The Cambridge Manuals of Science and Literature

THE NATURAL HISTORY OF CLAY

THE NATURAL

HISTORY OF CLAY

BY

ALFRED B. SEARLE

Cantor Lecturer on Brickmaking,

Author of British Clays, Shales

and Sands; The Clayworker's

Handbook, etc., etc.

Cambridge:

at the University Press

New York:

G. P. Putnam's Sons

1912

![]()

PRINTED BY JOHN CLAY, M.A.

AT THE UNIVERSITY PRESS

With the exception of the coat of arms at the foot, the design on the title page is a reproduction of one used by the earliest known Cambridge printer, John Siberch, 1521

Both as raw materials and in the form of pottery, bricks, tiles, terra-cotta and many other articles of use and ornament, clays are amongst the most important rock products. Yet the origin of the substances we know as 'clay,' the processes occurring in its formation and the causes of some of the most important of its characteristics are of such a nature that it is remarkable that its use should have become so extended in the arts and sciences, while we know so little of its properties when in a pure state.

In the following pages an attempt has been made to state in a simple form an outline of our present knowledge of the subject and to indicate the problems which still lie before us.

The experimental solution of these problems is rendered peculiarly difficult by the inertness of the materials at ordinary temperatures and the ease with which the clay molecule appears to break down into its constituent oxides at temperatures approaching red heat or as soon as it begins to react with alkaline or basic materials.

Another serious difficulty is the highly complex nature of that property known as 'plasticity' to which many clays owe their chief value. For many years this has been regarded as an elementary property such [vi] as hardness, cohesion or colour, but it is now known to be of so elusive a nature as almost to defy measurement with any degree of accuracy.

The thoroughness with which the methods of physical chemistry have been applied to geological and mineralogical problems during recent years has been of very great assistance to the student of clay problems, as will be seen on studying some of the works mentioned in the short bibliography at the end of the present volume. When the principles of hydrolysis, ionization, mass reaction and reactional velocity have been applied in still further detail to the study of clays, our knowledge of their natural history will increase even more rapidly than it has done during the past few years.

No industry exercises so great a fascination over those engaged in it as do the various branches of clayworking; no other substance offers so many problems of such absorbing interest to the artist, the craftsman, the geologist, the chemist and the general student of nature, whilst the differences in legal opinion as to the nature of clay could themselves occupy a volume far larger than the present one.

A. B. S.

The White Building,

Sheffield.

November 1911.

| CHAP. | PAGE | |

| Table of clay rocks | viii | |

| I | Introduction. The chemical and physical properties of clays | 1 |

| II | Clay and associated rocks | 48 |

| III | The origins of clays | 70 |

| IV | The modes of accumulation of clays | 84 |

| V | Some clays of commercial importance | 103 |

| VI | Clay-substance: theoretical and actual | 135 |

| Bibliography | 168 | |

| Index | 170 |

LIST OF ILLUSTRATIONS

| FIG. | ||

| 1 | Quartz crystals | 9 |

| 2 | Pyrite | 14 |

| 3 | Marcasite | 14 |

| 4 | Illustrating the structure of a 'clay crumb' | 24 |

| 5 | Chart showing rates of drying | 27 |

| 6 | Seger Cones indicating a temperature of 1250° C. | 34 |

| 7 | Ludwig's Chart | 36 |

| 8 | Coal Measures sequence in North Staffordshire | 55 |

| 9 | Lias clay being worked for the manufacture of hand-made sand-faced roofing tiles | 58 |

| 10 | Oxford clay near Peterborough | 60 |

| 11 | Cliffs of Boulder clay at Filey lying on Calcareous Crag | 66 |

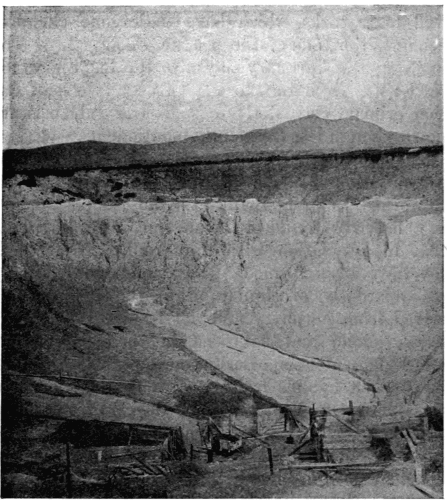

| 12 | China clay pit belonging to the North Cornwall China Clay Co. | 72 |

| 13 | Orthoclase Felspar | 75 |

| 14 | Illustrating the successive deposition of different strata | 90 |

| 15 | Lacustrine clay at Skipsea | 92 |

| 16 | Clay at Nostel, showing Marine Band | 94 |

| 17 | Kaolinite and Mica | 105 |

| 18 | Mining best Potter's clay in Devonshire | 111 |

THE CHIEF CLAY ROCKS (arranged geologically)

| Tertiary | Recent (alluvial clay, silt, brick earths, boulder clay) | |||

| Pliocene Miocene Oligocene Eocene |

(brick earths, ball clays, coarse pottery clays) | |||

| Secondary | Cretaceous (cement clays, brick clays) | |||

| Oolitic (brick and tile clays) | ||||

| Triassic (brick, tile and terra-cotta clays) | ||||

| Primary | Permian (brick, tile and flower-pot clays) | |||

| Carboniferous (brick clays, fireclays, ganister) | ||||

| Devonian Silurian Ordovician Cambrian Pre-Cambrian |

(clay schists, slates and clay shales) | |||

| Igneous Rocks occur on several horizons (china clays and kaolins) | ||||

(In the above Table only the clay-bearing strata are mentioned. The formations named consist chiefly of other rocks in which the clays form strata of variable thickness.)

INTRODUCTION. THE CHEMICAL AND PHYSICAL PROPERTIES OF CLAY

The chief uses of clay have been recognized since the earliest periods of civilization; the ancient Assyrian and Egyptian records contain numerous references to the employment of clay for the manufacture of bricks and for fulling or whitening cloth.

Clays are distributed so widely and in many cases are so readily accessible that their existence and some of their characteristics are known in entirely uncivilized regions. The use of certain white clays as a food, or at any rate as a means of staving off hunger, is common among some tribes of very primitive peoples. The more important uses of clays for building and other purposes are naturally confined to the more civilized nations.

The term clay (A.S. cloeg; Welsh clai; Dutch kley) although used in a scientific sense to include a variety of argillaceous earths (Fr. argile = clay) used in the manufacture of bricks, tiles, pottery [2] and ceramic products (Gr. keramos = potter's earth) generally, is really a word of popular origin and use. Consequently, it is necessary to bear in mind, when considering geological or other problems of a scientific nature, that this term has been incorporated into scientific terminology and that its use in this connection not infrequently leads to confusion. In short, whilst almost every dictionary includes one or more definitions of clay, and most text-books on geology, mineralogy, and allied sciences either attempt a definition or assume the reader's knowledge of one, there is no entirely satisfactory limitation in regard to the substances which may or may not be included under the term.

Clay is a popular term for a variety of substances of very varied origins, of great dissimilarity in their composition and in many of their chemical and physical properties, and differing greatly in almost every conceivable respect. It is commonly supposed that all clays are plastic, but some of the purest china clays are almost devoid of this property and some of the most impure earths used for brickmaking possess it in a striking degree. Shales, on the one hand—whilst clearly a variety of clay—are hard and rock-like, requiring to be reduced to powder and very thoroughly mixed with water before they become plastic; many impure surface deposits, on the other hand, are so highly plastic as to necessitate the [3] addition of other (sandy) materials before they can be used for the manufacture of bricks and tiles.

Attempts have been made to include in the term clay 'all minerals capable of becoming plastic when moistened or mixed with a suitable quantity of water,' but this definition is so wide as to be almost impracticable, and leads to the inclusion of many substances which have no real connection with clays. The limitation of the use of the word 'clay' to the plastic or potentially plastic materials of any single geological epoch is also impracticable, for clays appear to have been deposited in almost every geological period, though there is some difference of opinion as to the time of the formation of certain clays known as kaolins.

Clay is not infrequently termed a mineral, but this does not apply at all accurately to the many varieties of earths known as 'common clays,' which, together with the 'boulder clays,' contain many minerals and so cannot, as a whole, be included under this term.

Whatever may be the legal significance of the term 'mineral'—which has an important economic bearing on account of minerals being taxed or 'reserved' in some instances where non-minerals (including brick clay) are exempt—there can be no doubt that, scientifically, clay is not a mineral but a rock. Whatever mineral (if any) may give the chief [4] characteristic property to the clays as a class must be designated by a special title, for the general term 'clay' will not serve for this purpose. Geologically, the clays are sedimentary rocks, some being unaltered, whilst others—the slates—are notably metamorphosed and can seldom be used for the purposes for which clays are employed.

Most clays may be regarded as a mixture of quartz grains, undecomposed rock débris and various decomposition products of rocks; if the last-named consists chiefly of certain hydrous alumino-silicates, they may be termed 'clay substance' (see Chapter VI). The imperfections of this statement as a definition are obvious when it is remembered that it may include a mixture of fine sand and clay containing only 30 per cent. of the latter substance.

It is, at the present time, quite impossible to construct an accurate definition of the term 'clay.' The most satisfactory hitherto published defines 'clay' as 'a solid rock composed mainly of hydro-alumino-silicates or alumino-silicic acids, but often containing large proportions of other materials; the whole possessing the property of becoming plastic when treated with water, and of hardening to a stone-like mass when heated to redness.'

From what has already been written, it will be understood that there is no such entity as a standard clay, for the varieties are almost endless, and the [5] differences between them are sometimes so slight as to be scarcely distinguishable.

A further consideration of this branch of the subject may, however, conveniently be deferred to a subsequent chapter.

The best-known clays are the surface clays, loams and marls, the shales and other sub-surface clays, and the pottery and china clays. The values of these different materials vary enormously, some being almost worthless whilst others are highly valued.

The surface clays are chiefly used for the manufacture of bricks and tiles (though some are quite unsuitable for this purpose) and form the soil employed in agriculture in many districts.

The sub-surface clays and shales are harder, and usually require mechanical treatment before they can be used for brick and terra-cotta manufacture, or for the production of refractory and sanitary articles.

The pottery and china clays are usually more free from accessory constituents, and are regarded as the 'purest' clays on the market, though a considerable amount of latitude must be allowed in interpreting the term 'pure.' China clays are by no means pure in the state in which they occur, and require careful treatment before they can be sold.

Further information with regard to the characteristics of certain clays will be found in Chapter V.

The Chemical Properties of Clay.

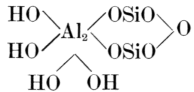

The chief constituents of all clays are alumina and silica, the latter being always in excess of the former. These two oxides are, apparently, combined to form a hydro-alumino-silicate or alumino-silicic acid corresponding to the formula H4Al2Si2O9[1], but many clays contain a much larger proportion of silica than is required to form this compound, and other alumino-silicates also occur in them in varying proportions (see Chapters V and VI).

All clays may, apparently, be regarded as consisting of a mixture of one or more hydrous alumino-silicates with free silica and other non-plastic minerals or rock granules, and their chemical properties are largely dependent on the nature and proportion of these accessory ingredients.

The purest forms of clay (china clays and ball clays) approximate to the formula above-mentioned, but others differ widely from it, as will be seen from the analyses on p. 16. The chemical properties of pure clay are described more fully in Chapter VI.

[1] This formula is commonly written Al2O32SiO22H2O, but although this is a convenient arrangement, it must not be understood to mean that clays contain water in a state of combination similar to that in such substances as washing soda—Na2CO324H2O, or zinc [7] sulphate crystals—ZnSO47H2O (see Chapter VI).

Taking china clay, which has been carefully purified by levigation, as representative of the composition of a 'pure' clay, it will be found that the chief impurities in clays are (a) stones, gravel and sand—removable by washing or sifting; (b) felspar, mica and other silicates and free silica—which cannot be completely removed without affecting the clay and (c) lime, magnesia, iron, potash and soda compounds, together with minute quantities of other oxides, all of which appear to be so closely connected with the clay as to be incapable of removal from it by any mechanical methods of purification.

To give a detailed description of the effect of each of the impurities just referred to would necessitate a much larger volume than the present, but a few brief notes on the more important ones are essential to a further consideration of the natural history of clay.

Stones, gravel and sand are most noticeable in the boulder clays, but they occur in clays of most geological ages, though in very varying proportions. Sometimes the stones are so large that they may be readily picked out by hand; in any case the stones, gravel and most of the sand may be removed by mixing the material with a sufficient quantity of water and passing the 'slip' through a fine sieve, or by allowing it to remain stationary for a few moments and then allowing the supernatant liquid to run off [8] into a settling tank. Some clays contain sand grains which are so fine that they cannot be removed in this manner and the clay must then be washed out by a stream of water with a velocity not exceeding 2 ft. per hour. Even then, the clay so removed may be found to contain minute grains of silt, much of which may be removed by a series of sedimentations for various periods, though a material perfectly free from non-plastic granules may be unattainable.

Most of the sand found associated with clays is in the form of fragments of quartz crystals (fig. 1), though it may be composed of irregular particles of other minerals or of amorphous silica.

Felspar, mica and other adventitious silicates occur in many natural clays in so fine a state of division that their removal would be unremunerative. In addition to this they act as fluxes when the clays are heated in kilns, binding the less fusible particles together and forming a far stronger mass than would otherwise be produced. Consequently, they are valuable constituents in clays used for the manufacture of articles in which strength or imperviousness is important. If these minerals are present in the form of particles which are sufficiently large to be removed by elutriation in the manner described on the previous page, the purification of the clay is not difficult. Usually, however, the most careful treatment fails to remove all these minerals; their presence [9] may then be detected by microscopical examination and by chemical analysis. For most of the purposes for which clays are used, small proportions of these silicates are unimportant, but where clays of a highly refractory nature are required; and for most of the purposes for which china clays (kaolins) are employed, [10] they must not be present to the extent of more than 5 per cent., smaller proportions being preferable.

Oxides, sulphides, sulphates and carbonates of various metals form the third class of impurities in clays. Of these, the most important are calcium oxide (lime), calcium carbonate (chalk and limestone), calcium sulphate (gypsum and selenite), the corresponding magnesia, magnesium carbonate, and sulphate, the various iron oxides, ferrous carbonate and iron sulphides (pyrite and marcasite) (p. 13).

Potash and soda compounds are commonly present as constituents of the felspar, mica, or other silicates present, and need no further description, though small proportions of soluble salts—chiefly sodium, potassium, calcium and magnesium sulphates—occur in most clays and may cause a white scum on bricks and terra-cotta made from them.

Lime and magnesia compounds may occur as silicates (varieties of felspar, mica, etc.), but their most important occurrence is as chalk or limestone. Chalk is a constant constituent of malms[2] and of many marls, but the latter may contain limestone particles. Limestone occurs in many marls and to a smaller extent in other clays. In the boulder clays it frequently forms a large portion of the stony material. If the grains are very small (as in chalk), the lime compounds [11] act as a flux, reducing the heat-resisting power of the clay and increasing the amount of vitrification; they produce in extreme cases a slag-like mass when the clay is intensely heated. If, on the contrary, the grains are larger (as frequently occurs with limestone), they are converted into lime or magnesia when the clay is 'burned' in a kiln, and the lime, on exposure to weather, absorbs moisture (i.e. slakes), swells, and may disintegrate the articles made from the clay. Limestone (except when in a very finely divided state) is almost invariably objectionable in clays, but chalk is frequently a valuable constituent.

Chalk is added to clay in the manufacture of malm-bricks to produce a more pleasing colour than would be obtained from the clay alone, to reduce the shrinkage of the clay to convenient limits and, less frequently, to form a more vitrifiable material. Chalk, on heating, combines with iron oxide and clay, forming a white silicate, so that some clays which would, alone, form a red brick, will, if mixed with chalk, form a white one.

Lime compounds have the serious objection of acting as very rapid and powerful fluxes, so that when clays containing them are heated sufficiently to start partial fusion, a very slight additional rise in temperature may easily reduce the whole to a shapeless, slag-like mass. Magnesia compounds act much more slowly in this respect and so are less harmful.

Gypsum—a calcium sulphate—occurs naturally in many sub-surface clays, often in well-defined crystalline masses. It reduces the heat-resisting power of the clays containing it and may, under some conditions, rise to the surface of the articles made from the clay, in the form of a white efflorescence or scum, such as is seen on some brick walls.

Iron compounds are highly important because they exercise a powerful influence on the colour of the burned clays. The red oxide (ferric oxide) is the most useful form in burned clay, but in the raw material ferrous oxide and ferrous carbonate may also occur, though they are converted into the red oxide on heating. The red iron oxide, which is closely related to 'iron rust,' occurs in so finely divided a state that its particles appear to be almost as small as those of the finest clays. Hence attempts to improve the colour of terra-cotta and bricks by the addition of commercial 'iron oxide' are seldom satisfactory, the finest material obtainable being far coarser than that occurring in clays.

It is a curious fact that red iron oxide does not appear to form any compound with the other constituents of clay under ordinary conditions of firing, and although a 'base' and capable of reducing the heat-resisting power of clays, it does not appear to do so as long as the conditions in the kiln are sufficiently oxidizing. It is this which enables red bricks and [13] other articles to be obtained with remarkable uniformity of colour combined with great physical strength. In a reducing atmosphere, on the contrary, ferrous oxide readily forms and attacks the clay, forming a dark grey vitreous mass. If the iron particles are separated from each other they will, on reduction, form small slag-like spots, but if they are in an extremely fine state of division and well distributed, the brick or other article will become slightly glossy and of an uniform black-grey tint. The famous Staffordshire 'blue' bricks owe their colour to this characteristic; they are not really 'blue' in colour. The effect of chalk on the colour of red-burning clays has already been mentioned.

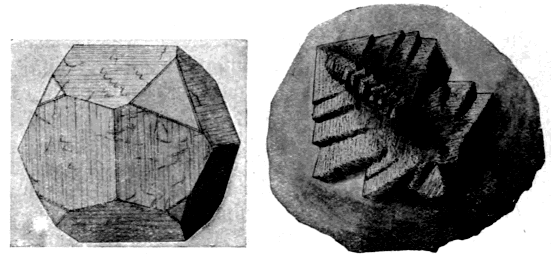

Iron pyrite (fig. 2) and marcasite (fig. 3)—both of which are forms of iron sulphide—occur in many clays, particularly those of the Coal Measures. Mundic is another form of pyrites which resembles roots or twigs, but when broken show a brassy fracture. When in pieces of observable size the pyrite may be readily distinguished by its resemblance to polished brass and the marcasite by its tin-white metallic lustre and both by their characteristic cubic, root-like and spherical forms; the latter only show a brass-like sheen when broken. Even when only a small proportion of mundic, pyrite or marcasite is present, it is highly objectionable for several reasons. In the first place, half the sulphur present is given off [14] at a dark red heat and is liable to cause troublesome defects on the goods. Secondly, because the remaining sulphur and iron are not readily oxidized, so that there is a great tendency to form slag-spots of ferrous silicate, owing to the iron attacking the clay at the same moment as it parts with its remaining sulphur. For this reason, clays containing any iron sulphide seldom burn red, but form products of a buff colour with black spots scattered irregularly over their surface and throughout the mass—an appearance readily observable on most hard-fired firebricks. If chalcopyrite (copper-iron sulphide) is present the spots may be bright green in colour.

Fig. 2. Pyrite.

Fig. 3. Marcasite.

Slightly magnified.

(From Miers' Mineralogy by permission of Macmillan & Co.)

Carbon, either free or as hydrocarbons (chiefly vegetable matter) or in other forms, is a constituent of most clays, though seldom reported in analyses. Its presence exercises an important influence in several respects. On heating the clay, with an ample supply of air, the carbonaceous matter may distil off (as shale oil), but more usually it decomposes and burns out leaving pores in the material. If the air-supply is insufficient and the heating is so rapid and intense that vitrification commences before the carbon is all burned away, the pores become filled with the fused ingredients of the clay, air can no longer reach the carbon particles and a black 'core' or heart is produced. Under peculiarly disadvantageous conditions the material may also swell greatly. This is a serious defect in many classes of clay used for brickmaking, and its causes and prevention have been exhaustively studied by Orton and Griffiths (1)[3] but, beyond the brief summary given above, these are beyond the scope of the present work.

Water is an essential constituent of all unburned clays, though the proportion in which it occurs varies within such wide limits that no definite standard can be stated. This water is found in two conditions: (a) as moisture or mechanically mixed with the clay particles and (b) in a state of chemical combination.

ANALYSES OF TYPICAL CLAYS

The samples were all dried at 105° C.

| Clay | China Clay | Ball Clay | Fireclay | Brick Clay | Boulder Clay | Marl |

| Locality | Cornwall | Dorset | Yorkshire | Midlands | Lancs. | Suffolk |

| Ultimate Analysis: | ||||||

| Silica | 47·1 | 49·1 | 68·9 | 57·7 | 63·7 | 43·7 |

| Alumina | 39·1 | 33·7 | 19·3 | 24·3 | 20·4 | 15·5 |

| Ferric oxide | ·6 | 1·2 | 1·0 | 5·0 | 3·0 | 5·2 |

| Titanium oxide | — | ·2 | 1·8 | ·1 | ·2 | — |

| Lime | ·4 | ·8 | ·9 | 3·7 | 4·3 | 16·3 |

| Magnesia | ·2 | ·3 | ·3 | 2·5 | 2·7 | 2·1 |

| Potash and Soda | ·3 | 2·5 | ·9 | 2·8 | 2·9 | ·7 |

| Carbon | 2·6 | 4·3 | 1·8 | 1·6 | ·4 | 1·6 |

| Water | 9·3 | 7·7 | 4·8 | 2·0 | 2·2 | 2·4 |

| Other Matter | ·4 | ·2 | ·3 | ·3 | ·2 | 12·5 |

| Total | 100·0 | 100·0 | 100·0 | 100·0 | 100·0 | 100·0 |

| Proximate Analysis: | ||||||

| Gravel and Sand | — | 8·4 | 4·6 | 22·1 | 23·1 | 9·2 |

| Silt | — | 4·8 | 9·0 | 3·1 | 8·4 | 16·0 |

| Felspar- and mica-dust | 5·2 | 15·4 | 10·3 | 24·3 | 18·5 | 8·9 |

| Silica-dust | 3·1 | 4·0 | 38·0 | 3·1 | 12·6 | 2·0 |

| Free calcium carbonate | — | — | — | 2·1 | ·2 | 28·4 |

| Free iron oxide and pyrites | ·4 | ·9 | ·7 | 4·2 | 1·6 | 3·9 |

| 'True clay' | 91·3 | 66·5 | 37·4 | 41·1 | 35·6 | 31·6 |

| Total | 100·0 | 100·0 | 100·0 | 100·0 | 100·0 | 100·0 |

For other analyses the books in the Bibliography at the end of the present volume should be consulted, particularly No. 2, i.e. British Clays, Shales and Sands.

The amount of mechanically mixed water will naturally vary with the conditions to which the clay has been subjected; it will be greatest in wet situations and will diminish as the clay is allowed to dry.

The 'combined water,' on the contrary, appears to be a function of the true clay present in the material, and reaches its highest proportions in the china clays and kaolins, which contain approximately 13 per cent. On heating a clay to 105° C. the moisture or mechanically mixed water is evaporated, but the combined water remains unaffected[4] until the temperature is raised to more than 600° C., when it is driven off and the clay is converted into a hard stone-like mass with properties entirely different from those it previously possessed (see Chapter VI).

[4] Strictly, there is a slight loss at lower temperatures, but it is too small to be important.

The Physical Characters of Clays.

The physical characters of clays are of far more interest and importance than their chemical ones, though the two are naturally connected in many ways, and just as the chemical composition of clays is a subject of extreme complexity so is a study of many of their physical properties. Hence only a [18] few of the more important characteristics can be mentioned here: for further details the reader must consult a larger treatise (2).

Clays are moderately soft, solid bodies, particularly when moistened, and can usually be cut with a knife, though some indurated clays and shales are almost as hard as felspar. Their apparent specific gravity varies greatly, some clays being much more porous than others, but the true specific gravity is usually between 2·5 and 2·65; it is similar to that of quartz and slightly lower than that of felspar and mica. Many clays appear to be devoid of structure, but those obtained from a considerable depth below the surface are frequently laminated and have a structure not unlike that of mica. This will be discussed later.

Examined under a microscope, clays are seen to consist of grains of a variety of sizes, the largest of which will usually be found to be composed of adventitious materials such as sand, quartz, felspar, mica, chalk and limestone. The smallest particles—to which clays owe their chief characteristics—are so minute as to make any examination of their shape very difficult, but they are usually composed of minute crystalline plates together with a much larger proportion of apparently amorphous material. The exact nature of both the crystals and the amorphous material is still unknown in spite of many [19] investigations; in the purer clays both forms of substance appear to have the same chemical composition, viz. that of kaolinite (H4Al2Si2O9), which the crystalline portion closely resembles.

Clays emit a characteristic yet indefinable odour when moist; the cause of this is very imperfectly understood, though it is not improbably due to decomposing organic matter, as this occurs in most clays.

The colours of freshly-dug clays are extremely varied and range from an almost pure white through all shades of yellow, red and brown to black. The predominating colours are grey or greyish brown and a peculiar yellow characteristic of some surface clays. The natural colour of a clay is no criterion as to its purity, for some of the darkest ball clays produce perfectly white ware on burning, whilst some of the paler clays are useless to the potter on account of the intensity of their colour when they come out of the kiln. The colour of raw clays is largely due to the carbonaceous matter they contain, and as this burns away in the kiln, the final colour of the ware bears no relation whatever to that of the original clay.

The colour of burned ware depends upon the iron compounds in the clay—these producing buff, red, brown or black (usually termed 'blue') articles—on the presence of finely divided calcium carbonate (chalk) [20] which can destroy the colouring power of iron compounds and produce white ware, and on the treatment the clay has received in the kiln. A clay which is white when underfired will usually darken in colour if heated to vitrification, and one which burns red in an oxidizing atmosphere may turn blue-grey or black under reducing conditions. The extent to which the carbonaceous matter is burned out also determines the colour of the fired ware.

The presence of adventitious minerals in the clay may also affect its colour, particularly when fired.

The most obvious feature in a piece of moist clay is its plasticity[5] or ability to alter its shape when kneaded or put under slight pressure and to retain its new shape after the pressure has been removed. It is this property which enables the production of ornaments, vessels of various kinds, and the many other articles which are the result of the application of modelling tools, of moulding or of the action of a potter's wheel. So long as clay contains a suitable proportion of moisture it is plastic and may be made into articles of any desired shape, but if the amount of moisture in it is reduced or removed completely, the material is no longer plastic. It may become so, however, on adding a further suitable quantity of [21] water and mixing, provided that it has not been excessively heated. If, in the removal of the moisture, the clay has been heated to 600° C. or more, it loses its power of becoming plastic and is converted into a material more closely resembling stone.

[5] A plastic substance is one with the characteristics of 'a fluid of so great a viscosity that it does not lose its shape under the influence of gravitation.'

The causes of plasticity appear to be somewhat numerous, though there is no generally accepted explanation of this remarkable quality which distinguishes clays from most other substances. It is true that wet sand, soap, wax, lead and some other materials possess a certain amount of plasticity, but not to anything like the same extent as clay.

So far as clays are concerned, their plasticity appears to be connected with the presence of combined water as well as of mechanically mixed water, for if either of these are removed, plasticity—both actual and potential—is destroyed. The part played by water is not, however, completely known, for the many theories which have been advanced only cover some of the conditions and facts.

A number of observers agree that the molecular constitution of clay is peculiar and that it is to this that plasticity is due. Yet the curious fact that the purest clays—the kaolins—are remarkably deficient in plasticity shows that molecular constitution is not, alone, sufficient. Others hold that the remarkably small size of clay particles enables them to pack together more closely than do particles of other [22] materials and to retain around them a film of water which acts partly as a lubricant, facilitating the change of shape of the mass when under pressure, and partly as an adhesive, causing the particles to adhere to each other when the pressure is removed.

Zschokke has laid much emphasis on the importance of molecular attraction between clay and water as a cause of plasticity, and has suggested that the absorption of the water effects a change in the surfaces of the clay particles, giving them a gelatinous nature and enabling them to change their form and yet keep in close contact.

The fact that mica, fluorspar and quartz, when in a sufficiently finely divided state, are also slightly plastic, appears to be opposed to the molecular constitution theory. Smallness of grain undoubtedly has an influence on the plasticity of clay, coarse-grained clays being notably less plastic than others.

Daubrée pointed out that felspar, when ground with water, develops plasticity to a small extent, and Olschewsky carried this observation further and has suggested that clays owe their plasticity to prolonged contact with water during their removal from their place of formation and previous to or during their deposition. A further confirmation of this theory is due to Mellor (3) who showed that on heating china clay with water under very considerable pressure its plasticity was increased and that felspar and some [23] other non-plastic materials developed plasticity under these conditions.

Johnson and Blake (21) supposed that plasticity is due to the clay being composed of extremely minute plates 'bunched together,' a view which was also held by Biedermann and Herzfield, Le Chatelier and others. Olschewsky enlarged this theory by suggesting that the plasticity of certain clays is dependent on the large surface and the interlocking of irregular particles with the plates just mentioned. These theories of interlocking are, however, incomplete, because the tensile strength of clays should accurately represent the plasticity if interlocking were the sole cause. Zschokke has shown that tensile strength is only one factor which must be determined in any attempt to measure plasticity.

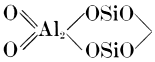

E. H. L. Schwarz (35) has suggested that many clays are composed of small globular masses of plates so arranged as to form an open network (fig. 4) which is sufficiently strong not to be destroyed by pressure. In the presence of water and much rubbing the plates are separated and are made to lie flat on each other, thereby giving a plastic and impermeable mass. If this is really the case it would explain the porosity and large surface of some clays and might account for their adsorptive power.

A theory which was first promulgated in 1850 by Way (4), but which has only received detailed [24] attention during the last few years, attributes plasticity to the presence of colloid substances in clay or to the fact that clay particles possess physical characters analogous to those of glue and other colloids. These colloid substances have a submicroscopic or micellian structure; they are web-like, porous and absorb water eagerly. This water may be removed by drying, only to be re-absorbed on cooling, but if the heating temperature is excessive the structure of the colloids is destroyed. This colloid theory explains many of the facts noted by earlier investigators such as Aron, Bischof, Seger, Olschewsky, etc., but it is not entirely satisfactory, though Rohland (5)—to whom the present prominence of this theory in Europe is largely due—persistently [25] maintains the contrary. One great objection is the fact that no characteristic inorganic colloid substance has been isolated from pure clay. It is possible that some of the so-called 'colloidal' properties of clay may be due to the smallness of its particles and to their great porosity, as suggested by Olschewsky.

Despite the present impossibility of producing a plastic material from artificially prepared colloidal hydro-alumino-silicates of the same ultimate composition as clay, and the fact that the addition of colloidal substances does not necessarily increase the true plasticity of clay, it cannot be denied that the presence of colloids has an important influence on it. The addition of starches, glue, gums and similar substances whilst apparently increasing the plasticity of clay does not do so in reality. The addition of 1 per cent. of tannin, on the contrary, has been found by Ries (6) to increase both plasticity and binding power.

Plasticity appears to be composed of a number of characteristics so that it is scarcely likely that any single cause can be assigned to it. On the contrary, a study of the binding power, tensile strength, extensibility, adsorption, texture and molecular constitution of clays suggests very strongly that all these properties are involved in the production of plasticity and that it is due to the chemical as well as the [26] physical nature of clay. No clay is entirely colloidal—or it would be elastic and not plastic—but all appear to contain both colloidal and non-colloidal (including plate-like) particles, and it is not improbable that materials in both these states are required, the colloidal matter acting as a cement. Ries (6) has, in fact, pointed out that colloids alone lack cohesiveness and solidity, and a fine mineral aggregate is necessary to change them into a plastic mass resembling clay. The relative proportions of the colloidal material and the sizes of the non-plastic grains will exercise an important influence on all the physical characteristics mentioned above, and therefore on the plasticity.

The manner in which slightly plastic clays become highly plastic in nature is by no means certainly known. It has long been understood that the increase of plasticity is due to changes undergone by the clay during transportation. The most illuminating suggestion is that made by Acheson in 1902, who concluded that it is due to impurities in the water used in transporting the clay or remaining in contact with it during and after its deposition. These impurities may be considered as derived from the washings of forests, and after many experiments with plant extracts Acheson believed the most important substance in this connection to be tannin or gallo-tannic acid, a dilute solution of which he found [27] increased the plasticity of china clay by 300 per cent. From this he further argued that the use of chopped straw by the Israelites in Egypt in the manufacture of bricks was unconsciously based on the tannin content of the straw increasing the plasticity of the material.

Beadle has stated that 2 per cent. of dissolved cellulose will increase the plasticity of china clay and make it equal to that of ordinary clay.

Plasticity is diminished by heating clays, and whilst much of it may be recovered if the temperature has not risen above 400° C. it cannot be completely restored. Moreover, a clay which has once been heated to a temperature above 100° C. dries in a somewhat different manner to a raw clay. This is well shown in fig. 5 in which are summarized the results obtained by A. V. Bleininger on a sample of ball clay from Dorset before heating and after portions of it had been heated for 16 hours to 200°, 250°, 300°, 350° and 400° C. respectively. It is not impossible that if subjected to the influence of water for a sufficiently long time the whole of the plasticity of a heated clay may be restored, providing that the temperature has not been sufficient to cause a destruction of the clay molecule, but as this resumption requires a certain amount of time, Bleininger has proposed to use the reduction in plasticity effected by the heating to enable excessively plastic clays to be worked without the necessity of adding non-plastic material to them. If any destruction of the clay-molecules has occurred, the plasticity of that portion of the clay can never be restored.

The binding power of clays is a characteristic closely connected with plasticity and occasionally confused with it. All plastic clays have the power of remaining plastic when mixed with materials such as sand, brick-dust ('grog') and other materials which [29] are quite devoid of plasticity. The extent to which a clay can thus bind other materials together into a plastic mass depends, apparently, on the plasticity of the clay itself and on the size and nature of the particles of the added material; the more plastic the clay the larger will be the amount of material it can thus 'bind,' and the finer the latter the more easily will it form a strong material when mixed with a plastic clay.

Rohland (5) has shown that the binding power of clay is not alone due to its cohesion, but that it is closely associated with the colloidal nature of plastic clays: 'fat' clays being those which are highly colloidal, highly plastic and possessing great binding power, whilst 'lean' clays are those deficient in these characteristics. The fact that, as a general rule, the dark coloured clays possess the most binding power, confirms this suggestion, as the dark colour is largely due to organic materials, probably in a colloidal state.

The shrinkage which all clays undergo on drying and when heated is another important characteristic. It is due to the fact that as water is removed the solid particles approach closer to each other, the volume of the whole mass being thereby reduced. In a wet piece of clay each particle is surrounded by a film of water, the thickness of which depends on the nature of the clay. As this water evaporates from [30] the surface of the clay its place is taken by water from the interior which rises to the surface by capillary attraction. So long as there is any water between the particles of clay there will be shrinkage when this water is removed, but a stage is eventually reached when the particles of clay are in contact with each other and no more shrinkage can occur. That this cessation of shrinkage may take place before all the water has been removed from the clay is easily understood when it is remembered that whilst the clay particles may be in contact, yet there are still places (pores) where the contact is incomplete, and in these pores water may be retained. The amount of shrinkage clays undergo on drying depends partly on the proportion of water added to them and partly on the sizes of the different particles of clay, sand, etc. present. An average reduction in volume of 12 to 38 per cent. may be regarded as normal, but coarse loams may shrink only 1 per cent. and very finely ground, highly plastic ball clays may shrink as much as 50 per cent., though this is unusual.

As all coagulated colloids, which have absorbed water, shrink on drying, this behaviour of clay appears to confirm the view as to its partially colloidal nature held by some investigators.

When a piece of dry clay is heated sufficiently a further shrinkage (technically known as kiln shrinkage) occurs. This begins somewhat below [31] a red heat and increases in rough proportion to the temperature and the duration of the heating. Prolonged heating at a lower temperature will effect the same amount of shrinkage as a short exposure to a higher temperature, but though the greater part of the shrinkage occurs in a comparatively short time, continued heating will be accompanied by a further reduction in volume.

This is due to the fact that clays have no definite melting point, but undergo partial fusion at all temperatures above 950° C. or, in some cases, at even lower ones. As a portion of the material fuses, it fills up the pores in the mass and attacks the unfused material, this process being continued until either the heating is stopped or the whole material is reduced to a viscous slag.

The reduction in the volume of commercial articles made of clay and placed in kilns varies greatly. With bricks, terra-cotta and pottery it must not, usually, exceed 40 per cent. or the warping and cracking which occur will be so great as to make the articles useless. The fineness of the particles exercises an important influence on the kiln shrinkage of a clay, and the latter is frequently reduced in commercial clayworking by adding burned clay ground to a coarse powder to the plastic clay before it is used. Sand is sometimes added for the same purpose, though its more frequent use is to reduce the shrinkage in drying.

Quartz and other forms of free silica expand on heating, so that clays containing them in large quantities shrink very slightly or may even expand.

As clays shrink equally in all directions it is usual to state the contraction in linear instead of volume form. Thus instead of stating that a certain clay when moulded into bricks, dried and burned, shrinks 18 per cent. by volume, it is customary to state that it shrinks 3/4 in. per (linear) foot. For many purposes, it is sufficient to regard the linear shrinkage as one-third the volume-shrinkage, but this is not strictly accurate.

The fusibility of clays is a characteristic which has been very imperfectly studied. Most clayworkers and investigators employ the term 'fusibility' in a special sense which is apt to be misleading. Owing to the extremely high temperatures to which refractory clays can be heated without even losing their shape, it is almost impossible to fuse them completely. In addition to this, clays are not perfectly homogeneous materials and some of their constituents melt at lower temperatures than others. For this reason a clay may show signs of fusion at 1100° C., but it may be heated for some hours at 1800° C. and yet not be completely melted! Consequently no single 'fusing point' can be stated.

In practice, a suggestion made many years ago by Seger (7) is used; the clay to be tested is made [33] into a small tetrahedron (fig. 6), heated slowly until it bends over and the point of the test-piece is almost on a level with the base. The temperature at which this occurs is termed the 'fusing point' though it really only indicates the heat-treatment which is sufficient to soften the material sufficiently to cause it to bend in the manner described. In spite of the apparent crudeness of the test this 'softening point' appears to be fairly constant for most refractory clays.

The bending of a test-piece in this manner is the result of the action of all fluxes[6] in the clay, and as this depends on the size of grain and the duration of the heating above incipient fusion and does not give a direct measure of temperature, nor is the softening effect under one rate of rise in temperature the same as that at another rate. Nevertheless a study of the behaviour of various clays heated simultaneously is valuable and the method forms a convenient means of comparing different materials.

The temperature may be measured by means of a pyrometer, but for the reason just stated it is more convenient and in some respects more accurate to use standard mixtures known as Seger Cones (fig. 6), and to state the softening point in terms of the 'cone' which behaves like the clay being tested. A medium fireclay will not soften below Seger Cone 26 (1650° C.) [34] and a really good one will have a softening point of cone 34 or 35 (1750° to 1800° C.).

The refractoriness of a clay, or its resistance to high temperatures, is an important requirement in bricks required for furnace linings, in crucibles, gas retorts and other articles used in the metallurgical and other industries. The term is much abused and is frequently understood to mean resistance to the cutting action of flue gases and flame, the corrosive action of slags, and the strains set up by the repeated changes in temperature. This is unfortunate, for the term refractoriness has a perfectly definite meaning and should be employed exclusively to denote that a given clay is capable of retaining its shape at a given [35] temperature or under given conditions when heated alone and without being subjected to any pressure. In Great Britain there is no officially recognized standard of minimum refractoriness[7], but where one is required the suggested minimum of Seger Cone 26 (1650° C.) made by E. Cramer (8) is usually employed. This is the recognized minimum in Germany for fireclays, and though objections may be urged against the use of Seger Cones as a standard, equally forcible ones may be brought against making a temperature-scale the basis of measurement. Under present circumstances, however, it is necessary to adopt one or other of these.

Various attempts have been made to ascertain the relationship (if any) between the refractoriness of clays and their chemical composition. If attention is confined strictly to the more refractory clays, some kind of relationship does appear to exist. Thus Richter found that the refractoriness of clay is influenced by certain oxides in the following order: magnesia, lime, ferrous oxide, soda and potash, but this only applies to clays containing less than 3 per cent. of all these oxides. Cramer, in 1895, found that free silica also interfered with the action of these oxides and more recently Ludwig (9) has devised a chart (fig. 7), on the upright sides of which are plotted the equivalents of the lime, magnesia and alkalies, [36] whilst the silica equivalents are plotted on the horizontal base. In each case the 'molecular formula' of the clay is calculated from its percentage composition, and this 'formula' is reduced so as to have one 'molecule' of alumina, thereby fixing the alumina as a constant and reducing the number of variables to two—the metallic oxides and the silica. Unfortunately Ludwig's chart is only applicable to the more refractory clays and cannot be relied upon even for these, though it is extremely useful for comparing clays from identical or similar geological formations.

Attempts to express the refractoriness of clays by means of formulae proving abortive, there only [37] remains the direct test of heating a clay under definite conditions in the manner previously described.

Vitrification is closely connected with the fusibility and refractoriness of clays, and, as a term, indicates the amount of fusion which has occurred under certain conditions of heating. As already mentioned, all clays, on being subjected to a high temperature, undergo partial fusion, the more powerful bases attacking the finest particles of clay and silica, forming molten silicates, and then slowly attacking the more refractory portion; this slow fusion and solution continues until the whole of the material is melted. If the heating is stopped before the fusion has begun, the clay will be porous and comparatively soft, but as more and more material fuses, the mass (on cooling) becomes harder and less porous, as the fused material occupies the pores and sets to a dense, firm glassy mass. The amount of vitrification, or partial fusion, which occurs is, therefore, of great importance in some industries, as by stopping it at an appropriate stage articles of any desired degree of porosity, translucency or strength may be obtained. Thus for common bricks, only sufficient vitrification is permitted to bind the particles firmly together, but in engineering bricks—where much greater strength is required—the vitrification is more complete. Porcelain and earthenware may be similarly distinguished.

The extent to which a given clay will vitrify depends on the amount of fluxing material (metallic compounds, and oxides other than ferric oxide and alumina) it contains, on the smallness of its particles and on the duration and intensity of the heating. Clays containing alkalies and lime compounds vitrify with great rapidity when once the necessary temperature has been reached, so that unless great care is exercised the action will proceed too far and the goods will be warped and twisted or may even form a rough slag. Refractory clays, on the contrary, vitrify more slowly and at much higher temperatures so that accidental overheatings of them are far less common.

The difference between the temperature at which sintering or vitrification occurs and that at which the clay melts completely—usually termed the 'vitrification range'—varies with the nature of the clay. In some cases the clay melts as soon as vitrification becomes noticeable, in others the vitrification occurs at a dull red heat, but the material does not lose its shape until after a prolonged heating at the highest temperature of a firebrick kiln or testing furnace.

Calcareous clays have the melting and sintering points close together, so that it is almost impossible to produce vitrified and impervious ware from them, as they lose their shape too readily. If, however, the difference between the sintering and fusing [39] temperatures can be enlarged—that is, if the vitrification range can be extended—more impervious ware can be made. The easiest means of extending the vitrification range consists in regulating the proportion of large and small particles. The former increase and the latter diminish the range.

Basic compounds and fluxes cause a lowering of the melting-point and a shortening of the vitrification range.

The porosity of raw clay is usually of small importance, but the porosity of fired clay or ware is often a serious factor in determining the suitability of certain articles for their intended purposes. In its natural state, clay does not readily absorb much water; on the contrary it becomes pasty and impervious unless it is disturbed and its texture destroyed, when it may be mixed with water to form a paste or, with more water, a thin 'cream' or 'slurry.'

When heated moderately, clay forms a porous material and, unless the heating is excessive, it will absorb about one-eighth of its weight of water. Further heating at a higher temperature reduces its porosity—the more easily fused material filling some of the pores—until a stage is reached when the material is completely vitrified and is no longer porous.

Porosity may thus be regarded as the opposite of vitrification; porous goods being relatively light and [40] soft whilst vitrified ones are dense and hard. For some purposes, porosity is an important characteristic: for example, building bricks which are moderately porous are preferable to those which are vitrified. The manufacture of porous blocks for the construction of light, sound-proof partitions, etc. has increased rapidly of late. They are made by adding sawdust or other combustible material to the clay. The added substances burn out on firing the goods in a kiln.

Clays which are porous can be dried more readily and with less risk of cracking than those which are more dense. For this reason, some clayworkers mix non-plastic material such as sand or burned clay with their raw material.

The impermeability of plastic clay to water is a characteristic which is important for many purposes.

The absorptive power of clays is closely related to their porosity so far as pure water is concerned, but if the water contains certain salts in solution a selective absorption occurs, the bases being retained by the clay in such a manner that they cannot be removed by washing. The selective action is known as adsorption and is most noticeable in highly plastic clays. Bourry (10) has shown that the slightly plastic china clays only exercise a small power of adsorbing calcium carbonate from solution, but highly plastic clays may adsorb 20 per cent. of it. The [41] alkaline chlorides and sulphates do not appear to be adsorbed in this manner, but the carbonates are readily removed from solution. All calcium and magnesium compounds appear to be adsorbed, though in variable quantities, the reaction being complicated when several soluble salts are present. Ries (6) has found that gallo-tannic acid is adsorbed readily and increases the plasticity of clay.

Ashley (11) has endeavoured to measure the plasticity of clays by determining their adsorption capacity for various aniline dyes, but his untimely decease prevented the investigation being completed. There is reason to suppose that the relation between adsorption and plasticity is extremely close in many clays and that the former may, to an important extent, be used as a measure of the latter. In some clays, however, this relationship does not exist.

Sand and burned clay only show faint adsorption phenomena; felspar shows them to a slight and almost negligible extent and most of the other non-plastic ingredients of clays are non-adsorptive.

Selective adsorption being an important characteristic of colloidal substances, the possession of this power by plastic clays supports the claim that plasticity is due, at least in part, to the presence of colloids.

The addition of small quantities of a solution of certain substances to a stiff clay paste usually reduces [42] its stiffness, and in some cases turns it into a liquid. The alkalies are particularly powerful in this respect and their action may be strikingly illustrated by mixing a few drops of caustic soda with a stiff clay paste. In a few moments the mixture will be sufficiently liquid to pour readily, but it may be rendered quite stiff again by adding sufficient acid to neutralize the alkali previously used. Weber (12) has utilized this characteristic to great advantage in the production of sanitary ware and crucibles for glass-making by a process of casting which he has patented.

The effect of adding water to a dry clay is curious. At first the particles in contact with the water become sticky and plastic, and if the proportion of water added is suitable and the mixing is sufficiently thorough a plastic mass will be produced, the characteristics of which will depend on the nature of the clay used. This process of mixing clay with a limited amount of water is known as 'tempering.' The proportion of water required to make a paste of suitable consistency for modelling appears to be constant for each clay. If, however, a larger proportion of water is added the particles of clay will be separated so widely from each other that they lose their cohesion, and instead of a plastic mass, the material will form a liquid of cream-like consistency. If a piece of stiff clay paste is suspended in a large volume of water without stirring, disintegration will [43] still occur (though a much longer time will be required) and the clay will be deposited as a sediment at the bottom of the vessel. The leaner the clay or the larger the proportion of non-plastic material it contains, the more rapidly will this disintegration take place. A highly plastic clay will become almost impervious and will retain its shape indefinitely.

If a mixture of clay and water in the form of a cream or slurry be allowed to rest, the larger and less plastic particles will settle, but many of the particles of true clay will remain suspended for several hours and some of them for several days. Some particles of clay are so small that it is doubtful if they would ever settle completely unless some coagulant were added, and as they readily pass through all ordinary filtering media it is extremely difficult to collect them in a pure state. These turbid suspensions of clay may be rapidly cleared by the addition of sodium chloride which increases the surface tension of the solution. The fine particles behave in the same way as colloidal substances, i.e. as if they possessed an electrostatic charge. Hence the addition of a salt (electrolyte), whose ions annul the opposite charges of the electric double layer assumed by Helmholtz to be present, enables the particles to coagulate in accordance with the ordinary laws of surface tension (14).

Exposure to the action of air and frost has a [44] marked effect on many clays. When freshly dug these may be hard and difficult to crush, but after exposure they break up readily into small fragments. Clays differ greatly in the extent to which they are affected by exposure; some are completely disintegrated by standing 48 hours in the open air, whilst others are scarcely affected by exposure in bleak places through several years of storm, sunshine and frost. Usually, however, the effect of a couple of nights exposure to hard frost will produce a marked disintegration of the material.

This process of exposure is known as 'weathering' and its effects are so important that it is employed whenever possible for clays requiring to be crushed before use. All clays are rendered more workable by exposure, but some of them are damaged by the oxidation of some impurities (e.g. pyrites) in them, though in other clays this very oxidation, if followed by the leaching action of rain, effects an important purification of the material.

Weathering appears to have no effect on the chemical composition of the particles of true clay in the material, though it may decompose the impurities present. On the clay itself its action is largely physical and consists chiefly in separating the particles slightly from each other, thereby enabling water to penetrate the material more readily and facilitating the production of a plastic paste. The disintegrating action [45] of the weather on some 'clays' is so complete that they require no crushing but can be converted into a homogeneous paste by simply kneading them with a suitable proportion of water.

It is possible that on exposure to the heat of the sun's rays—particularly in tropical climates—some chemical decomposition of the clay may occur, but compared with the purely physical action of weathering the amount of such chemical decomposition must be relatively unimportant in most cases. It may, however, account for the presence of free silica and free alumina in some clays.

The action of the weather on rocks, resulting in the formation of clays, is described in Chapter III.

Heat effects remarkable changes in the physical character of clays; the most important of these have already been noted. At a gentle heat, the clay is dried and retains most of its power of becoming plastic when moistened; very little, if any, decomposition occurs. At a higher temperature it loses its 'combined water,' the clay molecule apparently dissociating, and a hard stony mass—consisting of particles of free silica and free alumina cemented together by the more easily fusible impurities present—is formed. If the heating is continued the hardness of the material is increased owing to more molten silicate having been produced from the impurities present, and on cooling, its tensile strength [46] and resistance to crushing will be found to be enormously greater than those of the original clay. All potential plasticity is destroyed by heating to 700° C. and no method of restoring it has yet been devised. As clays are abundant, this is not a serious disadvantage for the specially desired characteristics of bricks, terra-cotta, pottery and porcelain are all such as to be incompatible with plasticity. The latter is extremely valuable in the shaping of the wares mentioned, but after the manufacture is completed, the destruction of the plasticity is an essential feature of their usefulness.

If the heating is very prolonged or is repeated several times, clays change other of their physical characters and become brittle and liable to crack under sudden changes of temperature. This is partly due to the further fusion (vitrification) which occurs and partly to the formation of crystalline silicates, notably Sillimanite (13).

The extent to which clays are ordinarily heated and the conditions under which they are cooled do not usually induce the formation of crystals; the object of the clayworker being to produce a homogeneous mass, the particles of which are securely held together. The result is that burned clay products are usually composed of amorphous particles cemented by a glass-like material formed by the fusion of some of the mineral ingredients of the [47] original substance. The silicates formed are, therefore, in a condition of solid, super-cooled solution in which the tendency to crystallize is restrained by viscosity.

On raising the temperature of firing or on prolonging the heating at the previous maximum temperature the viscosity of the fused portion is diminished and crystallization may then occur. The facility with which crystallization occurs varies greatly with the composition of the fused material, those silicates which are rich in lime and magnesia crystallizing more readily than those containing potash or soda. Vogt has stated that small quantities of alumina promote the formation of a glassy structure, and Morozewicz has shown that a large excess of this substance must be present if crystallization is to occur.

The study of the reactions which occur when clays are heated is, however, extremely complex, not only on account of the variety of substances present, but also on account of the high temperatures at which it is necessary to work, so that for a further consideration of it the reader should consult special treatises on the fusion of silicates. This subject has now become an important branch of physical chemistry.

CLAY AND ASSOCIATED ROCKS

Clay, as already mentioned, is geologically a rock and not a mineral, and belongs to the important group of sedimentary rocks which have been derived from the igneous or primary ones by processes of weathering, suspension in water and subsequent deposition or sedimentation.

Whatever may be the primary origin of clay, its chief occurrence is in geological formations which have undoubtedly been formed by aqueous action. The materials resulting from the exposure of primary rocks to the action of the elements have been carried away by water—often for long distances—and after undergoing various purifications have been deposited where the speed of the water has been sufficiently reduced.

In some cases they have again been transported and re-deposited and not infrequently clay deposits [49] are found which show signs of subsequent immersion at considerable depths and have every appearance of having been subjected to enormous pressures and possibly to high temperatures.

Some clays have only been carried by small streams and for short distances; these are seldom highly plastic and resemble the lean china clays and kaolins. Others have been carried by rapidly moving rivers and have been discharged into lakes or into the sea; they have thus undergone a process of gradual purification by elutriation, the sand and other heavier particles being first deposited and the far smaller particles of clay being carried a greater distance towards the centre of the lake or the quieter portions of the ocean. The nature of such deposits will, naturally, differ greatly from each other, the materials at first associated with the clay, or becoming mixed with it at a later stage, exercising an important influence on its texture, composition and properties. If the transporting stream flows through valleys whose sides are formed of limestone, chalk, sandstone or other materials, these will become mixed with the clay, and to so great an extent has the mixing occurred that very few clays occur in a state even approximating to purity. The majority of clays are contaminated with iron oxide, lime compounds and free silica in such a fine state of division that it is impossible to purify them completely without [50] destroying the nature of the clay. In addition to this it must be remembered that the land is continually rising or sinking owing to internal changes in the interior of the earth, and that these subterranean changes bring about tilting, folding, overturning and other secondary changes, which, later, cause a fresh set of materials to be mixed with the clays. Further than this, the action of the weather, of rivers and of the sea never ceases, so that a process of re-mixing and re-sorting of materials is continuously taking place, and has been doing so for countless ages. It is, therefore, a legitimate cause for wonder that such enormous deposits of clays of so uniform a character should occur throughout the length and breadth of Europe, and practically throughout the world. For although the composition of many of these beds is of a most highly complex nature, the general properties such as plasticity, behaviour on heating, etc., remain remarkably constant over large areas of country, and the clays of each geological formation are so much alike in different parts of the world as to be readily recognized by anyone familiar with the material of the same formations in this country. Considerable differences undoubtedly exist, but these are insignificant in comparison with the vastly different circumstances under which the deposits were accumulated.

Leaving the consideration of the modes of formation of the various clay deposits to later chapters [51] (III and IV), it is convenient here to enumerate some of the chief characteristics of the different clay deposits and their associated rocks. In this connection it is not proposed to enter into minute details, but rather to indicate in broad outline the chief characteristics of the clays from the different deposits. This general view is the more necessary as clay occurs in each main geological division of the sedimentary rocks and in almost every sub-division in various parts of the world.

The Precambrian, Cambrian, Silurian and Devonian 'clays' are chiefly in the form of shales or slates, the latter being clays which have undergone a metamorphic change; the latter resulted in the production of a hard and partially crystalline material with but little potential plasticity and therefore of small importance for the ordinary purposes of clay working.

Slates are distinguished from shales by their splitting into thin leaves which are not in the plane of original deposition, but are due to the deposited material being subjected to great lateral pressure. The re-arrangement of the particles thus produced has imparted to the material a cleavage quite independent of the original lamination.

The shales in these formations are occasionally soft and friable and are then termed marls, but this name is misleading as they contain no appreciable [52] proportion of finely divided calcium carbonate as do the true marls[8].

[8] Readers desiring more detailed information on the occurrence of the clays mentioned in this chapter should refer to the author's British Clays (No. 2 in Bibliography).

The clays in the Carboniferous Limestone are not, as a whole, of much importance, but the occurrence in this formation of pockets of white refractory clays in Staffordshire, North Wales (Mold) and Derbyshire is interesting, especially as these are used for the manufacture of firebricks and furnace linings. These clays are highly silicious and in composition are intermediate between the Yorkshire fireclays and ganister. Their origin is uncertain, but it is generally considered that they have been produced by the action of the weather and streams on the shales and grits of the Coal Measures which formerly occupied the higher ground around them, though Maw (16) states that 'it is scarcely open to question that they are the remnants of the subaerial dissolution of the limestone' (see 'Fireclays,' Chapter V).

In the Upper Carboniferous System the clays are highly important because of their general refractory nature, though they differ greatly in this respect, some red-burning shales of this formation having no greater power to resist heat than have some of the surface clays.

Those of the Coal Measures are of two main kinds—shales, or laminated rocks which readily split along the planes of deposition, and unstratified underclays. The shales usually occur above the seams of coal and are either of lacustrine or marine origin, differences in their fossils and lithological character supporting one origin for some deposits and the other for the remainder. Some of them are fairly uniform in composition, but others vary so greatly in their physical characters, that they are divided by miners into 'binds' or relatively pure shales, 'rock-binds,' or sandy shales, and sandstones. They also vary greatly in thickness in different localities, and whilst they form the main feature in some districts, in others they are replaced by sandstones.

The underclays are so called from their usually lying beneath the coal seams. They are not noticeably stratified and vary greatly in character from soft unctuous materials to hard, sandy rocks. In composition they vary enormously, the percentage of silica ranging from 50 per cent., or less, to as high as 97 per cent.

The mode of formation of the underclays is not certainly known. They do not appear to be soils or of terrestrial origin, but according to Arber (24) correspond closely to the black oozes of marine and semi-marine estuarine deposits of tropical swamps, or to the muds surrounding the stumps of trees in the buried forests of our coast-lines. They thus [54] appear to be quite distinct from the shales above them, both in origin and physical characters. The more silicious portions, known as Ganister[9], possess comparatively few of the characteristics of clay though used, like all the more refractory clays of the Coal Measures, for all purposes for which fireclay is employed. The term fireclay is, in fact, frequently applied to all the refractory deposits in the Coal Measures, without much regard to their composition (see Chapter V).

[9] The Dinas rock used in the Vale of Neath (Wales) is an even more silicious material found in the Millstone Grit immediately below the Coal Measures. It is largely employed for firebricks.

Valuable Coal Measure clays occur in enormous quantities in Northumberland, Durham, Yorkshire, Nottinghamshire, Derbyshire, Staffordshire, near Stourbridge, in Warwickshire, Shropshire, North and South Wales and South West Scotland. In Ireland, on the contrary, the Coal Measure clays are of little value except in the neighbourhood of Coal Island, co. Tyrone. The position of the 'Sagger Marls' of North Staffordshire (Keele Series and Etruria Marls), relative to the 'Farewell Rock' or Millstone Grit, is shown in fig. 8 in which the horizontal lines represent coal-seams and ironstone veins.

The dissimilarities in the fossils of the Coal Measure clays and shales in the Northern and Southern Hemispheres suggest that there is a considerable difference in their formation, but the number of clays and shales which have been examined is too small for any accurate conclusion to be drawn.

For many industrial purposes, particularly for the manufacture of refractory goods, the clays and shales of the Carboniferous System are highly important. The less valuable burn to a reddish colour, often spoiled with many grey spots of ferrous silicate derived from the pyrites in the clay, but the purer varieties burn to a delicate primrose or pale buff tint and are amongst the most heat-resisting materials known. The Coal Measure clays of Yorkshire are particularly esteemed for their refractory properties; for the manufacture of glazed bricks and for blocks for architectural purposes somewhat ambiguously termed 'glazed terra-cotta.' The inferior qualities are largely used for the manufacture of red engineering bricks, some of them competing successfully with the more widely known 'blue bricks' of Staffordshire.

The Coal Measure clays of Shropshire are noted for the manufacture of red roofing tiles, especially in the neighbourhood of Broseley.

Agriculturally, the Coal Measure clays are usually poor, but are occasionally of good quality. The shales produce heavy, cold clays and the yellow subsoil produces soils of a light, hungry character so that the two should, if possible, be mixed together.

Permian clays are of little value except for the manufacture of red building bricks. The Nottinghamshire Permian clays make excellent roofing tiles, flower pots and red bricks.

Agriculturally, the Permian clays are a free working loam yielding large crops of most of the ordinary farm products.

Triassic clays are of great importance in the Midlands, those upper portions of them known as the Keuper Marls being much used for the manufacture of bricks.

They are specially known amongst clayworkers as the material from which the Midland red bricks of Nottinghamshire and Leicestershire and the Somersetshire tiles are prepared.

Jurassic clays are an important group, of marine origin, occurring in close association with limestone. For this reason they form a valuable source of material for the manufacture of Portland cement, but are of less value to the brick and tile manufacturer. The Jurassic System contains so large a variety of clays, of such widely different ages and characteristics, that no general description of them can be given in the present volume.

Fig. 9. Lias clay being worked for the manufacture of hand-made sand-faced roofing tiles. (By courtesy of Messrs Webb Bros. Ltd., Cheltenham.)

The 'Lias clays'—the lowest of the Jurassic formation—are chiefly dark, bituminous shales, including the 'alum shales,' and are often seriously contaminated with pyrites and ironstone. When carefully selected [58] they may be used to advantage in the production of most red articles such as bricks, tiles, chimney pots, etc. They shrink less in the kiln than do most clays, [59] and are easily fusible on account of the lime they contain, but on the whole this formation is of great value for the manufacture of the articles just mentioned.

Agriculturally, the Lias clays are laid down for grass, but the lighter soils are useful for arable purposes.

The 'Oolitic clays,' which are also Jurassic, usually contain limestone in the form of nodules, but are nevertheless important. They form a broad belt above the Lias from Dorset to Yorkshire, and include the blue clays of the Purbeck beds, stiff blue bituminous Kimeridge clays, the irregular, sandy Coral Rag clays, the famous Oxford clay (from which the Peterborough and Fletton bricks are made), the Kellaways blue clay, and the Fuller's Earth deposits.

The 'Kimeridge clays' are dark, stiff laminated clays, closely resembling gault, and are much used in the West and Midlands for brickmaking. A well-known deposit of this character has long been used at Pickering in Yorkshire, but the most typical deposits are in Huntingdonshire. The Kimeridge clays contain a bituminous shale, or Sapropelic Coal, which evolves a characteristic odour on burning.

Agriculturally, the Kimeridge clays resemble gault and are difficult to work as arable land, though they form first-rate pasturage.