The Project Gutenberg EBook of Practical Bookbinding, by Paul Adam This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org/license Title: Practical Bookbinding Author: Paul Adam Translator: Thos. E. Maw Release Date: March 31, 2012 [EBook #39318] Language: English Character set encoding: ISO-8859-1 *** START OF THIS PROJECT GUTENBERG EBOOK PRACTICAL BOOKBINDING *** Produced by Chris Curnow, Hazel Batey and the Online Distributed Proofreading Team at http://www.pgdp.net (This file was produced from images generously made available by The Internet Archive)

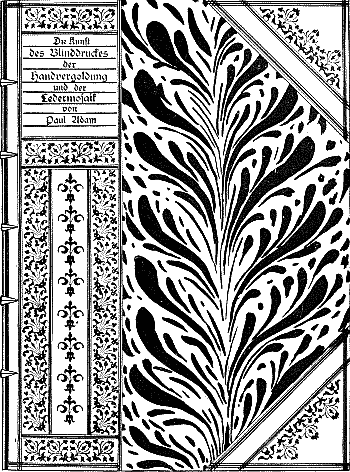

PRACTICAL BOOKBINDING

BY

PAUL ADAM,

Director of the Düsseldorf Technical School of Artistic and Practical Bookbinding.

TRANSLATED FROM THE GERMAN BY

THOS. E. MAW,

LIBRARIAN KING'S LYNN PUBLIC LIBRARY.

WITH 127 ILLUSTRATIONS.

LONDON

SCOTT, GREENWOOD & CO.

19 LUDGATE HILL, E.C.

NEW YORK

D. VAN NOSTRAND CO.

23 MURRAY STREET

1903

(The sole right of translation into English rests with Scott, Greenwood & Co.)

[Pg iv]

| Page. | |

| Metric and British Systems Compared | vi. |

| Preface | vii. |

| Introductory Remarks on Working Methods and Materials | 1 |

| A.—Materials for Sewing and Pasting | 1 |

| B.—Materials for Covering the Book | 4 |

| C.—Materials for Decorating and Finishing | 7 |

| D.—Tools | 9 |

| PART I. | |

| Forwarding. | |

| Chapter I.—General Preparatory Work | 13 |

| Chapter II.—Sewing | 40 |

| Chapter III.—Forwarding: Cutting, Rounding, and Backing | 54 |

| Chapter IV.—Forwarding: Decoration, of Edges and Headbanding | 62 |

| Chapter V.—Boarding | 85 |

| PART II. | |

| Finishing. | |

| The Book Cover | 93 |

| Chapter VI.—Making the Cover | 95 |

| Chapter VII.—Work with the Blocking Press | 103 |

| ChapterVIII.—Treatment of Sewn Books, Fastening in Covers, and Finishing Off | 119 |

| Chapter IX.—Hand Finishing | 129 |

| Chapter X.—Account Books | 157 |

| Chapter XI.—School Books, Mounting Maps, Drawings, &c. | 169 |

| Conclusion | 177 |

| Index | 180 |

| Page. | |||

| Fig. 1 | Glue-pot for heating by petroleum. | 3 | |

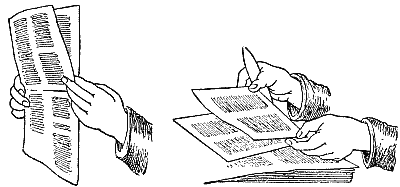

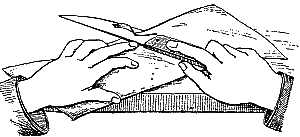

| Figs. 2 & 3 | Holding whilst folding. | 15 | |

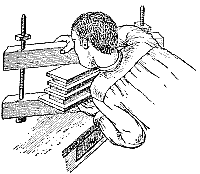

| Fig. 4 | Lifting into the Press. | 19 | |

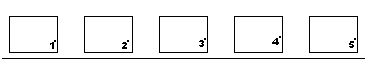

| Fig. 5 | Open sheets laid out for gathering. | 20 | |

| Fig. 6 | Sections fanned out for drawing out. | 22 | |

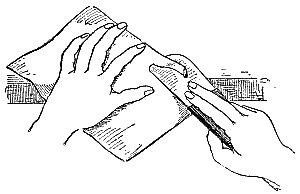

| Fig. 7 | Sections fanned out for pasting. | 23 | |

| Fig. 8 | Suggestions for mounting on guards. | 25 | |

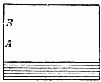

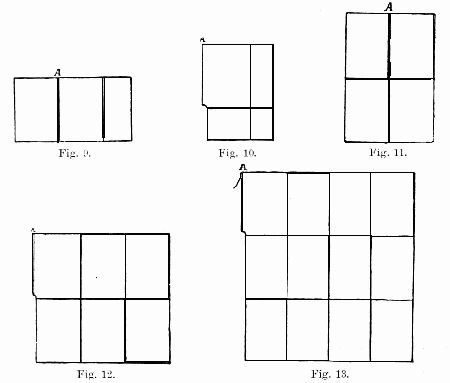

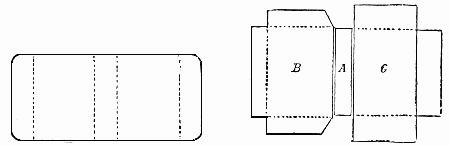

| Figs. 9-13 | Suggestions for folding plates and maps. | 26 | |

| Fig. 14 | Collating. | 28 | |

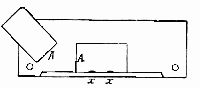

| Fig. 15 | Rolling machine. | 31 | |

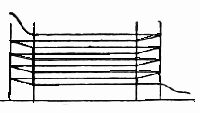

| Fig. 16 | Sewing frame. | 33 | |

| Fig. 17 | Arrangement on the sewing frame. | 33 | |

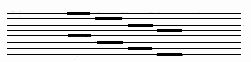

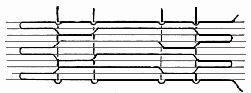

| Fig. 18 | Arrangement of threads in holländering. | 35 | |

| Fig. 19 | Small stapling machine for single sheets. | 35 | |

| Fig. 20 | Arrangement of staples in brochures. | 35 | |

| Fig. 21 | Arrangement of threads in old style of sewing. | 41 | |

| Fig. 22 | Arrangement of threads with double cords. | 41 | |

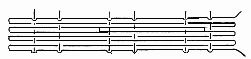

| Fig. 23 | Divisions for sawing-in. | 42 | |

| Fig. 24 | Machine for sawing-in. | 43 | |

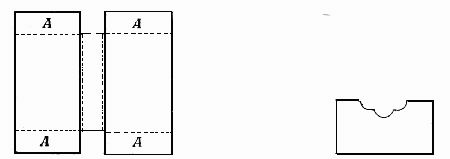

| Fig. 25 | Suggestions for single and double end papers. | 45 | |

| Fig. 26 | Suggestion for double end paper with tear-off. | 45 | |

| Fig. 27 | Overcast end paper. | 46 | |

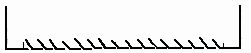

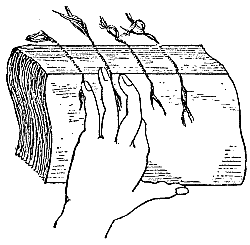

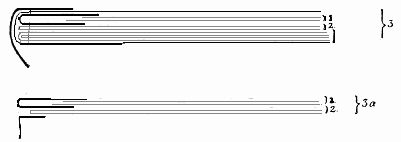

| Fig. 28 | Loops for attaching to frame hooks. | 47 | |

| Fig. 29 | Loops for taking frame keys. | 47 | |

| Fig. 30 | Suggestion for sewing on four cords. | 48 | |

| Fig. 31 | Suggestion for sewing on six cords. | 48 | |

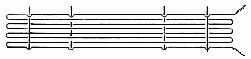

| Fig. 32 | Suggestion for sewing two-sheets-on. | 50 | |

| Fig. 33 | Thread-sewing machine. | 53 | |

| Fig. 34 | Wire-sewing machine. | 53 | |

| Fig. 35 | Rotary guillotine. | 54 | |

| Fig. 36 | Lever guillotine. | 55 | |

| Fig. 37 | Top edge arranged for when trimming three edges. | 56 | |

| Fig. 38 | Rounding the book. | 57 | |

| Fig. 39 | Rounding machine. | 58 | |

| Fig. 40 | Backing machine for small shops. | 59 | |

| Fig. 41 | Backing machine for large shops. | 59 | |

| Fig. 42 | Backed book arranged for trimming. | 60 | |

| Fig. 43 | Marbling outfit. | 66 | |

| Fig. 44 | Suggestion for sprinkling colour. | 68 | |

| Fig. 45 | Comb marbling. | 69 | |

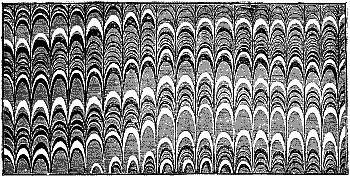

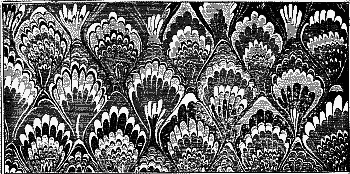

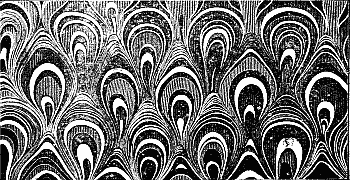

| Fig. 46 | Suggestion for curl marbling. | 69 | |

| Fig. 47 | Bouquet or peacock marbling. | 70 | |

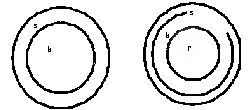

| Fig. 48 | Eye marbling. | 70 | |

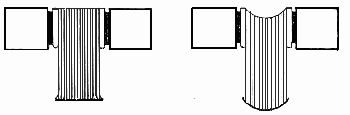

| Figs. 49 & 50 | Arrangement of flat and rounded edges. | 74 | |

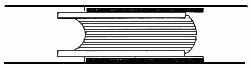

| Fig. 51 | Top edge arranged for gilding. | 80 | |

| Fig. 52 | Headband shears. | 82 | |

| Fig. 53 | Headband working. | 83 | |

| Fig. 54 | Board-cutting machine. | 86 | |

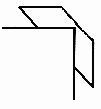

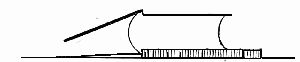

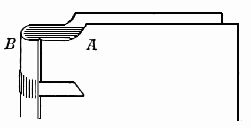

| Fig. 55 | Spring back. | 87 | |

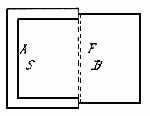

| Fig. 56 | Boarded book. | 88 | |

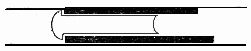

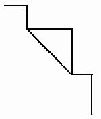

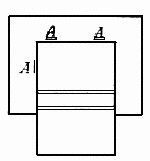

| Fig. 57 | Section of edge rule. | 89 | |

| Fig. 58 | English style of lacing boards. | 90 | |

| Fig. 59 | View of the most general styles of binding, showing the divisions of the work. (Table) | 94 | |

| Fig. 60 | Corners cut for turning in. | 96 | |

| Fig. 61 | Corners: Right and wrong. | 96 | |

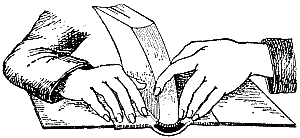

| Fig. 62 | Paring with Offenbach or Berlin knife. | 97 | |

| Fig. 63 | Paring with French knife. | 99 | |

| Fig. 64 | Blocking press. | 105 | |

| Fig. 65 | Appliances used in blocking backs. | 107 | |

| Fig. 66 | Colour roller. | 115 | |

| Fig. 67 | Stuck-on gauges. | 118 | |

| Fig. 68 | Turning in the head. | 121 | |

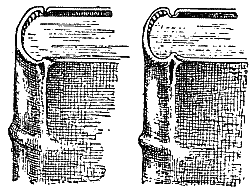

| Figs. 69 & 70 | The head: good and bad. | 122 | |

| Fig. 71 | The pasted-down book. | 125 | |

| Fig. 72 | Treatment of tear-off. | 128 | |

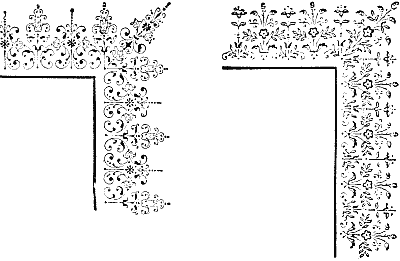

| Figs. 73 & 74 | Simple line designs. | 131 | |

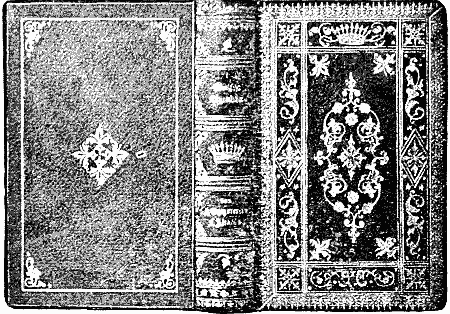

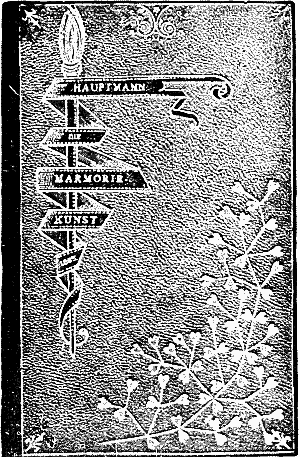

| Fig. 75 | Half-calf extra tooled in blind. | 133 | |

| Fig. 76 | Leather binding with simple design in blind. | 134 | |

| Fig. 77 | Simple gold tooling on sides. | 135 | |

| Fig. 78 | Tooled cover. | 136 | |

| Fig. 79 | Specimen of tooling done in the Düsseldorf Technical School. | 137 | |

| Fig. 80 | Leather binding by Oswald Kob, Bozen. | 138 | |

| Fig. 81 | Cover with laurel motive done in the Düsseldorf Technical School. | 139 | |

| Fig. 82 | Leather binding with fern motive done in the Düsseldorf Technical School. | 143 | |

| Fig. 83 | Simple gold tooling on squares. | 144 | |

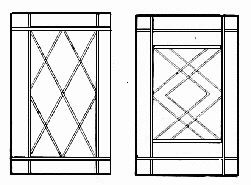

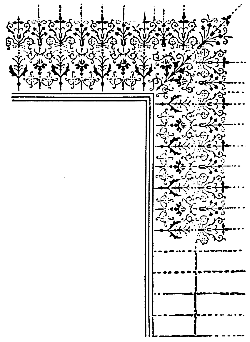

| Fig. 84 | Design in gold for squares. Tools by F. Clement, Leipzig. | 145 | |

| Figs. 85 & 86 | Two designs in gold for squares. | 145 | |

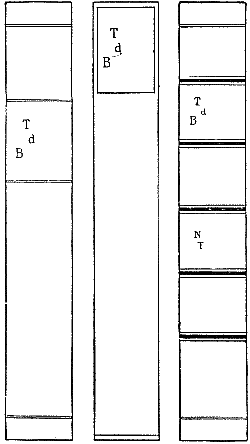

| Figs. 87, 88, & 89 | Three simple backs. T, d, B = Title; N, T = Sub Title. | 147 | |

| Fig. 90 | Type-holder with centre position. | 148 | |

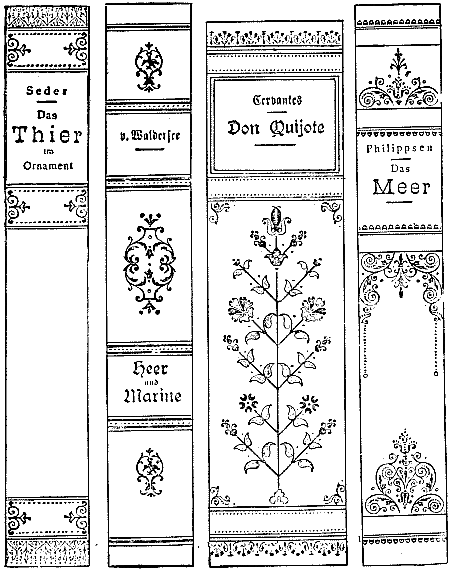

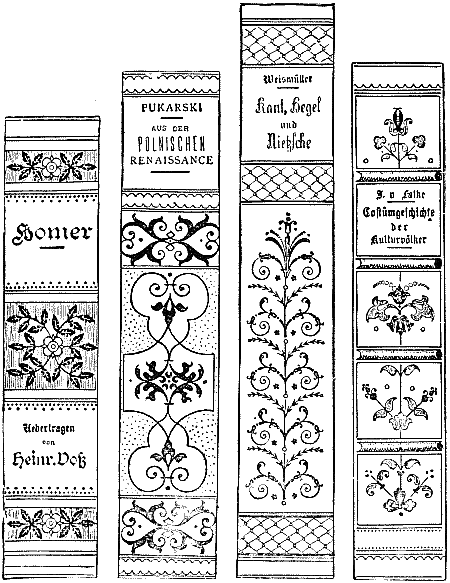

| Figs. 91, 92, 93, & 94 | Four backs tooled in the Düsseldorf Technical School. | 149 | |

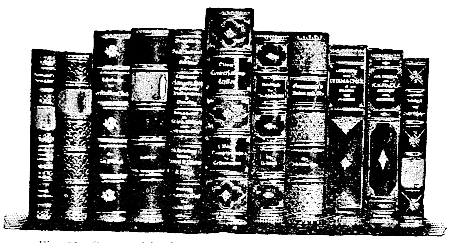

| Fig. 95 | Group of backs tooled in Carlsruhe Technical school. | 150 | |

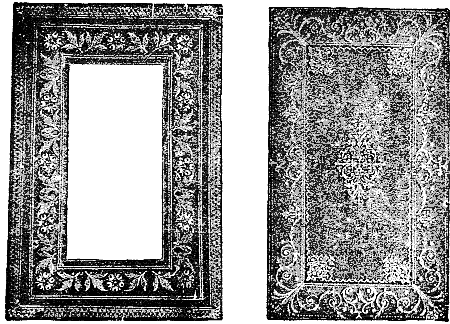

| Figs. 96 & 97 | Two richly decorated insides done in the Düsseldorf Technical School. | 150 | |

| Figs. 98, 99, 100 & 101 | Four richly tooled backs | 151 | |

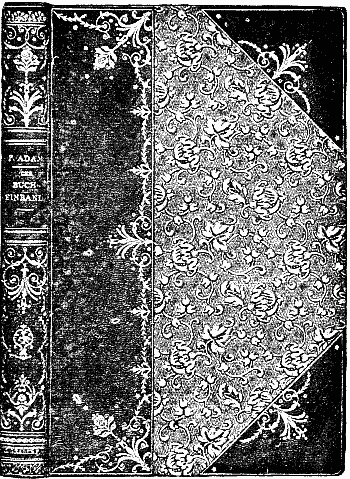

| Fig. 102 | Rich half-calf extra binding. | 152 | |

| Figs. 103 & 104 | Tooling on heads. | 153 | |

| Figs. 105, 106, & 107 | Tooling on the edges of the boards. | 154 | |

| Fig. 108 | Motive executed in the Düsseldorf TechnicalSchool. | 154 | |

| Fig. 109 | Case to protect book. | 155 | |

| Fig. 110 | Cut-out case. | 155 | |

| Fig. 111 | Book cover. | 155 | |

| Fig. 112 | Cover in case form. | 155 | |

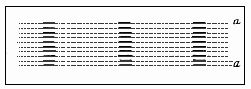

| Figs. 113 & 114 | End papers for account books. | 158 | |

| Fig. 115 | Boards cut out at head. | 160 | |

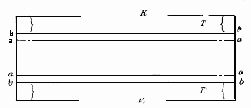

| Fig. 116 | Suggestion for account book back. _K_Pared edge; _T_Part to be pasted. | 161 | |

| Fig. 117 | Suggestion for account book back. | 162 | |

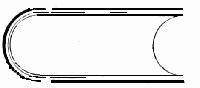

| Fig. 118 | Boarded account book. | 163 | |

| Fig. 119 | To show where turn-in is to be cut. | 164 | |

| Fig. 120 | Hand numbering machine. | 165 | |

| Fig. 121 | Suggestion for back of guard book. | 166 | |

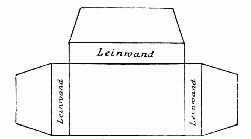

| Fig. 122 | Pattern for dust flaps. (Leinwand = Linen hinge.) | 167 | |

| Fig. 123 | Eyeleting machine. | 172 | |

| Figs. 124 to 127 | Showing stages of pinning down for stretching. | 173 |

| Metres. | Decimetres. | Centimetres | Millimeters. | Inches. |

| ·001 | ·01 | ·1 | 1 | ·039 |

| ·002 | ·02 | ·2 | 2 | ·079 |

| ·003 | ·03 | ·3 | 3 | ·118 |

| ·004 | ·04 | ·4 | 4 | ·157 |

| ·005 | ·05 | ·5 | 5 | ·197 |

| ·006 | ·06 | ·6 | 6 | ·236 |

| ·007 | ·07 | ·7 | 7 | ·276 |

| ·008 | ·08 | ·8 | 8 | ·315 |

| ·009 | ·09 | ·9 | 9 | ·354 |

| ·01 | ·1 | 1 | 10 | ·394 |

| ·02 | ·2 | 2 | 20 | ·787 |

| ·03 | ·3 | 3 | 30 | 1·181 |

| ·04 | ·4 | 4 | 40 | 1·575 |

| ·05 | ·5 | 5 | 50 | 1·968 |

| ·06 | ·6 | 6 | 60 | 2·362 |

| ·07 | ·7 | 7 | 70 | 2·756 |

| ·08 | ·8 | 8 | 80 | 3·150 |

| ·09 | ·9 | 9 | 90 | 3·543 |

| ·1 | 1 | 10 | 100 | 3·94 |

| ·2 | 2 | 20 | 200 | 7·87 |

| ·3 | 3 | 30 | 300 | 11·81 |

| ·4 | 4 | 40 | 400 | 15·75 |

| ·5 | 5 | 50 | 500 | 19·69 |

| ·6 | 6 | 60 | 600 | 23·62 |

| ·7 | 7 | 70 | 700 | 27·56 |

| ·8 | 8 | 80 | 800 | 31·50 |

| ·9 | 9 | 90 | 900 | 35·43 |

| 1 | 10 | 100 | 1000 | 39·37 |

1 gramme = 15·44 grains.

28-1/3 grammes = 1 oz. avoird.

1 kilogramme = 1000 grammes = 2·20 lb. avoird.

1 metre = 100 centimetres = 39·37 inches. Roughly speaking, 1 metre = a yard and a tenth. 1 centimetre = two-fifths of an inch. 1 kilometre = 1000 metres = five-eighths of a mile.

1 cubic metre = 1000 litres = 35·32 cubic feet.

1 litre = 1000 cubic centimetres = ·2202 gall.

1 calorie = 3·96 British thermal units.

| C. | F. | C. | F. | C. | F. | C. | F. | C. | F. | ||||

| -25 | -13 | 5 | 41 | 25 | 77 | 65 | 149 | 105 | 221 | ||||

| -20 | -4 | 8 | 46·4 | 30 | 86 | 70 | 158 | 110 | 230 | ||||

| -17 | 1·4 | 10 | 50 | 35 | 95 | 75 | 167 | 115 | 239 | ||||

| -15 | 5 | 12 | 53·6 | 40 | 104 | 80 | 176 | 120 | 248 | ||||

| -10 | 14 | 15 | 59 | 45 | 113 | 85 | 185 | 125 | 257 | ||||

| -5 | 23 | 17 | 62·6 | 50 | 122 | 90 | 194 | 130 | 266 | ||||

| 0 | 32 | 18 | 64·4 | 55 | 131 | 95 | 203 | 135 | 275 | ||||

| 1 | 33·8 | 20 | 68 | 60 | 140 | 100 | 212 | 140 | 284 |

To Convert:—

Degrees C. to Degrees F., multiply by 9, divide by 5, then add 32.[Pg vii]

Degrees F. to Degrees C., first subtract 32, then multiply by 5 and divide by 9.

Nowadays the bookbinder does not bind only those books given to him for this purpose as was the case in former years, for present conditions necessitate his undertaking many kinds of work which have little or nothing to do with the binding of books, particularly such as are connected with the making or finishing of printed matter and paper goods, or where pasting, gumming, and glueing are required, which, in their turn, are connected with paper and cardboard.

On the other hand, some branches of the bookbinder's craft have now become quite distinct, and have developed into special industries, and have so enlarged and extended that even their particular methods of working and technical terms have quite changed. Cardboard goods, leather goods, photo albums, maps, and even account-books are treated by particular firms as specialities.

As we must now keep within clearly defined limits, we shall treat here only the work of bookbinding proper as far as it is concerned with the making of the book for publisher, bookseller, and buyer, and also the making of account-books, whilst the other work given to the binder, commonly called "fancy goods," must be excluded. Editions de luxe,[Pg viii] charters, illuminated addresses, &c., are likewise excluded, as they are quite apart from the ordinary work of the bookbinder, belonging solely to artistic bookbinding. When any such work is required the intelligent worker will not be at a loss; besides, he will derive ample assistance from the illustrations for this class of work.

The parts of this little book have been so arranged as to correspond to our present-day division of work: preparatory work, forwarding, covering, and finishing. In England and France the various processes have for a long time been similarly termed, and although in Germany we could not follow their lead without any deviation, because our method of work and division of labour are so different, yet the basis of this arrangement has been used in this book.

Every text-book has some drawback, the greatest of these being that a practical demonstration on the subject is more helpful than the most detailed written description, and yet even in the latter a text-book is limited. For the rest, I have tried to be as brief and clear as ever possible and to avoid faults which I have discovered in my former writings of a similar kind.

Paul Adam.

Düsseldorf, Germany, 1898.

[Pg 1]

The bookbinder works with quite a large variety of materials which are mostly what we might call "half-made," that is to say, such materials as have already undergone some hand or machine process in order to make them fit for the work of the bookbinder. This is not the place to go into details as to the source of all these materials or the manner of their production: that may be seen in special treatises.

We separate into various groups the materials we use.

The bookbinder himself prepares his paste from wheaten flour and boiling water. Put in a shallow vessel, by preference a stone or enamelled metal wash-basin, the quantity of flour required for about eight days, pour in as much water as will make a mixture by soaking and stirring of the consistency of honey. Add to it boiling water, first slowly, then quicker, stirring all the time. It does not do to add the water too quickly, as that is likely to make the paste knotty or lumpy, because it cannot be stirred quickly enough and the gluten develops unequally. If added too slowly, the starch is not heated quickly enough and does not thicken[Pg 2] sufficiently or not quickly enough, and the paste turns out too thin.

Good paste, when cold, should not be stiff like pudding, but should be easily worked with a brush. In order to prevent a skin forming on the top whilst cooling, pour over the paste as much cold water as will cover the surface immediately after the mixing with the boiling water; this water is afterwards poured off.

In summer when the paste is made, and whilst still hot, add a few drops of turpentine and mix well; this preserves the paste and keeps off insects. The addition of alum to the paste tends to make it watery, besides having no preservative properties.

If required, paste may be thinned by adding a little warm water. Potato flour is often used fraudulently for making paste, but this should only be taken when it is possible to use it up quickly, and not for books, but only for fancy goods, as this flour does not possess great adhesive power and is unsuitable for leather.

Glue is made from the well-known cake glue. The best English glue, although the dearest, is the cheapest to use. Good glue whilst soaking in water should still retain a certain degree of stickiness, must not be greasy, and should have no disagreeable smell. Glue if weighed before soaking and afterwards dried and again weighed should give no perceptible loss in weight. Good glue should not have a disagreeable taste, and above all should not betray the presence of salt.

To obtain the proper consistency in glue for bookbinding, a quantity of the cakes is taken and sufficient water poured over it to cover well. The next day the gelatinous mass is taken out of the water and dissolved in the glue-pot by placing the softened glue in a pot standing in an outer vessel containing boiling water. Glue should never be boiled[Pg 3] nor placed directly on the fire, as that causes the loss of the best part of its adhesive property.

Glue and paste are generally worked with a brush. For paste a large hollow brush is used; this holds a large quantity of paste and covers a large surface. For glue a closer brush with a metal fastening is used, because here the hairs cannot be secured with pitch owing to the brush being constantly exposed to heat. On the paste brush there must be neither ring nor anything else of iron, as this used in paste would cause rust, and rust would give iron stains to light-coloured leathers. For the same reason no enamelled vessel should be used for paste after the enamel has once been chipped or worn.

Laying the glue or paste on a material is called glueing or pasting. A zinc-plate is the most serviceable pasting-board, as the paste is easily washed off. Glue can be scraped or soaked off and used again. Pasting-boards of mill-board or paper are hardly to be recommended, as their use entails a considerable loss of material.

Of other adhesive substances, dextrine, gum, gelatine, and isinglass are used for certain purposes. The two former are always used cold, the two latter warm. The former are dissolved in cold water; gelatine and isinglass are soaked exactly like glue, the water poured off, and then melted in the glue-pot.

Dextrine and gum are used by the bookbinder almost exclusively for pasting larger surfaces, and for laying on these substances a broad thin brush fastened with a metal strip is used.

To heat the glue and to maintain the heat a glue-heating apparatus is used. The upper part always consists of the glue-pot. The better kinds are made of copper or brass wrought or moulded in one piece. For the sake of convenience a partition is let into this pot so that thick and thin[Pg 4] glue may be ready for use at the same time. The glue is not heated directly over the flame, but by hot water; to do this the glue-pot is placed within a larger vessel containing water, the glue-pot at the same time closely fitting to the outer rim of the larger vessel. This contrivance is placed over a petroleum, gas, or spirit lamp, which gives the required heat. In some districts where brown coal is found, it is heated on a specially made contrivance with the brown coal waste.

The latest method of heating is by electricity. The apparatus necessary for this has been put on the market by the firm W. Leo, Stuttgart.

The majority of bookbinderies, large and small, use a strong linen hemp-spun thread for sewing, the strength of which depends upon the weight and size of the sheets to be sewn. As it is inconvenient to be obliged to be continually beginning a new thread or knotting, most bookbinders use a reel of thread. The so-called Marschall thread is the best.

The book is held together by cords, for which the so-called sewing cord is used. There are now special kinds made for the purposes of the bookbinder; these are lightly twisted out of a long fibrous material so that afterwards they can be easily undone for the subsequent necessary scraping out. Certain kinds of bindings are sewn upon tapes; strong raw linen tape of 1-1-1/2 cm. being the material most generally used.

For machine sewing, thread is generally used. Tinned iron wire, ready wound on spools, is also used. It is made in various sizes and used according to the weight of the sheets.

The real protection against outward injury to the book lies[Pg 5] in the cover, the inside of which consists of boards more or less strong. Of the kinds on the market the bookbinder uses grey-board, which is made from waste paper and rags. It is grey, very tough, and flexible, but dearer than other raw materials.

Straw-boards made from straw and waste paper are cheaper, but less flexible, and are easily broken. They take a very high polish under the calendering machine and become very hard, and are therefore very suitable for some work if flexibility is not essential. They are generally used in all cloth binding.

So-called leather-boards are unsuitable, for, in spite of great toughness and pliancy, they are certain to cockle and always remain spongy. Wooden-boards are unsuitable for bookbinding on account of their small resistance, but are indispensable for fancy goods and portfolios, as they can be so nicely cut and are less liable to subsequent cockling than any other kind.

Besides these, yellow and blue boards are made. These are coloured to suit and serve quite special purposes, mostly fancy goods; but they also are not used in bookbinding, on account of their high price.

The thinnest boards are known as middles. This is a strong whitish material made entirely from waste-paper. It is used for lining backs, limp bindings, and in all cases where flexibility, together with durability, is required.

In finished work—books, fancy goods, maps—the boards are never left exposed to view, but are covered with paper, cloth, or leather. For the inner side of the cover of the book white or coloured paper is frequently used, note-paper of the smallest size being more rarely used.

All marbled or pressed papers are made in one standard size. Besides the end papers for inside of books, a figured paper has of late been made known as "litho printed" for[Pg 6] fancy goods. This has been put on the market in the most varied kinds, and also with cloth-like impressions, under the names damask, brocade, and Leipzig end papers. The use of this paper has of late been almost discontinued. The dearest are those printed with designs in gold.

Cloth is more durable than paper, calico being mostly used. This is made in all colours and designs, and was formerly imported from England; but to-day German manufacturers produce a really good article. Plain linen cloth, black, green, or grey, sail cloth, buckram, mole-skin, and beaver are used in the making of account-books.

Silk is used in the bookbindery as end papers in extra work, and also for fancy goods and for lining boxes. The lower grades are seldom used, the better qualities being mostly taken.

To-day velvet is still used in the bindery, chiefly as a covering for portfolios, albums, and addresses, and except for metal clasps remains without ornamentation.

The bookbinder's best material, to which is given the choicest, most expensive, and most painstaking decoration, is leather in its various kinds. Sheep-skin, undyed or split and dyed, serves for school books and other cheap work. Goat-skin and morocco are better kinds, the latter being preferable both as regards price and quality.

Morocco is made from the skin of the goat. Morocco, Levant morocco, and maroquin all denote the same kind. It is a strong, coarse-grained leather imported from the Levant, very tough and durable.

Cape morocco, also called maroquin écrasé, is similar to this. This has a very large, artificially smooth-pressed grain, and hitherto has been higher in price than all other leathers.

Calf (matt or polished) is quite smooth and is only used for fine work. Cowhide is similar to this, but of coarser[Pg 7] texture, and is only used for leather goods, portfolios, and albums; for other work in the bindery it is not easily enough worked.

Celluloid is one of the latest materials used for covers. There is evidently a good opening for this in the wholesale manufacturies, stamped goods, and small fancy goods; whilst on the other hand it is of little value to the smaller shops, as it requires machinery for gilding.

For the decoration of our work, either during or after production, there will be a large variety of materials used. Colours are used for the decoration of the cut edges and the cut heads of books. The smooth, uniformly coloured edges are made by a body colour—carmine, scarlet, chrome yellow, silk green, indigo blue. All these colours must be very finely ground before using; the addition of a little paste or dissolved gelatine makes the colour adhere.

For marbling the edges Halfer's marbling colours are now exclusively used; these are to be had ready for use.

Amongst the binders' materials gold takes quite an important place. Leaf-gold in various colours is supplied either by the gold-beater or the wholesale dealer. The colour most used at the present time is orange gold, which is about the same in tint as our current gold coinage. Red gold is somewhat deeper in tone. Green gold and lemon gold are considerably altered by an alloy of silver, and are sold cheaper. Besides gold there are still other leaf-metals used, principally aluminium as a substitute for silver. The latter is still being used, but its unfortunate property of turning black will by-and-by drive it from our workshops. Bronze-leaf is also used for very small jobs in large quantities—makers' names on hat linings, ties, &c. Like[Pg 8] silver, it is also liable to rapid oxidization, which takes place with especial rapidity upon leather.

Gold leaf is made in various sizes. The larger size, about 85 mm., is the best to use, whilst the very small sizes are better suited for some work.

As a ground-work for gilt edges, the so-called poliment (Armenian bole) is now generally used. This is cleaned bole, made into a paste, and applied in a solution not too thin.

To make the gold stick to the surface, glair or white of egg is used in all cases. It must be properly diluted according to whether it is to be used for gilt edges or hand-tooling.

Finished work, especially smooth surfaces, is improved by the application of varnish, and is at the same time rendered damp-proof. The so-called bookbinder's or leather varnish is used for leather, cloth, or pressed dark papers. Map varnish, also sold as photographer's varnish, is suitable for light articles, maps, placards, &c. At present, spirit varnish with its quick drying and high surface is almost exclusively used for this purpose. Turpentine varnishes are no longer generally used in bookbinderies; in colour printing copal and amber varnishes are used.

The ready-made headband is an article specially manufactured for the bookbinder. It is fastened on the book in suitable lengths to cover the place where the body and back of books join at head and tail. These headbands are to be had in the most varied styles, according to price and requirement. For ordinary work a cheap cotton is good enough, for fine half-calf bindings a silk headband is used if it is not intended to weave by hand a headband of silk thread for decoration known as a worked headband.

Besides the headband, the book-marker is required, generally a silk braid in bright colours.

It is often necessary to fix clasps to heavy books and also to the smaller hymn-books and prayer-books. These are[Pg 9] made to suit all requirements and in various styles by firms making a speciality of this work. The stronger the metal used, the better the clasp and the easier for the worker to handle, as clasps of poorer quality are sometimes spoilt even whilst being fixed to the books.

Imitation metal fastenings are necessary for certain purposes, although their use is now considerably limited. These are the stamped metal rims and corner pieces, which are indispensable in the manufacture of sample cases, &c. The fancy goods with their decorated borders which were so popular at one time have disappeared from the trade; on the other hand, there has been a demand for fancy coloured cords made by twisting cords together.

The bookbinder's workshop of to-day presents quite a different aspect from that of our forefathers, even if we go back only 50 years.

The work benches as now found in small leather or jobbing shops stand near wide and lofty windows, each bench having a large drawer at each worker's place. Underneath, between the legs of the bench, there is a board fixed on supports upon which boxes containing colours or any other materials in use are placed within easy reach; and so that the board may not inconvenience the worker sitting in front of it, a semi-circular opening is cut at each worker's place. At each place there is a stool, somewhat higher than an ordinary chair, with three legs and a round flat seat. The legs are connected by strong bars for the worker to rest his feet upon. Shelves for the larger tools are conveniently arranged on the walls, so as not to be a hindrance, but still within easy reach. A few smaller chests with drawers are required for the storing of smaller tools and pieces of metal ornament, [Pg 10] &c.

A sufficient number of wooden presses, pressing boards in folio, quarto, and octavo, with the screw key, as well as the press jack belonging thereto, must be conveniently placed. The screw key is used when applying heavy pressure; the press jack serves as a support during certain work which necessitates laying the press on the edge of the bench. If we add a few larger and smaller cutting boards and a few sewing frames, we have completed the list of the large wooden tools.

The bookbinder requires very many small tools, even if we take into account only those necessary for ordinary shop-work. Iron rules and squares in various sizes, shears, knives, compasses and spring dividers, folders, files, pincers and hammers of different sizes, chisels, gouges, and punches.

The finisher's tools are: Gold cushion, gold knife, scraper, steel; and furthermore, for hand-tooling, letter-box, fillets, rolls, ornaments, and letters, all very fine and very dear tools, which must be kept in special cupboards and boxes so as to protect from possible injury. The higher the class of work done in the shop, the larger must be the stock of these tools.

These are the tools for general work and which no shop could be without; but what makes our modern workshop so different in character from what it was in former times are the many mechanical contrivances without the aid of which practical and profitable work is now inconceivable.

The most necessary iron ally of the bookbinder is the cutting machine, either with lever or wheel action, the former for light, the latter for heavy work. Machine manufacturers vie with one another in their efforts to introduce inventions and improvements; but to-day it would seem impossible to make a discovery likely to be of any importance.

The second most necessary machine is for cutting boards. Those with a wooden pedestal and table are not so much to be recommended as those made entirely of iron.[Pg 11]

When gilding in large quantities has to be done, a blocking press is necessary; lever action is always to be preferred to the balance or rotary action, the latter being of advantage for blocking or relief work, and also for fancy paper work. Even the best blocking press has some drawback; to be of any value, it necessitates quite an arsenal of plates and dies for blocking, and also calls for the constant replenishing and renewing of the same.

The standing press is used for heavy pressure applied to large batches of books. An iron press with two uprights will be found sufficient even for heavy use in most bookbinderies.

The rounding machine is now out of use. The binder rounds the back of the book with a hammer, and then it is backed in a backing machine, which puts the ridges on both sides of the book. The latest machine now being used in some of our large binding shops for this purpose is called the rounding and backing machine, which completely rounds and backs the book.

The rolling machine of to-day is lighter than were the first models of this machine; besides, the work is in many cases unnecessary, as modern printed books are generally carefully rolled before they leave the printer.

The wire-stitching machine came into use in England about 20 years ago, but is now abandoned. The wire-stapling machine is used for pamphlets, school-books, &c. Eyeleting and round-cornering machines are smaller appliances, whilst the backing machine mentioned above is a very useful ally. Machines for scraping and paring leather are used least of all, as there is little for them to do in a small bookbindery.

The foregoing is not an exhaustive list of our tools and machines, but we will bring to a close these introductory remarks on the usual appliances, as mention will be made of the others in their proper place.[Pg 13]

Books reach the bookbinder either in the sheets just as they left the printing press or folded and stitched. This folding and stitching is, of course, part of the binder's work, so we will begin with the sheet as it left the press; this sheet must in the first place be folded ready for further manipulations.

By folding we mean the arranging of the parts of a sheet in the order of succession required for reading. To facilitate this work the printer marks not only the page numbers on each sheet but also gives each sheet a number, these numbers being known as signatures. Every sheet is printed on both sides; the front side is called the first side, the other side the perfecting impression. Both sides are marked by a number or (more rarely) a letter. This mark stands at the right-hand side at foot of first page and is called the first signature; the second signature takes the same position on the second side of the sheet, that is, on page 3. Take any book haphazard and you will find the true signature on the first and the second[Pg 14] signature on the perfecting impression, always in the same position. In order to show at a glance whether the signature is the first or the second, the compositor adds an asterisk, thus—

| 1 | 1* | or | A | A* | |

| first | second | first | second | signature. |

We will see later that there is still another reason for the signature in the place mentioned.

When the sheets are to be folded, all the sheets of an impression are laid one on top of the other and all lying the same way. The modern quick-printing presses gather the sheets automatically, so that a sheet is rarely laid the wrong way, excepting through want of care in looking over them, or in the knocking-up in the printing office a few sheets or a whole batch are thrown out of order. According as we are dealing with folio, 4to, or 8vo format we must order the gathering of the sheets and, of course, the position of the signature. The commonest format is 8vo, that is to say, the size which gives eight printed leaves (or 16 pages) to the sheet. At the same time, the method of folding this format is the most economical and includes the others as well.

When folding 8vo sheets the pile lies in front of the worker in such a way that all the second signatures lie uppermost at the foot of the outside right page and all the first signatures at the left on the under side of the sheet; or, in other words, all first-side leaves are turned face downward and perfecting impressions face upward.

Printed sheets are never folded according to the edges of the paper, but always registered by the printed columns or the page numbers. The novice finds this by holding the sheet against the light, but the experienced worker is able to fold the sheet without so much as lifting it from the table.[Pg 15]

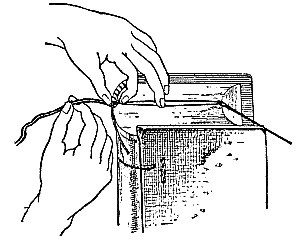

Figs. 2 and 3—Holding whilst folding.

Figs. 2 and 3—Holding whilst folding.

The manipulations for the folding of an 8vo sheet are as follows: The right hand holds the paper-folder and creases down the folds, the left gathers the sheets and moves them about aided by the right.

1.—The right hand takes hold of the sheet at the right a little below the middle, brings it over to the left, when it is taken by the left hand and properly adjusted according to page numbers or corner of printed page (Fig. 2).

2.—Crease with folder from bottom to top (the folder is held slanting to the crease, but the edge is used).

3.—With the right hand the right and the left hand the left of the folded sheet are taken hold of at about the middle of the longer sides, nip together, make a short turn so that the left hand brings the sheet with its fore-edge to the folder's body, the left hand lets go, takes hold of the sheet between both ends at the middle fold, and adjusts pages and edge of fold alike (Fig. 3).

4.—The right hand creases from top to bottom.

5.—Left hand turns sheet over to other side, both hands take hold as before, nip together last fold, and adjust pages and fold.

6.—Crease from top to bottom, laying aside sheet to left, fold lying to right.[Pg 16]

The whole process, which demands considerable dexterity, is only to be thoroughly learned by example and imitation; but study the illustrations, which are correctly drawn from life.

This is the way sheets are folded when they come direct from the press; but if they had already been folded in quires, as is usually the case with school and hymn books, the sheets would simply be folded in the middle for convenience of storage and despatch.

In this case the quires must first be opened, the crease taken out, and the sheets laid open. This work is called "breaking the backs." The unfolded sheets are folded in exactly the same manner, but before the last crease the sheet is turned, creased from bottom to top, and put aside in such a way that the sheet is turned over, that is face downwards. If this precaution is not observed, the folded sheets would afterwards be found in wrong order.

At this point we might remark that the top, both of the book and the single page, is called the head, the bottom the tail. These commonly used terms will very frequently crop up.

The folding of a 4to sheet is exactly the same, excepting that the last fold is omitted; the second signature lies face upwards at top on the right, the first signature lies downwards at top left hand.

Folios are made up but rarely nowadays, except in artistic éditions de luxe, Bibles, and missals; they are simply folded in the middle; the signatures appear as in 8vo format.

Duodecimo format, that is, a sheet printed to make 12 pages on each side, is so printed that the third part of the sheet has to be cut off with a knife or machine. This work is done in various ways: the sheet may be folded without regard to the one-sided elongation; after folding the part is cut off with a knife or machine at the proper place and the[Pg 17] detached portion inserted in the middle of the main section; the small section is therefore called "the inset." On the other hand, the inset may be cut off before folding and then separately folded and inserted. This is the more usual method.

The cutting off of the inset prior to folding can be done in such a way with the modern quick-printing presses that the sheets are adjusted and cut off in the machine, or they may be folded in sections of six—eight sheets and cut open in the fold. For cutting open such sections a very sharp knife is required, either the usual bookbinder's knife or, better still, a somewhat longer two-edged paper-knife rounded at the end.

Formerly, when printing was not done with such accuracy as now, the sheets were folded into sections by means of points. The compositor made a point on both sides between main sheet and inset in the furniture where the division had to be made; if pins were stuck into the table through these points each of the sheets following could be placed on the pins.

Thus all sheets are brought to perfect register and may be cut with knife and rule or machine exactly through the points. This work is called "working to points."

The detached portion appears as a long printed slip upon which are four pages or columns side by side. They are folded in a very simple manner.

The page on the right is brought over to lie on the page to the left, registered, and creased in the middle, and the double sheet is now folded once more in exactly the same way.

Inserting is done as follows: The sheets for insertion are placed to the right, the main sheets at the left side of them; the right hand takes a sheet to be inserted at about the middle of the fore-edge, the left hand at the same time taking a main sheet in such a way that thumb, middle, and index finger open the sheet about the middle of the upper fold, and raise it so that the right hand can easily slip in the[Pg 18] insertion. Whilst doing this, the left hand slips to the back, where the forefinger manages the adjustment of the sheet inserted. The insertion is nicely fitted into the back and must lie close to it. This work is also very easy, but it also is much easier to learn it from example and imitation than by written instruction.

If the insets were already arranged before folding, that is to say, had the sheets been arranged according to page numbers immediately after printing as before mentioned, strict attention must be given to see that each main sheet has its insertion, otherwise the page sequence would be thrown into confusion in binding.

In folding, every fold must be sharply creased down; but a firmness of body in the sheets, a smoothness of the single sheet, and a proper sharpness in each separate fold can only be obtained by pressing the sheets. For this purpose the sheets must first be "knocked up," that is, they must first be adjusted at head and back by knocking them together on the table. Sheets are never pressed without being counted at the same time; this is done both for convenience in pressing and for checking the work.

Knocking-up can only be done upon a firm level surface; the beginner had better not take too many sheets at one time, say from 20 to 25: these are moved to and fro between the palms of the hands so that the back fold and upper fold are worked in turn, and at these sides the sheets are brought into line.

Knocking-up proceeds quickly if the sheets are handled lightly and freely. The single batches thus levelled are brought together and they in turn knocked up in the same way. Care must be taken that single sheets do not hang back, i.e., that all sheets come up to the levelled edge.

The knocked-up sheets are counted off—thin paper in hundreds, thick paper in fifties. To do this any big lot is taken[Pg 19] hold of with the right hand—one soon learns to judge the quantity to be taken by the fingers—by the fore-edge, giving the hand a turn so as to bring the backs uppermost, when the sheets will fan out at the back and thus make the counting an easy matter. The left hand counts—pardon, the head counts, but the left hand tells off the sheets in such a way that the middle and index fingers are alternately inserted in 4, 8, 12, 16, &c., whilst counting 1, 2, 3, 4, &c., and at the same time throwing over the sheets held. Every 25th lot of four sheets gives 100, and, of course, any other number you please can be counted in the same manner. Each lot is once more knocked up, placed in piles crosswise, and afterwards pressed.

Fig. 4—Lifting into the Press.

Fig. 4—Lifting into the Press.

The contrivance for pressing most generally used nowadays is still the bookbinder's little wooden hand-press, with wooden, or perhaps iron, screws; the former are lighter and handier, the latter heavier but more durable and therefore of advantage where heavy pressure is demanded. Each lot is placed between pressing-boards; these are about 1-1/2 cm. thick and vary in length and width according to the sheets or books to be pressed. According to the grain of the wood we speak of long and cross boards. On top of the upper and underneath the lower batch we[Pg 20] place a cross board; it does not matter which way the grain runs in the other boards used. This precaution is taken to obviate the probable breakage when the cheeks of the press run parallel with the grain of the two outer pressing-boards.

The pile of sheets between the pressing-boards is so placed that the nuts of the press are at first raised as high as the pile about to be pressed requires, then the press is put on the table to the right in front of the worker so that the head of one screw at the front touches the table edge. The pile is drawn on to the front edge of the table, the left hand slips underneath, and the chin presses on top. Whilst raising the upper cheek of the press with the right hand, the pile is inserted between the opened cheeks, is adjusted, and the press screwed up, first by the hand screws and then by the screw key used for this purpose. To do this the press with its high cheeks is held firmly between the legs and the nuts screwed up with the screw key as tightly as ever possible.

At this stage we might mention a work which is very frequently done in the printery, but seldom in the bindery: this is the so-called gathering before folding. This work, as we have already mentioned, is done so that printed matter for publication can be properly stored or prepared for sending away.

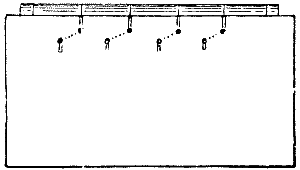

Fig. 5—Open sheets laid out for gathering.

Fig. 5—Open sheets laid out for gathering.

The sheets are taken just as they left the press and piled up side by side in a row in order of number on a long table, each pile of sheets in exactly the same position as the others and just as they would be placed for folding; that is to say, for 8vos the first signature at the bottom left-hand side underneath, the second signature being at the bottom right-hand side on the top.[Pg 21]

Generally the work is gathered in batches of 5-6 sheets. The sheets in question are then laid out (see Fig. 5).

The worker takes a board the required size, upon which he places the sheets when gathered; he begins at No. 1 pile, takes off the top sheet, being very careful not to take two, lays it upon the board, and so he goes the length of the table, taking the top sheet from each pile. He lays the pile of gathered sheets on the end of the table or another table standing behind. They are there received by another worker, knocked up, and folded in the middle. If only one worker can be spared for the job, the gathered sections are placed to one side, but each is laid crosswise over the other so that they are easily picked up afterwards for knocking up and folding. If the work has more than five or six sections, the separately gathered sections must be afterwards again gathered in the same manner. Perhaps there may be placed in the last section parts of a sheet—the title, addenda, corrigenda, frontispiece, diagrams, &c. The treatment of these will be dealt with presently (pp. 22-24).

Sheets so gathered must be afterwards opened out for folding in the bindery. The section is opened, the crease well pressed out, and the whole smoothed down quite flat, care being taken that all sheets lie the same way, the opened sections lying side by side according to the signatures.

Before the folded sheets are arranged or gathered, there is frequently still some pasting to be done. The title, for instance, is seldom printed with the first sheet, but is usually made up with the preface, contents, &c., after printing the last page, often as part of the last sheet.

On this account the last sheet must be examined before folding to see how it is composed. If it happens that the sheet is to be exactly halved, it is best to cut the sheet in the middle and fold each half separately. It is even worth[Pg 22] while cutting the sheet into quarters if the sheets can be pinned on, because it is then possible to fold the cut sheets in lots of five or six and to draw out each one singly, as it is commonly called "pulling out."

This pulling out is very easy work; each folded batch is separately opened in the middle, fanned out with a paper folder so that each sheet stands back about 1/2-1 cm. behind the other, and the batch folded together again; it would then appear as in Fig. 6.

Fig. 6—Sections fanned out for drawing out.

Take the batch lightly between the finger and the thumb of the left hand, and with the right draw off the sheets from the top one by one, knock them up, and firmly press down the back fold.

Every part of a sheet which after folding makes less than four pages (equal to two leaves) must be pasted on. To do this the parts to be pasted are fanned out from the back with the pasting side uppermost, that is to say, the sheets are fanned out with the folder in the same way as described for "pulling out," until they lie like steps or stairs, each sheet displaying an edge of about 3 mm. In this manner all sheets so lie upon each other that each is about 3 mm. behind the one under it.

The narrow margin is pasted; to avoid pasting more than the proper margin of the top sheet, a piece of waste paper should be laid on top at the right distance from the edge. Each leaf has thus a narrow pasted edge by which it is secured to the main sheet. So that the pasted edges do not stick together whilst each sheet is being fixed in its place, which,[Pg 23] of course, takes time, the batch is taken between the fingers immediately after pasting, and by a few light movements the sheets are worked a little further apart.

Fig. 7—Sections fanned out for pasting.

Take the batch at A between the finger and thumb of the right hand, at B in the same way with the left; the upper leaves slip gently backwards if the right hand bends the batch lightly upwards so that the sheets are pushed to B, the left first allows the sheets to slip back and then holds them firmly so that the right may repeat this movement several times.

The batch is then so placed across the table that it lies to the right of the worker with the pasted edge away from him, whilst the pile of sheets to which the parts are to be pasted lies to the left, also with the back edge away from him. Leaf after leaf is taken up, carefully adjusted to back and upper fold, and pasted on to the main section and lightly rubbed down to right and left with the finger-tips, putting aside to the left each sheet as finished.

Under certain conditions, the pasting on of a so-called correction may be a very disagreeable task. If errors have been made in composing or printing a page which escaped notice and correction at the proper time, a revised page is printed, and this must be inserted by the binder in the place of the faulty one. This inserting is done after the folding; the faulty leaf is so cut off that a narrow margin is left in the back to which the rectified leaf is pasted.

If maps or plans accompany the work these also must be[Pg 24] inserted; thin sheets need simply be pasted on the back edge like other sheets and fixed in their right place; but thick paper is not easily pasted on and, besides, would always pull away the next leaf. It is therefore joined to a narrow strip of paper about 1 cm. in width and this is pasted and fixed in the back. If several plates have to be inserted at the same place, or to be fixed at the end of the book, they are joined together in sections of suitable thickness. For this, thin paper is hinged in the back of the book, that is, the two plates are pasted over each other after pasting a narrow margin of about 3 mm. When dry, the double leaf so obtained is folded together in the middle of the pasted little guard. As this process lessens the leaf which has the back-fold by as much as is pasted to the other, the latter is cut down by 3 mm. beforehand.

If there are many such plates to be joined together, they are made up in sections of 4 or 6 according to the thickness of the paper, and every 2 or 3 cut down according to circumstances, and the same number left the full size. When all have been properly cut, the edges are fanned out and pasted. Then as many as make up a section are taken up and fanned out a little further, the pasted edge of No. 1 is laid on 6, 2 on 5, 3 on 4, and the batch set aside on the left and the same process gone through with the next lot. When dry, the plates thus guarded together are creased together at the back.

Plates on thick paper must likewise be mounted on strips of paper. These are cut from thin, strong note-paper and are so arranged that their thickness in the back is the same as the thickness of the plates. It is well to select a paper which when double is as thick as the plates. In case the plates are extra thick, the guard is made four-fold. The width of the guard must be measured to correspond. If a guard of double thickness only is required for filling up, it is cut twice[Pg 25] the width of the guard and 3 mm. added for pasting on the plate. This gives 2 × 1 cm. + 3 mm. = 23 mm. If a guard of four-fold thickness is necessary, the result is 4 × 1 cm. + 3 mm. = 43 mm. The plates are fanned out narrowly with the back edge uppermost, pasted, and each plate affixed to one of the made guards. This work is called "mounting on guards."

When the pasted plates are dry they are folded in the back on the following plan according to whether the guard must be two-fold or three-fold.

Thus the folded guard completely fills out the space in the back of the book. Besides, two, three, or more plates can easily be made into a section if the little guards are made up within each other.

Despite this levelling work, the pasted part will still be noticeable; the thoroughly dried sections are therefore taken in batches of four or five, knocked up at the back edge, and the thick part carefully hammered on a stone or iron bed.

Just as paper strips have been used in this work, linen can be used for guarding atlases and mounting large maps which are intended for long and constant use. To fill out the back, cardboard or thick drawing-paper the thickness of the plates (or, if anything, a little less) is used. Of this material strips are cut 1 cm. in width and same length as the height of the work, cutting a strip for each plate of course. Besides these strips, cut some soft white calico into strips 3 cm. in width. These are pasted, laid quite straight upon a clean board, two strips of paper are placed in the centre side by side on top of the pasted strip, and at right and left of each a map is hinged on, the first face downwards, the second face upwards. When dry, the section so made is creased in the middle,[Pg 26] knocked down with the hammer, and pressed for a time. By this method two plates are hinged on each guard; by the other each plate had its own guard.

Many books are issued with plates larger than the format of the book itself; they must be brought to the right size by folding, but in such a way that the folded plate is secure from injury during any subsequent trimming.

Before making a single fold in the plate, the worker should clearly see his way through his scheme for folding, so as to bring the plate to the size required with the smallest possible number of creases. Plates which are slightly wider and longer than the size of the book are easily made to fit if they are folded once or, if necessary, twice across the middle, pasting the edge of one fold on a guard and then fixing in its place in the book.

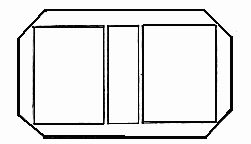

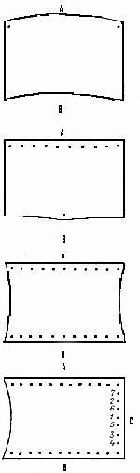

Figs. 9-13—Suggestions for folding plates and maps.

Figs. 9-13—Suggestions for folding plates and maps.

If this will not do, the plate must first be folded up from the bottom edge far enough to escape damage in trimming, and then the long side must be similarly folded. Larger plates must take more folds, always working on the principle that the length of the book should first be obtained in the best possible way, and afterwards the width is taken as the guide in making the folds.

In doing this the plate must be folded now to the front, then to the back, so that on drawing it out it opens in a zigzag fashion. For the sake of clearness we give illustrations showing the most general methods of folding. The part marked A is secured in its place in the book by mounting on a paper guard; but one may, by cutting out the map properly, leave a small margin which will serve as a guard as shown in Figs. 10, 12, and 13.

In all cases, however, it is essential that the thickness of the folded plates should be equalised by inserting guards in the back of the book.

Formerly, when several plates were inserted one after the other, it was customary to place them in such a way that they were trimmed at top and bottom alternately; now they are placed so that they are all trimmed at the top edge: this is much better, because it keeps the top edge smooth and close, thereby keeping out dust and insects. The accompanying sketches are based upon this principle.

The so-called two-page illustrations in periodicals must be treated in the same way. These are only possible in the middle of a section, where they would be caught into the back and injured if the following precaution were not observed. Such illustrations are taken out, the back edge pasted, and then placed in the back so as to adhere to the following sheets, projecting about 1/2 cm.

The printed sheets thus treated must now be collected by[Pg 28] the same process—that is if they have not been gathered in open sheets in the printery—into volumes; this work is generally known as gathering after folding.

As in gathering open sheets, the piles of folded sheets are placed side by side; but as these take up so much less room than the open sheets, in most cases the whole work may be laid out at one time.

Clear the longest table procurable, which if not long enough must be extended by the addition of small tables, trestles, &c., upon which are laid the batches of sheets in fifties, and, beginning with the last sheet, work up the row until the title page is reached and the gathering ended. Starting from the left, the gathered sheets are placed to the right; after the last sheet, i.e., the title page, there should be sufficient room for placing the gathered sheets and also, if possible, for knocking up and collating, that is, checking the sequence of the sheets. The gatherer begins with the last sheet on the left, draws the top sheet with the right hand on to the left hand held flat to receive it, and so goes along the row, drawing from each pile one sheet, which drops into its place on top of the preceding one in the left hand. This work can be carried on simultaneously by several persons following each other, but there must be a sufficient number of persons stationed at the end ready to knock up and collate the gathered sheets. In order to simplify this work and to enable one to take up the completed gathering at the title page, the pile containing the title page sheet is plainly marked across the back with a blue or red pencil, so that one sees on the back of each single sheet a coloured mark easily seen in the gathered and knocked-up sheets.

Fig. 14—Collating.

Fig. 14—Collating.

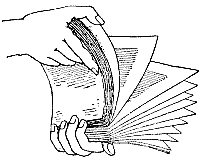

To collate a book it is taken in both hands. Taking a good hold of it by the right hand at the top edge, it is lightly held by the left at the bottom towards the back. Now make a turn downwards with the right so that the whole[Pg 29] pack of sheets springs upwards and spreads out at the back like a fan, and the controlling left hand lets them go one at a time, whilst checking the sequence of the signatures, that is to say, the sheets must be checked to see whether instead of the right signatures following in due order there is not a second signature or perhaps none at all. In such a case the sheet must be taken out and re-folded.

It may be well to refer now to another more detailed branch of this work which is necessary for certain purposes. If books which have already been used or bound are sent for re-binding it would be very unsafe to rely upon the pages being in proper order, especially if they have been much torn and have to be mended. Very frequently the leaves of a section have been misplaced. In such cases the book is laid flat upon the table, the head lying to the top, and, beginning at the title, leaf by leaf is lifted with the point of a knife after the way some ignorant persons have of using a moistened finger. The knife point is not inserted under the leaf lying uppermost but is lightly placed at the top of the leaf near the page number and the leaf pushed up from the side so that the left index finger takes it as it separates from the succeeding leaf whilst the eye scans the page numbers 1, 3, 5, 7, 9, &c. Also with other things that do not admit of any other method of collating, e.g., ledgers, documents, &c., this is the only possible way of doing it.

Nowadays, paper received in the printery has been so well calendered beforehand—that is to say, polished between rollers—and after printing the sheets are once more so well[Pg 30] rolled that the gathered sheets may at once be prepared for sewing. Old paper, however, must be beaten or rolled to make it firm and solid. The former work will be completely forgotten at no very distant date, as the younger generation of masters and men show less and less inclination to learn it. For beating, a stone about the height of a low table, and a surface about the size of a sheet may be used, or a cast-iron plate about 6 cm. in thickness embedded in a block of wood the same height as the stone. Upon this firm base—which, of course, must stand on the ground floor or in the cellar—the book, or section of it if too thick, is beaten with a short-handled iron hammer, the face of which measures about 100 sq. cm. All corners and edges are well rounded off, and the face is slightly convex. The handle must be short, not above 12 cm. long, cut oval, and just thick enough to be well grasped. The hole in the hammer is made so that the handle drops a little at the (outer) end.

In beating, the sections should be held by the left hand after being knocked up. In order to prevent injury to the paper, the sections are placed between pieces of waste paper of same size, also a mill-board or piece of waste paper to size is laid upon the beating stone. The right hand wields the hammer, which must strike the sections (or book) fairly and squarely with the full face. The beating is begun at the edge, and blow after blow is given in gradually lessening circles until the centre is reached, the left hand, of course, keeping up the necessary motion of the sections. It requires considerable practice to do this without shifting the sections, but if this happens they must again be knocked up.

The experienced workman knows by the touch where the book has been beaten much or little and works accordingly. The main thing in this, as in all other work, is that the book should be again pressed for some time—for a night at the least. The beaten volumes are divided into several lots or[Pg 31] sections about a finger thick, and pressing-boards placed between them. If any sections show folds or creases even after pressing, they must be once more beaten and pressed.

The work of beating, as already said, has been almost entirely superseded by the rolling machine. In treatises by theorists, one finds over and over again that books are not so well bound nowadays owing to the "practice of hand-beating being discontinued." This opinion is absurd, and arises from a very superficial technical knowledge and wholly imperfect acquaintance with the requirements of our craft. A machine-rolled or unbeaten book is always much better than one imperfectly beaten, for here nothing is demanded but sheer force, and that is always exercised with better results by a machine. As already pointed out, our modern printed books do not require any such work; besides, the so-called surface papers and printed illustrations prohibit both beating and rolling, as such work would destroy the high surface of the paper. Old books, on the contrary, where the paper is unsized, spongy, and swollen, require some such work, as pressing alone, even for days, has not the required effect.

In beating, the work should be divided into sections or lots of 15 to 20 sheets; they need not be counted, they are measured by the eye. For rolling, however, the sheets must be counted off exactly, from 8 to 12; they are knocked up and placed between zinc plates of same size and passed[Pg 32] through the rollers obliquely, the upper back corner being first inserted. It is well to introduce the second lot before the first has quite passed through the rollers; this not only saves the rollers but avoids the extra pressure on the lower corner when a section leaves the rollers. For this reason it is advisable to insert the lots right and left alternately. The first lot rolled should be examined to test the amount of pressure, and at first a lighter pressure should be applied to avoid risk of injury.

We have now come to the end of the processes through which a book has to pass before it is actually made up into book form. Before we take up this work there is incidental work to be mentioned which comes before the work of binding proper. This is the stitching and treatment of stitched or bound books for binding and the necessary repairs thereto.

The stitched or brochured book is no true book form; it is nothing more than the gathered sheets of a work in a temporary form, handier and more convenient, and therefore more saleable.

To prevent leaves from falling out in the event of their being cut open, they are lightly stitched together—holländert.

How did the name originate? It is difficult to say. Perhaps books stitched in this manner were first brought out in Holland.

With this method of sewing, the sheet only gets one short thread in the middle; but as the sewing of each sheet separately would entail a considerable loss of time, that old contrivance of the bookbinder for most kinds of sewing work, the sewing frame, is here made use of. A base or bed has on each front corner a perpendicular screw, upon which is placed a movable cross-bar with a slit. This bar is regulated by two screws; lay cords are fastened to hooks which are slipped through the slits, the other ends being knotted to[Pg 33] metal keys fixed under the base. A narrow movable bar, bevelled to the front of the bed, holds these keys when the lay cords are tightened.

There are no lay cords on the sewing frame for the work of Holländering as in other kinds of sewing, but two strips of zinc plate about 1 to 1-1/2 cm. in width are fastened so that at the top they are attached to the hooks and at the bottom are held with a pin. The lot to be sewn is placed rather slant-wise on the bed of the frame to the left, the back turned outwards, the head to the sewer, all sheets, therefore, facing away from the worker.

Fig. 17—Arrangement on the sewing frame.

The left hand takes the upper sheet with thumb and middle finger, so that the forefinger at once falls in the middle of the sheet, turning the sheet so that the head A lies to the left and face upwards as shown in the illustration; zinc strips are stretched at the points x. The left hand is introduced into the opened sheets from behind to take the needle when pushed in and then to draw it out again; the right hand inserts the needle from outside, and also draws out the needle inserted from inside by the left hand.

All kinds of sewing on the sewing frame are divided between both hands in the same way.

The threaded needle is now introduced into the sheets to[Pg 34] the right of the right strip at the back fold and again brought out to the right of the left strip, the sheets being meanwhile held open by the left hand. The thread is drawn out, except for a short end, the second sheet taken and laid open, and the needle is now introduced to the left of the left strip and brought out to the left of the right strip; and so on, each time introducing the needle from the right side to the right of the strip and from the left side to the left of the strip, drawing out accordingly. The thread is only to be seen on the outside of the strips.

The so-called English darning-needle—a long needle with a long eye—is used by the bookbinder. A special thread is made on purpose, the highest number being used for holländering.

When the sewing frame is packed so full that the sheets can no longer be kept properly squared, a sharp knife is taken and the threads cut off along the metal strips, and the sheets are then removed from the sewing frame. Every sheet is now independent of the other, and has a thread in the middle, of which a little may be seen at each needle-hole. These ends are afterwards pasted up in the work to follow. It is clear from this method of sewing that it is not necessary to tie a second thread on to the first when finished, but simply to begin with a new thread, letting the ends always project a little.

This method is the more recent and practical. It admits of one kind of sheet being sewn immediately after folding: nay, more: whilst one folder is still busy folding, another may begin to holländer. It is not till afterwards that the sheets are gathered. Gathered sheets are sewn in the same way, and are more easily knocked up than when sewn on cords and the threads left uncut after the old style instead of on metal bands. In holländert sheets the threads lie as shown in Fig. 18.[Pg 35]

Fig. 18—Arrangement of threads in holländering.

Fig. 18—Arrangement of threads in holländering.

Lately, in brochuring, the sheets are not holländert, but sewn with wire on the machine. This is a very good method when the finest possible staple closing from the outside is used. For this work a small machine is used, similar to those used for wiring documents, copy-books, and single sheets, which have an automatic wire-drawing action.

The batch of sheets is here arranged face upwards to the right of the worker. The right hand takes the sheet by the head, opening it at the same time with the forefinger, and inserts it in the groove of the machine, which is at the same moment set in motion. With each different sheet the position of the staple must be changed so that all do not stand the same height, as it would cause the paper to be cut through in pressing.

The accompanying sketch shows the arrangement of the collected brochures.

Fig. 20—Arrangement of staples in brochures.

It is barbarous to sew more tightly with wire, for in the necessary pulling to pieces to bring them to their former[Pg 36] state for binding they are sure to be more or less damaged. Sewing with a large machine using strips of gauze cannot be recommended.

The further treatment of holländert or wire-sewn sheets is dealt with towards the end of the chapter.

Most of the books given to the small binder do not come to him fresh from the printer, but sewn, used or unused, cut open, or as published. The sheets for binding must, as far as possible, be restored to the condition they were in before they were sewn. It is absolutely necessary that they should be made into loose single sheets. This work is called "pulling to pieces." The outer cover is torn off, the thread or wire inside the sheet removed, and the sheets very carefully separated one by one. When they are all pulled to pieces they are pushed open a little at the back, first to one side, then to the other, and scraped with a knife from top to bottom so as to remove all dirt, glue, &c., adhering.

Where the sheets had been cut open and the inner leaves worked out of place, they must be well pushed into the back again. The sheet is lightly held half-open in the left hand, and the leaves are knocked into the back with a long folder or knife.

If sheets are found badly folded they must now be properly re-folded. Any torn places must be repaired. A special chapter ought really to be devoted to this, for repairing and restoring is an art in itself. Here, only the most necessary work can be mentioned.

There are three different kinds of tears: tears in the print, in the margin, and in the back. The first may be torn with slanting edges; in such a case, both edges must be carefully pasted, fitted to each other, a piece of paper laid over and under, and then well rubbed down. If the tear has not slanting edges, but is clean cut, it is always best to paste the[Pg 37] edges likewise and to join the pieces by overlapping very slightly. It always looks better than the patching with strips of paper—a method adopted even by good workmen. The pasting on of pieces of tissue paper is to be condemned.

In cases of repairs like the foregoing, a piece of unpasted tissue paper may be laid on the repaired place and rubbed down, so that any paste exuding cannot do harm, and besides, it will serve to strengthen a weak place. It may be used, however, only on condition that the tint is exactly the same as that of the other paper.

Tears at the margin are repaired by pasting on strips of the same paper or of a kind as near as possible in texture and tint. To make the mend less noticeable, the paper should be torn beforehand, that is to say, by tearing one side of the paper the edge is less sharply defined and appears more like part of the sheet and is hardly perceptible.

Tears in the back (if outside) leaves are mended by pasting them down on to the following inner leaf; afterwards the glue makes this place still stronger. If the middle leaf is likewise torn, a narrow strip is pasted into the back. This may be cut true by the straight-edge if a very narrow strip suffices, but if the tear is here also sideways a piece of torn paper must be pasted on. If there are backs, torn off corners, or the like to be put in, a suitable paper is selected, a piece a little larger than the missing piece cut off the edge of the damaged leaf neatly pasted, the patch laid on slightly overlapping, and well rubbed down under a piece of waste paper. When thoroughly dry, the loose edges of the patch should be carefully torn off so as to slope and taper off nicely.

When all parts are repaired and the sheets again in proper order, the book is pressed for a while between boards.

It is thus that good books are treated, and although it would be better to return books of no special value as not[Pg 38] worth the labour, still it does happen that cheap books—mostly school books and periodicals—have to be repaired. A quick way of getting through such work is as follows:—

A larger piece of similar paper is well pasted and laid upon a clean cutting-board, and from this piece strips of the required width are cut, laid down in their place, and cut to length with the shears, and well rubbed down under waste paper. If the pasted piece becomes dry before it is used it must be coated again.

All repaired sheets must be laid between mill-boards to dry.

Worn and damaged periodicals are repaired in the same way. Generally the numbers are curled towards the fore-edge. Before commencing to pull to pieces they should be rolled towards the back, especially close to the back, to straighten them. The leaves must all be well pushed into the back, turned down corners (so-called dogs' ears) must be turned up, and two-page illustrations must be pasted away from the back. There are generally single or double leaves at the end of each copy or sheet—these must be pasted on. This work is not done singly, but the whole volume is at once laid open from back to front for pasting. All parts of the sheets to be pasted are placed at the front edge of the table, the edges fanned out, the other sheets wherein they are to be placed being meanwhile pushed further back so that they are not touched during pasting. The fanned-out sheets are pasted and each is rubbed down on to the sheet following.

It has already been said that in pulling to pieces the wire or thread sewing must be removed; this is not always easy. To begin with, the wires must be first bent upwards; if they are firmly glued to the outside of the back, the latter has first to be softened by smearing it very thickly with paste, and after leaving it some little time the glue may be scraped off and[Pg 39] the wires loosened. Not until then can the wires inside the sheets be removed and the sheets separated. The backs of books that have been bound are softened in the same way.

Even to-day—Heaven help us!—well-got-up books, even illustrated works, are sewn through sideways with coarse wire staples. Great care must be used in removing these and in separating the sheets, so that the bookbinder may at least try to undo the harm caused by barbarous methods practised either in thoughtlessness or ignorance.

It sometimes happens that the back of a book is so bad that it is necessary to cut it clean off. The leaves are then made up into sections of 6 to 8, levelled at the back, and overcast with a fine needle and fine thread. This work can be done quicker with an ordinary sewing-machine, adjusting it for the longest stitch.

New works consisting of thin single sheets are done in the same way.[Pg 40]

Modern books are fastened together by sewing; as a rule thread is used, and always in sewing good books. Thread sewing is very much better than wire stitching. In the first place, thread has not the disadvantage of rusting, to which wire is always subject; secondly, thread does not break the paper in the back, as so frequently happens when cheap paper containing much wood fibre is wire-stitched. The greatest advantage of thread sewing over wire lies in the flexibility of the spun thread; with sharp pressure it lies flat in the sheet, whilst wire does not give at all. Besides, it is flexible the whole length, and this adds greatly to the life of the book.

All thread sewing is now done by machinery and is really satisfactory. Only the very smallest job shops sew their books by hand.

The principle of sewing is to fasten each sheet to several cords or bands by means of a long thread running right along the inside of the sheet. These cords give the book its hold to the cover; therefore the more cords used, the more firmly is the book secured to its cover. There are now two methods of fastening the sheets on the cords; first, there is the older method of passing the thread along and out of the sheet, around the cord, and again into the sheet, and repeating the same movement at the next band.[Pg 41]

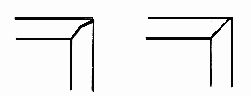

Fig. 21—Arrangement of threads in old style of sewing.

Nowadays, this method is almost entirely discarded. When for special reasons, or on account of its greater strength, it is desired to imitate the old method, the sewing is done on double cords; that is to say, for every cord two cords are stretched alongside each other and regarded as one. This sewing is more tedious, as the thread must take up each cord as shown in Fig. 22.

Fig. 22—Arrangement of threads with double cords.

These somewhat elaborate modes of sewing have been simplified in recent years by making saw-cuts in the back, in which the cords are laid. By this means the sewing thread never actually passes out of the sheet, but is drawn behind the cord lying in the saw-cut and thus holds it.