| Transcriber’s note: |

A few typographical errors have been corrected. They

appear in the text like this, and the

explanation will appear when the mouse pointer is moved over the marked

passage. Sections in Greek will yield a transliteration

when the pointer is moved over them, and words using diacritic characters in the

Latin Extended Additional block, which may not display in some fonts or browsers, will

display an unaccented version. Links to other EB articles: Links to articles residing in other EB volumes will be made available when the respective volumes are introduced online. |

Articles in This Slice

LIGHTFOOT, JOSEPH BARBER (1828-1889), English theologian and bishop of Durham, was born at Liverpool on the 13th of April 1828. His father was a Liverpool accountant. He was educated at King Edward’s school, Birmingham, under James Prince Lee, afterwards bishop of Manchester, and had as contemporaries B. F. Westcott and E. W. Benson. In 1847 Lightfoot went up to Trinity College, Cambridge, and there read for his degree with Westcott. He graduated senior classic and 30th wrangler, and was elected a fellow of his college. From 1854 to 1859 he edited the Journal of Classical and Sacred Philology. In 1857 he became tutor and his fame as a scholar grew rapidly. He was made Hulsean professor in 1861, and shortly afterwards chaplain to the Prince Consort and honorary chaplain in ordinary to the queen. In 1866 he was Whitehall 627 preacher, and in 1871 he became canon of St Paul’s. His sermons were not remarkable for eloquence, but a certain solidity and balance of judgment, an absence of partisanship, a sobriety of expression combined with clearness and force of diction, attracted hearers and inspired them with confidence. As was written of him in The Times after his death, “his personal character carried immense weight, but his great position depended still more on the universally recognized fact that his belief in Christian truth and his defence of it were supported by learning as solid and comprehensive as could be found anywhere in Europe, and by a temper not only of the utmost candour but of the highest scientific capacity. The days in which his university influence was asserted were a time of much shaking of old beliefs. The disintegrating speculations of an influential school of criticism in Germany were making their way among English men of culture just about the time, as is usually the case, when the tide was turning against them in their own country. The peculiar service which was rendered at this juncture by the ‘Cambridge School’ was that, instead of opposing a mere dogmatic opposition to the Tübingen critics, they met them frankly on their own ground; and instead of arguing that their conclusions ought not to be and could not be true, they simply proved that their facts and their premisses were wrong. It was a characteristic of equal importance that Dr Lightfoot, like Dr Westcott, never discussed these subjects in the mere spirit of controversy. It was always patent that what he was chiefly concerned with was the substance and the life of Christian truth, and that his whole energies were employed in this inquiry because his whole heart was engaged in the truths and facts which were at stake. He was not diverted by controversy to side-issues; and his labour was devoted to the positive elucidation of the sacred documents in which the Christian truth is enshrined.”

In 1872 the anonymous publication of Supernatural Religion created considerable sensation. In a series of masterly papers in the Contemporary Review, between December 1874 and May 1877, Lightfoot successfully undertook the defence of the New Testament canon. The articles were published in collected form in 1889. About the same time he was engaged in contributions to W. Smith’s Dictionary of Christian Biography and Dictionary of the Bible, and he also joined the committee for revising the translation of the New Testament. In 1875 he became Lady Margaret professor of divinity in succession to William Selwyn. He had previously written his commentaries on the epistles to the Galatians (1865), Philippians (1868) and Colossians (1875), the notes to which were distinguished by sound judgment and enriched from his large store of patristic and classical learning. These commentaries may be described as to a certain extent a new departure in New Testament exegesis. Before Lightfoot’s time commentaries, especially on the epistles, had not infrequently consisted either of short homilies on particular portions of the text, or of endeavours to enforce foregone conclusions, or of attempts to decide with infinite industry and ingenuity between the interpretations of former commentators. Lightfoot, on the contrary, endeavoured to make his author interpret himself, and by considering the general drift of his argument to discover his meaning where it appeared doubtful. Thus he was able often to recover the meaning of a passage which had long been buried under a heap of contradictory glosses, and he founded a school in which sobriety and common sense were added to the industry and ingenuity of former commentators. In 1879 Lightfoot was consecrated bishop of Durham in succession to C. Baring. His moderation, good sense, wisdom, temper, firmness and erudition made him as successful in this position as he had been when professor of theology, and he speedily surrounded himself with a band of scholarly young men. He endeavoured to combine his habits of theological study with the practical work of administration. He exercised a large liberality and did much to further the work of temperance and purity organizations. He continued to work at his editions of the Apostolic Fathers, and in 1885 published an edition of the Epistles of Ignatius and Polycarp, collecting also a large store of valuable materials for a second edition of Clement of Rome, which was published after his death (1st ed., 1869). His defence of the authenticity of the Epistles of Ignatius is one of the most important contributions to that very difficult controversy. His unremitting labours impaired his health and shortened his splendid career at Durham. He was never married. He died at Bournemouth on the 21st of December 1889, and was succeeded in the episcopate by Westcott, his schoolfellow and lifelong friend.

Four volumes of his Sermons were published in 1890.

LIGHTHOUSE, a form of building erected to carry a light for the purpose of warning or guidance, especially at sea.

1. Early History.—The earliest lighthouses, of which records exist, were the towers built by the Libyans and Cushites in Lower Egypt, beacon fires being maintained in some of them by the priests. Lesches, a Greek poet (c. 660 B.C.) mentions a lighthouse at Sigeum (now Cape Incihisari) in the Troad. This appears to have been the first light regularly maintained for the guidance of mariners. The famous Pharos1 of Alexandria, built by Sostratus of Cnidus in the reign of Ptolemy II. (283-247 B.C.) was regarded as one of the wonders of the world. The tower, which took its name from that of the small island on which it was built, is said to have been 600 ft. in height, but the evidence in support of this statement is doubtful. It was destroyed by an earthquake in the 13th century, but remains are said to have been visible as late as 1350. The name Pharos became the general term for all lighthouses, and the term “pharology” has been used for the science of lighthouse construction.

The tower at Ostia was built by the emperor Claudius (A.D. 50). Other famous Roman lighthouses were those at Ravenna, Pozzuoli and Messina. The ancient Pharos at Dover and that at Boulogne, later known as la Tour d’Ordre, were built by the Romans and were probably the earliest lighthouses erected in western Europe. Both are now demolished.

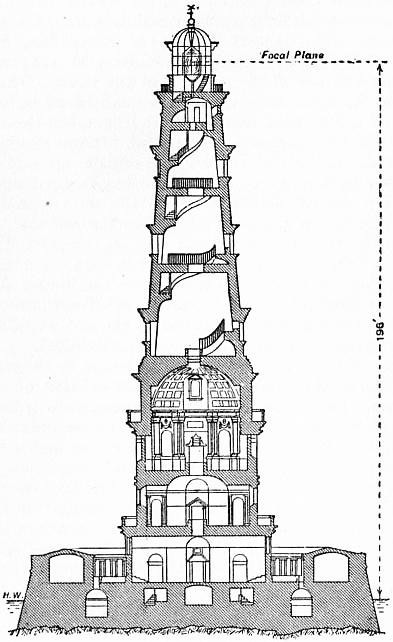

The light of Cordouan, on a rock in the sea at the mouth of the Gironde, is the earliest example now existing of a wave-swept tower. Earlier towers on the same rock are attributed the first to Louis le Debonnaire (c. A.D. 805) and the second to Edward the Black Prince. The existing structure was begun in 1584 during the reign of Henri II. of France and completed in 1611. The upper part of the beautiful Renaissance building was removed towards the end of the 18th century and replaced by a loftier cylindrical structure rising to a height of 207 ft. above the rock and with the focal plane of the light 196 ft. above high water (fig. 1). Until the 18th century the light exhibited from the tower was from an oak log fire, and subsequently a coal fire was in use for many years. The ancient tower at Corunna, known as the Pillar of Hercules, is supposed to have been a Roman Pharos. The Torre del Capo at Genoa originally stood on the promontory of San Berrique. It was built in 1139 and first used as a lighthouse in 1326. It was rebuilt on its present site in 1643. This beautiful tower rises 236 ft. above the cliff, the light being elevated 384 ft. above sea-level. A lens light was first installed in 1841. The Pharos of Meloria was constructed by the Pisans in 1154 and was several times rebuilt until finally destroyed in 1290. On the abandonment of Meloria by the Pisans, they erected the still existing tower at Leghorn in 1304.

In the 17th and 18th centuries numerous towers, on which were erected braziers or grates containing wood or coal fires, were established in various positions on the coasts of Europe. Among such stations in the United Kingdom were Tynemouth (c. 1608), the Isle of May (1636), St Agnes (1680), St Bees (1718) and the Lizard (1751). The oldest lighthouse in the United States is believed to be the Boston light situated on Little Brewster Island on the south side of the main entrance to Boston Harbour, Mass. It was established in 1716, the present structure dating from 1859. During the American War of Independence the lighthouse suffered many vicissitudes and was successively destroyed and rebuilt three times by the American or British 628 forces. At the third rebuilding in 1783 a stone tower 68 ft. in height was erected, the illuminant consisting of four oil lamps. Other early lighthouse structures on the New England coast were those at Beaver Tail, near the entrance to Newport Harbour (1740), and the Brant at the entrance to Nantucket Harbour (1754). A watch-house and beacon appear to have been erected on Beacon or Lighthouse Island as well as on Point Allerton Hill near Boston, prior to 1673, but these structures would seem to have been in the nature of look-out stations in time of war rather than lighthouses for the guidance of mariners.

2. Lighthouse Structures.—The structures of lighthouses may be divided into two classes, (a) those on rocks, shoals or in other situations exposed to the force of the sea, and (b) the more numerous class of land structures.

|

| Fig. 1.—Cordouan Lighthouse. |

Wave-swept Towers.—In determining the design of a lighthouse tower to be erected in a wave-swept position consideration must be given to the physical features of the site and its surroundings. Towers of this description are classified as follows: (1) Masonry and concrete structures; (2) Openwork steel and iron-framed erections on pile or other foundations; (3) Cast iron plated towers; (4) Structures erected on cylinder foundations.

(1) Masonry Towers.—Masonry or concrete towers are generally preferred for erection on wave-swept rocks affording good foundation, and have also been constructed in other situations where adequate foundations have been made by sinking caissons into a soft sea bed. Smeaton’s tower on the Eddystone Rock is the model upon which most later designs of masonry towers have been based, although many improvements in detail have since been made. In situations of great exposure the following requirements in design should be observed: (a) The centre of gravity of the tower structure should be as low as possible. (b) The mass of the structure superimposed at any horizontal section must be sufficient to prevent its displacement by the combined forces of wind and waves without dependence on the adhesion at horizontal joint faces or on the dovetailing of stones introduced as an additional safeguard. (c) The structure should be circular in plan throughout, this form affording the least resistance to wave stroke and wind pressure in any direction. (d) The lower portion of the tower exposed to the direct horizontal stroke of the waves should, for preference, be constructed with vertical face. The upper portion to be either straight with uniform batter or continuously curved in the vertical plane. External projections from the face of the tower, except in the case of a gallery under the lantern, should be avoided, the surface throughout being smooth. (e) The height from sea-level to the top of the tower should be sufficient to avoid the obscuration of the light by broken water or dense spray driving over the lantern. (f) The foundation of the tower should be carried well into the solid rock. (g) The materials of which the tower is built should be of high density and of resistant nature. (h) The stones used in the construction of the tower, at any rate those on the outer face, should be dovetailed or joggled one to the other in order to prevent their being dislodged by the sea during the process of construction and as an additional safeguard of stability. Of late years, cement concrete has been used to a considerable extent for maritime structures, including lighthouses, either alone or faced with masonry.

(2) Openwork Structures.—Many examples of openwork steel and iron lighthouses exist. Some typical examples are described hereafter. This form of design is suitable for situations where the tower has to be carried on a foundation of iron or steel piles driven or screwed into an insecure or sandy bottom, such as on shoals, coral reefs and sand banks or in places where other materials of construction are exceptionally costly and where facility of erection is a desideratum.

(3) Cast iron Towers.—Cast iron plated towers have been erected in many situations where the cost of stone or scarcity of labour would have made the erection of a masonry tower excessively expensive.

(4) Caisson Foundations.—Cylinder or caisson foundations have been used for lighthouse towers in numerous cases where such structures have been erected on sand banks or shoals. A remarkable instance is the Rothersand Tower. Two attempts have been made to sink a caisson in the outer Diamond Shoal off Cape Hatteras on the Atlantic coast of the United States, but these have proved futile.

The following are brief descriptions of the more important wave-swept towers in various parts of the world.

Eddystone (Winstanley’s Tower).—The Eddystone rocks, which lie about 14 m. off Plymouth, are fully exposed to south-west seas. The reef is submerged at high water of spring tides. Four towers have been constructed on the reef. The first lighthouse (fig. 2) was polygonal in plan and highly ornamented with galleries and projections which offered considerable resistance to the sea stroke. The work was begun by Henry Winstanley, a gentleman of Essex, in 1695. In 1698 it was finished to a height of 80 ft. to the wind vane and the light exhibited, but in the following year, in consequence of damage by storms, the tower was increased in diameter from 16 ft. to 24 ft. by the addition of an outer ring of masonry and made solid to a height of 20 ft. above the rock, the tower being raised to nearly 120 ft. The work was completed in the year 1700. The lower part of the structure appears to have been of stone, the upper part and lantern of timber. During the great storm of the 20th of November 1703 the tower was swept away, those in it at the time, including the builder, being drowned.

Eddystone (Rudyerd’s Tower, fig. 3).—This structure was begun in 1706 and completed in 1709. It was a frustum of a cone 22 ft. 8 in. in diameter at the base and 14 ft. 3 in. at the top. The tower was 92 ft. in height to the top of the lantern. The work consisted principally of oak timbers securely bolted and cramped together, the lower part being filled in solid with stone to add weight to the structure. The simplicity of the design and the absence of projections from the outer face rendered the tower very suitable to withstand the onslaught of the waves. The lighthouse was destroyed by fire in 1755.

Eddystone (Smeaton’s Tower, fig. 4).—This famous work, which consisted entirely of stone, was begun in 1756, the light being first exhibited in 1759. John Smeaton was the first engineer to use dovetailed joints for the stones in a lighthouse structure. The stones, which averaged 1 ton in weight, were fastened to each other by means of dovetailed vertical joint faces, oak key wedges, and by oak tree-nails wedged top and bottom, extending vertically from every course into the stones beneath it. During the 19th century the tower was strengthened on two occasions by the addition of heavy wrought iron ties, and the overhanging cornice was reduced in diameter to prevent the waves from lifting the stones from their beds. In 1877, owing partly to the undermining of the rock on which the tower was built and the insufficient height of the structure, 629 the Corporation of Trinity House determined on the erection of a new lighthouse in place of Smeaton’s tower.

| |||

| Fig. 2. | Fig. 3. | Fig. 4. | Fig. 5. |

| Lighthouses on the Eddystone. | |||

|

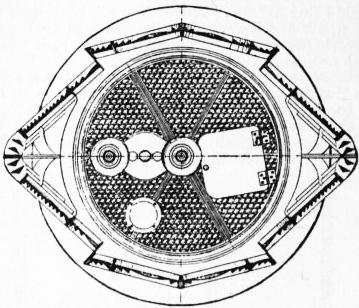

| Fig. 6.—Plan of Entrance Floor, Eddystone Lighthouse. |

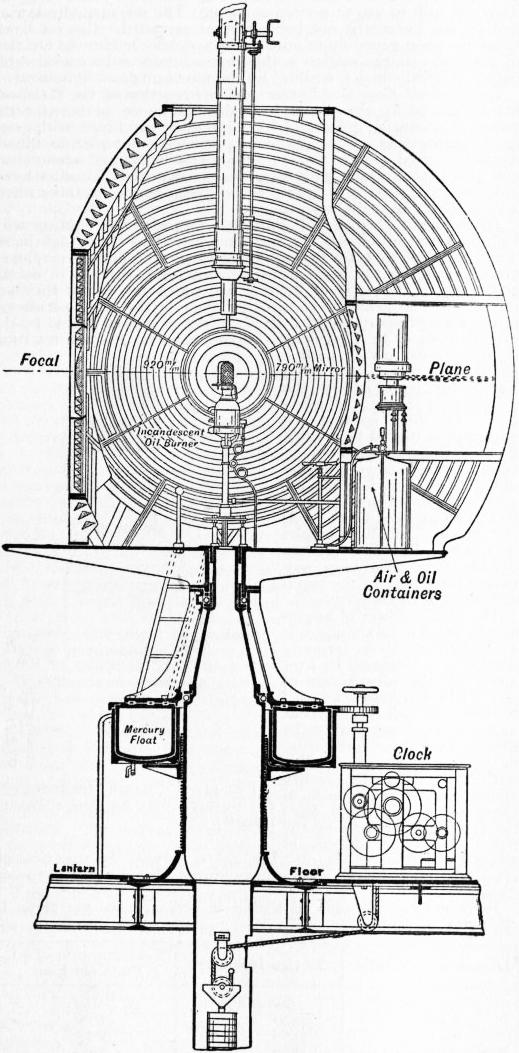

Eddystone, New Lighthouse (J. N. Douglass).—The site selected for the new tower is 120 ft. S.S.E. from Smeaton’s lighthouse, where a suitable foundation was found, although a considerable section of the lower courses had to be laid below the level of low water. The vertical base is 44 ft. in diameter and 22 ft. in height. The tower (figs. 5 and 6) is a concave elliptic frustum, and is solid, with the exception of a fresh-water tank, to a height of 25 ft. 6 in. above high-water level. The walls above this level vary in thickness from 8 ft. 6 in. to 2 ft. 3 in. under the gallery. All the stones are dovetailed, both horizontally and vertically, on all joint faces, the stones of the foundation course being secured to the rock by Muntz metal bolts. The tower contains 62,133 cub. ft. of granite, weighing 4668 tons. The height of the structure from low water ordinary spring tides to the mean focal plane is 149 ft. and it stands 133 ft. above high water. The lantern is a cylindrical helically framed structure with domed roof. The astragals are of gun-metal and the pedestal of cast iron. The optical apparatus consists of two superposed tiers of refracting lens panels, 12 in each tier of 920 mm. focal distance. The lenses subtend an angle of 92° vertically. The 12 lens panels are arranged in groups of two, thus producing a group flashing light showing 2 flashes of 1½ seconds’ duration every half minute, the apparatus revolving once in 3 minutes. The burners originally fitted in the apparatus were of 6-wick pattern, but these were replaced in 1904 by incandescent oil vapour burners. The intensity of the combined beam of light from the two apparatus is 292,000 candles. At the time of the completion of the lighthouse two bells, weighing 2 tons each and struck by mechanical power, were installed for fog-signalling purposes. Since that date an explosive gun-cotton fog signal has been erected, the bells being removed. At a lower level in the tower are installed 2 21-in. parabolic silvered reflectors with 2-wick burners, throwing a fixed light of 8000 candle-power over a danger known as the Hand Deeps. The work of preparing the foundation was begun on the 17th of July 1878, the foundation stone being laid by the late duke of Edinburgh on the 19th of August 1879. The last stone was laid on the 1st of June 1881, and the light was exhibited for the first time on the 18th of May 1882. The upper portion of Smeaton’s tower, which was removed on completion of the new lighthouse, was re-erected on Plymouth Hoe, where it replaced the old Trinity House sea mark. One of the principal features in the design of the new Eddystone lighthouse tower is the solid vertical base. This construction was much criticized at the time, but experience has proved that heavy seas striking the massive cylindrical structure are immediately broken up and rush round to the opposite side, spray alone ascending to the height of the lantern gallery. On the other hand, the waves striking the old tower at its foundation ran up the surface, which presented a curved face to the waves, and, unimpeded by any projection until arriving at the lantern gallery, were partially broken up by the cornice and then spent themselves in heavy spray over the lantern. The shock to which the cornice of the gallery was exposed was so great that stones were sometimes lifted from their beds. The new Eddystone tower presents another point of dissimilarity from Smeaton’s structure, in that the stones forming the floors consist of single corbels built into the wall and constituting solid portions thereof. In Smeaton’s tower the floors consisted of stone arches, the thrust being taken by the walls of the tower itself, which were strengthened for the purpose by building in chains in the form of hoops (fig. 7). The system of constructing corbelled stone floors was first adopted by R. Stevenson in the Bell Rock lighthouse (fig. 8).

|

| Fig. 7.—Floor, Smeaton’s Eddystone Lighthouse. |

Bell Rock Lighthouse (fig. 9).—The Bell Rock, which lies 12 m. off the coast of Forfarshire, is exposed to a considerable extent at low water. The tower is submerged to a depth of about 16 ft. at high water of spring tides. The rock is of hard sandstone. The lighthouse was constructed by Robert Stevenson and is 100 ft. in height, the solid portion being carried to a height of 21 ft. above high water. The work of construction was begun in 1807, and finished in 1810, the light being first exhibited in 1811. The total weight of the tower is 2076 tons. A new lantern and dioptric apparatus were erected on the tower in 1902. The focal plane of the light is elevated 93 ft. above high water.

|

| Fig. 8.—Floor, Stevenson’s Bell Rock Lighthouse. |

Skerryvore Lighthouse (fig. 10).—The Skerryvore Rocks, 12 m. off the island of Tyree in Argyllshire, are wholly open to the Atlantic. The work, designed by Alan Stevenson, was begun in 1838 and finished in 1844. The tower, the profile of which is a hyperbolic curve, is 138 ft. high to the lantern base, 42 ft. diameter at the base, and 16 ft. at the top. Its weight is 4308 tons. The structure contains 9 rooms in addition to the lantern chamber. It is solid to a height of 26 ft. above the base.

Heaux de Brehat Lighthouse.—The reef on which this tower is constructed lies off the coast of Brittany, and is submerged at high tide. The work was carried out in 1836-1839. The tower is circular in plan with a gallery at a height of about 70 ft. above the base. The tower is 156 ft. in height from base to lantern floor.

Haut Banc du Nord Lighthouse.—This tower is placed on a reef at the north-west extremity of the Île de Ré, and was constructed in 1849-1853. It is 86 ft. in height to the lantern floor.

| |||

| Fig. 9.—Bell Rock. | Fig. 10.—Skerryvore. | Fig. 11.—Bishop Rock. | Fig. 12.—Bishop Rock. |

Bishop Rock Lighthouse.—The lighthouse on the Bishop Rock, which is the westernmost landfall rock of the Scilly Islands, occupies perhaps a more exposed situation than any other in the world. 630 The first lighthouse erected there was begun in 1847 under the direction of N. Douglass. The tower consisted of a cast and wrought iron openwork structure having the columns deeply sunk into the rock. On the 5th of February 1850, when the tower was ready for the erection of the lantern and illuminating apparatus, a heavy storm swept away the whole of the structure. This tower was designed for an elevation of 94 ft. to the focal plane. In 1851 the erection of a granite tower, from the designs of James Walker, was begun; the light was first exhibited in 1858. The tower (fig. 11) had an elevation to the focal plane of 110 ft., the lower 14 courses being arranged in steps, or offsets, to break up the force of the waves. This structure also proved insufficient to withstand the very heavy seas to which it was exposed. Soon after its completion the 5-cwt. fog bell, fixed to the lantern gallery 100 ft. above high-water mark, was washed away, together with the flagstaff and ladder. The tower vibrated considerably during storms, and it was found that some of the external blocks of granite had been split by the excessive stress to which they had been exposed. In 1874 the tower was strengthened by bolting continuous iron ties to the internal surfaces of the walls. In 1881, when further signs of damage appeared, it was determined to remove the upper storey or service room of the lighthouse, and to case the structure from its base upwards with granite blocks securely dovetailed to each other and to the existing work. At the same time it was considered advisable to increase the elevation of the light, and place the mean focal plane of the new apparatus at an elevation of 146 ft. above high-water mark. The work was begun in 1883, and the new apparatus was first illuminated on the 25th of October 1887. During the operation of heightening the tower it was necessary to install a temporary light, consisting of a cylindrical lightship lantern with catoptric apparatus; this was raised from time to time in advance of the structure as the work proceeded. The additional masonry built into the tower amounts approximately to 3220 tons. Profiting by the experience gained after the construction of the new Eddystone tower, Sir J. N. Douglass decided to build the lower portion of the improved Bishop Rock tower in the form of a cylinder, but with considerably increased elevation (figs. 12 and 13). The cylindrical base is 40 ft. in diameter, and rises to 25 ft. above high-water mark. The lantern is cylindrical and helically framed, 14 ft. in diameter, the glazing being 15 ft. in height. The optical apparatus consists of two superposed tiers of lenses of 1330 mm. focal distance, the lenses subtending a horizontal angle of 36° and a vertical angle of 80°. The apparatus consists of 5 groups of lenses each group producing a double flashing light of one minute period, the whole apparatus revolving once in five minutes. The maximum aggregate candle-power of the flash is 622,000 candles. A gun-cotton explosive fog signal is attached to the lantern. The cost of the various lighthouses on the Bishop Rock has been as follows:

| 1. Cast iron lighthouse | £12,500 | 0 | 0 |

| 2. Granite lighthouse | 34,559 | 18 | 9 |

| 3. Improved granite lighthouse | 64,889 | 0 | 0 |

The Smalls Lighthouse.—A lighthouse has existed on the Smalls rock, 18½ m. off Milford Haven, since 1776, when an oak pile structure was erected by Henry Whiteside. The existing structure, after the model of the second lighthouse on the Bishop Rock, was erected in 1856-1861 by the Trinity House and is 114 ft. in height from the foundation to the lantern floor. A new optical apparatus was installed in 1907.

Minot’s Ledge Lighthouse.—The tower, which is 89 ft. in height, is built of granite upon a reef off Boston Harbor, Mass., and occupied five years in construction, being completed in 1860 at a cost of £62,500. The rock just bares at low water. The stones are dovetailed vertically but not on their horizontal beds in the case of the lower 40 ft. or solid portion of the tower, bonding bolts being substituted for the horizontal dovetailed joints used in the case of the Wolf and other English towers. The shape of the tower is a conical frustum.

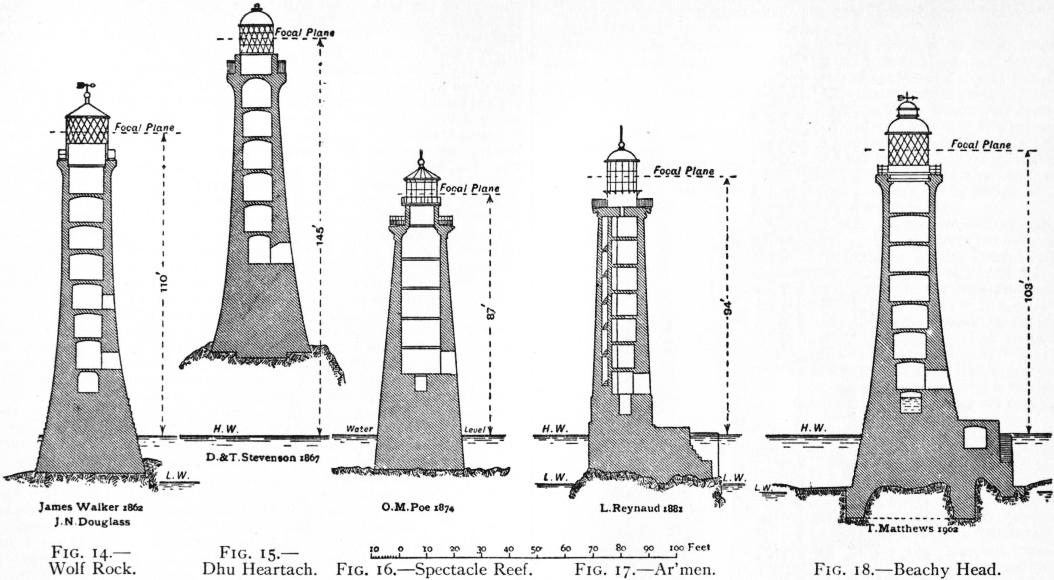

Wolf Rock Lighthouse.—This much exposed rock lies midway between the Scilly Isles and the Lizard Point, and is submerged to the depth of about 6 ft. at high water. The tower was erected in 1862-1869 (fig. 14). It is 116 ft. 6 in. high, 41 ft. 8 in. diameter at the base, decreasing to 17 ft. at the top. The walls are 7 ft. 9½ in. thick, decreasing to 2 ft. 3 in. The shaft is a concave elliptic frustum, and contains 3296 tons. The lower part of the tower has projecting scarcements in order to break up the sea.

Dhu Heartach Rock Lighthouse.—The Dhu Heartach Rock, 35 ft. above high water, is 14 m. from the island of Mull, which is the nearest shore. The maximum diameter of the tower (fig. 15), which is of parabolic outline, is 36 ft., decreasing to 16 ft.; the shaft is solid for 32 ft. above the rock; the masonry weighs 3115 tons, of which 1810 are contained in the solid part. This tower occupied six years in erection, and was completed in 1872.

Great Basses Lighthouse, Ceylon.—The Great Basses lighthouse lies 6 m. from the nearest land. The cylindrical base is 32 ft. in diameter, above which is a tower 67 ft. 5 in. high and 23 ft. in diameter. The walls vary in thickness from 5 ft. to 2 ft. The tower, including the base, contains about 2768 tons. The work was finished in three years, 1870-1873.

Spectacle Reef Lighthouse, Lake Huron.—This is a structure similar to that on Minot’s ledge, standing on a limestone reef at the northern end of the lake. The tower (fig. 16) was constructed with a view to withstanding the effects of ice massing in solid fields thousands of acres in extent and travelling at considerable velocity. The tower is in shape the frustum of a cone, 32 ft. in diameter at the base and 93 ft. in height to the coping of the gallery. The focal plane is at a level of 97 ft. above the base. The lower 34 ft. of the tower is solid. The work was completed in 1874, having occupied four years. The cost amounted to approximately £78,000.

Chicken Rock Lighthouse.—The Chicken Rock lies 1 m. off the Calf of Man. The curve of the tower, which is 123 ft. 4 in. high, is hyperbolic, the diameter varying from 42 ft. to 16 ft. The tower is submerged 5 ft. at high-water springs. The solid part is 32 ft. 6 in. in height, weighing 2050 tons, the whole weight of the tower being 3557 tons. The walls decrease from 9 ft. 3 in. to 2 ft. 3 in. in thickness. The work was begun in 1869 and completed in 1874.

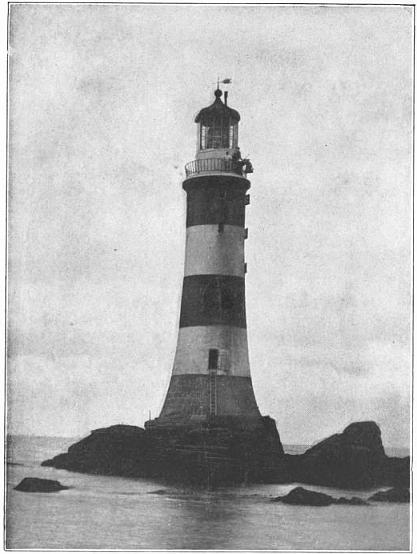

Ar’men Lighthouse.—The masonry tower, erected by the French Lighthouse Service, on the Ar’men Rock off the western extremity of the Île de Sein, Finistère, occupied fifteen years in construction (1867-1881). The rock is of small area, barely uncovered at low water, and it was therefore found impossible to construct a tower having a base diameter greater than 24 ft. The focal plane of the light is 94 ft. above high water (fig. 17).

St George’s Reef Lighthouse, California.—This structure consists of a square pyramidal stone tower rising from the easterly end of an oval masonry pier, built on a rock to a height of 60 ft. above the water. The focal plane is at an elevation of 146 ft. above high water. The site is an exceedingly dangerous one, and the work, which was completed in 1891, cost approximately £144,000.

Rattray Head Lighthouse.—This lighthouse was constructed between the years 1892 and 1895 by the Northern Lighthouse Commissioners upon the Ron Rock, lying about one-fifth of a mile off Rattray Head, Aberdeenshire. The focal plane is 91 ft. above high water, the building being approximately 113 ft. in height. In the tower there is a fog-horn worked by compressed air.

Fastnet Lighthouse.—In the year 1895 it was reported to the Irish Lights Commissioners that the then existing lighthouse on the Fastnet Rock off the south-west coast of Ireland, which was completed in 1854 and consisted of a circular cast iron tower 86 ft. in height on the summit of the rock, was considerably undermined. It was subsequently determined to proceed with the erection of a granite structure of increased height and founded upon a sound ledge of rock on one side of the higher, but now considerably undermined. 631 portion of the reef. This lighthouse tower has its foundation laid near high-water level. The focal plane is at a level of 158 ft. above high-water mark. The cost of the structure, which was commenced in 1899 and completed in 1904, was £79,000.

|

| Fig. 13.—Bishop Rock Lighthouse. |

Beachy Head Lighthouse.—A lighthouse has been erected upon the foreshore at the foot of Beachy Head, near Eastbourne, to replace the old structure on the cliff having an elevation of 284 ft. above high-water mark. Experience proved that the light of the latter was frequently obscured by banks of mist or fog, while at the lower level the transparency of the atmosphere was considerably less impaired. The Trinity House therefore decided in the year 1899 to proceed with the construction of a granite tower upon the foreshore at a distance of some 570 ft. from the base of the cliff (fig. 18). The foreshore at this point consists of chalk, and the selected site just bares at low water ordinary spring tides. The foundation course was laid at a depth of 10 ft. below the surface, the area being excavated within a coffer-dam. The tower, which is 47 ft. in diameter at the base, has an elevation to the focal plane above high water of 103 ft., or a total height from foundation course to gallery coping of 123 ft. 6 in. The lower or solid portion of the tower has its face stones constructed in vertical offsets or steps in a similar manner to that adopted at the Wolf Rock and elsewhere. The tower is constructed with a facing of granite, all the stones being dovetailed in the usual manner. The hearting of the base is largely composed of concrete. The work was completed in 1902 and cost £56,000.

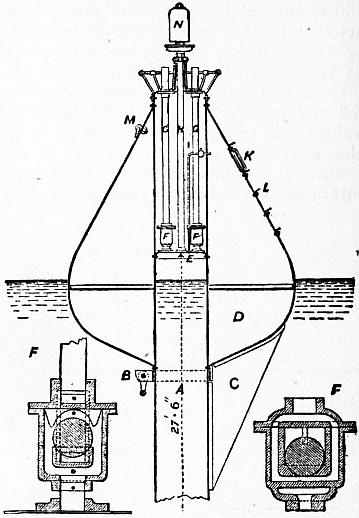

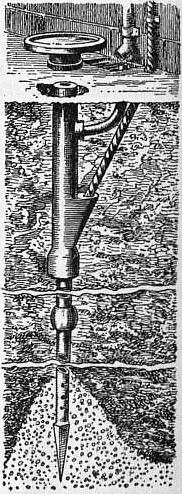

Maplin Lighthouse.—The screw pile lighthouse erected on the Maplin Sand in the estuary of the river Thames in 1838 is the earliest of its kind and served as a model for numerous similar structures in various parts of the world. The piles are nine in number, 5 in. diameter of solid wrought iron with screws 4 ft. diameter (fig. 19).

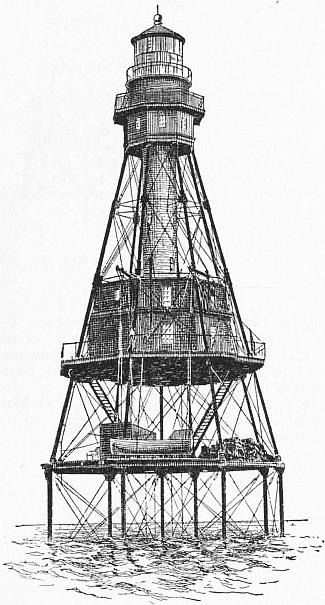

Fowey Rocks Lighthouse, Florida.—This iron structure, which was begun in 1875 and completed in 1878, stands on the extreme northern point of the Florida reefs. The height of the tower, which is founded on wrought iron piles driven 10 ft. into the coral rock, is 110 ft. from high water to focal plane. The iron openwork pyramidal structure encloses a plated iron dwelling for the accommodation of the keepers. The cost of construction amounted to £32,600.

Alligator Reef Lighthouse, Florida.—This tower is one of the finest iron sea-swept lighthouse structures in the world. It consists of a pyramidal iron framework 135 ft. 6 in. in height, standing on the Florida Reef in 5 ft. of water. The cost of the structure, which is similar to the Fowey Rocks tower, was £37,000.

American Shoal Lighthouse, Florida.—This tower (fig. 20) is typical of the openwork pile structures on the Florida reefs, and was completed in 1880. The focal plane of the light is at an elevation of 109 ft. above high water.

Wolf Trap Lighthouse.—This building was erected during the years 1893 and 1894 on Wolf Trap Spit in Chesapeake Bay, near the site of the old openwork structure which was swept away by ice early in 1893. The new tower is formed upon a cast iron caisson 30 ft. in diameter sunk 18 ft. into the sandy bottom. The depth of water on the shoal is 16 ft. at low water. The caisson was filled with concrete, and is surmounted by a brick superstructure 52 ft. in height from low water to the focal plane of the light. A somewhat similar structure was erected in 1885-1887 on the Fourteen Foot Bank in Delaware Bay, at a cost of £24,700. The foundation in this case was, however, shifting sand, and the caisson was carried to a greater depth.

Rothersand Lighthouse.—This lighthouse, off the entrance to the river Weser (Germany), is a structure of great interest on account of the difficulties met with in its construction. The tower had to be founded on a bottom of shifting sand 20 ft. below low water and in a very exposed situation. Work was begun in May 1881, when attempts were made to sink an iron caisson under pneumatic pressure. Owing to the enormous scour removing the sand from one side of the caisson it tilted to an alarming angle, but eventually it was sunk to a level of 70 ft. below low-water mark. In October of the same year the whole structure collapsed. Another attempt, made in May 1883, to sink a caisson of bi-convex shape in plan 47 ft. long, 37 ft. wide and 62 ft. in height, met with success, and after many difficulties the structure was sunk to a depth of 73 ft. below low water, the sides being raised by the addition of iron plating as the caisson sank. The sand was removed from the interior by suction. Around the caisson foundation were placed 74,000 cub. yds. of mattress work and stones, the interior being filled with concrete. Towards the end of 1885 the lighthouse was completed, at a total cost, including the first attempt, of over £65,000. The tower is an iron structure in the shape of a concave elliptic frustum, its base being founded upon the caisson foundation at about half-tide level (fig. 21). The light is electric, the current being supplied by cable from the shore. The focal plane is 78 ft. above high water or 109 ft. from the sand level. The total height from the foundation of the caisson to the top of the vane is 185 ft.

Other famous wave-swept towers are those at Haulbowline Rock (Carlingford Lough, Ireland, 1823); Horsburgh (Singapore, 1851); Bayes d’Olonne (Bay of Biscay, 1861); Hanois (Alderney, 1862); Daedalus Reef, iron tower (Red Sea, 1863); Alguada Reef (Bay of Bengal, 1865); Longships (Land’s End, 1872); the Prongs (Bombay, 1874); Little Basses (Ceylon, 1878); the Graves (Boston, U.S.A., 1905); Jument d’Ouessant (France, 1907); and Roche Bonne (France, building 1910).

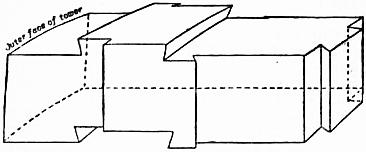

Jointing of Stones in Rock Towers.—Various methods of jointing the stones in rock towers are shown in figs. 6 and 22. The great distinction between the towers built by successive engineers to the Trinity House and other rock lighthouses is that, in the former the stones of each course are dovetailed together both laterally and vertically and are not connected by metal or wooden pins and wedges and dowled as in most other cases. This dovetail method was first adopted at the Hanois Rock at the suggestion of Nicholas Douglass. On the upper face, one side and at one end of each block is a dovetailed projection. On the under face and the other side and end, corresponding dovetailed recesses are formed with just sufficient clearance for the raised bands to enter in setting (fig. 23). The cement mortar in the joint formed between the faces so locks the dovetails that the stones cannot be separated without breaking (fig. 24).

Table I.—Comparative Cost of Exposed Rock Towers.

| Name of Structure. | Total Cost. | Cub. ft. | Cost per cub. ft. of Masonry. | ||||

| Eddystone, Smeaton (1759) | £40,000 | 0 | 0 | 13,343 | £2 | 9 | 11½ |

| Bell Rock, Firth of Forth (1811) | 55,619 | 12 | 1 | 28,530 | 1 | 19 | 0 |

| Skerryvore, west coast of Scotland (1844) | 72,200 | 11 | 6 | 58,580 | 1 | 4 | 7¾ |

| Bishop Rock, first granite tower (1858) | 34,559 | 18 | 9 | 35,209 | 0 | 19 | 7½ |

| Smalls, Bristol Channel (1861) | 50,124 | 11 | 8 | 46,386 | 1 | 1 | 7¼ |

| Hanois, Alderney (1862) | 25,296 | 0 | 0 | 24,542 | 1 | 0 | 7¼ |

| Wolf Rock, Land’s End (1869) | 62,726 | 0 | 0 | 59,070 | 1 | 1 | 3 |

| Dhu Heartach, west coast of Scotland (1872) | 72,584 | 9 | 7 | 42,050 | 1 | 14 | 6 |

| Longships, Land’s End (1872) | 43,869 | 8 | 11 | 47,610 | 0 | 18 | 5 |

| Eddystone, Douglass (1882) | 59,255 | 0 | 0 | 65,198 | 0 | 18 | 2 |

| Bishop Rock, strengthening and part reconstruction (1887) | 64,889 | 0 | 0 | 45,080 | 1 | 8 | 9 |

| Great Basses, Ceylon (1873) | 63,560 | 0 | 0 | 47,819 | 1 | 6 | 7 |

| Minot’s Ledge, Boston, Mass. (1860) | 62,500 | 0 | 0 | 36,322 | 1 | 17 | 2 |

| Spectacle Reef, Lake Huron (1874) | 78,125 | 0 | 0 | 42,742 | 1 | 16 | 2 |

| Ar’men, France (1881) | 37,692 | 0 | 0 | 32,400 | 1 | 3 | 3 |

| Fastnet, Ireland (1904) | 79,000 | 0 | 0 | 62,600 | 1 | 5 | 5½ |

Effect of Waves.—The wave stroke to which rock lighthouse towers are exposed is often considerable. At the Dhu Heartach, during the erection of the tower, 14 joggled stones, each of 2 tons weight, were washed away after having been set in cement at a height of 37 ft. above high water, and similar damage was done during the construction of the Bell Rock tower. The effect of waves on the Bishop Rock and Eddystone towers has been noted above.

Land Structures for Lighthouses.—The erection of lighthouse towers and other buildings on land presents no difficulties of construction, and such buildings are of ordinary architectural character. It will therefore be unnecessary to refer to them in detail. Attention is directed to the Phare d’Eckmühl at Penmarc’h (Finistère), completed in 1897. The cost of this magnificent structure, 207 ft. in height from the ground, was largely defrayed by a bequest of £12,000 left by the marquis de Blocqueville. It is constructed entirely of granite, and is octagonal in plan. The total cost of the tower and other lighthouse buildings amounted to £16,000.

|

| Fig. 19.—Maplin Pile Lighthouse. |

The tower at Île Vierge (Finistère), completed in 1902, has an elevation of 247 ft. from the ground level to the focal plane, and is probably the highest structure of its kind in the world.

The brick tower, constructed at Spurn Point, at the entrance to the Humber and completed in 1895, replaced an earlier structure erected by Smeaton at the end of the 18th century. The existing tower is constructed on a foundation consisting of concrete cylinders sunk in the shingle beach. The focal plane of the light is elevated 120 ft. above high water.

Besides being built of stone or brick, land towers are frequently 633 constructed of cast iron plates or open steel-work with a view to economy. Fine examples of the former are to be found in many British colonies and elsewhere, that on Dassen Island (Cape of Good Hope), 105 ft. in height to the focal plane, being typical (fig. 25). Many openwork structures up to 200 ft. in height have been built. Recent examples are the towers erected at Cape San Thomé (Brazil) in 1882, 148 ft. in height (fig. 26), Mocha (Red Sea) in 1903, 180 ft. and Sanganeb Reef (Red Sea) 1906, 165 ft. in height to the focal plane.

|

| Fig. 20.—American Shoal Lighthouse, Florida. |

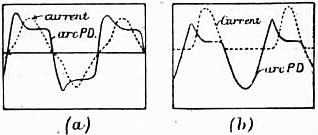

3. Optical Apparatus.—Optical apparatus in lighthouses is required for one or other of three distinct purposes: (1) the concentration of the rays derived from the light source into a belt of light distributed evenly around the horizon, condensation in the vertical plane only being employed; (2) the concentration of the rays both vertically and horizontally into a pencil or cone of small angle directed towards the horizon and caused to revolve about the light source as a centre, thus producing a flashing light; and (3) the condensation of the light in the vertical plane and also in the horizontal plane in such a manner as to concentrate the rays over a limited azimuth only.

Apparatus falling under the first category produce a fixed light, and further distinction can be provided in this class by mechanical means of occultation, resulting in the production of an occulting or intermittent light. Apparatus included in the second class are usually employed to produce flashing lights, but sometimes the dual condensation is taken advantage of to produce a fixed pencil of rays thrown towards the horizon for the purpose of marking an isolated danger or the limits of a narrow channel. Such lights are best described by the French term feux de direction. Catoptric apparatus, by which dual condensation is produced, are moreover sometimes used for fixed lights, the light pencils overlapping each other in azimuth. Apparatus of the third class are employed for sector lights or those throwing a beam of light over a wider azimuth than can be conveniently covered by an apparatus of the second class, and for reinforcing the beam of light emergent from a fixed apparatus in any required direction.

The above classification of apparatus depends on the resultant effect of the optical elements. Another classification divides the instruments themselves into three classes: (a) catoptric, (b) dioptric and (c) catadioptric.

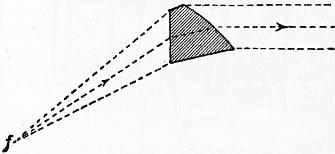

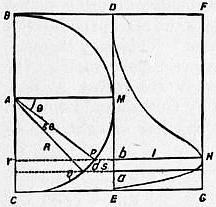

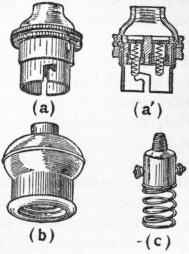

Catoptric apparatus are those by which the light rays are reflected only from the faces of incidence, such as silvered mirrors of plane, spherical, parabolic or other profile. Dioptric elements are those in which the light rays pass through the optical glass, suffering refraction at the incident and emergent faces (fig. 27). Catadioptric elements are combined of the two foregoing and consist of optical prisms in which the light rays suffer refraction at the incident face, total internal reflexion at a second face and again refraction on emergence at the third face (fig. 28).

|

| Fig. 21.—Rothersand Lighthouse. |

The object of these several forms of optical apparatus is not only to produce characteristics or distinctions in lights to enable them to be readily recognized by mariners, but to utilize the light rays in directions above and below the horizontal plane, and also, in the case of revolving or flashing lights, in azimuths not requiring to be illuminated for strengthening the beam in the direction of the mariner. It will be seen that the effective condensation in flashing lights is very much greater than in fixed belts, thus enabling higher intensities to be obtained by the use of flashing lights than with fixed apparatus.

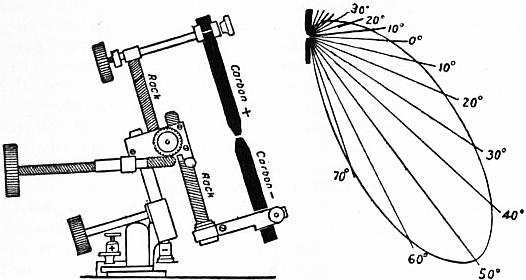

Catoptric System.—Parabolic reflectors, consisting of small facets of silvered glass set in plaster of Paris, were first used about the year 1763 in some of the Mersey lights by Mr Hutchinson, then dock master at Liverpool (fig. 29). Spherical metallic reflectors were introduced in France in 1781, followed by parabolic reflectors on silvered copper in 1790 in England and France, and in Scotland in 1803. The earlier lights were of fixed type, a number of reflectors being arranged on a frame or stand in such a manner that the pencils of emergent rays overlapped and thus illuminated the whole horizon continuously. In 1783 the first revolving light was erected at Marstrand in Sweden. Similar apparatus were installed at Cordouan (1790), Flamborough Head (1806) and at the Bell Rock (1811). To produce a revolving or flashing light the reflectors were fixed on a revolving carriage having several faces. Three or more reflectors in a face were set with their axes parallel.

A type of parabolic reflector now in use is shown in fig. 30. The sizes in general use vary from 21 in. to 24 in. diameter. These instruments are still largely used for light-vessel illumination, and a few important land lights are at the present time of catoptric type, including those at St Agnes (Scilly Islands), Cromer and St Anthony (Falmouth).

|

| Fig. 22.—Courses of various Lighthouse Towers. |

|

|

| Fig. 23.—Perspective drawing of Dovetailed Stone (Wolf Rock). |

Fig. 24.—Section of Dovetail. |

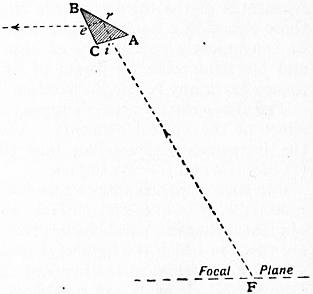

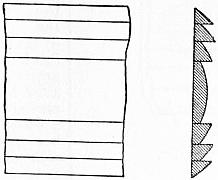

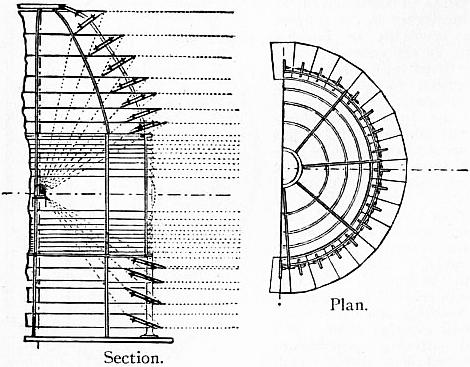

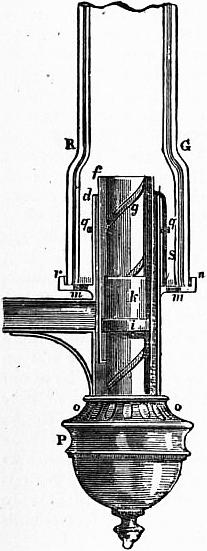

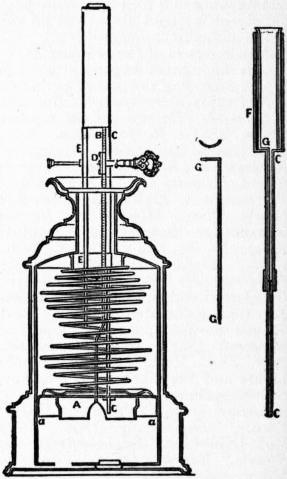

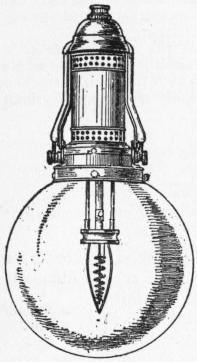

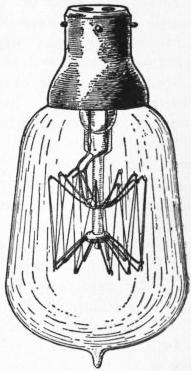

Dioptric System.—The first adaptation of dioptric lenses to lighthouses is probably due to T. Rogers, who used lenses at one of the Portland lighthouses between 1786 and 1790. Subsequently lenses by the same maker were used at Howth, Waterford and the North Foreland. Count Buffon had in 1748 proposed to grind out of a solid piece of glass a lens in steps or concentric zones in order to reduce the thickness to a minimum (fig. 31). Condorcet in 1773 and Sir D. Brewster in 1811 designed built-up lenses consisting of stepped annular rings. Neither of these proposals, however, was intended to apply to lighthouse purposes. In 1822 Augustin Fresnel constructed a built-up annular lens in which the centres of curvature of the different rings receded from the axis according to their distances from the centre, so as practically to eliminate spherical aberration; the only spherical surface being the small central part or “bull’s eye” (fig. 32). These lenses were intended for revolving lights only. Fresnel next produced his cylindric refractor or lens belt, consisting 634 of a zone of glass generated by the revolution round a vertical axis of a medial section of the annular lens (fig. 33). The lens belt condensed and parallelized the light rays in the vertical plane only, while the annular lens does so in every plane. The first revolving light constructed from Fresnel’s designs was erected at the Cordouan lighthouse in 1823. It consisted of 8 panels of annular lenses placed round the lamp at a focal distance of 920 mm. To utilize the light, which would otherwise escape above the lenses, Fresnel introduced a series of 8 plain silvered mirrors, on which the light was thrown by a system of lenses. At a subsequent period mirrors were also placed in the lower part of the optic. The apparatus was revolved by clockwork. This optic embodied the first combination of dioptric and catoptric elements in one design (fig. 34). In the following year Fresnel designed a dioptric lens with catoptric mirrors for fixed light, which was the first of its kind installed in a lighthouse. It was erected at the Chassiron lighthouse in 1827 (fig. 35). This combination is geometrically perfect, but not so practically on account of the great loss of light entailed by metallic reflection which is at least 25% greater than the system described under. Before his death in 1827 Fresnel devised his totally reflecting or catadioptric prisms to take the place of the silvered reflectors previously used above and below the lens elements (fig. 28). The ray Fi falling on the prismoidal ring ABC is refracted in the direction i r and meeting the face AB at an angle of incidence greater than the critical, is totally reflected in the direction r e emerging after second refraction in a horizontal direction. Fresnel devised these prisms for use in fixed light apparatus, but the principle was, at a later date, also applied to flashing lights, in the first instance by T. Stevenson. Both the dioptric lens and catadioptric prism invented by Fresnel are still in general use, the mathematical calculations of the great French designer still forming the basis upon which lighthouse opticians work.

|

|

| Fig. 25.—Dassen Island Lighthouse (cast iron). |

Fig. 26.—Cape San Thomé Lighthouse. |

|

|

| Fig. 27.—Dioptric Prism. | Fig. 28.—Catadioptric or Reflecting Prism. |

Fresnel also designed a form of fixed and flashing light in which the distinction of a fixed light, varied by flashes, was produced by placing panels of straight refracting prisms in a vertical position on a revolving carriage outside the fixed light apparatus. The revolution of the upright prisms periodically increased the power of the beam, by condensation of the rays emergent from the fixed apparatus, in the horizontal plane.

The lens segments in Fresnel’s early apparatus were of polygonal form instead of cylindrical, but subsequently manufacturers succeeded in grinding glass in cylindrical rings of the form now used. The first apparatus of this description was made by Messrs Cookson of Newcastle in 1836 at the suggestion of Alan Stevenson and erected at Inchkeith.

In 1825 the French Commission des Phares decided upon the exclusive use of lenticular apparatus in its service. The Scottish Lighthouse Board followed with the Inchkeith revolving apparatus in 1835 and the Isle of May fixed optic in 1836. In the latter instrument Alan Stevenson introduced helical frames for holding the glass prisms in place, thus avoiding complete obstruction of the light rays in any azimuth. The first dioptric light erected by the Trinity House was that formerly at Start Point in Devonshire, constructed in 1836. Catadioptric or reflecting prisms for revolving lights were not used until 1850, when Alan Stevenson designed them for the North Ronaldshay lighthouse.

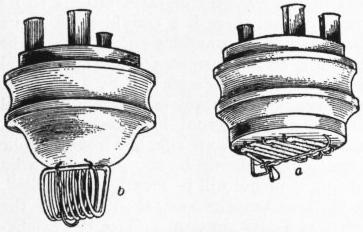

Dioptric Mirror.—The next important improvement in lighthouse optical work was the invention of the dioptric spherical mirror by Mr (afterwards Sir) J. T. Chance in 1862. The zones or prisms are generated round a vertical axis and divided into segments. This form of mirror is still in general use (figs. 36 and 37).

|

|

| Fig. 29.—Early Reflector and Lamp (1763). | Fig. 30.—Modern Parabolic Reflector. |

Azimuthal Condensing Prisms.—Previous to 1850 all apparatus were designed to emit light of equal power in every azimuth either constantly or periodically. The only exception was where a light was situated on a stretch of coast where a mirror could be placed behind the flame to utilize the rays, which would otherwise pass landward, and reflect them back, passing through the flame and lens in a seaward direction. In order to increase the intensity of lights in certain azimuths T. Stevenson devised his azimuthal condensing prisms which, in various forms and methods of application, have been largely used for the purpose of strengthening the light rays in required directions as, for instance, where coloured sectors are provided. Applications of this system will be referred to subsequently.

Optical Glass for Lighthouses.—In the early days of lens lights the only glass used for the prisms was made in France at the St Gobain and Premontré works, which have long been celebrated for the high quality of optical glass produced. The early dioptric lights erected in the United Kingdom, some 13 in all, were made by Messrs Cookson of South Shields, who were instructed by Léonor Fresnel, the brother of Augustin. At first they tried to mould the lens and then to grind it out of one thick sheet of glass. The successors of the Cookson firm abandoned the manufacture of lenses in 1845, and the firm of Letourneau & Lepaute of Paris again became the monopolists. In 1850 Messrs Chance Bros. & Co. of Birmingham began the manufacture of optical glass, assisted by M. Tabouret, a French expert who had been a colleague of Augustin Fresnel himself. The first light made by the firm was shown at the Great Exhibition of 1851, since when numerous dioptric apparatus have been constructed by Messrs Chance, who are, at this time, the only manufacturers of lighthouse glass in the United Kingdom. Most of the glass used for apparatus constructed in France is manufactured at St Gobain. Some of the glass used by German constructors is made at Rathenow in Prussia and Goslar in the Harz.

The glass generally employed for lighthouse optics has for its refractive index a mean value of µ = 1.51, the corresponding critical angle being 41° 30′. Messrs Chance have used dense flint glass for the upper and lower refracting rings of high angle lenses and for dioptric mirrors in certain cases. This glass has a value of µ = l.62 with critical angle 38° 5′.

|

|

|

| Fig. 31. Buffon’s Lens. |

Fig. 32. Fresnel’s Annular Lens. |

Fig. 33. Fresnel’s Lens Belt. |

|

| Fig. 34.—Fresnel’s Revolving Apparatus at Cordouan Lighthouse. |

Occulting Lights.—During the last 25 years of the 19th century the disadvantages of fixed lights became more and more apparent. At the present day the practice of installing such, except occasionally in the case of the smaller and less important of harbour or river lights, has practically ceased. The necessity for providing a distinctive characteristic for every light when possible has led to the conversion of many of the fixed-light apparatus of earlier years into occulting lights, and often to their supersession by more modern and powerful flashing apparatus. An occulting apparatus in general use consists of a cylindrical screen, fitting over the burner, rapidly lowered and raised by means of a cam-wheel at stated intervals. The cam-wheel is actuated by means of a weight or spring clock. Varying characteristics may be procured by means of such a contrivance—single, double, triple or other systems of occultation. The eclipses or periods of darkness bear much the same relation to the times of illumination as do the flashes to the eclipses in a revolving or flashing light. In the case of a first-order fixed light the cost of conversion to an occulting characteristic does not exceed £250 to £300. With apparatus illuminated by gas the occultations may be produced by successively raising and lowering the gas at stated intervals. Another form of occulting mechanism employed consists of a series of vertical screens mounted on a carriage and revolving round the burner. The carriage is rotated on rollers or ball bearings or carried upon a small mercury float. The usual driving mechanism employed is a spring clock. “Otter” screens are used in cases when it is desired to produce different periods of occultations in two or more positions in azimuth in order to differentiate sectors marking shoals, &c. The screens are of sheet metal blacked and arranged vertically, some what in the manner of the laths of a venetian blind, and operated by mechanical means.

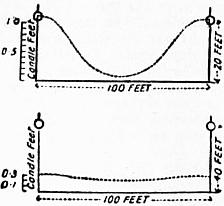

Leading Lights.—In the case of lights designed to act as a lead through a narrow channel or as direction lights, it is undesirable to employ a flashing apparatus. Fixed-light optics are employed to meet such cases, and are generally fitted with occulting mechanism. A typical apparatus of this description is that at Gage Roads, Fremantle, West Australia (fig. 38). The occulting bright light covers the fairway, and is flanked by sectors of occulting red and green light marking dangers and intensified by vertical condensing prisms. A good example of a holophotal direction light was exhibited at the 1900 Paris Exhibition, and afterwards erected at Suzac lighthouse (France). The light consists of an annular lens 500 mm. focal distance, of 180° horizontal angle and 157° vertical, with a mirror of 180° at the back. The lens throws a red beam of about 4½° amplitude in azimuth, and 50,000 candle-power over a narrow channel. The illuminant is an incandescent petroleum vapour burner. Holophotal direction lenses of this type can only be applied where the sector to be marked is of comparatively small angle. Silvered metallic mirrors of parabolic form are also used for the purpose. The use of single direction lights frequently renders the construction of separate towers for leading lights unnecessary.

If two distinct lights are employed to indicate the line of navigation through a channel or between dangers they must be sufficiently far apart to afford a good lead, the front or seaward light being situated at a lower elevation than the rear or landward one.

Coloured Lights.—Colour is used as seldom as possible as a distinction, entailing as it does a considerable reduction in the power of the light. It is necessary in some instances for differentiating sectors over dangers and for harbour lighting purposes. The use of coloured lights as alternating flashes for lighthouse lights is not to be commended, on account of the unequal absorption of the coloured 636 and bright rays by the atmosphere. When such distinction has been employed, as in the Wolf Rock apparatus, the red and white beams can be approximately equalized in initial intensity by constructing the lens and prism panels for the red light of larger angle than those for the white beams. Owing to the absorption by the red colouring, the power of a red beam is only 40% of the intensity of the corresponding white light. The corresponding intensity of green light is 25%. When red or green sectors are employed they should invariably be reinforced by mirrors, azimuthal condensing prisms, or other means to raise the coloured beam to approximately the same intensity as the white light. With the introduction of group-flashing characteristics the necessity for using colour as a means of distinction disappeared.

|

| Fig. 35.—Fixed Apparatus at Chassiron Lighthouse (1827). |

|

| Fig. 36.—Vertical Section. Prism of Dioptric Spherical Mirror. |

High-Angle Vertical Lenses.—Messrs Chance of Birmingham have manufactured lenses having 97° of vertical amplitude, but this result was only attained by using dense flint glass of high refractive index for the upper and lower elements. It is doubtful, however, whether the use of refracting elements for a greater angle than 80° vertically is attended by any material corresponding advantage.

|

| Fig. 37.—Chance’s Dioptric Spherical Mirror. |

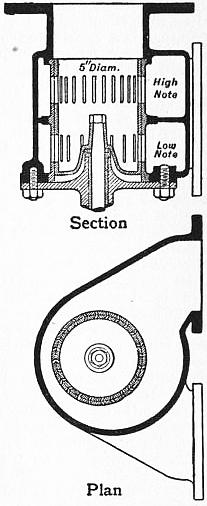

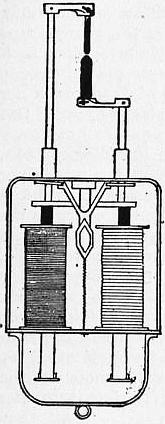

Group Flashing Lights.—One of the most useful distinctions consists in the grouping of two or more flashes separated by short intervals of darkness, the group being succeeded by a longer eclipse. Thus two, three or more flashes of, say, half second duration or less follow each other at intervals of about 2 seconds and are succeeded by an eclipse of, say, 10 seconds, the sequence being completed in a period of, say, 15 seconds. In 1874 Dr John Hopkinson introduced the very valuable improvement of dividing the lenses of a dioptric revolving light with the panels of reflecting prisms above and below them, setting them at an angle to produce the group-flashing characteristic. The first apparatus of this type constructed were those now in use at Tampico, Mexico and the Little Basses lighthouse, Ceylon (double flashing). The Casquets apparatus (triple flashing) was installed in 1877. A group-flashing catoptric light had, however, been exhibited from the “Royal Sovereign” light-vessel in 1875. A sectional plan of the quadruple-flashing first order apparatus at Pendeen in Cornwall is shown in fig. 39; and fig. 55 (Plate 1.) illustrates a double flashing first order light at Pachena Point in British Columbia. Hopkinson’s system has been very extensively used, most of the group-flashing lights shown in the accompanying tables, being designed upon the general lines he introduced. A modification of the system consists in grouping two or more lenses together separated by equal angles, and filling the remaining angle in azimuth by a reinforcing mirror or screen. A group-flashing distinction was proposed for gas lights by J. R. Wigham of Dublin, who obtained it in the case of a revolving apparatus by alternately raising and lowering the flame. The first apparatus in which this method was employed was erected at Galley Head, Co. Cork (1878). At this lighthouse 4 of Wigham’s large gas burners with four tiers of first-order revolving lenses, eight in each tier, were adopted. By successive lowering and raising of the gas flame at the focus of each tier of lenses he produced the group-flashing distinction. The light showed, instead of one prolonged flash at intervals of one minute, as would be produced by the apparatus in the absence of a gas occulter, a group of short flashes varying in number between six and seven. The uncertainty, however, in the number of flashes contained in each group is found to be an objection to the arrangement. This device was adopted at other gas-illuminated stations in Ireland at subsequent dates. The quadriform apparatus and gas installation at Galley Head were superseded in 1907 by a first order bi-form apparatus with incandescent oil vapour burner showing five flashes every 20 seconds.

|

| Fig. 38.—Gage Roads Direction Light. |

|

| Fig. 39.—Pendeen Apparatus. Plan at Focal Plane. |

Flashing Lights indicating Numbers.—Captain F. A. Mahan, late engineer secretary to the United States Lighthouse Board, devised for that service a system of flashing lights to indicate certain numbers. The apparatus installed at Minot’s Ledge lighthouse near Boston Harbour, Massachusetts, has a flash indicating the number 143, thus: - ---- ---, the dashes indicating short flashes. Each group is separated by a longer period of darkness than that between successive members of a group. The flashes in a group indicating a figure are about 1½ seconds apart, the groups being 3 seconds apart, an interval of 16 seconds’ darkness occurring between each repetition. Thus the number is repeated every half minute. Two examples of this system were exhibited by the United States Lighthouse Board at the Chicago Exhibition in 1893, viz. the second-order apparatus just mentioned and a similar light of the first order for Cape Charles on the Virginian coast. The lenses are arranged in a somewhat 637 similar manner to an ordinary group-flashing light, the groups of lenses being placed on one side of the optic, while the other is provided with a catadioptric mirror. This system of numerical flashing for lighthouses has been frequently proposed in various forms, notably by Lord Kelvin. The installation of the lights described is, however, the first practical application of the system to large and important coast lights. The great cost involved in the alteration of the lights of any country to comply with the requirements of a numerical system is one of the objections to its general adoption.

Plate I.

|

|

| Fig. 54.—FASTNET LIGHTHOUSE—FIRST ORDER SINGLE-FLASHING BIFORM APPARATUS. | Fig. 55.—PACHENA POINT LIGHTHOUSE, B.C.—FIRST ORDER DOUBLE-FLASHING APPARATUS. |

Plate II.

|

|

| Fig. 56.—OLD EDDYSTONE LIGHTHOUSE. | Fig. 57.—EDDYSTONE LIGHTHOUSE. |

|

|

| Fig. 58.—ILE VIERGE LIGHTHOUSE. | Fig. 59.—MINOT’S LEDGE LIGHTHOUSE. |

|

| Fig. 40.—Sule Skerry Apparatus. |

Hyper-radial Apparatus.—In 1885 Messrs Barbier of Paris constructed the first hyper-radial apparatus (1330 mm. focal distance) to the design of Messrs D. and C. Stevenson. This had a height of 1812 mm. It was tested during the South Foreland experiments in comparison with other lenses, and found to give excellent results with burners of large focal diameter. Apparatus of similar focal distance (1330 mm.) were subsequently established at Round Island, Bishop Rock, and Spurn Point in England, Fair Isle and Sule Skerry (fig. 40) in Scotland, Bull Rock and Tory Island in Ireland, Cape d’Antifer in France, Pei Yu-shan in China and a lighthouse in Brazil.

The light erected in 1907 at Cape Race, Newfoundland, is a fine example of a four-sided hyper-radial apparatus mounted on a mercury float. The total weight of the revolving part of the light amounts to 7 tons, while the motive clock weight required to rotate this large mass at a speed of two complete revolutions a minute is only 8 cwt. and the weight of mercury required for flotation 950 ℔. A similar apparatus was placed at Manora Point, Karachi, India, in 1908 (fig. 41).

The introduction of incandescent and other burners of focal compactness and high intensity has rendered the use of optics of such large dimensions as the above, intended for burners of great focal diameter, unnecessary. It is now possible to obtain with a second-order optic (or one of 700 mm. focal distance), having a powerful incandescent petroleum burner in focus, a beam of equal intensity to that which would be obtained from the apparatus having a 10-wick oil burner or 108-jet gas burner at its focus.

Stephenson’s Spherical Lenses and Equiangular Prisms.—Mr C. A. Stephenson in 1888 designed a form of lens spherical in the horizontal and vertical sections. This admitted of the construction of lenses of long focal distance without the otherwise corresponding necessity of increased diameter of lantern. A lens of this type and of 1330 mm. focal distance was constructed in 1890 for Fair Isle lighthouse. The spherical form loses in efficiency if carried beyond an angle subtending 20° at the focus, and to obviate this loss Mr Stephenson designed his equiangular prisms, which have an inclination outwards. It is claimed by the designer that the use of equiangular prisms results in less loss of light and less divergence than is the case when either the spherical or Fresnel form is adopted. An example of this design is seen (fig. 40) in the Sule Skerry apparatus (1895).

Fixed and Flashing Lights.—The use of these lights, which show a fixed beam varied at intervals by more powerful flashes, is not to be recommended, though a large number were constructed in the earlier years of dioptric illumination and many are still in existence. The distinction can be produced in one or other of three ways: (a) by the revolution of detached panels of straight condensing lens prisms placed vertically around a fixed light optic, (b) by utilizing revolving lens panels in the middle portion of the optic to produce the flashing light, the upper and lower sections of the apparatus being fixed zones of catadioptric or reflecting elements emitting a fixed belt of light, and (c) by interposing panels of fixed light section between the flashing light panels of a revolving apparatus. In certain conditions of the atmosphere it is possible for the fixed light of low power to be entirely obscured while the flashes are visible, thus vitiating the true characteristic of the light. Cases have frequently occurred of such lights being mistaken for, and even described in lists of light as, revolving or flashing lights.

”Cute” and Screens.—Screens of coloured glass, intended to distinguish the light in particular azimuths, and of sheet iron, when it is desired to “cut off” the light sharply on any angle, should be fixed as far from the centre of the light as possible in order to reduce the escape of light rays due to divergence. These screens are usually attached to the lantern framing.

Divergence.—A dioptric apparatus designed to bend all incident rays of light from the light source in a horizontal direction would, if the flame could be a point, have the effect of projecting a horizontal band or zone of light, in the case of a fixed apparatus, and a cylinder of light rays, in the case of a flashing light, towards the horizon. Thus the mariner in the near distance would receive no light, the rays, visible only at or near the horizon, passing above the level of his eye. In practice this does not occur, sufficient natural divergence being produced ordinarily owing to the magnitude of the flame. Where the electric arc is employed it is often necessary to design the prisms so as to produce artificial divergence. The measure of the natural divergence for any point of the lens is the angle whose sine is the ratio of the diameter of the flame to the distance of the point from centre of flame.

In the case of vertical divergence the mean height of the flame must be substituted for the diameter. The angle thus obtained is the total divergence, that is, the sum of the angles above and below the horizontal plane or to right and left of the medial section. In fixed dioptric lights there is, of course, no divergence in the horizontal plane. In flashing lights the horizontal divergence is a matter of considerable importance, determining as it does the duration or length of time the flash is visible to the mariner.

Feux-Éclairs or Quick Flashing Lights.—One of the most important developments in the character of lighthouse illuminating apparatus that has occurred in recent years has been in the direction of reducing the length of flash. The initiative in this matter was taken by the French lighthouse authorities, and in France alone forty lights of this type were established between 1892 and 1901. The use of short flash lights rapidly spread to other parts of the world. In England the lighthouse at Pendeen (1900) exhibits a quadruple flash every 15 seconds, the flashes being about ¼ second duration (fig. 39), while the bivalve apparatus erected on Lundy Island (1897) shows 2 flashes of 1⁄3 second duration in quick succession every 20 seconds. Since 1900 many quick flashing lights have been erected on the coasts of the United Kingdom and in other countries. The early feux-éclairs, designed by the French engineers and others, had usually a flash of 1⁄10th to 1⁄3rd of a second duration. As a result of experiments carried out in France in 1903-1904, 3⁄10 second has been adopted by the French authorities as the minimum duration for white flashing lights. If shorter flashes are used it is found that the reduction in duration is attended by a corresponding, but not proportionate, diminution in effective intensity. In the case of many electric flashing lights the duration is of necessity reduced, but the greater initial intensity of the flash permits this loss without serious detriment to efficiency. Red or green requires a considerably greater duration than do white flashes. The intervals between the flashes in lights of this character are also small, 2½ seconds to 7 seconds. In group-flashing lights the intervals between the flashes are about 2 seconds or even less, with periods of 7 to 10 or 15 seconds between the groups. The flashes are arranged in single, double, triple or even quadruple groups, as in the older forms of apparatus. The feu-éclair type of apparatus enables a far higher intensity of flash to be obtained than was previously possible without any corresponding increase in the luminous power of the burner or other source of light. This result depends entirely upon the greater ratio of condensation of light employed, panels of greater angular breadth than was customary in the older forms of apparatus being used with a higher rotatory velocity. It has been urged that short flashes are insufficient for taking bearings, but the utility of a light in this respect does not seem to depend so much upon the actual length of the flash as upon its frequent recurrence at short intervals. At the Paris Exhibition of 1900 was exhibited a fifth-order flashing light giving short flashes at 1 second intervals; this represents the extreme to which the movement towards the reduction of the period of flashing lights has yet been carried.

Mercury Floats.—It has naturally been found impracticable to revolve the optical apparatus of a light with its mountings, sometimes weighing over 7 tons, at the high rate of speed required for feux-éclairs by means of the old system of roller carriages, though for some small quick-revolving lights ball bearings have been successfully adopted. It has therefore become almost the universal practice to carry the rotating portions of the apparatus upon a mercury float. This beautiful application of mercury rotation was the invention of Bourdelles, and is now utilized not only for the high-speed apparatus, but also generally for the few examples of the older type still being constructed. The arrangement consists of an annular cast iron bath or trough of such dimensions that a similar but slightly smaller annular float immersed in the bath and surrounded by mercury displaces a volume of the liquid metal whose weight is equal to that of the apparatus supported. Thus a comparatively insignificant quantity of mercury, say 2 cwt., serves to ensure the flotation of a mass of over 3 tons. Certain differences exist between the type of float usually constructed in France and those generally designed by English engineers. In all cases provision is made for lowering the mercury bath or raising the float and apparatus for examination. Examples of mercury floats are shown in figs. 41, 42, 43 and Plate I., figs. 54 and 55.

|

| Fig. 41.—Manora Point Apparatus and Lantern. |

Multiform Apparatus.—In order to double the power to be obtained from a single apparatus at stations where lights of exceptionally high intensity are desired, the expedient of placing one complete lens apparatus above another has sometimes been adopted, as at the Bishop Rock (fig. 13), and at the Fastnet lighthouse in Ireland (Plate I., fig. 54). Triform and quadriform apparatus have also been erected in Ireland; particulars of the Tory Island triform apparatus will be found in table VII. The adoption of the multiform system involves the use of lanterns of increased height.

Twin Apparatus.—Another method of doubling the power of a light is by mounting two complete and distinct optics side by side on the same revolving table, as I shown in fig. 43 of the Île Vierge apparatus. Several such lights have been installed by the French Lighthouse Service.

Port Lights.—Small self-contained lanterns and lights are in common use for marking the entrances to harbours and in other similar positions where neither high power nor long range is requisite. Many such lights are unattended in the sense that they do not require the attention of a keeper for days and even weeks together. These are described in more detail in section 6 of this article. A typical port light consists of a copper or brass lantern containing a lens of the fourth order (250 mm. focal distance) or smaller, and a single wick or 2-wick Argand capillary burner. Duplex burners are also used. The apparatus may exhibit a fixed light or, more usually, an occulting characteristic is produced by the revolution of screens actuated by spring clockwork around the burner. The lantern may be placed at the top of a column, or suspended from the head of a mast. Coal gas and electricity are also used as illuminants for port lights when local supplies are available. The optical apparatus used in connexion with electric light is described below.

”Orders” of Apparatus.—Augustin Fresnel divided the dioptric lenses, designed by him, into “orders” or sizes depending on their local distance. This division is still used, although two additional “orders,” known as “small third order” and “hyper-radial” respectively are in ordinary use. The following 639 table gives the principal dimensions of the several sizes in use:—

Table II.

| Order. | Focal Distance, mm. | Vertical Angles of Optics. (Ordinary Dimensions.) | |||

| Dioptric Belt only. | Holophotal Optics. | ||||

| Lower Prisms. | Lens. | Upper Prisms. | |||

| Hyper-Radial | 1330 | 80° | 21° | 57° | 48° |

| 1st order | 920 | 92°, 80°, 58° | 21° | 57° | 48° |

| 2nd order | 700 | 80° | 21° | 57° | 48° |

| 3rd order | 500 | 80° | 21° | 57° | 48° |

| Small 3rd order | 375 | 80° | 21° | 57° | 48° |

| 4th order | 250 | 80° | 21° | 57° | 48° |

| 5th order | 187.5 | 80° | 21° | 57° | 48° |

| 6th order | 150 | 80° | 21° | 57° | 48° |

Lenses of small focal distance are also made for buoy and beacon lights.

|

| Fig. 42.—Cape Naturaliste Apparatus. |

|

| Fig. 43.—Île Vierge Apparatus. |