The Project Gutenberg EBook of A Dictionary of Arts, Manufactures and Mines, by

Andrew Ure

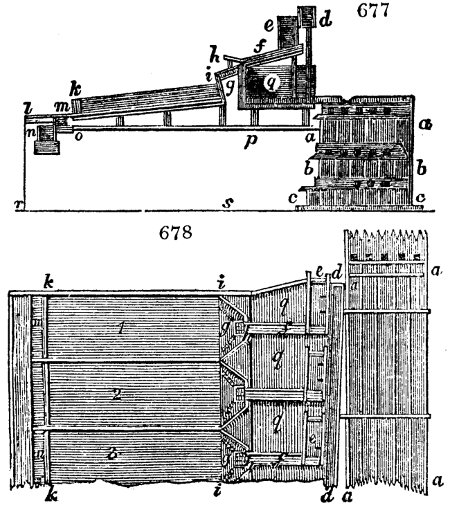

This eBook is for the use of anyone anywhere at no cost and with

almost no restrictions whatsoever. You may copy it, give it away or

re-use it under the terms of the Project Gutenberg License included

with this eBook or online at www.gutenberg.org

Title: A Dictionary of Arts, Manufactures and Mines

containing a clear exposition of their principles and practice

Author: Andrew Ure

Release Date: January 1, 2014 [EBook #44562]

Language: English

Character set encoding: ISO-8859-1

*** START OF THIS PROJECT GUTENBERG EBOOK DICTIONARY OF ARTS, MFRS, MINES ***

Produced by Malcolm Farmer, Harry Lamé and the Online

Distributed Proofreading Team at http://www.pgdp.net

A

DICTIONARY

OF

ARTS, MANUFACTURES,

AND

MINES:

CONTAINING

A CLEAR EXPOSITION

OF THEIR PRINCIPLES

AND PRACTICE.

BY

ANDREW URE, M.D.

F.R.S. M.G.S. M.A.S. LOND.; M. ACAD. N.S. PHILAD.; S. PH. SOC. N. GERM.

HANOV.; MULII. ETC. ETC.

ILLUSTRATED WITH TWELVE HUNDRED AND FORTY

ENGRAVINGS ON WOOD.

Second Edition.

LONDON:

PRINTED FOR

LONGMAN, ORME, BROWN, GREEN, & LONGMANS,

PATERNOSTER-ROW.

1840.

London:

Printed by A. Spottiswoode,

New-Street-Square.

[iii]

PREFACE.

It is the business of operative industry to produce, transform, and distribute

all such material objects as are suited to satisfy the wants of

mankind. The primary production of these objects is assigned to the

husbandman, the fisherman, and the miner; their transformation to the

manufacturer and artisan; and their distribution to the engineer, shipwright,

and sailor.[1] The unworked or raw materials are derived,—1.

from the organic processes of vegetables and animals, conducted

either without or with the fostering care of man; 2. from the boundless

stores of mineral and metallic wealth, arranged upon or within the

surface of the earth by the benignant Parent of our being, in the fittest

condition to exercise our physical and intellectual powers in turning

them to the uses of life.

The task which I have undertaken in the present work, is to describe

and explain the transformations of these primary materials, by mechanical

and chemical agencies, into general objects of exchangeable value;

leaving, on the one hand, to the mechanical engineer, that of investigating

the motive powers of transformation and transport; and, on the other

hand, to the handicraftsman, that of tracing their modifications into objects

of special or local demand. Contemplated in this view, an art or manufacture

may be defined to be that species of industry which effects a

certain change in a substance, to suit it for the general market, by combining

its parts in a new order and form, through mechanical or chemical

means. Iron will serve the purpose of illustrating the nature of the distinctions

here laid down, between mechanical engineering; arts and

manufactures; and handicraft trades. The engineer perforates the ground

with a shaft, or a drift, to the level of the ore, erects the pumps for

drainage, the ventilating, and hoisting apparatus, along with the requisite[iv]

steam or water power; he constructs the roads, the bridges, canals,

railways, harbours, docks, cranes, &c., subservient to the transport of the

ore and metal; he mounts the steam or water power, and bellows for

working the blast-furnaces, the forges, and the cupolas; his principal

end and aim on all occasions being to overcome the forces of inertia,

gravity, and cohesion. The ores extracted and sorted by the miner,

and transported by the engineer to the smelting station, are there skilfully

blended by the iron-master (manufacturer), who treats them in a

furnace appropriately constructed, along with their due proportions of

flux and fuel, whereby he reduces them to cast iron of certain quality,

which he runs off at the right periods into rough pigs or regular

moulds; he then transforms this crude metal, by mechanical and chemical

agencies, into bar and plate iron of various sizes and shapes, fit for

the general market; he finally converts the best of the bars into steel,

by the cementation furnace, the forge, and the tilt-hammer; or the best

of the plates into tin-plate. When farther worked by definite and

nearly uniform processes into objects of very general demand in all

civilized countries, these iron and steel bars still belong to the domain

of manufactures; as, for example, when made into anchors, chain-cables,

files, nails, needles, wire, &c.; but when the iron is fashioned,

into ever varying and capricious forms, they belong either to the

general business of the founder and cutler, or to the particular calling

of some handicraft, as the locksmith, gratesmith, coachsmith, gunsmith,

tinman, &c.

Such are the principles which have served to guide me in selecting

articles for the present volume. By them, as a clue, I have endeavoured

to hold a steady course through the vast and otherwise perplexing labyrinth

of arts, manufactures, and mines; avoiding alike engineering and

mechanical arts, which cause no change in the texture or constitution of

matter,—and handicraft operations, which are multiform, capricious, and

hardly susceptible of scientific investigation. In fact, had such topics

been introduced into the volume, it would have presented a miscellaneous

farrago of incongruous articles, too numerous to allow of their being

expounded in a manner either interesting or instructive to the manufacturer

and the metallurgist. I readily acknowledge, however, that I have

not been able to adhere always so rigorously as I could have wished to

the above rule of selection; having been constrained by intelligent and

influential friends to introduce a few articles which I would gladly have

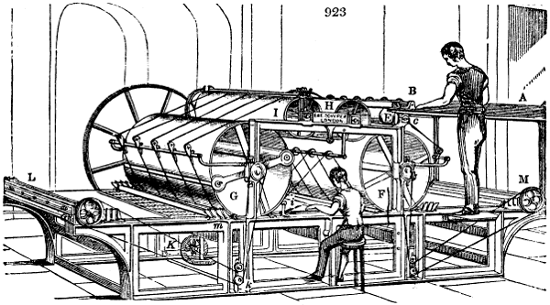

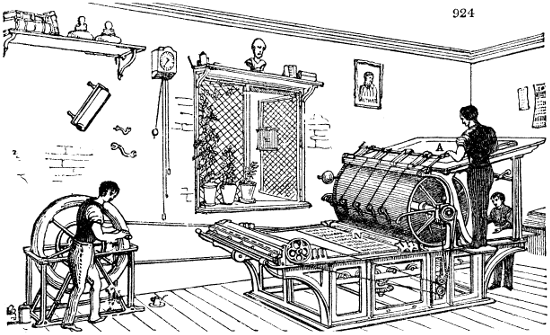

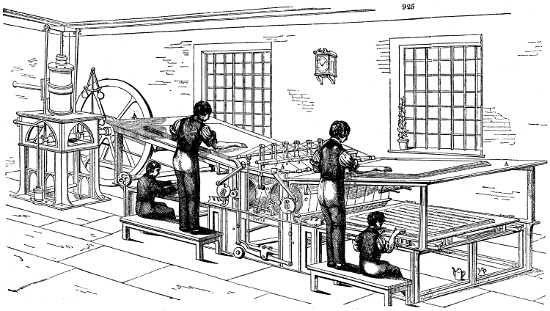

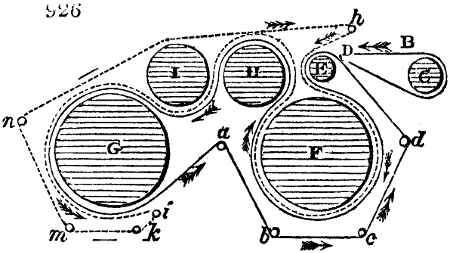

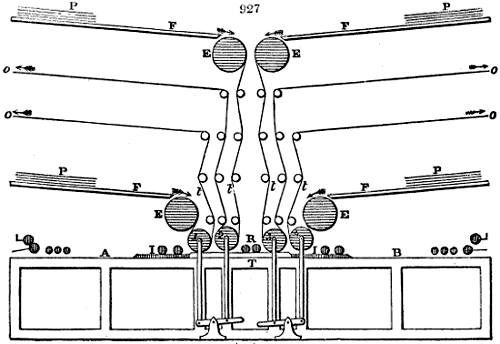

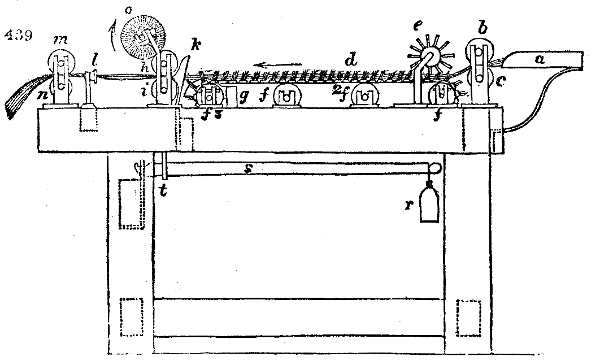

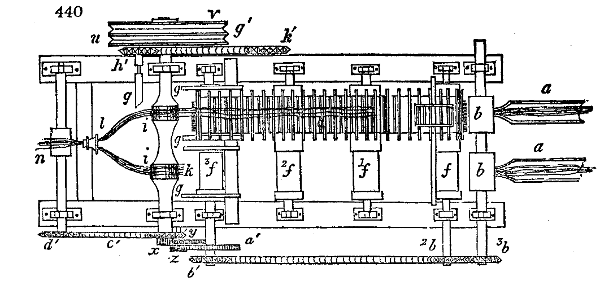

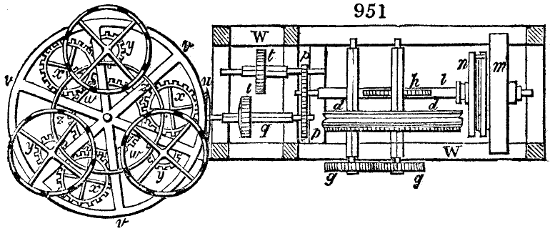

left to the mechanical engineer. Of these Printing is one, which, having

had no provision made for it in my original plan, was too hastily

compiled to admit of my describing, with suitable figures, the flat-printing

automatic machine of Mr. Spottiswoode, wherewith the pages of this

volume were worked off; a mechanism which I regard as the most

elegant, precise, and productive, hitherto employed to execute the best

style of letter press.

I have embodied in this work the results of my long experience as a

Professor of Practical Science. Since the year 1805, when I entered at

an early age upon the arduous task of conducting the schools of chemistry[v]

and manufactures in the Andersonian Institution, up to the

present day, I have been assiduously engaged in the study and improvement

of most of the chemical and many of the mechanical arts.

Consulted professionally by proprietors of factories, workshops, and

mines, of various descriptions, both in this country and abroad, concerning

derangements in their operations, or defects in their products, I have

enjoyed peculiar opportunities of becoming familiar with their minutest

details, and have frequently had the good fortune to rectify what was

amiss, or to supply what was wanting. Of the stores of information

thus acquired, I have availed myself on the present occasion; careful,

meanwhile, to neglect no means of knowledge which my extensive

intercourse with foreign nations affords.

I therefore humbly hope that this work will prove a valuable contribution

to the literature of science, serving—

In the first place, to instruct the Manufacturer, Metallurgist, and

Tradesman, in the principles of their respective processes, so as to render

them in reality the masters of their business, and to emancipate them

from a state of bondage to operatives, too commonly the slaves of blind

prejudice and vicious routine.

Secondly, to afford to Merchants, Brokers, Drysalters, Druggists, and

Officers of the Revenue, characteristic descriptions of the commodities

which pass through their hands.

Thirdly, by exhibiting some of the finest developments of chemistry

and physics, to lay open an excellent practical school to students of these

kindred sciences.

Fourthly, to teach Capitalists, who may be desirous of placing their

funds in some productive bank of industry, to select judiciously among

plausible claimants.

Fifthly, to enable Gentlemen of the Law to become well acquainted

with the nature of those patent schemes which are so apt to give rise to

litigation.

Sixthly, to present to our Legislators such a clear exposition of our

staple manufactures, as may dissuade them from enacting laws which

obstruct industry, or cherish one branch of it to the injury of many

others: and,

Lastly, to give the General Reader, intent chiefly on intellectual cultivation,

a view of many of the noblest achievements of science, in effecting

those grand transformations of matter to which Great Britain owes her

paramount wealth, rank, and power among the kingdoms.

The latest statistics of every important object of manufacture is given,

from the best, and, usually, from official authority, at the end of each

article.[2]

The following summary of our manufactures is extracted from

Mr. Macqueen’s General Statistics of the British Empire, published

in 1836. It shows the amount of capital embarked in the various[vi]

departments of manufacturing industry, and of the returns of that

capital:—

| |

Capital. |

Produce. |

| |

£ |

£ |

| Cotton |

manufactures |

40,973,872 |

52,513,586 |

| Woollen |

ditto |

36,000,000 |

44,250,000 |

| Silk |

ditto |

8,000,000 |

10,000,000 |

| Linen |

ditto |

12,000,000 |

15,421,186 |

| Leather |

ditto |

13,000,000 |

16,000,000 |

| Iron |

ditto, to making pig iron |

10,000,000 |

7,098,000 |

| Ditto, |

hardware, cutlery, &c. |

25,000,000 |

31,072,600 |

| Copper and brass |

3,600,000 |

4,673,186 |

| China, glass, &c. |

8,600,000 |

10,892,794 |

| Paper, furniture, books, &c. |

10,000,000 |

14,000,000 |

| Spirits (British), ales, soap, &c. |

37,600,000 |

47,163,847 |

| Sundries additional |

|

9,000,000 |

| Totals |

204,773,872 |

262,085,199 |

In consequence of an arrangement with Mr. William Newton,

patent agent, and proprietor of the London Journal of Arts, Sciences,

and Manufactures, I have been permitted to enrich this Dictionary

with many interesting descriptions and illustrative figures of modern

patent inventions and improvements, which I could not otherwise

have presented to my readers. Mr. Newton has lately enhanced the

value of his Journal by annexing to it a catalogue raisonnée, entitled

“An Analytical Index to the Subjects contained in the 23 Volumes,”

which constitute the first and second series. The subsequent 13 volumes,

of his Conjoined Series, are of still superior interest; and the whole form

a vast storehouse of Mechanical and Chemical Invention.

Although I am conscious of having used much diligence for many

years in collecting information for this work, from every quarter within

my reach, the utmost pains in preparing it for publication, and incessant

vigilance during its passage through the press, yet I am fully aware that

it must contain several errors and defects. These I shall study to

rectify, should the Public deem this volume worthy of a supplement.

In this hope, I earnestly solicit the suggestions of my readers; trusting

that ere long our Post Office system will cease to be such an obstacle

as it has long been to the collection and diffusion of useful knowledge,

and a tax upon science which the remuneration of its literature cannot

by any means bear.

Since this book is not a Methodical Treatise, but a Dictionary, one

extensive subject may be necessarily dispersed through many articles.

Thus, for example, information upon the manufacture of Colours will be

found under azure; black pigment; bone-black; bronze; brown dye;

calico-printing; carmine; carthamus; chromium; cochineal; crayons;

dyeing; enamels; gold; gilding; gamboge; gray dye; green dye;

green paints; indigo; kermes; lac dye; lakes; madder; massicot;

mercury, periodide of; Naples yellow; orange dye; orpiment; paints,

grinding of; ochres; paper-hangings; pastes; pearl white; Persian

berries; pottery pigments; Prussian blue; purple of Cassius; red lead;[vii]

rouge; Scheele’s green; Schweinfurth green; stained glass; terra di

Sienna; ultramarine; umber; verditer; vermilion; vitrifiable colours,

weld, white lead; woad; yellow, king’s.

A casual consulter of the Dictionary, who did not advert to this distribution,

might surmise it to be most deficient, where it is in reality

most copious.

The elaborate and costly Encyclopedias, and Dictionaries of Arts,

which have appeared from time to time in this country, and abroad,

have, for the most part, treated of the mechanical manufactures, more

fully and correctly than of the chemical. The operations of the former

are, in fact, tolerably obvious and accessible to the inspection of the

curious; nor are they difficult to transfer into a book, with the aid of a

draughtsman, even by a person but moderately versed in their principles.

But those of the latter are not unfrequently involved in complicated

manipulations, and depend, for their success, upon a delicate play of

affinities, not to be understood without an operative familiarity with the

processes themselves. Having enjoyed the best opportunities of studying

the chemical arts upon the greatest scale in this kingdom and on the

Continent, I may venture, without the imputation of arrogance, to claim

for my work, in this respect, more precision and copiousness than its

predecessors possess. I have gone as far in describing several curious

processes, hitherto veiled in mystery, as I felt warranted, without breach

of confidence, to go; regarding it as a sacred duty never to publish any

secret whatever, without the consent of its proprietor. During my

numerous tours through the factory districts of Great Britain, France,

&c., many suggestions, however, have been presented to my mind,

which I am quite at liberty to communicate in private, or carry into

execution, in other districts too remote to excite injurious competition

against the original inventors. I am also possessed of many plans

of constructing manufactories, of which the limits of this volume did

not permit me to avail myself, but which I am ready to furnish, upon

moderate terms, to proper applicants. I conclude by pointing attention

to the very insecure tenure by which patents for chemical or chemico-mechanical

inventions are held; of which there is hardly one on record

which may not be readily evaded by a person skilled in the resources of

practical chemistry, or which could stand the ordeal of a court of law

directed by an experienced chemist. The specifications of such patents

stand in need of a thorough reform; being for the most part not only

discreditable and delusive to the patentees, but calculated to involve them

in one of the greatest of evils—a chancery suit.

London:

13. Charlotte Street, Bedford Square,

March 1. 1839.

Dr. URE is preparing for publication, in one large volume, 8vo., Chemistry in

Theory and Practice; embodying a New System of Research, of such facility and

precision, as will enable chemical manufacturers of every class, medical practitioners,

metallurgists, farmers, merchants, brokers, druggists, drysalters, officers of the revenue,

as well as general students, to analyze their respective objects in much less time than

is usually required at present by professional chemists. A descriptive Index will be

annexed for converting this systematic work into a Dictionary of Chemical Science.

[1]

A

DICTIONARY

OF

ARTS, MANUFACTURES, AND MINES.

A.

ABB-WOOL. Among clothiers, this term signifies the woof or weft.

ACETATE. (Acétate, Fr.; Essigsäure, Germ.) Any saline compound of which

the acetic is the acid constituent; as acetate of soda, of iron, of copper, &c.

ACETATE OF ALUMINA, see Red Liquor and Mordant; of Copper, see

Copper; of Iron, see Iron; of Lead, see Lead; of Lime, see Pyrolignous Acid.

ACETIC ACID (Acide Acétique, Fr.; Essigsäure, Germ.) is the name of the sour

principle which exists in vinegar. It occurs, ready formed, in several products of

the vegetable kingdom, and is generated during the spontaneous fermentation of many

vegetable and animal juices. The sambucus nigra, or black elder, the phœnix dactilifera,

and the rhus typhinus are plants which afford a notable quantity of vinegar. It

is found, likewise, in the sweat, urine, milk, and stomach of animals. All infusions of

animal or vegetable matters in water, when exposed for some time to the air, at a moderate

temperature, ferment into vinegar; and most vegetables, when subjected to

decomposition by fire, give off condensable vapours of acetic acid. All liquids containing

alcohol are susceptible of passing into the state of vinegar; but the pre-existence

of alcohol is not necessary to this change, as we learn from the acetification of vegetable

soups, infusion of cabbage, starch—paste, &c.

Vinegar may be distinguished into four varieties, according to the mode of its production,

though all of them are capable of being converted, by chemical means, into

one identical acetic acid. 1. Wine vinegar. 2. Malt vinegar. 3. Sugar vinegar.

4. Wood vinegar, or pyrolignous acid. Fermentation is the source of the acid in the

first three varieties. Here alcohol is first generated, and is next converted into vinegar

by the influence of the air at a genial temperature; a change which will be investigated

under Fermentation. But the conversion of spirit of wine into acetic acid may be demonstrated

by direct experiment. When the vapour of alcohol is brought into contact

in the atmosphere with the black powder obtained by mixing muriate of platina, potash,

and alcohol, vinegar is rapidly formed at the expense of the alcohol. In Germany, where

crude alcohol bears a low price, the manufacture of vinegar has been arranged upon that

principle, which, as throwing some light on the process of acetification, I shall briefly

describe. See Platinum for the mode of preparing the above powder.

Under a large case, which for experimental purposes may be made of glass, several

saucer-shaped dishes of pottery or wood are to be placed in rows, upon shelves over

each other, a few inches apart. A portion of the black platina powder moistened being

suspended over each dish, let as much vinous spirits be put into them as the oxygen of

the included air shall be adequate to acidify. This quantity may be inferred from

the fact, that 1000 cubic inches of air can oxygenate 110 grains of absolute alcohol, converting

them into 122 grains of absolute acetic acid, and 641⁄2 grains of water.

The above simple apparatus is to be set in a light place (in sunshine, if convenient),

at a temperature of from 68° to 86° Fahr., and the evaporation of the alcohol is to be

promoted by hanging several leaves of porous paper in the case, with their bottom edges

dipped in the spirit. In the course of a few minutes, a most interesting phenomenon

will be perceived. The mutual action of the platina and the alcohol will be displayed

by an increase of temperature, and a generation of acid vapours, which, condensing on

the sides of the glass-case, trickle in streams to the bottom. This striking transformation

continues till all the oxygen of the air be consumed. If we wish, then, to renew

the process, we must open the case for a little, and replenish it with air. With a box

of 12 cubic feet in capacity, and with a provision of 7 or 8 ounces of the platina powder[2]

we can, in the course of a day, convert one pound of alcohol into pure acetic acid, fit for

every purpose, culinary or chemical. With from 20 to 30 pounds of the platina powder

(which does not waste), we may transform, daily, nearly 300 pounds of bad spirits into

the finest vinegar. Though our revenue laws preclude the adoption of this elegant

process upon the manufacturing scale in this country, it may be regarded as one of the

greatest triumphs of chemistry, where art has rivalled nature in one of her most mysterious

operations.

To readers acquainted with chemical symbols, the following numerical representation

of the conversion of alcohol into acetic acid may be acceptable:—

| 580·64 |

parts by weight |

of alcohol |

= |

H12 C4 O2 |

consist of |

| 74·88 |

|

of hydrogen |

= |

H12 |

| 305·76 |

|

of carbon |

= |

C4 |

| 200·00 |

|

of oxygen |

= |

O2 |

If we combine with this mixture, 400 parts of oxygen = O4, we have,—

| of water |

= |

337·44 |

= |

H6 O3 |

| acetic acid |

= |

643·20 |

= |

H6 C4 O3 |

Hence, in this formation of vinegar, 100 parts by weight of alcohol take 68·89 parts of

oxygen; and there are produced 58·11 parts of water, and 110·78 of acetic acid.

These beautiful experiments prove, that when in a mere mixture of alcohol and water,

under the influence of the atmospheric air and heat, some vinegar comes to be formed

after a considerable time, the same formation of vinegar takes place in a similar, but

more effective, manner, when a ferment is present, which acts here in a somewhat

analogous way to the platina powder in the preceding case. Several azotized substances

serve as re-agents towards the acetous fermentation,—such as vinegar ready-made,

vinegar-yeast, or lees, barley bread, leaven, beer barm, and similar vegetable

matters, which contain gluten. The best and purest ferment is, however, vinegar itself.

With this ferment we must conjoin, as an essential condition of acetification, the free

access of atmospheric air.

It is a well-known fact, that spirituous liquors, as weak brandy, wine, and beer, &c.,

may be preserved for years in close vessels, without undergoing the acetous fermentation,

even when they repose upon a layer of lees. It is equally well known, that these very

liquors, if they stand for some time in open vessels, become readily sour, especially if exposed,

also, to a somewhat high temperature. If we fill a flask with common brandy,

and subject it, without a stopper, to the influence of air and warmth, the contained

liquor may, at the end of many weeks, discover no sensible acidity: if we add to the

same brandy a ferment, and stop the flask air-tight, everything will still remain unchanged;

but if we leave a portion of air in the flask, or leave it uncorked, vinegar will

soon make its appearance in the brandy.

If we investigate the nature of the air which remains over brandy in the act of acetification,

we shall find that it consists entirely of carbonic acid and azote, the oxygen being

absorbed and combined in the acetic acid and water formed.

Since this absorption of oxygen from the air can take place only at the surface of the

fermenting liquors, we thus see the necessity and the practical importance of amplifying

that surface, in order to accelerate and complete the acetification, by multiplying the

points of contact between the alcohol and the oxygen. The essence of the new German

method of rapid acetification depends upon this principle.

Temperature has also a remarkable influence on the formation of vinegar. The acid

fermentation proceeds very feebly in the cold, but takes an accelerated pace as the heat

is raised. It would even appear that spirituous vapours brought by themselves in

contact with atmospheric air, without the aid of any ferment, are capable of being converted

into acetic acid, since it has happened in the rectification of brandy, in a still

furnished with a large capital and adopter pipe into which air was allowed to enter, that

vinegar made its appearance. Hence, warmth does not seem to act as a promoter of the

combination of alcohol with oxygen in a merely chemical point of view, but it acts, so to

speak, physically. Over the warm liquor a stratum of spirit vapour appears to float,

which, coming there into conflict with the atmospherical oxygen, probably causes the

generation of some acetic acid, and thus accelerates the operation, much more than by

the mere contact of the oxygen with the liquid surface.

When we expose any spirituous liquors, as wine, beer, &c., with the requisite

ferment, to the external air, at a temperature of from 64° to 68° Fahr., the fluid, however

clear before, becomes soon turbid; filamentous slimy particles begin to appear

moving in the middle and on the sides of the vessel, and then form a scum on the top of

the liquor. When this scum has acquired a certain thickness and consistence, it falls in

a sediment to the bottom. The Germans call it the vinegar mother, as it serves to excite

acetification in fresh liquors. Meanwhile, the liquor has become warmer than the surrounding[3]

air, and the vinegar process betrays itself by diffusing a peculiar aroma in the

apartment. Whenever all the alcohol present has been converted into acetic acid, the

liquor comes into a state of repose; its temperature sinks to the pitch of the atmosphere;

it becomes bright, and is the article well known by its taste and smell under the name

of vinegar.

Genuine wine or raisin vinegar differs from that formed either from apples, or sugar,

beer, &c., in containing wine-stone or tartar; by which peculiarity it may be distinguished,

except in those cases where crude tartar has been artificially added to the

other vinegars, as a disguise. Barley-malt vinegar contains some phosphoric acid, in

the state of phosphate of lime or magnesia, derived from the grain.

After these general observations upon acetification, we shall now proceed to describe

the processes for manufacturing vinegar on the commercial scale.

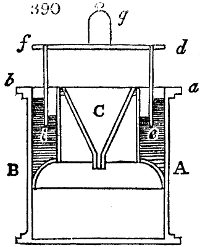

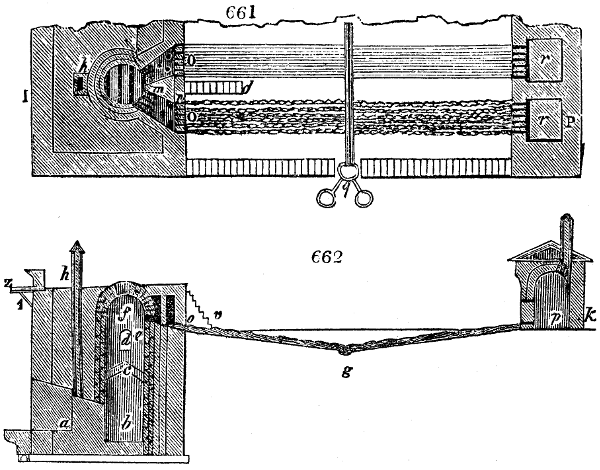

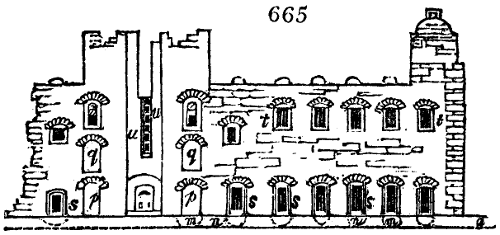

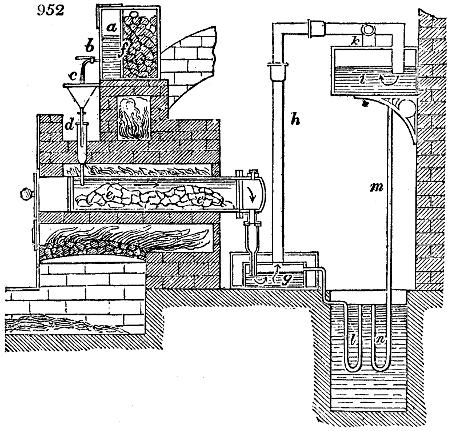

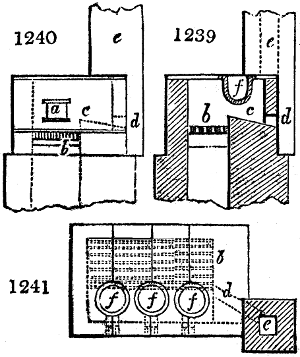

1. Wine vinegar.—The first consideration with a vinegar maker is a good fermenting

room, in which the wines may be exposed to a steady temperature, with an adequate

supply of atmospherical air. As this air is soon deprived of its oxygenous constituent,

facilities ought to be provided for a renewal of it by moderate ventilation. The air

holes for this purpose ought to be so contrived that they may be shut up when the

temperature begins to fall too low, or in windy weather. The best mode of communicating

the proper warmth to a chamber of this kind is by means of fire-flues or hot

water pipes, running along its floor at the sides and ends, as in a hothouse; the fireplace

being on the outside, so that no dust may be created by it within. The flue is best made

of bricks, and may have a cross section of 10 or 12 inches by 15 deep. The soot deposited,

even when coals are burned, will find ample space in the bottom of the flue, without

interfering essentially with the draught, for a very long period, if it be made of the

above dimensions. Low-roofed apartments are preferable to high ones; and those built

with thick walls, of imperfectly conducting materials, such as bricks, lined with lath

and plaster work. Should the chamber, however, have a high ceiling, the fermenting

tuns must be raised to a suitable height on scaffolding, so as to benefit by the warmest

air. Sometimes the vinegar vessels are placed at different levels; in which case the

upper ones acetify their contents much sooner than the under, unless they are emptied

and filled alternately, which is a good plan.

Orleans is the place most famous for vinegars. The building there destined to their

manufacture is called a vinaigrerie, and is placed, indifferently, either on the ground floor

or the floor above it; but it has always a southern exposure, to receive the influence

of the sunbeams. The vessels employed for carrying on the fermentation are casks,

called mothers. Formerly they were of a large capacity, containing about 460 litres

(115 gallons, Eng.); but at the present day they are barrels of half that capacity, or

somewhat less than an old English hogshead. It is now known that the wine passes

sooner into vinegar the smaller the mass operated upon, the more extensive its contact

with the air, and the more genial its warmth. These casks were formerly arranged in

three ranks by means of massive scaffolding; they are now set in four ranks, but they

rest on much smaller rafters, sustained by uprights, and can be packed closer together.

The casks, which are laid horizontally, are pierced at the upper surface of their front end

with two holes: one, to which the name of eye is given, is two inches in diameter; it

serves for putting in the charge, and drawing off the vinegar when it is made; the

other hole is much smaller, and is placed immediately alongside; it is merely an air

hole, and is necessary to allow the air to escape, because the funnel completely fills the

other hole in the act of filling the cask.

When new vessels are mounted in a vinegar work, they must be one third filled with

the best vinegar that can be procured, which becomes the true mother of the vinegar

to be made; because it is upon this portion that the wine to be acidified is successively

added. At the ordinary rate of work, they put at first upon the mother, which occupies

one third of the vessel, a broc of 10 litres of red or white wine; eight days afterwards

they add a second broc; then a third, and a fourth, always observing the same interval of

time, 8 days. After this last charge, they draw off about 40 litres of vinegar, and then

recommence the successive additions.

It is necessary that the vessel be always one third empty if we wish the acetification

to go on steadily; but as a portion of the tartar and the lees forms and accumulates in

the lower part of the cask, so as eventually to counteract the fermentation, the time

arrives when it is requisite to interrupt it, in order to remove this residuum, by clearing

out all the contents. The whole materials must be renovated every 10 years; but the

casks, if well made and repaired, will serve for 25 years.

We have mentioned a definite period at which the vinegar may be drawn off; but that

was on the supposition that the process had all the success we could wish: there are

circumstances, difficult to appreciate, which modify its progress, as we shall presently

show. We ought, therefore, before discharging the vinegar, to test and see if the fermentation[4]

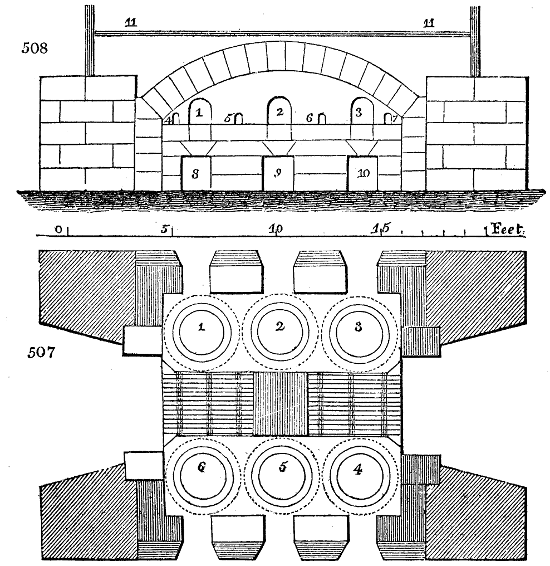

has been complete. We proceed as follows: we plunge into the liquor a

white stick or rod, bent at one end, and then draw it out in a horizontal direction: if it

be covered with a white thick froth, to which is given the name of work (travail), we

judge that the operation is terminated; but if the work, instead of being white and

pearly, be red, the manufacturers regard the fermentation to be unfinished, and they

endeavour to make it advance, by adding fresh wine, or by increasing the heat of the

apartment.

It is not always easy to explain why the fermentation does not go on as rapidly in one

case as in another. There are even certain things which seem at present to be entirely

inexplicable. It happens sometimes, for example, that although all the vessels have been

equally charged, and with the same wine, yet the fermentation does not form in the same

manner in the whole; it will move rapidly in some, be languid, or altogether inert,

in others. This is a very puzzling anomaly; which has been ascribed to electrical and

other obscure causes, because it is not owing to want of heat, the casks in the warmest

positions being frequently in fault; nor to the timber of the cask. It, however, paralyses

the process so completely that the most expert vinegar makers have nothing else

for it, when this accident happens, than to empty entirely what they call the lazy

cask, and to fill it with their best vinegar. The fermentation now begins, and proceeds

as well in it as in the others. See Fermentation.

We must here make an important remark, relatively to the temperature which should

prevail in the fermentation room. In many chemical works we find it stated, that the

heat should not exceed 18° R., or 65° Fahr., for fear of obtaining bad products. But

the vinegar makers constantly keep up the heat at from 24° to 25° R., 75° to 77° F.;

when the acetification advances much more rapidly, and the vinegar is equally strong.

The best proof of this heat not being too high is, that under it, the vessels in the upper

part of the room, work best and quickest. In Orleans, cast-iron stoves and wood fuel are

used for communicating the requisite warmth.

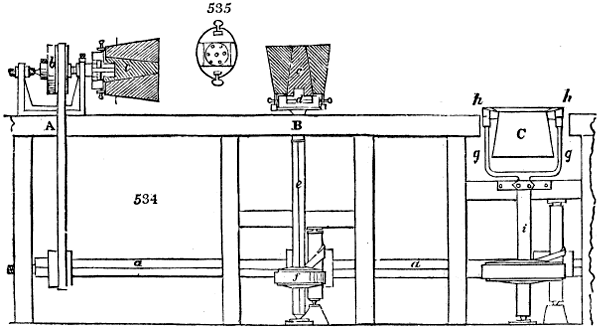

Before pouring the wine into the mothers, it is clarified in the following manner.

There are tuns which can contain from 12 to 15 pieces of wine. Their upper end has at

its centre an opening of four or five inches diameter, which may be closed afterwards

with a wooden cover; this opening is for the purpose of receiving a large funnel.

The inside of the tun is filled with chips of beechwood, well pressed down. The wine

is poured upon these chips, allowed to remain for some time, and then gently drawn off

by a pipe in the lower part of the vessel. The lees are deposited upon the chips, and

the wine runs off quite clear. However, it happens sometimes, notwithstanding this

precaution, that the vinegar, after it is made, requires to be clarified, more particularly if

the wine employed had been weak. The vinegar must be filtered in the same way; and

it derives an advantage from it, as the products of different casks get thereby mixed and

made uniform.

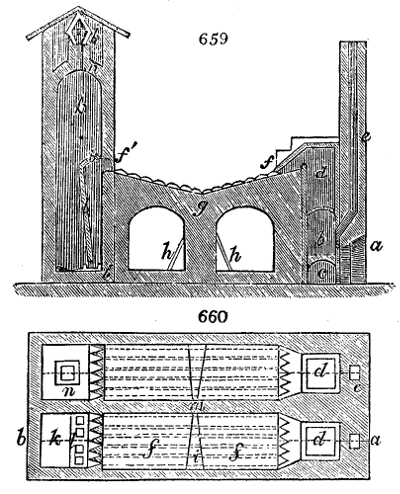

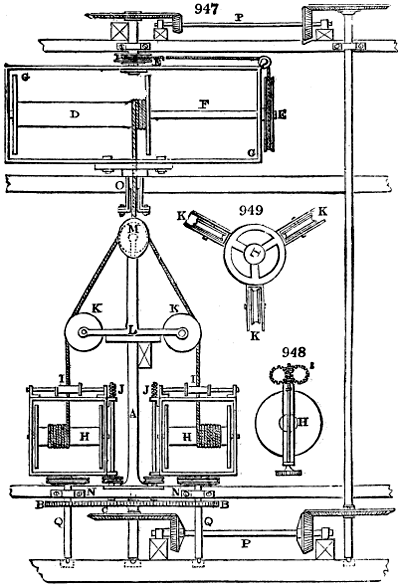

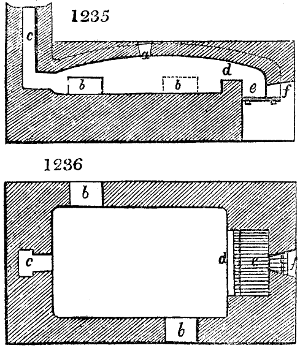

By this Orleans method several weeks elapse before the acetification is finished; but

a plan has been lately devised in Germany to quicken greatly the acid fermentation by

peculiar constructions. This system is called, the quick vinegar work, because it will

complete the process in the course of 2 or 3 days, or even in a shorter time. It depends,

chiefly, upon the peculiar construction of the fermenting vessels, whereby the vinous

liquor is exposed on a vastly expanded surface to the action of the atmospheric air.

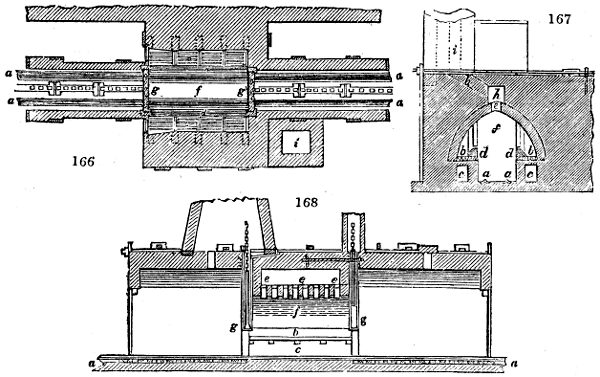

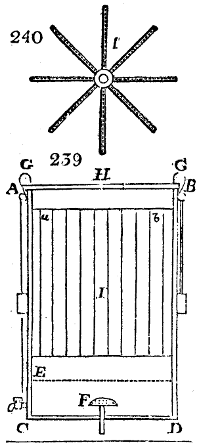

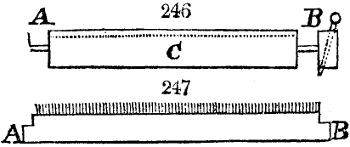

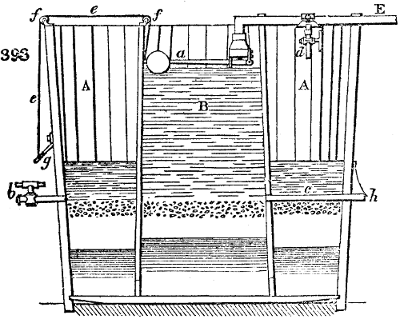

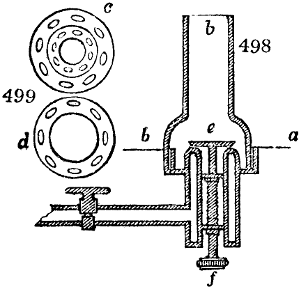

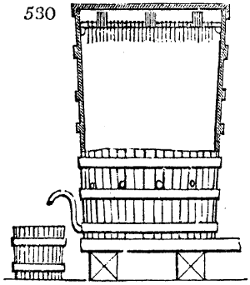

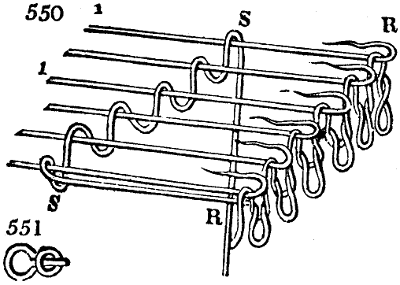

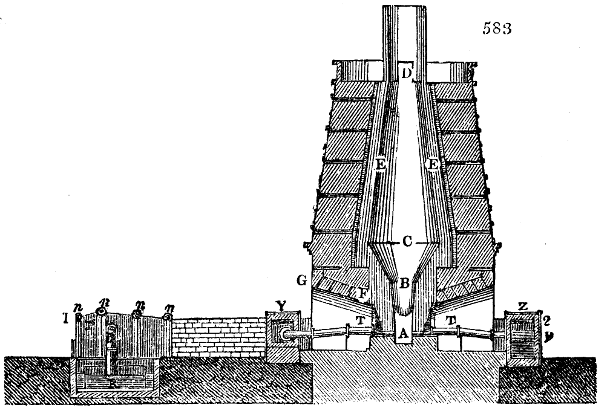

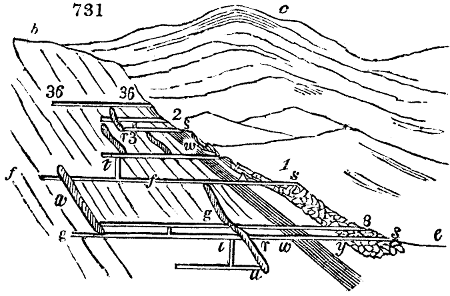

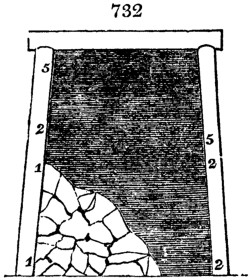

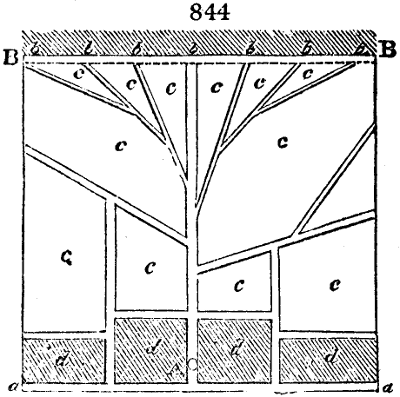

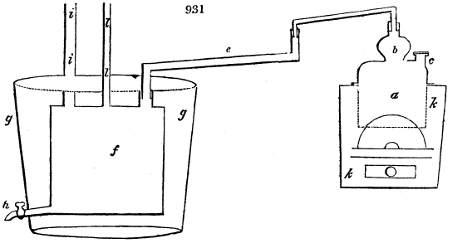

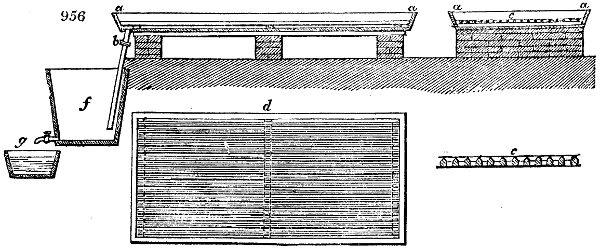

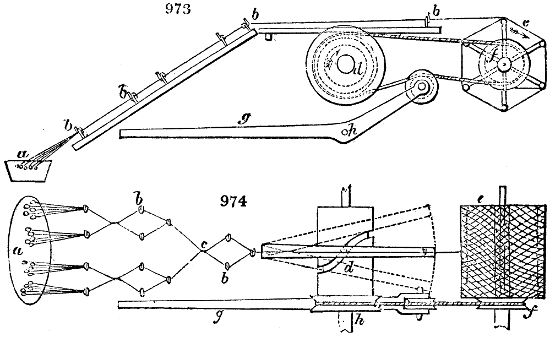

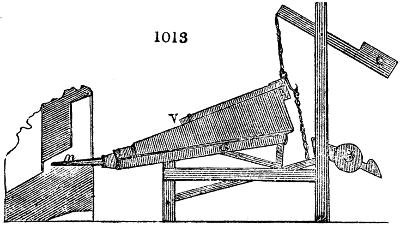

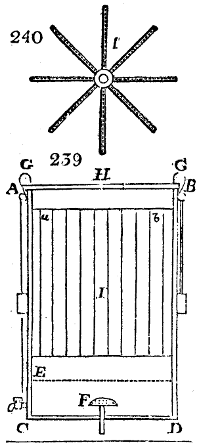

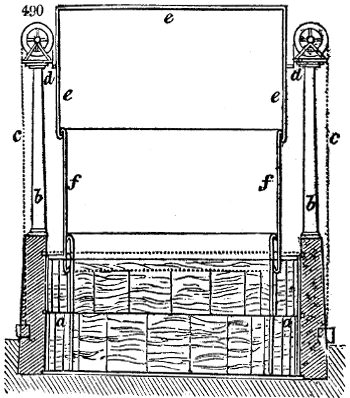

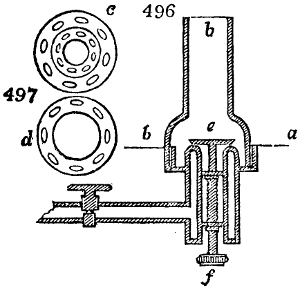

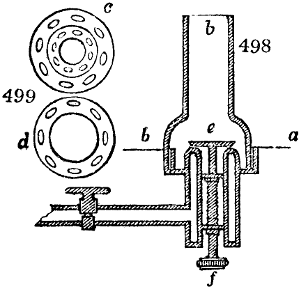

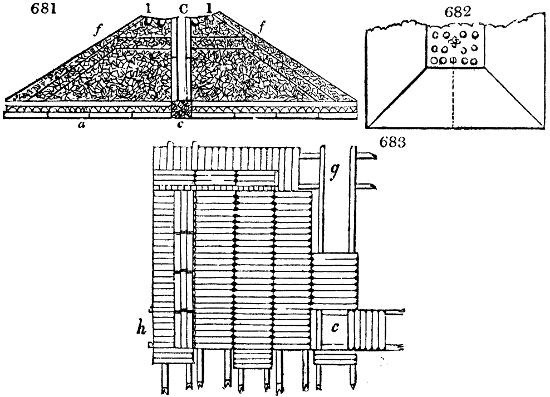

An oaken tub, somewhat narrower at the bottom than the top, from 6 to 7 feet high

and 3 feet in diameter, is furnished with a well-fitted grooved, but loose, cover. About

half a foot from its mouth, the tub has a strong oak or beech hoop fitted to its inside

surface, sufficiently firm to support a second cover, also well fitted, but moveable. The

space under this second cover is destined to contain the vinous liquor, and in order to

bring it very amply into contact with the atmosphere, the following contrivances have

been resorted to: This cover is perforated, like a sieve, with small holes, of from 1 to 2

lines in diameter, and about 11⁄2 inch apart. Through each of these holes a wick of pack-thread

or cotton is drawn, about 6 inches long, which is prevented from falling through

by a knot on its upper end, while its under part hangs free in the lower space. The

wicks must be just so thick as to allow of the liquor poured above the cover passing

through the holes in drops. The edges of the lid must be packed with tow or hemp to

prevent the liquor running down through the interval.

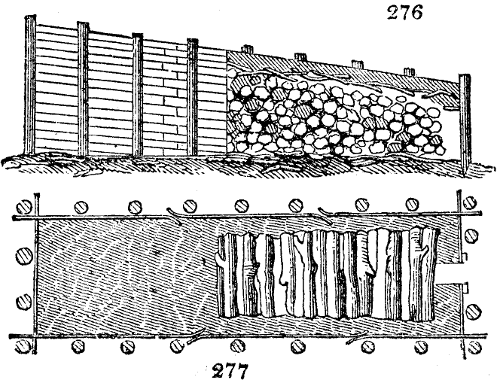

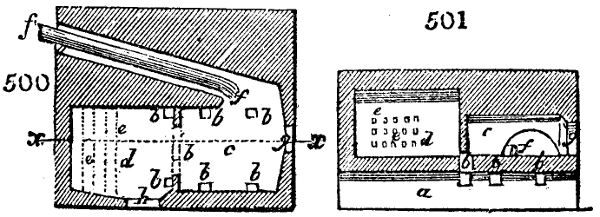

The whole lower compartment is now to be filled with chips of beechwood up to

nearly the perforated cover. The liquor, as it trickles through the holes, diffuses itself

over the chips, and, sinking slowly, collects at the bottom of the tub. The chips should

be prepared for this purpose by being repeatedly scalded in boiling water, then dried,

and imbued with hot vinegar. The same measures may also be adopted for the tub.

To provide for the renewal of the air, the tub is perforated at about a foot from its

bottom with eight holes, set equally apart round the circumference, two thirds of an inch

wide, and sloping down, through which the air may enter into this lower compartment,

without the trickling liquor being allowed to flow out. In order that the foul air which has[5]

become useless may escape, four large holes are pierced in the sieve cover, at equal distances

asunder and from the centre, whose united areas are rather smaller than the total areas

of the holes in the side of the tub. Into these four holes open glass tubes must be

inserted, so as to stand some inches above the cover, and to prevent any of the liquor

from running through them. The proper circulation of the air takes place through

these draught holes. This air may afterwards pass off through a hole of 21⁄2 inches

diameter in the uppermost cover, in which a funnel is placed for the supply of liquor as

it is wanted to keep up the percolation.

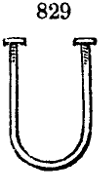

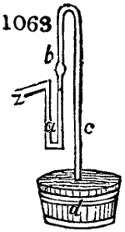

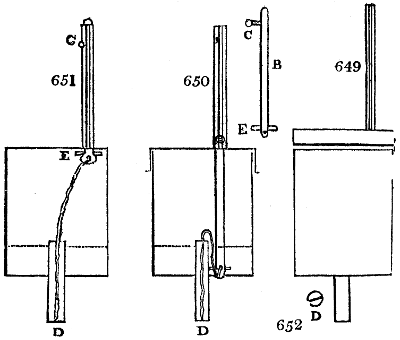

The temperature of the fermenting compartment is ascertained by means of a thermometer,

whose bulb is inserted in a hole through its side, and fastened by a perforated

cork. The liquor collected in the under vessel runs off by a syphon inserted near its

bottom, the leg of which turns up to nearly the level of the ventilating air pipes before it

is bent outwards and downwards. Thus the liquor will begin to flow out of the under

compartment only when it stands in it a little below the sieve cover, and then it will run

slowly off at the inclined mouth of the syphon, at a level of about 3 inches below the

lower end of the glass tubes. There is a vessel placed below, upon the ground, to

receive it. The tub itself is supported upon a wooden frame, or a pier of brickwork, a

foot or 18 inches high.

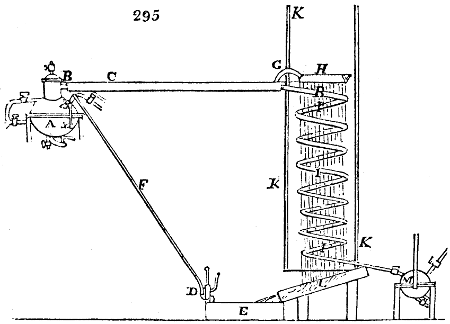

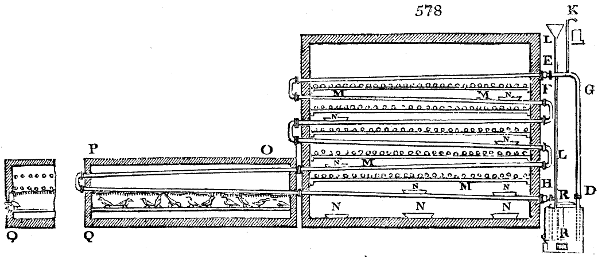

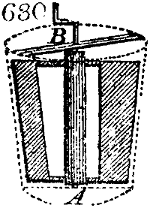

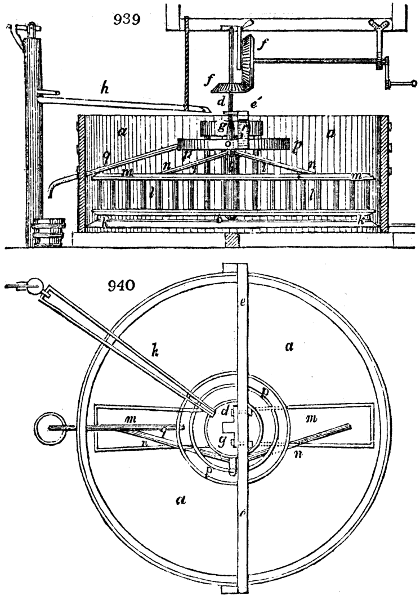

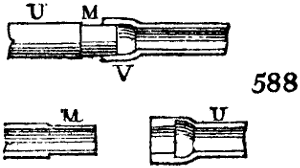

A tub constructed like the above is called a GRADUATION VESSEL, which see. It is worked

in the following way:—The vinegar room must be, in the first place, heated to from 100°

to 110° F., or till the thermometer in the graduation vessel indicates at least 77°. The

heat may then be modified. We now pour through the uppermost cover of the tub a

mixture, warmed to 144° F., of 8 parts proof spirits, 25 parts soft water, 15 parts of

good vinegar, and as much clear wine or beer. The water should be first heated, and then

the vinegar, spirits, and wine may be added to it. Of this mixture, so much should

be poured in as is necessary to cover over the second lid, 2 or 3 inches deep, with the

liquor; after which, the rest may be poured slowly in, as it is wanted.

When the liquor has run for the first time through the graduation vessel, it is not yet

sufficiently acidified; but the weak vinegar collected in the exterior receiving cistern

must be a second time, and, if need be, a third time, passed through the graduation tub,

in order to convert all the alcohol into acetic acid. In general, we may remark, that

the stronger the vinous liquor the more difficult and tedious is its conversion into

vinegar, but it is so much the stronger. To lessen this difficulty somewhat, it would be

well not to put all the spirits at first into the wash, or mixed liquors, but to add a little

more of it at the second and the third running, especially when we desire to have very strong

vinegar.

After the graduation vessel has been some days at work, it is no longer necessary to

add vinegar to the mixture of spirits and water, since the sides of the graduation tub, the

beech chips, and the packthreads, are all impregnated with the ferment, and supply its

place. The mixture must, however, be always maintained at the temperature of 100°.

Instead of the above mixture of brandy, water, and wine, we may employ, according to

Dingler, a clear fermented wort of malt, mixed with a little spirits. The perfect vinegar,

which collects in the receiving cistern, may be immediately racked off into the store

casks for sale.

It has been objected to this process, that, in consequence of the mixture of saccharine

and glutinous materials, which are contained in beer or worts, along with the acetous

fermentation, there is also, partially, a vinous fermentation, and much carbonic acid,

thereby disengaged, so as to obstruct the acetification. This obstruction may be remedied

by a freer circulation of air, or by the exposure of quicklime in the chamber. It is a

more substantial objection, that, from the addition of beer, &c., more lees, or dregs, are

deposited in the graduation tub, whereby a more frequent cleansing of it, and of the

beech chips, with a loss of time and vinegar, becomes necessary. The only mode of

obviating this difficulty is, to take well-clarified fermented wash.

Another evil attendant on the quick process is, the evaporation of the spirituous

liquors. Since, in the graduation tub, there is a temperature of 110°, it is impossible to

avoid a loss of spirit from the circulation and efflux of the air. The air, indeed, that

issues from the top hole in the uppermost cover, might be conducted over an extensive

surface of fresh water, where its spirit would be condensed in a great measure. But,

after all, this fear of great loss is, I believe, groundless; because the spirit is rapidly

acidified by the oxygen of the air, and thereby rapidly loses its volatility.

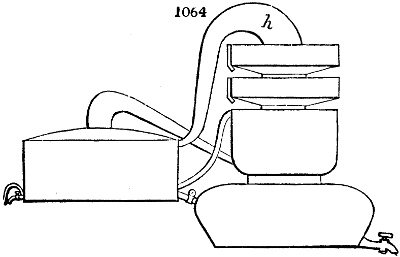

The supply of the warm wash should be drawn from a cistern placed near the ceiling,

where the temperature of the apartment is hottest; and it may be replenished from the

partly acetified liquor in the cistern on the floor. With this view, two cisterns should

be placed above, so that one of them may always contain liquor sufficiently hot, and thus

the process will suffer no interruption.

When malt wash is used for this quick process, the resulting vinegar must be clarified[6]

in a tun with beech chips, as above described. In two or three days the impurities will

be deposited, and the fine vinegar may be racked off.

The following prescription, for preparing what he calls malt wine, is given by Dr.

Kastner. Eighty pounds of pale barley malt, and 40 pounds of pale wheat malt, are to

be crushed together. These 120 pounds are to be infused with 150 quarts of water, at

the temperature of 122° Fahr., afterwards with 300 quarts of boiling water, and the

whole body is to be mashed thoroughly, till all the lumps disappear. It is then to

be left at rest in a large covered tub, for two or three hours, to allow the grains to

settle down, from which the wort is to be drawn off. When it has fallen to the temperature

of 64° Fahr., 15 pounds of good yeast are to be stirred in, and it must now be

left for two or three days to ferment, in a loosely covered tun. When the vinous fermentation

has taken place, the clear liquor must be drawn off by a tap hole, a little above

the bottom, so as to leave the lees and scum in the tun. This malt wine, he adds, may

be kept for a long time in close vessels, and is always ready for making quick vinegar.

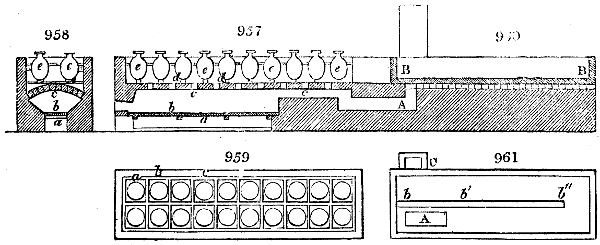

2. Malt Vinegar.—The greater part of British vinegar is made from malt, by the

following process:—1 boll of good barley malt, properly crushed, is to be mashed with

water at 160° Fahr. The first water should have that temperature; the second must be

hotter than 160°, and the third water, for the extraction of all the soluble matter, may

be boiling hot. Upon the whole, not more than 100 gallons of wort should be extracted.

After the liquor has cooled to 75° Fahr., 3 or 4 gallons of beer yeast are poured in, and

well mixed with a proper stirrer. In 36 or 40 hours, according to the temperature of

the air, and the fermenting quality of the wash, it is racked off into casks, which are

laid upon their sides in the fermenting apartment of the vinegar work, which should be

kept at a temperature of 70° at least; in summer partly by the heat of the sun, but in

general by the agency of proper stoves, as above described. The bung-holes should be

left open, and the casks should not be full, in order that the air may act over an extensive

surface of the liquor. It would be proper to secure a freer circulation to the air, by

boring a hole in each end of the cask, near its upper edge. As the liquor, by evaporation,

would be generally a few degrees colder than the air of the apartment, a circulation of

air would be established in at the bung-hole, and out by the end holes. By the ordinary

methods, three months are required to make this vinegar marketable, or fit for the

manufacture of sugar of lead.

In making vinegar for domestic purposes, the casks are usually set on their ends; and

they have, sometimes, a false bottom, pierced with holes, placed about a foot above the

true one. On this bottom, a quantity of rape, or the refuse raisins, &c. from the making

of British wines, is laid. The malt liquor has a proper quantity of yeast added to it. In

about 24 hours it becomes warm, and is then racked off into another similar cask.

After some time, this racking process is discontinued, and the vinegar is allowed to complete

its fermentation quietly. The proper temperature must always be kept up, by

placing the cask in a warm situation. A little wine-stone (argal) added to the malt

wash, would make the vinegar liker that made from wine. Sometimes a little isinglass

is employed to clarify vinegar. A portion of sulphuric acid is often added to it.

3. Sugar vinegar.—By pursuing the following plan, an excellent sugar vinegar may be

made. In 158 quarts of boiling water dissolve 10 pounds of sugar, and 6 pounds of

wine-stone; put the solution into a fermenting cask, and when it is cooled to the temperature

of from 75° to 80°, add 4 quarts of beer yeast to it. Stir the mixture well,

then cover the vessel loosely, and expose it for 6 or 8 days to the vinous fermentation, at

a temperature of from 70° to 75° Fahr. When it has become clear, draw off the vinous

liquor, and either acetify it in the graduation tub above described, or by the common

vinegar process. Before it is finished, we should add to it 12 quarts of strong spirits

(brandy), and 15 quarts of good vinegar, to complete the acetous fermentation. With

a graduation tub which has been used, this addition of vinegar is unnecessary.

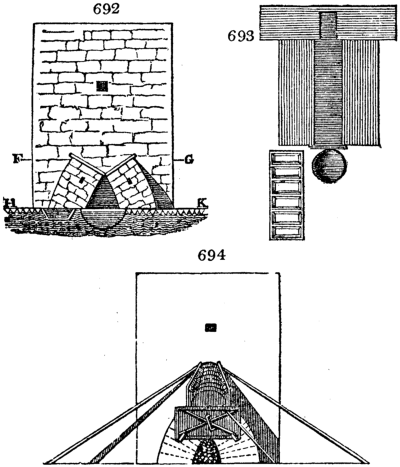

The following simpler prescription for making sugar vinegar deserves attention. For

every gallon of hot water take 18 ounces of sugar; and when the syrup has cooled to

75°, add 4 per cent., by measure, of yeast. When the vinous fermentation is pretty well

advanced, in the course of 2 or 3 days, rack off the clear wash from the lees into a proper

cask, and add 1 ounce of wine-stone, and 1 of crushed raisins, for every gallon of water.

Expose it in a proper manner, and for a proper time, to the acetifying process; and then

rack off the vinegar, and fine it upon beech chips. It should be afterwards put into

bottles, which are to be well corked.

Vinegar obtained by the preceding methods has always a yellowish or brownish

colour. It may be rendered colourless by distillation. For nicer chemical purposes,

this is done in a glass retort; but on a large scale, it is usually performed in a clean

copper still, furnished with a capital and worm-refrigeratory, either of silver or block

tin. It is volatile at the boiling temperature of water; and if the process be carried on

briskly, it will not sensibly corrode the copper. But we can never obtain, in this way,

a strong article; for, as soon as the vinegar gets concentrated to a certain degree, we[7]

cannot force off the remainder by heat, for fear of giving it an empyreumatic odour;

because the gluten, colouring matter, &c. begin to adhere to the bottom of the still. We

are, therefore, obliged to suspend the operation at the very time when the acid is acquiring

strength. It has been also proposed to concentrate vinegar by the process of congelation;

but much of it remains entangled among the frozen water; and common distilled vinegar

is so weak, that it congeals in one mass.

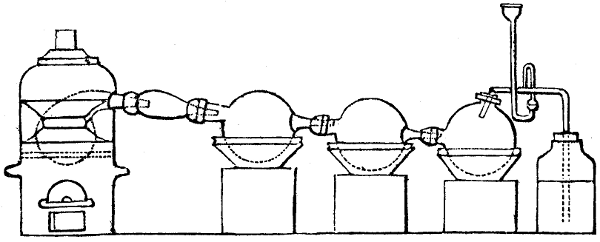

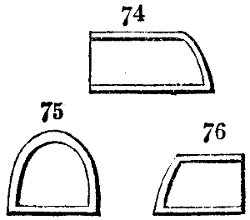

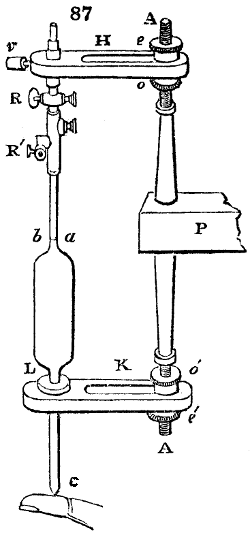

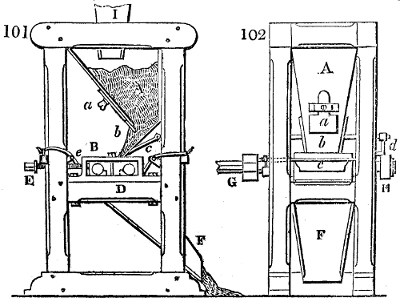

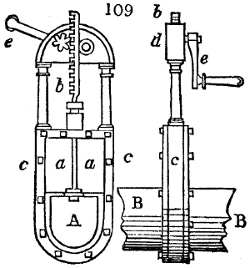

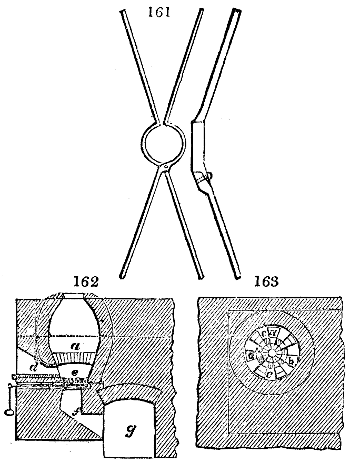

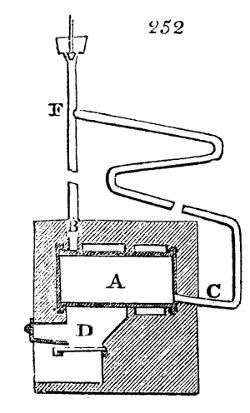

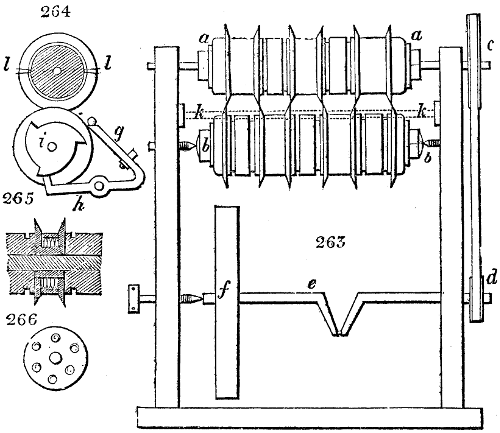

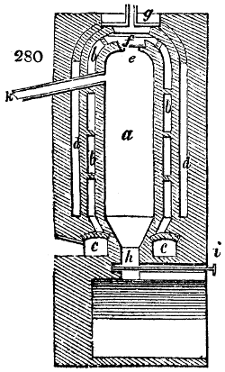

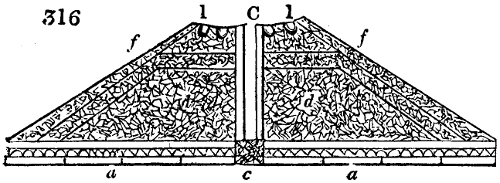

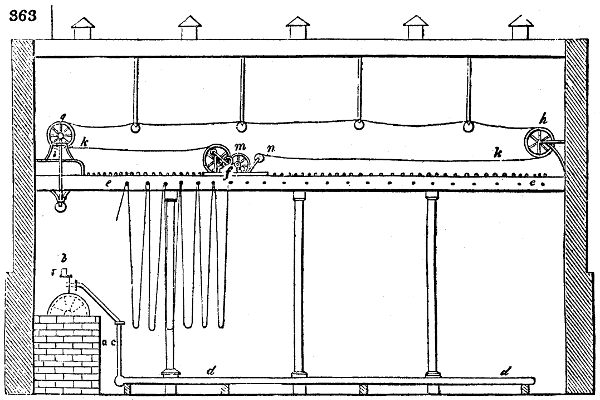

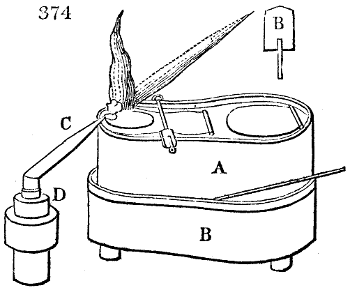

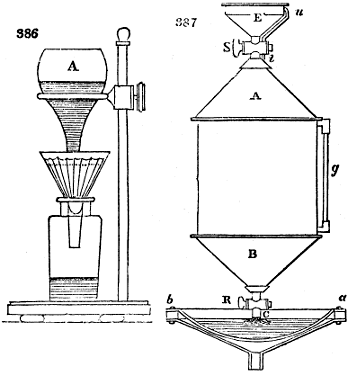

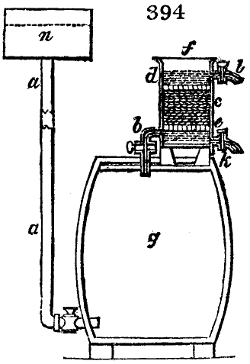

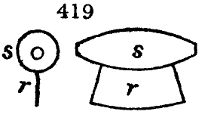

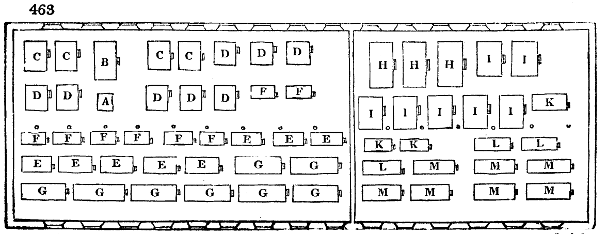

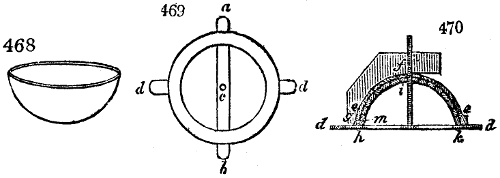

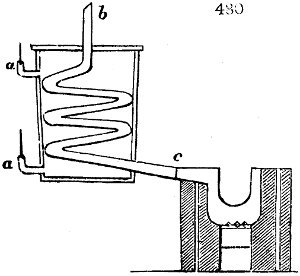

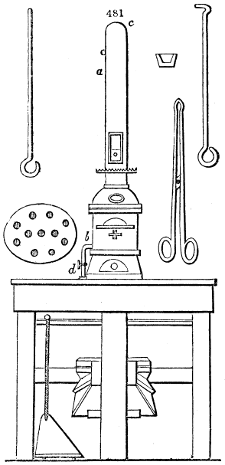

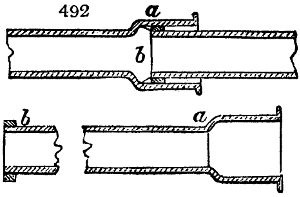

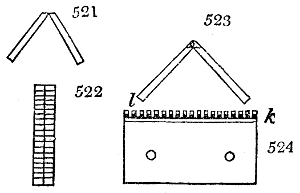

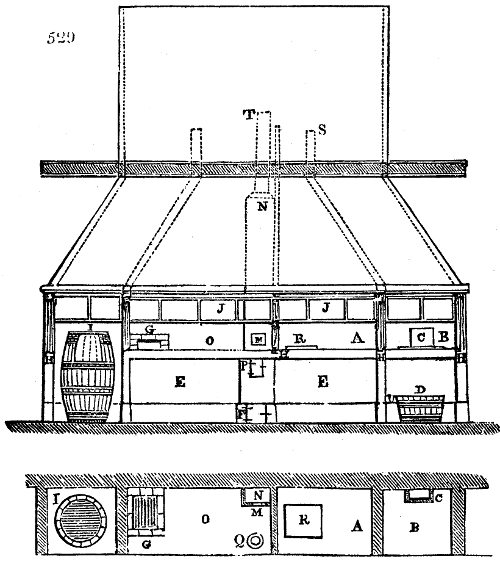

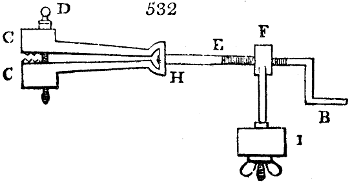

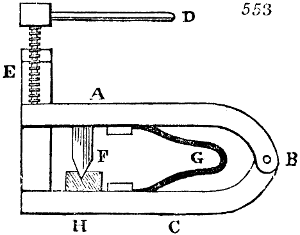

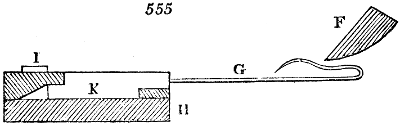

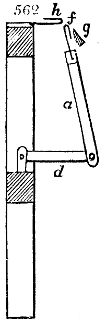

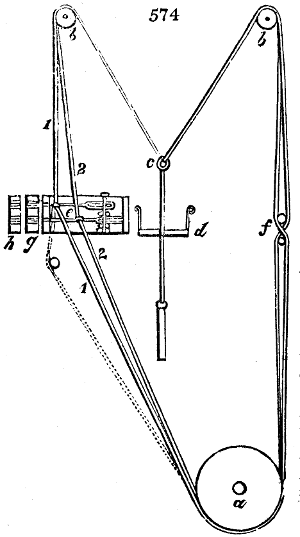

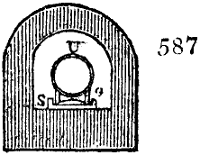

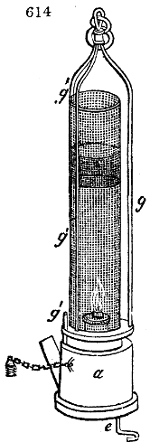

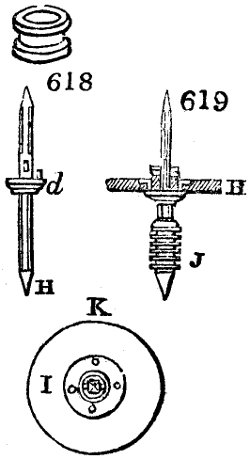

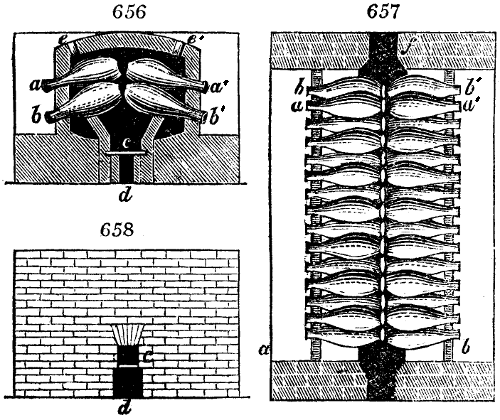

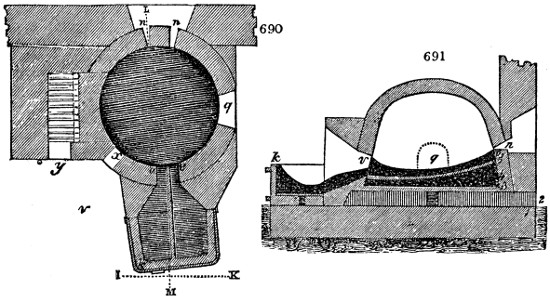

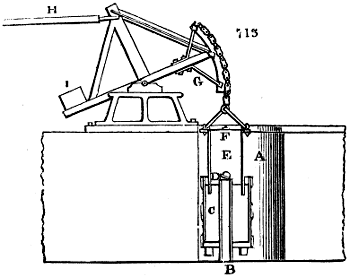

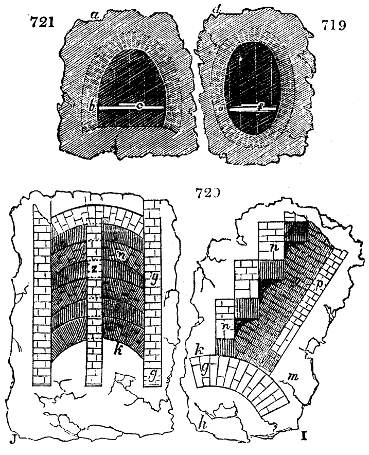

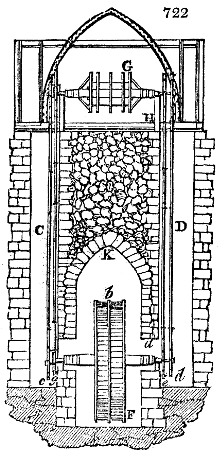

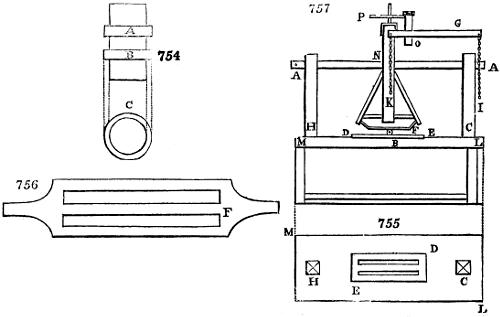

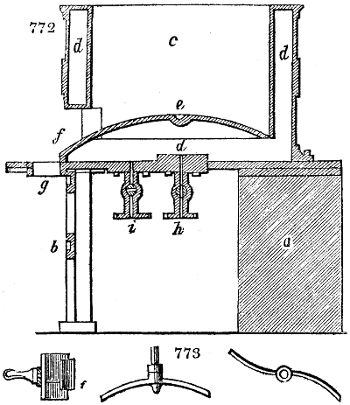

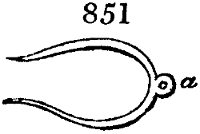

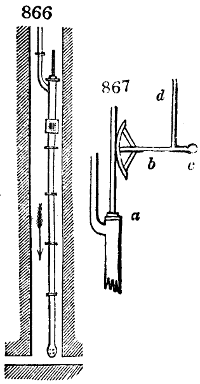

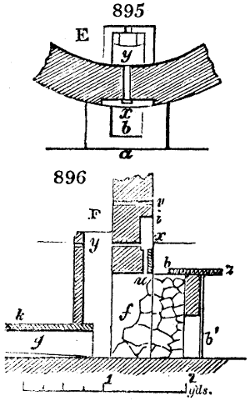

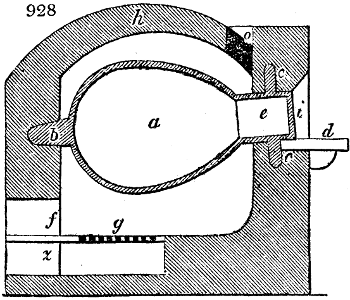

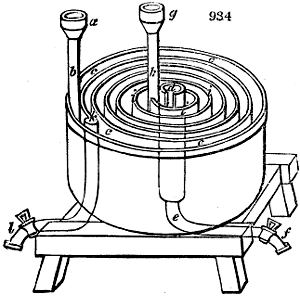

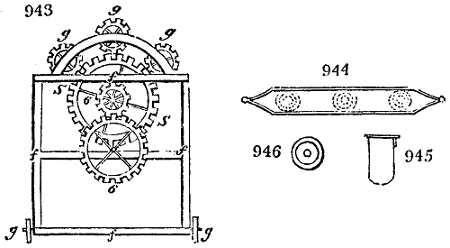

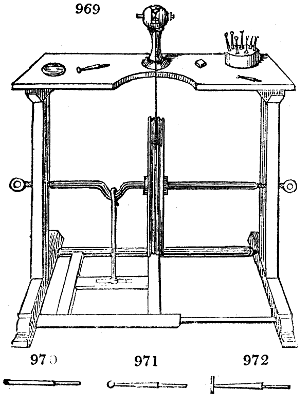

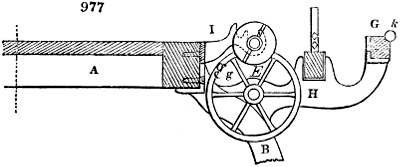

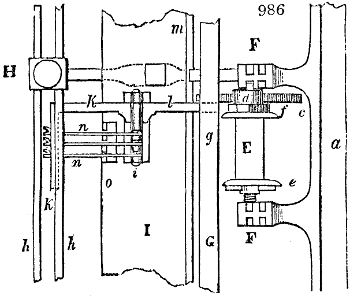

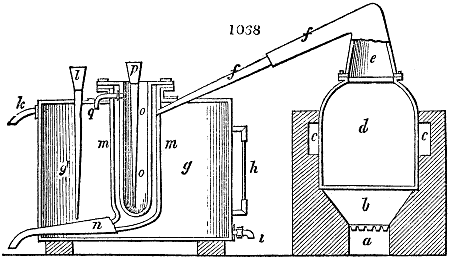

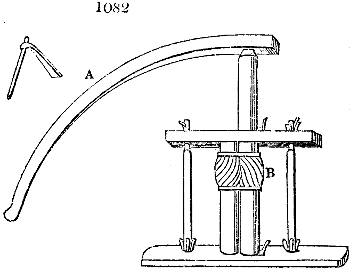

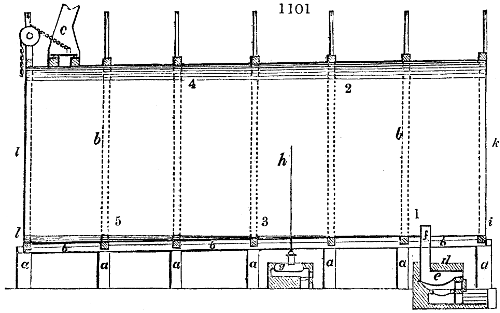

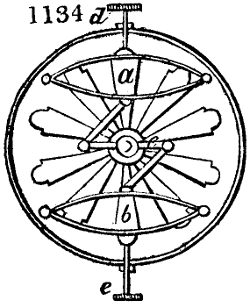

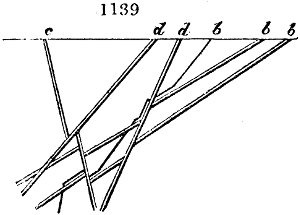

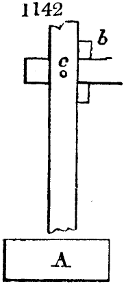

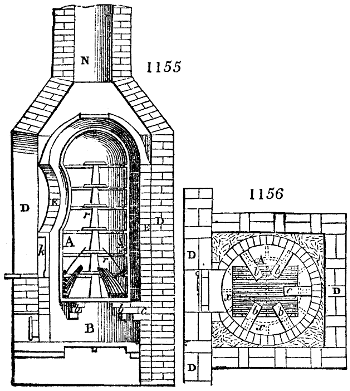

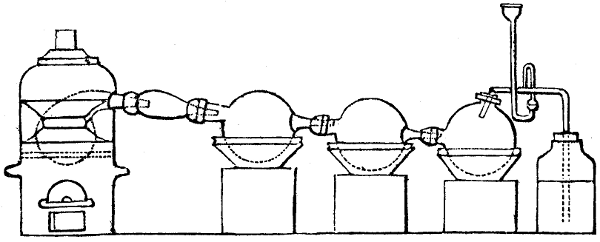

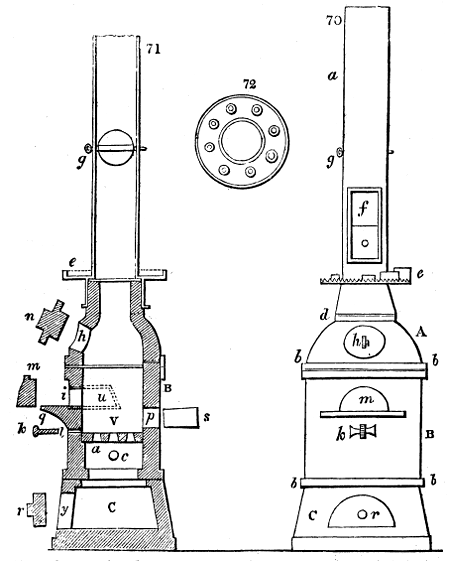

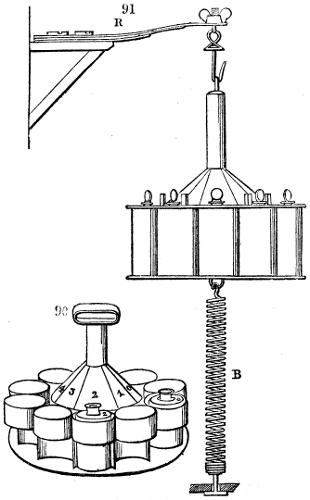

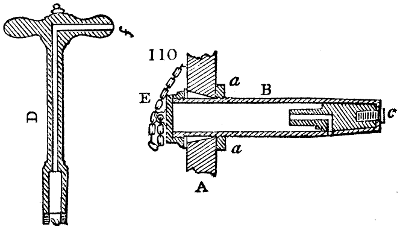

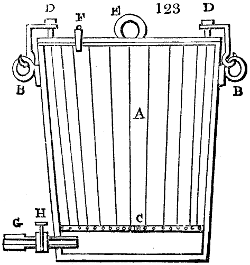

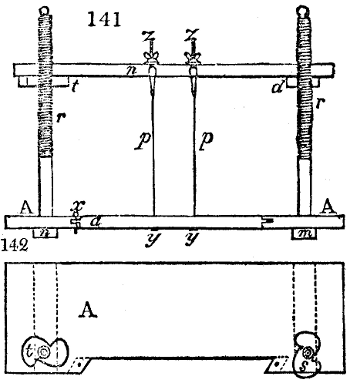

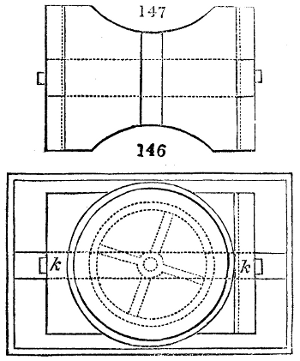

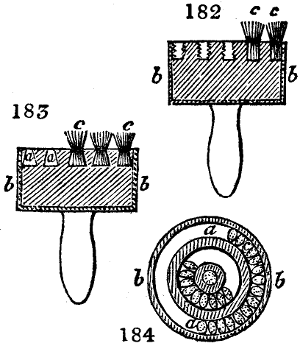

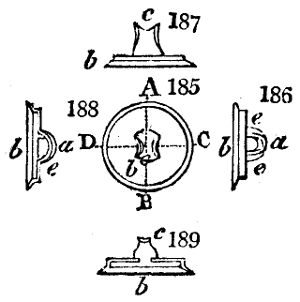

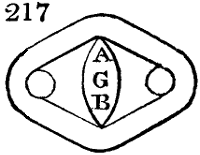

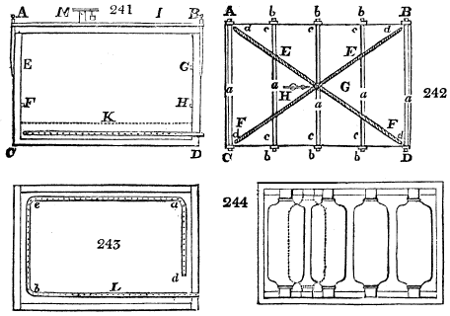

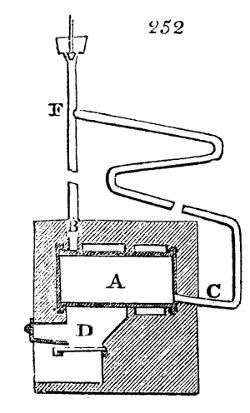

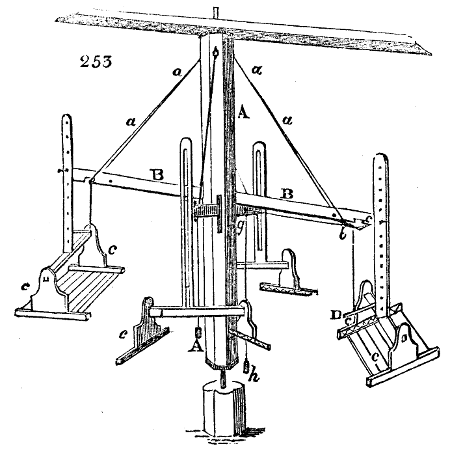

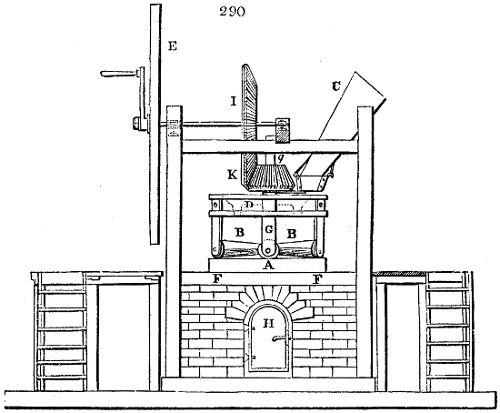

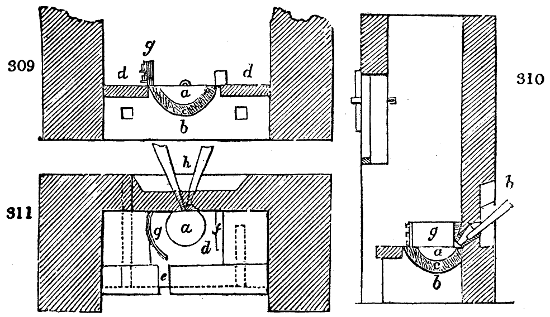

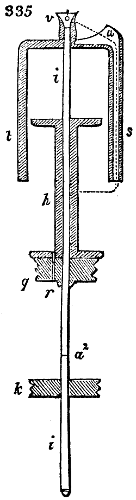

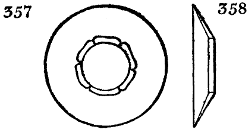

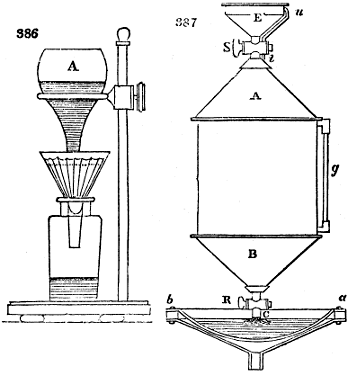

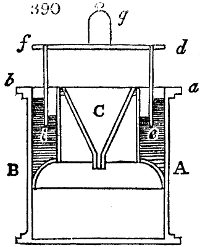

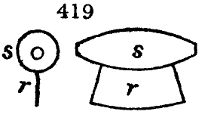

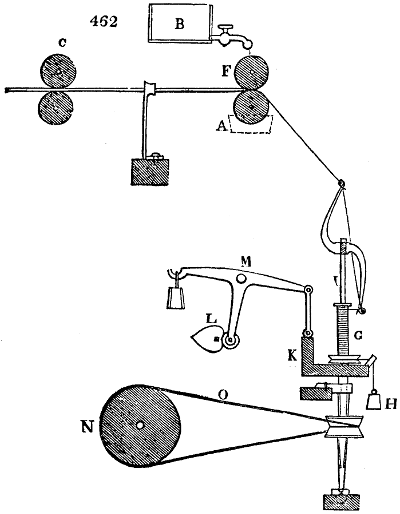

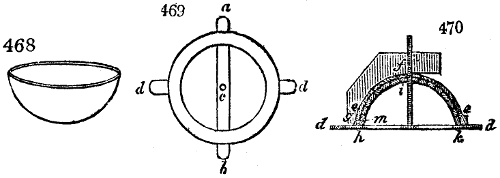

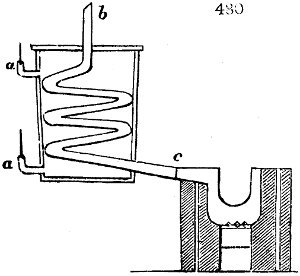

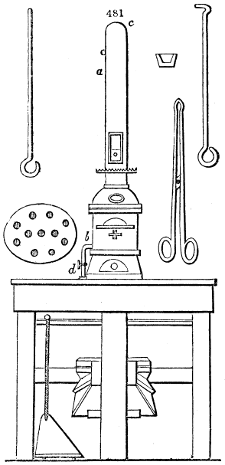

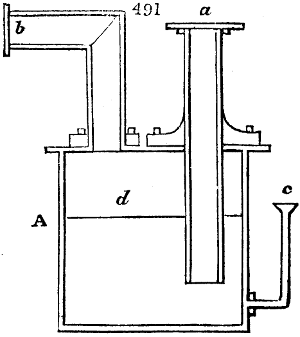

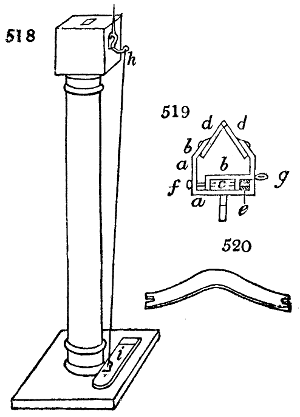

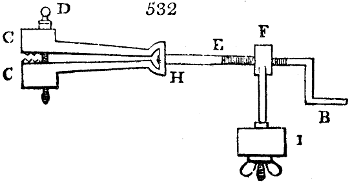

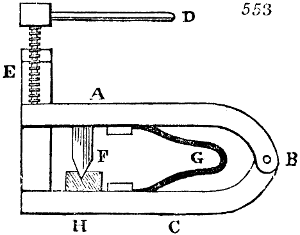

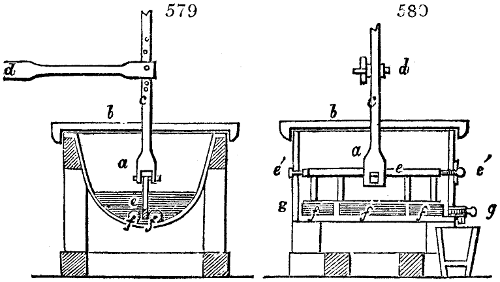

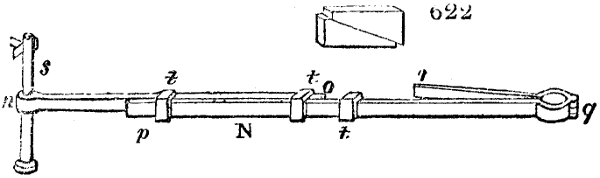

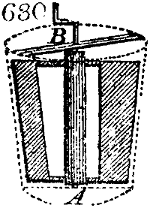

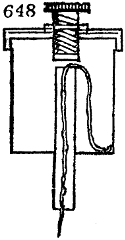

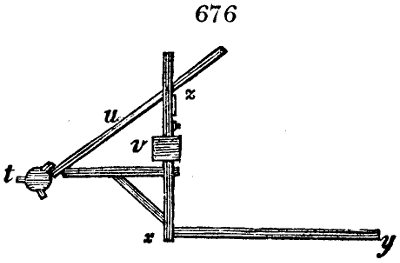

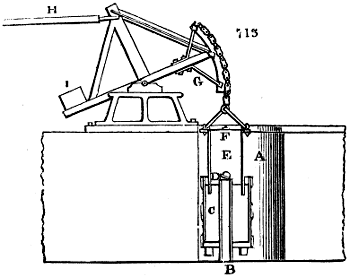

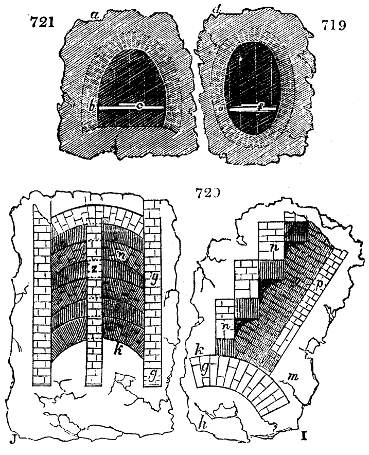

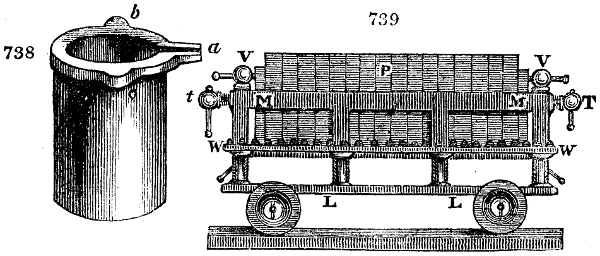

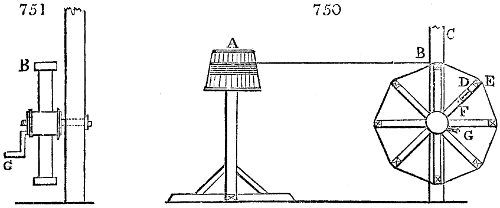

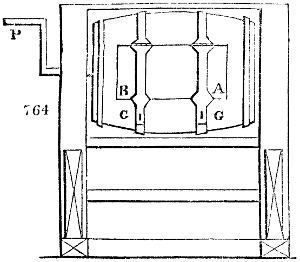

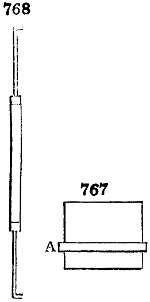

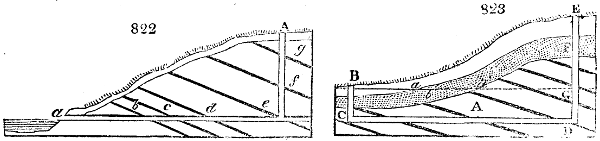

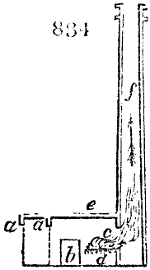

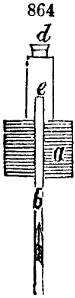

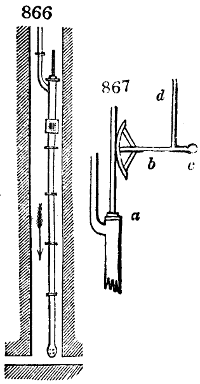

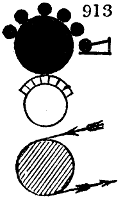

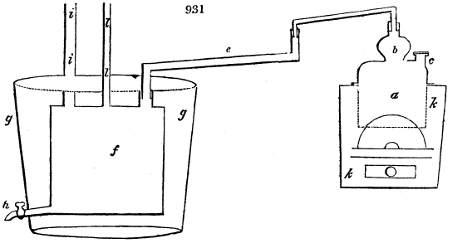

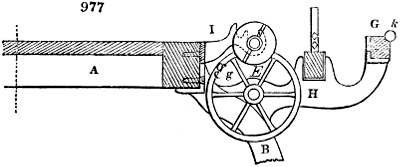

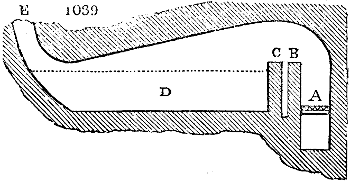

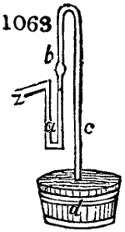

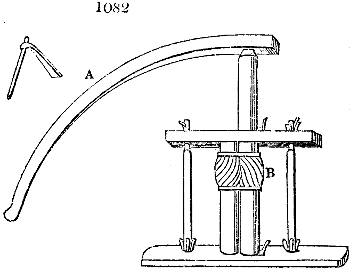

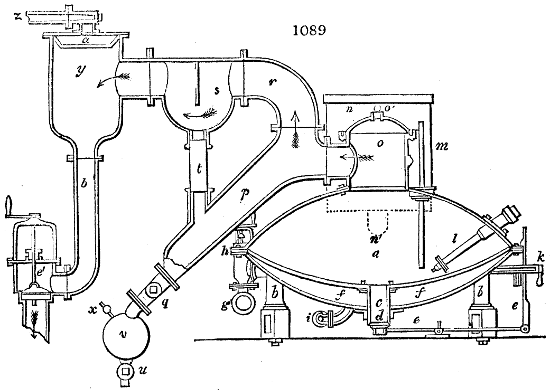

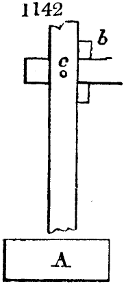

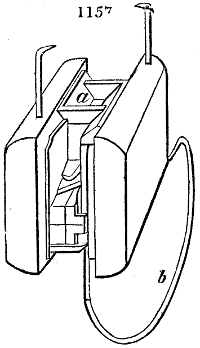

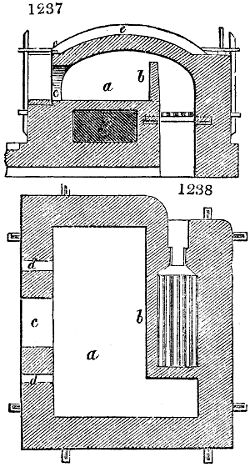

Fig. 1.

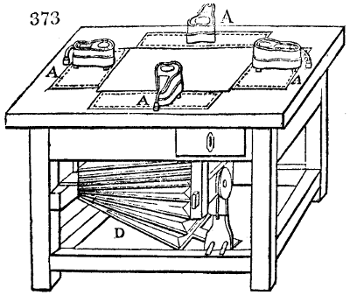

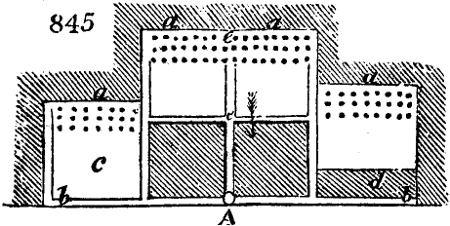

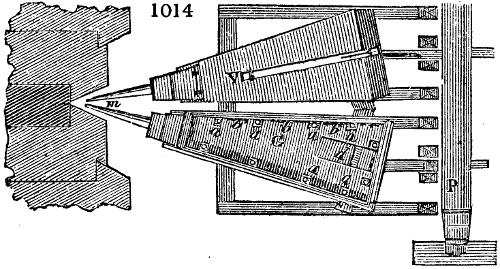

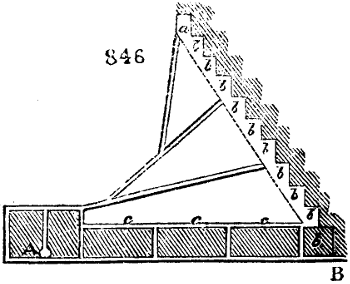

Before the process for pyrolignous acid, or wood vinegar, was known, there was only

one method of obtaining strong vinegar practised by chemists; and it is still followed by

some operators, to prepare what is called radical or aromatic vinegar. This consists in

decomposing, by heat alone, the crystallised binacetate of copper, commonly, but improperly,

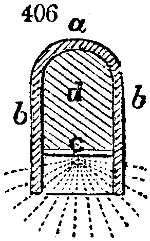

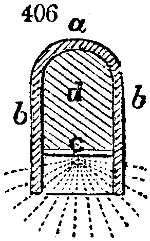

called distilled verdigris. With this view, we take a stoneware retort, (fig. 1.)

of a size suited to the

quantity we wish to operate

upon; and coat it with

a mixture of fire clay and

horsedung, to make it

stand the heat better.

When this coating is dry,

we introduce into the retort

the crystallised acetate

slightly bruised, but

very dry; we fill it as far

as it will hold without

spilling when the beak is considerably inclined. We then set it in a proper furnace.

We attach to its neck an adopter pipe, and two or three globes with opposite tubulures,

and a last globe with a vertical tubulure. The apparatus is terminated by a

Welter’s tube, with a double branch; the shorter issues from the last globe, and the

other dips into a flask filled with distilled vinegar. Every thing being thus arranged,

we lute the joinings with a putty made of pipeclay and linseed oil, and cover them with

glue paper. Each globe is placed in a separate basin of cold water, or the whole may

be put into an oblong trough, through which a constant stream of cold water is made to

flow. The tubes must be allowed a day to dry. Next day we proceed to the distillation,

tempering the heat very nicely at the beginning, and increasing it by very slow

degrees till we see the drops follow each other pretty rapidly from the neck of the retort, or

the end of the adopter tube. The vapours which pass over are very hot, whence a series

of globes are necessary to condense them. We should renew, from time to time, the

water of the basins, and keep moist pieces of cloth upon the globes; but this demands

great care, especially if the fire be a little too brisk, for the vessels become, in that case,

so hot, that they would infallibly be broken, if touched suddenly with cold water. It is

always easy for us to regulate this operation, according to the emission of gas from the

extremity of the apparatus. When the air bubbles succeed each other with great

rapidity, we must damp the fire.

The liquor which passes in the first half hour is weakest; it proceeds, in some

measure, from a little water sometimes left in the crystals, which when well made,

however, ought to be anhydrous. A period arrives towards the middle of the process

when we see the extremity of the beak of the retort, and of the adopter, covered with

crystals of a lamellar or needle shape, and of a pale green tint. By degrees these

crystals are carried into the condensed liquid by the acid vapours, and give a colour to

the product. These crystals are merely some of the cupreous salt forced over by the

heat. As the process approaches its conclusion, we find more difficulty in raising the

vapours; and we must then augment the intensity of the heat, in order to continue their

disengagement. Finally, we judge that the process is altogether finished, when the

globes become cold, notwithstanding the furnace is at the hottest, and when no more

vapours are evolved. The fire may then be allowed to go out, and the retort to cool.

As the acid thus obtained is slightly tinged with copper, it must be rectified before

bringing it into the market. For this purpose we may make use of the same apparatus,

only substituting for the stoneware retort a glass one, placed in a sand bath. All the

globes ought to be perfectly clean and dry. The distillation is to be conducted in the

usual way. If we divide the product into thirds, the first yields the feeblest acid, and

the third the strongest. We should not push the process quite to dryness, because

there remains in the last portions certain impurities, which would injure the flavour of

the acid.

The total acid thus obtained forms nearly one half of the weight of the acetate

employed, and the residuum forms three tenths; so that about two tenths of the acid

have been decomposed by the heat, and are lost. As the oxide of copper is readily

reduced to the metallic state, its oxygen goes to the elements of one part of the acid, and

forms water, which mingles with the products of carbonic acid, carburetted hydrogen, and[8]

carbonic oxide gases which are disengaged; and there remains in the retort some charcoal

mixed with metallic copper. These two combustibles are in such a state of division, that

the residuum is pyrophoric. Hence it often takes fire the moment of its being removed

from the cold retort. The very considerable loss experienced in this operation has

induced chemists to try different methods to obtain all the acid contained in the acetate.

Thus, for example, a certain addition of sulphuric acid has been prescribed; but, besides

that the radical vinegar obtained in this way always contains sulphurous acid, from

which it is difficult to free it, it is thereby deprived of that spirit called the pyro-acetic,

which tempers the sharpness of its smell, and gives it an agreeable aroma. It is to be

presumed, therefore, that the preceding process will continue to be preferred for making

aromatic vinegar. Its odour is often further modified by essential oils, such as those of

rosemary, lavender, &c.

4. Pyrolignous Acid, or Wood Vinegar.—The process for making this acid is founded

upon the general property of heat, to separate the elements of vegetable substances, and

to unite them anew in another order, with the production of compounds which did not

exist in the bodies subjected to its action. The respective proportion of these products

varies, not only in the different substances, but also in the same substance, according as

the degree of heat has been greater or less, or conducted with more or less skill. When

we distil a vegetable body in a close vessel, we obtain at first the included water, or that

of vegetation; there is next formed another portion of water, at the expense of the

oxygen and hydrogen of the body; a proportional quantity of charcoal is set free, and,

with the successive increase of the heat, a small portion of charcoal combines with the

oxygen and hydrogen to form acetic acid. This was considered, for some time, as a

peculiar acid, and was accordingly called pyrolignous acid. As the proportion of carbon

becomes preponderant, it combines with the other principles, and then some empyreumatic

oil is volatilised, of little colour, but which becomes thicker, and of a darker tint,

always getting more loaded with carbon.

Several elastic fluids accompany these different products. Carbonic acid comes over,

but in small quantity, much carburetted hydrogen, and, towards the end, a considerable

proportion of carbonic oxide. The remainder of the charcoal, which could not be carried

off in these several combinations, is found in the retort, and preserves, usually, the form

of the vegetable body which furnished it. Since mankind have begun to reason on the

different operations of the arts, and to raise them to a level with scientific researches

they have introduced into several branches of manufacture a multitude of improvements, of

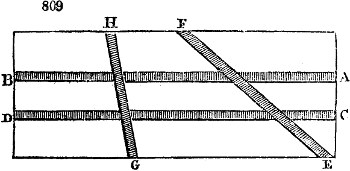

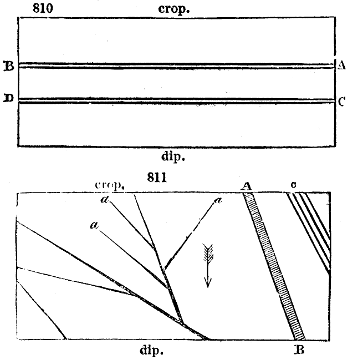

which, formerly, they would hardly have deemed them susceptible. Thus, in particular,

the process for carbonising wood has been singularly meliorated, and in reference to the

preceding observations, advantage has been derived from several products that formerly

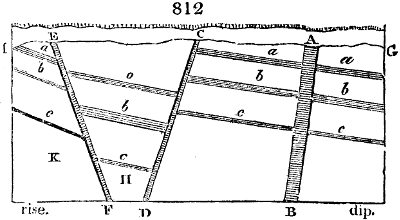

were not even collected.

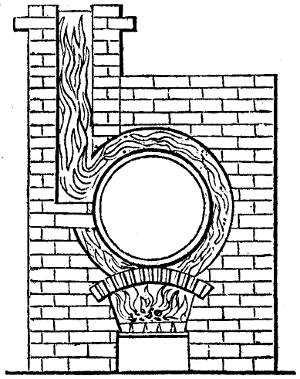

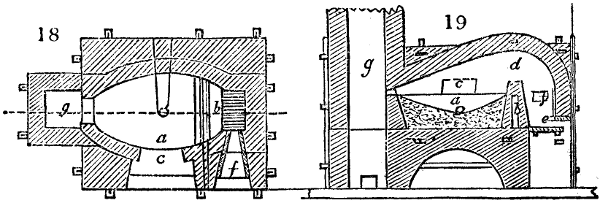

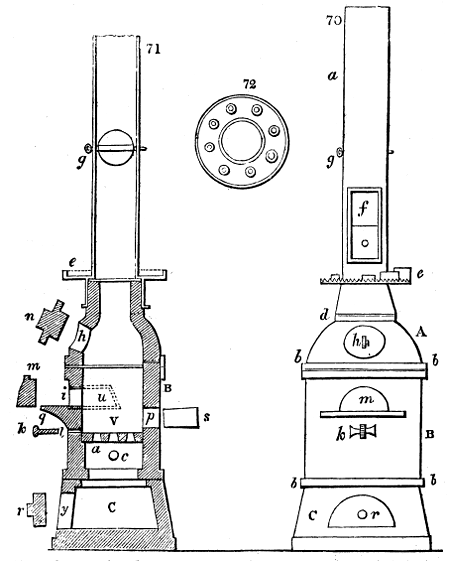

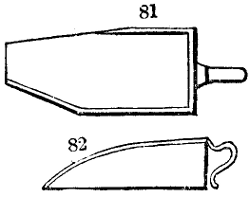

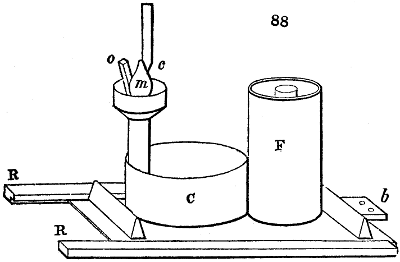

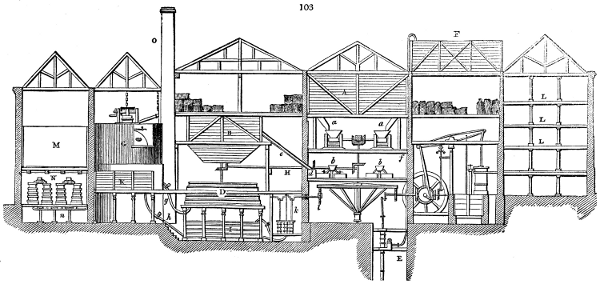

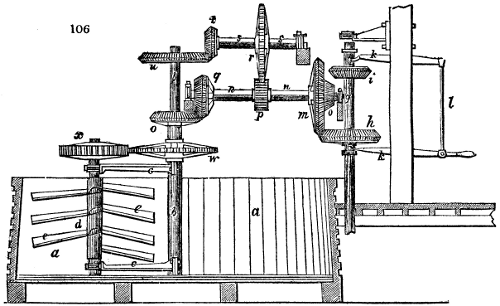

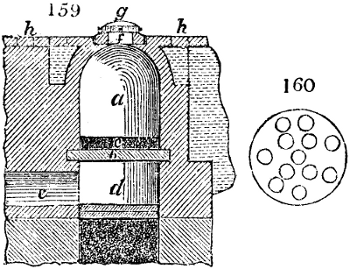

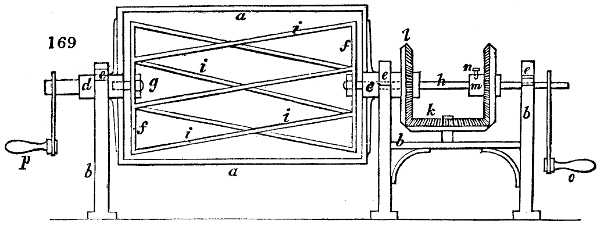

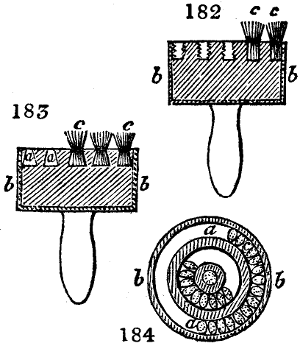

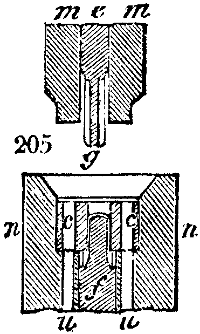

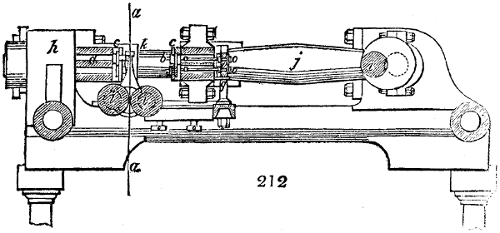

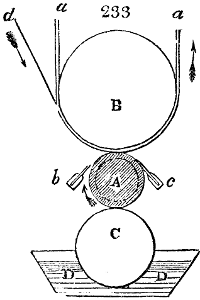

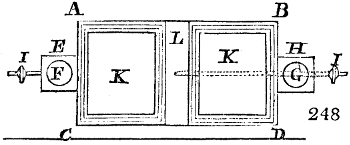

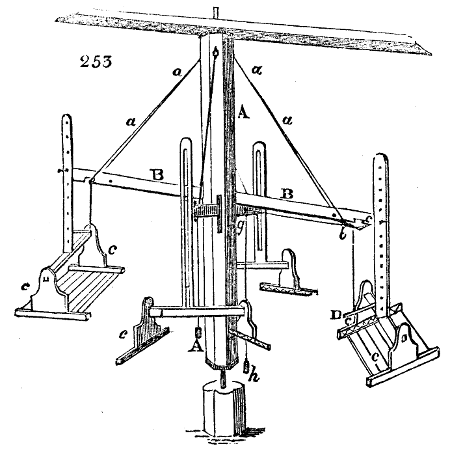

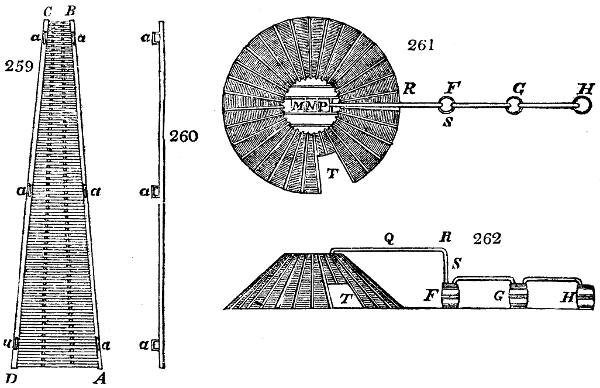

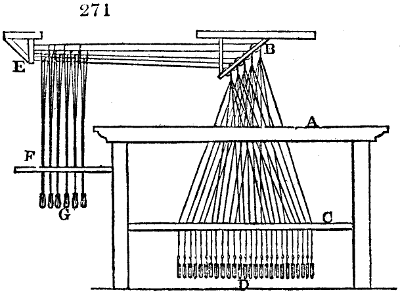

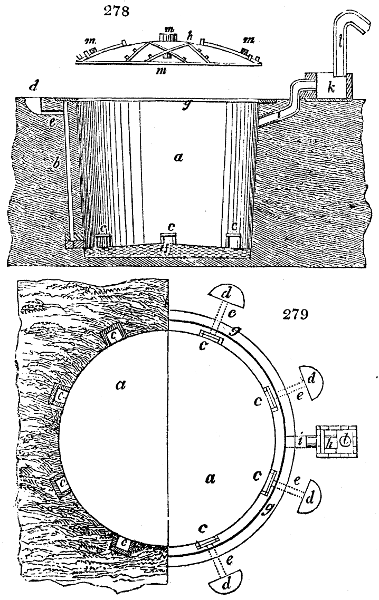

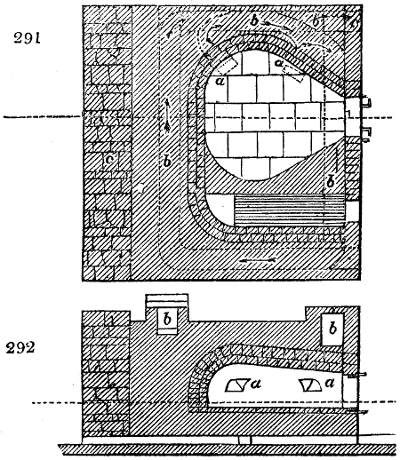

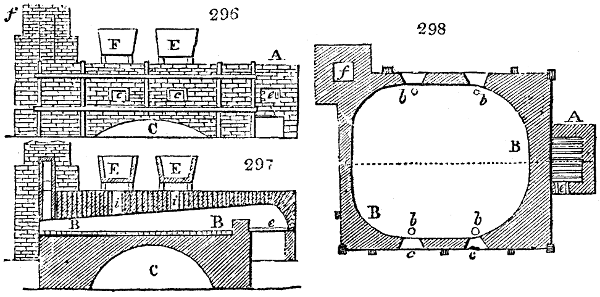

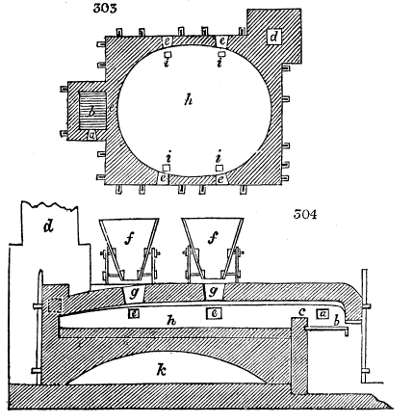

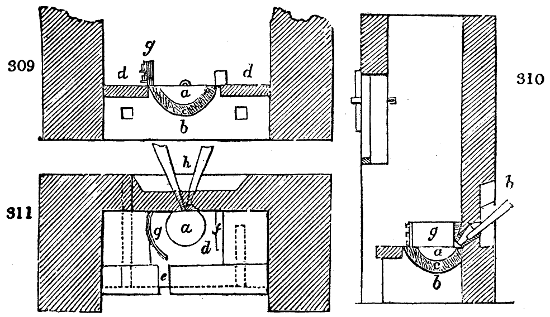

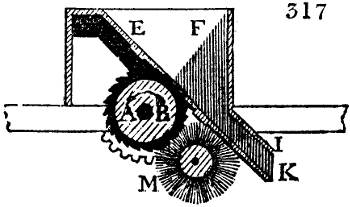

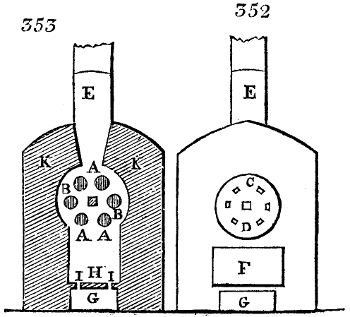

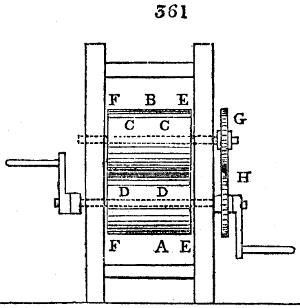

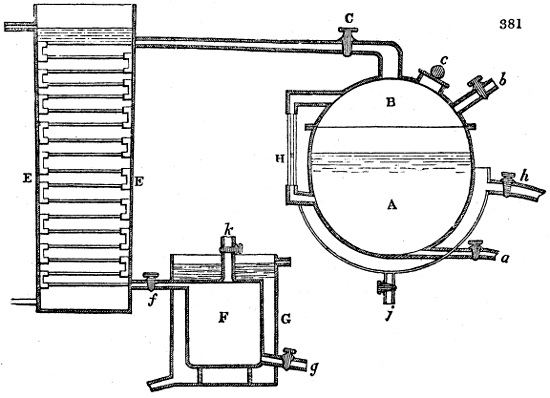

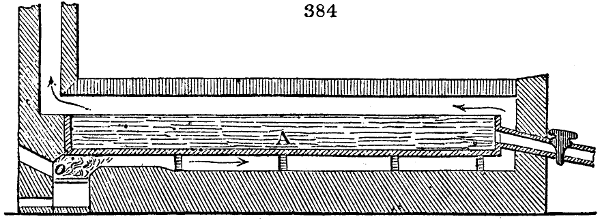

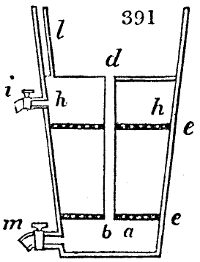

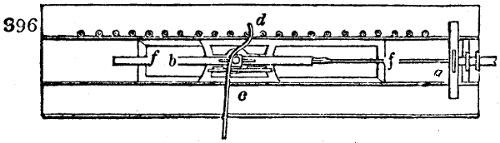

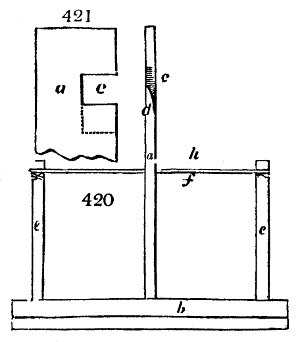

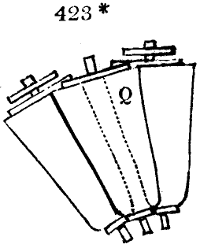

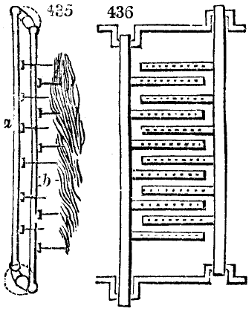

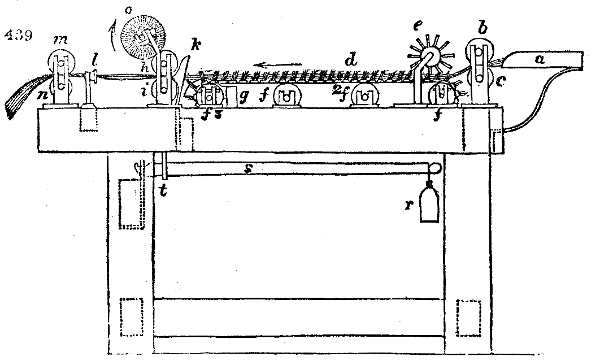

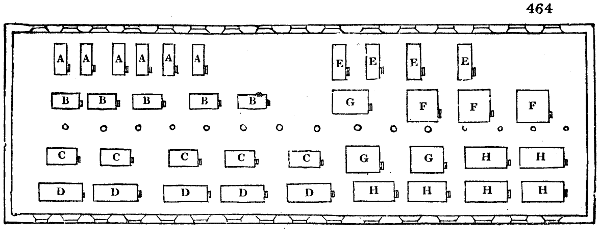

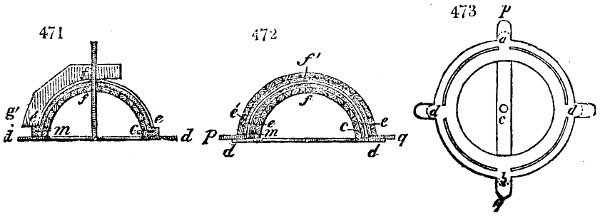

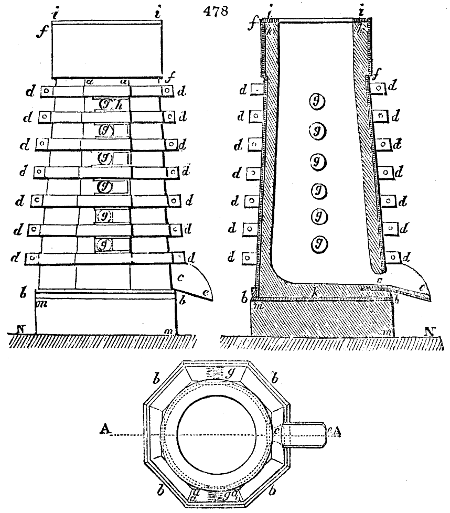

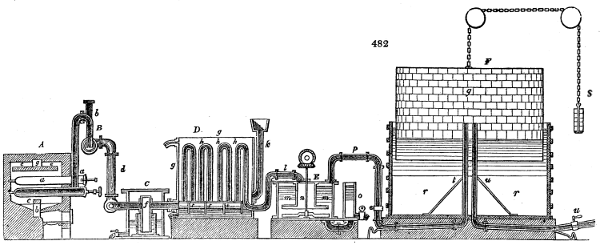

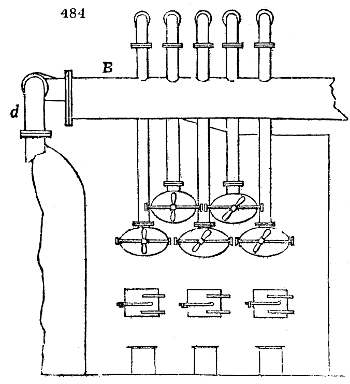

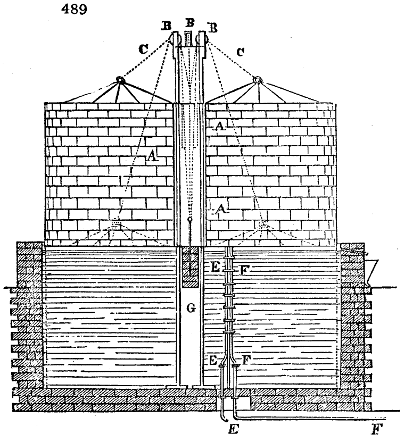

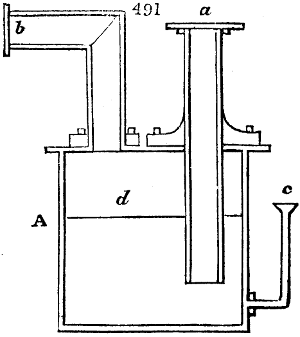

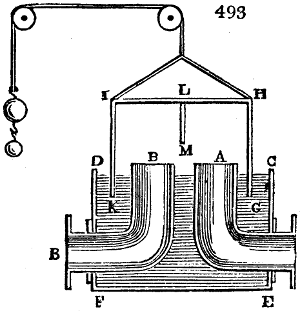

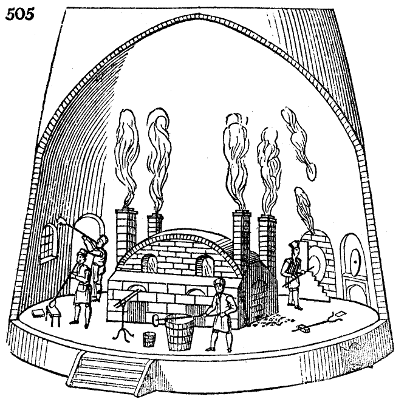

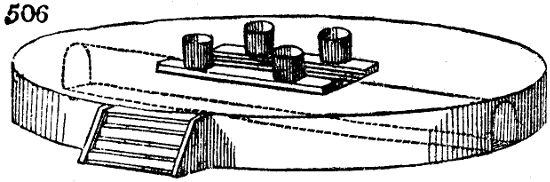

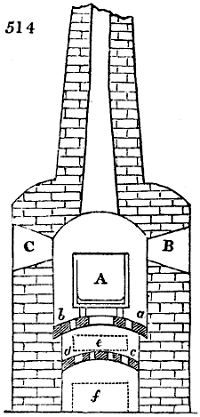

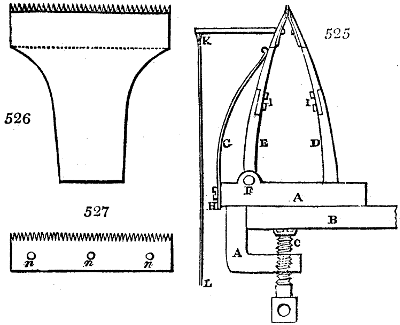

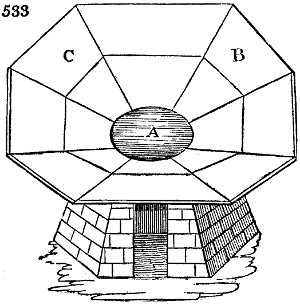

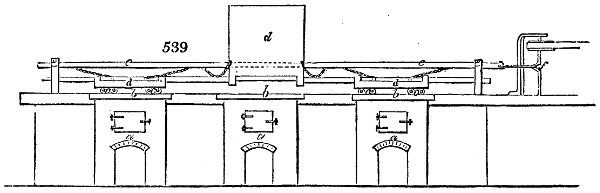

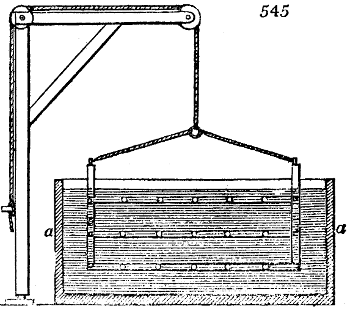

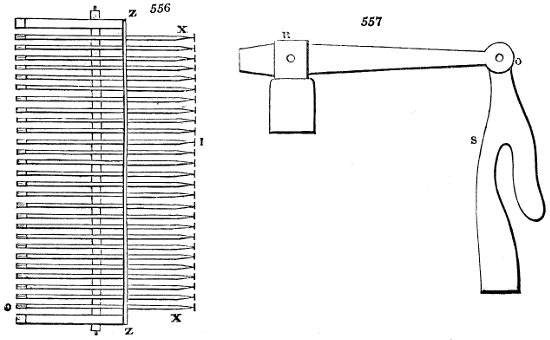

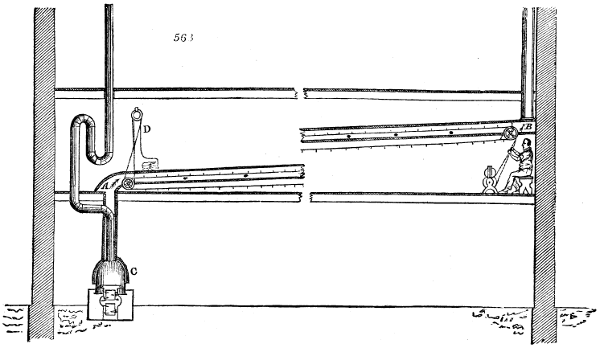

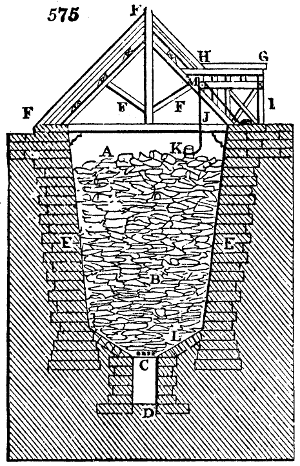

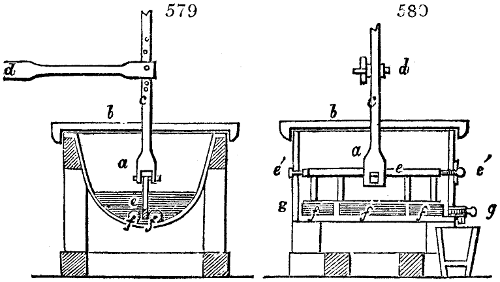

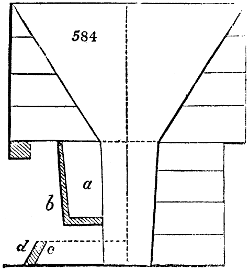

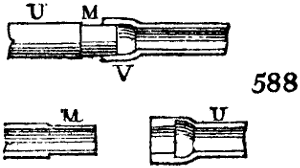

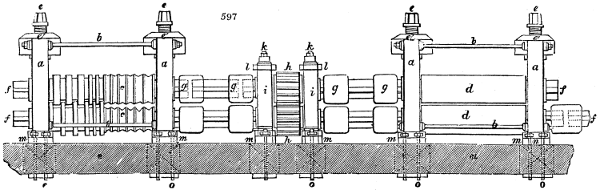

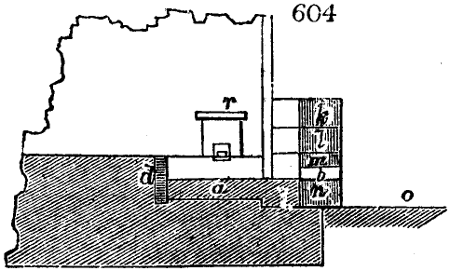

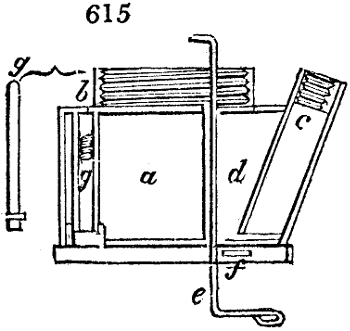

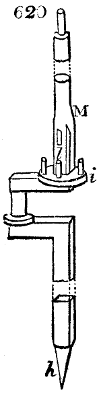

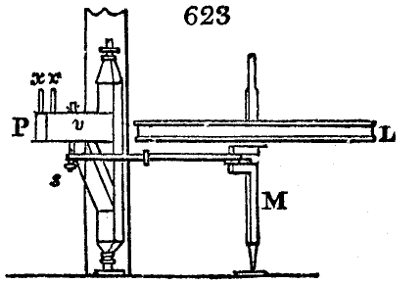

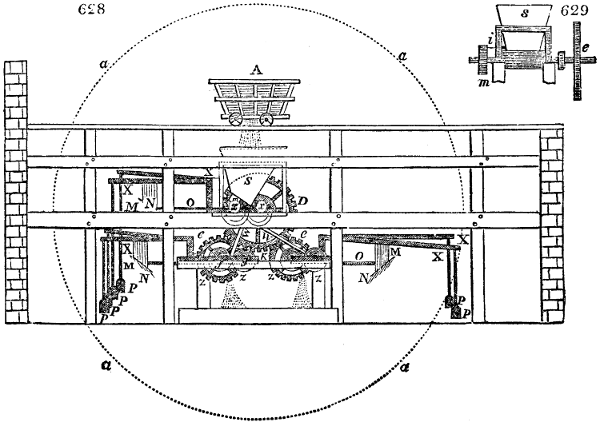

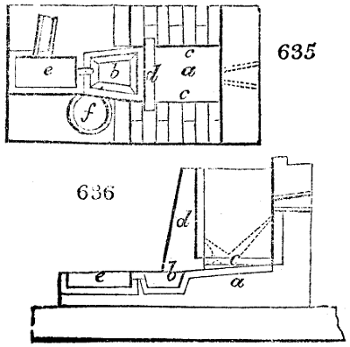

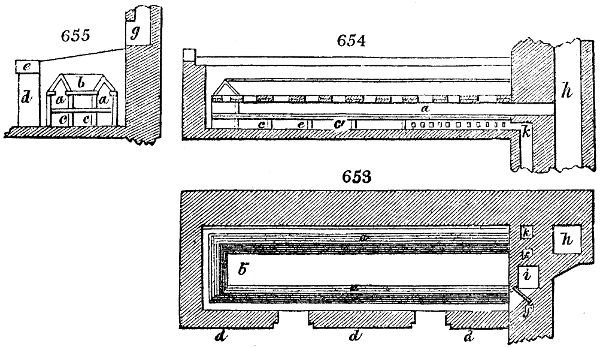

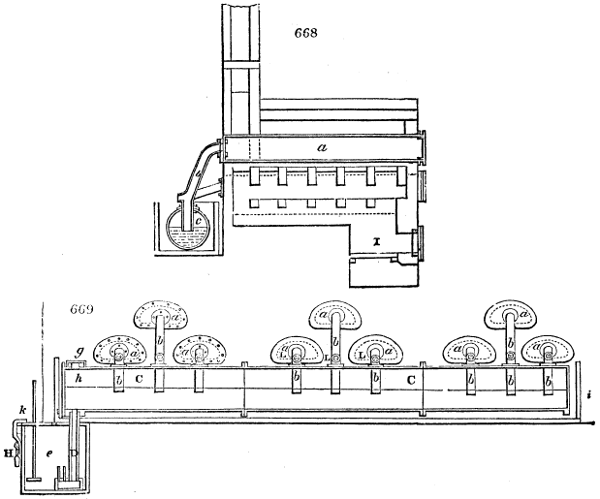

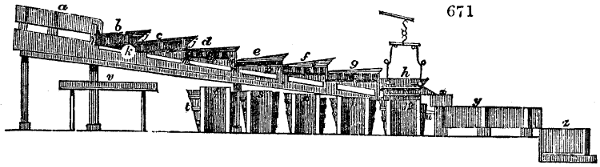

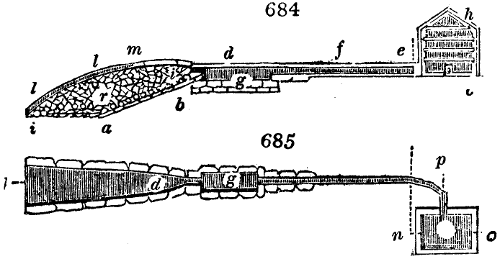

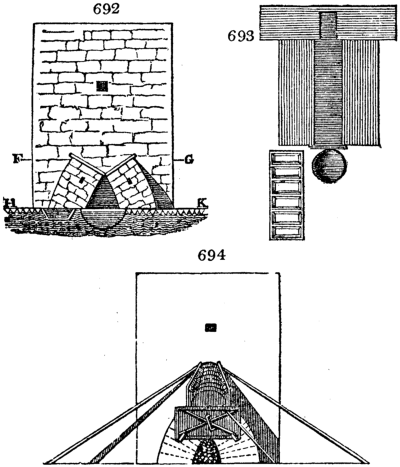

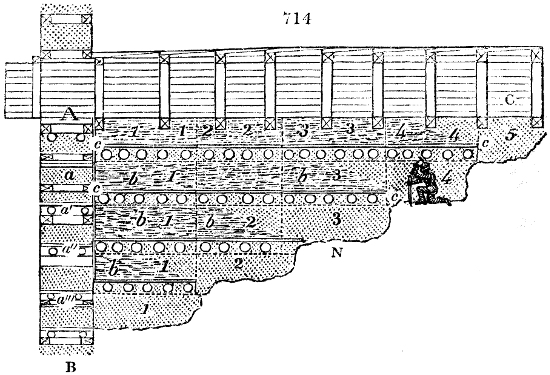

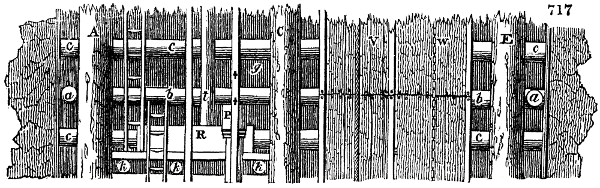

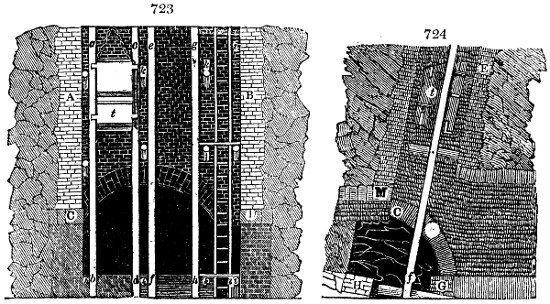

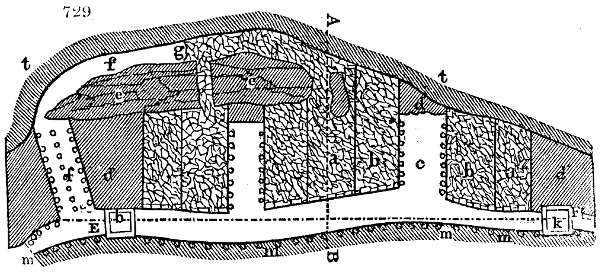

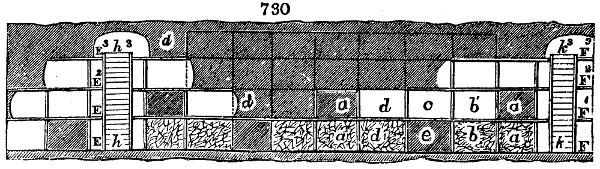

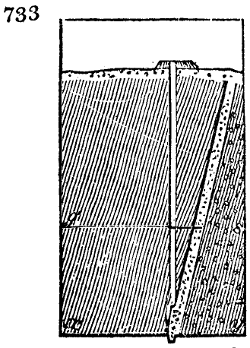

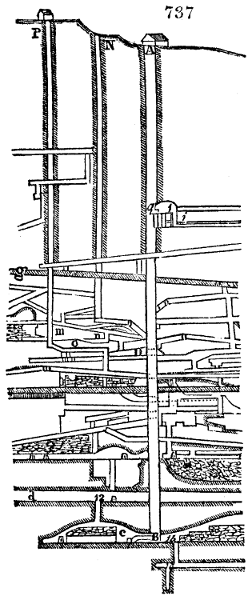

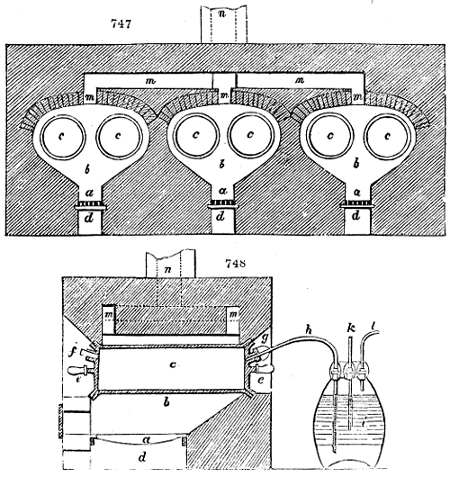

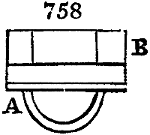

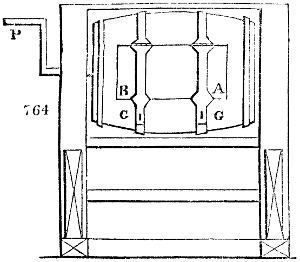

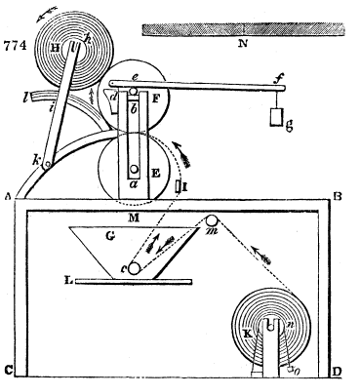

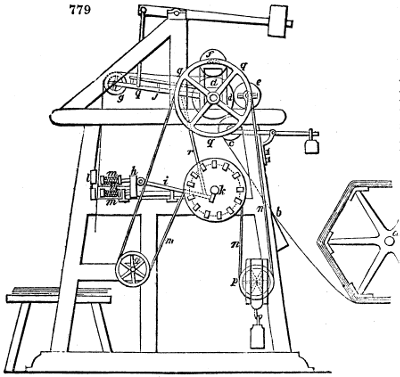

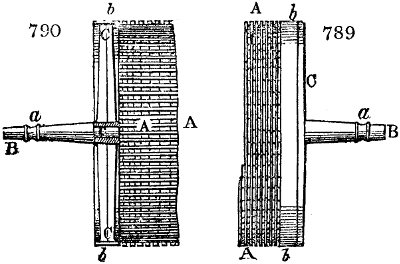

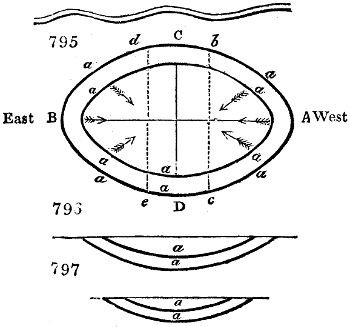

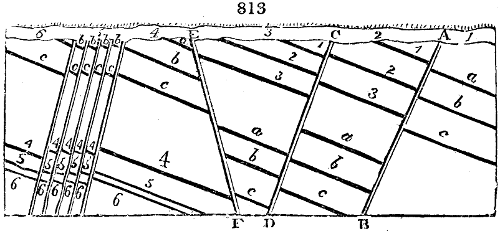

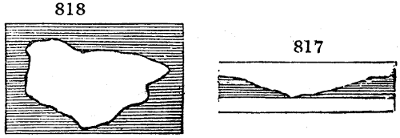

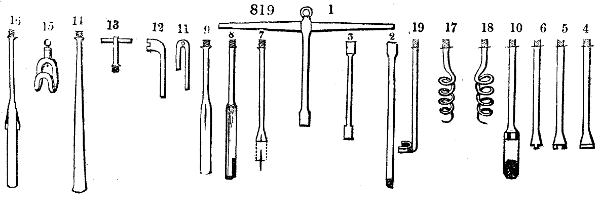

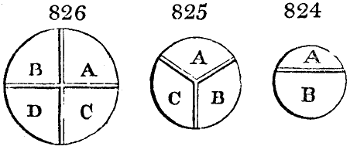

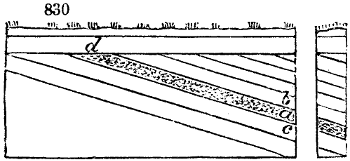

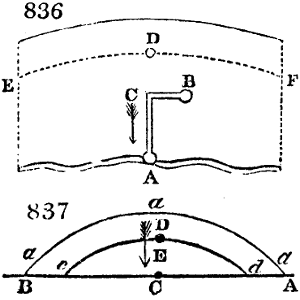

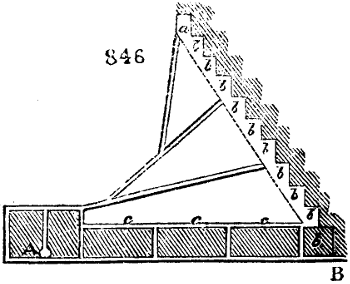

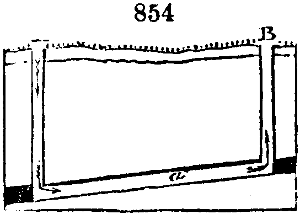

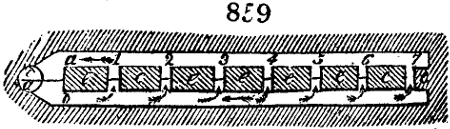

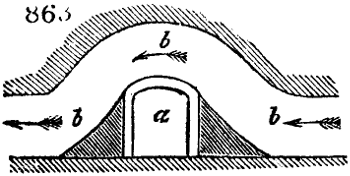

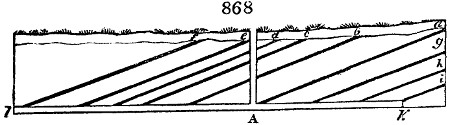

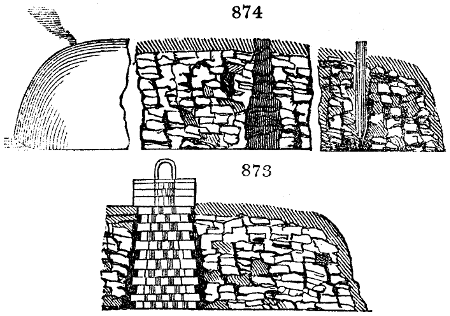

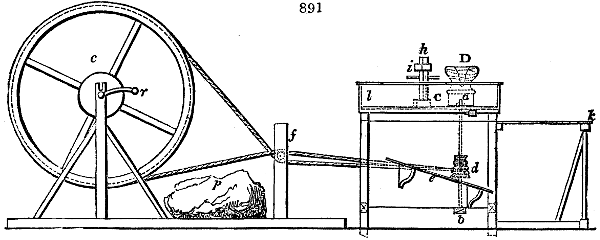

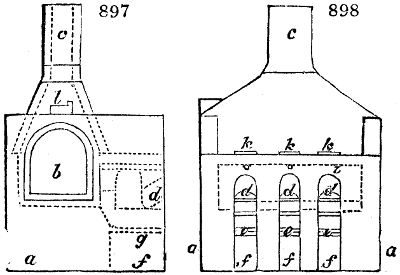

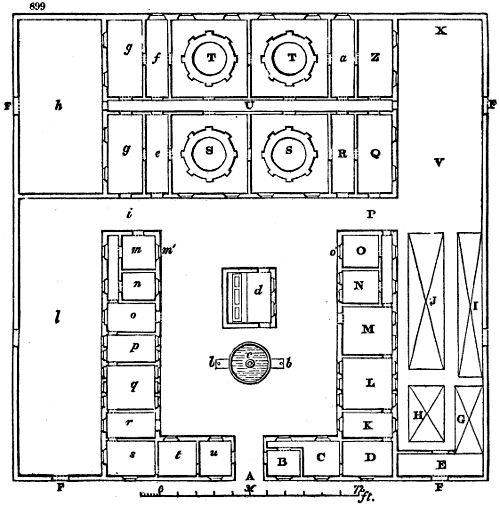

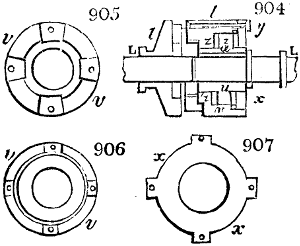

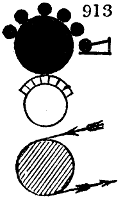

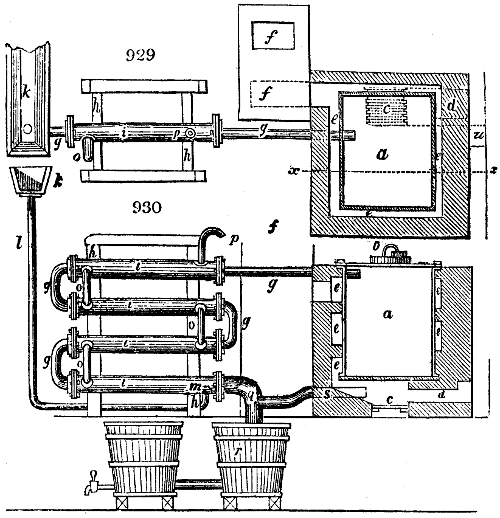

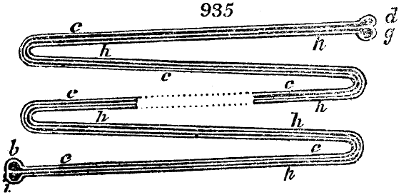

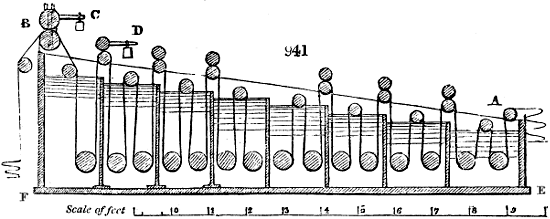

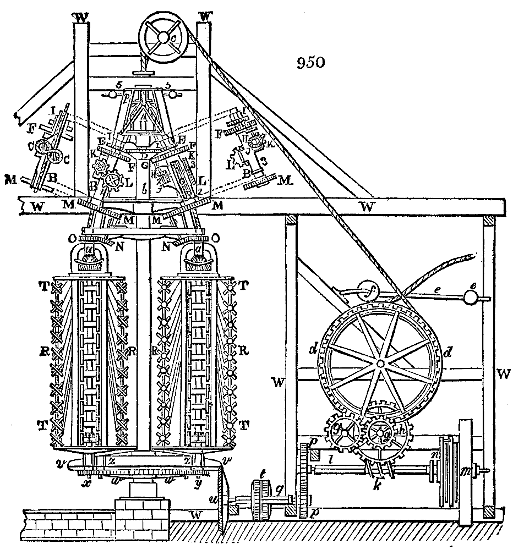

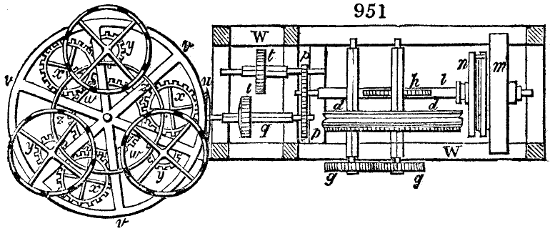

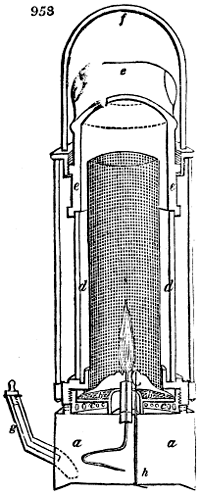

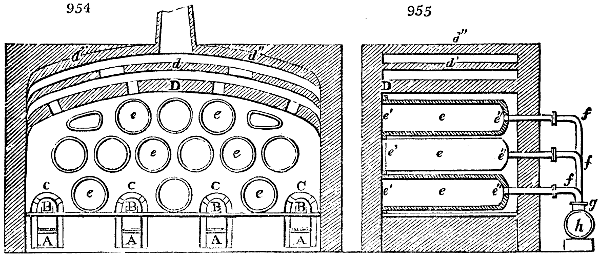

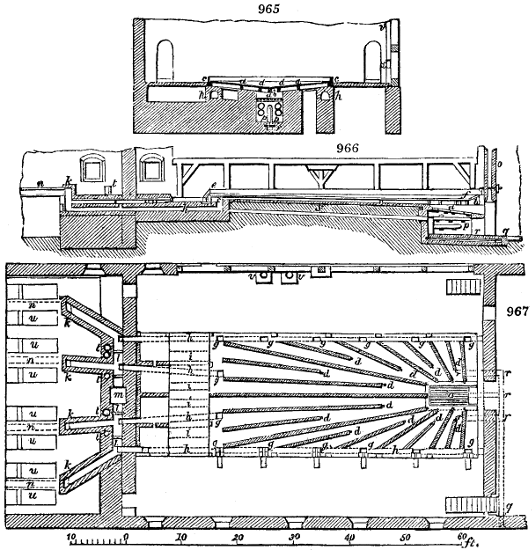

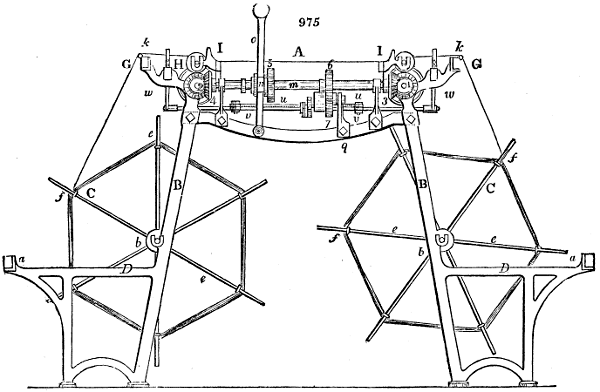

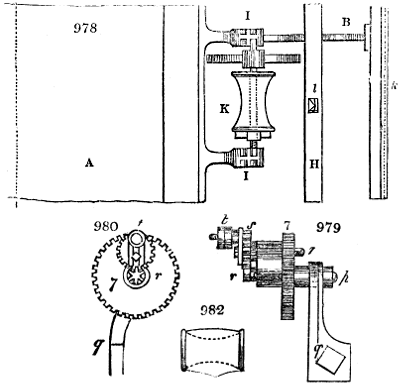

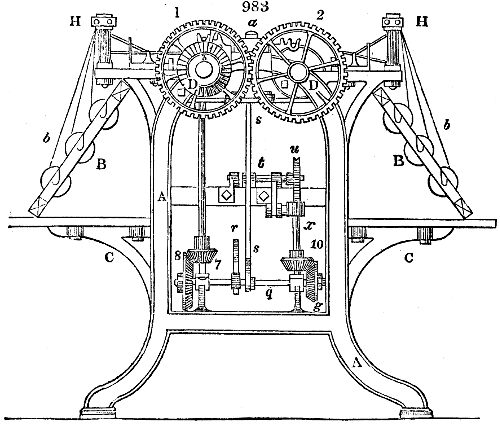

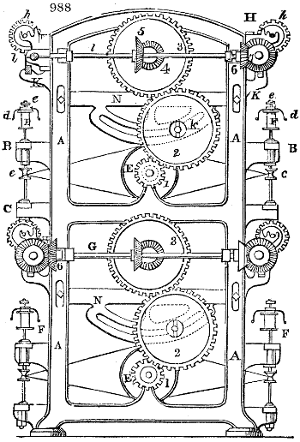

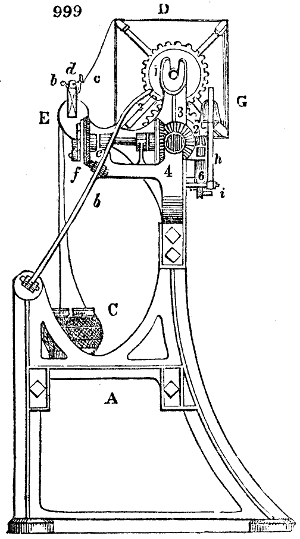

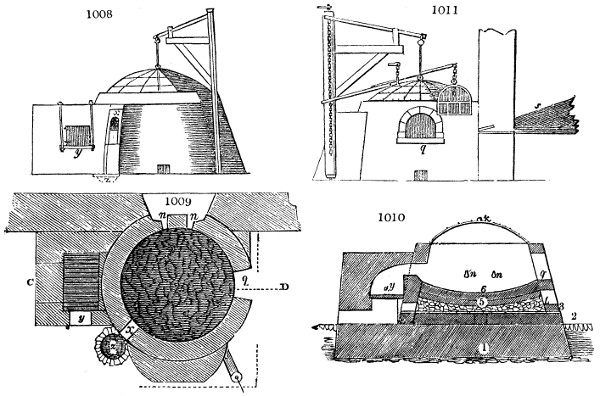

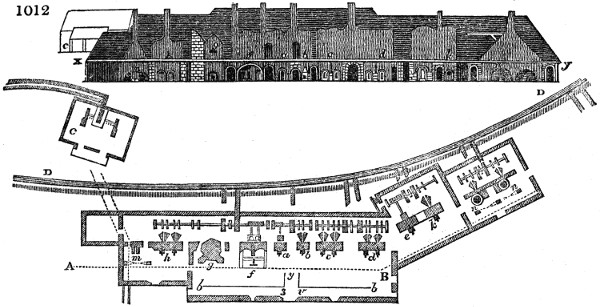

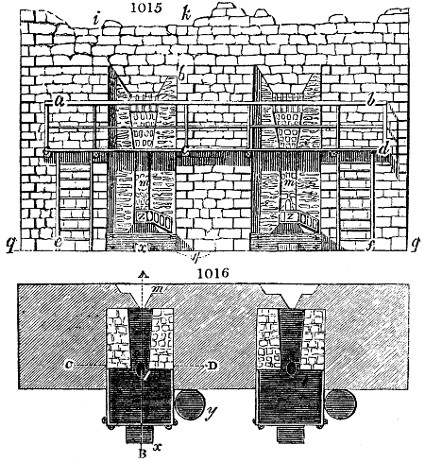

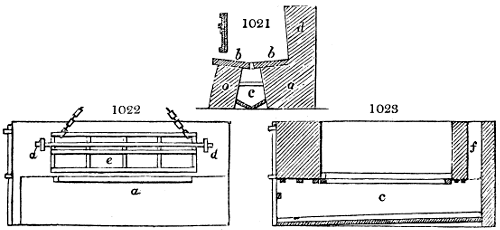

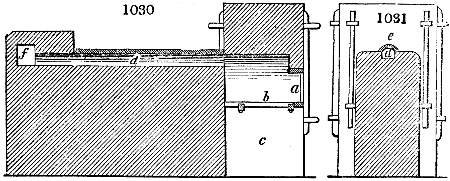

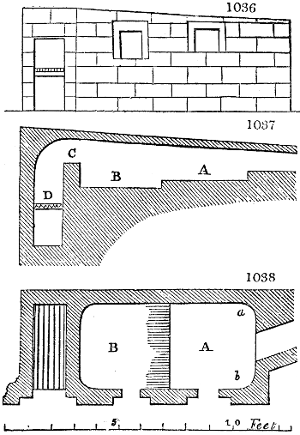

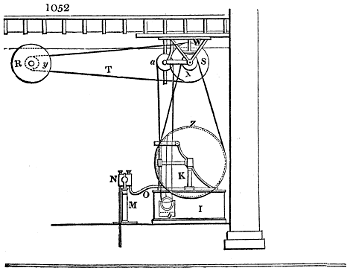

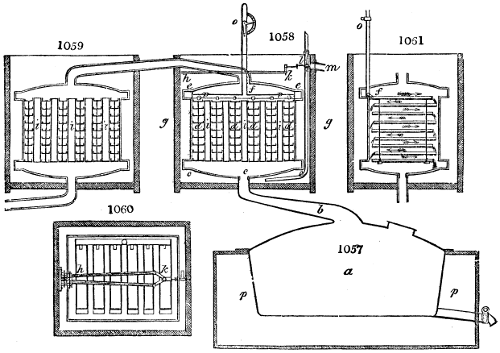

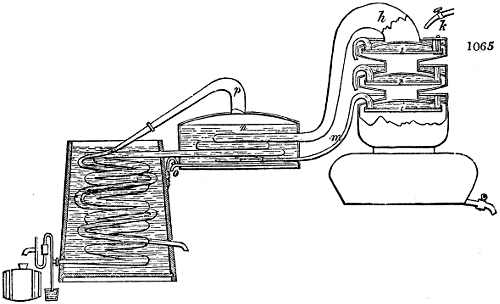

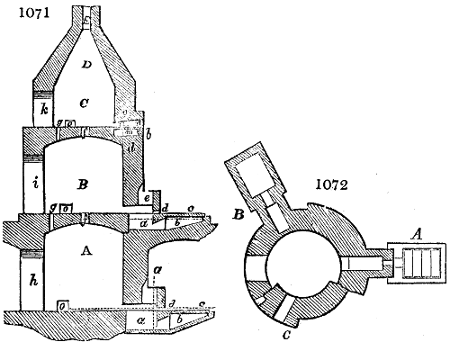

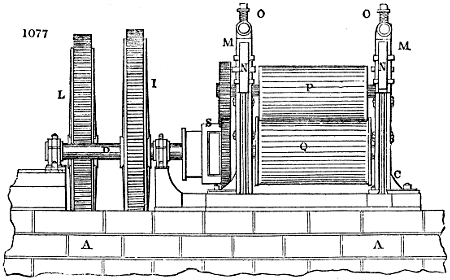

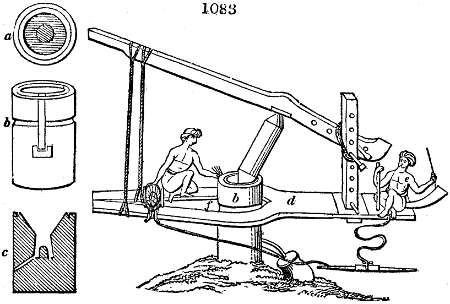

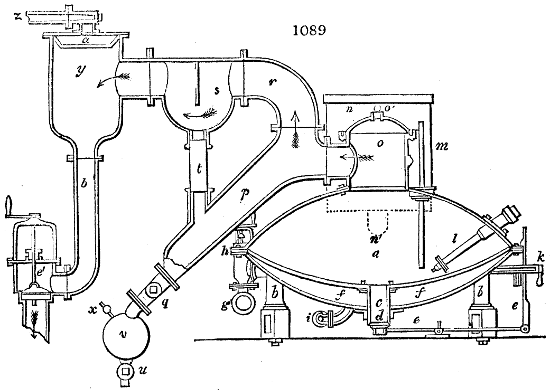

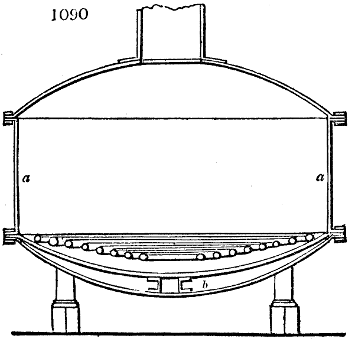

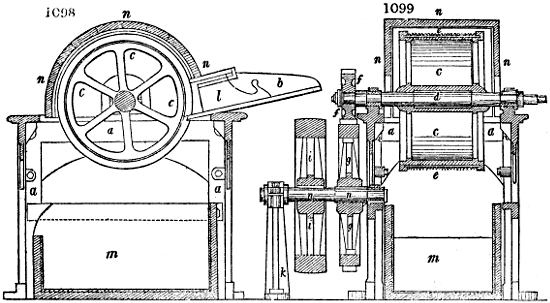

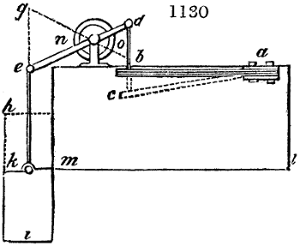

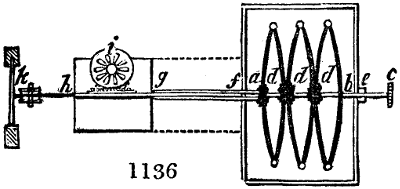

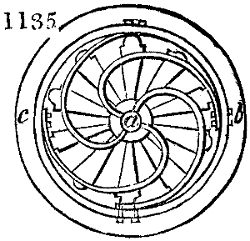

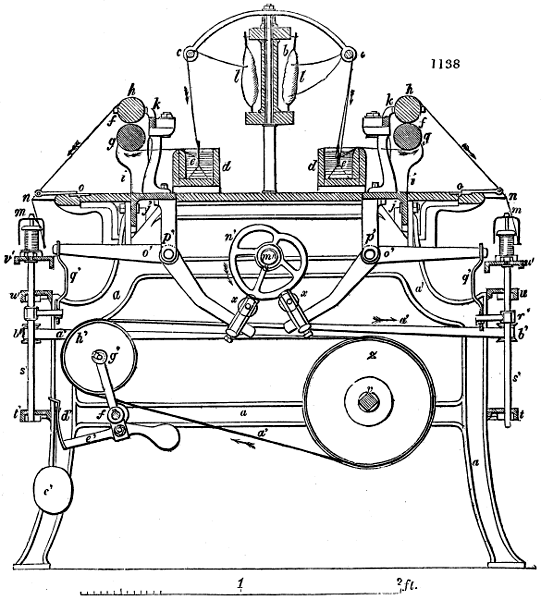

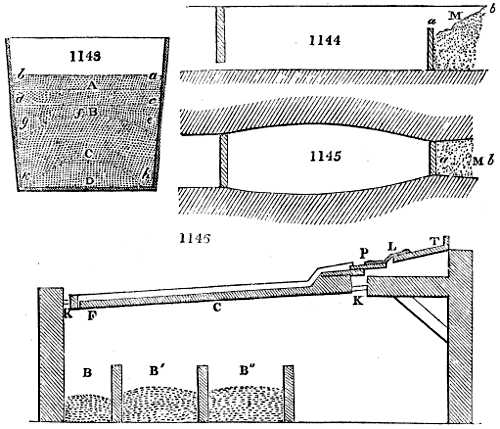

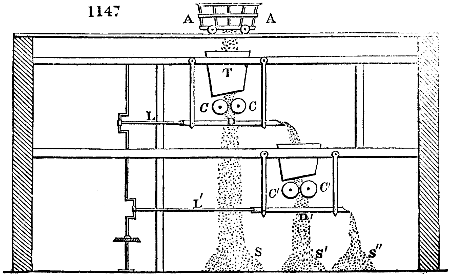

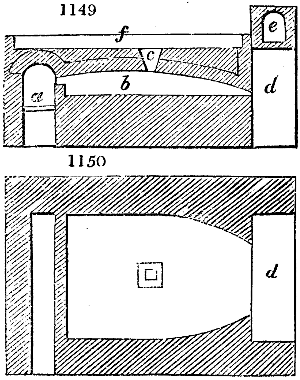

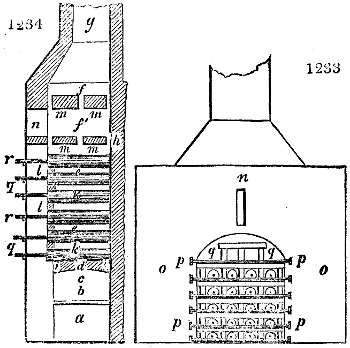

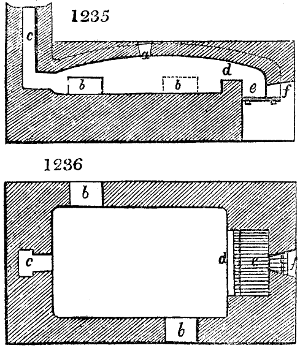

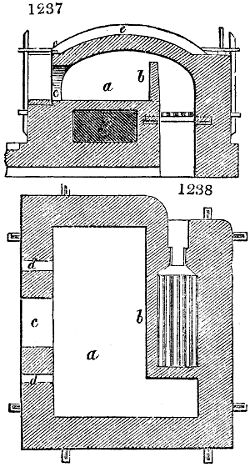

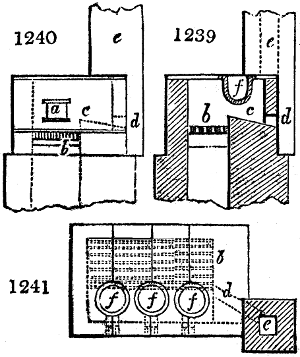

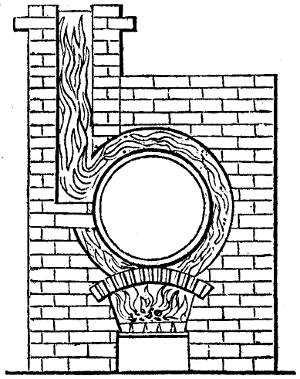

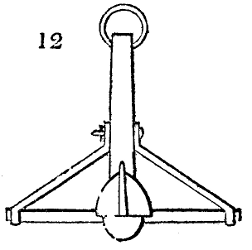

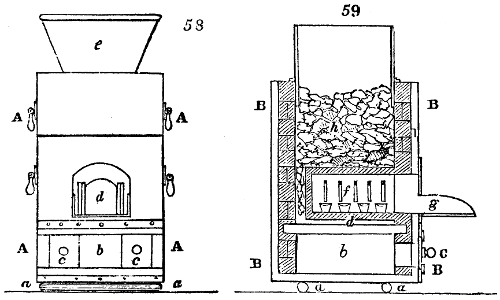

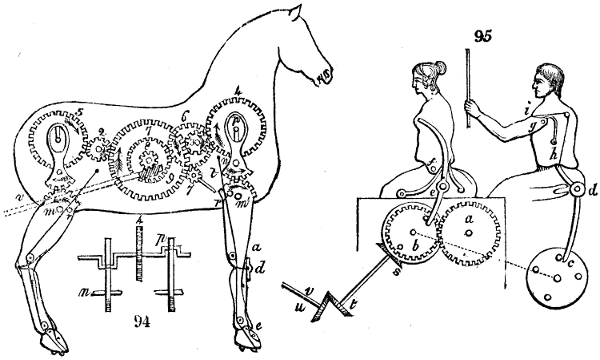

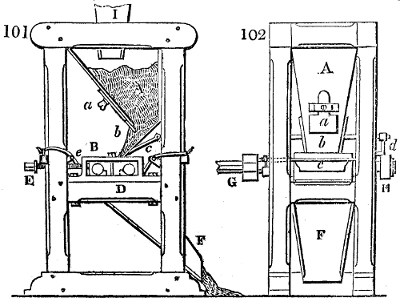

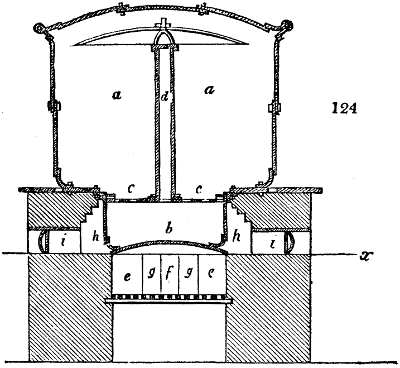

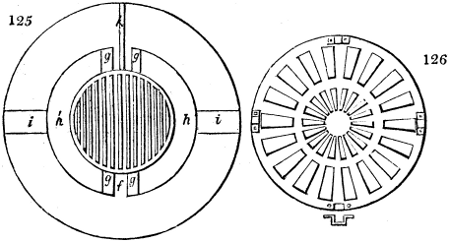

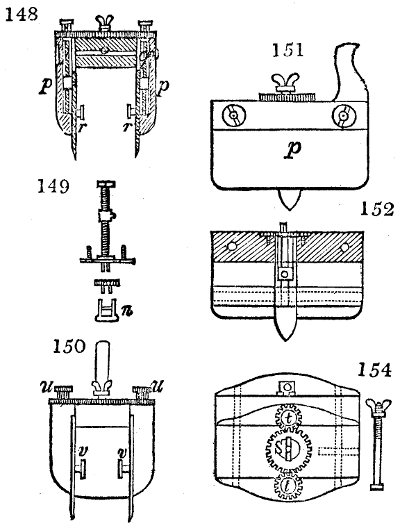

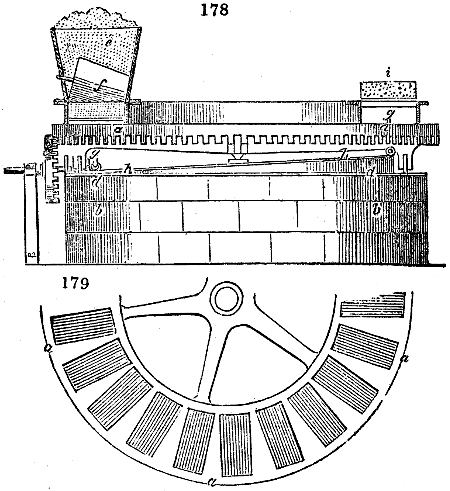

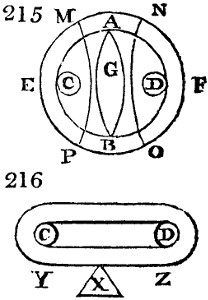

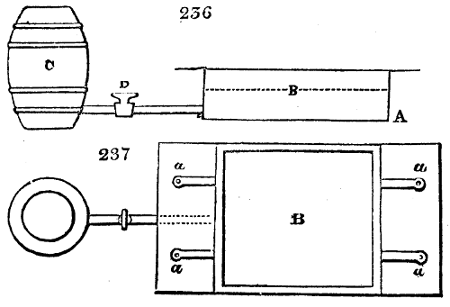

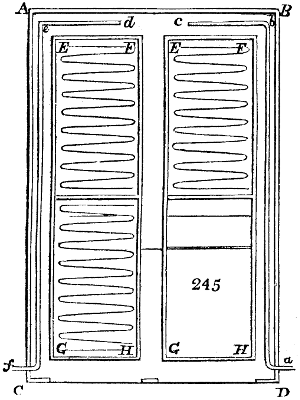

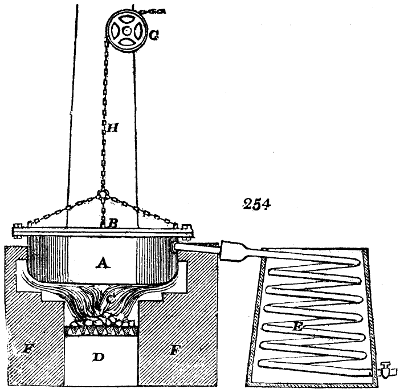

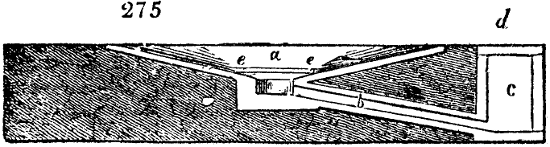

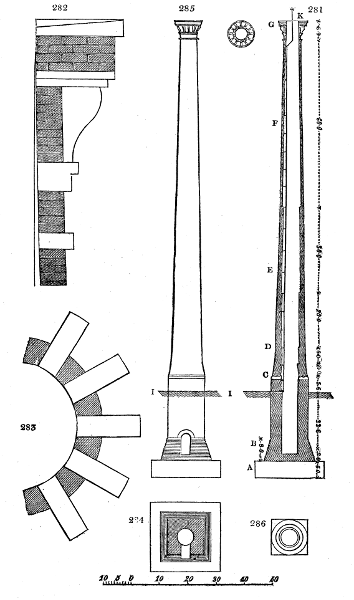

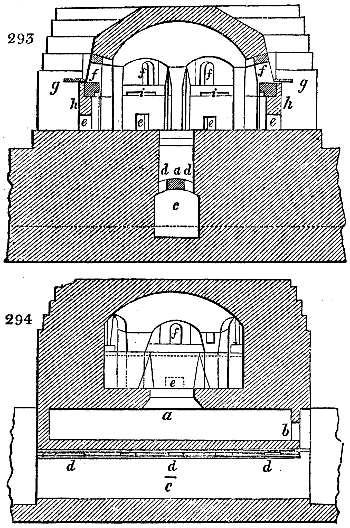

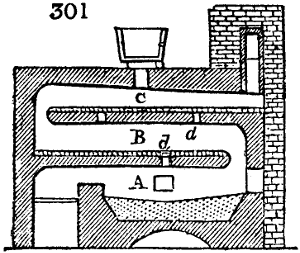

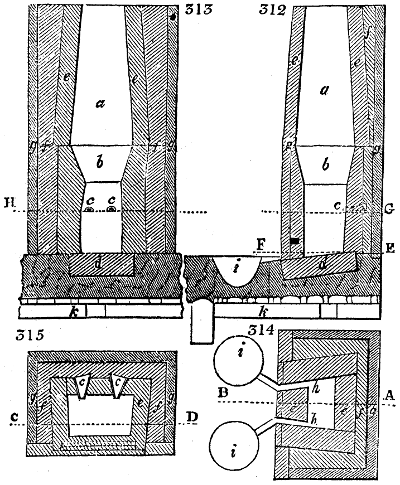

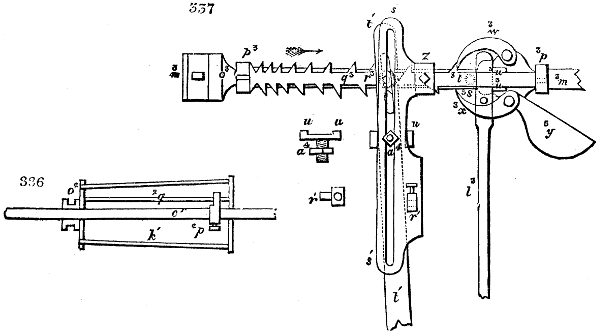

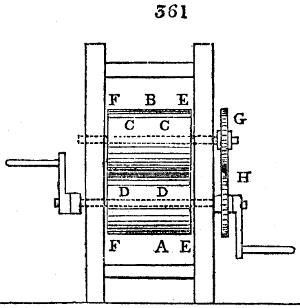

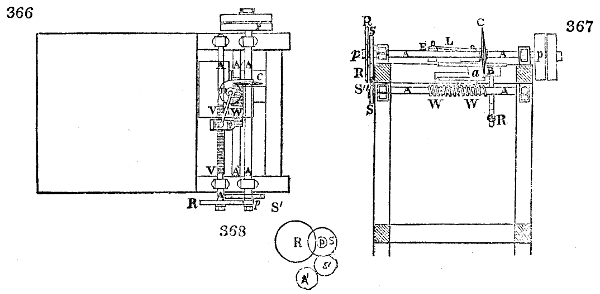

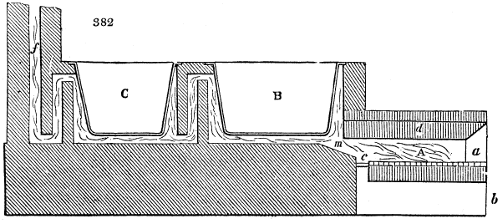

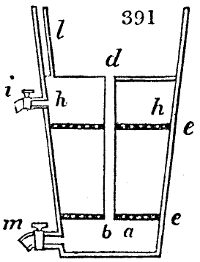

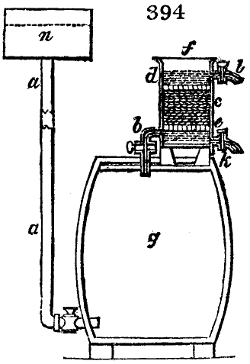

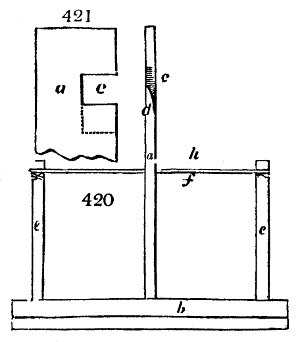

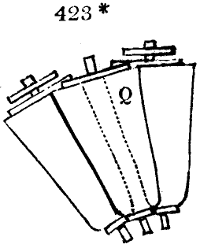

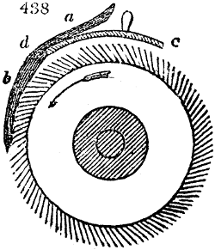

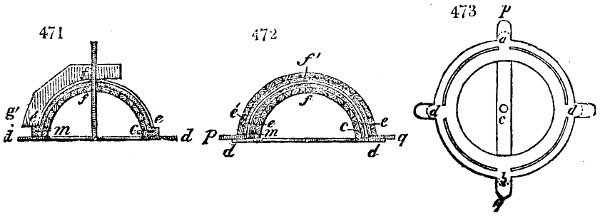

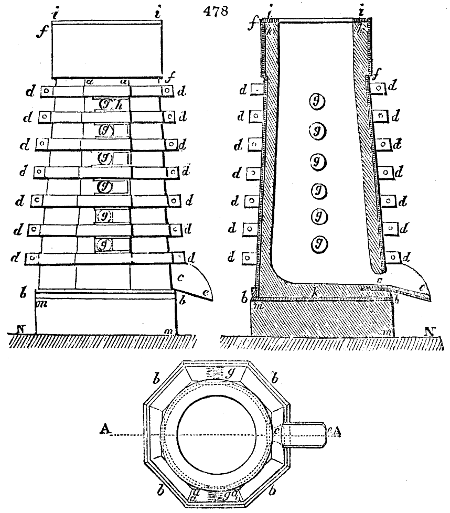

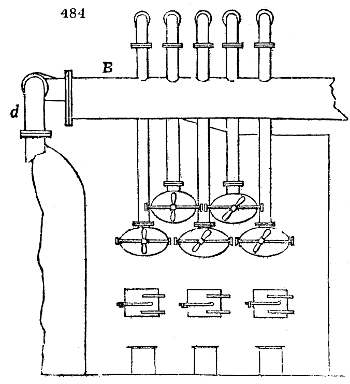

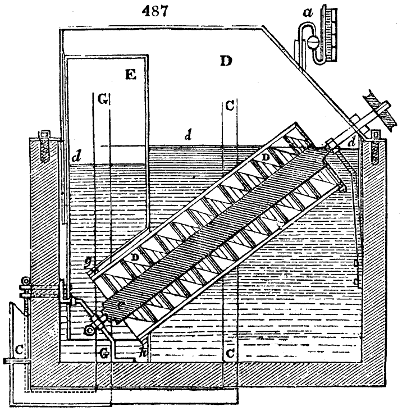

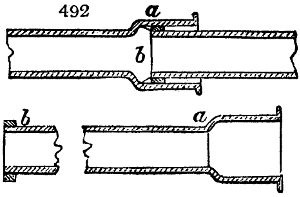

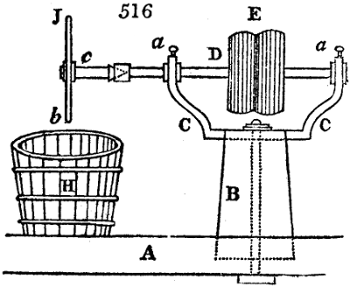

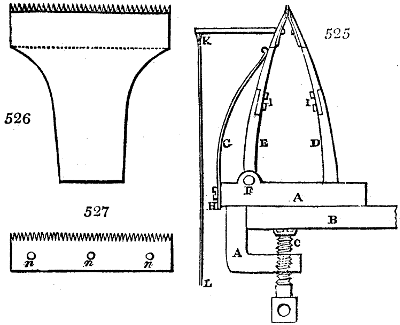

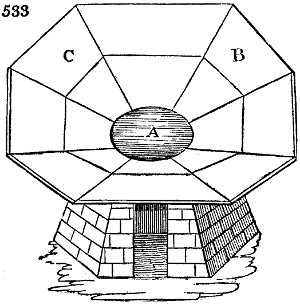

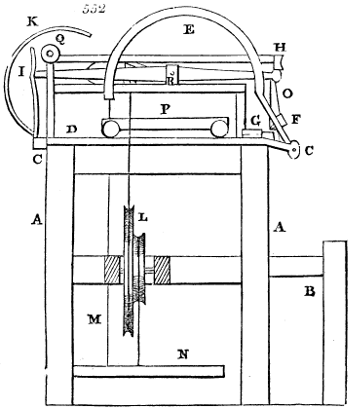

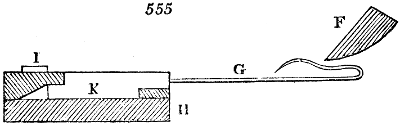

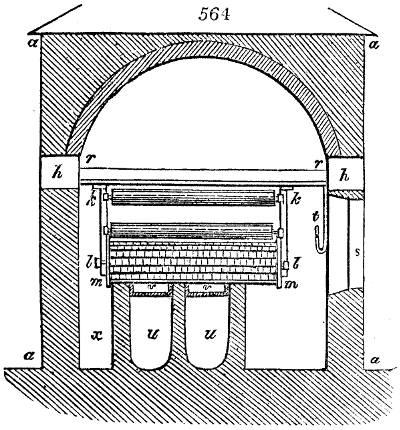

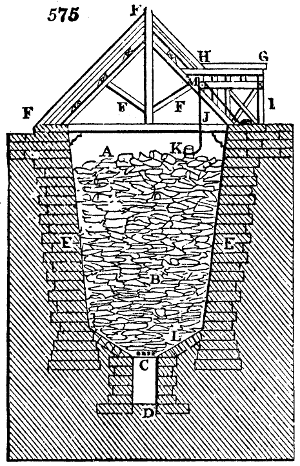

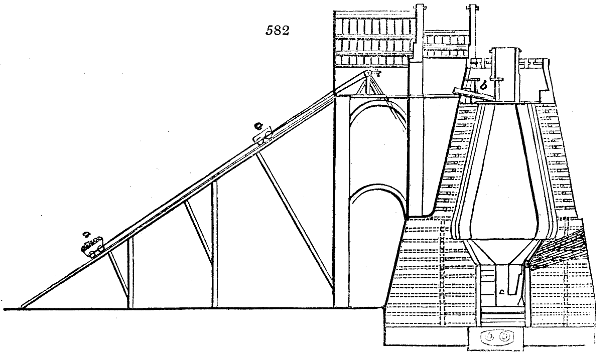

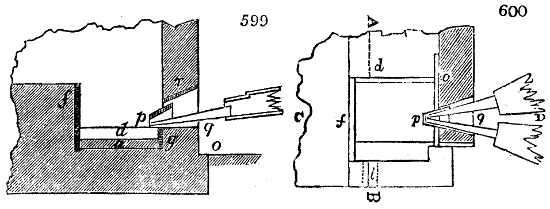

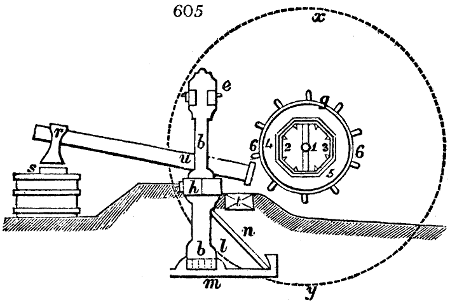

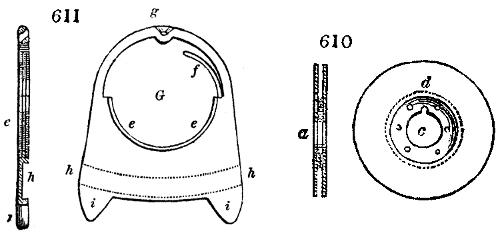

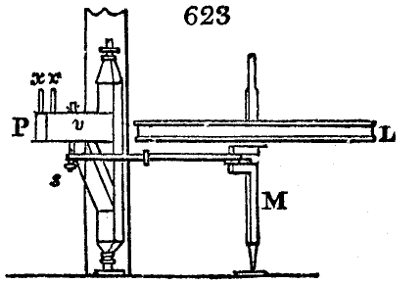

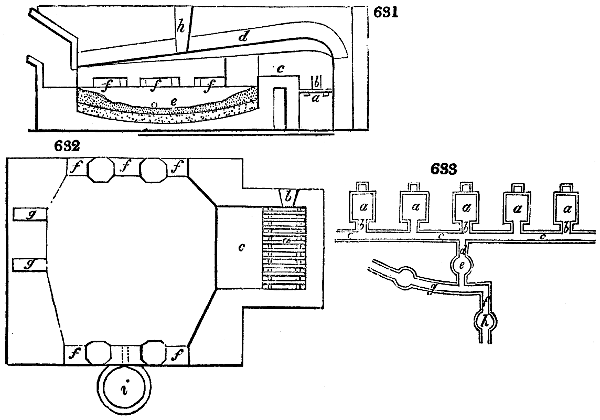

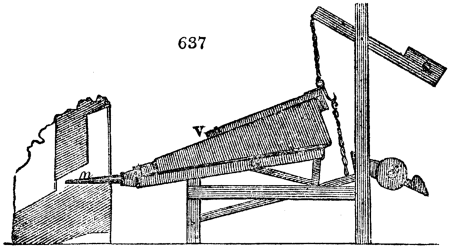

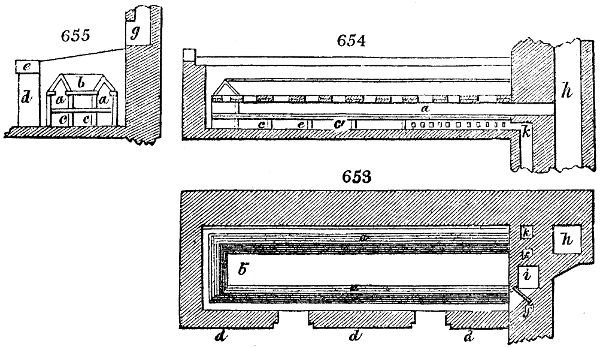

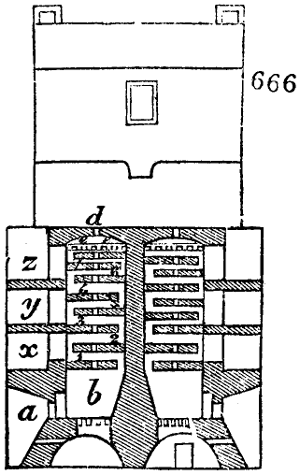

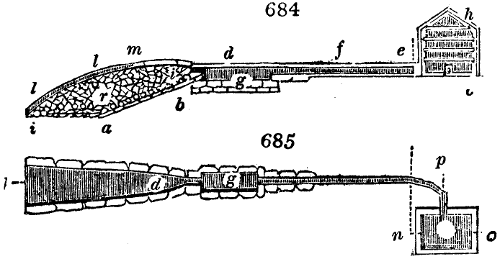

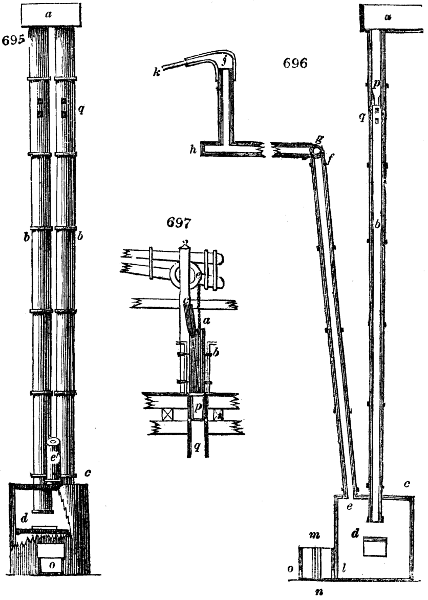

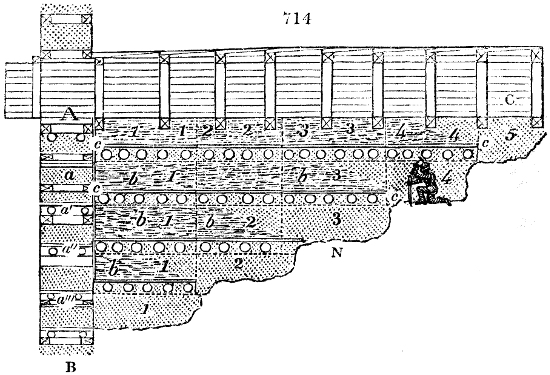

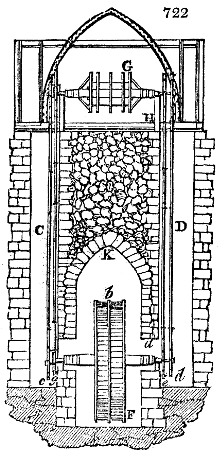

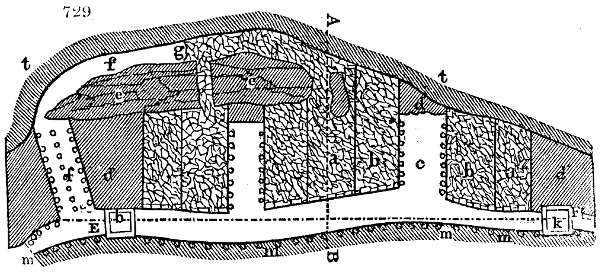

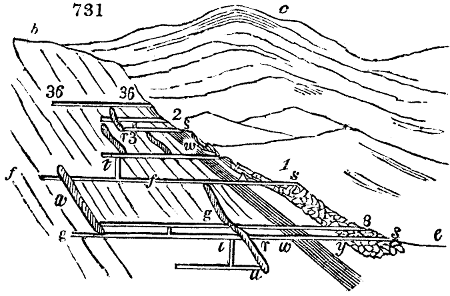

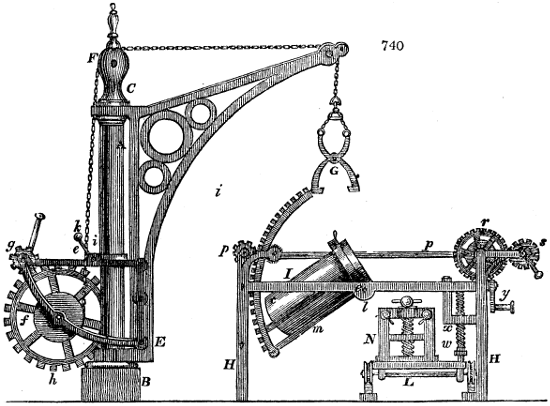

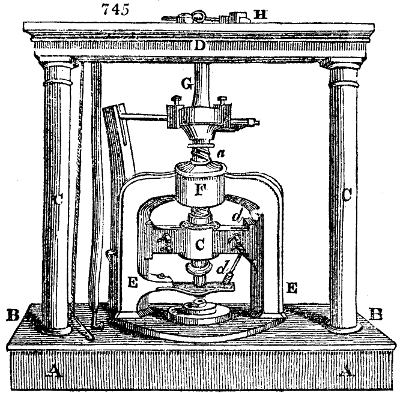

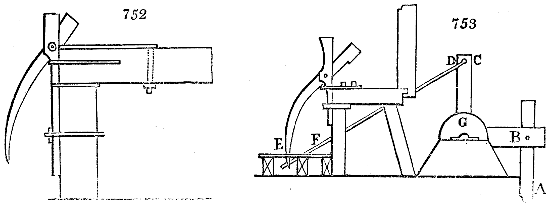

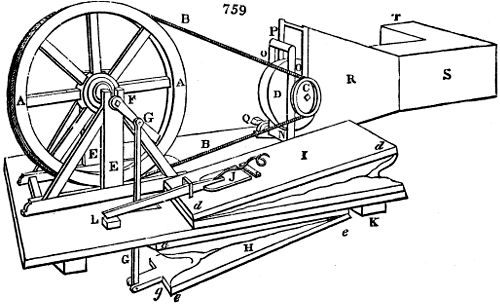

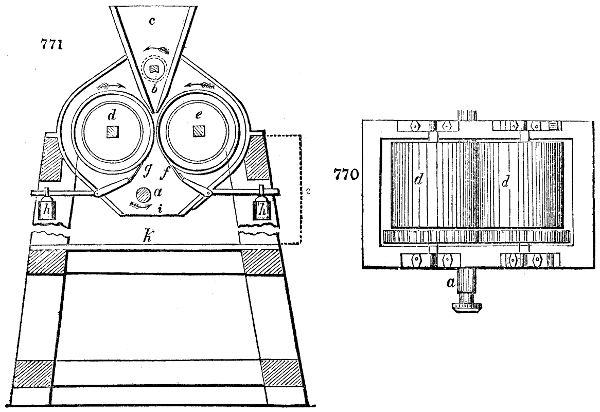

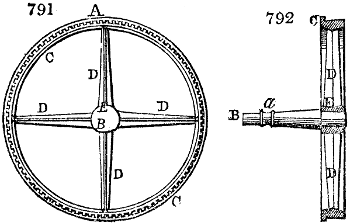

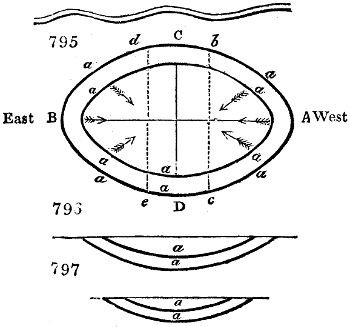

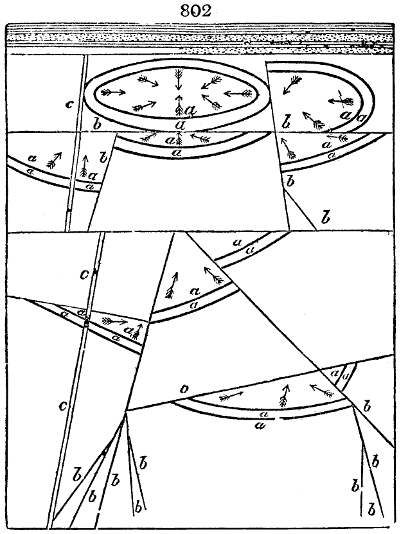

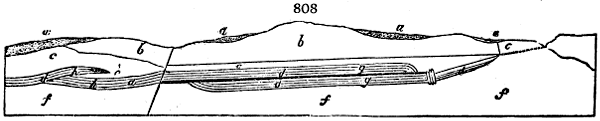

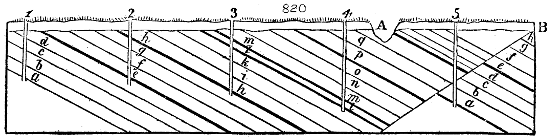

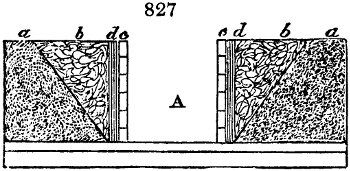

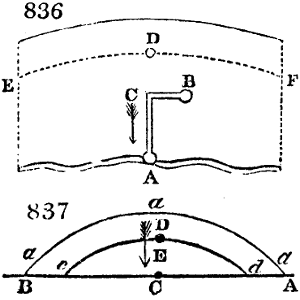

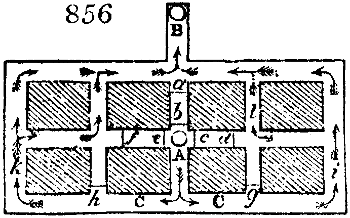

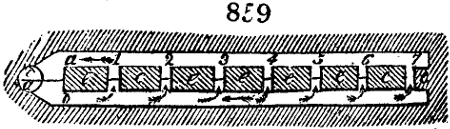

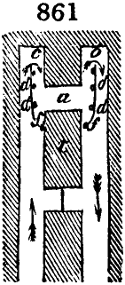

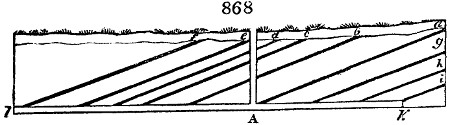

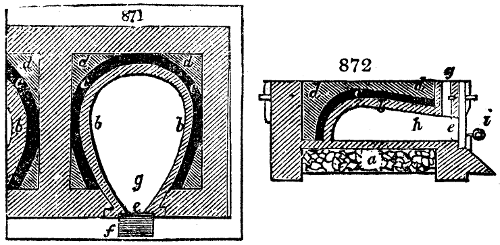

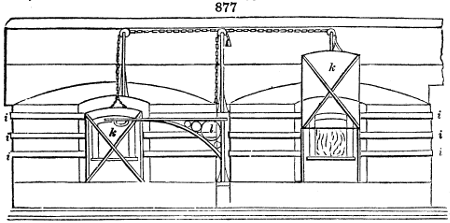

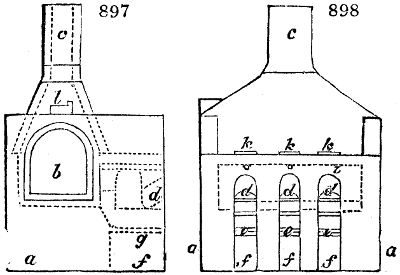

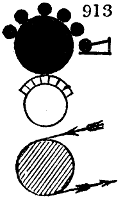

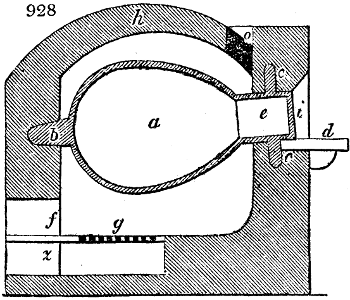

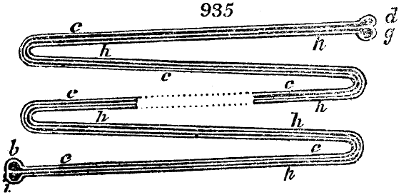

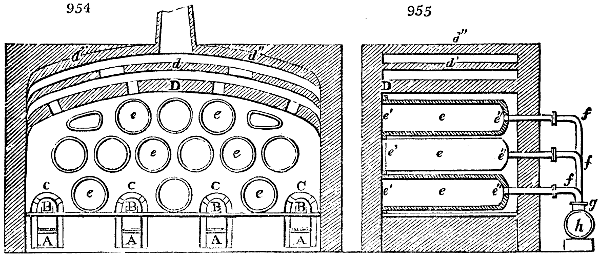

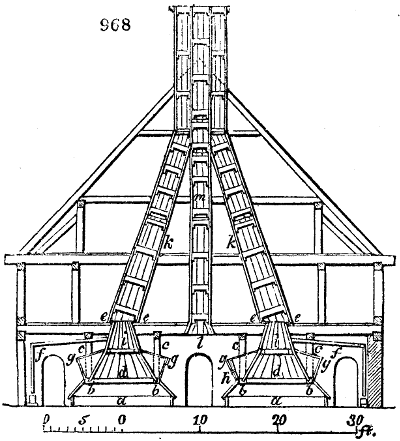

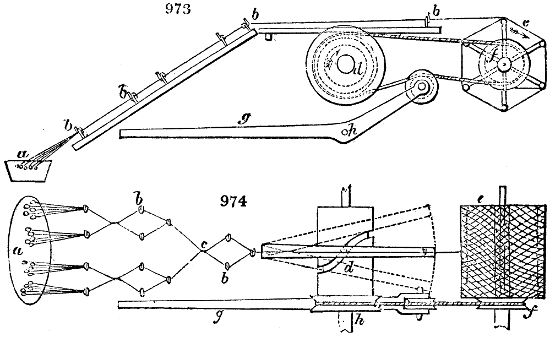

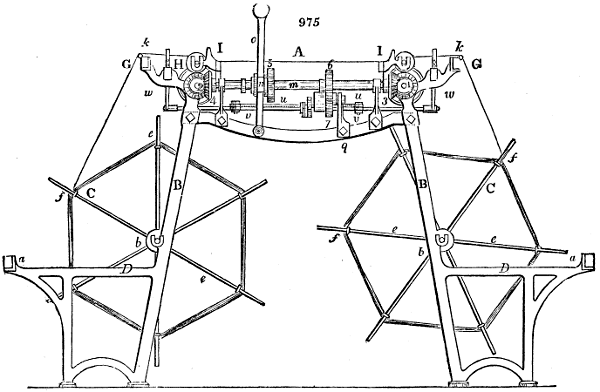

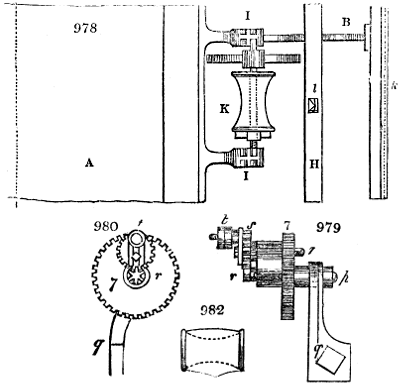

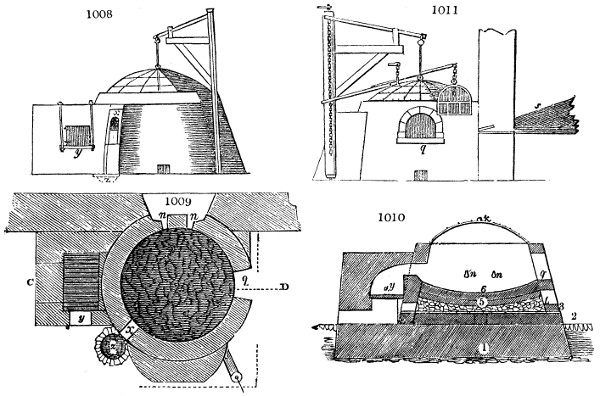

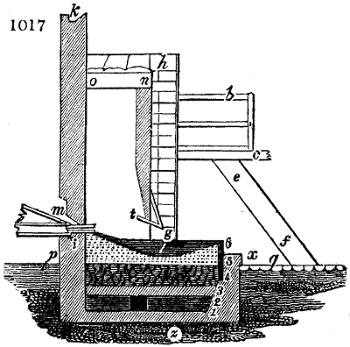

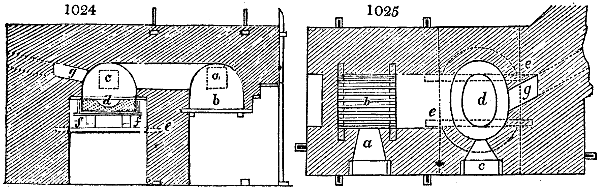

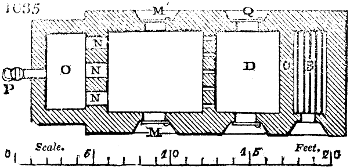

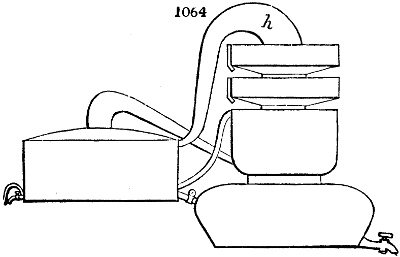

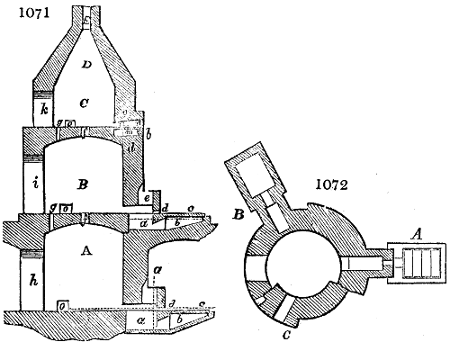

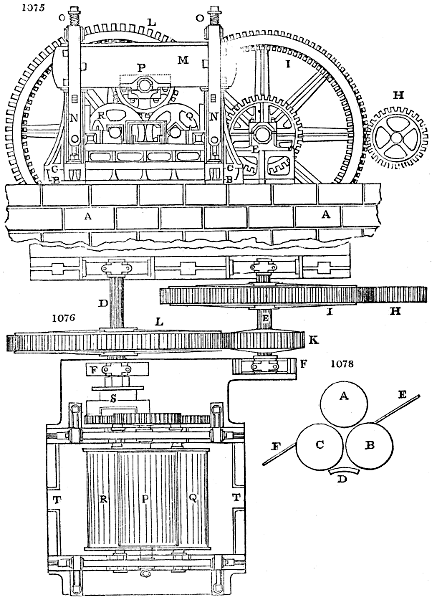

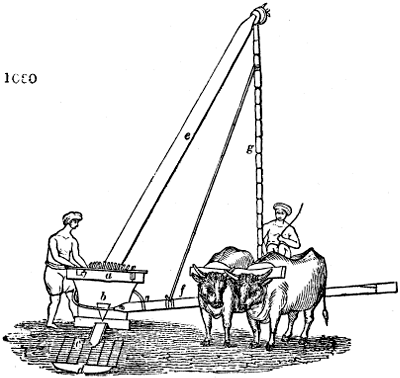

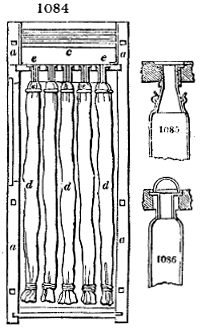

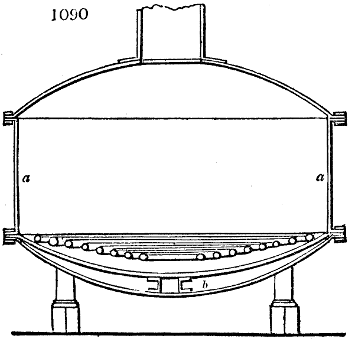

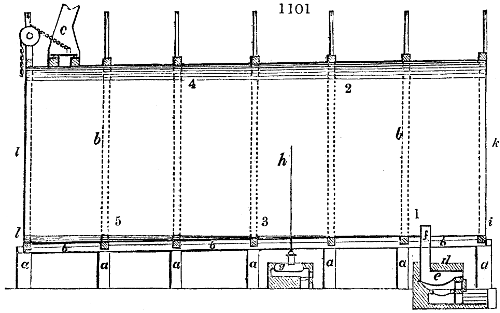

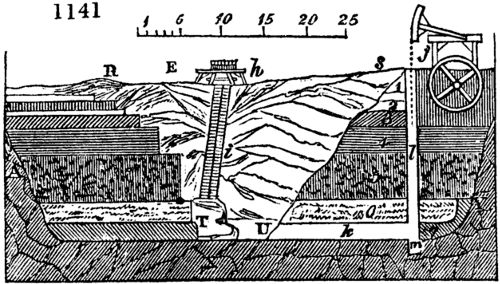

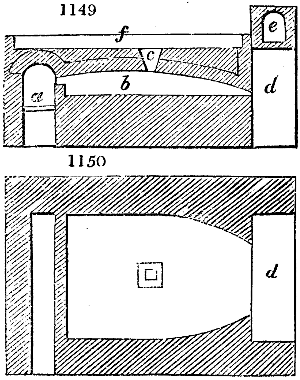

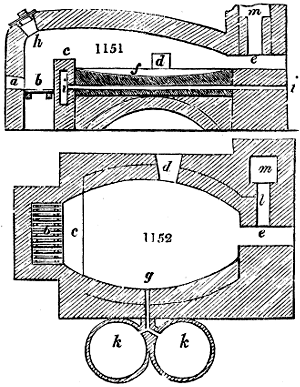

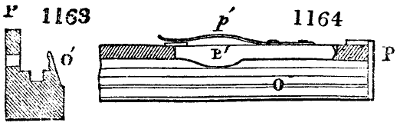

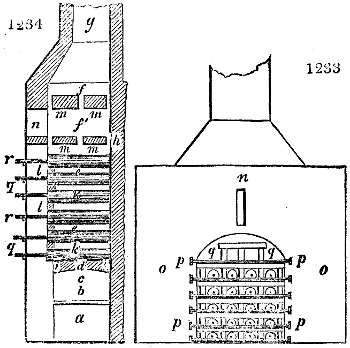

Fig. 2.

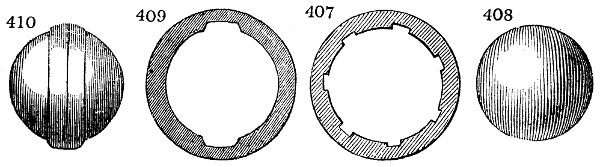

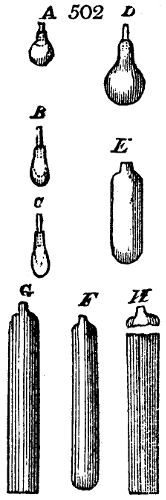

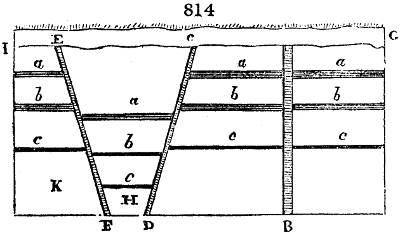

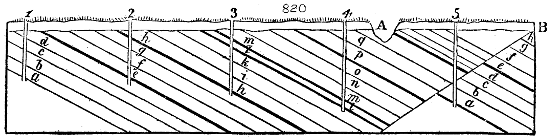

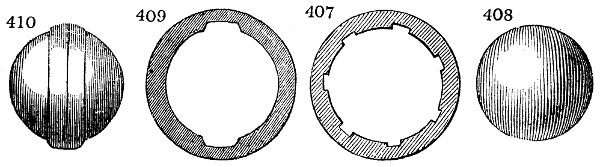

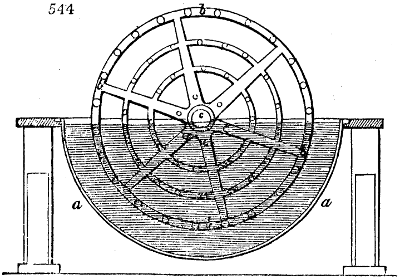

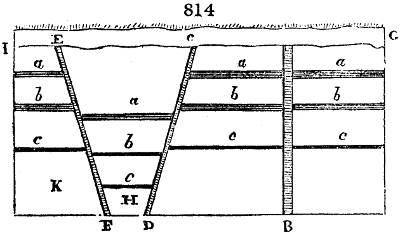

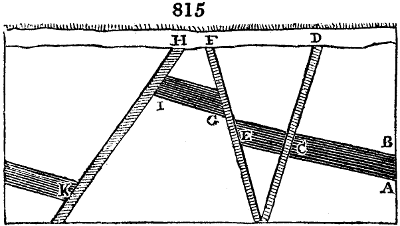

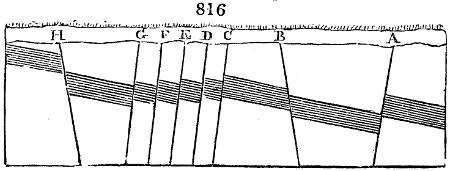

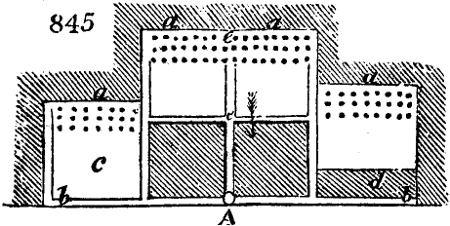

The apparatus employed for obtaining crude vinegar from wood, by the agency of heat,

are large iron cylinders. In this country they are made

of cast iron, and are laid horizontally in the furnace; in

France, they are made of sheet iron riveted together, and

they are set upright in the fire. Fig. 2. will give an accurate

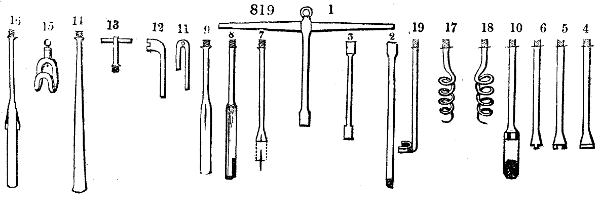

idea of the British plan, which is much the same as

that adopted for decomposing pit coal in gas works, only

that the cylinders for the pyrolignous acid manufacture are

generally larger, being frequently 4 feet in diameter, and

6 or 8 feet long, and built horizontally in brickwork, so

that the flame of one furnace may play around two of

them. It would, probably, answer better, if their size

were brought nearer the dimensions of the gas-light retorts,

and if the whole system of working them were assimilated

to that of coal gas.

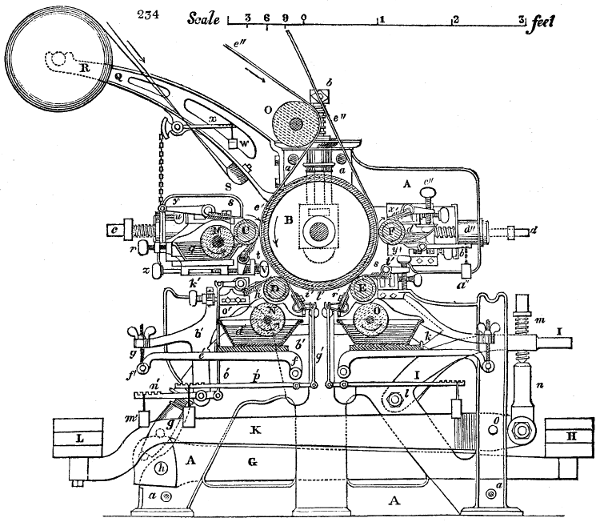

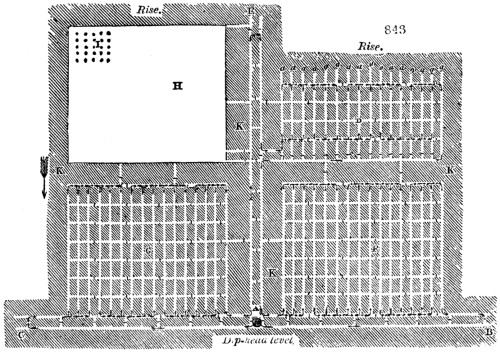

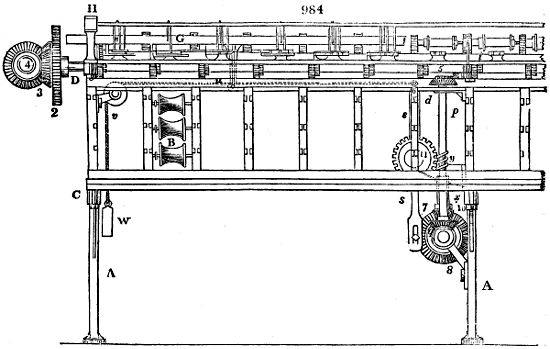

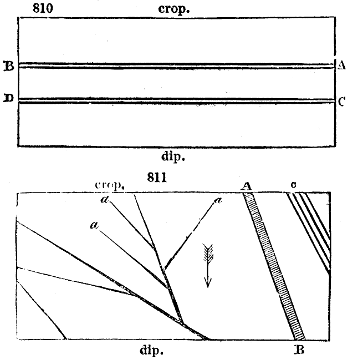

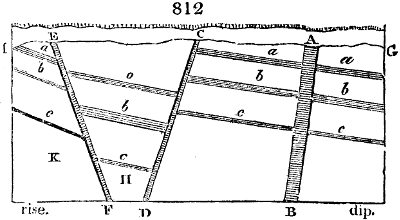

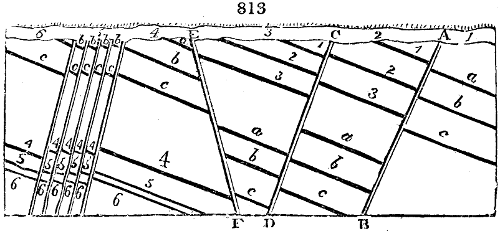

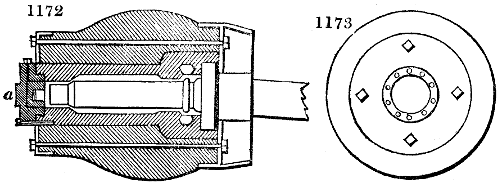

The following arrangement is adopted in an excellent establishment

in Glasgow, where the above large cylinders are

6 feet long, and both ends of them project a very little beyond

the brickwork. One end has a disc or round plate of cast iron, well fitted, and firmly bolted

to it, from the centre of which disc an iron tube, about 6 inches diameter, proceeds and

enters, at a right angle, the main tube of refrigeration. The diameter of this tube may be

from 9 to 14 inches, according to the number of cylinders. The other end of the cylinder

is called the mouth of the retort; this is closed by a disc of iron, smeared round its edge by

clay lute, and secured in its place by fir wedges. The charge of wood for such a cylinder

is about 8 cwt. The hard woods—oak, ash, birch, and beech—are alone used; fir does

not answer. The heat is kept up during the day-time, and the furnace is allowed to cool

during the night. Next morning, the door is opened, the charcoal removed, and a new

charge of wood is introduced. The average product of crude vinegar called pyrolignous

acid, is 35 gallons. It is much contaminated with tar, is of a deep brown colour,[9]

and has a sp. gr. of 1·025. Its total weight is therefore about 300 lbs., but the

residuary charcoal is found to weigh no more than one fifth of the wood employed;

hence nearly one half of the ponderable matter of the wood is dissipated in incondensable

gases. Count Rumford states, that the charcoal is equal in weight to more than

four tenths of the wood from which it is made. The count’s error seems to have arisen

from the slight heat of an oven to which his wood was exposed in a glass cylinder. The

result now given, is the experience of an eminent manufacturing chemist.

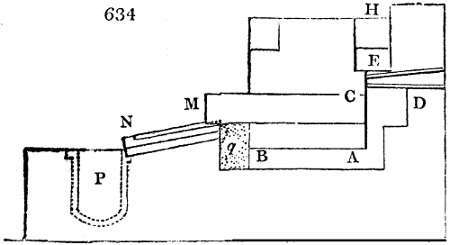

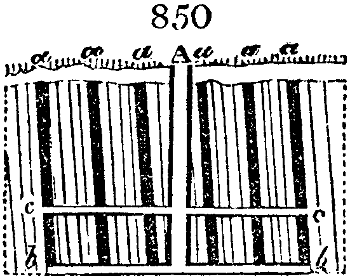

The crude pyrolignous acid is rectified by a second distillation in a copper still, in the

body of which about 20 gallons of viscid tarry matter are left from every 100. It has

now become a transparent brown vinegar, having a considerably empyreumatic smell,

and a sp. gr. of 1·013. Its acid powers are superior to those of the best household

vinegar, in the proportion of three to two. By redistillation, saturation with quicklime,

evaporation of the liquid acetate to dryness, and conversion into acetate of soda by

sulphate of soda, the empyreumatic matter is so completely dissipated, that on decomposing

the pure acetate of soda by sulphuric acid, a perfectly colourless and grateful

vinegar rises in distillation. Its strength will be proportionable to the concentration of

the decomposing acid.

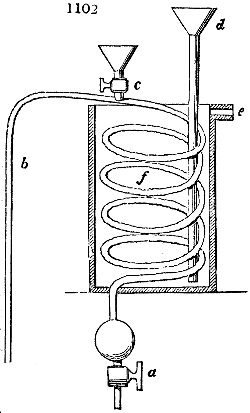

The acetic acid of the chemist may be prepared also in the following modes:—1. Two

parts of fused acetate of potash, with one of the strongest oil of vitriol, yield, by slow

distillation from a glass retort into a refrigerated receiver, concentrated acetic acid. A

small portion of sulphurous acid, which contaminates it, may be removed by redistillation

from a little acetate of lead. 2. Or four parts of good sugar of lead, with one part of

sulphuric acid, treated in the same way, afford a slightly weaker acetic acid. 3. Gently

calcined sulphate of iron, or green vitriol, mixed with sugar of lead, in the proportion of 1

of the former to 21⁄2 of the latter, or with acetate of copper, and carefully distilled from a

porcelain retort into a cool receiver, may be also considered an economical process. But

that with binacetate of copper above described, is preferable to any of these.

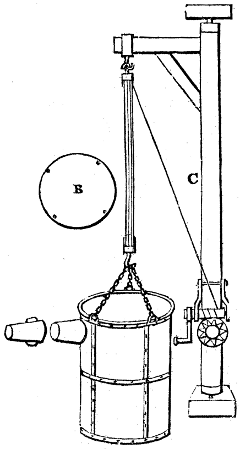

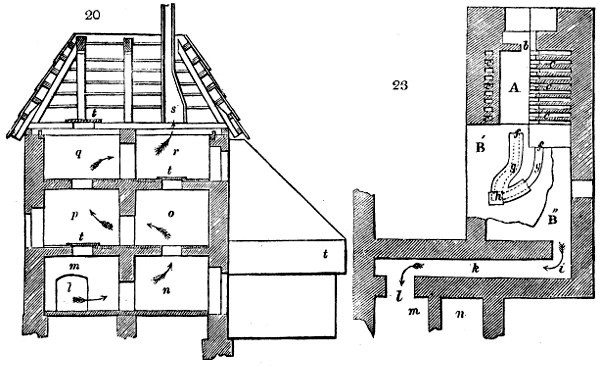

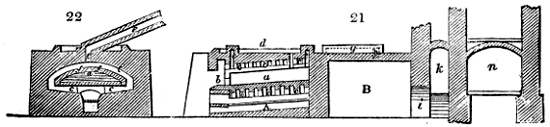

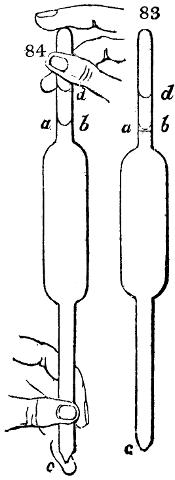

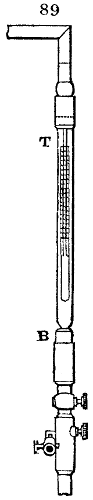

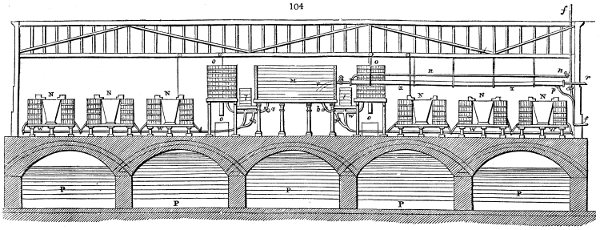

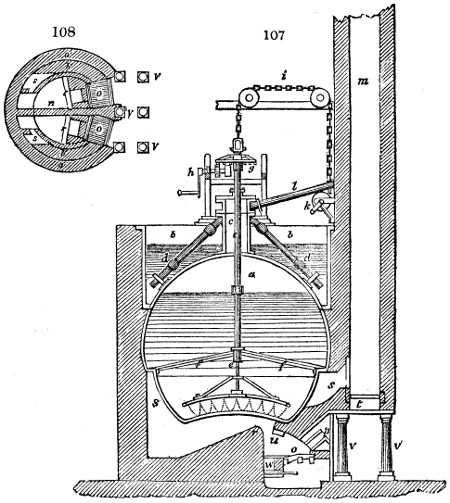

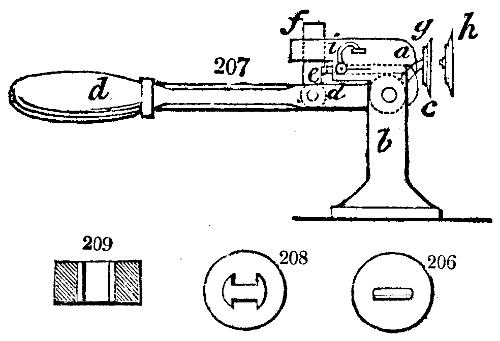

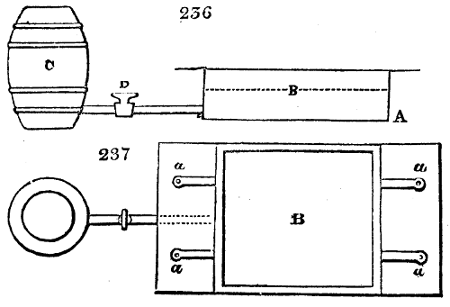

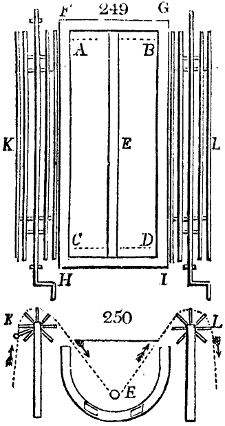

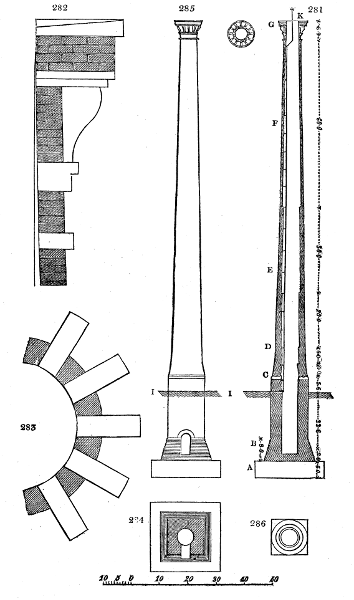

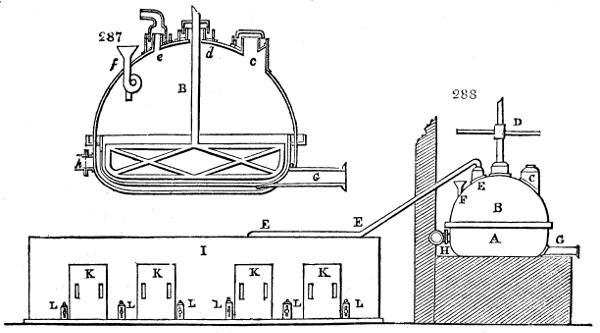

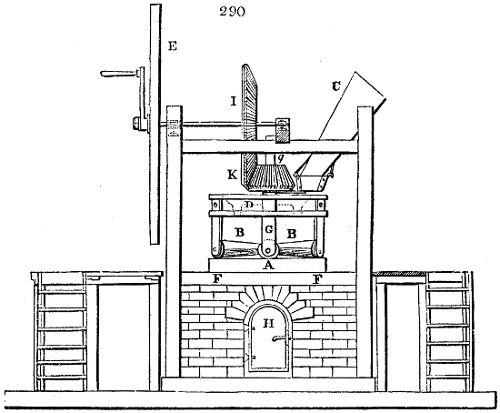

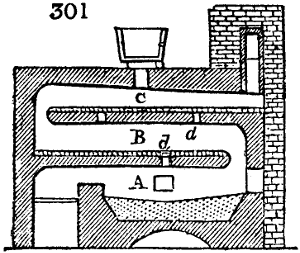

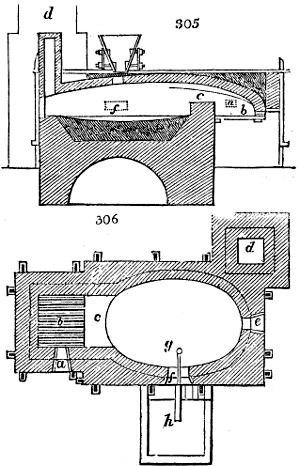

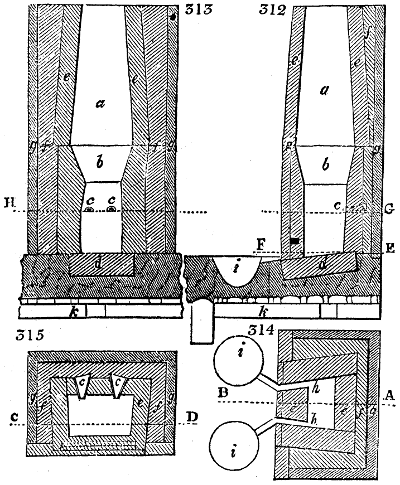

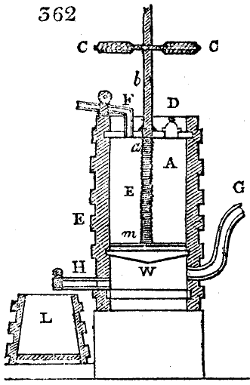

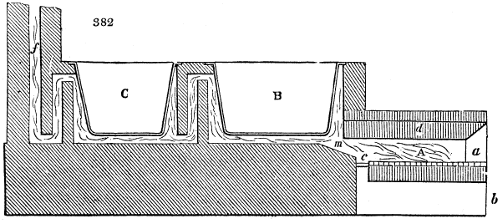

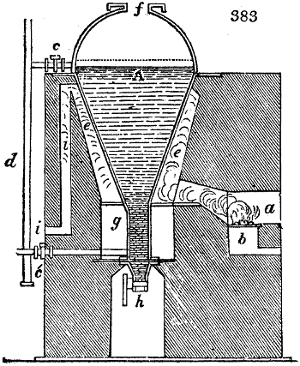

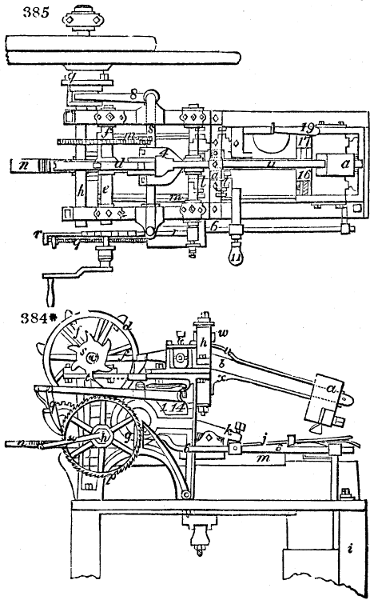

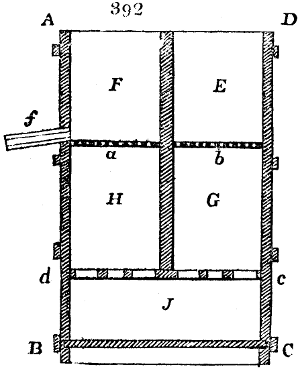

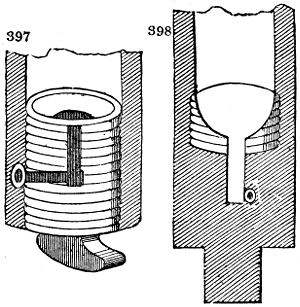

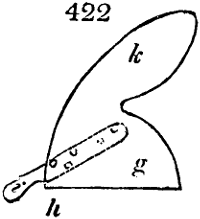

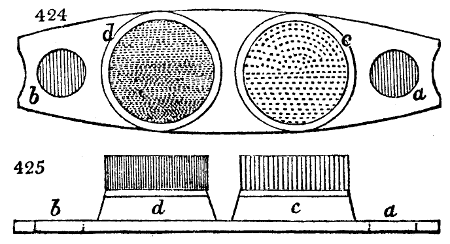

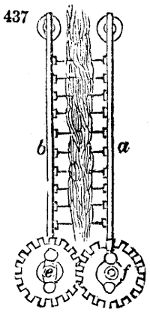

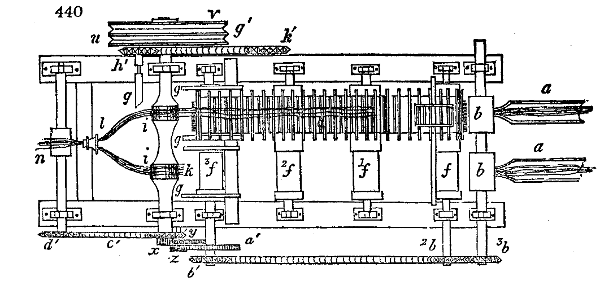

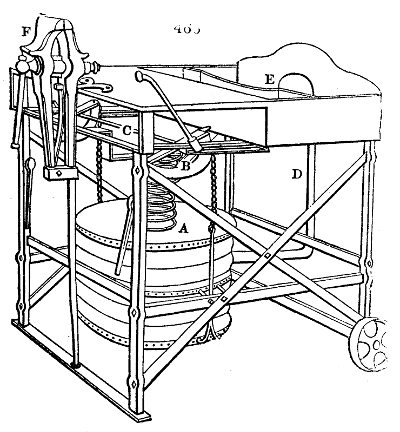

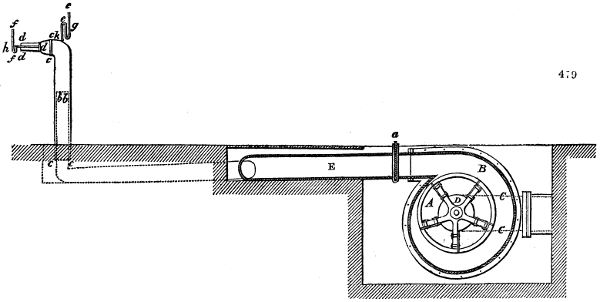

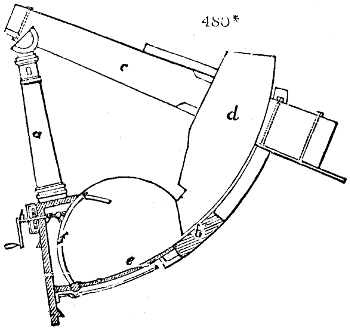

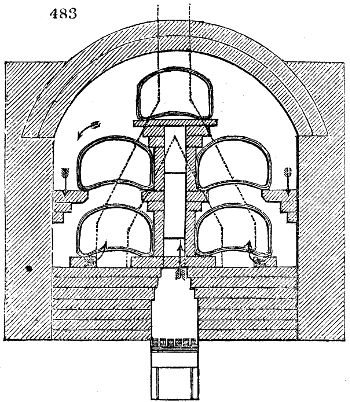

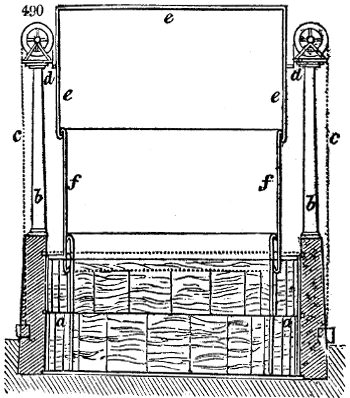

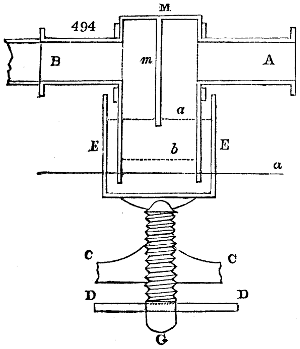

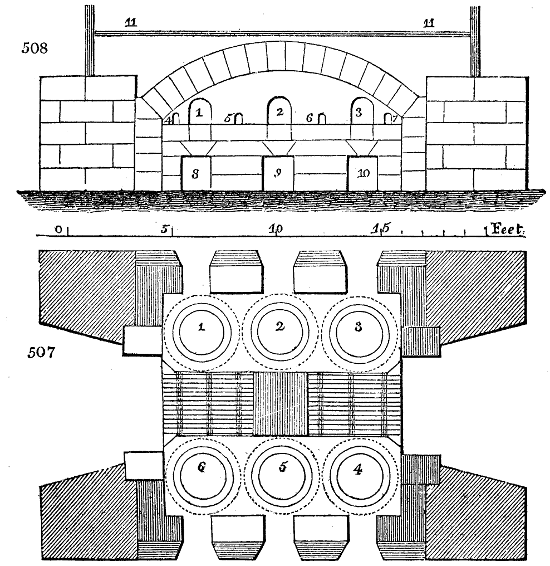

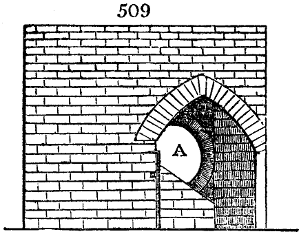

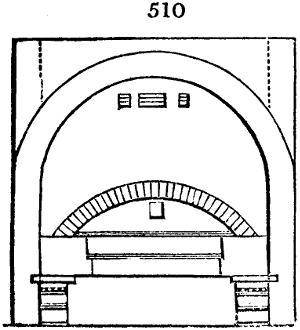

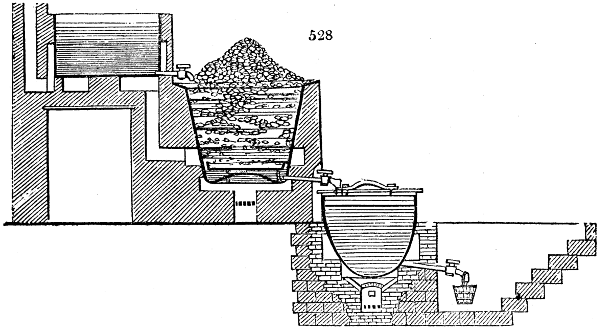

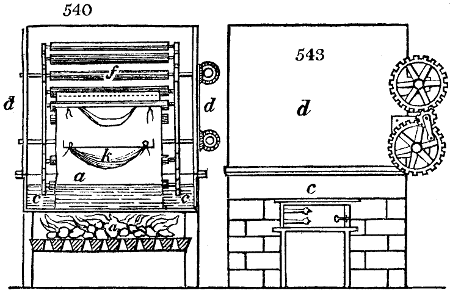

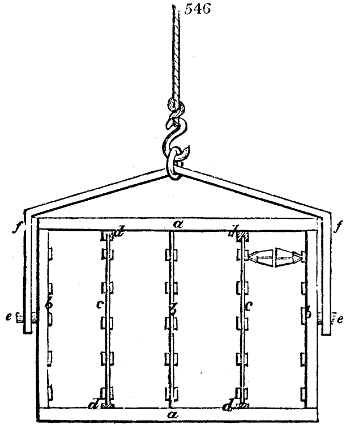

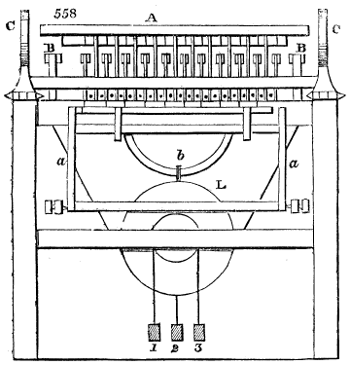

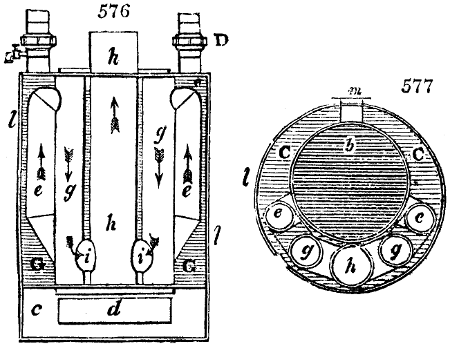

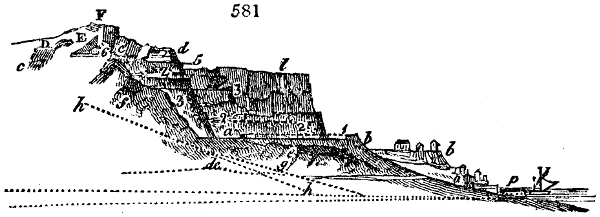

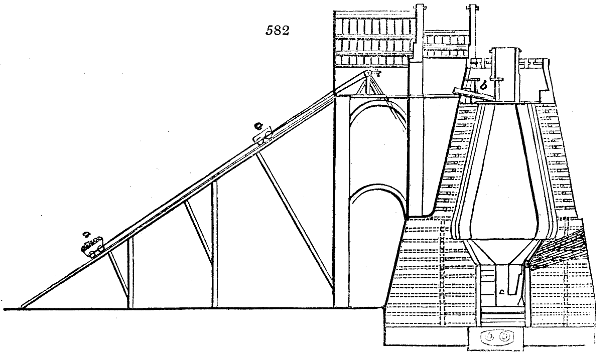

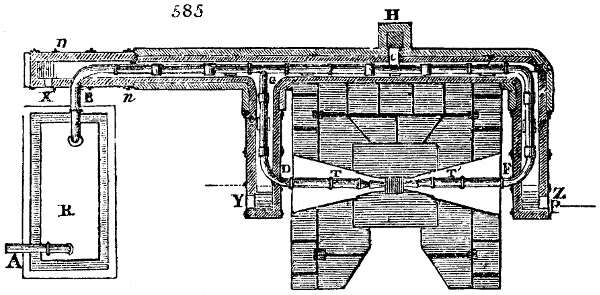

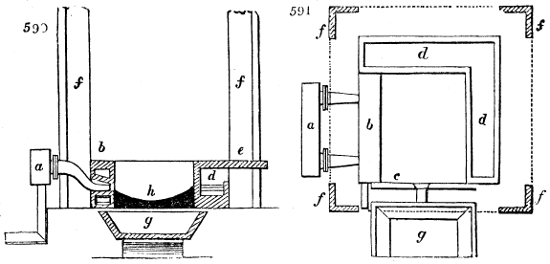

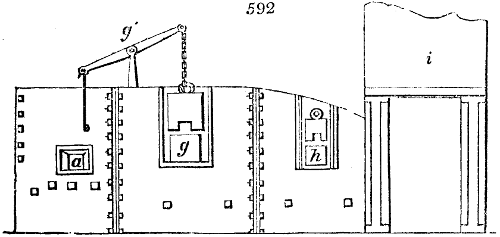

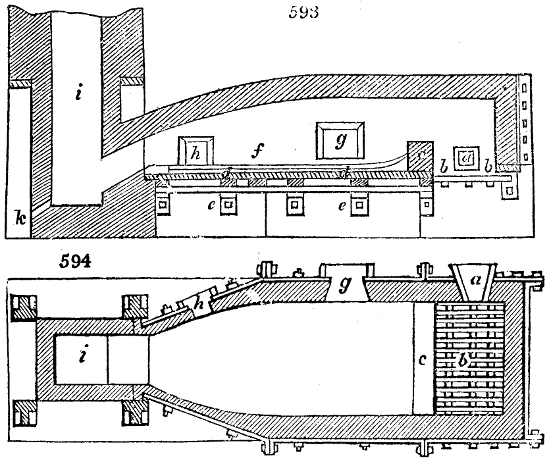

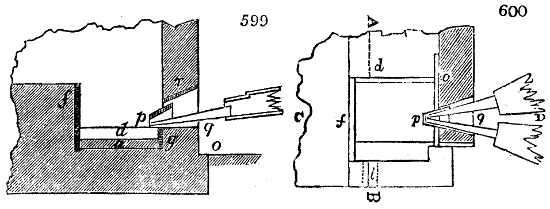

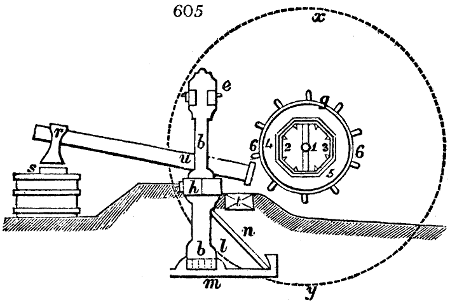

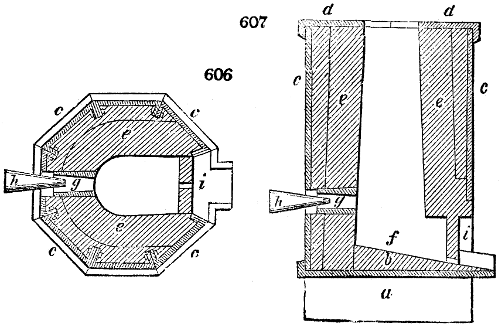

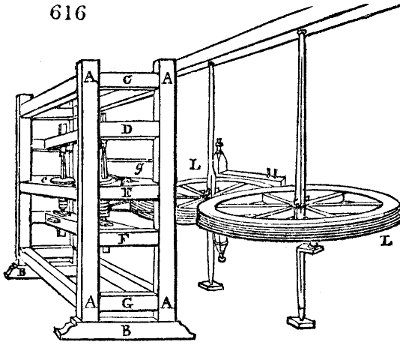

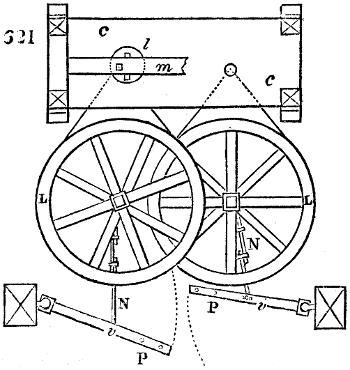

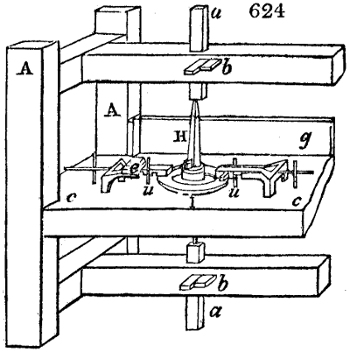

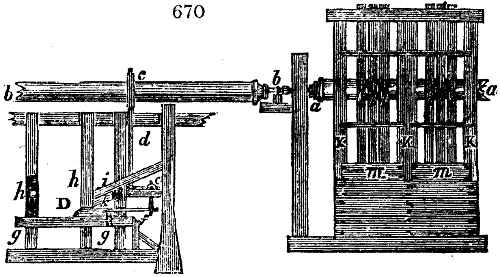

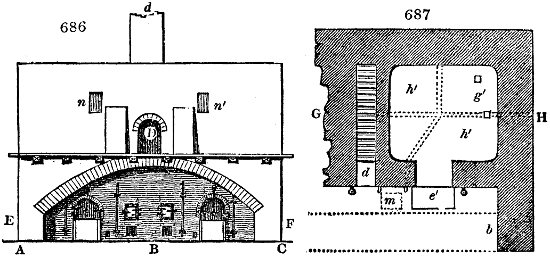

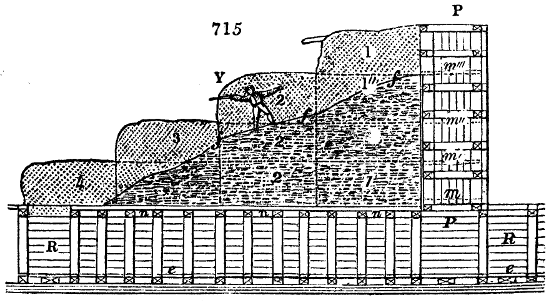

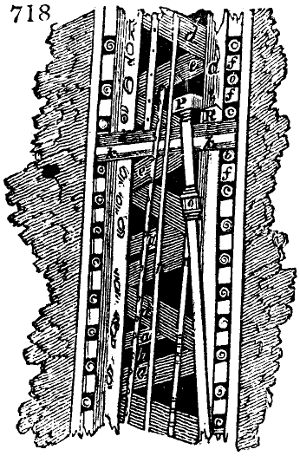

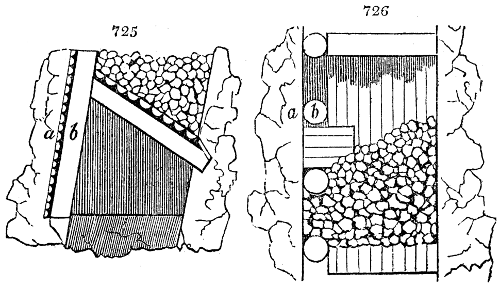

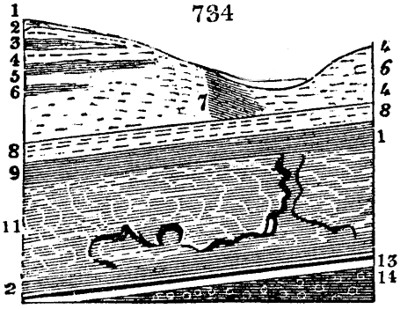

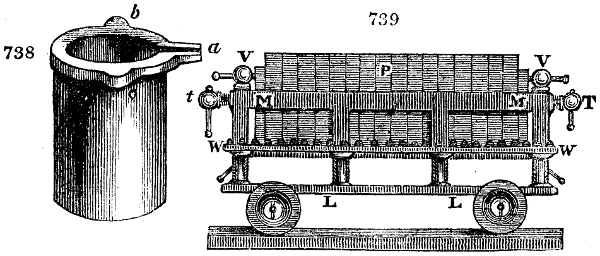

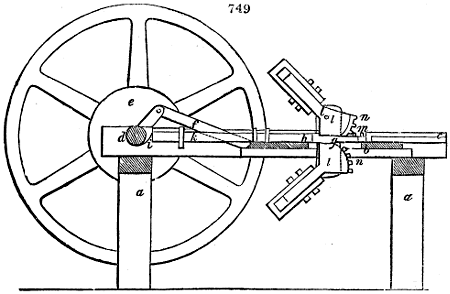

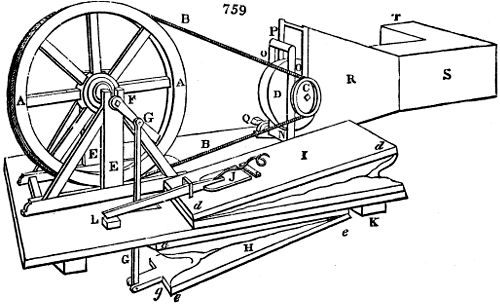

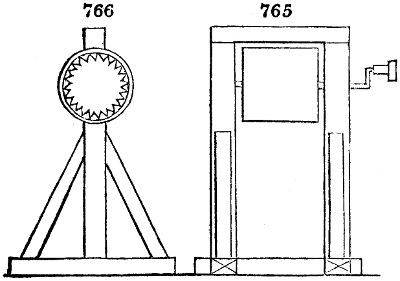

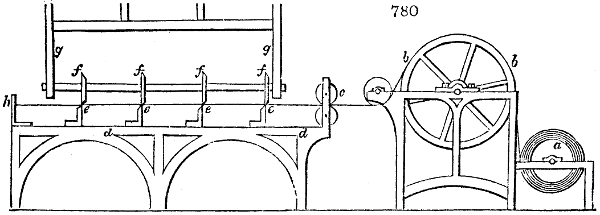

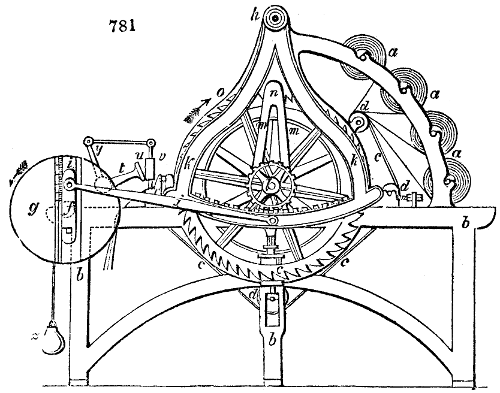

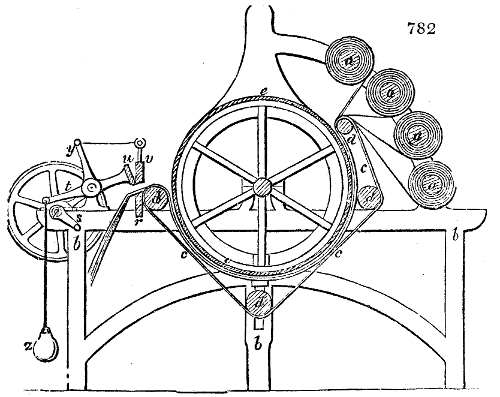

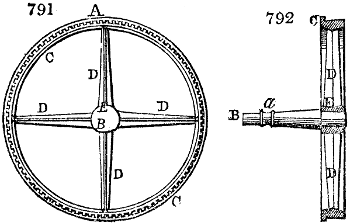

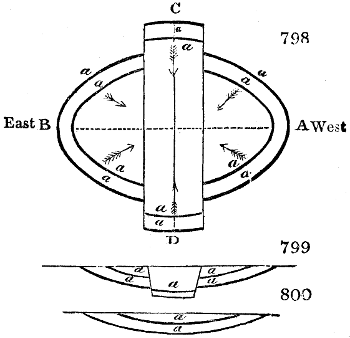

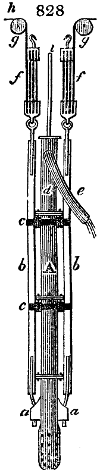

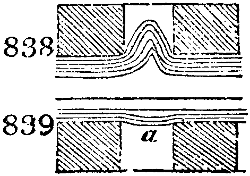

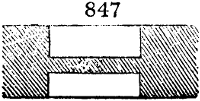

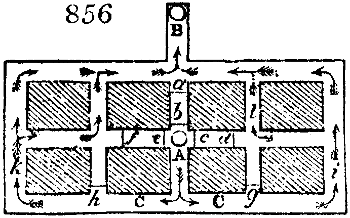

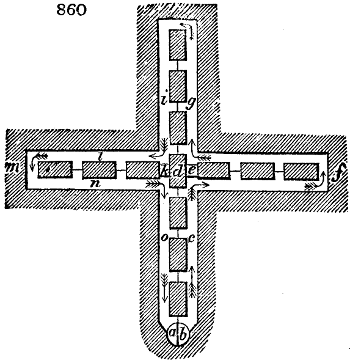

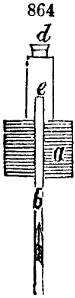

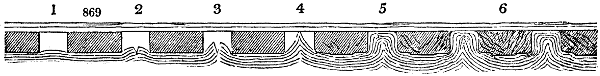

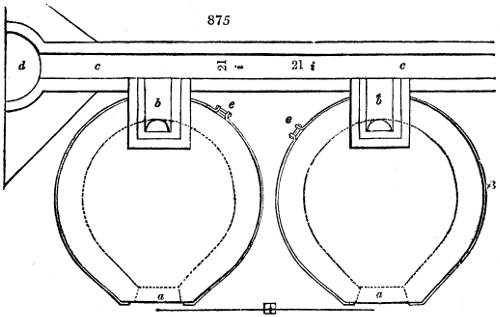

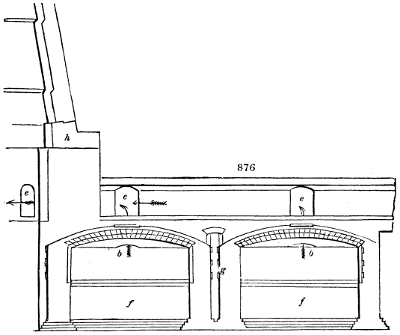

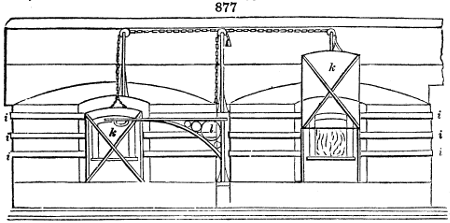

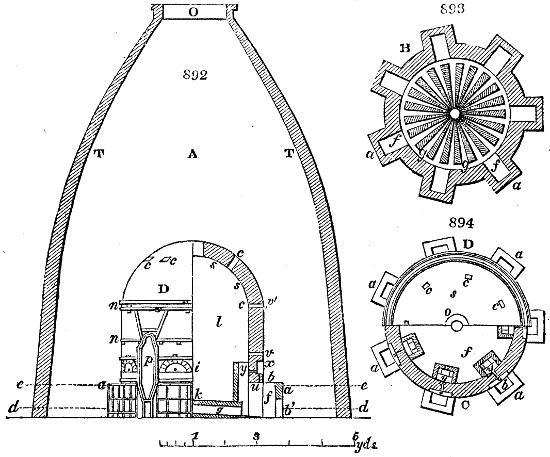

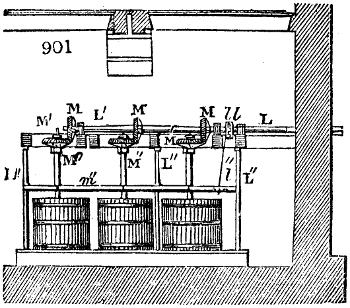

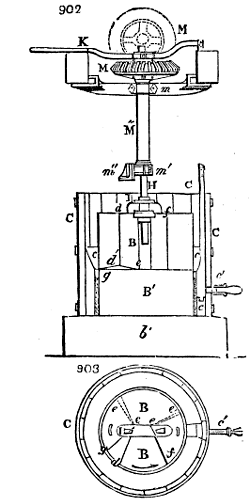

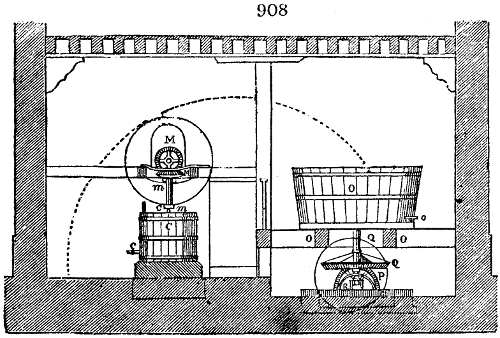

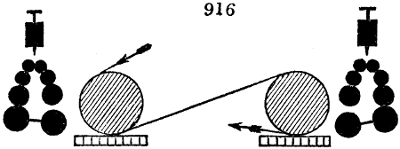

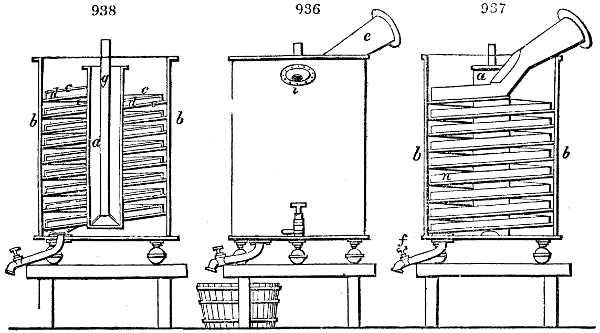

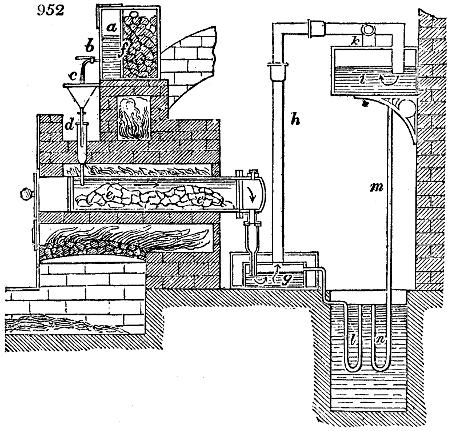

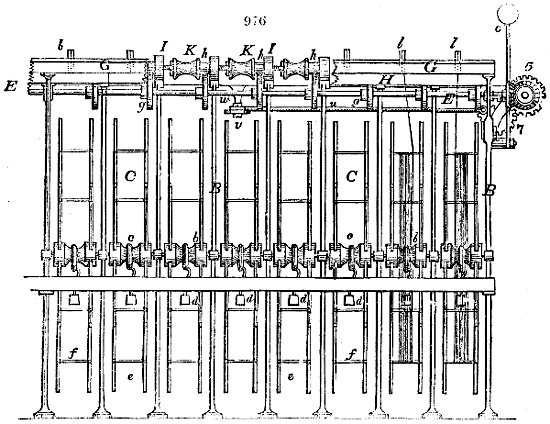

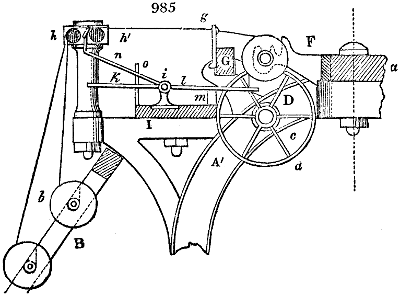

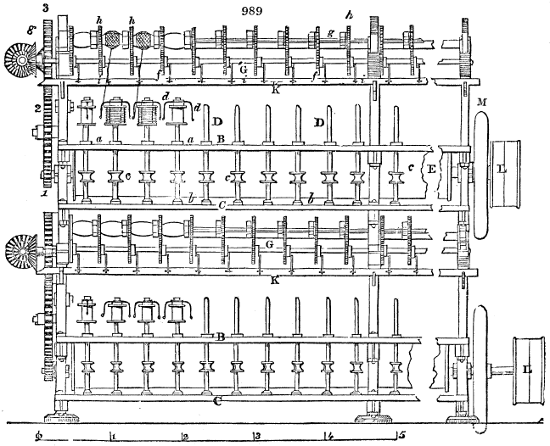

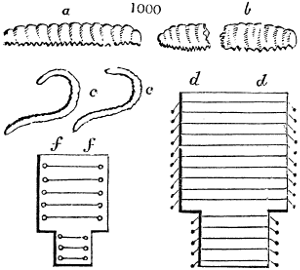

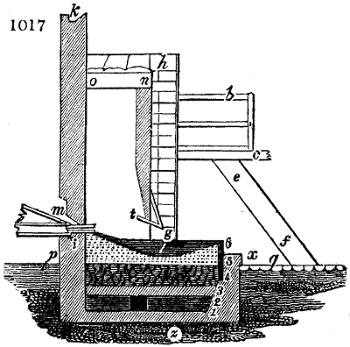

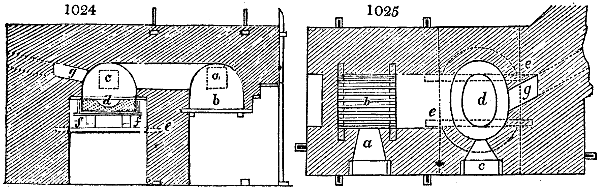

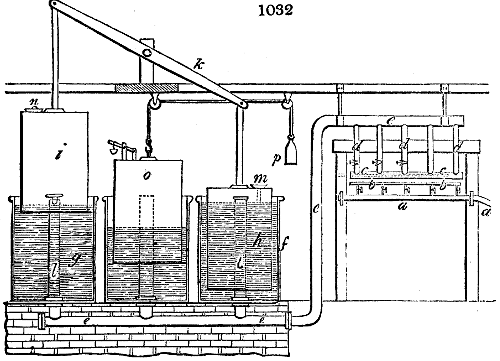

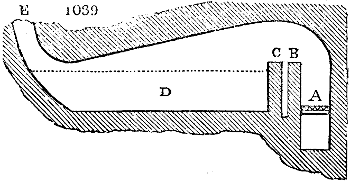

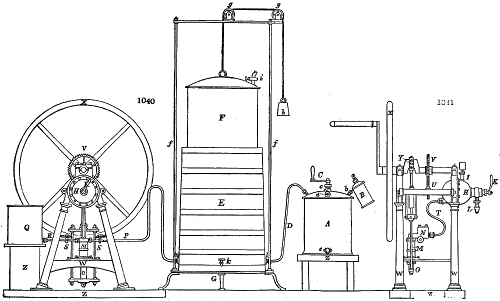

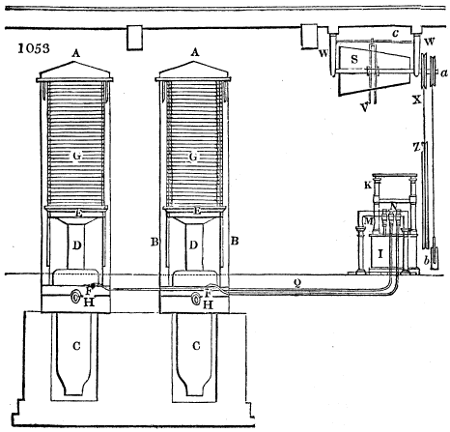

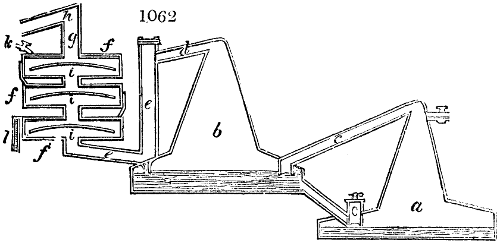

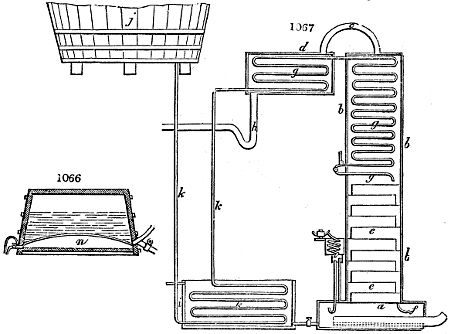

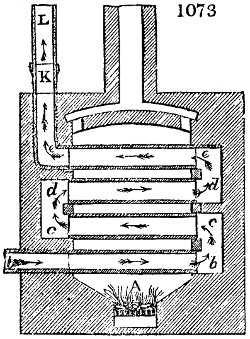

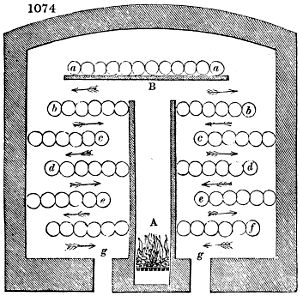

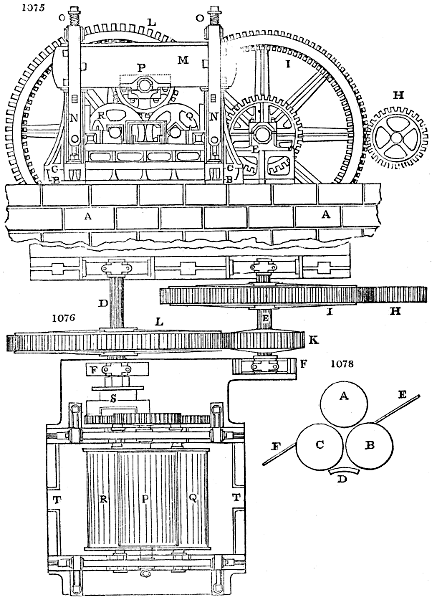

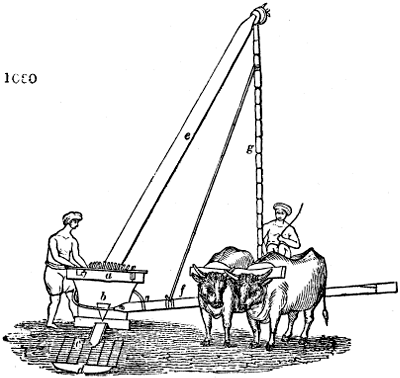

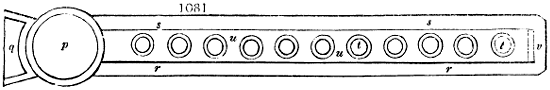

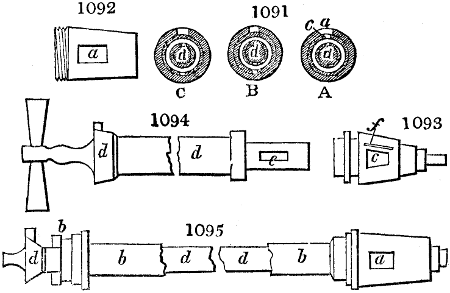

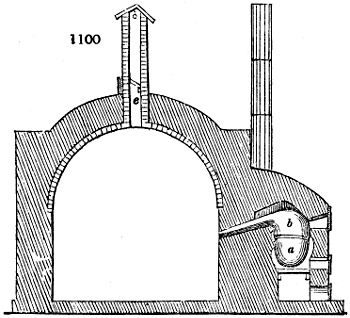

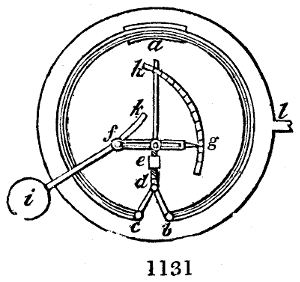

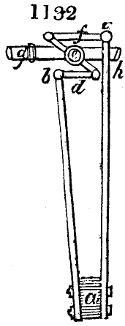

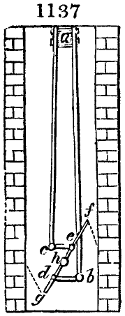

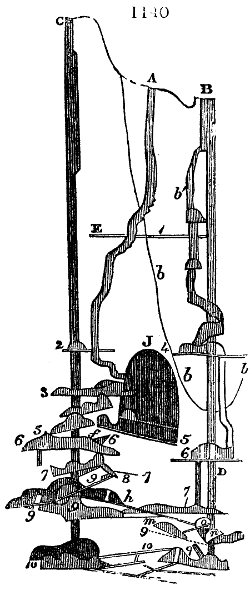

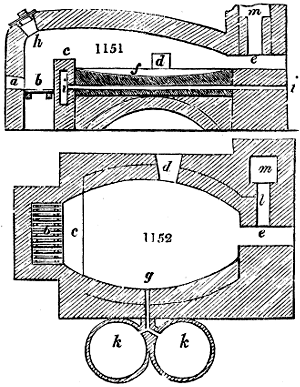

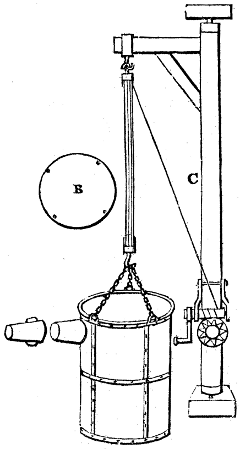

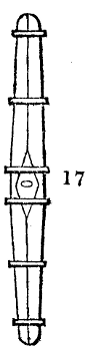

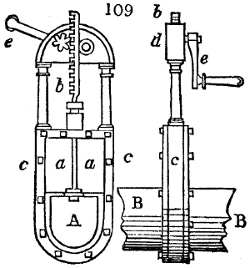

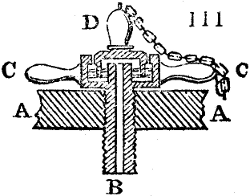

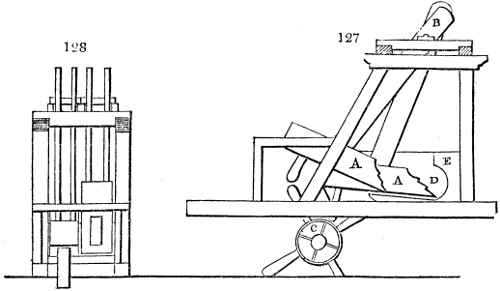

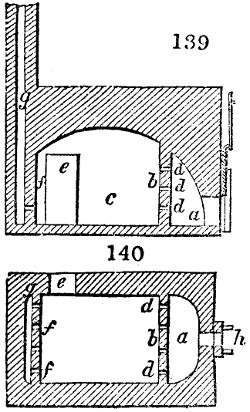

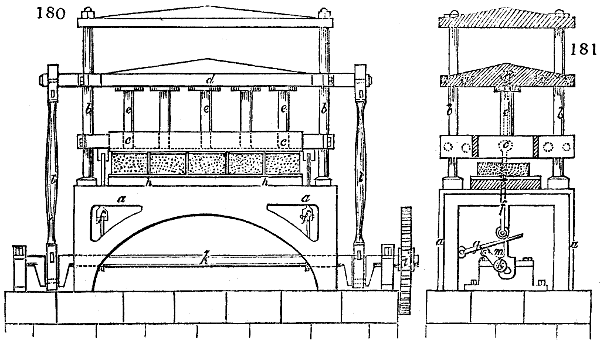

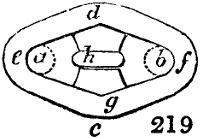

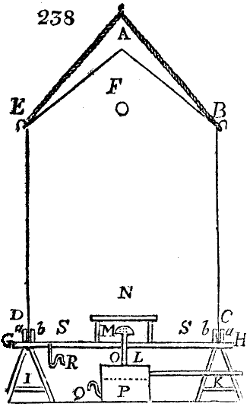

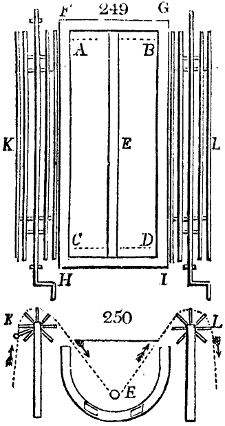

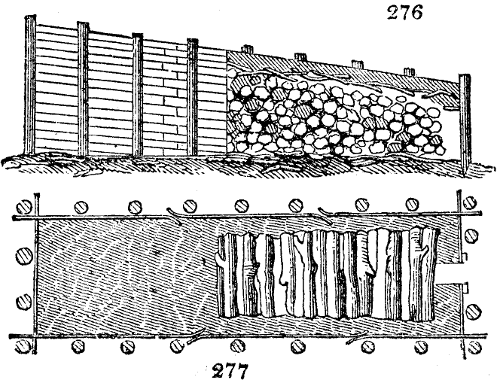

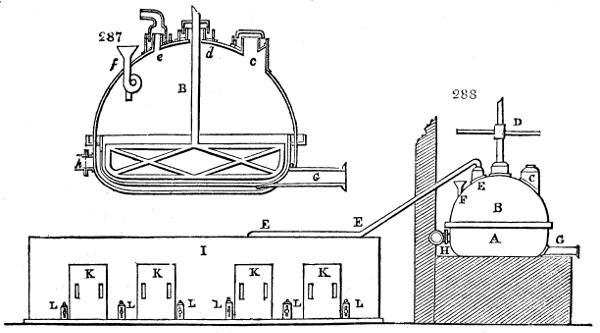

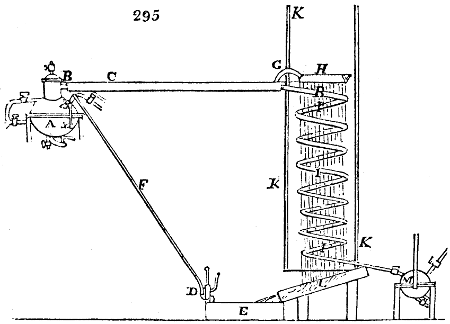

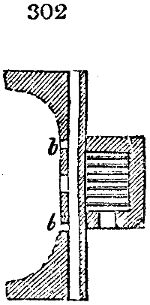

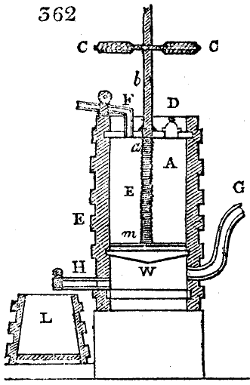

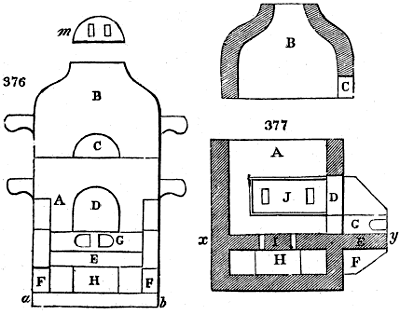

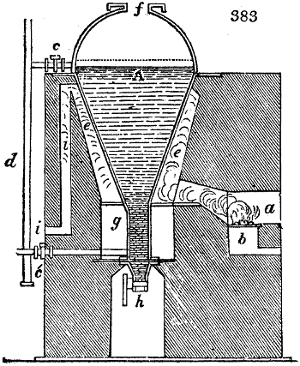

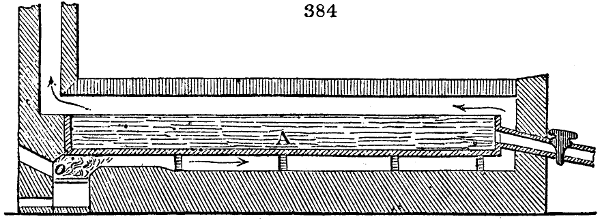

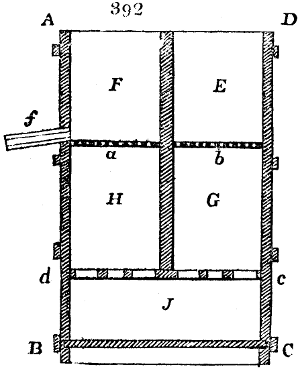

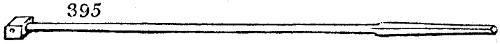

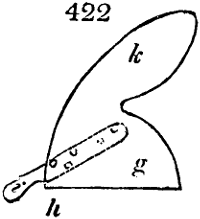

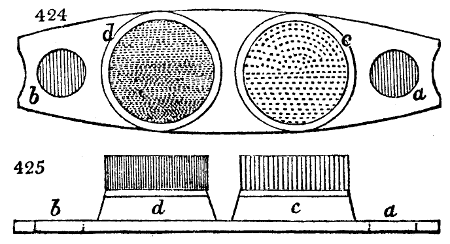

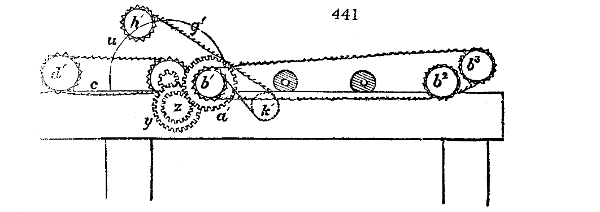

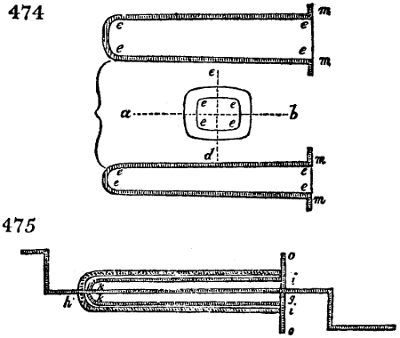

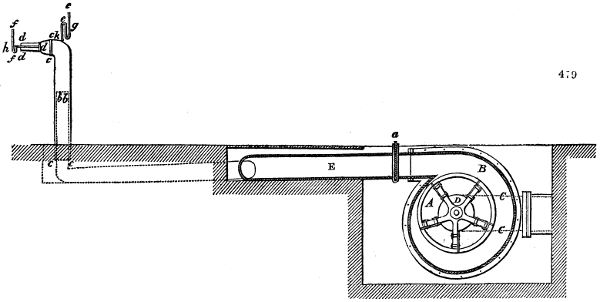

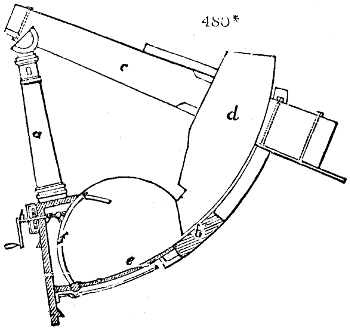

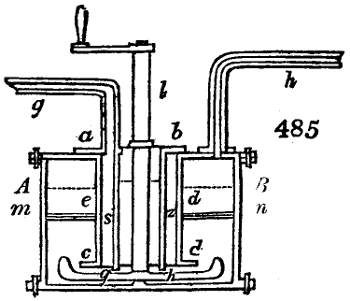

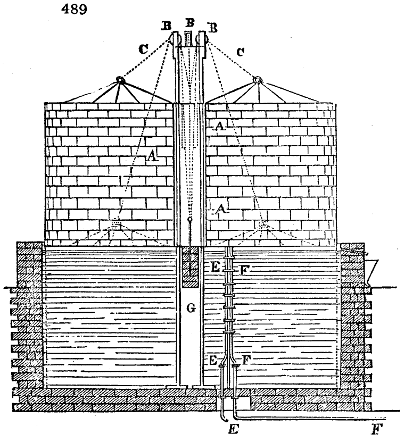

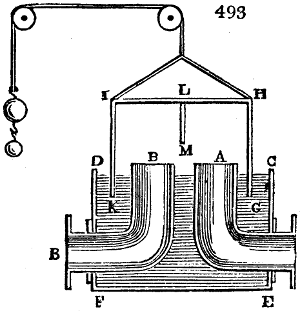

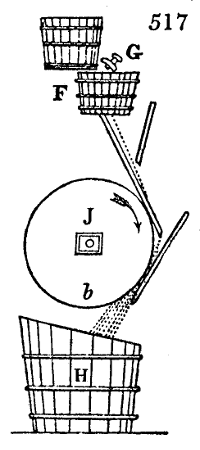

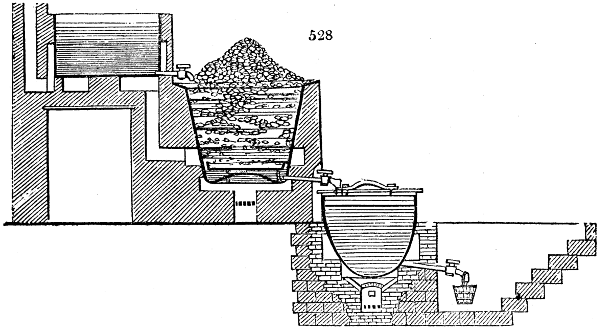

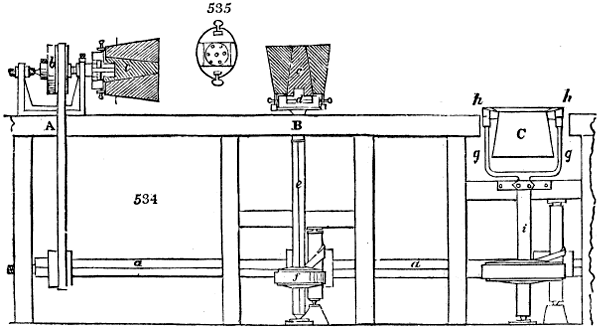

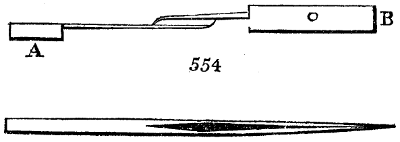

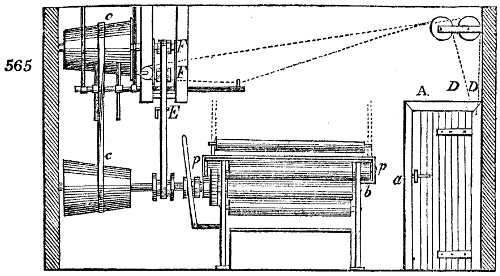

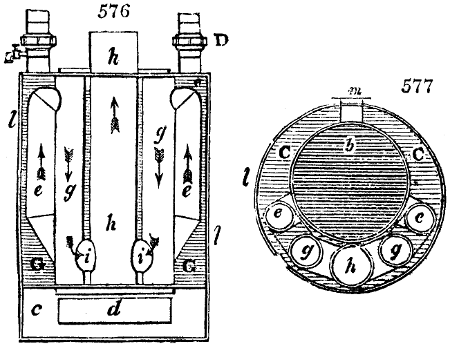

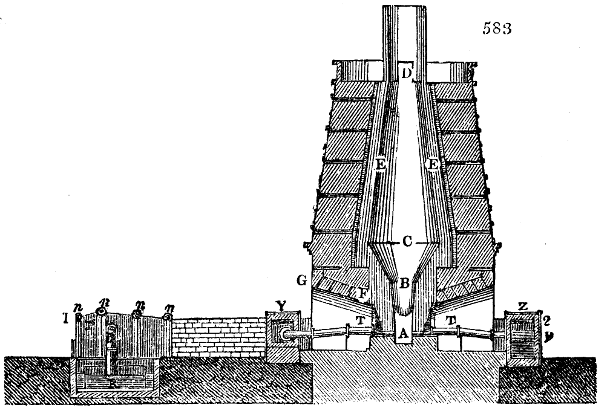

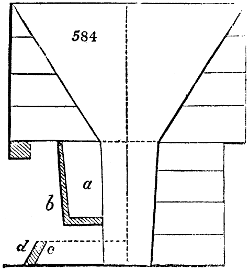

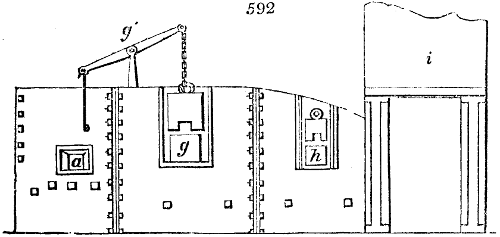

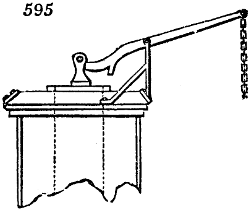

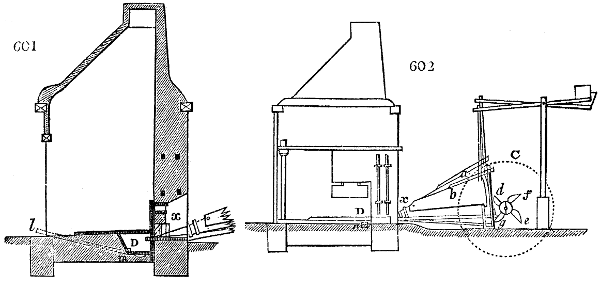

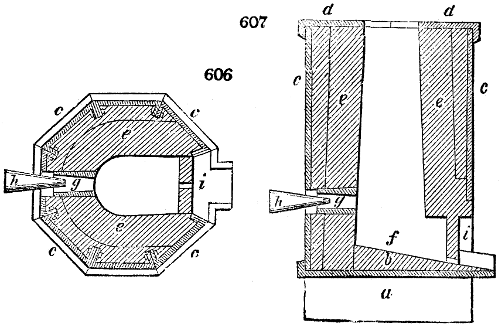

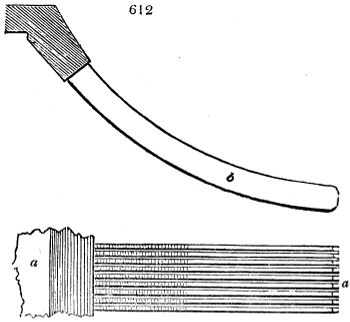

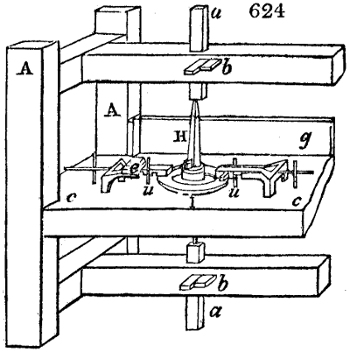

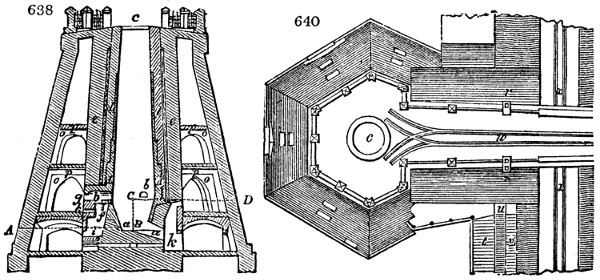

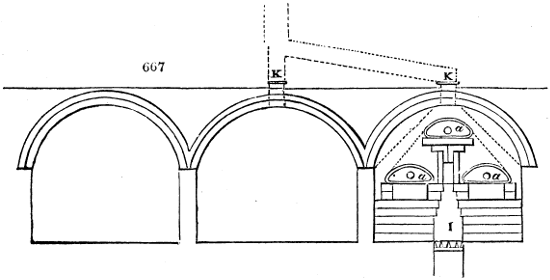

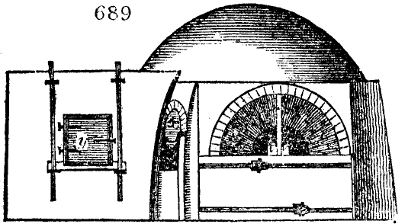

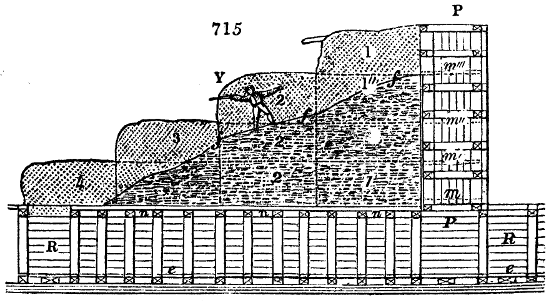

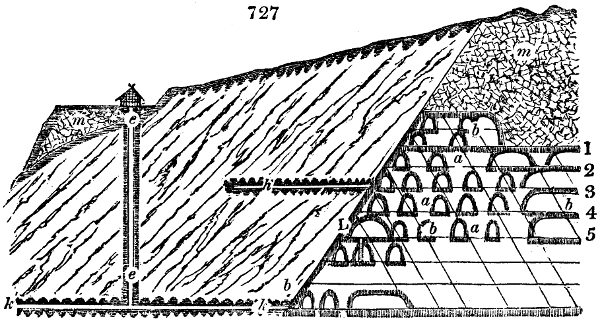

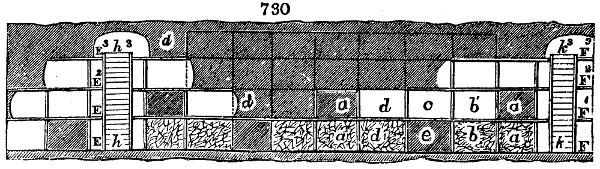

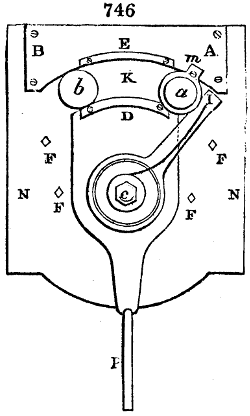

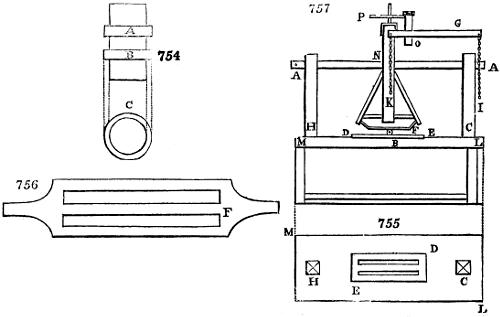

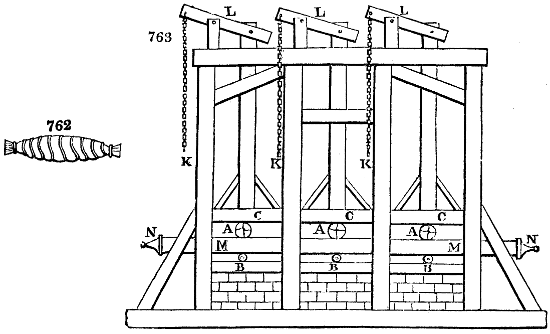

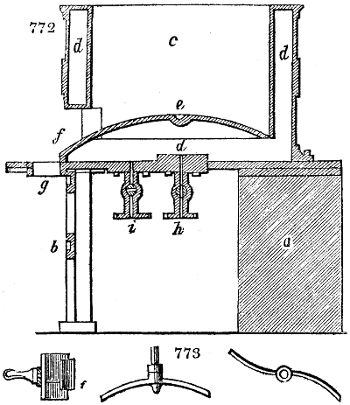

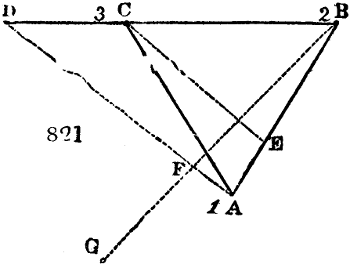

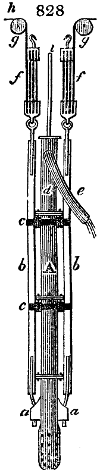

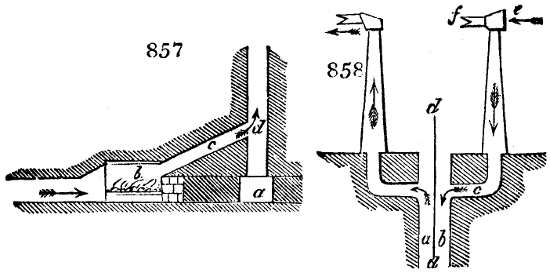

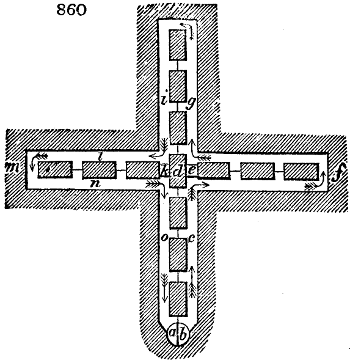

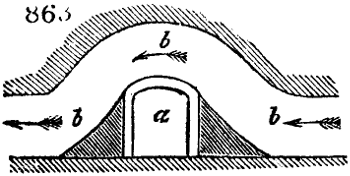

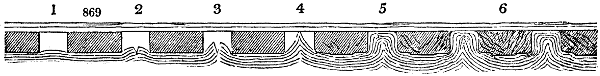

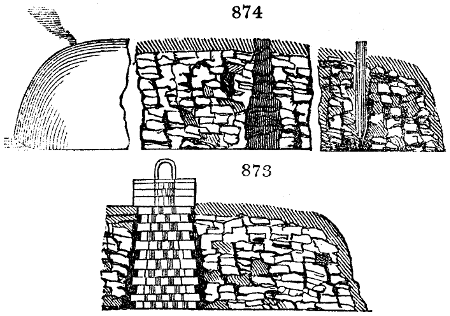

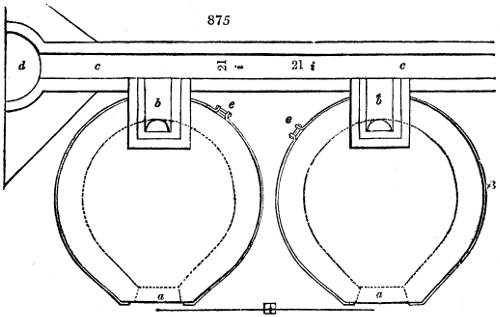

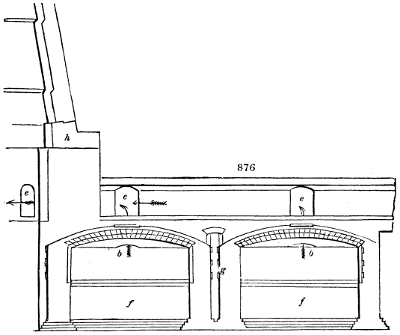

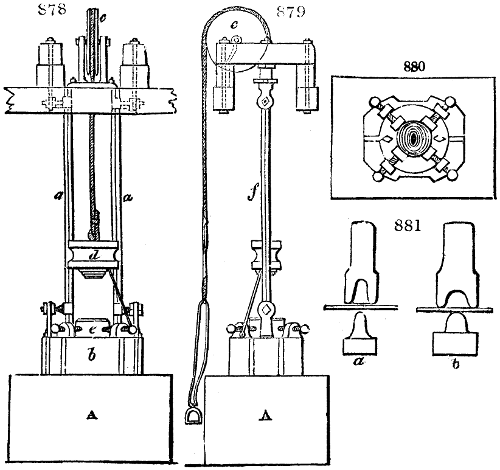

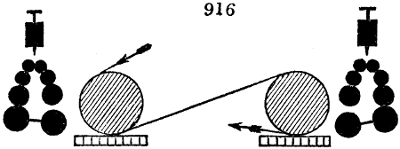

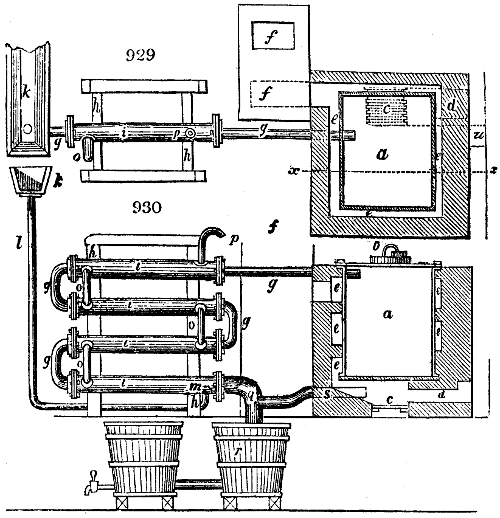

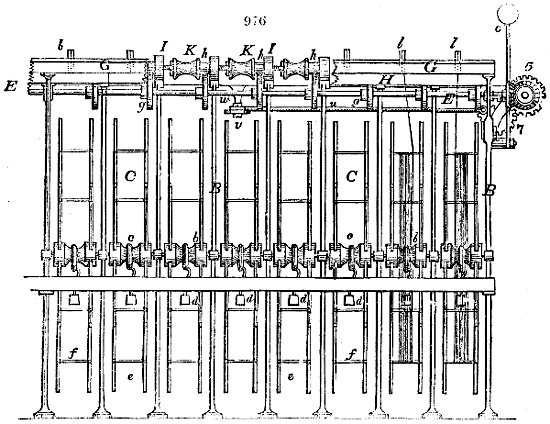

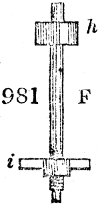

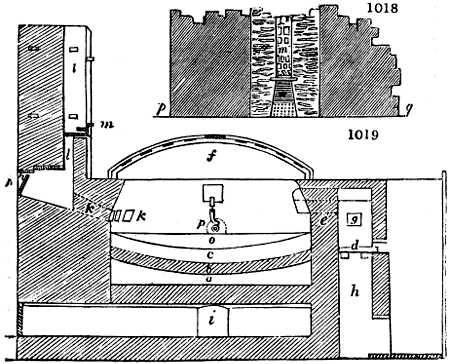

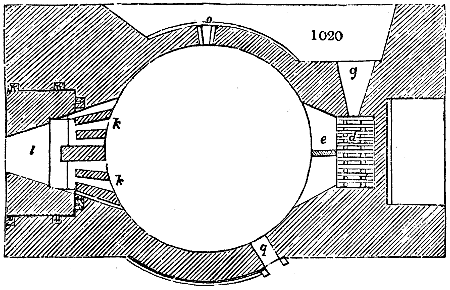

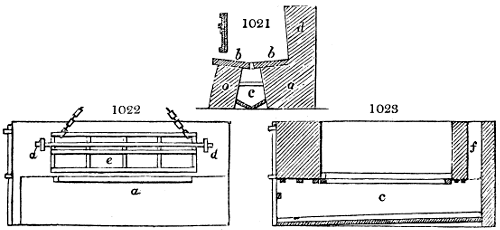

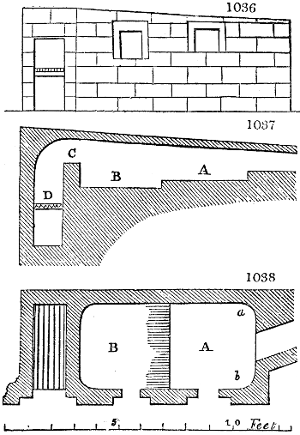

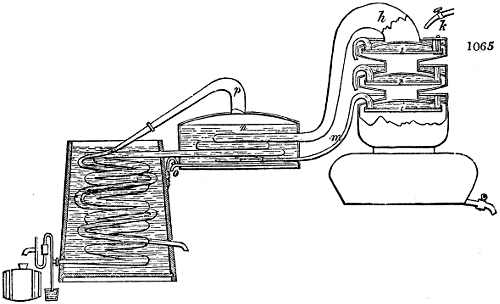

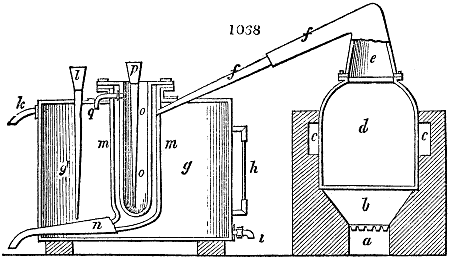

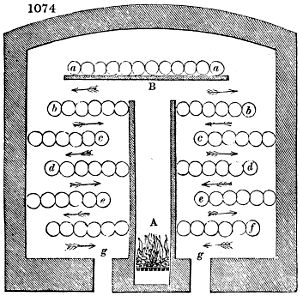

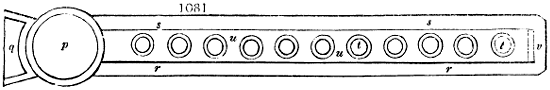

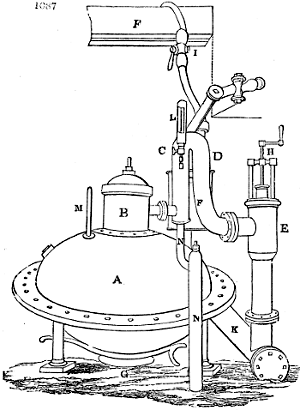

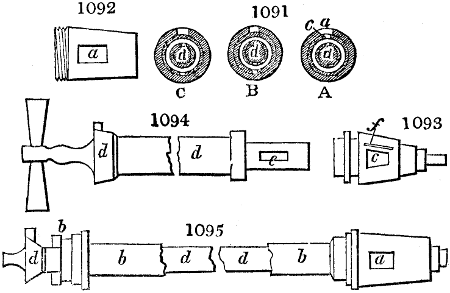

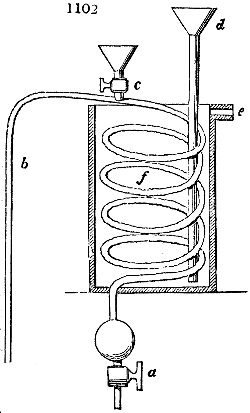

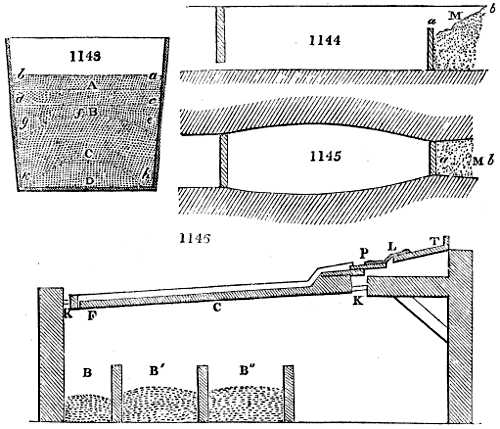

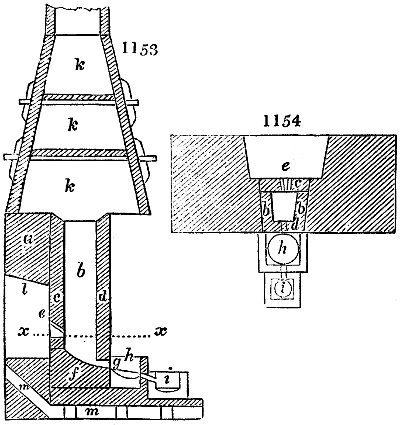

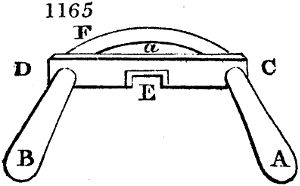

Fig. 3.

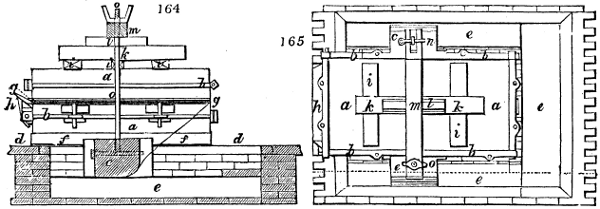

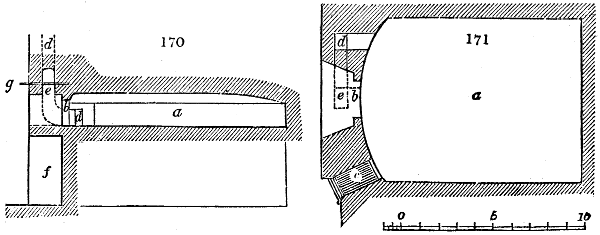

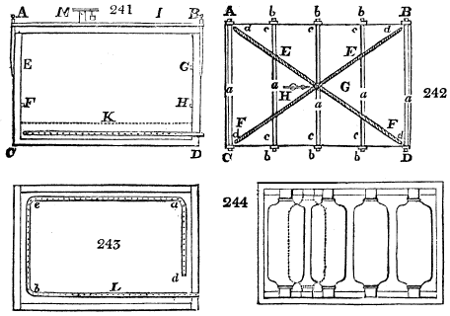

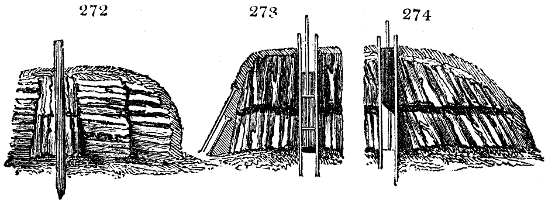

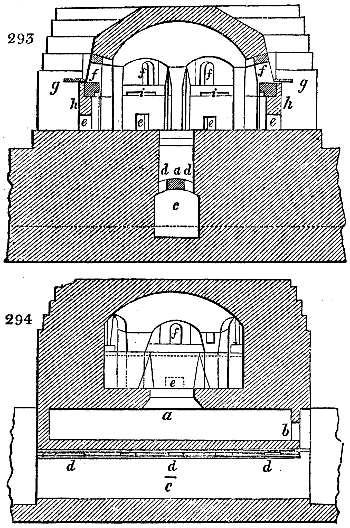

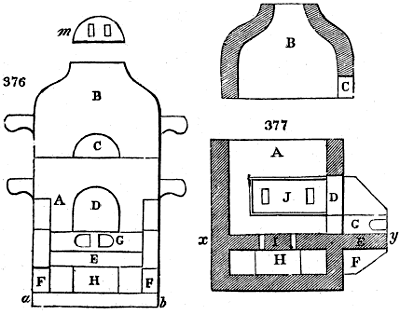

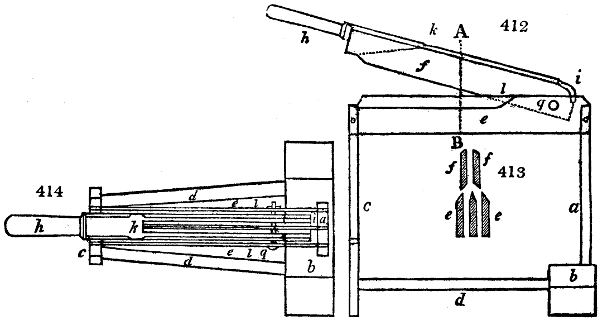

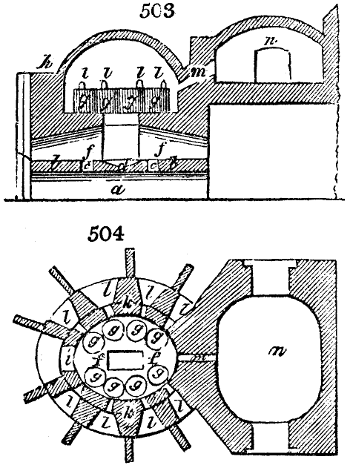

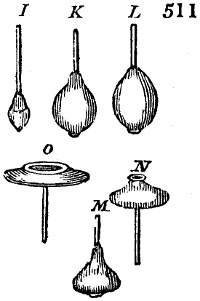

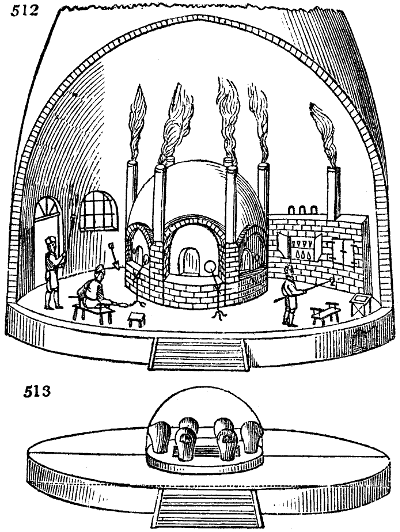

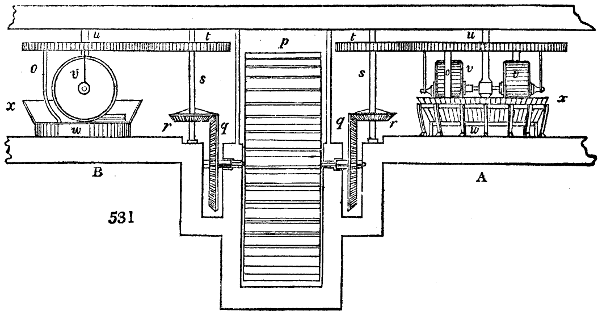

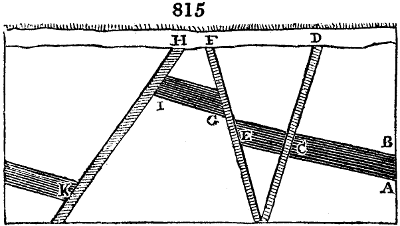

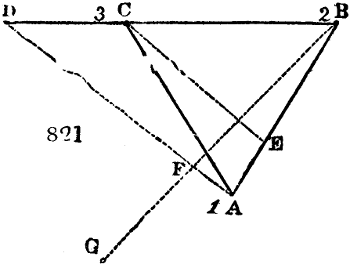

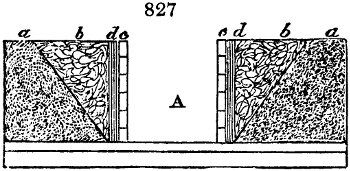

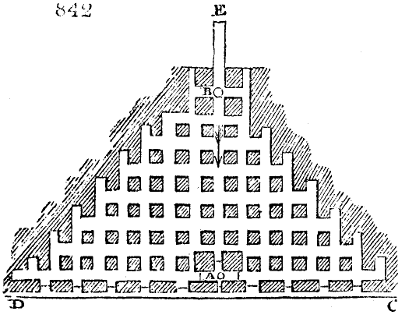

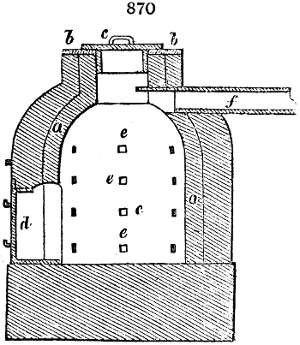

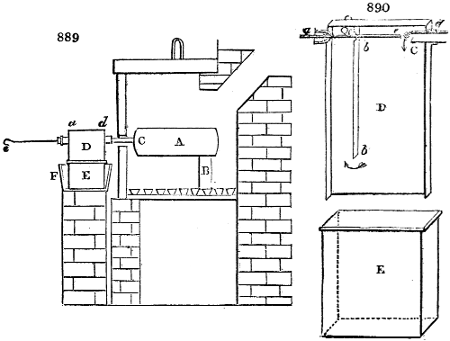

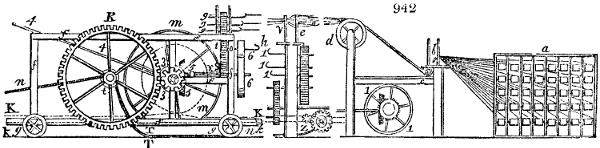

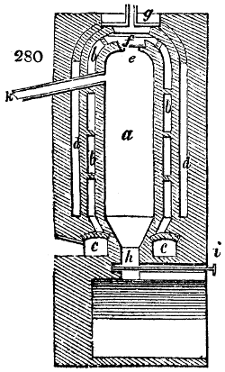

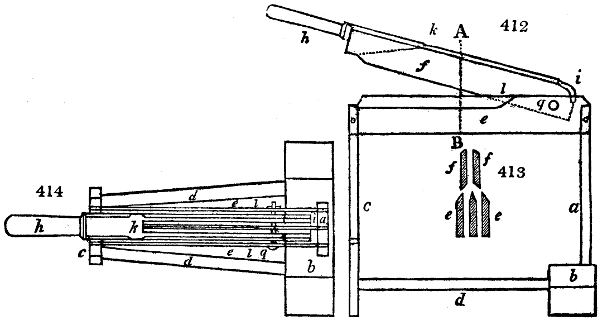

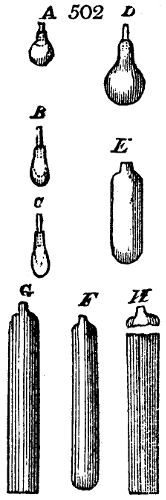

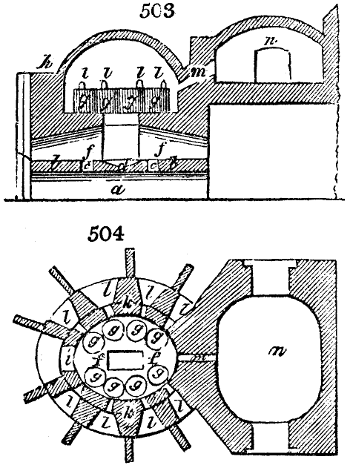

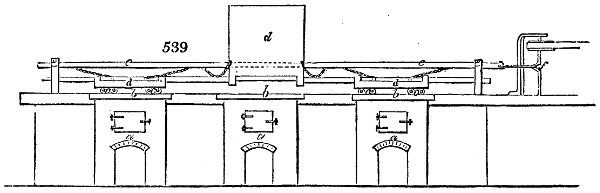

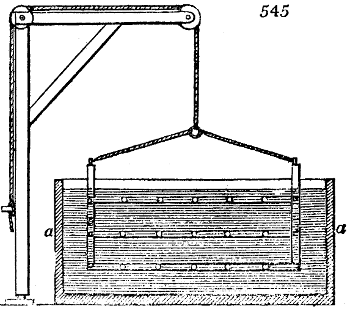

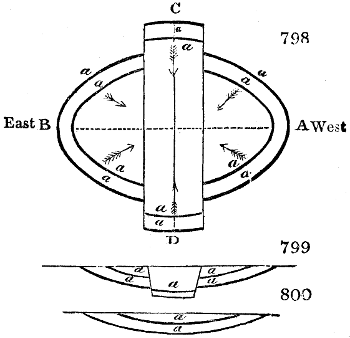

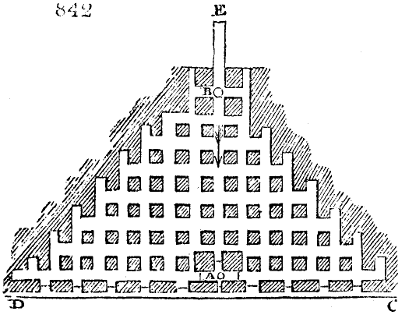

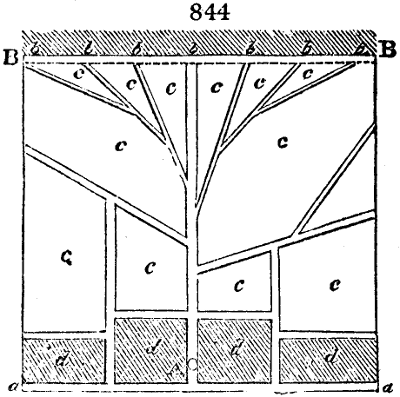

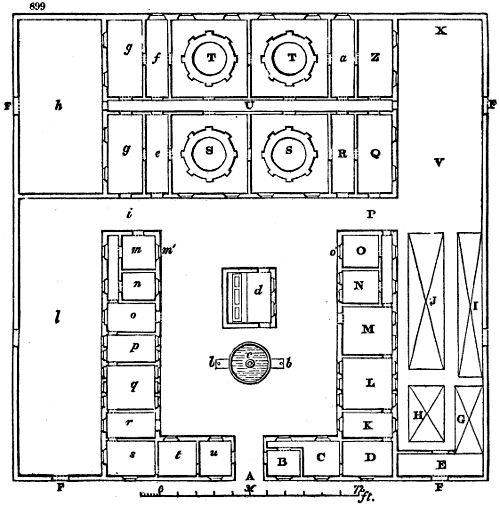

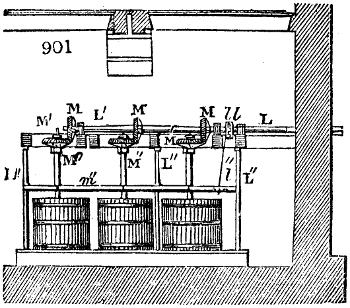

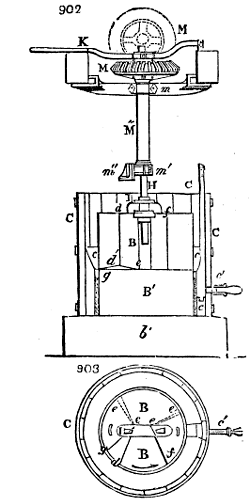

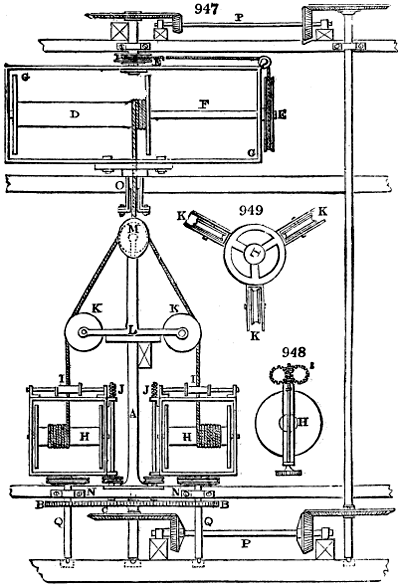

The manufacture of pyrolignous acid is conducted in

the following way in France. Into large cylindrical

vessels (fig. 3.) made of rivetted sheet iron, and having

at their top and side a small sheet iron cylinder, the wood

intended for making charcoal is introduced. To the

upper part of this vessel a cover of sheet iron, B, is

adapted, which is fixed with bolts. This vessel, thus

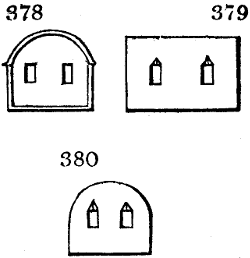

closed, represents, as we see, a vast retort. When it is

prepared, as we have said, it is lifted by means of a swing

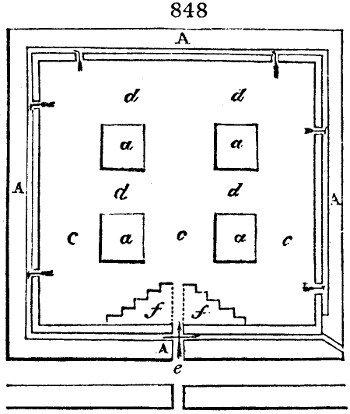

crane, C, and placed in a furnace, D, (fig. 4.) of a

form relative to that of the vessel, and the opening of the

furnace is covered with a dome, E, made of masonry or

brickwork. The whole being thus arranged, heat is applied

in the furnace at the bottom. The moisture of

the wood is first dissipated, but by degrees the liquor

ceases to be transparent, and becomes sooty. An adopter

tube, A, is then fitted to the lateral cylinder. This adopter

enters into another tube at the same degree of inclination

which commences the condensing apparatus. The means

of condensation vary according to the localities. In certain

works they cool by means of air, by making the

vapour pass through a long series of cylinders, or sometimes,

even, through a series of casks connected together;

but most usually water is used for condensing, when it

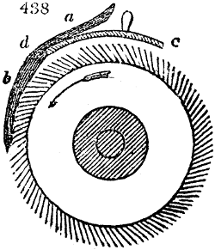

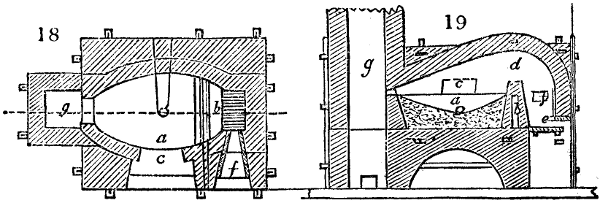

can be easily procured in abundance. The most simple

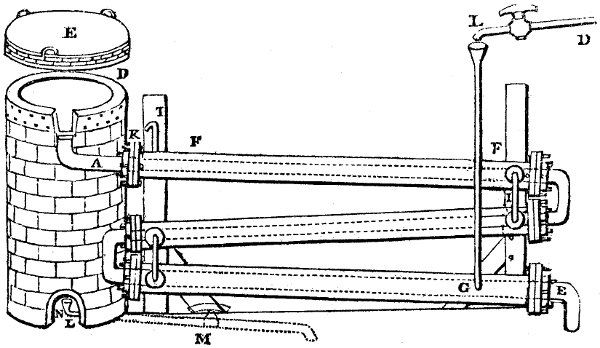

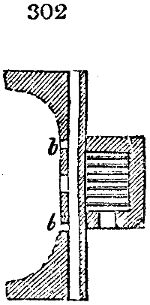

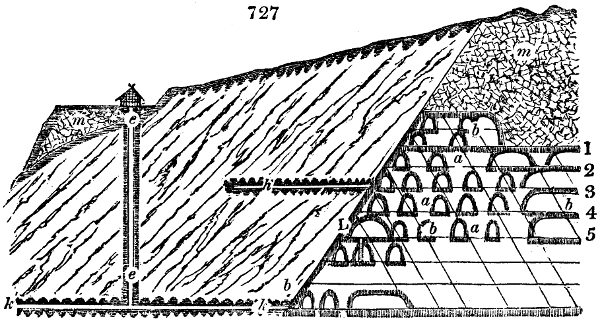

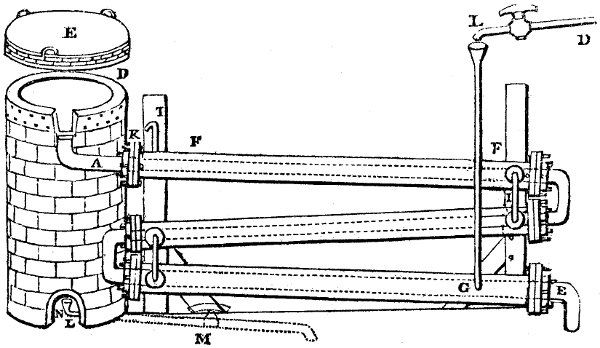

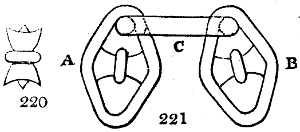

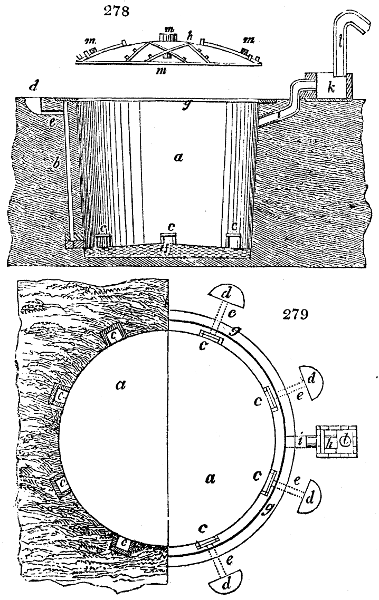

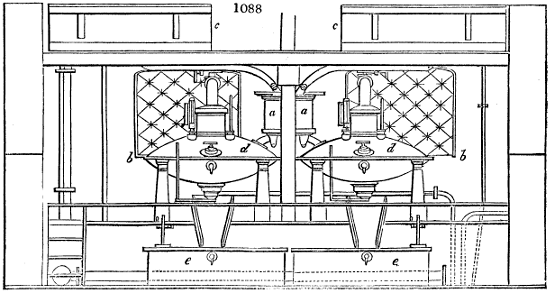

apparatus employed for

this purpose consists of

two cylinders, F, F, (fig. 4.)

the one within the other,

and which leave between

them a sufficient space to

allow a considerable body

of water to circulate along

and cool the vapours. This

double cylinder is adapted

to the distilling vessel, and

placed at a certain inclination.

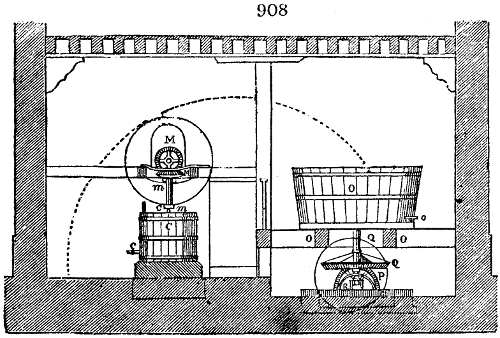

To the first double

tube, F, F, a second, and[10]

sometimes a third, entirely similar, are connected, which, to save space, return upon themselves

in a zigzag fashion. The water is set in circulation by an ingenious means

now adopted in many different manufactories. From the lower extremity, G, of the

system of condensers, a perpendicular tube rises, whose length should be a little more

than the most elevated point of the system. The water, furnished by a reservoir, L,

enters by means of the perpendicular tube through the lower part of the system, and

fills the whole space between the double cylinders. When the apparatus is in action,

the vapours, as they condense, raise the temperature of the water, which, by the column

in L G, is pressed to the upper part of the cylinders, and runs over by the spout K.

To this point a very short tube is attached, which is bent towards the ground, and

serves as an overflow.

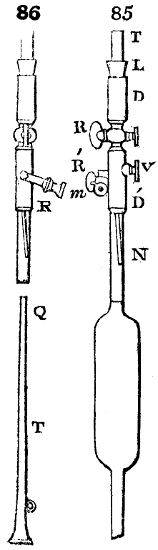

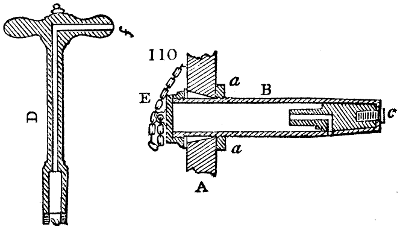

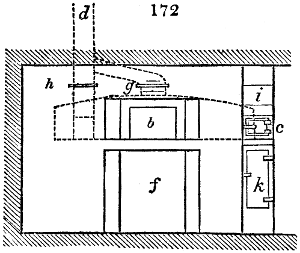

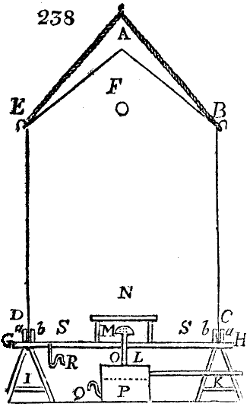

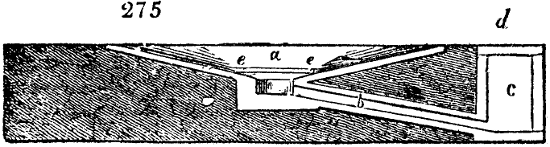

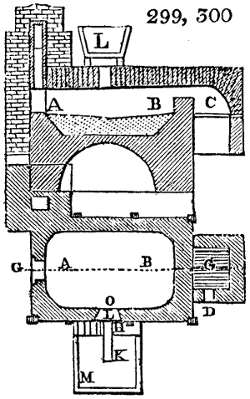

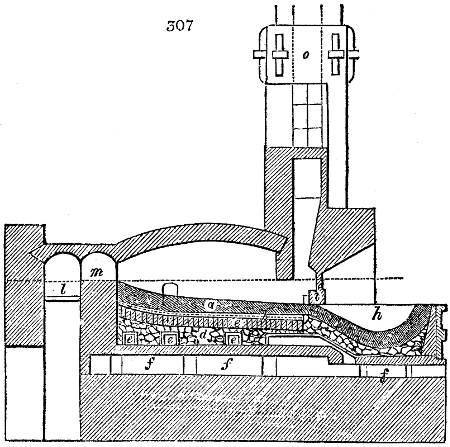

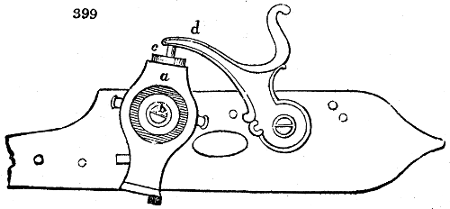

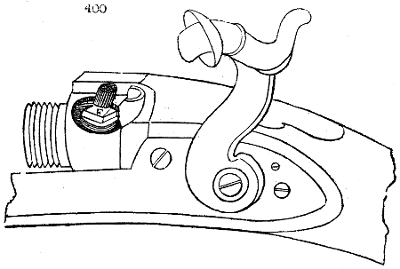

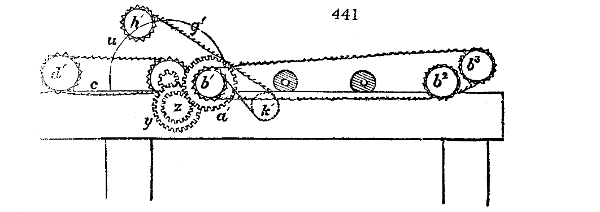

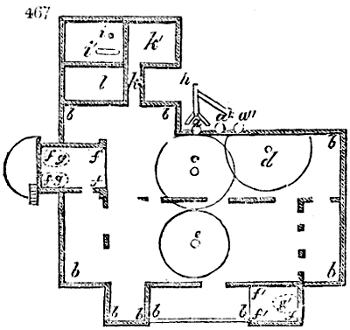

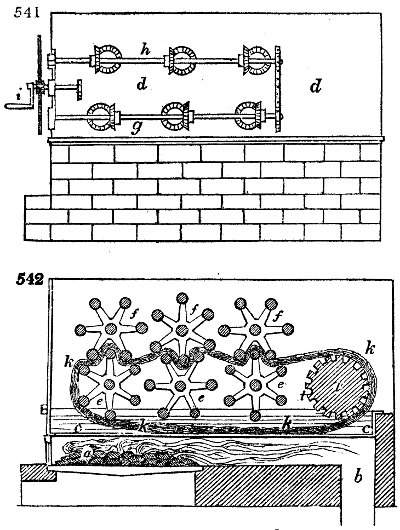

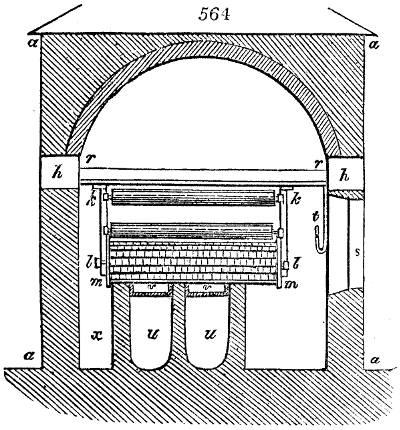

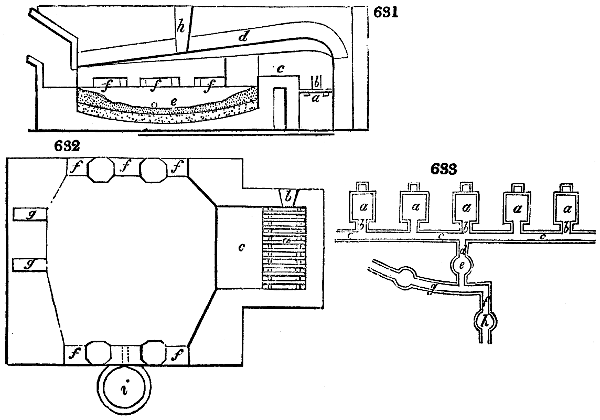

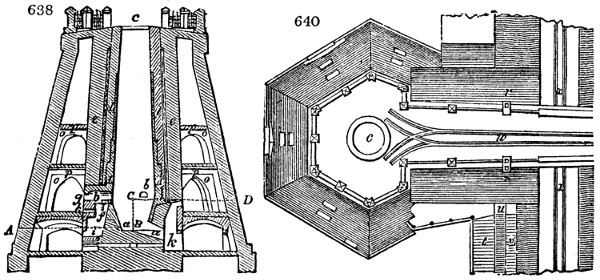

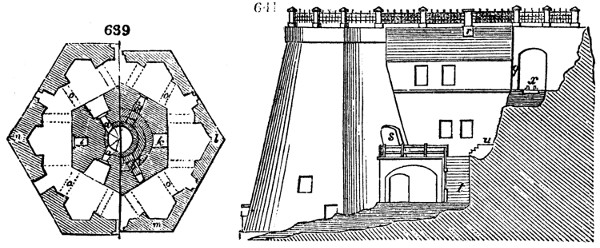

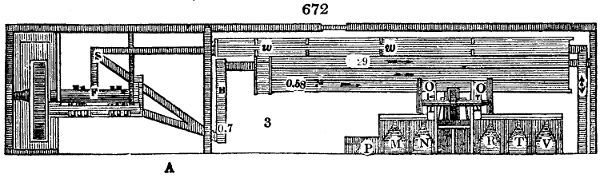

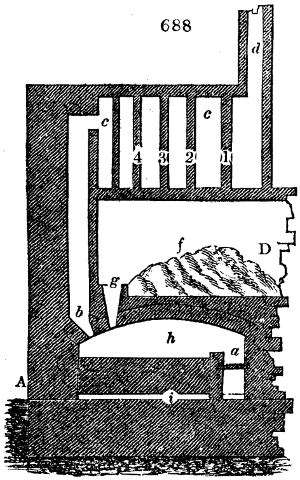

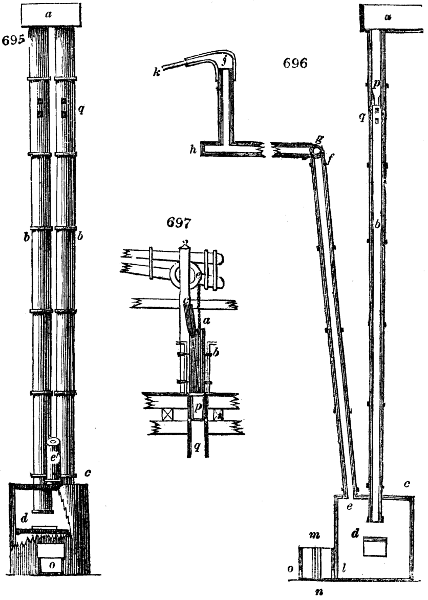

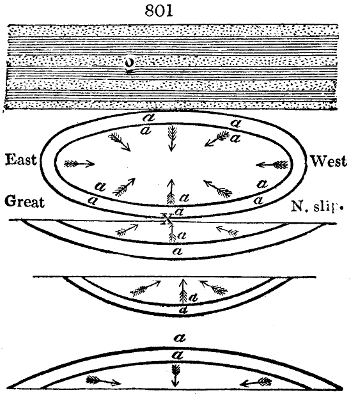

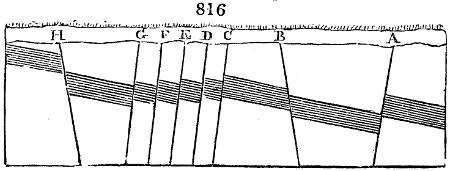

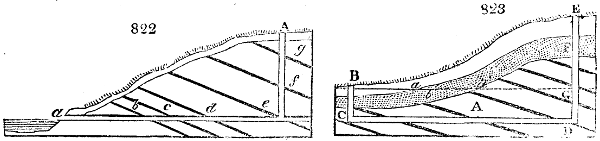

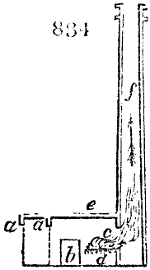

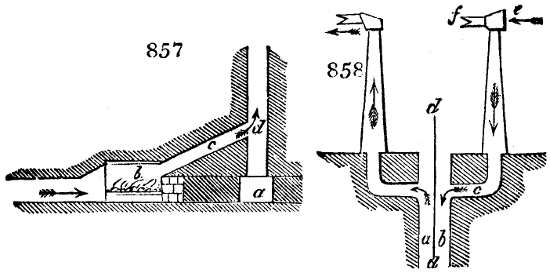

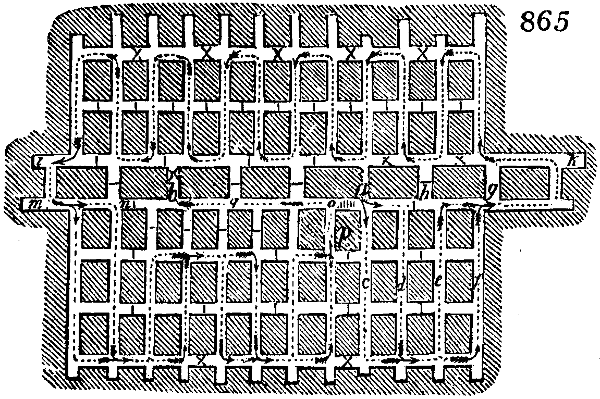

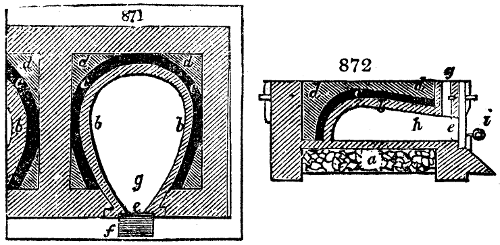

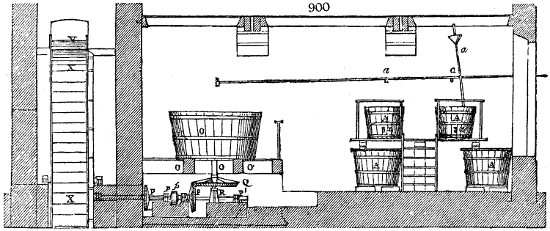

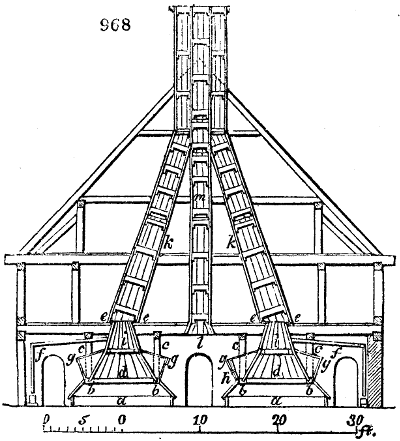

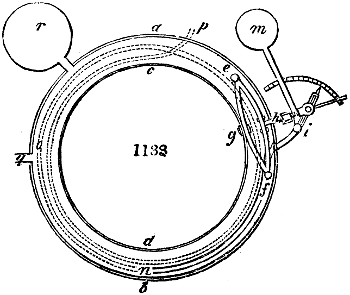

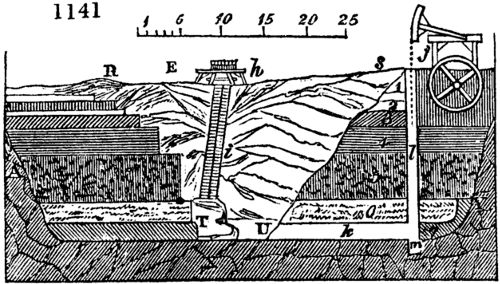

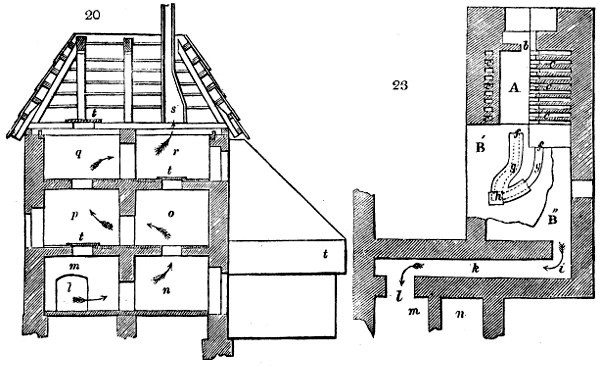

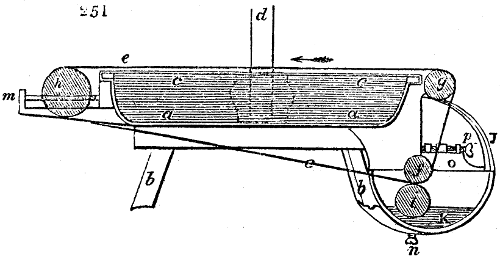

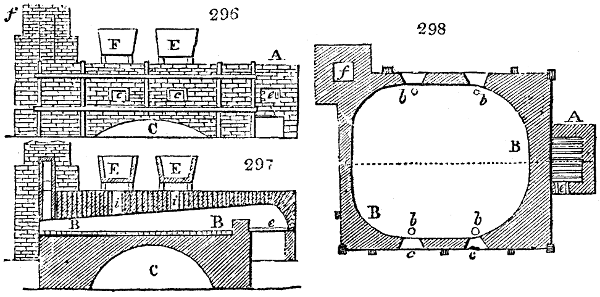

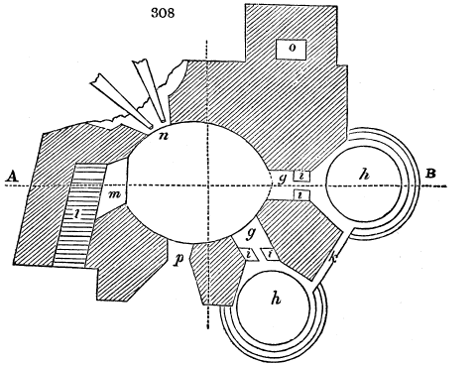

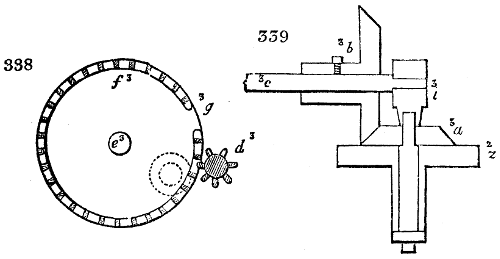

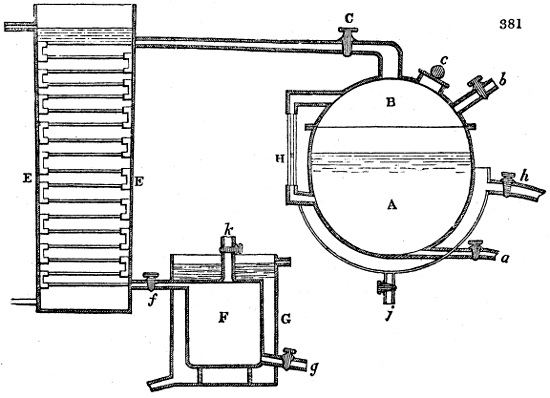

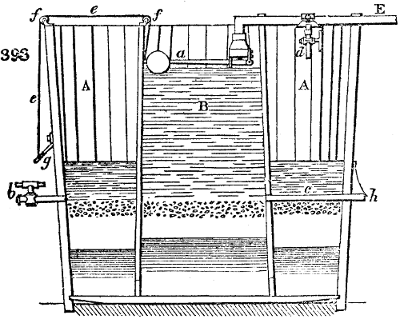

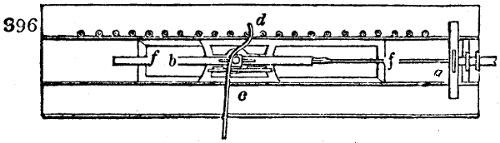

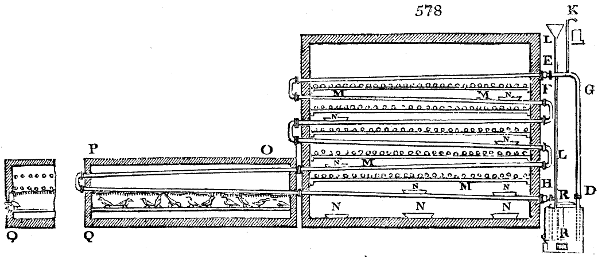

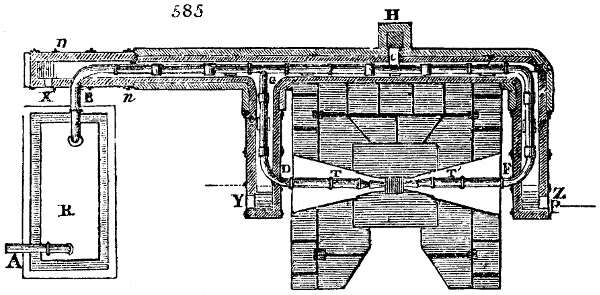

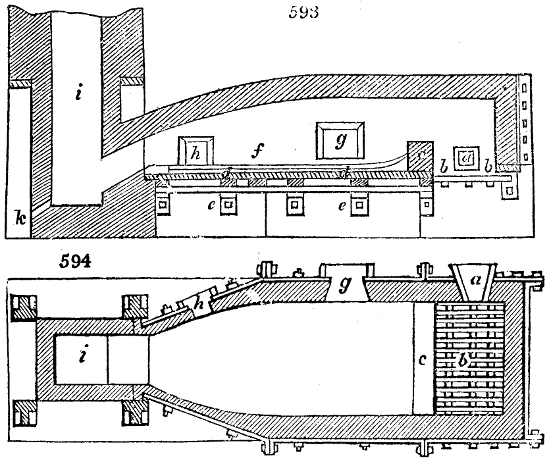

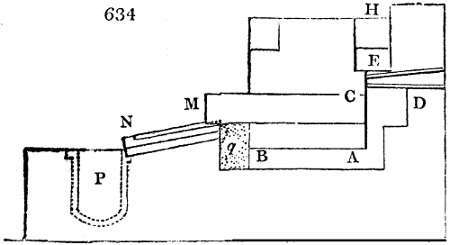

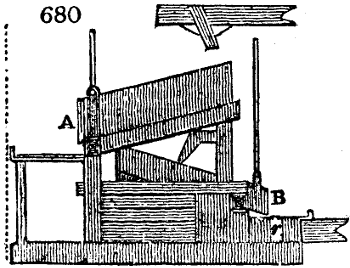

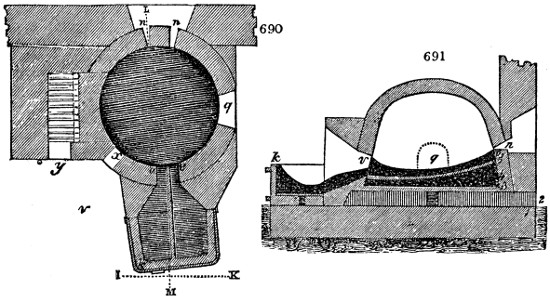

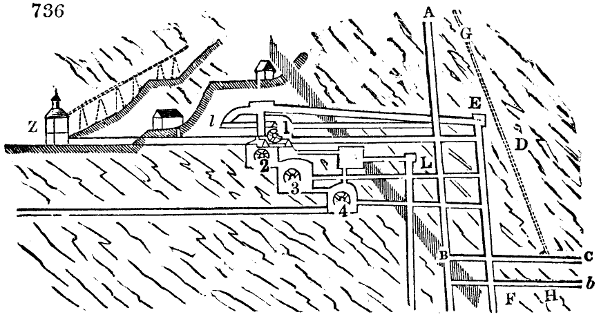

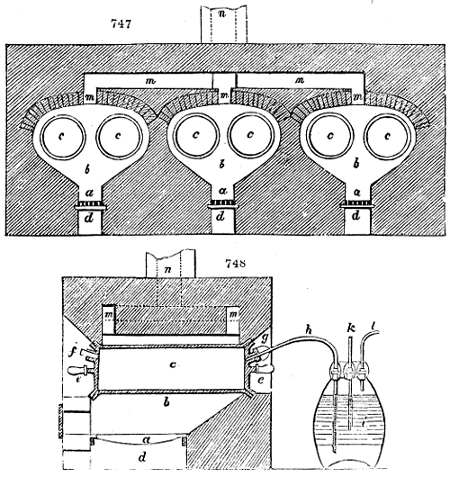

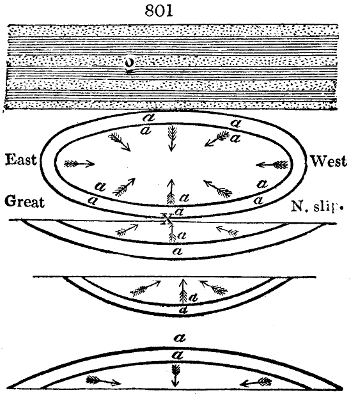

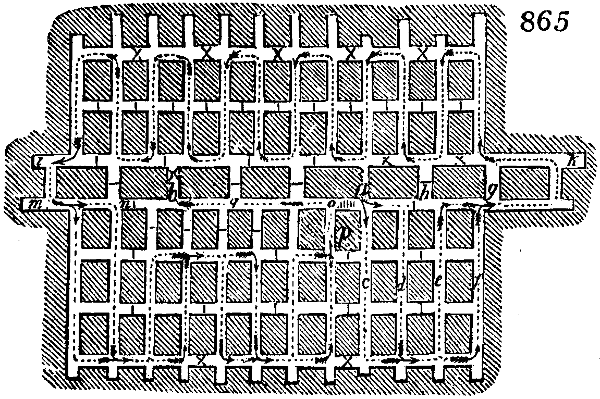

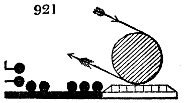

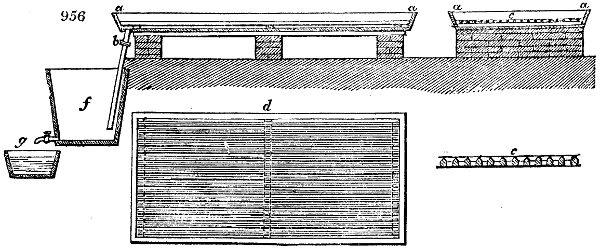

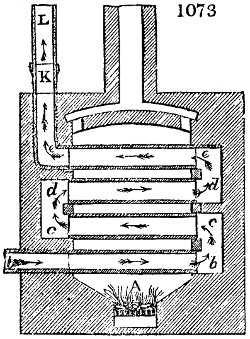

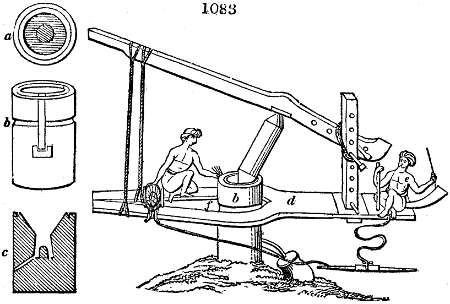

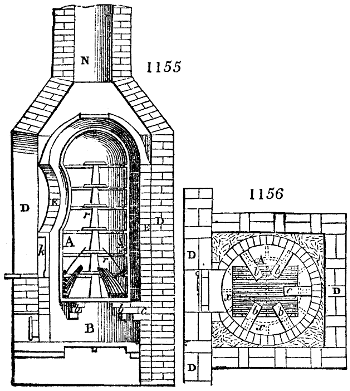

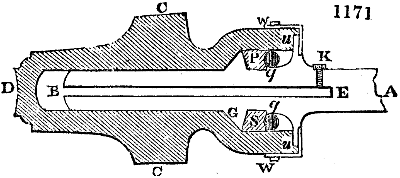

Fig. 4.

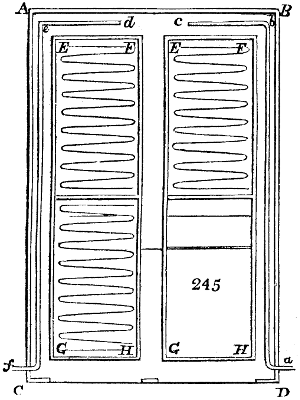

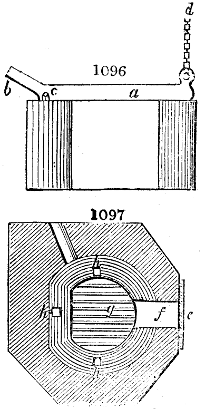

The condensing apparatus is terminated by a conduit in bricks covered and sunk in

the ground. At the extremity of this species of gutter is a bent tube, E, which

discharges the liquid product into the first cistern. When it is full, it empties itself, by

means of an overflow pipe, into a great reservoir; the tube which terminates the gutter

plunges into the liquid, and thus intercepts communication with the inside of the apparatus.

The disengaged gas is brought back by means of pipes M L, from one of the

sides of the conduit to the under part of the ash pit of the furnace. These pipes are

furnished with stopcocks M, at some distance in front of the furnace, for the purpose of

regulating the jet of the gas, and interrupting, at pleasure, communication with the inside of

the apparatus. The part of the pipes which terminates in the furnace rises perpendicularly

several inches above the ground, and is expanded like the rose of a watering can, N. The

gas, by means of this disposition, can distribute itself uniformly under the vessel, without

suffering the pipe which conducts it to be obstructed by the fuel or the ashes.

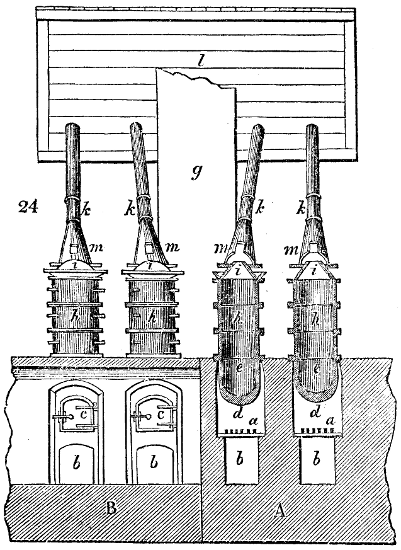

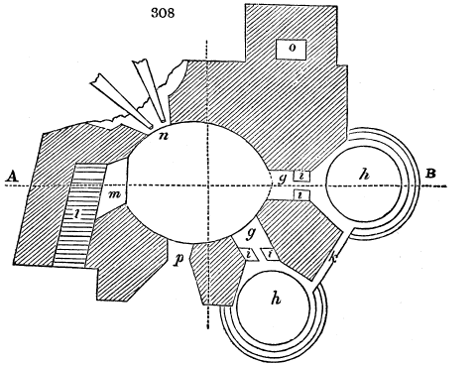

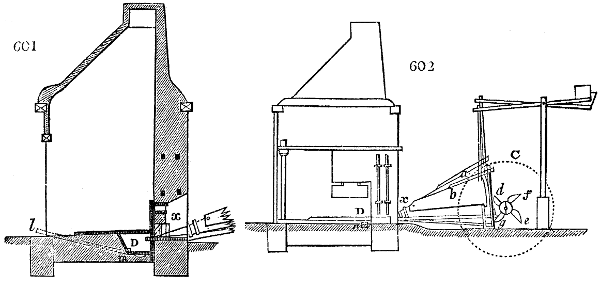

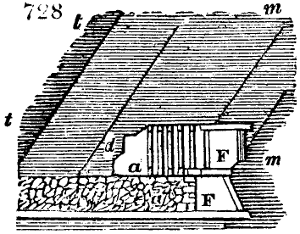

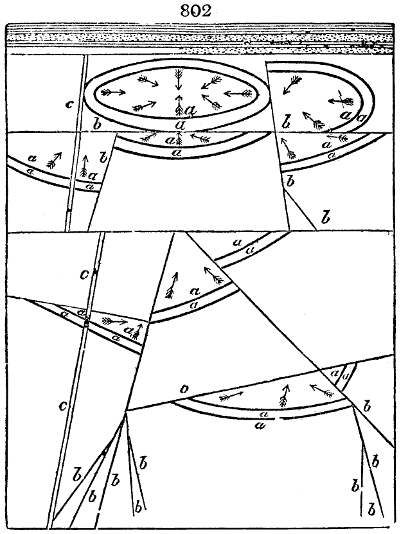

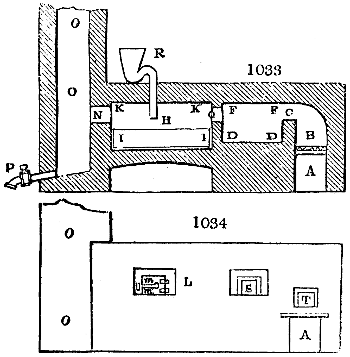

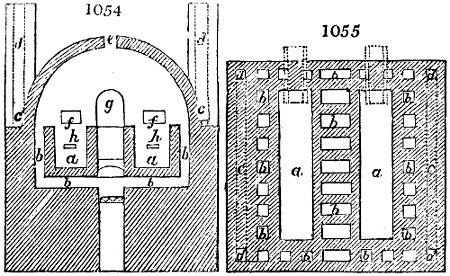

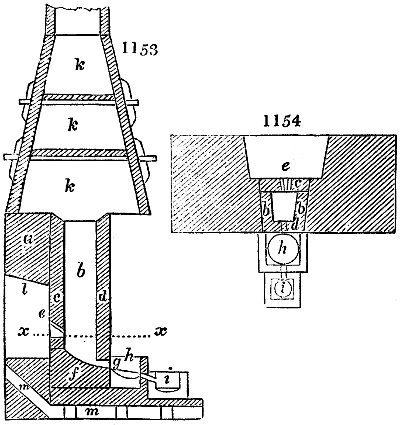

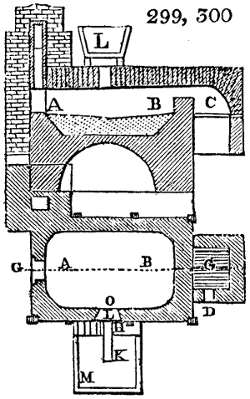

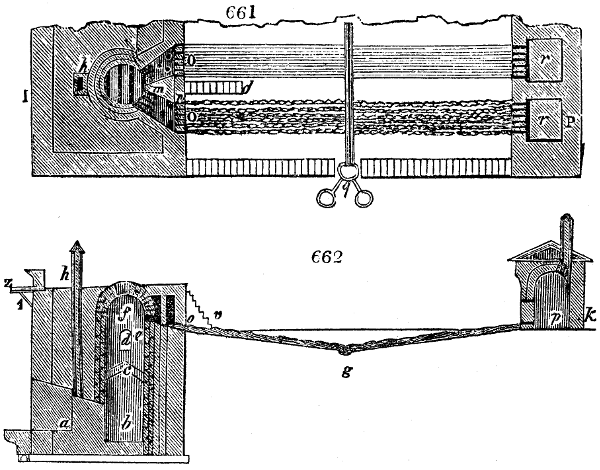

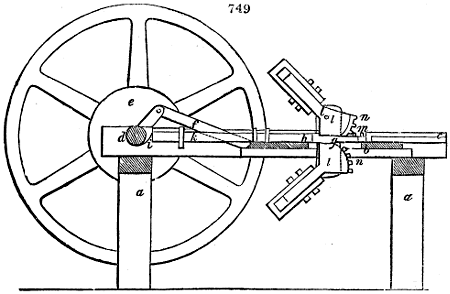

The temperature necessary to effect the carbonisation is not considerable: however, at

the last it is raised so high as to make the vessels red hot; and the duration of the process is

necessarily proportional to the quantity of wood carbonised. For a vessel which shall

contain about 5 meters cube (nearly 6 cubic yds.), 8 hours of fire is sufficient. It is

known that the carbonisation is complete by the colour of the flame of the gas: it is

first of a yellowish red; it becomes afterwards blue, when more carbonic oxide than

carbonic hydrogen is evolved; and towards the end it becomes entirely white,—a circumstance

owing, probably, to the furnace being more heated at this period, and the

combustion being more complete. There is still another means of knowing the state of

the process, to which recourse is more frequently had; that is the cooling of the first

tubes, which are not surrounded with water: a few drops of this fluid are thrown upon

their surface, and if they evaporate quietly, it is judged that the calcination is sufficient.

The adopter tube is then unluted, and is slid into its junction pipe; the orifices are

immediately stopped with plates of iron and plaster loam. The brick cover, E, of the

furnace is first removed by means of the swing crane, then the cylinder itself is lifted

out and replaced immediately by another one previously charged. When the cylinder which

has been taken out of the furnace is entirely cooled, its cover is removed, and the charcoal

is emptied. Five cubic meters of wood furnish about 7 chaldrons (voies) and a half of

charcoal. (For modifications of the wood-vinegar apparatus, see Charcoal and

Pyrolignous Acid.)

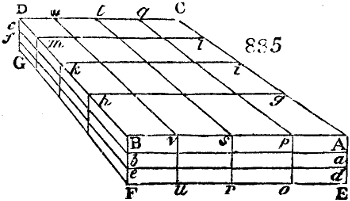

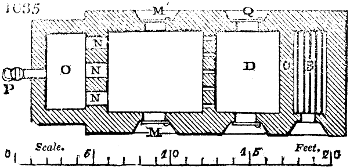

The different qualities of wood employed in this operation give nearly similar product

in reference to the acid; but this is not the case with the charcoal, for it is better the

harder the wood; and it has been remarked, that wood long exposed to the air furnishes

a charcoal of a worse quality than wood carbonised soon after it is cut.

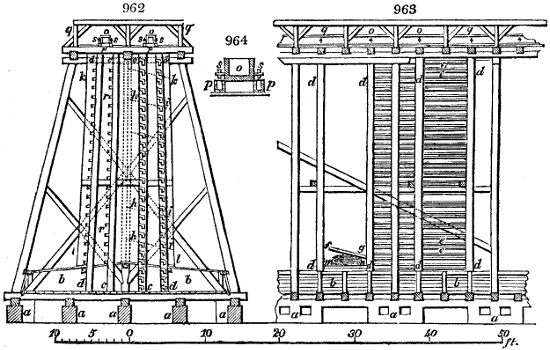

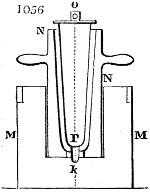

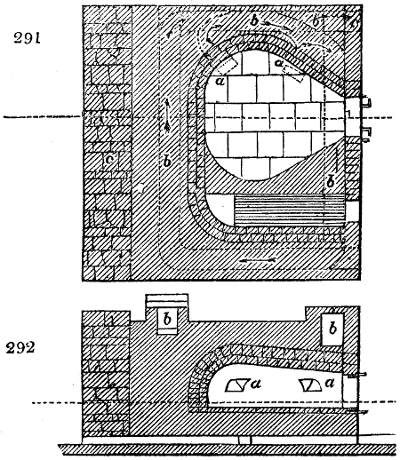

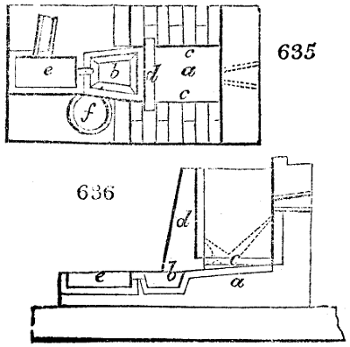

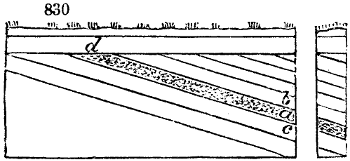

Having described the kind of apparatus employed to obtain pyrolignous acid, I shall

now detail the best mode of purifying it. This acid has a reddish brown colour; it holds

in solution a portion of empyreumatic oil and of the tar which were formed at the same

time; another portion of these products is in the state of a simple mixture; the latter

may be separated by repose alone. It is stated, above, that the distilling apparatus

terminates in a subterranean reservoir, where the products of all the vessels are mixed.

A common pump communicates with the reservoir, and sinks to its very bottom, in order

that it may draw off only the stratum of tar, which, according to its greater density,

occupies the lower part. From time to time the pump is worked to remove the

tar as it is deposited. The reservoir has at its top an overflow pipe, which discharges

the clearest acid into a cistern, from which it is taken by means of a second pump.

The pyrolignous acid thus separated from the undissolved tar is transferred from this

cistern into large sheet iron boilers, where its saturation is effected either by quicklime

or by chalk; the latter of which is preferable, as the lime is apt to take some of the tar

into combination. The acid parts by saturation with a new portion of the tar, which is

removed by skimmers. The neutral solution is then allowed to rest for a sufficient time

to let its clear parts be drawn off by decantation.

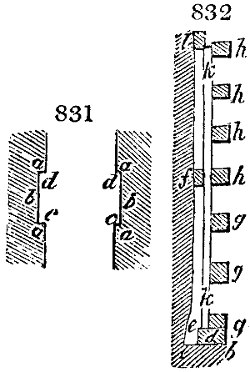

The acetate of lime thus obtained indicates by the hydrometer, before being mixed with

the waters of edulcoration, a degree corresponding to the acidimetric degree of the acid[11]

employed. This solution must be evaporated till it reaches a specific gravity of 1·114

(15° Baumé), after which there is added to it a saturated solution of sulphate of soda.

The acids exchange bases; sulphate of lime precipitates, and acetate of soda remains in

solution. In some manufactures, instead of pursuing the above plan, the sulphate of

soda is dissolved in the hot pyrolignous acid, which is afterwards saturated with chalk

or lime. By this means no water need be employed to dissolve the sulphate, and

accordingly the liquor is obtained in a concentrated form without evaporation. In both

modes the sulphate of lime is allowed to settle, and the solution of acetate of soda is decanted.

The residuum is set aside to be edulcorated, and the last waters are employed

for washing fresh portions.

The acetate of soda which results from this double decomposition is afterwards

evaporated till it attains to the density of 1·225 or 1·23, according to the season. This

solution is poured into large crystallising vessels, from which, at the end of 3 or 4 days,

according to their capacity, the mother waters are decanted, and a first crystallisation is

obtained of rhomboidal prisms, which are highly coloured and very bulky. Their

facettes are finely polished, and their edges very sharp. The mother waters are submitted

to successive evaporations and crystallisations till they refuse to crystallise, and they are

then burnt to convert them into carbonate of soda.

To avoid guesswork proportions, which are always injurious, by the loss of time which

they occasion, and by the bad results to which they often lead, we should determine

experimentally, beforehand, the quantities absolutely necessary for the reciprocal decomposition,

especially when we change the acid or the sulphate. But it may be remarked

that, notwithstanding all the precautions we can take, there is always a notable quantity

of sulphate of soda and acetic acid, which disappear totally in this decomposition. This

arises from the circumstance that sulphate of soda and acetate of lime do not completely

decompose each other, as I have ascertained by experiments on a very considerable scale;

and thus a portion of each of them is always lost with the mother waters. It might be

supposed that by calcining the acetate of lime we could completely destroy its empyreumatic

oil; but, though I have made many experiments, with this view I never could

obtain an acetate capable of affording a tolerable acid. Some manufacturers prefer to

make the acetate of soda by direct saturation of the acid with the alkali, and think

that the higher price of this substance is compensated by the economy of time and fuel

which it produces.

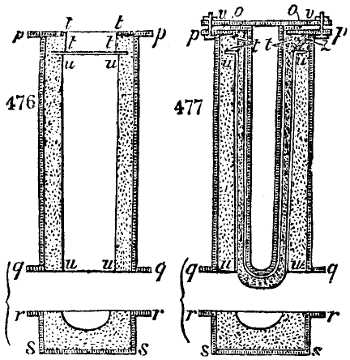

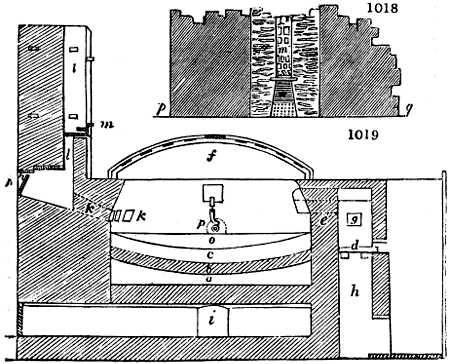

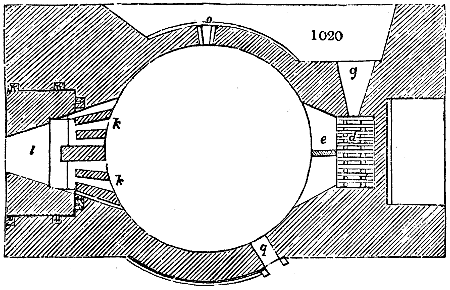

The acetate of soda is easily purified by crystallisations and torrefaction; the latter

process, when well conducted, freeing it completely from every particle of tar. This

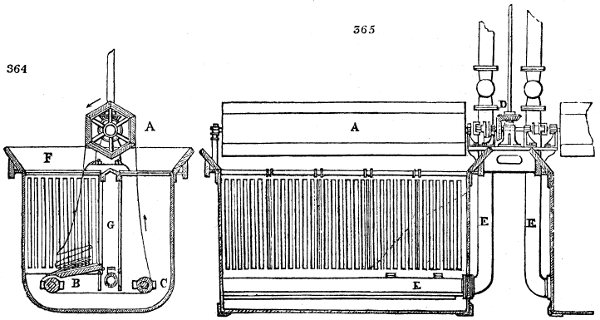

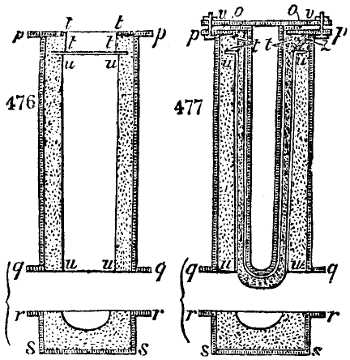

torrefaction, to which the name of fusion may be given, requires great care and dexterity.

It is usually done in shallow cast iron boilers of a hemispherical shape. During all the

time that the heat of about 500° Fahr. is applied, the fused mass must be diligently

worked with rakes; an operation which continues about 24 hours for half a ton of materials.

We must carefully avoid raising the temperature so high as to decompose the

acetate, and be sure that the heat is equally distributed; for if any point of the mass

enters into decomposition, it is propagated with such rapidity, as to be excessively difficult

to stop its progress in destroying the whole. The heat should never be so great as

to disengage any smoke, even when the whole acetate is liquefied. When there is no

more frothing up, and the mass flows like oil, the operation is finished. It is now

allowed to cool in a body, or it may be ladled out into moulds, which is preferable.

When the acetate is dissolved in water, the charcoaly matter proceeding from the

decomposition of the tar must be separated by filtration, or by boiling up the liquor to

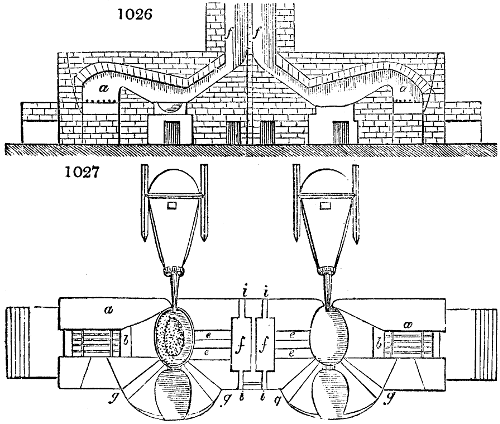

the specific gravity 1·114, when the carbonaceous matter falls to the bottom. On evaporating

the clear liquor, we obtain an acetate perfectly fine, which yields beautiful crystals

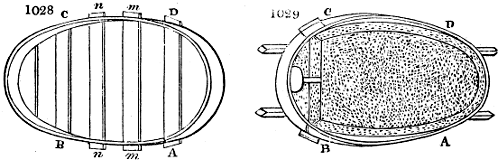

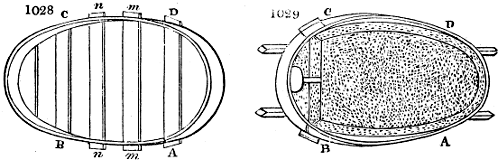

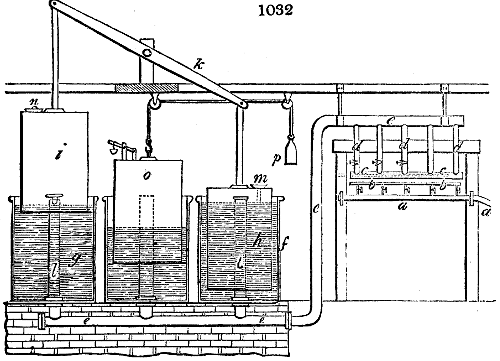

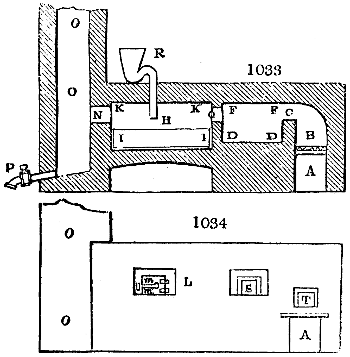

on cooling. In this state of purity it is decomposed by sulphuric acid, in order to separate

its acetic acid.

This last operation, however simple it appears, requires no little care and skill. The

acetate of soda crystallised and ground is put into a copper, and the necessary quantity

of sulphuric acid of 1·842 (about 35 per cent. of the salt) to decompose almost, but not

all, the acetate, is poured on. The materials are left to act on each other; by degrees

the acetic acid quits its combination, and swims upon the surface; the greater part of

the resulting sulphate of soda falls in a pulverulent form, or in small granular crystals, to

the bottom. Another portion remains dissolved in the liquid, which has a specific

gravity of 1·08. By distillation we separate this remainder of the sulphate, and finally

obtain acetic acid, having a specific gravity of 1·05, an agreeable taste and smell, though

towards the end it becomes a little empyreumatic, and coloured; for which reason, the

last portions must be kept apart. The acid destined for table use ought to be distilled

in an alembic whose capital and condensing worm are of silver; and to make it very

fine, it may be afterwards infused over a little washed bone-black. It is usually obtained

in a pretty concentrated state; but when we wish to give it the highest degree of concentration,

we mix with it a quantity of dry muriate of lime, and distil anew. This acid may[12]

be afterwards exposed to congelation, when the strongest will crystallise. It is decanted,

and the crystals are melted by exposing them to a temperature of from 60° to 70° Fahr.;

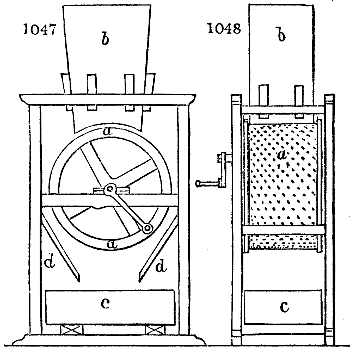

this process is repeated till the acid congeals without remainder, at the temperature of 55°

Fahr. It has then attained its maximum strength, and has a specific gravity of 1·063.

We shall add an observation on the above mode of decomposing the acetate of soda by

sulphuric acid. Many difficulties are experienced in this process, if the sulphuric acid

be poured on in small quantities at a time; for then such acrid fumes of acetic acid

are disengaged, that the workmen are obliged to retire. This inconvenience may be

saved by adding all the sulphuric acid at once; it occupies the lower part of the vessel,

and decomposes only the portion of the acetate in contact with it; the heat evolved in

consequence of this reaction is diffused through a great mass, and produces no sensible

effect. When the sulphuric acid forms an opening, or a species of little crater, the

workman, by means of a rake, depresses the acetate into it by degrees, and then the

decomposition proceeds as slowly as he desires.

The acetic acid, like the nitric, chloric, and some others, has not hitherto been

obtained free from water, and the greatest degree of concentration which we have been

able to give it is that in which it contains only the quantity of water equivalent to the

atomic weight of another oxidized body; a quantity which amounts to 14·89 per cent.

The processes prescribed for preparing concentrated acetic acid sometimes tend to

deprive it of that water without which it could not exist: hence, in all such cases,

there is a part of the acid itself decomposed to furnish the water necessary to the constitution

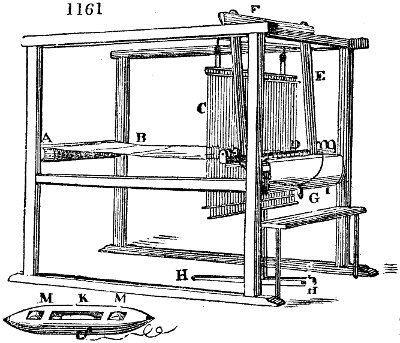

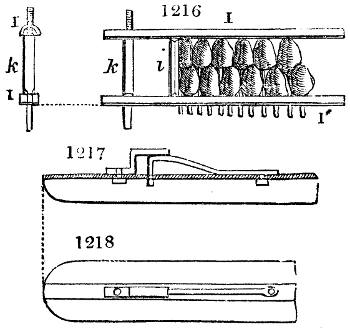

of the remainder. The constituent principles of the decomposed portion then