Transcriber's Note: The Table of Contents can be found at the end of the book.

FROM

TECHNICAL SCIENTIFIC PRINCIPLES

BY JOSEF HALFER

WITH A SUPPLEMENT ON THE

DECORATION OF BOOK EDGES

Translated by Herman Dieck, Philadelphia

BUFFALO, N. Y.:

THE AMERICAN BOOKBINDER

CO.

1894.

Copyright, 1893,

By LOUIS H. KINDER.

No product finds so many and ample applications as color. Nearly every trade requires it for the decoration of its products so as to adapt them more generally and pleasantly to the present demands.

The art of marbling is that branch of our trade, in which color is brought into use for the decoration of bindings, yet it has not found the desirable general introduction into our book-binderies because practical men have not so intently employed their time and endeavors, to overcome the difficulties, which resist its general application.

Who could solve easier and more correctly than the mechanics, to whom these difficulties and obstacles offer themselves in practice? He is the only one to find the remedy, scientific men not possessing sufficient technical knowledge. Only he is ready and able to stand up for such special trades, to work and to fight for them, who is himself interested and who not only learned to understand the art of marbling from former instructions and traditions, but from his own practical experience.

To him only, will it be possible to gain by close[4] study true points, on which to further develop the whole subject.

My original plan was, not only to remove the technical difficulties of the art of marbling, but also to ascertain the correct colors from the mass at present manufactured, for the purpose of manufacturing marbling colors.

But in this I did not succeed as easily as I expected. Every color manufactory possesses another system to produce its products, and after thousands of experiments I was finally forced to resort to chemistry for the purpose of gaining a knowledge of the raw products viz: earths, metals, acids, bases and their conditions and qualities in order to study their compositions and precipitations, the coloring composite of lake colors and their bodies, and to subject them to investigation on their effects on marbling size.

This was a tiresome work which demanded much patience and pertinacity. During these investigations, I have learned to know the influence of sizing upon colors and how it hindered or expedited a beautiful marbling or comb edging.

Through these experiments I unexpectedly gained a certain knowledge which enabled me to overcome the technical difficulties of the marbling art. The greater the difficulties the more they aroused my zeal to surmount them and the greater my joy when victory was won. During my investigations I saw, that not the color itself, but[5] its body, to which the color is bound either in a natural or chemical way, forms the important part of the colors necessary to our purpose. No branch puts so many critical demands upon the preparation of colors as the art of marbling, because, aside from the most careful grating which can only be done by using the best of painter's colors, there must be a great power of divisibility and excellent covering qualities so that the pigments do not turn pale by the propelling power of the ox-gall expanding on the size, but retain in a dry state, their full lustre. It is therefore impossible without a more thorough knowledge of the chemistry of colors to find from the legion of colors, which are thrown upon the market, the ones best adapted to our art. So much more so as, in most recent times, by simplification in the manufacture of most colors their quality, for marbling, has most essentially deteriorated.

Colors which are used for painting, lithography and printing with the greatest success may be entirely unfit for marbling. The cause is not to be found in their preparation for our purposes, but in the manufacture itself, as the qualities, which are indispensable are not known.

The main attention in the manufacture is directed to the finding of colors free from poison and which will not fade, when exposed to light, if they are intended for a wholesale consumption in painting and the graphical art.[6]

All colors which we intend to use for marbling purposes must have body, because bodiless colors become mixed with the size and run off from the paper in marbling, they therefore can be designated as useless for our purpose. The most important composite parts of colors for marbling are certain substances, among which hydrates of argillaceous earths, tin and lead oxides and sulphate of barium are named as the best.

A great number of coloring matters of organic origin, which are soluble in water, have the propensity in mixing with a solution of salts of lead, tin, and argillaceous earths, with a metallic oxide to form a compound which is soluble with difficulty (and is termed insoluble,) when the latter is precipitated from the solution by an alkali. The precipitations which are obtained in this way are known as lake dyes. Of greater importance for the quality of the marbling colors are the physical conditions of these precipitates, they are either crystallized or amorphous, the former not possessing any value to us.

The serviceable, i. e. the amorphous precipitates, by their quality of great divisibility give excellent colors.

Among the great number of numeral colors there are many which in spite of their amorphous properties are bad marbling colors, such as the compounds of copper, zinc and arsenic. Often it depends upon the manner of manufacturing, even if the[7] color have a good body whether it can be used by us, as, for instance, white lead and barium both of which can be produced as good or useless colors.

The general idea, that light colors are the best, is erroneous, even heavy oxides of metal being excellent colors. Not in weight but in divisibility rests the excellence, for instance I mention pure oxide of iron, cadmium, sulphate of mercury and mercury iodide. These are all heavy metallic oxides and good colors.

Exclusive of the colors the different ways of sizing are most essential parts of marbling. They exercise a great influence on the success of beautiful edges and for that reason I directed my closest attention to them. The more homogeneous and the smaller the viscosity of the mucilage of the sizing, the better for comb, peacock and bouquet edging.

Marbled and veined edges demand more viscosity of the mucilage, which, if the sizing does not possess it, is usually formed during the first stage of decomposition, when the normal time for using it for comb edges has passed. I will mention further on the ox-gall and the sprinkling water, which are indispensable on account of their binding and expanding powers for the purposes of marbling.

It is an easy manipulation to prepare ox-gall, so that it does not decompose, but on the other hand a much greater attention must be paid to the binding and expanding powers of the same, as[8] they may have, in spite of its excellent qualities for color, by insufficient caution in their handling the most deleterious influences on the colors as well, as on the sizing and in most cases are the causes of the failure of the edging. There are several substances, which possess qualities similar to ox-gall and many others which possess only its expansibility.

To the former belong resins which are insoluble but which can be dissolved by the addition of ammonia or borax, to the latter fatty acids of alkali, which we know by the name of soaps and which I shall describe in the article on ox-gall.

Sprinkling-water is mostly used on account of its greater expansibility and its propensity to form circular spots on the marbling ground, (sizing) for veined edges, or as an addition to the ground color of the marble edge. Although it does not possess the binding power of ox-gall for colors in such a degree, it is nevertheless, worthy of our attention. It was the aim of my investigations during many years to bring this all into a harmonious ensemble, and produce a fine and paying work.

In composing this book, I have aimed to arrange it in such a way, that it will be a guide not only to the uninitiated, but also to the practical mechanic. For this reason the book will only give such methods of the marbling as will be crowned with sure success and which have given me satisfactory results.[9]

As books, which are intended for practical men, can only obtain an intrinsic value by combination of facts, gained by practical experience, with scientific principles, I have attempted to attain this object and I hope to have created a lasting work of our trade-literature.

Budapest.

Josef Halfer,

Bookbinder

May, 1884. [10]

It is a pleasure and a satisfaction to every author to write the preface to the second edition of his work, as the sale of the first proves sufficiently, that it has found recognition and commendation.

In the second edition, I have given the results of my uninterrupted studies and the new observations I have made during the last five years. It is my hope not only, that I shall make the study easier to the inexperienced, but also to offer to the experienced marbler a practical compendium in cases of frequently arising difficulties.

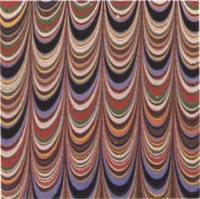

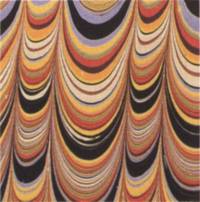

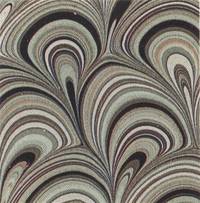

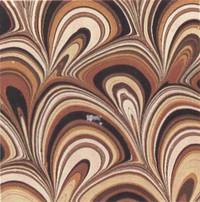

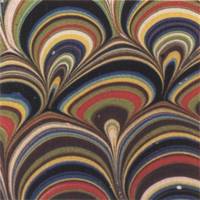

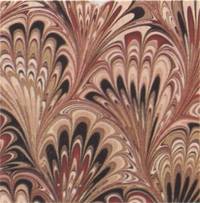

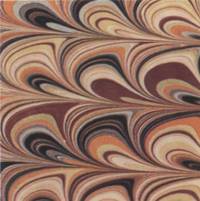

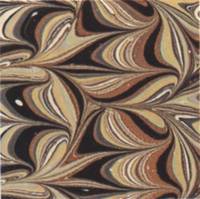

The publisher of this new edition has added to it a number of samples, which were collected under my supervision and which certainly will be highly welcome.

I hope and wish that the new edition with its practical arrangement, with its description of my newest observations and with its tables of samples and the other additions and improvements, will find the approval of the trade and will increase the number of friends and patrons of the marbling art.

Budapest,

Very

respectfully,

Josef Halfer.

October, 1890.

Every branch of industrial art possesses its champions and originators, who have employed their whole intellectual and physical powers to solve problems for the purpose of enhancing and furthering their material welfare.

Often from small beginnings, within a longer or shorter period of time, great enterprises spring into existence, which greatly further our development in culture, science and arts, and are blessings to the whole civilized world. The material welfare arising from them renders it necessary that new champions continuously enter the arena and combat in the cause of progressive industry.

The industries of color and paper making which play most important parts in the art of marbling shall be the first subjects of my essay.

The paper industry which is very highly developed will have a much better future on account of its possibilities in the line of improvement. To-day, in the iron-age, we speak of a paper-age, and for good reasons, because there hardly passes a year which does not bring new discoveries, showing the extraordinary adaptability of paper. One branch of the paper industry which to-day is considered as an especial part of the industry is[14] the manufacture of colored paper, the origin of which, as far as our literature is able to state, extends as far back as the first part of the last century.

From it springs the art of marbling, which in latter years was introduced into our trade.

The manufacture of colored paper makes a second branch of industry indispensable and one which stands on as high a stage of development as the paper industry; this is the manufacture of colors, which deserve the greatest attention on our part on account of the marbling art.

There is hardly a second branch of chemistry which is of such a great old age, historically proven, as the color industry.

We hardly know of a nation on the whole globe which does not make use of color in some way. The use of color for the purpose of embellishment and adornment dates back to historical times. Nature itself, by the beauty of the colors of her flowers and minerals acted as a teacher in the artistic development of the human race.

Egyptian wall paintings show richly developed forms and figures adorned with multi-colored fabrics.

This is a proof that the Egyptians not only understood the art of the manufacture of colors but that they also knew the much higher art of fastening the color on textile fabrics, i. e., the art of dyeing.[15]

In olden times for the coloring of objects, mineral colors which occur in nature the result of a decomposition of metals and earths and had only to be put through a sieve and washed to adapt them to the painters use, were exclusively used.

To alchemy, which was the origin of Chemistry of to-day, we owe a surprisingly large number of artificial mineral colors, for the reason that with predilection it brought metals, earths and mineral compounds within the sphere of its researches which were aimed at the production of gold, but which all were ineffective in this direction. But the time and labor, which were employed in these investigations, were not thrown away. By alchemy an immense number of chemical compounds became known, without which knowledge the chemistry of to-day would not have reached its exalted stage of perfection.

Exclusive of mineral colors several organic colors came into use, the most being applied in the dyeing establishments as they were bodiless colors and at that time the art of binding them to metallic oxides was unknown.

By and by it became known in what way to bind the coloring matter of plants to bodies and to make them serviceable in the art of painting and the graphic arts. Since that time progress in this field has been so rapid that we gaze in astonishment upon the achievements of the color chemistry of to-day.[16]

The progress which developed industrial art and caused it to flourish, was enhanced by a new and highly important invention, the industry of tar colors.

It is wonderful how man through the vigor of his intellect, tears from nature her hidden treasures which have lain in obscurity for thousands and thousands of years.

Who would have thought, that the antediluvian vegetation with its splendor of thousands of colors should celebrate its resurrection in aniline colors which by their splendid qualities of richness and intensity over-shadowed everything before them? It is a pity that we are only able to use these colors in limited numbers in our trade.

Up to this time they are used more for dyeing purposes, because they are without body and possess two apparently insurmountable proclivities, 1st, they do not mix so intimately with oxides of metal as the organic coloring stuffs of plants and they cannot for a long period withstand the influence of light.

In the meantime it is to be hoped with confidence, that science will soon find the solution for these difficulties. Already the forerunners of body colors have been discovered, a few which could withstand light have followed, as geranium lake in which the coloring matter is only bound to oxide of lead by surface adhesion. Furthermore scarlet lake, which, although bound to oxide of lead, has[17] been put in such a state that it does not run and lastly the artificial krapp-(madder) lake and indigo, which have been produced from coal-tar and nearly equal to the good color lakes of the animal and floral kingdoms.

The main attention in the production of these colors is directed to the end of finding those which are free of poison and will not fade, to make them serviceable to the historic art of painting.

For the aniline color there is therefore a wide field open to experiment.

Whether our interests and demands in regard to colors will be fulfilled is a question of time.

Even the newer productions of the animal and vegetable kingdom already differ in quality from those indispensable to the art of marbling.

I recommend to my honored colleagues to read my book with attention, so that the intended gain shall not be missed and the beautiful art of marbling may attain a larger circle of friends.

The Author.

[18]

The first process in marbling is the preparation of the size on which the colors are to be floated.

By the name of size is meant a consistent glutinous mass, which is obtained by boiling or dissolving with water certain bodies derived from the vegetable kingdom.

Mucilage is found in many plants, especially in the outer skin of seeds, also in many roots, barks, stems and leaves, but its solubility and consistency are very much varied.

Generally the mucilage of plants is classed among the gums; but there is a large difference from them in this, that it will not give a perfect, diaphanous and homogeneous solution, but only swells in it to a thick, massy and viscous fluid, which is similar to starch paste. It is composed of small quantities of gum, starch, sugar and consistent plant-mucilage. If prepared from certain plants, for example the algae of the sea, it also contains small quantities of iodine.

Starch swells in hot water, while with mucilage the same result is achieved by using cold water.

Smaller quantities of mucilage are found in every plant, but larger in gum tragacanth, carrageen or Iceland moss, salep, the leaves of mallows,[22] or of colts foot or tussilage, the roots of marsh mallow, seeds of plantago-psyllium, (flea-bane) linseed and quinces.

Of this number but few are of interest to us, which I shall mention further on.

The density and proper consistency of the size depends on the bodies, from which the viscous or glutinous substance is derived and also from the quantity of water, in which it is dissolved. The consistency of the size is also materially influenced by the temperature, the warmer, the less substantial and the more pliable; the colder, the more consistent and stiff it is.

A good marbling size should be an entirely homogeneous mucilage, i. e., a solution, which should be free of any vestiges of seeds or strings undissolved. A less viscous size is more adapted to the production of comb-edges, while a more viscous size to the production of marbled or veined edges. The consistency of the mucilage of every kind of size will soon experience an essential change, which becomes apparent by the fact, that the size becomes less consistent, until finally an acid reacting fluid remains, which has no more value for marbling purposes.

This chemical process is produced by the transformation of the sugar parts of the dissolved starch contained in the size into acid and lactic-acid. The more starch and sugar that is contained in the size, the sooner the acid will be generated, while[23] pure plant mucilage containing but little sugar and starch will resist much longer disintegration.

All plant-mucilages, which are soluble in cold water, i. e., swell, will keep much longer than those dissolved in boiling water, because the soluble parts remain inclosed in one cell which is only broken by the boiling heat or by the formation of acid. This is the reason why they only swell up in cold solution.

A homogeneous mucilage will serve for marbling much better, than that, which is produced by swelling, because the latter has an injurious influence on the fine distribution of color for veined, comb and other edges. Although the surface of such a size seems to be smooth, the eye will discover on closer investigation the undissolved bodies in the small granules of the size.

The mucilages obtained by swelling are always milky-cloudy and never permit the colors distributed upon them to expand with the same purity and smoothness as the homogeneous varieties, on account of the small granules hindering the drawing of the colors on their surface. On the other hand there are varieties of size, which are very viscous on account of a too homogeneous mucilage and therefore from their nature are not adaptable to any kinds of edging which must be drawn by the stylus. The colors can simply not be drawn on the surface, because this very viscous mucilage is drawn along by the stylus instead of being cut by it.[24]

In investigating the different varieties of size I have noticed a very surprising action of the extremely viscous mucilage, which nearly confused me for the moment. I have scalded with boiling water plantago-psyllium (flea-bane) and have beaten it with wicker-rods tied together so as to produce in a better manner, the mucilage found on the outside of the seed. After cooling it off, I filtered it through a linen cloth and poured it into the trough but have not waited till the very viscous thread of mucilage parted after the trough was filled to a certain height, but have placed the vessel on the floor and to my utter surprise the thread of the size spread out and reached the vessel on the floor, becoming gradually thicker until finally the whole size flowed in a white stream with great velocity over the rim of the trough (2 inches high) and returned to the vessel standing on the floor until the trough emptied. This was done in a very short time. The cause of my surprise was in the very consistent mucilage which took along ever-increasing quantities of the size and finally entirely emptied the trough.

Prepared colors, which on a less viscous size are normally distributed expand with a greater velocity to a greater extent on a more viscous size and therefore become pale.

For such kinds of sizes the earth colors are preferable but only for marbled edges.

The normal strength of size can be discerned[25] without araometer or other recommended apparatus. My opinion is that 2/5 of an ounce of good carrageen moss to a quart of water are sufficient, as carrageen excels all other glutinous bodies by the quantity of mucilage contained in it. To test the correct strength of the size pour some of it into a flat vessel, as a plate or dish, and throw a drop of color upon it; if the color does not spread out, but rather sinks down a drop of ox-gall must be added. Renew the test and so on until the color spreads out to about 2 inches, then take the stylus and draw the color into lines as in producing comb-edges. If the size be too thick the color will be drawn along by the stylus and cannot be cut clean through. On the other hand if the size be too thin it can be seen immediately in its quivering and the running of the color, which cannot be drawn into straight lines. In the former case some clean water must be added to the size, in the latter case which, if the size be well boiled, seldom occurs, thick size must be added by boiling more. The real consistency of the size is so easily learned in practice that a mere feeling with the fingers will be sufficient.

The preparation of the colors is carried on separately on a small part of the size, so that the whole quantity is not rendered useless. If the colors are rightly prepared in proportion to their expansibilities in relation to each other, the new size is to be poured into the trough and the marbling may begin.[26]

The mistake which is commonly made in marbling is, that too little attention is paid to the size and color. Frequently the size is soiled and the colors are spoiled by adding too much gall before an edge is produced. For this there are generally three causes, either the size is too fresh, too thick or the colors have been prepared on the same size by which the edges are to be produced.

Each size which is boiled should only be taken into use after perfect cooling and after several hours have elapsed, since in a warm state it would not permit the colors to expand even by adding a large quantity of gall. Only after the expiration of ten or twelve hours after boiling will it have the correct quantity of mucilage and then only the size possesses its full value. This time having elapsed, the size is filtered through a cloth and is then ready for use.

A size when too thick, allows the colors to expand only with great difficulty and demands a three fold larger quantity of gall than when it possesses its normal consistency. It is very difficult to remove from a too consistent size the remnants of colors.

They always unite with the size and in this way the size not only becomes soiled but it is impregnated with a large quantity of gall. As I said before, the colors should always be prepared on a separate size which can be poured into a flat vessel as it is nearly impossible to prevent several drops of color sinking to the bottom.[27]

If this precaution be taken and if the colors are prepared according to their relative expansibilities as they are used in the order prescribed, the process will not meet with any obstruction or difficulty. As the size plays such an important part in marbling, great attention must be paid to its preparation if it is desired to make a good base for the colors. I especially recommend to laymen that they direct their attention to the consistency of the size, as this is always the key to the production of good edges.

The different peculiarities of the varieties of sizes, viz; evaporation, influence of temperature, starry formation of colors, formation of angular scales in comb-edges, and all other things which have influence on colors, will be treated of in a special article on the varieties of size.[28]

The Carrageen or Iceland moss, or lichen is one of the algae of the sea. Chondrus Crispus grows on the cliffs of the Atlantic Ocean and the North Sea. Carrageen smells slightly of iodine and when uncleaned tastes offensively salty. Like all seaweeds it contains a great quantity of mucilage and small quantities of salts of iodine and bromine. When washed in sweetened water it becomes nearly tasteless and is without smell. On account of the great quantity of mucilage contained in it, and of its action as an alleviative to pulmonary complaints it has found many applications in medicinal practice and is given to the patient boiled in water, milk or bouillon or as gelatine in cases of coughs and diarrhoea, being a slightly nutritious substance.

The carrageen moss or Iceland moss or weed is a lichen and consists of a tuft of flat deeply divided cartilaginous fronds of an olive brown, sometimes yellowish or reddish white color; the tuft is sometimes 2 to 5 inches long.

The moss is used in many ways; as size for marbling edges, for clarifying beer, as linen-weavers starch, for finishing cloth and in the production of iodine.[32]

The good pure carrageen is horn-like, yellowish-white, contains a great quantity of mucilage and gives the best size for marbling, as it complies with all the requirements of a good size. It is homogeneous, of great consistency, not extraordinarily viscous and cheaper than all the other materials containing mucilage which are used for marbling, but is inferior to gum tragacanth as far as durability is concerned, and that it must be subjected to boiling, but this trouble is amply repaid by the beauty of the productions.

On this size all varieties of edges can be produced, and by its diaphanous watery mucilage it gives an excellent ground to work upon.

The preparation of carrageen size is confined to one ever recurring manipulation, which must be repeated every eight days, if an always good and useful size is desired; the expenses are very trifling, a few cents for the best kind of carrageen. If bought in larger quantities the expenses for carrageen can still be reduced. For the preparation of the size take a new pot, which must always be used for this purpose exclusively, pour in six quarts of water, which quantity is sufficient to twice or three times fill the usual marbling trough, add 2-1/2 ounces of Carrageen moss and boil until the water bubbles up several times. A longer boiling is injurious because the mucilage becomes flaky and muddy. 2/5 of an ounce of Carrageen to one quart of water is fully sufficient to[33] produce a consistent size, provided that only the best Carrageen is used.

Soft water or rain water was formerly used exclusively for preparing the size, as by using it a greater durability was obtained.

During my researches, regarding the durability of the varieties of sizes, I found means by which the influence of hard water on the ground can be suspended, so that spring and pump water can now be used without any danger.

Every kind of hard water contains mineral salts, spring water especially containing lime in smaller or larger quantities. This can be seen, when the soap, which is used in such water, curdles, because of the ingredients of soap stearine palmitic or fatty acids of sodium or potassium, form a combination with the lime, to carbonate of lime, and the potash soap is converted into an insoluble lime soap. If we add to hard water a quantity of sodium or potassium, the carbonate of lime is precipitated as a white or yellowish powder, according to the quantity of iron contained in the water, and a soft water remains.

The sun produces on a great scale in nature, what the chemist achieves on a smaller scale by evaporation or precipitation and cooling of steam, a water free of all mineral salts, which we call distilled water. Rain water is the same, but the flowing water derived from a river already contains mineral salts in greater or smaller quantities,[34] which are brought into it by different springs and substances. The water gained by precipitations is considered soft. Carbonates of sodium or potassium are strong bases, exactly the opposite of acids, and they therefore prohibit the oxidation in plant mucilages. This chemical reaction against the formation of acids I used for the purpose of prohibiting a deterioration of the size by adding sodium, in which I was thoroughly successful, as it can easily be preserved in a cool place for even eight or ten days.

Two obstacles offered themselves, which I have overcome after a tireless and thorough investigation, first the strongly alkaline property of the size which was generated by the added carbonate of sodium and second the fermentation of lactic acid which occurred notwithstanding the sodium and made the size useless.

The presence of alkalies was injurious to such colors, chemically bound to bodies, among which red is most affected. The coloring matter was removed from the bodies and became mixed by running with the size, causing the size to become soiled. Even the shade of the color was changed to another which was nearer to purple, and in this way, the beauty of the color was greatly lessened. The second obstacle is the fermentation of lactic acids which always occurs where starch flour is in the solution, causing in consistent sizes a gradual thinning out and even a destruction of the size.[35]

It was not my aim to save the size from destruction forever, as this is impossible (laws of nature cannot be obliterated at will) but to keep it useful for a certain period of time, and this I achieved after many experiments by using borax.

Borax is a neutral salt of strongly antiseptic properties, prohibiting fermentation and decomposition where neither base nor acid predominate. Borax is produced by neutralization of boracic acid with carbonate of sodium and can be bought at every drug-store.

This salt is sold in crystals of the size of walnuts; for our purpose it is ground to powder and is kept for use in a closed vessel. The size is first used without any addition of borax as it is then better adapted for producing comb and other drawn edges, and only after some time has elapsed, in summer 36, in winter 48 hours, are 150 grains of borax added to the size, whereupon the size, having been repeatedly stirred to dissolve the salt, will keep entirely good and useful for a period of eight days without doing any harm to the colors. On a size which contains borax, the colors expand in a much greater degree than upon unadulterated size, without impairing the consistency of the mucilage. An unadulterated size is therefore, better for marbled and veined edges, but if it be desired to produce only marbled and veined edges on the size, it is advisable to add borax to the water before boiling the carrageen moss.[36]

As the influence of temperature is important in marbling, and the production of beautiful edges is often jeopardized by it, it should therefore have the most careful attention. Every glutinous mass acquires, according to the difference of the temperature of the size and air, in one-half to one-quarter of a minute, a film (top) which forms through natural evaporation.

On a size which has such a film, or top, the colors do not spread out in such circular forms as on a size on which the colors are quickly thrown right after the film (top) has been taken off, but form star-like veined spots which are torn by the film in all directions.

Even in the normal expansion of the drops of color, it often happens, that the rim of the drop is jagged, the cause being that the size already possessed a thin top, which was not yet sufficient to prevent the expanding of the colors. If the size be left standing for a half-hour or an hour before throwing on the color without having at first removed the top of the size, the drop will tear a hole into this film and will sink, even if quite a large quantity of gall had been added. This explains the contraction and the sinking down of colors on a still warm size, inasmuch as the top is formed by evaporation of the warm mucilage, so quickly and so thick, that the color which had already begun to spread out is pressed together by it and is forced to sink.[37]

The greater the difference of temperature between the size and air, the quicker is the top formed. It is therefore a rule, that the size should be allowed to cool off in the same room, in which the marbling occurs, because in this way a symmetrical degree of heat or cold of the size and air will be gained. On such a size, the formation of the top is much slower and thinner, so that even after one to one and a half minutes after removal of the top of the size, the colors can be thrown on without the occurrence of the starry formation.

I will here mention a fact to show the importance of temperature. As this point has given me much trouble and has taken much time and labor, it was my aim to find that mysterious effect which I was unable to overcome despite my numerous chemical experiments, until my eyes became opened and I saw accidentally that this obstacle was the difference of temperature of size and air. From that time on I was able to prosecute my labors without the slightest difficulty.

To show the excellence of my marbling colors, I used a great number of samples, perhaps several thousand, and in order to produce them I worked on Sunday so that I could employ my whole time to the good purpose. It was winter; on every Saturday I ordered two pots of size to be boiled, and to cool them off I placed them in a room, in which there was no heat. On Sunday morning I filtered the size through a loose linen cloth; it was as[38] clear as crystal, it possessed the necessary consistency, and I was much pleased with the results, which I had expected to achieve.

I commenced the preparation of the colors in a separate flat vessel, using but little size, so as to keep the rest from being soiled, but I was greatly astonished, when the colors in spite of the addition of gall, which of course was carefully done by drops, first spread out and then again were contracted, the starry formation of the colors took place, whenever I was not quick enough after the taking off of the top to throw on the colors.

I was dumbfounded and could give no explanation for it; the size was sufficiently cooled off, it had been standing the proper length of time, the mucilage was excellent but in spite of all that, these difficulties occurred.

Thinking that I might be more successful, if I should do the marbling in the trough where there is more surface offered to the color to spread out, I filled the trough with size of a sufficient height and then commenced the marbling, but immediately after the first trial I instantly recognized that even here my experiments would have the same result. Although I threw on the color with great alacrity, right after the top had been taken off, the first drop spread out normally 4 inches, the second but three, the third two, and the fifth and sixth only one inch. In this way I received instead of an equally wide band of thrown on color, one[39] which tapered to a point. If I had not worked according to the system which I shall describe in the chapter of throwing on of colors, I would have received already with the fourth drop, a star-like formation.

Whatever I did to avoid this obstacle was worthless, it was and remained a mystery and I was unable on that day to produce anything beautiful or worthy of consideration. This happened several times until, by accident, and through careful study I found the cause which was nothing but the fact, that the size was much colder than the air in the room in which I worked. The evaporation on the surface of the size was so great, that the top was formed nearly as quick as on warm size and therefore a favorable result was impossible.

Another abnormity which arises from cold temperature acting on the size is the fig-like formation occurring during the drawing of the colors. The cold in some way seasons the surface; this surface becomes mixed in filtering with the liquid part of the size in numberless small particles which although the size is well stirred up in the trough by the fingers, are not dissolved and this hinders the drawing of the colors.

They adhere to the stylus and follow it and arrange themselves between the color lines in a way similar to a green fig, having a broad upper and a pointed lower end. Such an edge traversed by the comb will give an ugly result. A difference[40] of temperature of the size and the air can also occur when the working room is suddenly heated, or, when in summer time, the size is kept in a cold cellar. To effectively obviate this difficulty it is necessary to bring the temperatures of the air and size carefully to the same height which is made easy by leaving the size, after boiling, in the room, where the marbling is executed.

In winter, when the room is heated, the size should be poured into the trough one hour before using, in summer the thing regulates itself because it is then unnecessary to keep the size in a cool place, the addition of borax being a sufficient protection against spoiling. But in spite of it all, in winter-time when in drawing the colors the fig-like formation should occur, it is advisable to return the size to the pot and to warm it up slightly so that the seasoned particles are dissolved, until an equal temperature is reached, whereupon after the lapse of one hour the marbling can again be proceeded with.

Should the size be too thick the trouble can be remedied by the addition of some warm water.

The quantity of mucilage contained in carrageen moss varies greatly, and the consistency of the size often depends upon the quality of the moss. The quantity which I gave as essential to the preparation of the size means first class moss.

Should the consistency of the size be insufficient after the first trial then from 1/2 to 1 ounce of[41] moss should be added as it is clear that the carrageen moss is not of prime quality. Before I speak of another variety of size, I will repeat the main condition which should meet with the attention of every layman and which are as follows; the size must not boil too long, in order that it may not become flaky and muddy, it should remain for cooling in the same room in which the marbling is carried on, so that the temperature of of it and the air are the same; the colors should be prepared separately on a small quantity of size so that the whole size cannot become soiled and, lastly, the top of the size should be taken off before the colors are thrown on, so that no film can form before the colors cover the surface of the size.

The quicker the manipulation of marbling is executed the prettier are the edges produced. As soon as the size is covered with color, the formation of the film is prevented.

As the size is one of the most important parts in the process of marbling, I recommend these main points to the special consideration of the reader.[42]

Gum tragacanth, also called gum-dragon, is the product of various species of astragalus which is found in Greece and Turkey and is a natural exudation of shrubs and from exudations resulting from incisions made in the stem near the root. This shrub is from 28 to 35 inches high and two inches in diameter. It is collected in July and August after the exudations have ceased. It is a hard, tough substance more or less white according to its purity in very irregular flattened shapes and in tortuous vermicular filaments. It contains aside from a little gum and starch, a consistent plant-mucilage without smell or taste and it is used in technical ways, in printing of textile fabrics and finishing, in producing plastic masses, as a binding medium for the production of confections and in the book-bindery for marbling size.

The leaf tragacanth of Smyrna is the best. It is brought to the markets of the world via Constantinople or via Smyrna in boxes of 100 to 200 lbs.

It forms flat ribbon-like pieces which consist of peculiar layers of horn-like consistency, white and diaphanous; when broken it is dull and splintered.[46]

An inferior quality is the tragacanth of Morea, which generally comes from Greece via Trieste. This consists of oddly shaped, peculiarly twisted pieces, partly of pure white, partly of yellowish and brownish colors. For a long while, tragacanth was known as a good material for marbling size and, for that reason, it is used to-day in a good many of our book-binderies for this purpose.

It is much more liked than carrageen moss because the consistency of its mucilage and its durability are great and the preparation of the colors does not demand such great attention. But since my experiments and investigations upon the excellent effects of borax on the durability of carrageen size have become known, tragacanth has lost much of its popularity, because with it the edges can never be produced in a similar fine way as with carrageen size and besides the price is higher. Tragacanth is one of these short-viscous plant mucilages which swell in cold water but do not give a perfectly homogeneous solution. The mucilage consists of innumerable small granules, in which the starch is enclosed by cells.

These small granules prohibit, within the first two or three days of a fresh tragacanth size, the drawing of edges, as they make the colors thrown on appear rugged, and in drawing injure the fine hair lines. Five or six days after the dissolving of the tragacanth, the mucilage becomes more homogeneous and therefore better adapted for marbling.[47]

If the swelled up mucilage is boiled, after the first or second day, then the solution will become perfectly homogeneous and will be as good as carrageen size except that the colors, which normally spread out on carrageen size, will expand much more on tragacanth size as it possesses more consistency and therefore they will become paler. The more dense the size, the thicker colors and the less gall is necessary to produce a normal expansion. The same difference in the power of expansion of the colors as in carrageen and the tragacanth is noticed in colors which normally spread out on tragacanth but which, very largely, expand on the size of plantago-psyllium (flea-bane) because the latter has the most consistency and homogeneity of them all. The different effects of the varieties of size on the colors are due to the consistency and to the different conditions of gravity. The objections of the consumers of my marbling colors who use tragacanth, are, that they consider the edges too pale. The cause of this is that my products are only prepared for carrageen size, inasmuch as my investigations have shown that it is the best, the cheapest and the most adapted for all varieties of edges.

The homogeneousness of the tragacanth mucilage in cold solution comes naturally after the size is five or six days old, because within this time fermentation of lactic acid occurs, which opens the cells of the small granules of starch while at the[48] same time boiling heat has an immediate result in the same direction.

As soon as these cells are opened the formation of acids of the sugary parts and the fermentation of lactic acid of the starch contained in the size take place as fast as in any other variety of size, hence the size of tragacanth has no superiority over any other, besides the best, or picked-leaf tragacanth of Smyrna costs about four times the price of the best Carrageen.

For the preparation of the size, take 3 ounces of tragacanth, pour two quarts of water over it, leave it stand for 24 hours, then stir well and leave it standing for 12 hours more, repeat this until the homogeneous thick mucilage has been produced, then add 4 quarts of water, again stir it up well and filter it and the size is ready for the marbling process.

For tragacanth size, colors of great consistency, mostly fine earth colors are the best. They must be ground exceedingly well and very little ox-gall is to be added. But as these earth colors lack in the power to spread out and in divisibility, a characteristic of colors prepared for carrageen size, and as they never will have such fineness and smoothness, always appearing rugged, it is impossible for me to recommend gum tragacanth for the preparation of size.

I must mention further an effect, which earth colors exert on tragacanth size, viz., that they[49] can be used on paper not prepared with alum, without running, while this is not the case with colors, which were prepared for the Carrageen size. In another chapter upon ox-gall I shall explain why the colors used with Carrageen size must be transferred on alum paper.[50]

Radix salep are called the dried tubers of several species of orchids, they are round, quite flat, yellowish white, horn-like, semi-diaphanous, very hard and without taste or smell. Formerly salep was imported mostly from Persia, but now the tubers of orchids grown at home are collected and do not in any way differ from those coming from Asia. They contain a good quantity of gum and on that account are used for finishing silks and for medicinal purposes. It is sold ground, or as powder and can be bought at every drug-store. As marbling size, salep possesses very excellent properties, similar to carrageen moss, but its high price prohibits its general application. In preparing size, use, to 6 quarts of water 2-1/2 ounces of powdered salep which must be well boiled for a long period so that it may become entirely dissolved. After standing 24 hours, it can be used in the same way, as carrageen size.

Plantago-Psyllium (Flea-bane, Flohsamen, Flohkrautsamen) is the seed of different species of Way Bread belonging to the family of the plantaginea viz., plantago-psyllium, Pl-Arenaria, Pl-Cynops, the second of which is found in Eastern[54] Germany, Switzerland, Hungary, etc. on sandy fields, the other two on the sea-shores of southern Europe.

The seed is small with one side flat and the other concave and has a furrow upon which is located the eye or navel. It is lustrous and of a reddish brown color, the best varieties coming from southern France. In consequence of the great quantity of plant-mucilage or gum, that it contains, by treating with hot water a consistent mucilage or size is obtained and used in the manufacture of marbled paper and for finishing textile fabrics.

To prepare the size, place 4 ounces of flea-bane in a wide wooden tub, pour 6 quarts of boiling water over it and beat well with a switch of wicker-rods until the gum is entirely separated from the seeds, allow it to cool and after 10 or 12 hours filter through a linen cloth, when it is ready for use. The mucilage of flea-bane is quite homogeneous and of great consistency, is very viscous, forming strings very readily and is therefore not used for drawn edges since the colors will be drawn along by the stylus without being cut. It is mostly used for producing thickly veined, ordinary marbled edges, but flea-bane size is also much more expensive than that of carrageen moss and on the other hand its quality is so much inferior to that of the other that I cannot recommend it for use as size.[55]

I will briefly mention the other vegetable matters containing an especially large quantity of gum or mucilage, but which have not come into use for preparing marbling size on account of their cost and of the less consistency of their mucilages.

The richest in this regard are the seeds of quinces and linseed. Their mucilage is as viscous as that of flea-bane. Much less gum is contained in the leaves of mallows of colts-foot or of marsh-mallows.

In closing this chapter upon the mucilages of plants and their applications as sizing for marbling I again recommend carrageen moss as the best size, because it has given me during my investigations and in practice, surprising results of its usefulness for all kinds of marbled edges.[56]

In the bile of every animal are two peculiar acids both containing nitrogen. One of them free of sulphur, the other containing it, both by boiling with acids and alkalis yield the same acid free of nitrogen, which is called cholic acid.

If these two acids be separated from each other in a chemical way we obtain glycocholic acid, an acid free of sulphur and the other taurocholic acid containing sulphur. The alkali salts contained in bile are quite soluble in water or alcohol but insoluble in ether. To produce it in a pure state mix the bile with as much animal coal, (spodium) so that finally, on evaporation in the water-bath a dry powder results, from which is drawn, by the use of absolute alcohol, the now colorless cholic acid esters, cholesterine, choline, lactic acid, etc. When ether containing a little water is added, the cholic acid esters are precipitated as colorless plaster-like masses and crystallize, when left in the fluid for some time.

The so-called crystallized bile is the final material for the preparation of acids. The acids of ox-gall have been investigated in the most thorough manner.[60]

Glycocholic acid is obtained as a colorless precipitate from a watery solution of crystallized ox-gall, by adding dilute sulphuric acid until the fluid becomes flocculent, which after a while, especially, if the water contains a little ether, is changed into a voluminous 'magma' of fine white needles.

If collected upon a filter, these needles unite and form a lustrous felt.

Glycocholic acid is sparingly soluble in water but soluble in alcohol. It forms the principal constituent of bile, it reacts feebly with acid and tastes bitter-sweet. Taurocholic acid is found only in small quantities in ox-gall and has no important effect on the colors.

By chemical analysis we have seen that glycocholic acid is the principal constituent of ox-gall and in combination with taurocholic acid, glycin, choline and lactic acid is soluble in water. On the other hand, when pure, it is soluble with difficulty and therefore is only of use to us when in combination with other acids, as it must combine intimately with water-colors.

The atomic weight of gall and the insolubility of pure glycocholic acid in water are the most valuable properties of it for the marbling colors.

The first gives to the colors the expanding power, the latter the adhesion to paper.

All the lower fatty acids, among which ox-gall may be numbered, possess properties similar to[61] fatty bodies, namely a less atomic weight than water. They differ from fatty bodies in this, that they mix with water.

The expanding power and lightness of ox-gall are, consequently, peculiarities of equal value. Marbling size forms the base for the colors, which by the consistency of the glutinous mass and by the gall added to them are prevented from sinking to the bottom. They float like drops of oil upon the water and only differ from them by the fact that the colors will spread out on the size, while the drops of oil on the water are contracted to circular spots of small size. If a drop of oil were thrown upon the size it would spread out very quickly.

This purely physical occurrence is caused by the different weights of the bodies and the consistency of the size. The fatty bodies, which are much lighter than water, float upon it but the gravity of the drop itself prohibits its spreading out, as it sinks somewhat and is held together by it. It is different with the size; by the consistency of the glutinous mass the gravity of the drop is antagonized and as a result it flattens and spreads out.

As I have already mentioned the insolubility of glycocholic acid binds the color to the paper. To explain this I will mention a few examples; the saturated alum solution will cause glycocholic acid to curdle. If, therefore, we add to ox-gall[62] which is basic the saturated solution of alum, a soft plaster-like mass is precipitated which consists of glycocholate of aluminium, insoluble in water. This chemical reaction explains the durability of the colors. If we desire to marble books or papers we impregnate them with alum water, allow them to dry partly and take the edge from the size.

In the same moment that the paper soaked with alum comes in contact with the colors, the latter become bound by the formation of glycocholates of aluminium and do not run. They have the same property of fixing colors that resinous soaps used in the paper manufacture for gluing machine paper have. If this resinous soap were not too strongly basic, which is injurious to many colors, it might be applied as a surrogate for ox-gall.

As the resinous soap on account of its binding quality and insolubility could also be used in marbling with such colors, upon which it exercises no injurious effect, I will here give its preparation and former use in the manufacture of paper. If 2-5 ounces of rosin be boiled with 1-1/3 ounces of sodium lye and if you add by teaspoonful from time to time so much lye until a sample of it is dissolved by hot water to a clear fluid, the mass on cooling congeals and forms a quite solid soap. If we mix a solution of resinous soap with one of alum then we obtain an insoluble compound of resinous acids and aluminium. In this way[63] resinous soap is used in gluing paper by adding to the paper pulp, first resinous soap and then a solution of alum. During this process a thin layer of insoluble soap of aluminium is formed around every particle of the paper and thus the running of the ink is prohibited. The same process occurs with ox-gall contained in the colors, when the edge is lifted off on paper or book-edges impregnated with alum, by which the running of the colors is prohibited.

The preparation of ox-gall to be used in marbling is simple. Take a quart of fresh bile (ox-gall or fish-gall), place in a bottle which contains when filled from 1-1/2 to 2 quarts, add 1/2 pint of absolute alcohol, shake well and leave stand for from 14 days to 3 weeks. Within this time all particles of gum and all fatty substances which are present in some galls in comparatively large quantities, will fall to the bottom and the gall will be thin-fluid, pure and diaphanous, brownish, yellow or greenish according to the nourishment of the animal from which it was taken.

Cow-gall contains more gum and fatty substances, than ox-gall; fish-gall, on the other hand, is thinner than ox-gall and would be the most useful of them all, if it could be obtained in sufficient quantities. If the gall is thin and pure it is filtered through paper which is easily and quickly done as it runs like water. If by filtering the[64] dregs of the gall the filter should become clogged, a new one must be used.

The addition of alcohol causes the precipitation of glutinous and fatty substances and preserves the gall from decomposition. If prepared in such a way it can be preserved for years without spoiling.

All colors which we intend to use for marbling must be bound to bodies absolutely insoluble in water; it is therefore a mistake to say, that the colors dissolve in water. You may grind the color on a marble slab or in a machine as long as you please, but you will only obtain a great degree of fineness of the bodies but never a dissolution of the same.

Each body possesses its limit of divisibility; in amorphous bodies the high divisibility is but natural, but in crystalline bodies this division must be produced by grinding or washing.

The gall does not combine with these bodies, nor does it penetrate them, but only clings to them loosely. It can be readily removed in case the colors should be rendered useless by the addition of too much gall. The color is allowed to precipitate in the bottle and the water standing above is poured off, fresh water is added and this manipulation is repeated several times.

The gall which surrounds every particle of color forms, as it were, the support of it and adapts it to float upon the size.

Bodiless colors, which give a complete solution[65] with water will run into each other on being thrown on the size and will flow from the paper when it is lifted off. The insolubility of the color bodies therefore prevents them from running although they are disarranged on the size in drawing and although one color may be compressed or expanded by a second, yet they all remain separate without mixing, except, perhaps, that the shade of the first color becomes more intense, because its color particles are pushed together by the more violent expansion of the second color.

From this it will be seen that the colors, to be useful for our purposes, must be thoroughly insoluble. The gall is added during the process of grinding the color, so that the particles of colors are fully surrounded by the gall. The gall has an excellent effect on the colors but it also can act very injuriously if the necessary precautions are not taken. Carelessness is mostly the reason that the edges do not possess the demanded lustre of color and why they appear pale, as the marbler often uses the gall too soon when he notices the smallest obstacle, (due in most cases to the size.) It is therefore not astonishing that brilliant comb or peacock-edges are so rarely seen.

It is an obstacle to marbling, that the gall mixes so easily with the size. It often happens that the gall spoils the size before an edge was ever produced on it. This happens especially when the size on which the colors are prepared according to the old[66] method, is too thick. The size is frequently soiled and spoiled when the colors are prepared, because the colors can not be perfectly drawn off on thick size. There will always remain some particles which will not only soil the size but impregnate it with gall, and which will cause the entire uselessness of size and color.

A very consistent size will make the preparation of colors extremely difficult, as they need a double quantity of gall for the purpose of spreading out. If there is but one color used, the preparation on such a size would be possible without spoiling it, but with four colors this is entirely impossible because the repeated drawing off of the colors, which always leaves particles behind, will, by and by, impregnate the size so that when the fourth color is prepared the first will not spread out any further.

The more the impregnation of the gall and size increases, the power of expansion of the colors decreases and this continues until both materials are useless.

It is therefore advisable, as I have already stated, in the chapter upon the varieties of sizes that the colors should be prepared separately on a small part of size to determine the correct consistency of the latter and to prohibit the whole size being soiled.

The gall should be kept in a small bottle containing about 1/10 quart with a perforated stop[67]per from which a small tube protrudes and from which the gall can be added to the colors in drops.

Although the preparation of the color in this way takes more time, this trouble is amply repaid by the result.

Fatty bodies are injurious to the size, therefore they must be carefully avoided because they have the same effect as the gall, they form, although not insoluble in water, a combination with the size and prohibit the colors from spreading out. Fatty bodies can be transferred by glutinous fluids into a state of the most minute division and they then form emulsions.

Natural emulsions are milk, the yolk of egg, and the milky saps of plants. For this reason, in many establishments raw milk is used as a propelling medium for hair-veined edges.

There are also fatty bodies which, in an artificial way, form an emulsion even with water; for instance, almond, poppy and hemp, if they are ground to a pulp with a little water yield a milky mixture. All these emulsions artificial as well as natural, can be employed as expanding mediums and give better results for marbling than petroleum or naptha.[68]

There are rosins which are soluble in ammonia or borax. These solutions possess properties similar to gall and either can be used as an expanding medium or as an addition to colors. Different experiments with these solutions gave very good results.

To produce them pour a quart of water into a vessel, warm, add 2/5 of an ounce of shellac or rosin and a 1/100 part of a quart of ammonia or 2/5 of an ounce of borax so that the rosin becomes dissolved, and then bring the mixture to a boiling temperature.

Ammonia dissolves the rosins much more quickly and thoroughly than borax, but the solution in ammonia has the property of gelatinizing the colors after they have remained standing a short time. They therefore can only be used in a greatly diluted condition. The borax solution, on the other hand, has no such effect; not even the concentrated solution. I mention these two solutions especially, to instigate further investigations.[72]

Sprinkling water is one of the newer discoveries in the art of marbling and deserves full consideration on account of its good properties. Its advantages consist in this, that it produces circular forms upon the size and has a greater expanding power than gall.

Sprinkling water is used for hair-veined edges and as an addition to the ground color in marbling.

To prepare it take 1-1/2 ounces of Venetian soap, finely chipped, place them in a pot with a quart of alcohol, warm up some water in a second and large vessel in which the pot containing the alcohol and soap is put, bring the whole to boiling, when the soap will be entirely dissolved in the alcohol. Keep a quintuple quantity of water in readiness into which the solution of soap is poured and stir well, the sprinkling water is then ready for use. The solution of soap in alcohol is carried out in a water-bath to avoid the ignition of the volatile vapors which are generated by this process. The alcohol prevents the foaming of the soap, the soft water the curdling.

The solution when ready is to be kept in a closed bottle.

Generally to the colors which are used for hair-[76]veined edges and marble more gall is added than to those used for drawn edges. It is, therefore, easily understood that with these, a more intensively acting expanding medium must be used to spread out the strong colors into veins.

The sprinkling water is here of great service, because, although ox-gall in its pure state possesses a sufficient expanding power it is here more desirable to produce beauty of forms. In this respect the gall is much inferior to sprinkling water, the former producing all kinds of forms, the latter only beautifully round and oval ones.

For marbling, the ground color is prepared with gall so far, until it slightly pushes the other colors aside and then, by and by, so much sprinkling water is added until the desired expanding power is reached.

Every ground color which is prepared with sprinkling water spoils on standing two or three days becoming slimy and viscous, and, for economy's sake, not more color should be prepared with sprinkling water than is required for one marbling process.

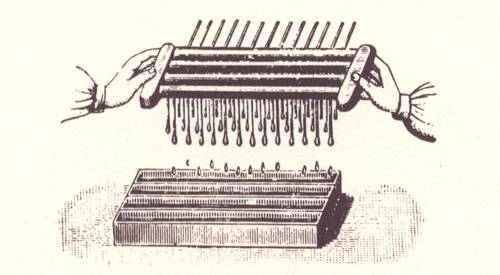

For hair-veined edges, the sprinkling water is used in the same way as gall. Use a large painter's brush or whisk and move the colors by beating into veins, with this brush or whisk through a slot, or throw the sprinkling-water upon the color by means of the sprinkling brush and sieve. In both cases the same result will be achieved.[77]

In the chapter upon gall I have mentioned in a general way the action of alum water upon the edges, it remains only therefore to explain the preparation and application of the same.

To achieve beautiful results from the colors it is indispensable to wet the book edges or the paper, to be marbled, with concentrated alum water, so that no spot is left free from moisture, because at that spot the color would not take.

Concentrated alum water is prepared in the following way; put 2 quarts of water and 13 ounces of alum into a pot and heat until the alum is entirely dissolved. This concentrated solution is permitted to cool and is bottled tightly.

A solution of alum in cold water is much too weak for the above purpose as alum is but sparingly soluble in cold water.

The book edge or paper, which is to be marbled, is wet with a sponge dipped into this cold concentrated alum solution and must be allowed to dry for from 5 to 8 minutes, after which the produced edge may be lifted from the size. Generally this point finds but too little consideration in our book-binding establishments.

Edges which have not been treated with this[80] alum water show as a consequence poor and blotted results, although such little trouble is necessary to wet the edges with alum water.

With hair-veined edges, where colors are thrown on the size only in very small quantities, this wetting may be omitted; but with comb, peacock and bouquet edges, for which four to six colors are used, it is unavoidably necessary to prepare the edges with alum water because the glycocholate aluminium formed by the color while in connection with the alum water is essential to fix the color in such quantities.

Therefore, if it is desired to produce clean and lustrous edges in which the white lines appear without a trace of color, then this advice is to be followed, the small trouble being amply repaid by the beauty of the edges.

Ordinary earth and several of the lake-colors take without wetting of edges with alum water, but these colors leave much to be desired in their divisibility and fineness and always appear rugged.

A much finer fixing medium is the acetate of aluminium which can be easily produced.

Dissolve 1 pound of alum in 3 quarts of warm water, prepare another solution with the same quantity of soda, mix these two, whereupon the hydrate of aluminium is precipitated. Allow the latter to settle, pour the water above carefully off, and filter; the white body which remains consists of hydrate of aluminium which is readily[81] dissolved by a little acetic acid, into a clear fluid and can be diluted with the same volume of water. Then heat the whole liquid, when the excess of acetic acid is evaporated, we have the desired acetate of aluminium which can be used in the same way as alum water.

Edges and paper which are to be marbled should only be moistened with alum water or aluminium acetate shortly before the marbling and should stand not longer than a half-hour after the sizing of the edges, because later on, an insoluble layer is formed which only takes color with great difficulty. It is therefore best to prepare the colors before commencing the sizing of the edges. If there are a large number of books, it is better to divide them into two or three lots.[82]

The want of knowledge of colors gave me the greatest trouble when I began their manufacture as I had no information as to why this or that color was unfit for marbling.

The numberless experiments I made to this end remained without results. It was an exceedingly great trial to my patience, but by the pertinacity with which I clung to my investigations, I, at last, succeeded in making the important discovery, that the real value of color for marbling purposes is its body and that the color itself, which is bound to the body either naturally or chemically, is of less importance. By this discovery every difficulty that I had so long experienced was cleared away and it was made manifest, why it had been impossible for the marbling art to become sufficiently popular.

From this time on I had a foundation, upon which to continue my investigations with greater surety. Finally I succeeded in finding that the colors named later on are good and useful marbling colors.

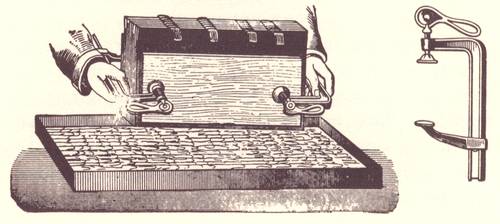

When we look over the different special branches of our trade, we find everywhere great progress,[86] which is even noticeable in the smallest workshop. Already, these wonderful achievements have become common property, only the art of marbling stood still on account of insufficient instruction and it has not made any progress in the last decade. This was due to a large number of men in our trade using mechanical marblers to avoid those obstacles, which had hitherto offered themselves in marbling.

The expectations which were placed on the mechanical marblers were not fulfilled, because, after a short use, and when not carefully kept clean, they became sticky from dust and color mixing so that they gave but very indifferent productions. The necessity of continually cleaning these mechanical marblers and their lack of uniformity are by no means recommendable properties.

Mechanical marblers should be retired to small book-binderies for use upon single books, where they are eminently in the right place, driving away the primitive sprinkled or starched edges.

The interest which was shown in mechanical marblers is a proof that all members of our trade, who use them, possess a liking for the marbling art and would be zealous friends of the same, if they but knew of the methods of marbling, that would give beautiful results without great difficulty.

To judge rightly the value of a new invention, we have only to see, whether it is introduced into the wholesale trade and is in continual use. This[87] is the best test of inventions and the only proper basis, upon which to judge them correctly. We find the mechanical marblers exclusively in the small shop, because they do not answer the demands of the wholesale manufacturer in any way.

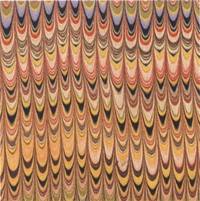

What the marbling art is able to offer, a person can only judge, who has seen exemplary edges and to whom marbling is not a stranger. No kind of edge, to which color is applied, can be compared to the effective splendor of marbled edges. In thousands of variations it imitates nature and delights the eye by its products. Although marbling has hardly reached the middle rung of the ladder of its development, it to-day stands unrivalled.

It is clear, that such an art should be fostered and nursed, if it is to grow to its full development. But here the investigation of one man is insufficient, a general interest is demanded and I hope, that this will be aroused by my work. After this slight diversion I will now begin to treat my real subject, the preparation of colors, and for that purpose, I will divide the marbling art into three important parts: the size, the color and the technical application.

The size and the technical application of the colors demand great attention and practice; on the other hand, the preparation of colors but labor. The colors are divided into two groups,[88] mineral and lake colors. In the lake colors, if they are good and strong, the coloring matter bound to the metallic oxides is equal to one-half of the whole weight of the color, therefore they can be prepared as good marbling colors without adding anything but gall. On the other hand, in mineral colors, which in a natural or chemical way are bound to bodies, the body weighs much more than the coloring substance and even if the metallic oxide is the real coloring substance, as is the case with ferric hydrate, the organic coloring matters derived from the vegetable or animal kingdom are preferable to the inorganic substances.

Why this is the case we shall see further on. In those coloring substances, which I have recommended as good marbling colors, the aggregate state of the body is amorphous and admits of the greatest divisibility. If such a coloring substance is ground in the finest way possible, the division of the body is a very great one, but an intimate union of the particles can never take place because first, the color is insoluble in water and, second, because the division (diminution) of a body has its limits. For this reason particles are isolated and lay loosely alongside of each other.

If a mineral color is mixed with the necessary amount of water and gall and thrown upon the size the drop expands to a round disc, which upon close investigation, is found to consist of numberless small dots. When such coloring stuffs are used,[89] the union of the particles must be brought about by some glutinous matter. This is unnecessary with lake colors, where the coloring matter is as heavy as the body to which it is bound, as all organic substances possess a sufficient quantity of glutinous matter to form a union of the particles.

The clearest proof of the correctness of my allegations we find in a mineral color, in which the metallic oxide was precipitated by a semi organic salt, I mean French blue, which without any substance unites the particles quite well if the washing of the precipitate after the blueing, was a perfect one.

The glutinous matter used with mineral colors must be entirely free of any acids as the smallest particle of acid, which in warm weather is often formed after long standing causes an isolation of the coloring matter in such a way, that it will become curdled when thrown upon the size. The best glutinous matter, that can be used, is dissolved isinglass or parchment-glue with gum tragacanth. As the first two named materials are expensive they can be replaced by fine gum arabic free of acid. Take 4/6 of an ounce of gum tragacanth let it swell in 1 pint of water and dissolve fully by boiling. In this way we obtain a glutinous mass, which is mixed by stirring with a thick solution of gum-arabic. This mixture is used to unite the particles of the body of mineral colors.

To grind the colors use a very smooth marble[90] slab, a roller and a palette knife, of wood or horn, as those of steel produce some change upon red colors.

The colors which are sold in the market are either in the form of grooved pieces, little cones, or powder. If the color is in pieces or little cones, it is first ground to powder in a dry state and is then mixed with a little water and from 10 to 15 drops of ox-gall to a thick paste. If a mineral color, add a piece of the glutinous matter the size of a nut, if, on the contrary, we have a lake color, the addition of water and gall is fully sufficient.

Now commences the grinding. With a muller you continually run in a circular motion over the color using a moderate pressure of the hands. After about two or three hours have elapsed the color will have the requisite fineness which is shown by its greasy, lacquer-lustrous appearance. During the grinding, move the color from time to time into the center of the marble with the palette knife and at the same time the adhering color is removed from the roller.

When the color is ground fine it must be diluted with water in a glass vessel and is then ready for use. Bottle tightly and keep it in a cool place, best in the cellar.

For grinding the colors and diluting the same, river or rain water should be used, of course, proportionately to the quantity of color so that the latter will not become too thin.[91]

The grinding of a color is done mostly by apprentices as the time of a journeyman would be too valuable. In most cases this part of the preparation gives the greatest trouble, since the colors are seldom gotten to that fineness necessary to marbling. This is easily explained as the grinding demands practice and a certain perseverance. From the point of view that time is money, the majority of book-binders concluded to use ready ground colors and this was profitable to them as they could buy them better and finer ground and much cheaper. But, even here, we sometimes find articles, which leave much to be desired, but which, in most cases, can be used.

For fifteen years I have been carrying on the manufacture of marbling colors and must always endeavor to keep pace with the progress of the chemistry of the colors as new products are continually offered for sale superior to the old in quality and beauty.

To give to the trade an idea of the manufacture of marbling colors I will briefly describe it.

It is a well known fact that among the great number of colors produced by a factory, there are always several, which excel by their especially good quality. I selected, therefore, from among the colors of several factories, those which were especially excellent and I now control an assortment, which hardly any single factory is able to supply.[92]

In preparing them 20 pounds are always ground at once. The color is ground upon a large marble slab with water and gall, to mineral colors the necessary glutinous matter is added and this is formed to a thick paste and then ground in the color-mill. The grinding in the mill is essential to obtain a homogeneous mass and then this paste is ground twice on a color grinding machine with three porphyry rollers in the finest possible way.

The color having been diluted is then prepared on a size, which is gotten up for this purpose and then preserved in stone jugs.

It is easily explainable, that the best results must be obtained with such a carefully and excellently prepared color, I, therefore recommend to my fellow marblers, the marbling colors manufactured by me.[A]

Before using, the color must always be well shaken and there must only be taken from the bottle enough necessary to one marbling process. The remaining portion of the color must not be poured back into the bottle, because if this be repeated several times the whole color would be spoiled by the gall.

A small quantity of, say from 40 to 50 drops of color, is sufficient for marbling the edges of even a large number of books, the colors must always[93] be kept tightly bottled up as they may be spoiled by being exposed to the air for a longer period.[94]