been accurately determined. The reasons for this great difference in behaviour will be discussed later on, after the various factors concerned in fermentation have been considered (p. 123).

In all cases of fermentation by yeast-juice and zymin, the relative amounts of carbon dioxide and alcohol produced are substantially in the ratio of the molecular weights of the compounds, that is as 44: 46, so that for 1 part of carbon dioxide 1·04 of alcohol are formed. This has been shown for the juice and zymin from bottom yeasts by Buchner [Buchner, E. and H., and Hahn, 1903, pp. 210, 211], who obtained the ratios 1·01, 0·98, 1·01, and 0·99 from experiments in which from 8 to 15 grams of alcohol were produced. Similar numbers, 0·90, 1·12, 0·95, 0·91 and 0·92, have been obtained for the juice from top yeasts by Harden and Young [1904], who worked with much smaller quantities. The variable results obtained with juice from top yeast by Macfadyen, Morris and Rowland [1900], have not been confirmed.

The construction of a balance-sheet between the sugar fermented and the products formed is of special interest in the case of alcoholic fermentation by yeast-juice, because, there being no cell growth as in the case of living yeast, an opportunity appears to be afforded of ascertaining whether the whole of the sugar is converted into alcohol and carbon dioxide, or whether some fraction of the sugar passes into any of the well-known subsidiary products of alcoholic fermentation by yeast, such as glycerol, fusel oil, or succinic acid. Unfortunately the question cannot be settled in this way. When the loss of sugar during the fermentation is estimated directly, it is usually found to be considerably greater than the sum of the alcohol and carbon dioxide produced from it. This fact was first observed by Macfadyen, Morris and Rowland [1900], and was then confirmed by Buchner [Buchner, E. and H., and Hahn, 1903, p. 212], in one instance, the excess of sugar lost over products being in this case about 15 per cent. of the total sugar which had disappeared. The matter was then more thoroughly investigated by Harden and Young [1904]. [p031]