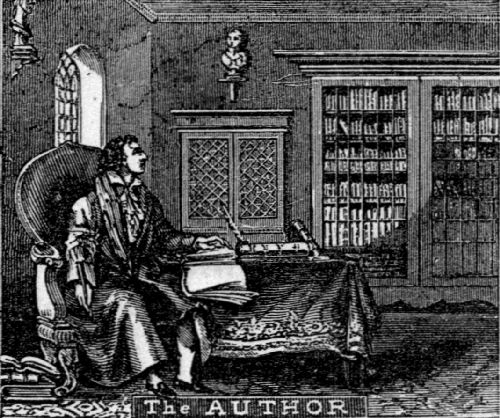

AUTHOR OF

"THE SYMBOLICAL SPELLING-BOOK," "THE SPELLER AND

DEFINER," AND "A PRACTICAL GRAMMAR."

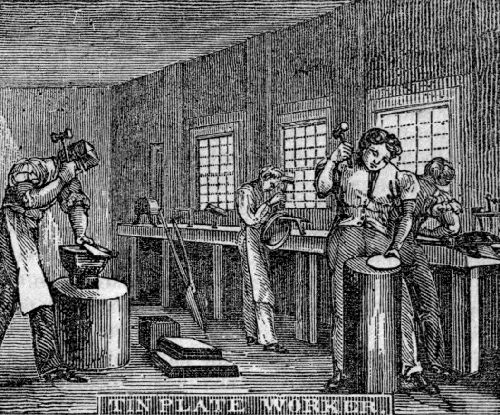

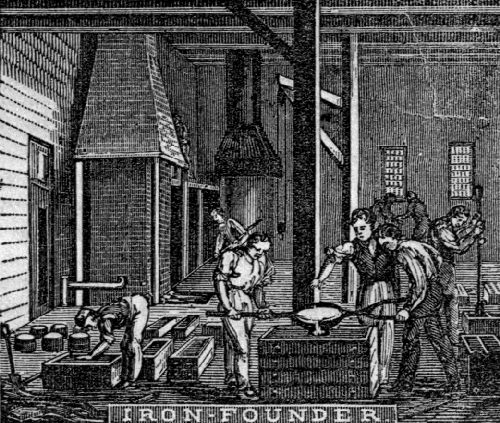

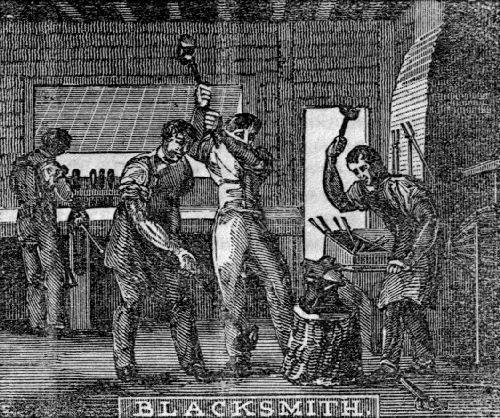

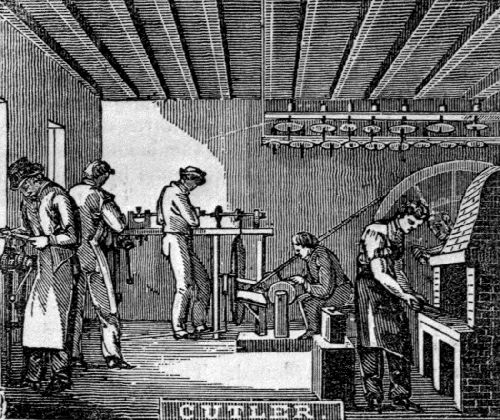

EMBELLISHED WITH EIGHTY-ONE ENGRAVINGS.

IN TWO VOLUMES.

NEW YORK:

HARPER & BROTHERS, PUBLISHERS.

1870.

Entered, according to Act of Congress, in the year 1841, by

Harper & Brothers,

in the Clerk's Office of the Southern District of New York.

1. The word Music, in its modern application, has reference to the science which treats of the combination of sounds. It is founded upon the law of our nature, that every leading passion has its peculiar tone or note of expression understood by all human beings. Music, therefore, may be supposed to have been practised in the earliest ages; although it must have been a long time before it arose to the importance of a science.

2. According to the Mosaic records, Jubal, one of the descendants of Cain, played upon musical instruments, many hundred years before the flood. In the early period of the nations of antiquity, and in fact[8] among all semi-barbarous people of later periods, the character of poet and singer were united in the same individual; and the voice was frequently accompanied by musical instruments. The oldest song which has descended to our times, and which is stated to have been exhibited in this manner, was that sung by Miriam, the sister of Moses, on the occasion of the passage of the Red Sea by the children of Israel.

3. The Hebrews employed music in their celebration of religious worship, which consisted, in part, in chanting solemn psalms with instrumental accompaniments. It was also used by them on the occasion of entertainments, as well as in the family circle. It reached its greatest perfection amongst the Jews, in the days of David and Solomon. It is supposed, that the priests of Egypt were versed in music, before the settlement of the family of Jacob in that country; but how far the Israelites were indebted to them for a knowledge of this pleasing art, is altogether uncertain.

4. Music was held in very high estimation among the Greeks, who attributed to it incredible effects. They even assure us that it is the chief amusement of the gods, and the principal employment of the blessed in heaven. Many of their laws, and the information relative to the gods and heroes, as well as exhortations to virtue, were written in verse, and sung publicly in chorus to the sound of instruments.

5. It was the opinion of the philosophers of Greece, that music was necessary to mould the character of a nation to virtue; and Plato asserts, that the music of his countrymen could not be altered, without affecting the constitution of the state itself. But in his time and afterwards, complaints were made of the degeneracy in this art, and a deterioration of national manners through its influence. The degeneracy probably consisted in its application to the expression[9] of the tender passions; it having been previously applied, in most cases, to awaken patriotic and religious feeling.

6. The invention of music and of musical instruments, as in the cases of most of the arts and sciences among the Greeks, was attributed by the poets to some of the gods, or else to individuals of their own nation. It appears, however, from their traditions, that they received this art, or at least great improvements in its execution, from Phœnicia or Asia Minor. It began to be cultivated scientifically in Greece about 600 years before the advent of Christ.

7. The Romans seem to have derived the music which they employed in religious services from the Etruscans, but that used in war and on the stage from the Greeks. At an early period of their history, it was a great impediment to the progress of the art, that it was practised only by slaves.

8. The Roman orators pitched their voice, and regulated the different intonations through their speech, by the sound of instruments; and on the stage, the song, as well as part of the play itself, was accompanied with flutes. Wind-instruments of various kinds, comprised under the general name of tibiæ, and sometimes the cythera and harp, accompanied the chorus. In all these applications of music, the Romans had been preceded by the Greeks.

9. The Hebrews employed accents to express musical tones, but most other nations of antiquity used letters of the alphabet for this purpose; and, as they had not yet conceived the idea of the octave or parallel lines, to express a variety of tones in a similar manner by the aid of a key, they required a number of notes that must have been exceedingly perplexing.

10. The Greeks are said to have had about one thousand notes, half of which were for vocal, and the other half, for instrumental music. All these were[10] expressed by placing the letters of their alphabet, or parts of them, in different positions. Accents were also used, partly by themselves, and in connexion with the letters.

11. The lines of a poem, set to music, were placed under the letters expressing the tones. The letters for the instrumental part were placed first, and under them those for the voice. The notes of the Greeks and Romans were not required to indicate the time in which they were to be pronounced, since in general the syllables of their language had a natural and distinct quantity. In the cases in which there was a liability to mistake, the syllables were marked with A, if long, and with B, if short.

12. The Romans expressed the fifteen chief tones of the Greeks with the fifteen first letters of the Latin alphabet; and these were reduced to seven, by Pope Gregory I., towards the end of the sixth century; so that the first seven capital letters were used for the first octave, the small letters for the higher octave, and the small letters doubled, for the highest octave. Parallel lines were soon after invented, on which the letters were written.

13. Musical sounds were expressed in this manner until the year 1024, when, according to some authors, Guido Aretine, a monk of Arezzo, invented points and rhombuses. He also introduced the use of five parallel lines, upon and between which his notes were written. The seven letters which had formerly been used as notes, now became clefs.

14. Still, however, the means of determining the duration of sound belonging to each note, without consulting the quantity of syllables in the verses to be sung, were yet to be provided. This desideratum was supplied by one Franco, a German of Cologne, who lived towards the end of the eleventh century. Some, however, attribute this improvement to John de Murs.[11] The division of one note into others of less value was invented, in the sixteenth century, by Jean Mouton, chapel-master to King Francis I. of France.

15. The knowledge of music, as a science, was preserved in Europe, after the overthrow of the Western empire, through the influence of the Church. The apostles, and Hebrew converts generally, had been accustomed to the sacred music of the Jews; and, on this account, it was easy to continue the use of the same psalms and hymns in the Christian Church.

16. Many of the Grecian and Roman melodies were also set to words adapted to Christian worship. In regard to the manner of singing, in the early days of the Church, it was sometimes in solo, sometimes in alternate strains, and at other times in chorus; in which the whole assembly joined, repeating what had been before sung or read. In the fourth century, with the view of securing the proper execution of this part of divine worship, precentors were instituted, who were considered regular officers of the Church.

17. Pope Gregory I., surnamed the Great, distinguished himself by establishing a new singing-school, which became a model for many others, in the western division of the Church. In consequence of these schools, the singing became more artificial; and this, together with the circumstance that the hymns were in Latin, which had become obsolete, at length excluded the people from any participation in this part of the public worship.

18. Gregory also made a selection of the existing songs of the Church, and introduced a chant, which, through his influence, and that of his successors, was at length extended throughout Europe. It received the appellation of the Gregorian chant from his name. It was also called the choral song, because it was sung by a choir. This chant is said to be the foundation of our present church-music.[12]

19. Music, in distinct parts, was not known until after the introduction of the improved method of writing music, invented, as before stated, by Guido Aretine and Franco. The development of harmony, in four parts, was assisted by the choral; but it was more particularly advanced by musical instruments, and especially by the organ. In the fifteenth century, music began again to be treated scientifically.

20. The Reformation produced great changes in the character of sacred music. Before that event took place, this part of religious worship was confined to a few fixed forms of texts, as in the mass, and this is still the case in the Roman Catholic Church; but the Protestants allow great variety both in the poetry and music. Luther's agency in the production of these changes was very considerable. During the seventeenth and eighteenth centuries, church music became continually more brilliant, and always more corrupted, by the intermixture of profane music.

21. In the sixteenth and seventeenth centuries, there grew up, at the courts of the European monarchs, the free chamber style, from which arose that which was afterwards used in the theatre. The opera, which originated with three young noblemen at Florence in 1594, has contributed especially to the splendor and variety of modern vocal music, the advancement of which is claimed particularly by the Italians, as that of the instrumental kind is claimed by the Germans and French.

22. The composition of music, and its execution either vocally or instrumentally, as well as the business of imparting a knowledge of it to others, are embraced in the employment of the musician; although it is seldom, that all these branches are practised by one and the same individual. Music is one of the fine arts, and, during the middle ages, was one of the branches of what was then considered a learned education.[13]

23. Since the scientific revival of music, the art has had so many distinguished professors, that we will not even attempt to give a list of their names. Their number was increased, and the art greatly perfected, by the singing-schools, called conservatories, established especially in Italy, either at the public expense, or by the liberality of individuals.

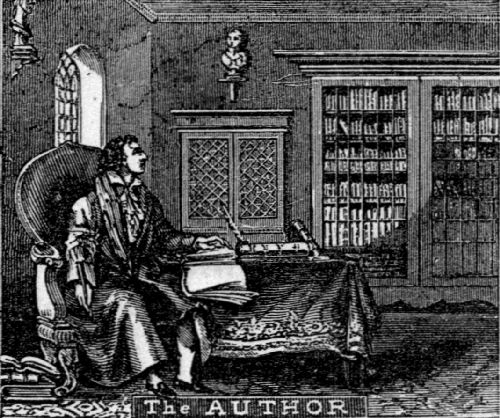

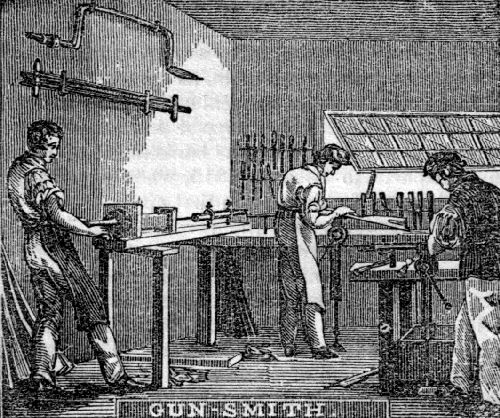

1. This artist unites in his business some of the operations of the cabinet-maker, turner, and brazier. He also is dependent upon the wire-drawer, and the tanner and currier, for some of his materials. So great, however, is the number of musical instruments, and so different their nature and construction, that the business of making them is divided into several branches, all of which are never pursued, or carried on, by one person. But, without reference to the several divisions of this business, we will proceed to mention or describe the principal instruments which are now in most common use.

2. The organ is the largest of all musical instruments, and, in its improved state, so complex that a mere description of it cannot be well understood. Nevertheless, we will endeavor to give the reader some idea of the general principles on which it is constructed.

3. The most essential and prominent parts of this machine are the wind-chest, the pipes, and the bellows. The former of these is an oblong box, made perfectly air-tight, and placed in a horizontal position. The top of this chest is perforated with several rows of holes of different sizes, and into these are inserted the pipes. Those for the higher notes are of a cylindrical form, and are made of a mixture of metals, chiefly of tin and lead; but those designed for the expression of the lowest notes of the base are made[14] of wood, in a square form. The dimensions of these pipes are regulated by a diapason, or scale.

4. There are as many of these rows of pipes, which are called stops, as there are kinds of tones in the organ; and to every row or stop is a plug, attached to a slide, which is denominated a register, and which is designed to regulate the admission of wind into the pipes. The pipes are also furnished with valves, which can be opened at pleasure, by means of keys similar to those of the piano-forte. Some organs have few, others have many stops; and, in order to regulate the force of sound, most church organs have two or three rows of keys, whereby a greater or less number of pipes may be filled, and the powers of the instrument may be controlled in what is called the small organ, or let loose, so as to become the full organ.

5. The fingering of an organ is similar to that of the piano-forte, so far as relates to the position of the keys; but, on account of the great number of holding notes in organ music, and the manner in which the sound is produced, the fingers are more kept down; whence it is considered injurious for performers on the piano-forte to practise on the organ, lest that lightness of touch, so necessary for the former instrument, be affected. It is hardly necessary to remark that, during the performance on the organ, the wind-chest is filled by means of the bellows.

6. The structure of the organ is lofty, elegant, and majestic; and its solemnity, grandeur, and volume of tone, have obtained for it a pre-eminence over every other instrument for the sacred purposes to which it has been applied. The largest organ known is in St. Peter's Church, at Rome. It has one hundred stops.

7. The church organ was probably suggested by the water organ of the Greeks, which was invented[15] five or six hundred years before our era. At what period, organs began to be employed in churches, cannot now be ascertained. By some, it is said that Pope Vitelianus caused them to be used in Rome in the seventh century. Others are of opinion, that they were not introduced until three hundred years later. But, be this as it may, the church organ was not in common use until the fourteenth century; and now it is very different in its construction from that of early times. It has received many additions and improvements since the beginning of the fifteenth century.

8. The hand or barrel organ consists of a moveable cylinder, on which, by means of wires, pins, and staples, are marked the tunes which it is intended to perform. These pins and staples, by the revolution of the barrel, act upon the keys within, and give admission to the wind from the bellows to the pipes. The hand organ is so contrived that the revolution of the barrel gives motion to the bellows.

9. There are several instruments belonging to the class of horns, all of which are made of brass or silver. Those of the latter kind of metal are by far the softest in tone, but brass is the material most commonly employed. The chief instruments belonging to this class are the trumpet, the French horn, the bugle, the Kent bugle, the trombone, and the bass-horn. The serpent seems to be the connecting link between the trumpet and the flute.

10. The instruments classed with the flute, are the common flutes of various keys, German flutes, and several kinds of flageolets. Nearly allied to these are the clarionet, the hautboy, and bassoon. The breath is applied to the flageolet through an ivory tube at the end; and, in the three last named instruments, a thin reed, capable of a free vibration, is a part of the mouth-piece.[16]

11. Of the instruments which produce musical sounds by the vibration of strings, there are a great number, of which the following are the principal;—the lyre, the harp, the guitar, the lute, the dulcimer, the harpsichord, the spinnet, the piano-forte, the violin, the violincello, and the base-viol. The strings of the three last are agitated with a bow; but those of this class first mentioned, are vibrated by the thumb and fingers, by some little instrument held in the hand, or by little hammers, moved by keys, as in the piano-forte.

12. The piano-forte is said to be the invention of Gottlieb Schroder, of Hohenstein, in Saxony, born in Dresden, about the year 1717. Before the introduction of this instrument, the clavichord, harpsichord, and spinnet, supplied its place. On all of these instruments complete harmony can be produced by a single performer, and the most difficult series of tones can be executed with rapidity, by means of a simple mechanism.

13. The piano-forte has been gradually improved, until it has become one of the most elegant instruments in the whole compass of musical practice. In firmness and strength of tone, the English piano-fortes formerly surpassed all others; but, within a few years, they have been equalled, and in some respects excelled, by those of American workmanship. The manufacture of this instrument constitutes the most extensive branch of musical instrument-making.

14. The instruments of percussion are the military drum, base-drum, kettle-drum, tabor, tamborine, and the triangle. The kettle-drum has received its name from its conformation. It has but one head, and is used in orchestres, and by the cavalry of modern armies, especially in Europe. The tabor has two heads, about three inches apart, and is beaten with one stick. The tamborine has one head, drawn over a hoop, to[17] which are attached small bells and bits of tin, to make a jingling sound. The time is beaten on the head with the hand.

15. The bag-pipe is a wind instrument of high antiquity among the northern nations of Europe; but it has been so long a favorite with the natives of Scotland, that it may be considered their national instrument. It consists of a leather bag and three pipes. The first of the pipes is that by which the droning noise is produced, the second emits wind from the bottom of the bag, and the third is that on which the music is made.

16. During the performance on the bag-pipes, the bag is placed under the arm, and worked like a bellows, while the notes are modulated as on a flute or hautboy, by stopping and opening the holes, nine in number, with the ends of the fingers and thumb. The bag is filled by means of the breath blown into it through a pipe. In Rome, at the time of Advent, the peasants of the mountains express their veneration for the Virgin by playing on this instrument before her image.

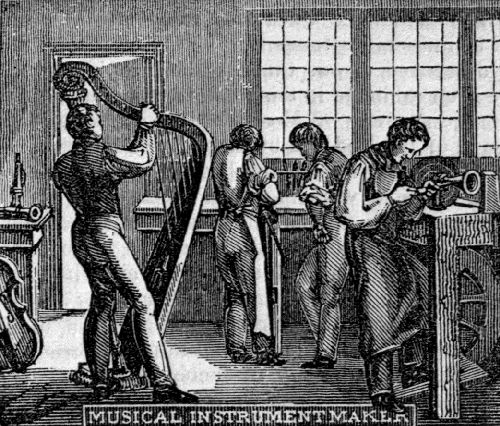

1. Sculpture is one of the fine arts. In its most extended sense, it includes not only modelling figures in clay, wax, and plaster of Paris, and carving them in wood, stone, and marble, but also casting them in bronze, lead, or iron, as well as enchasing and engraving.

2. The productions of this art are known under various denominations, but the principal are statues, busts, and bas-reliefs. The first of these are entire representations of men or animals in full relief; the second are upper parts of statues; and the last are figures more or less elevated from the body or ground on which they are formed.

3. The different degrees of elevation in reliefs, are expressed by various terms borrowed from the Italian.[19] A figure is said to be in alto relievo, or high relief, when but a small proportion of it is buried in the back-ground; in mezzo relievo, or middle relief, when one half of it is above the surface; and in basso relievo, or low relief, when but little elevated, like figures upon coin. Bas-reliefs are usually applied as ornaments to buildings, and to the pediments of statues.

4. The subjects of sculpture, with a few exceptions, are the same as those of painting; and the course of study essential to proficiency in either, is very similar. They both require much taste and practice, and a thorough knowledge of the human form and other objects frequently represented. The young artist begins with imitating the most perfect models of Grecian art; and, after having become well acquainted with their beauties, he proceeds to the imitation of nature.

5. When any considerable work in stone or marble is to be done, the sculptor forms a model of clay or wax, to guide him in the execution. The soft material is moulded to the proposed form with the hands and small instruments of ivory. The model is by far the most difficult part of the work, and it is here the genius of the artist is to be displayed. The process of copying the model in stone or in any other substance, is an operation merely mechanical, and can often be done by another person as well as by the scientific sculptor himself.

6. The model having been prepared, the block of marble or stone is marked at certain points corresponding to its chief elevation and concavities. The material is then wrought to the rough outline of the figure, by means of strong steel points, drills, and other perforating tools; and the asperities are afterwards removed with chisels, and with rasps and files of different shapes. When a high polish is required, it is produced by friction with pumice-stone, tripoli, and straw ashes.[20]

7. Marble and stone are carved in a similar manner; but the latter, being softer, can be wrought with less difficulty. The defects which may be met with in the stone are repaired with a composition of plaster of Paris and the same stone, pulverized and mixed with water.

8. Casts in plaster of Paris and bronze are taken from models, statues, busts, bas-reliefs, and living persons. To do this, it is necessary to form a mould from the subject to be copied. This is done by spreading over it some soft substance, which can be readily forced into all the cavities, and which will harden by drying or cooling. Plaster of Paris is the most usual material employed for this purpose.

9. When the subject is a bas-relief, or any other one-sided figure of a similar kind, the mould can be withdrawn without injury, in a single piece; but if it is a statue, or any other figure of like form, it is necessary to divide the mould into several pieces, in order to a safe removal. These pieces again united constitute a perfect mould. While the artist is forming the mould on the face of a living person, the latter breathes through tubes inserted into the nostrils.

10. In taking casts from such a mould, the internal surface is oiled to prevent adhesion, and then plaster mixed with water is poured into it through a small orifice. The mould is afterwards turned in every direction, that the plaster may cover every part of the surface; and when a sufficiency of it has been distributed to produce the requisite strength, and the plaster has acquired the proper solidity, the several pieces are removed from the cast, which, of course, is an exact resemblance of the subject on which the mould was formed.

11. Superfluous portions of the material, produced by the seams in the mould, are removed with suitable instruments, and applications of fresh plaster are[21] made, where necessary to repair blemishes. The cast is finished by dipping it in a varnish made of soap, white wax, and water, and afterwards rubbing it with soft linen. The polish produced in this manner, approaches that of marble.

12. The durability of plaster casts, exposed to the weather, is greatly increased by saturating them with linseed oil combined with wax or rosin. They are made to resemble bronze by the application of a soap composed of linseed oil and soda, and colored with the sulphate of copper and iron.

13. Moulds are, also, formed of a warm solution of glue, which hardens upon cooling, and such are called elastic moulds. This material is sometimes preferred on account of its more easy separation from irregular surfaces. For small and delicate impressions in bas-relief, melted sulphur is sometimes employed; also a strong solution of isinglass in proof spirits. All three of the substances last mentioned yield sharper impressions than plaster of Paris.

14. Statues designed to occupy situations in which they may be exposed to the weather and mechanical violence, are often made of bronze cast in moulds. The external portions of the mould are made on the pattern, out of plaster, brick-dust, and water. The mould is then covered on the inside with a coating of clay as thick as the bronze is intended to be, and the several pieces are afterwards put together, or closed. The internal cavity is next filled with a composition like that on the other side of the clay.

15. When this has been done, the several pieces forming the outside of the mould are separated, and the clay carefully removed. These having been again united, and the core or internal portion of the mould secured in its true position, the whole is bound with iron hoops, and thoroughly dried. The melted bronze is poured into the cavity formed by the removal[22] of the clay, through an aperture made for the purpose. The cast is afterwards rendered smooth by mechanical means.

16. It is conjectured with much reason, that sculpture was one of the arts practised before the deluge, and that it was transmitted to posterity by the survivors of that catastrophe. The first images were probably made for the purpose of perpetuating the memory of the dead; but, in process of time, they became objects of adoration. As the Chaldeans were unquestionably the first idolators after the flood, so are they supposed to have been the first who made progress in sculpture.

17. The first notice of this art in the Mosaic writings, is found in the passage relative to the teraphim, or idols, which Rachel, the wife of Jacob, carried clandestinely from her father's house; and the first persons mentioned in the Bible, as artists, are Aholiab and Bezaleel, who formed the cherubim which covered the mercy-seat, together with some other furniture of the tabernacle, and the sculptured ornaments of the garments of the high-priest.

18. From the same authority, we learn that the nations expelled from Canaan, by the Jewish people, were not ignorant of sculpture and painting; for Moses repeatedly commands the latter to destroy the pictures and molten images which might be discovered in their progress through the land. The Israelites crossed the river Jordan about 1500 years before the commencement of our era.

19. From this time to the end of the Jewish polity, we often meet in the Scriptures with indications of the fine arts; but the splendor of Solomon's temple, clearly points out the days of that prince as the period in which they had attained their greatest perfection in Judea.

20. The Babylonians, Assyrians, and Phœnicians,[23] became considerably skilful in sculpture, at a very early period, as we learn from early history, and some existing remains. The same remark is also applicable to the inhabitants of Hindostan. But writers have been more particular in noticing the style of design among the Egyptians, because the progress of the arts among that people is more easily traced, and because it is supposed to elucidate that of most other ancient nations.

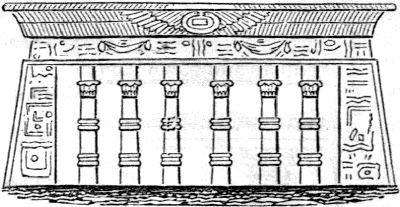

21. The chief objects of sculpture, among the Egyptians, were pillars, and other architectural ornaments, idols, the human figure, animals, and hieroglyphics, engraved in a kind of bas-relief on public edifices, and the forms of animals. Most of the great works of this nation are supposed to have been executed during and after the reign of Sesostris, who lived in the days of Rehoboam, king of Israel, or about 1000 years before the Christian era.

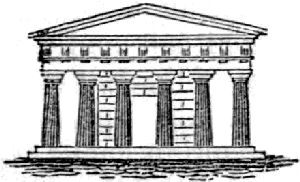

22. But of all the nations of antiquity, the Greeks were the most distinguished for sculpture. They derived the first rudiments of the art from the Phœnicians, or Egyptians, although they assert that they themselves were its inventors. Its existence, in a rude state, among that people, preceded that of letters or scientific architecture.

23. Dædalus, who lived about 100 years after Moses, was the first sculptor among the Greeks, of any notoriety. The statues made before his time, were stiff, formal figures, having the arms attached to the body, and the legs united, like the mummy-shaped productions of Egyptian art. He separated the legs of his statues, and placed them, and the upper extremities, in a natural position. He also was the first sculptor who made the eyes of his statues open. On account of these improvements, the Greeks said, that his divine genius made statues walk, and see, and speak.[24]

24. The disciples and imitators of Dædalus were called his sons, and artists, generally, Dædalides. Soon after this period, schools of design were established in the island of Ægina, at Corinth, at Sicyon, and in Etruria, in Italy: but it seems that no good representations of the human form were effected until near the time of Phidias, who was born 444 years before Christ.

25. This most distinguished of all the votaries of sculpture, flourished at or near the same time with the dramatic poets, Æschylus, Euripides, and Sophocles; the philosophers, Socrates, Plato, and Anaxagoras; and the statesmen and commanders, Pericles, Miltiades, Themistocles, Cimon, and Xenophon. This was the most refined period of Grecian history, and of all others, the most favorable in its moral and political circumstances, for the development of genius.

26. Phidias was the author of the ideal style, which, in the fine arts, may be defined, the union of the perfections of any class of figures. Among the distinguished productions of this artist, the colossal statues of Minerva and Jupiter Olympius, made of gold and ivory, have excited the greatest astonishment. The former, executed for the Parthenon of Athens, was twenty-six cubits in height; and the latter, for a splendid temple at Elis, was about the same height, although seated upon a throne.

27. The favorite disciples of Phidias, were Alcamenes, of Attica, and Agoracritus, of Paros; and at the same time with them, flourished Polycletus, of Argos, Miron, of Bœotia, and Pythagoras, of Rhegium. The beautiful style soon succeeded to the ideal; the authors of which, were Praxiteles and Scopas, who brought the art to the highest perfection,—since, in their productions, they united beauty and grace. After the days of these two artists, sculpture began to decline; although it continued to be practised with[25] considerable success, for some centuries after this period.

28. The great superiority of the Greeks in the art of sculpture, is ascribed to various causes; among which are classed, their innate love of beauty, and their own elegance of form, combined with the frequent opportunities of studying the human figure, in places where youth were in the habit of performing athletic exercises in a state of nudity. To these may be added, the practice of awarding to citizens a statue of their own persons, for eminent services to the state, and for excelling in exercises at the public games.

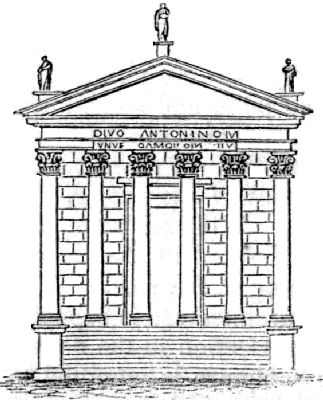

29. The fine arts were nearly extinguished in Greece, by the conquest of the Romans; who, with ruthless rapacity, seized upon, and transferred to their metropolis and villas, the superb works of taste with which the country abounded. By these means, however, a taste for the arts was produced among the Romans, who encouraged with great liberality the Greek artists who resorted in great numbers to their city.

30. The arts at length declined at Rome, and finally became nearly extinct in that city, soon after Byzantium was made the capital of the Roman empire, in 329 of the Christian era. The new capitol was enriched by the most valuable statuary of the old metropolis, and by a farther pillage of Greece. Artists were also encouraged with a munificence similar to that of former times; and many new subjects in painting and sculpture, in illustration of the Christian scriptures, were executed as embellishments for the sacred buildings of the city.

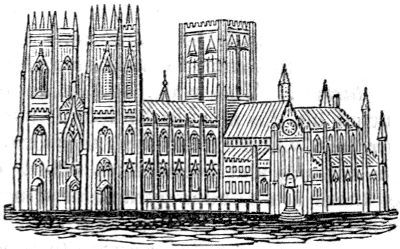

31. The art of sculpture necessarily declined during the time of the unsettled state of Europe, which followed the conquests by the barbarous nations. It, however, was not altogether lost, but was occasionally[26] practised, although in a very rude manner, in several kingdoms of Europe. In the eleventh century, after the terrors of the northern invasions had passed away, and the governments had become more established, the arts of design began a regular course of improvement, which has been denominated their revival.

32. This improvement was promoted by means of the frequent intercourse which had sprung up between the commercial cities of Italy and the Greek empire. In 1016, the Pisans founded their great church, called the Dome of Pisa; and, in its construction, they employed many noble pillars and other fragments of Grecian edifices. They also engaged upon the work several Grecian sculptors and painters, who exerted in their service the little skill which had come down from antiquity.

33. The specimens of ancient art thus introduced at Pisa, and the works of these artists, at length incited several Italians to emulation; among whom was Nicolo Pisano, who became the restorer of true taste in the arts, in the thirteenth century. At this period, the crusades had diffused such a zeal for the Christian religion, that magnificent churches were built in every part of Italy, in the designing of which, and in their decoration with sculpture, Pisano and his scholars were universally employed.

34. John Pisano, the son of Nicolo, was also an architect and sculptor of eminence; and by him was built, for King Charles, a castle, and several churches, at Naples. He also executed several pieces of sculpture, and superintended the construction of some edifices in Tuscany. This sculptor, who died in 1320, had several pupils, of whom Agostino and Agnolo Sanesi were the best sculptors of the time.

35. In 1350, an academy of design was formed at Florence by the union of several painters, sculptors,[27] and architects. This institution was called after St. Luke, whom tradition makes a painter by profession. The society was afterwards munificently patronised by the Medici, a noble and wealthy family of that city.

36. From this school, there soon proceeded a great number of skilful artists, among whom were the sculptors Lorenzo Ghiberti, Donatello, and Brunileschi; and after these, others perhaps still more distinguished, until it produced Michael Angelo Buonarotti, who, as a universal genius in the arts of design, has excelled every other artist, whether ancient or modern.

37. This great man was born in Florence, in 1474. His father, having discovered his talent for designing, made him a pupil of Dominic Ghirlandaio, who instructed him in the first principles of the art of drawing. He studied statuary under Bartoldo; and, in his sixteenth year, copied the head of a satyr in marble, to the admiration of all connoisseurs. On account of his great promise, he was liberally patronised by Lorenzo de Medicis, who, besides allowing him a pension, gave him a lodging in the palace, and a place at his table. After the death of this prince, he enjoyed the same favors from his son, Pietro de Medicis.

38. His reputation as an artist having been established at Florence, he was called to Rome by Julius II. From this time, he remained chiefly in the service of the popes, for whom he executed many inimitable works, both of sculpture and painting. He was also an architect of the first order; and, as such, was employed on St. Peter's Church, as well as on several other public edifices. He died in 1564, at an advanced age.

39. Sculpture, having been brought to as high a state of perfection as it was ever likely to be carried, began to decline in Italy, as it had done before, under similar circumstances, in ancient times; but as barbarism did not again occur to overwhelm it, it did not[28] entirely disappear. It continued to be practised, although in a very inferior degree, until it was again revived by Antonio Canoya, near the close of the eighteenth century.

40. The French nation, from its vicinity and intercourse with Italy, obtained from that country the means of improvement in every branch of the fine arts. Accordingly, native artists of considerable merit occasionally appeared. The kings of France, also, often employed Italian architects and sculptors on their great public works. In the reign of Francis I., Leonardo da Vinci, and two other artists from Italy, established a school of fine arts similar to that of St. Luke, at Florence; and the genius of the people, added to national munificence, have kept a respectable school of sculpture to the present time.

41. Considerable ability in sculpture has likewise been exhibited by native artists of Spain, Germany, Holland, England, and some other countries of Europe; but whatever skill has been displayed in any of these countries has been derived, in an indirect manner, at least, from Italy. In the United States, the fine arts have been cultivated with considerable spirit. An academy for this purpose has been established both in New York and Philadelphia, and a picture gallery has been connected with the Athenæum in Boston, in which the annual exhibition of paintings is respectable.

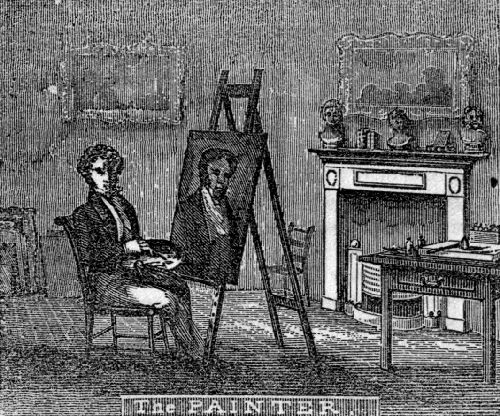

1. Painting is the art of representing visible objects, by means of lines and colors, on a plane surface, so as to produce the appearance of relief. It is justly ranked among the highest of that class of arts denominated fine, or liberal; and its tendencies and powers being similar to those of poetry, it is considered an employment worthy of men of the most exalted rank.

2. The theory and practice of this ingenious and delightful art, are divided by its professors into five distinct branches,——invention, composition, design, chiaro-scuro, and coloring. Invention relates to the choice of subjects to be introduced into a picture. It is this which gives the highest character to the artist, as it[30] affords the greatest opportunity to display the powers of his mind.

3. Composition regards the general distribution and grouping of figures, the choice of attitudes, the disposal of draperies, the situation of the scene itself, as well as the arrangement and connexion of the various parts of the scenery. Invention and composition are employed particularly in the first rough sketch of a picture.

4. Design refers to the expression of a proposed picture in simple contour, or outlines. It is applied in making the first rough sketch of the picture, whether in miniature or in its full size, as well as in the more accurate expression of the form of the figures, in its final finish. The artist, in making his design, is guided in drawing his lines by the rules of perspective, according to which he is able to foreshorten objects, and thereby diminish the space which they occupy, without giving them the appearance of diminished magnitude.

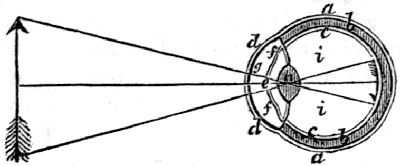

5. Perspective has been defined the art of delineating the outlines of objects on any given surface, as they would appear to the eye, if that surface were transparent, and the objects themselves were seen through it, from a fixed position. For example; when we look through a window at a mass of buildings, and observe that part of the glass to which each object, line, or point appears opposite, we find that their apparent position is very different from their real. A delineation of these objects on the glass, as they appear, would be termed a representation in perspective.

6. Correct perspective is the foundation of scientific painting; and, next in importance to this, is a proper distribution of light and shade. This branch of the art is called chiaro obscuro, or, when abridged, chiaro-scuro. The term is Italian in its origin, and[31] its literal meaning is clear and obscure. To the skilful management of light and shade, we are indebted for the strength and liveliness of pictures, and their relief, or the elevation which certain parts appear to assume above the plane upon which the objects are represented.

7. By the aid of perspective and chiaro-scuro, very good representations in one color are attained. Drawings in India-ink and crayons, as well as pictures taken from engraved plates and wood-cuts, are specimens of such productions. But a nearer approach to the appearance of nature, is made by the employment of colors analogous to those which are found to exist in the objects to be represented.

8. To produce various hues in painting, the artist employs coloring substances, which, either alone or by mixture, are analogous to them all; and, in their use, he is careful to apply them in such a manner, that the true colors remain distinct from the lights and shades necessary to produce the objects in relief. Artificial colors are divided into warm and cold. The former are those in which red and yellow predominate; the latter are blue, gray, and others allied to them.

9. Before coloring substances can be applied in painting, they must be reduced to extreme fineness, and be mixed with some tenacious fluid, to cause them to adhere to the surface on which they are to be spread. The fluid employed for this purpose, and the mode of applying the colors, have given rise to the different kinds of painting, of which the following are the principal: crayon, water-color, distemper, fresco, and oil-painting.

10. The most simple mode of applying the colors is by means of crayons. They are made of black lead, a species of chalk, or of a mixture of coloring matter with gum, size, or clay. For painting in water-colors,[32] the substances employed in communicating the tints are combined with gum, and formed into cakes or lozenges. When about to be used, they are dissolved in water, on glass or a glazed surface. The application in painting, is made by means of a camel's-hair pencil.

11. Painting in distemper is used for the execution of works on a large scale, such as stage scenery, and the walls of apartments. The coloring substances are mixed with water, rendered tenacious by size or solutions of glue, or by skimmed milk, increased in tenacity by a small quantity of thyme. Linseed or poppy oil often serves as a vehicle for the colors, in this kind of painting.

12. Paintings in fresco are executed on walls of plaster. The coloring matter mixed with water, being applied to the plaster while the latter is in a fresh state, sinks in, and incorporates itself with it, so as to become very durable. During the execution of the work, the plaster is applied to the wall in successive portions, no more being added at a time, than can be conveniently painted before it becomes dry. Works of this kind must be executed with great rapidity; and, on this account, patterns, called cartoons, are previously drawn on large paper, to guide the artist in his operations.

13. Oil painting derives its name from the mixture of the colors in oil. The oils used for this purpose are extracted from vegetables; and, on account of the rapidity with which they dry, are denominated drying oils. For most purposes, this mode of painting is decidedly superior to all others. It admits of a higher finish, as it allows the artist to retouch his works with greater precision. The colors also blend together more agreeably, and produce a more delicate effect. Oil paintings are executed on canvas, wood, or copper.[33]

14. Paintings are imitated with surprising elegance, by cementing together colored pieces of glass and marble, as well as those of wood. Representations by these means, are called Mosaics, or Mosaic paintings. The cause of their having received this appellation cannot be ascertained. Some, without much reason, attribute the origin and name of this branch of the art to Moses. Others suppose that works of this kind have been thus denominated, because they were first employed in grottoes dedicated to the Muses.

15. Drawings and paintings are divided into classes, according to the nature of the objects represented, the principal of which are historical, architectural, landscape, marine, portrait, still life, grotesque, botanical, and animal. The subordinate divisions of these branches are very numerous.

16. The propensity to imitation, so deeply rooted in the human mind, is the foundation of the arts of design; and there can scarcely be indicated a lengthened period in the history of man, in which it was entirely inactive. It may have first been accidentally exhibited in tracing the form of some object in the sand; or resemblances in sticks and stones, may have originally suggested the idea of imitations by means of lines and colors.

17. Although painting and sculpture may be supposed to have existed, at least in a rude state, at a very early period, and even before the deluge, yet the reign of Semiramis, queen of Assyria, 2000 years before Christ, is the earliest to which authentic history extends. Diodorus Siculus relates that the queen, having thrown a bridge across the Euphrates, at Babylon, erected a castle at each end of it, and inclosed them with walls of considerable height, with towers upon them. The bricks of which they were constructed, were painted before they underwent the[34] fire, and were so put together, that single figures, and even groups of them, were represented in colors.

18. This author supposes also, that the arts had attained nearly an equal degree of cultivation about the same time in Egypt, sculpture, as best serving idolatrous purposes, being in both countries much in advance of the sister art of painting. But, in neither country, was painting or sculpture brought to a great degree of perfection.

19. In Egypt, independent selection of objects, and variety of exhibition, never appear to have been much regarded. When a specific form of character had been once adopted, so it remained, and was repeated unchanged for ages. Little action, and no expression, was given to figures. The chief employment of the Egyptian artists, seems to have been the painting of the chests of mummies, and the ornaments on barges and earthenware.

20. Painting, in the early days of its existence, was employed chiefly in the exhibition and preservation of historical facts; and, wherever it remained faithful to these objects, it was obliged to sacrifice the beautiful to the significant. Only in those countries where alphabetical writing existed, could painting elevate itself to a fine art.

21. The Pelasgi, who expelled or subdued the earlier inhabitants of Greece, and colonized that country, probably brought with them the rudiments of this art; and it at length grew up with its sister arts. In some of the stages of its progress, this intelligent people, no doubt, received useful hints from other countries, and especially from Egypt; yet they finally surpassed all the nations of antiquity in this branch of art.

22. The Greeks, with singular care, have preserved the names of their artists from the earliest periods of their practice. Ardens, of Corinth, Telephanes and Crato, of Sycion, and some others, are noticed as[35] such, when painting had advanced no farther than the mere circumscription of shadows by single lines.

23. The different kinds of painting, as marked by the successive stages of the art among the Greeks, are as follows; 1. The skiagram, or drawing in simple outlines, as in the circumscriptions of shadows. 2. The monogram, including both the outlines and others within them. 3. The monochrom, or picture in a single color. 4. The polychrom, or picture of many colors.

24. Although the names of the Grecian artists were carefully preserved, the time in which they lived was not distinctly marked until the 16th Olympiad, or 719 years before the commencement of our era. At this time, Candaules, king of Lydia, purchased a picture called the Battle of the Magnetes, for which he paid its weight in gold, although painted on boards. The name of the fortunate artist was Bularchus.

25. Notwithstanding the fame of this picture, Aglaophon and Polygnotus, of Thasos, who flourished 300 years after this period, were the first eminent painters. Polygnotus is said to have been the first who gave a pleasing air to the draperies and head-dresses of females, and to have opened the mouth so far as to exhibit the beauty of the teeth.

26. Still, painting is considered to have been in an inferior state, until the appearance of Timanthes, Parrhasius, and Zeuxis, who flourished about 375 years before Christ. These again were surpassed by their successors, Protogenes, Pamphilus, Melanthius, Antiphilus, Theon, Euphranor, Apelles, and Aristides, who carried the art to the greatest perfection to which it attained in ancient times.

27. Of the preceding list of artists, Apelles was the most famous, especially as a portrait painter. He was the intimate friend of Alexander the Great, who[36] would never permit any other person to paint his likeness. His most celebrated painting, was this prince holding the lightning with which the picture is chiefly illuminated. By a happy application of perspective and chiaro-scuro, the hand with the lightning seemed to project from the picture.

28. From the time of these great masters, painting gradually declined, although the art continued to be practised by a succession of eminent men, who contended against the blighting influence of the luxury and the internal broils of their countrymen. But soon after Greece became subject to the Roman power, the practice of the fine arts nearly ceased in that country.

29. Before the foundation of Rome, the arts were cultivated, to some extent, in Etruria and Calabria; but the first Roman painter mentioned in history, was Fabius, a noble patrician, who painted, in the year of the city 450, the temple of the goddess Salus, and thereby obtained for himself and family the surname of Pictor. Yet the citizens do not seem to have profited by this example; for no other painter appeared among them until 150 years after that period. At this time, Pacuvius, the poet, amused himself, in the decline of life, with painting the temple of Hercules.

30. They were thus inattentive to the cultivation of this, as well as of the other fine arts, because they considered warfare, and the arts which tended directly to support this interest, as alone worthy of the attention of a citizen of their republic; and painting, even after the time of Pacuvius, was considered effeminate and disgraceful. Rome, therefore, cannot be said, at any time, to have produced a single artist who could approach the excellences of those of its refined neighbors, the Greeks.

31. They, however, having ornamented their metropolis[37] and villas with specimens of the arts plundered from the cities of Greece and Sicily, began, at length, to appreciate their excellences; and finally, under the first emperors, they encouraged, with great munificence, the Greeks who resorted to their city for employment.

32. But, both sculpture and painting, as well as architecture, declined with Roman civilization. Still, they continued to exist, especially in the Byzantine or Eastern empire, although in a very inferior state. The art under consideration was preserved chiefly by its application to the purposes of Christianity. It was revived in Italy, in the beginning of the twelfth century, by means of several Grecian artists, who had been employed to ornament the churches, and other edifices at Pisa, Venice, and Florence.

33. The works of Apollonius, one of these Greeks, excited in Giovanni Cimabue a spirit of emulation; and, having been initiated into the practice of the art, he executed a picture of the Virgin Mary, as large as life, for a church dedicated to her, at Florence. This production excited enthusiastic delight in his fellow-citizens, who carried it in procession, with the sound of trumpets, to its place of destination, and celebrated the day as a public feast.

34. Encouraged by this applause, Cimabue pursued the art with ardor; and, although considered a prodigy in his time, his utmost efforts failed to produce tolerable specimens of the art. He, however, far excelled his immediate predecessors; and, by introducing more correct proportions, by giving more life and expression to his figures, and by some other improvements, he became the founder of the art as it exists in modern times. He was born at Florence, in 1240, and died at the age of sixty.

35. The favorite pupil of Cimabue, was Giotto, whom he raised from a shepherd to be a painter; and[38] by him the art was still more relieved from the Greek imperfections. He abandoned the use of labels as means of distinguishing the different figures of a picture, and aimed at, and attained to, real expression. He marked out to the Italians the course in which the art should be pursued, as Polygnotus had done to the Greeks near 1800 years before; although, like him, he failed in fully exemplifying his principles.

36. His abilities procured him the patronage of Pope Boniface VIII., who employed him at Rome. From this time, the art of painting became attached to the papal dignity, and few succeeding pontiffs have neglected its use. The skill and celebrity of this ingenious artist excited great emulation, and the arts having obtained an earnest of profit and honor, no longer wanted skilful professors or illustrious patrons.

37. In 1350, fourteen years after the death of Giotto, his disciple, Jacopo Cassentino, and nine other artists, founded the Academy of St. Luke, at Florence. This was a grand epoch of the arts; as from this institution arose a large display of talent, increasing in splendor until, within 150 years, it gave to the world, Masaccio, Leonardo da Vinci, Michael Angelo Buonarotti, and Raphael, besides others of great ability.

38. The art advanced but little after the time of Giotto, until the appearance of Masaccio. Under the hand of this great master, painting is said to have been greatly improved; and it was to him, that the artists who succeeded were indebted for a more sure and full direction of the course in which they ought to proceed. He was born in 1402, and died in 1443.

39. Leonardo da Vinci, who was born about two years after the death of Masaccio, brought the art to still greater perfection; and being endowed with uncommon genius, all the arts and sciences did not seem to afford a field sufficient for the exertion of his talents.[39] He grasped at all, and succeeded far better than his predecessors in everything he undertook; but he wasted much of his time in experiments. Had he confined his great powers to the art of painting, he would probably have never been exceeded.

40. About the year 1410, oil came to be used as a vehicle for paints. It seems to have been first applied to this purpose in Flanders, by John Van Eyck, of Brussels; or it was, at least, first used by him successfully. The first hint of its utility in this application is thought, with reason, to have been obtained from its use as a varnish to pictures painted in water-colors.

41. The art of painting was introduced into Flanders about the time of Giotto, by several Flemings, who had been to Italy for the express purpose of learning it. It was also diffused in practice, about the same time, in Germany; and a particular style of the art grew up in each of these countries. But it was in Italy alone that the art may be said to have flourished in a high state of cultivation; and even there, the principal productions originated from artists of the Florentine school.

42. The art of painting was perfected, perhaps, as far as human ability can carry it, in the first half of the sixteenth century, by Michael Angelo Buonarotti, Raphael, Titian, and Correggio; although it cannot be said that all its excellences were united in the productions of any one of these distinguished professors. Such a union has never yet been displayed, nor can it hardly be expected.

43. The art was essentially aided in its progressive stages of advancement by the liberal patronage of the family of the Medici, at Florence, and by the pontiffs, at Rome. Angelo and Raphael were both employed at Rome by Julius II. and Leo X., as well as by others who succeeded them in the papal chair,[40] in ornamenting the palaces and sacred buildings. Their productions have never been exceeded in any country, and they still remain the objects of careful study by artists of this profession.

44. Titian was also liberally patronised at Rome, and in other parts of Italy, as well as in Spain and Germany, chiefly as a portrait and landscape painter. The unrivalled productions of these great masters, however, were fatal to the art in Italy, since their superior excellence extinguished emulation, by destroying the prospect of equal or superior success.

45. The flourishing state of the art in Italy, for so long a period, might be expected to have produced a taste for its cultivation in other parts of Europe; but this was the case only to a limited extent. No other countries have yet been particularly distinguished for artists in this branch of the fine arts, except Flanders and Holland; and these were chiefly indebted for the distinction to Peter Paul Rubens, of Antwerp, who was born at Cologne, in 1577, and to Paul Van Rhyn Rembrandt, who was born in 1606, in his father's mill, near Leyden. Some of the scholars of these masters were eminent painters. Anthony Vandyck, a pupil of the former, in particular, is said to have never yet been equalled as a portrait-painter.

46. Very little is known of the art in Spain, until about the year 1500, although it is supposed to have been cultivated with some success before that time. The examples which were left there by Titian produced a favorable impression, and several native artists of considerable eminence afterwards appeared; but the art became nearly extinct in the following age.

47. The proximity of France to Italy, and the employment of Leonardo da Vinci and other eminent artists of Italy by Francis I., together with the establishment of a school of fine arts, as stated in the preceding[41] article, might have been expected to lay the foundation of exalted taste in this kingdom. Nevertheless, the only French painters whose names have come down to us with any pretensions to excellence for one hundred and fifty years, were Jean Cousin, Jaques Blanchard, Nicholas Poussin, and Charles Le Brun. The last, although inferior to Poussin, is at the head of the French school of painting.

48. The successors of Le Brun were not wanting in ability, yet, with a few exceptions, they failed in reaching an enviable eminence in the art, on account of their servile imitation of the false taste of their popular model. The fantastic style of Le Brun became unpopular in France some time previous to the revolution in that country; and another, of an opposite character, and by artists of other nations thought to be equally distant from true taste, has been since adopted.

49. Very little is known of the state of the fine arts in England until the time of Henry VIII., who encouraged the abilities of Hans Holbein, an eminent painter from Switzerland. But painting and sculpture, and particularly the former, having become intimately interwoven with the religion of the Church of Rome, fell into disrepute in England after the change of opinion on this subject in that country. They, however, began to revive in the eighteenth century, and England and English America have since produced some eminent painters, among whom are Hogarth, Reynolds, Opie, West, Copley, Trumbull, and Peale.

Engraving is the art of cutting letters or figures in wood, metals, or stone. It was practised in very ancient times, and in different countries, for the purposes of ornament and monumental inscription; but the idea of taking impressions on paper, or on any other substance, from engraved surfaces, is comparatively modern.

1. The Chinese are said to have been the first who engraved figures or letters on wood, for the purpose of printing. The precise time at which they commenced the practice, is totally unknown; but a book printed by them in the tenth century, is now extant. It is thought by some antiquarians, that the Europeans[43] derived the art from the Chinese, through the Venitians, who traded in that part of the world earlier than any other Europeans.

2. This opinion is somewhat probable, from the circumstance that the tools employed by the early engravers in Europe, are similar to those used in China; and also, like the Chinese, they engraved on the side of the grain. However this may be, it is certain that the art was practised in various parts of Europe in the fourteenth century. The earliest subjects executed, were figures of saints, rudely engraved in outline. The prints taken from them were gaily colored, and sold to the common people as original paintings. The principal persons engaged in this traffic were monks, to whom the art was confined for a considerable time.

3. At length, larger subjects, with inscriptions in imitation of manuscript, were executed. The success of these prints gave rise to a more extensive application of the art. Scriptural subjects, of many figures, with texts of scripture, were engraved, and impressions were taken from them on one side of the paper, two sheets being pasted together to form a leaf. Entire sets were bound up together, and thus were formed the first printed books, which, being produced entirely from wood-cuts, are known by the name of block-books. These books made their appearance about the year 1420.

4. One of the earliest of these productions is denominated "The Apocalypse of St. John;" another, "The Poor Man's Bible." But one of the latest and most celebrated, is called "The Mirror of Salvation," published in 1440. Part of the text was printed from solid blocks, and part, from moveable wooden types. From this fact, it is easy to discover the origin of printing. After this, most, if not all, of the books, were printed from moveable types; but, as they were[44] embellished with wood cuts, the demand for such engravings was very much increased, although they were, at first, by no means elegant.

5. Near the close of the fifteenth century, the art began to assume a higher character, principally by the talents of Michael Wolgermuth and William Pluydenwurf. Albert Durer made still greater improvements, and, in 1498, published his celebrated Apocalypse of St. John, printed from folio blocks. Other celebrated engravers succeeded him in the sixteenth century, which may be considered the era when wood engraving was at its highest point of elevation. After this, the art declined, and was considered of little importance, until it was revived in 1775, by the distinguished William Bewick, of Newcastle, England. It is still practised, especially in England and the United States, in a manner which reflects credit on the ingenuity of the age.

6. The earlier artists operated on various kinds of wood, such as the apple, pear, and beech; but these, being too soft, are now used only for calico-printing and other common purposes. Box-wood, on account of its superior texture, is used for every subject that can be termed a work of art. That from Turkey is the best.

7. The engravers, in the infancy of the art, prepared the wood as the common block-cutters now do. The tree was cut the way of the grain, in planks, and of course they engraved on the side of the grain, as upon a board. This mode of preparation enabled them to execute larger subjects. The engravers now prefer the end of the grain, and therefore cut the log transversely.

8. The end on which the engraver is to exert his skill, is planed and scraped, to render the surface smooth, and the block having been cut to the proper size, the drawing is made upon it in India ink, or with[45] a lead-pencil. The block is now ready for the artist who, in executing the work, holds it with one hand, on a cushion made of sand and leather, while, with the other, he cuts away the superfluous wood. The part intended to make the impression in printing, is left standing.

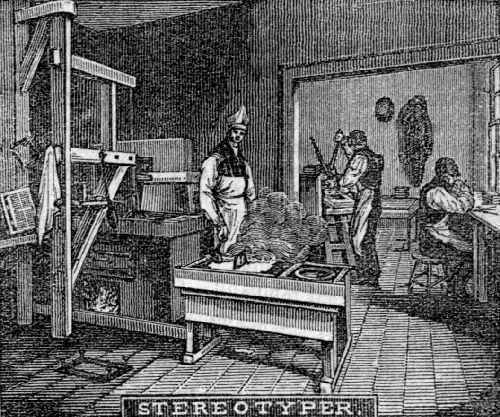

9. Wood engravings, well executed, are scarcely inferior to those of copper and steel, and, for many purposes, they are preferred. They are remarkably convenient, since they can be inserted into a page of types, where illustrations or embellishments may be required, and be printed without separate expense. They will also bear a great number of impressions—generally 100,000. In this respect, they are decidedly superior to metallic plates. They can likewise be multiplied indefinitely by the process of stereotyping.

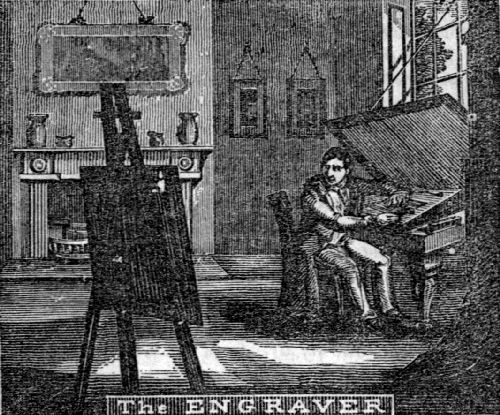

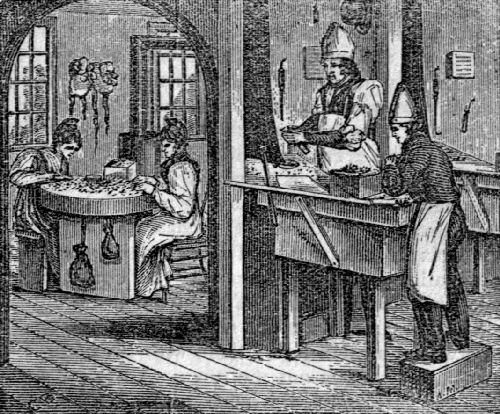

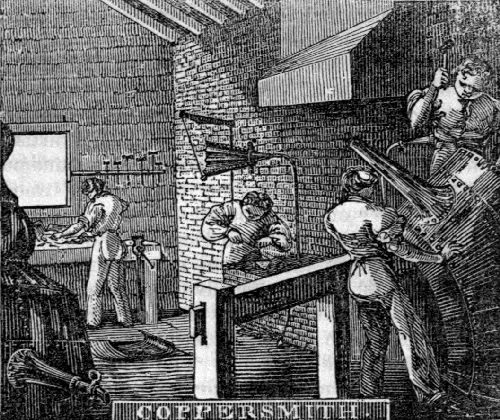

1. The engravers on metallic surfaces are termed copperplate engravers, not because copper is the only metal on which they exert their skill, but because it is the one on which they usually operate. The plates are prepared for the artist by the coppersmith, by rubbing them with brickdust and charcoal, after having cut them of a proper size from sheets of copper.

2. The instruments employed by this artist are few and simple, the principal of which are, the graver, the dry-point, the scraper, and the burnisher. The graver is a small bar of steel, of a square or lozenge form, and, with the short handle into which it is inserted, about five inches in length. One of the angles of the bar is always on the under side of the instrument, and the point is formed by bevelling the end from the upper side, or angle. The square form is used for broad strokes, and the lozenge for fine ones.

3. The dry-point, or needle, is a steel wire with a[46] long cylindrical handle; or it is simply a wire of sufficient length and size to be used without a handle. The scraper has nearly the form of a triangular pyramid; and the cutting part, which has three edges, is two or three inches long. The burnisher has a form nearly conical, and, without the handle, is about three inches long. The last two instruments are frequently made of the same piece of steel, properly forged at each end. In such case, the middle part of the steel is the handle by which they are held.

4. Of engraving on copper, the following are the principal varieties or styles: 1. Line engraving; 2. Stippling; 3. Etching; 4. Mezzotinto; 5. Aquatinta. For the purpose of conveying some idea of these different branches, we will describe them under distinct heads.

5. Line engraving. The first thing done, in this species of engraving, is to transfer to the plate an exact copy of the outlines of the design to be executed. In accomplishing this, the plate is moderately heated, and covered with a thin coating of white wax. A piece of transparent paper is then laid over the design to be copied, and traced in outline with a black-lead pencil. The outline thus sketched is turned down upon the coating of white wax, and the whole is subjected to the action of a rolling-press; or it is kept for a while under heavy weights. By the application of this pressure, the lines are transferred from the paper to the wax on the plate in a reversed position, which is necessary to make the impression of the finished plate resemble the original.

6. The pencil-marks on the wax having been lightly traced on the copper with the dry-point, and the wax having been melted off, a perfect outline is found on the plate. Small subordinate parts of the design are transferred to the plate in the same manner, except that the transparent paper is brought in forcible[47] contact with the waxed surface by means of the burnisher.

7. At this stage of the process, the artist commences the use of the graver. While operating with this instrument, he holds the handle in the palm of his hand, and pushes the point forward with a firm and steady motion, until a line is produced by a removal of a portion of the metal. By a succession of such strokes, judiciously applied, the work is completed. The burrs, or little elevations of the copper, left by the graver on each side of the lines, are removed by means of the scraper and burnisher. Mistakes or blemishes are erased from the plate, either with the burnisher, or by friction with charcoal.

8. Stippling. The second mode of engraving is called stippling. This resembles the last method in its process, except that the effect is produced by means of minute punctures or excavations, instead of lines. These are made either with the dry-point or graver. When produced by the former instrument, they are of a circular form; when by the latter, they are rhomboidal or triangular. This style of work is always more slow, and consequently more expensive, than engraving in lines. It has, however, some advantages in the softness and delicacy of its lights and shades, and the prints struck from it approach more nearly to paintings.

9. Etching. This mode of engraving is far more easy than any other, being performed chiefly by chemical corrosion. In fact, any person who can draw, may etch coarse designs tolerably well, after having learned the theory of the operation. To perform it, the plate is first covered with a thin coating of some resinous substance, upon which the acid employed can have no action. The design, and all the lines it requires, are next traced on the plate with steel points, called etching needles, which are instruments similar to the dry-point.[48]

10. The second part of the process is the corrosion, or, as it is technically called, biting in. This is effected by pouring upon the design a quantity of diluted nitric acid, after having surrounded the edges of the plate with a wall of soft wax, to prevent the escape of the fluid. A chemical action immediately takes place in all the lines or points where the copper has been denuded by the needle. After the first biting has been continued long enough, in the judgment of the operator, the acid is poured off, and the plate examined.

11. The light shades, if found sufficiently deep, are then covered with varnish, to protect them from further corrosion. The biting is then continued for the second shades, in the same manner, and afterwards, for the third and succeeding shades, until the piece shall have been finished. The plate having been cleaned, and carefully examined by the aid of a proof impression, the deficiencies which may be discovered are supplied with the graver.

12. Mezzotinto. In the production of this kind of engraving, the whole surface of the plate is first roughened, or covered with minute prominences and excavations too small to be obvious to the naked eye; so that an impression taken from it, in this state, would present a uniform velvety, black appearance. This roughness is produced mechanically by means of a small toothed instrument, called a cradle.

13. When the plate has been thus prepared, the rest of the process is comparatively easy. It consists in pressing down or rubbing out the roughness of certain parts of the plate, with the burnisher and scraper. Where strong lights are required, the plate is restored to a smooth surface; for a medium light, it is moderately burnished, or partially erased; and, for the deepest shades, the ground is left entire, and sometimes etched, and corroded with nitric acid.[49] Impressions from mezzotinto plates approach more nearly to oil paintings than any other prints. This kind of engraving was invented by Prince Rupert, in 1649.

14. Aqua-tinta. There are several methods by which this kind of engraving can be executed; we, however, will describe the one which seems to be the most simple and obvious. The outline of the picture having been etched or engraved in the usual manner, the surface of the copper is sprinkled equally with minute particles of rosin. This dust is fixed to the surface by heating the plate until the rosin has melted.

15. The ground having been thus laid, the parts of the plates not intended to be occupied by the design are stopped out by means of thick varnish. The plate is now surrounded with a wall of wax, as for etching, and diluted nitric acid is poured upon it. A chemical action immediately takes place, by which the surface exposed between the resinous particles is minutely excavated.

16. The lighter shades are stopped out at an early stage of the process, and the biting in is continued for the darker ones. After the plate is judged to be sufficiently corroded, it is cleansed, and an impression is taken on paper. The process is finished by burnishing the shades, to give them greater softness, and by touching up the defective parts with the graver.

17. This mode of engraving is well adapted to light subjects, sketches, landscapes, &c.; but, owing to the fineness of the ground, the plates wear out rapidly, and seldom yield, when of ordinary strength, more than six hundred impressions. The prints taken from such plates bear a strong resemblance to paintings in Indian ink, or to drawings in black-lead pencil. Aqua-tinta is the most precarious kind of engraving, and requires much attention on the part of the artist. It was invented by a Frenchman, named Leprince,[50] who, for a time, kept the process a secret, and sold his impressions for original drawings.

18. Steel engraving. The process of engraving on steel plates differs but little in its details from that on copper plates; and the chief advantage derived from this method, arises from the hardness or toughness of the material, which renders it capable of yielding a greater number of impressions.

19. This mode of engraving was first practised, in England, by the calico-printers; but steel was first employed for bank-notes, and for common designs, by Jacob Perkins, of Newburyport, Massachusetts; and by him, in conjunction with Asa Spencer, of New-London, and Gideon Fairman, of Philadelphia, the use of steel in this application was generally introduced, not only in the United States, but also in Great Britain, some time before the year 1820.

20. The plates are prepared for the engraver from sheets of steel about one-sixth of an inch in thickness. A plate cut from a sheet of this kind is first softened by heating it with charcoal, and suffering it to cool gradually in the atmosphere. It is next planished, or hammered on a peculiar kind of anvil, to make it perfectly level, and afterwards ground on one side upon a grindstone. The operation is completed by polishing it with Scotch stone and charcoal. When steel was first substituted for copper, it was hardened before it was used in printing; but it is now used in its soft state, as it comes from the hands of the artist.

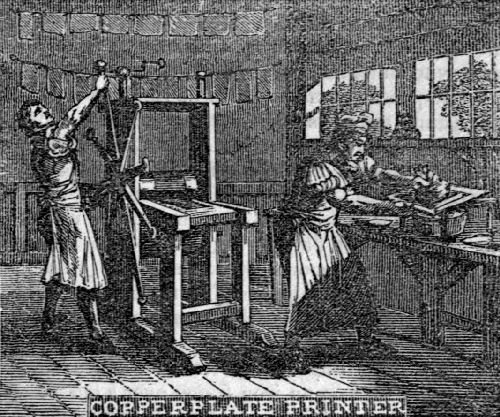

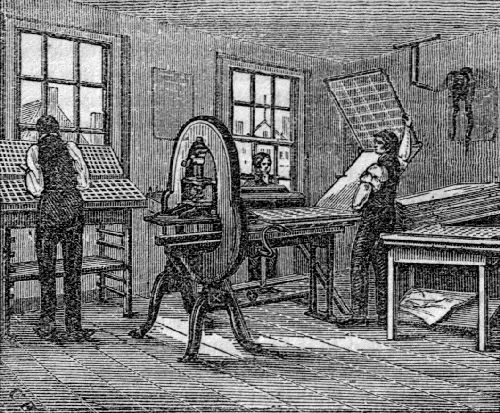

1. The copperplate-printer takes impressions on paper from engraved plates by means of a rolling press. This machine, together with some of the operations in its application, are well exhibited in the above picture.

2. The period at which the practice of printing from engraved plates commenced, cannot be ascertained with any degree of certainty. The Dutch, the Germans, and the Italians, contend for the honor of introducing it; but the weight of testimony seems to be in favor of the claims of the Italian sculptor and goldsmith, Tommaso Finiguera, who flourished at Florence, about the middle of the fifteenth century.

3. It is stated that this artist, accidentally spilling some melted brimstone on an engraved plate, found,[52] on its removal, an exact impression of the engraving, marked with black, taken out of the strokes. This suggested to him the idea of taking an impression in ink on paper, by the aid of a roller. It is hardly necessary to state, that the experiment succeeded. Copperplate-printing was not used in England until about 150 years after its first employment at Florence, when it was introduced from Antwerp, by Speed.

4. The ink used in this kind of printing is made of a carbonaceous substance, called Frankfort black, and linseed or nut oil. Oil is used, instead of water, that the ink may not dry during the process; and it is boiled till it has become thick and viscid, that it may not spread on the paper. The materials are incorporated and prepared with the stone and muller, as painters prepare their colors.

5. In taking impressions from an engraved plate, it is first placed on an iron frame over a heated stove, or over a charcoal fire in a furnace, and while in this position, the ink is spread over it with a roller covered with coarse cloth, or with a ball of rubber made of the same material, and faced with buckskin. The heat renders the ink so thin that it can penetrate the minute excavations of the engraving. The plate having been thus sufficiently charged, is wiped first with a rag, then with the hand, until the ink has been removed from every portion of it, except from the lines of the engraving.

6. The plate is next placed on the platform of the press, with its face upwards, and the paper, which has been previously dampened, is laid upon it. A turn of the cylinders, by means of the arms of the cross, carries the plate under a strong pressure, by which portions of the paper are forced into all the cavities of the engraving. The ink, or part of it, leaves the plate, and adheres to the paper, giving an exact representation of the whole work of the artist. The roller[53] by which the pressure is applied is covered with several thicknesses of broadcloth.

7. The number of good impressions yielded by engraved copperplates, depends upon various circumstances, but chiefly on the fineness and depth of the work; and these qualities depend mainly upon the style in which it has been executed. Line engravings will admit of four or five thousand, and, after having been retouched, a considerable number more.

8. Plates of steel will yield near ten times as many good impressions as those of copper, and this too without being hardened. Besides, an engraving on steel may be transferred to a softened steel cylinder, in such a manner that the lines may stand in relief; and this cylinder, after having been hardened, may be brought in forcible contact with another plate, and thus the design may be multiplied at pleasure.

9. The bank-note engravers have now a great variety of designs and figures on steel rollers, which they can easily transfer to new plates. This practice, as applied to plates for bank-notes, originated with Jacob Perkins. It is supposed that he must have been led to it by an English engraver in his employ, who may have explained to him the manner in which the British calico-printers produced engravings on copper cylinders. This is not altogether improbable, since the principle in both cases is substantially the same.

10. In consequence of the increased demand for maps and pictorial embellishments in books, as well as for single prints as ornaments for rooms, engraving and copperplate-printing have become employments of considerable importance; and these arts must doubtless continue to flourish to an indefinite extent, in a country where the taste for the fine arts is rapidly improving, and where wealth affords the means of liberal patronage.