This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org

Title: The Woman's Part

A Record of Munitions Work

Author: L. K. Yates

Release Date: December 29, 2011 [eBook #38437]

Language: English

Character set encoding: ISO-8859-1

***START OF THE PROJECT GUTENBERG EBOOK THE WOMAN'S PART***

| Note: | Images of the original pages are available through Internet Archive. See http://www.archive.org/details/womanspartarecor00yate |

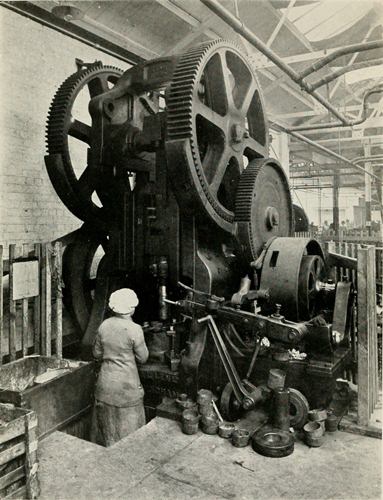

THE MANUFACTURE OF 4.5-INCH CARTRIDGE CASES:

OPERATING THE DRAWING PRESS

THE

WOMAN’S PART

A Record of Munitions Work

BY

L. K. YATES

NEW YORK

GEORGE H. DORAN COMPANY

| CHAPTER | PAGE | |

| I. | The Advent of Women in Engineering Trades | 7 |

| SHARING A COMMON TASK | 9 | |

| DILUTION | 11 | |

| HEROISM IN THE WORKSHOP | 12 | |

| II. | Training the Munition Worker | 14 |

| THE QUINTESSENCE OF THE WORK | 15 | |

| THE INSTRUCTIONAL FACTORY | 17 | |

| FIRST STEPS IN INDUSTRIAL LIFE | 18 | |

| III. | At Work—I. | 20 |

| SHELLS AND SHELL CASES | 21 | |

| IN THE FUSE-SHOP | 23 | |

| CARTRIDGES AND BULLETS | 25 | |

| IV. | At Work—II. | 28 |

| THE MAKING OF AIRCRAFT | 28 | |

| OPTICAL INSTRUMENTS | 30 | |

| IN THE SHIPYARDS | 33 | |

| V. | Comfort and Safety | 37 |

| WELFARE SUPERVISION | 37 | |

| PROTECTIVE CLOTHING | 41 | |

| REST-ROOMS AND FIRST AID | 42 | |

| WOMEN POLICE | 43 | |

| VI. | Outside Welfare | 45 |

| RECREATION | 45 | |

| MOTHERHOOD | 47 | |

| THE FACTORY NURSERY | 48 | |

| VII. | Growth of the Industrial Canteen | 52 |

| GENERAL PRINCIPLES | 54 | |

| THE WORKER’S OASIS | 55 | |

| VIII. | Housing | 57 |

| BILLETING | 58 | |

| TEMPORARY ACCOMMODATION | 59 | |

| PERMANENT ACCOMMODATION | 61 |

| The Manufacture of 4.5-inch Cartridge Cases: Operating the Drawing Press | Frontispiece |

| PAGE | |

| Turning the Copper Band of a 9.2-inch High-explosive Shell | 16 |

| Drilling Safety-pin Hole in Fuse | 16 |

| Inspecting and Gauging Fuses | 17 |

| Turning the Outside and Forming the Nose-end of a 9.2-inch High-explosive Shell | 17 |

| Assembling Fuses | 20 |

| Cooling Shell Forgings | 20 |

| Operating a Lumsden Plain Grinder: Re-forming 8-inch High-explosive Cutters | 21 |

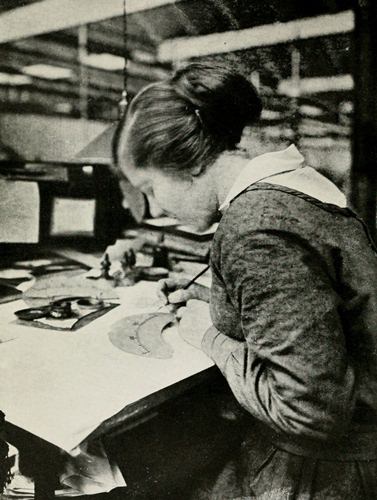

| Engraving Metal Parts for Compasses | 28 |

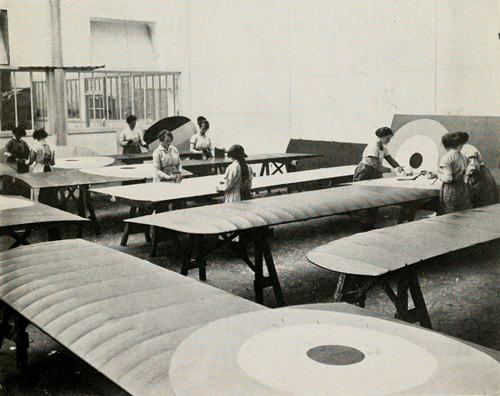

| Colouring Aeroplane Planes | 28 |

| Chipping and Grinding Blades of Cast Iron Propeller with Portable Tools | 29 |

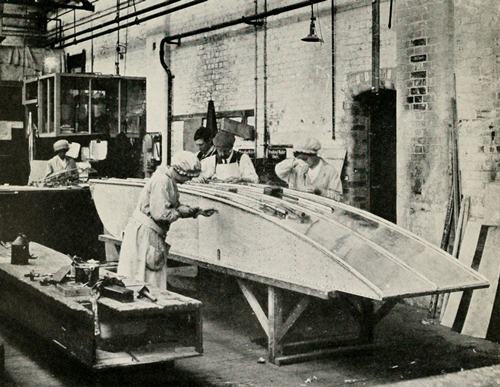

| Woman Acting as Mate to Joiner Making Sea-plane Floats | 29 |

| Cutting Frayed-edge Tape | 36 |

| Brazing Turbine Rotor Segment | 36 |

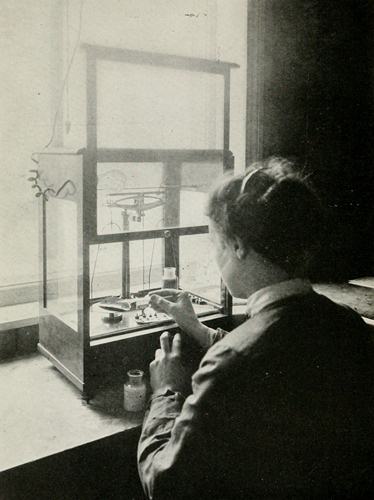

| Mounting Cards for Dry Compasses | 37 |

| Treadle Polishing-machines, for Smoothing Lenses | 37 |

| Slitting and Roughing Optical Glass | 44 |

| View of Canteen Kitchen | 44 |

| Weighing Ferro Chrome for Analysis | 45 |

| Balsaming Lenses | 52 |

| Making Instrument Scales | 53 |

| Painting a Ship’s Side in Dry Dock | 60 |

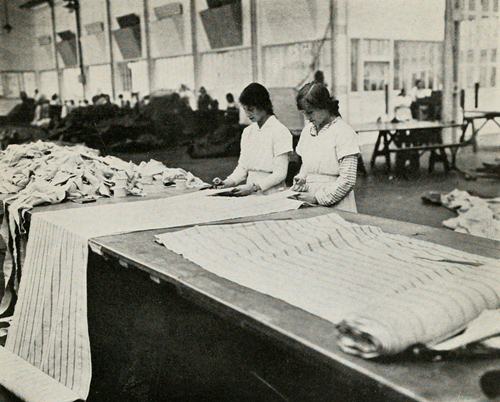

| General View of Women at Work on Aircraft Fabric | 61 |

| The Canteen | 61 |

THE WOMAN’S PART

SHARING A COMMON TASK—DILUTION—HEROISM IN THE WORKSHOP

In a period of titanic events it is difficult to characterize a single group of happenings as of special significance, yet at the end of the war it is likely that Great Britain will look back to the transformation of her home industries for war purposes as one of the greatest feats she has ever accomplished. The arousing of a nation to fight to the death for the principle of Liberty is doubtless one of the most stirring of spectacles in the human drama; it has repeated itself throughout history; but it has been left to this century to witness in the midst of such an upheaval the complete reorganization of a nation’s industry, built up slowly and painfully by a modern civilization for its material support and utility.

Before the outbreak of hostilities Great Britain was supplying the world with the products of her workshops, but these products were mainly those needed by nations at peace. The coal mines of Northumberland, the foundries of the Midlands, the cotton mills of Lancashire were aiding vast populations in their daily human struggle, but the demand of 1914 for vast requirements for war purposes found Great Britain unprepared. The instantaneous rearrangement of industries for war purposes, possible to Germany by reason of forty years of stealthy war preparations, was out of the question for a nation that neither contemplated nor prepared for a European conflagration. Eight or nine months had to elapse before the people of Great Britain were aroused to the realities of modern warfare.

It was then only that a large public became aware that the Herculean struggle was not merely a conflict between armies and navies, but between British science and German science, between British chemists and German chemists, between British workshops and the workshops of Germany. The realization of these facts led to the creation of the Ministry of Munitions in May 1915 and the rapid rearrangement of industries and industrial conditions. Before the war, three National factories in Great Britain[Pg 8] were sufficient to fulfil the demand for output for possible war purposes; to-day, there are more than 150 National factories and over 5,000 Controlled Establishments, scattered up and down the country, all producing munitions of war. The whole of the North Country and the whole of the Midlands have, in fact, become a vast arsenal.

Standing on an eminence in the North, one may by day watch ascending the smoke of from 400 to 500 munition factories, and by night at many a point in the Midland counties one may survey an encircling zone of flames as they belch forth from the chimneys of the engineering works of war. The vast majority of these workshops had previously to the war never produced a gun, a shell, or a cartridge. To-day, makers of agricultural and textile machinery are engaged on munitions, producers of lead pencils are turning out shrapnel; a manufacturer of gramophones is producing fuses; a court jeweller is engaged in the manufacture of optical instruments; a maker of cream separators has now an output of primers. Nor is this all. New industries have been started and languishing trades have been revived.

The work of reorganization has been prodigious, and when the history of Britain’s share in the war comes to be written in the leisured days of peace, it is unlikely that the record will transmit to a future generation how much effort it has taken to produce the preponderance in munitions now achieved. With the huge task of securing an adequate supply of raw material has gone hand in hand the production of a sufficiency of suitable machinery and machine tools, the equipment of laboratories for chemical research, the erection, or adaptation, of accommodation in which to house the new ‘plant’, and the supply of a continuous stream of suitable labour. In face of the growing needs of the Navy and Army this labour question has been a crucial test; it is a testimony to the ‘will to win’ of the whole people that the problem from the outset has found its solution. As soon as the importance of the demand for munitions workers was widely understood, a supply of labour has continuously streamed into the factory gates. There are now 2,000,000 persons employed in munitions industries—exclusive of Admiralty work—of which one-third are women.

The advent of the women in the engineering shops and their success in a group of fresh trades may be accounted as an omen of deep significance. Women in this country have, it is true, taken their place in factory life from the moment that machinery swept away the spinning-wheel from the domestic hearth, and it is more often the woman mill-hand, or factory ‘lass’, who is the wealthier partner in many a Lancashire home. Women before the war, to be sure, took part in factory life where such [Pg 9]commodities as textiles, clothing, food, household goods, &c., were produced, but by consensus of opinion—feminine as well as masculine—her presence in Engineering Works, save on mere routine work, or on a few delicate processes, was considered in the pre-war period as unsuitable and undesirable.

Sharing a Common Task

At the outbreak of hostilities, a few of the most far-sighted employers, contemplating a shortage of labour through the recruitment of men for military service, hazarded the opinion that women might be employed on all kinds of simple repetition work in the Engineering Shops. Further than that even the optimist did not go. There was also no indication that women would be willing to adventure into a world where long hours and night-work prevailed, from which evils they were protected in the days of peace by stringent Factory Acts. Events have proved that the women of Great Britain are as ready as their menfolk to sacrifice comfort and personal convenience to the demands of a great cause, and as soon as it was made known that their services were required, they came forward in their hundreds of thousands.

They have come from the office and the shop, from domestic service and the dressmaker’s room, from the High Schools and the Colleges, and from the quietude of the stately homes of the leisured rich. They have travelled from far-off corners in the United Kingdom as well as from homesteads in Australia and New Zealand, and from lonely farms in South Africa and Canada. Every stratum of society has provided its share of willing women workers eager from one cause or another to ‘do their bit’.

Even in the early days of the advent of women in the munitions shops, I have seen working together, side by side, the daughter of an earl, a shopkeeper’s widow, a graduate from Girton, a domestic servant and a young woman from a lonely farm in Rhodesia, whose husband had joined the colours. Social status, so stiff a barrier in this country in pre-war days, was forgotten in the factory, as in the trenches, and they were all working together as happily as the members of a united family.

Employers and former employees likewise often share a common task in the workshops of the war. At Woolwich, for example, a lady of delicate upbringing could, at one period, have been seen arriving at the Arsenal in the early hours of each morning, accompanied by her former maid, both being the while ‘hands’ in the employ of the State. It is well known in certain circles how Lady Scott, the widow of the famous Antarctic explorer, put aside all private interests to take up work in a munitions factory, how Lady Gertrude Crawford became an official, supervising[Pg 10] women’s work in shipyards, and how Lady Mary Hamilton (now Mrs. Kenyon Slaney), the eldest daughter of the Duke of Abercorn, and Miss Stella Drummond, daughter of General Drummond, have won distinction as workers in ‘advanced’ processes of munitions production.

These are but a few distinguished names amongst a crowd of women of all degrees of society who have achieved unexpected success in work to which they were entirely unaccustomed. Amongst this nameless multitude, attention has been called from time to time to the remarkable feats in the engineering and chemical trades, in electrical works, and in the shipyards, of kitchen-maids and of dressmakers, of governesses and children’s nurses.

The underlying motives, all actuated by war conditions, which have turned the tide of women’s work into new and unfamiliar occupations, are, however, more diverse than is generally supposed. Unquestionably, the two main driving forces have been patriotism and economic pressure, and of these patriotism, the love of country, the pride of Empire, accounts for a large proportion of women recruits. Yet there are other motives at work: the old human forces of family love and self-sacrifice, pride, anger, hatred, and even humour. I have questioned workers at the lathes and in doping rooms, in Filling Factories, and in wood-workers’ shops, and find the mass of new labour in the munitions works is there from distinctive individual reasons. It is only by the recognition of all these forces that successful management of a new factor in the labour problem is possible. An indication of the life-history of one or two individual munitions workers may exemplify the point.

There is the case of a girl tool-setter in a factory near London. She is the only child of an old Army family. When war broke out, she realized that for the first time in many generations her family could send no representative to fight the country’s battles. Her father was an old man, long past military age. The girl, although in much request at home, took up work in a base hospital in France, but at the end of a year, when broken down from over-strain, was ordered six months’ rest in England. Recovery followed in two months, and again, spurred by the thought of inaction in a time of national peril, she entered a munitions factory as an ordinary employee. After nine months’ work she had only lost five minutes’ time.

Another factory worker is a mother of seven sons, proud-spirited, efficient, and accustomed to rule her family. The seven sons enlisted and she felt her claim to headship was endangered. She entered a munitions factory and, to soothe her pride, sent weekly to each son a detailed account of her industrial work. At length, the eldest son wrote that he thought his[Pg 11] mother was probably killing more Germans than any of the family. Since then, she says, she has had peace of mind.

In another factory, in the West of England, there is an arduous munitions maker who works tirelessly through the longest shifts. Before her entry into the industrial world she was a stewardess on a passenger-ship. The vessel was torpedoed by a German submarine, and she was one of the few survivors. Daily she works off her hatred on a capstan lathe, hoping, as she tells the visitors, some day to get equal with the unspeakable Huns.

Then there is a typical case of a wife who has learned some of life’s little ironies through her work on munitions production. Her husband, an old sailor, worked for the same firm before the war. He used to come home daily and complain of the hardness of his lot. It was ‘a dog’s life’, he constantly reiterated, and his wife was careful to make reparation at home.

War broke out and the naval reserve man was recalled to sea. The firm were put to it, in the labour shortage, for a substitute, and invited the wife’s aid. Having heard so much of the hardships of the work, she refused, but after some persuasion agreed to give the job a trial. At the end of a week, she surmised the task was not so hard as she contemplated; after a month had passed she realized the position. The job had been a capital excuse to ensure forgiveness for domestic short-comings. The wife awaits her husband’s return with a certain grim humour.

Having arrived in the engineering trades, actuated by whatever motives, the woman munitions maker has more than justified the hopes of the pioneer employers who sponsored her cause. As soon as organized labour agreed that trade union rules and pre-war shop practice should be suspended for the duration of the war, women were rapidly initiated in the simple repetition processes of shell-making and shell-filling. Machinery was adapted to the new-comers, and the skilled men workers were distributed amongst the factories to undertake the jobs possible only to experienced hands.

Dilution

Thus, the principle of dilution, as old as Plato’s Republic, which as a theory was reintroduced to British students by Adam Smith, has widely come into practice through the urgency of the war. Women have been successfully introduced into a new group of occupations, men have been ‘upgraded’, so that many semi-skilled men have become skilled; and the skilled men have been allocated entirely to employment on skilled jobs.

Once introduced to the munitions shops, women soon mastered the repetition processes, such as ‘turning’, ‘milling’ and ‘grinding’, as well as the simpler operations connected with shell-filling. The keenest[Pg 12] amongst them were then found fit for more ‘advanced’ work where accuracy, a nice judgment, and deftness of manipulation are essential. Such are the processes connected with tool and gauge-making, where the work must be finished to within the finest limits—a fraction of the width of a human hair; such are the requirements for the work of overlooking, or inspection of output; and such are the many processes of aeroplane manufacture and optical glass production, upon which women are being increasingly employed.

They are also undertaking operations dependent on physical strength, which in pre-war days would have been regarded as wholly unsuitable to female capacity. War necessity has, however, killed old-time prejudice and has proved how readily women adapt themselves to any task within their physical powers. One may, for example, to-day watch women in the shipyards of the North hard at work, chipping and cleaning the ships’ decks, repairing hulls, or laying electric wire on board H.M. battleships. High up in the gantry cranes which move majestically across the vaulted factory roof, one may see women sitting aloft guiding the movement of the huge molten ingots; in the foundries, one may run across a woman smith; in the aeroplane factories, women welders work be-goggled at the anvils.

An engineering shop is now sometimes staffed almost entirely by women ‘hands’, and it is no uncommon sight to find in the centre of the shop women operators at work on the machines; at one end a group of women tool-setters, and at another women gaugers who test the products of this combined women’s labour. In the packing-rooms the lustier types of women may be seen dispatching finished shells, and on the factory platforms gartered women in tunic suits push the loaded trollies to waiting railway-trucks for conveyance to the front. One of the most surprising revelations of the war in this country has, indeed, been the capacity of women for engineering work, and to none has the discovery been more surprising and more exhilarating than to the women themselves.

Heroism in the Workshop

The work has, in fact, called for personal qualities usually thought to be abnormal in women. The women in the engineering shops have disproved any such surmise. Where occasion has demanded physical courage from the workers, the virtue has leaped forth from the average woman, as from the average man. Where circumstances call for grit and endurance, there has been no shirking in the factories by the majority of the operators of either sex. The heroism of the battlefields has frequently been equalled by the ordinary civilian in the factory, whether man or woman. Sometimes incidents of women’s courage in the works have been[Pg 13] reported in the press as matters for surprise. They are merely typical instances of the spirit that animates the general mass of the workers in Great Britain.

A few examples may be added in illustration. On a recent occasion, a woman lost the first finger and thumb of her left hand through the jamming of a piece of metal in a press. After an absence of six weeks, she returned to work and was soon getting an even greater output than before.

Another instance relates to a serious accident in an explosives factory, when several women were killed and many were injured. Within a few days a considerable number of the remaining female operators applied and were accepted for positions in the Danger Zone at another factory. Another incident is reported from some chemical works in the North. The key controlling a valve fell off and dropped into a pit below, rendering the woman in charge unable to control the steam. An accident seemed imminent and the woman, in spite of the likelihood of dangerous results to herself, got down to the pit, regained the key and averted disaster.

In a shipyard on the North-East coast, a woman of 23 years had been engaged for some time in electric-wiring a large battleship. One day, when working overhead, a drill came through from the deck, piercing her cotton cap and entering her head. She was attended to in the firm’s First Aid room and sent home. To the surprise of every one concerned, she returned to work at 6 a.m. on the following day, and laughingly remarked that she was quite satisfied that it was better to lose a little hair than her head.

In the trivial accidents which are, of course, of more frequent occurrence, the women display similar calmness and will stand unflinchingly while particles of grit, or metal, are removed from the eyes, or while small wounds—often due to their own carelessness—are dressed and bound. The endurance displayed during the early period of munitions production, when holidays were voluntarily abandoned and work continued through Sundays, and in many hours of overtime, was no less remarkable in the women than in the men. Action is continuously taken by the Ministry of Munitions to reduce the hours of overtime, to abolish Sunday labour, and to promote the well-being of the workers, but without the zeal and courage of the women munitions makers the valour of the soldiers at the Front would often be in vain.

As the Premier remarked in a recent speech: ‘I do not know what would have happened to this land when the men had to go away fighting if the women had not come forward and done their share of the work. It would have been utterly impossible for us to have waged a successful war, had it not been for the skill and ardour, enthusiasm and industry, which the women of the country have thrown into the work of the war’.

THE QUINTESSENCE OF THE WORK—THE INSTRUCTIONAL FACTORY—FIRST STEPS IN INDUSTRIAL LIFE

When, in answer to the demand for shells and more shells, factories were built, or adapted to the requirements of war, it was soon found that a supply of suitable labour must be ensured, if the maximum output was to be maintained. The existing practice of the engineering shops, by which a boy arrived by gradual steps, counted in years, from apprenticeship to the work of a skilled operator, was obviously impossible where an immediate demand for thousands of employees of varying efficiency had to be fulfilled. The needs of the Navy and Army further complicated the problem by the withdrawal of men of all degrees of skill from factory to battlefield.

The discovery of an untapped reservoir of labour in women’s work, and the adaptation of a larger proportion of machines to a ‘fool-proof’ standard, certainly eased the situation, yet the problem remained of the immediate provision of workers able to undertake ‘advanced’, as well as simple work, in the engineering shops. Factory employers were from the outset alive to the situation, and at once adopted measures for the training of new-comers within their shops, but harassed as the managers were by the supreme need for output, it was hardly possible to develop extensive schemes for training within the factory gates. Hence, arose a movement throughout the United Kingdom among the governing bodies of many institutions of University rank, among Local Education Authorities, and among various feminist groups, to make use of existing Technical Schools and Institutions for the training of recruits in engineering work.

The effort was at first mainly confined to the instruction of men in elementary machine work, and the London County Council may fairly claim to have acted as pioneer in this connexion. Yet, as early as August 1915, a group of women connected with the National Union of Women’s Suffrage Societies (of which Mrs. Fawcett, widow of a former Postmaster-General, is the president) decided to finance a scheme for the training[Pg 15] of women oxy-acetylene welders, converting for this purpose a small workshop run by a woman silversmith.

It was soon observed by the Ministry of Munitions that these sporadic efforts—sometimes successful beyond expectation, and sometimes failing for want of funds, or for lack of intimacy between training-ground and factory employer—must be co-ordinated, if they were to tackle successfully the growing task imposed by war conditions. The conception of a Training Section for factory workers within the Ministry of Munitions arose, took root. The section was established in the early autumn of 1915.

In the October of that year, authority to finance approved training schemes throughout the country was given to the new department. Some fifty colleges and schools, undertaking independent schemes, were then brought into touch with the Ministry, and steps were taken to develop the existing systems. Equipment was thereby improved, recruiting of students stimulated, and a scheme for the payment of maintenance during training—such as the Manhattan Schools in New York had previously introduced to social investigators in this country—was established. The extension of the courses of training from instruction in simple processes to such advanced engineering work as lead-burning, tool-setting, and gauge-making soon followed, and was accompanied by necessary theoretical instruction in the methods of calculation of fine measurements.

The Quintessence of the Work

For these advanced classes, men alone were at first eligible as students, women being only instructed at the outset in elementary parts of the work. In the early days, the women were invited ‘to do their bit’, by learning how to bore, how to drill, how to plane, how to shape, and above all, how to work to size. The chief battle of the Training Centre with regard to the instruction of women was then, and still remains, the implanting of a feeling for exactitude in persons accustomed to measure ribbons or lace within a margin of a quarter of a yard or so, or to prepare food by a guess-work mixture of ingredients. I remember, at the beginning of a course of training for women, how an instructor at a large metropolitan Centre remarked that ‘ninety-nine per cent. of the new students do not know what accuracy means’, and he detailed how difficult it was to instil into their mind ‘that quintessence of their work’.

Scientific methods of tuition, helped no doubt by women’s proverbial patience, have, however, enabled the lesson to be learned after a few weeks’ intensive training. The courses last but six to eight weeks and, at the conclusion of the carefully graduated tasks, it is not too much to[Pg 16] say that the success of the women has been, in an overwhelming number of cases, surprising both to teachers and pupils.

I have before me a batch of letters from factory employers, written in the early period of the training schemes. They all bear testimony to the value of the outside instruction. One manager notes how the trained women from the Schools were able ‘to become producers almost at once’; another states that the drafting of the women students from School to factory has enabled the work of munitions to be carried on ‘with greater expedition than would otherwise have been the case’, and yet another, with a scarcely concealed note of astonishment, relates that his students were able to be engaged at once on ‘all kinds of machinery, capstan lathes, turning lathes, milling and wheel cutting machinery’.

This discovery of the employer, of the potentialities of women’s work in the engineering trades, soon led to a development of the instruction of female students in the Training Centres; more advanced machine work was added to the curriculum, as well as tuition in aeroplane woodwork and construction, in core-making and moulding, in draughtsmanship and electrical work, in optical-instrument making, including the delicate and highly-skilled work of lens and prism making.

New Training Centres are constantly being opened in provincial areas, the instruction being adapted to the needs of local factories. There are now (December, 1917) over forty training schools for engineering work in Great Britain, as well as nine instructional factories and workshops, and the proportion of women to men trained in all the processes may be reckoned roughly as two to one.

The system of instruction is based, in some of the Centres, on the general principle that the School undertakes the preliminary work of tuition in the simpler engineering processes; the Instructional Factory, or workshop, specializing in the more skilled processes, acts as a clearing-house for promising students from the schools. The urgency of warfare does not, however, permit the application of any hard-and-fast rules. I have seen specimens of some of the most ‘advanced’ work produced in a School; indeed, the delicate work of lens polishing and centring, the intricacies of engineering draughtsmanship, the precise art of tool-setting and gauge-making have become specialisms of the Schools in certain localities.

TURNING THE COPPER BAND OF A 9.2-INCH HIGH-EXPLOSIVE SHELL

DRILLING SAFETY-PIN HOLE IN FUSE

INSPECTING AND GAUGING FUSES

TURNING THE OUTSIDE AND FORMING THE NOSE-END OF A 9.2-INCH HIGH-EXPLOSIVE SHELL

As I write, the face of an eager girl of 21 years recurs to memory. She was showing me, the other day, a master gauge produced at a School in the Eastern counties. ‘I made it all myself,’ she said joyfully, ‘dead exact, and all the other gauges of this size in the School are made from it. I have just been appointed assistant instructor in gauge-making.’ When it is recalled that the deviation in the measurements of a gauge is only[Pg 17] tolerated within such limits as a 3⁄10000 part of an inch, the production in a School of a master gauge, ‘dead exact’ in all its dimensions, is a proof that the student has already gone some way in the mastery of the craft of the engineer.

The Instructional Factory

On the other hand, the Instructional Factory is often forced by war conditions to enrol raw recruits who seem likely material for the urgent needs of surrounding factories. In such cases, the candidate is placed on trial for a week or two in the Instructional Workshop, as in the School. If, at the close of the period of probation, she is deemed unsuitable, she is advised at that preliminary stage to return to her former occupation.

Speaking generally, the rejects are extraordinarily few, and although it would be premature to draw definite conclusions, the experience of the Training Section suggests that there is considerable latent capacity for engineering work in a large number of women. A tour of the Instructional Workshops emphasizes the point; everywhere, women may be seen mastering in the short intensive course the one advanced job for which each is being trained. In the Instructional Workshop, the atmosphere of a School is exchanged for that of a factory, the conditions of a modern engineering shop being reflected within its precincts. Thus the students ‘clock on and off’ on arrival and on departure, observe factory shifts, work on actual commercial jobs, obtain their tools from an attached store, and so on. The work varies in these Instructional Factories as in the engineering shop of the commercial world.

In one section of such a hall of tuition you may see the women intent on the production of screws, or bolts, or nuts; in another part, such objects as fuse needles may be in the course of manufacture. You stop to see the magic which is answerable for the birth of the tiny factor which shall detonate the explosive, and you are amazed to find that a fuse needle requires six tools for its production and eight to nine gauges for testing the accuracy of its measurements. Or, you may perhaps pause before a machine which is turning out tiny grub screws. To see a rod of steel offer itself, as it were, to the rightful instruments on a complicated machine to impress the thread and slit, to watch it proceeding on its way until a tiny section is divided and a complete screw is handed over to a tray outside the machine, is, to the uninitiated, a miracle in itself.

To see the whole of these complicated processes guided and operated by a smiling girl makes one hopeful for the national industries of the future. Setters-up of tools are at work in another section of the same Instructional Factory and at other machines are students grinding, milling, or profiling.

[Pg 18]You may then visit another Instructional Factory to find that aircraft is the specialty. I recall one such training-ground in a bay of an aeroplane factory. There the girls learn almost every part of aircraft production, from the handling of the tiny hammers used on the woodwork for the body and wings, to the assembling, or putting together the tested parts. In this training factory, a system prevails of lectures by the practical instructors on the use of necessary tools; questions from the students are encouraged at the close of the lecture, and, I was informed, when on one occasion I was one of the audience, that the saving of the instructor’s time by the adoption of this method was beyond expected results.

Again, you may visit an Instructional Factory where foundry work is included in the curriculum, or where advanced machine work is a feature. I have stood in one Instructional Workshop where some 600 machines were whirring simultaneously, and where the spirit of energy and goodwill of both students and instructors seemed as tangible as the metal objects produced. In this institution all the accomplished work is for production; night as well as day shifts are worked, and the needs of our armies, or those of our Allies, are frankly discussed with the operators. There is no occasion for other incentive: raw recruits, students from the Schools, discharged soldiers from the Front, men unfit for active service, all these denizens of the training-shop vie with each other to produce a maximum output.

It speaks volumes for this workshop that in spite of the continual changes of operators—each set of students remaining only for a course of six to eight weeks—it is entirely maintained on a commercial basis. To reach such a standard in these circumstances is to imply that the heroism of the workshop has become an ingrained habit in operators and staff.

First Steps in Industrial Life

I remember watching in this training-ground the manufacture of small aero-engine parts, exact in dimensions to within the smallest limits of tolerance. I put a query as to the wastage of material in such an operation, when handled by comparative new-comers. ‘Scrapping from this process’, replied the production manager with pride, ‘does not exceed a total average of one per cent.’ The women at work at the time had come from the most varied occupations. A large proportion had never worked outside their own home, others were domestic servants, cooks, housemaids, and so on, others were dressmakers from small towns, and one, I recall, was an assistant from a spa, where she had been engaged handing out ‘waters’ to invalids. ‘It is not the rank of society from which the student is drawn that matters,’ remarked an instructor; ‘it is the personality of the individual that counts.’

[Pg 19]Every care has been taken by the Ministry of Munitions to make it easy for women of all classes to participate in their schemes of instruction. The middle class girl who has never undertaken independent work, the woman who has always lived and worked within the shelter of her own home, undoubtedly felt in many cases debarred from entering industrial life. The necessity of living away from her family, in order to enter a Training-School, the absence of home conditions in school or factory, the dread of an entirely masculine superintendence, all helped to strengthen artificial barriers between potential students and the needed engineering work. The Training Section, watching the development of its schemes, became aware of the necessity of making arrangements for students from the Welfare point of view, and an organization has thus developed by which the first steps in industrial life are made easy for the most apprehensive of new-comers.

Girl students by rail are met by a responsible woman official and are accompanied to suitable lodgings, or to hostels. In the event of pressure in accommodation, the new student is introduced to temporary apartments, or to a ‘Clearing Hostel’, where she awaits in comfort a vacancy. In the large Training Centres, a woman supervisor is in charge. She makes all arrangements as to the provision of meals, rest-rooms, cloak-rooms, First-Aid centres, and so on, and is ready to advise the women students on all points relating to their personal interests.

Women students are also enabled to wear a khaki uniform, as members of the Mechanical Unit of the Women’s Legion, a privilege found to be of distinct value to girls unaccustomed to steering an independent course in the more boisterous streams of life. The appreciation of the students of the safe-guarding of their individual desires crops out in unexpected places. In a handful of correspondence from students, one gleans such remarks as the following:

‘Mrs. H. never spares herself any trouble as long as she can make things pleasant for me, she considers it her “war work” to make munition workers happy, and it is very nice to meet people that appreciate what we are doing for our country.’...

‘We were met at the station by the works motor. All at once we turned up an avenue of lime-trees and drew up at the door of our country estate. It is a real lovely house and we revel in the glories of fresh air, lawns and gardens, good beds and well-spread tables. We cross a field to the works. Dinner and tea await us when we get here, and there is a well-stocked vegetable garden to give us fresh vegetables, so we all feel indeed that our lines are fallen in pleasant places, and we are very grateful.’

In these ways a bridge has been built by the Ministry of Munitions between the normal life of the women in this country and the work in the munitions factory.

SHELLS AND SHELL CASES—IN THE FUSE SHOP—CARTRIDGES AND BULLETS

Arrived in the munitions factory, the new-comer, whether from a Government Training Centre, or from another occupation, is given two or three weeks’ trial on the task she has come to undertake. Only a very small proportion of the women offering their services—one experienced manager puts it at 5 per cent.—are found unsuitable, and these are discharged during the probationary period.

Except in the case of those who have received a preliminary training, or of those who have merely transferred their energies from other factory work, the average woman has, at the initial stage in the munitions shops, to overcome an instinctive fear of the machine. Occasionally, the fear is intensified into an unreasoning phase of terror. ‘One has to coax the women to stay with such as these,’ said one understanding foreman, pointing to a monster machine with huge-toothed wheels. ‘We don’t ask a woman to sit alone with these at first, for she wouldn’t do it, so we put a man with her, and let her sit and watch a bit, and after a while she loses her fear and won’t work anything else, if she can help it.’

The women, in fact, soon get attached to the machines they are working, in a manner probably unknown to the men. ‘I’ve been here a year on this machine, and I can’t do near so well on any other,’ is a remark many a girl has made to me as I have watched her on a difficult job. From time to time, a girl will even confess that she ‘can’t bear to think of some one on the night-shift working her machine’. An understanding has arisen between the machine and the operator which amounts almost to affection. I have often noticed the expression of this emotion in the workshops; the caressing touch of a woman’s fingers, for instance, as a bore is being urged on to the job on the machine. This touch, which cannot be taught, or imparted, enables the operation to be started in the most effective method possible, and goes to the making of an excellent and accurate worker.

The femininity of the worker has, however, its drawbacks, and for the sake of successful handling of women in the munitions factory, it is as well that these psychological points should be noted. If, for example, a machine[Pg 21] is out of gear, or if the operation is held up for any other cause, the women munition makers will sometimes behave in an unreasonable manner, quite bewildering to a foreman accustomed only to dealing with men. The temporary cessation of work may make only a slight money difference to the woman operator by the end of the week: ‘not enough to fuss about,’ as the foreman judges. But the woman nevertheless often does fuss, because in her eyes the wages do not loom so large as the interruption to her work. She ‘hates standing-by’, she will say, for she cannot express the emotion of which she is but dimly conscious, that a woman’s deep instinct is to give freely of her fullness, and it frets her very soul to be balked in the middle of a job.

ASSEMBLING FUSES

COOLING SHELL FORGINGS

OPERATING A LUMSDEN PLAIN GRINDER: RE-FORMING 8-INCH HIGH-EXPLOSIVE CUTTERS

Other initial obstacles in the employment of ‘new’ female labour in the factories result from the exchange of the manifold duties of the woman in her own home for repetition work performed in the company of hundreds of other human beings. These difficulties are, however, soon overcome, and the new-comer, generally speaking, rapidly becomes one of a large and merry company. The whirr of the wheels and the persistent throb of the machinery may at first distract her, but after a short time the factory noises are unnoticed, save as an accompaniment to her thoughts, her laughter, or her song. I have indeed met in the England of to-day nothing more inspiriting, outside the soldiers’ camps, than the women munition workers at work or at play.

In August 1916, there were some 500 different munitions processes upon which women were engaged. To-day, they are employed upon practically every operation in factory, in foundry, in laboratory, and chemical works, of which they are physically capable. Within the limits of this publication it is not possible to follow them into every field of their endeavours, yet a glance at their work in a few typical products may give some slight indication of women’s contribution to Britain’s effort in the World War.

Shells and Shell Cases

Of the numbers of operations that go to the making of a shell, women now undertake every process, in some works, including even the forging of the billets in the foundry. It was the urgent need of a greatly increased output of shells in 1915 which led to the widespread introduction into the engineering shops of female labour, and the women have repaid this unique opportunity by their unqualified success. So rapid, and so marked, has been their progress in shell production that by the spring of 1917 the official announcement was justified, that, by March 31 of that year,[Pg 22] Government contracts for shells of certain dimensions would only be given where 80 per cent. of the employees were women.

At first, the women were mainly engaged in simple machine operations, such as boring, drilling, and turning, or in filling the shells. They are, at present, working hydraulic presses, guiding huge overhead cranes, ‘tonging’, or lifting the molten billets, ‘setting’, or fitting the tools in the machines, inspecting and gauging, painting the finished shell cases, making the boxes for dispatch of the finished product, and trucking these when finally screwed up and ready for exit from the factory to the Front. It is not possible to describe here in detail women’s entire contribution to the production of a shell, but, from foundry to railway truck, she has become an alert and promising worker.

In the foundry, her appearance is as yet exceptional, yet in the North country it is no unusual sight to find a woman in the cage suspended from the overhead travelling crane, operating its protruding arm. Now, she will pick up with the clumsy iron fingers a pig of iron and thrust it into the glowing depths of a furnace, or she will lift the red-hot billet and bring it to the hydraulic press, where it is roughly hollowed into its predestined shape.

In the shell shop proper you may watch the woman operator on some scores of processes; at one machine, she may be attacking the centre of the billet with a revolving nose, at another she may be ‘turning’ the outside of a shell. The shavings curl off in this process like hot bacon rind and fall in iridescent rings around her: blue, purple, peacock, or gleaming silver. Or, you may watch the woman worker ‘threading’ the shell, a process by which the screw threads are provided, into which the nose of the shell is afterwards fitted; or, you may stand and marvel at the skill of the worker who so deftly rivets the base-plate into the shell’s lower end. But, perhaps, the most attractive operation to the visitor to the shell shop is the fitting and grooving of the shell’s copper band, a process which leaves the machine and worker half-hidden in the glory of sunset tints, as the copper scrap falls thickly from the machine.

At every stage, the shell is gauged and tested, examined and re-examined, since accuracy is the watch-word of its production. Sometimes, the machine-operator will gauge her own product; at other stages, the shell passes into the hands of women overlookers of the factory, the final tests being made by Government ‘viewers’. The inside, as well as the outside of the shell is submitted to such inspection, and you may see women peering into the interior of the shells, aided by the light from a tiny electric bulb, mounted on a stick. This contrivance is thrust successively into rows and rows of shells.

[Pg 23]Women are now exclusively used for the painting of the shells, a process accomplished, not by means of a brush and paint-pot, but by the operator playing a fine electrically-worked syringe on to the surface of the shell. This process is undertaken in what is often called ‘the butcher’s shop’, the shells, in pairs, being swung up on a rope into a compartment where the operator works from behind a protective iron screen.

In the Filling shops, women’s devotion to their work has been proved once and again. Whether the process undertaken be in company of a few comrades, or in isolated huts where lonely vigils are kept over stores of explosives, the munition-girls are hardly known to flinch in their duty.

Sometimes, they have volunteered to work throughout the night when air-raids are in progress, at other times, women-workers have returned to the Danger Zone immediately after some bad experience there; and, in every case, the woman worker in the Filling Factory cheerfully sacrifices much which she holds dear in life. It may signify but little to a man to give up his small personal possessions whilst at work in the danger areas, but to many a woman worker it means much, that she may not wear a brooch, or a flower, while on duty, and that her wedding-ring, the only allowable trinket, must be bound with thread while she works. Her tresses, which she normally loves to braid, or twist into varying fashions, must also be left hairpinless beneath her cap. She must relinquish her personal belongings before going to her allotted task; no crochet-hook or knitting-pin may accompany her into the zone where friction of steel, or hard metal, might spell death to a multitude of employees. Yet this sacrifice of individuality is given freely by the woman in the Filling shop, and she is still merry-hearted and blithe as she fills the small bags with deadly powder, or binds the charge which shall fire the shell.

When the shell is finally filled and passed ‘O.K.’, or perfect, it is a woman who packs it into its box and who wheels it on a truck, sometimes for a mile or more over narrow platforms, to hand it to another woman who stacks it into the waiting railway-wagon. Any one who has watched throughout the production of a shell in a factory of to-day can only echo a well-known author’s recent salute: ‘Hats off to the Women’.

In the Fuse Shop

The fuse, that small and complicated object which explodes the shell, is a war-product now largely produced by women’s labour. A few inches in length, it requires some hundreds of operations for its manufacture, even if the initial processes on the metal are excluded from the count. In section, it looks like a complicated metal jig-saw puzzle of[Pg 24] exquisite finish and cohesion: viewing it externally, a child might mistake it for a conjurer’s ‘property’, a bright metal egg, or roll often surrounded by a metal ring marked with time measurements.

The care and accuracy necessary for the production of this small object can hardly be imagined by the uninitiated: it is measured and re-measured in every diameter, since on its perfection depends the life of the gunner and his team. The fuse shop is usually characterized by its cleanliness and quietude. I recall one such shop stretching far away into distance both in length and breadth. Under its roof some 1,500 women were at work. Conversation could be held in any part of the shop, undisturbed by the usual factory noises. The fuse parts are, indeed, so small that the machinery is necessarily light, and in such a shop it is dexterity and accuracy that tell, rather than physical strength.

Rows of graceful women and girls were standing at their machines, and I recall how their overalls and caps of varied hues made a rainbow effect, as one watched from a distant corner. Some were in cream colour and some in russet-brown, or apple green, the caps sometimes matching the overall and sometimes offering a strong contrast. A splash of purple, or a deep magenta, mingled with the head-dresses of softer hue, for in this shop, away from the Danger Zone, no insistence was made on uniformity of factory costume. Other women, wearing a distinctive armlet, were passing in and out between the rows of workers, now stopping and bending over a machine, now making some bright remark to the operator, as a ripple of laughter indicated, or again, pointing out in sterner wise some danger, or some error in the job. These itinerary women are the overlookers, who since the war have perfected themselves in their special job and can now supervise the operators.

At long tables, other women were sitting; some quite elderly and grey-haired, some mere girls. They were measuring with small gauges parts of the fuse, some the size of a good-sized bead. There are 150 different gauges authorized for the measurement of one type of fuse, and in practice even more are used, to ensure perfection of accuracy. I stood spell-bound at one of these gauging tables and watched the examination of small screws and flash plugs. There were six little squares of felt on the table, on which the examiner placed rejects, classified according to the detected flaw. The work proceeded with the utmost dispatch, the ‘accepted’ or ‘perfect’ heap growing as if by magic.

At another table, a girl was testing springs of about an inch long. If any of these showed the smallest fraction too much length after being submitted to a given pressure, they were put aside as ‘scrap’. At yet another table, tiny fuse needles were being examined for length, thickness[Pg 25] of phlange, and accuracy of point, and on a high flat desk, near a machine, I noticed seventeen different gauges were ranged for the examination of the percussion end of the fuse-body, one ten-thousandth part of an inch being the limitation or variation allowed in such parts.

When all the parts have been examined they are passed to other tables for assembling, or putting together. In this operation almost superhuman care is required, and the work is reserved for the best operators and time-keepers as a reward for long service. ‘Assembling’ is regarded as the plum of the fuse-room. The operators are well aware of the importance of the task, as they stow away in the time fuses the pea-ball, pellet, spring, stirrup, ferrule, and other components of the fuse. The needle is fixed by blows from a small hammer, and at length the fuse is completed and passes out of the room of its creation to receive its ‘filling’ from other hands.

Cartridges and Bullets

The production of cartridges and bullets is another branch of munitions production in which women are mainly employed. These objects, which, when completed, are together no longer than a ball-room pencil, make in their manufacture no great demand on physical strength.

On entering a cartridge and bullet shop, one is at once struck with its individuality. There is more stir and movement than in a fuse-room, but less of the imperiousness of the machinery than in the shell or gun shop. There is in the cartridge and bullet room still the whirr of wheels and, above that, the deep constant throb of the driving-force, that makes conversation almost inaudible to the new-comer. But beneath this bass accompaniment, one can hear the lesser sounds belonging to the cartridge and bullet-room alone. There may be the buzz of the circulating gas machines—which resemble miniature merry-go-rounds—the tap, tap, of the cartridges as they are thrown out of the machine into a box below, and the tinkle of bullets as they are poured into weighing machines, or on to tables, or into huge barrels, such as are used on the wharves for the transport of herrings.

A cartridge and bullet-shop sometimes is as animated and as picturesque as an open-air market under a southern sky. I remember such a shop where the girls were in various factory costumes, some at the machines in khaki and some in cream-coloured overalls and caps; some, who were ‘trucking’, or removing the product in boxes, were in cream trouser-suits, with smart head-dresses fashioned from brightly-coloured oriental handkerchiefs. In between the rows of girls men in dark suits were passing to and fro, now stopping to examine, or alter a machine and now taking up a box of bullets[Pg 26] and pouring out its glittering contents like a silver stream, so that the output from each worker might be weighed and assessed.

Through an open door, at one side of the shop, one could see other men, like stern magicians, dropping cartridges into vats of acid, and just to the side of the vats I caught sight of two girls vigorously shaking a sack of cartridges, hot from the furnace. As they shook, they sang an army refrain: ‘Take me back to dear old Blighty,’ with a chorus of laughter. At the extreme end of the shop, near the door whence the product made its exit, were long narrow tables, piled with bullets, reminding one of a haul of silver sprats on the quay-side. These were the inspecting tables where the bullets receive minute attention from women viewers.

The women’s work in the bullet-shop is of extraordinary interest to the onlooker, although many of the processes must be infinitely more monotonous, from the worker’s standpoint, than operations in other munitions productions. The elongation of the little metal vessel, resembling an acorn-cup, into a full-length cartridge, or bullet, necessitates many operations in which the dexterity of human fingers and the ingenuity of the machine both come into play. In the shop I recall, in one machine employed for semi-annealing, the cartridge was being ‘fed’ into a metal revolving plate. This passed behind an asbestos screen into a double row of gas jets, where the semi-annealing or hardening process was being accomplished. The dexterity of the operators was so great that one woman was often feeding two machines, apparently without effort, and never missed placing the cartridge into the correct aperture in the revolving plate.

In another process, I watched young girls sitting round a table and placing bullets into circular apertures in small trays, resembling solitaire-boards. Many of the girls were working with such speed that it was impossible to follow the movements of their fingers, but they, unconscious of their prowess, worked with averted heads, smiling in amusement at the visitor’s astonishment.

In yet another operation, it was the machine that held one’s attention. The operator was feeding cartridges into a metal band which slipped out of view while the process of ‘tapering’ was performed. When finished, a metal thumb and index finger appeared, which delicately picked up the cartridges, one by one, and threw them aside. The displaced cartridge then hopped out of the machine into a box at the side of the machine.

Entranced by the many mysteries in the production of cartridges and bullets in the shop I am recalling, I had not noticed that the tea-interval had arrived, and suddenly found that the work-room was almost empty of human beings. Only two girls remained. They were sitting sewing,[Pg 27] whilst they devoured thick slices of bread and butter out of a newspaper packet. The woman inspector, who was my guide, turned sharply. ‘What are you doing here?’ she said, ‘Eating your tea in the workshop, instead of outside, or in the canteen. Be off at once into the fresh air.’ Then, with the indignation fading out of a good-humoured face: ‘What next?’ she said.

Looking out of the open door at the streams of bright and happy girls laughing, singing, dancing, and running, as only healthy youth can do in the midst of these dark days of war, I seemed to see other and brighter days ahead stretching out into the years of the future, when the workfolk would all taste a fuller joy in life. With renewed hope, I gave her back her challenge: ‘Well! and what next?’

THE MAKING OF AIRCRAFT—OPTICAL INSTRUMENTS—IN THE SHIPYARDS

The Making of Aircraft

The production of aircraft, undertaken in this country on a large scale only since the outbreak of the war, has fallen more naturally into the hands of women. The work is for the most part light, and the new factories, often erected in open country, are bright, airy, and largely free from the noise of machinery. Added to these special attractions to the woman worker, there is apparently a distinct appeal to the youth of both sexes and to women of all ages in anything connected with the art of flying.

It is no secret that our output of aircraft is steadily increasing, and that during 1917 it has been doubled. In one factory in London, the output has been trebled within three months; in Lancashire, there are instances in which it has been doubled, and other areas show an improved production varying from 25 to 50 per cent. Yet the increased demand for labour for this work has always been immediately answered, and there is a steady flow into the factories of the best type of women workers from every class of society. Here and there, one already meets a woman who, during the short period of the war, has risen to be manager or partner in an aircraft factory. Unconsciously, such a one emphasizes the fact that the mastery of the element of the future is likely to be an affair of both the sexes.

A visit to any aeroplane factory repeats the hint, and reveals the extraordinary versatility of skill latent in women, which can well be applied to this form of industry. ‘Women must have been cabin’d, cribbed, and confined before the war’, said a foreman in taking me over his shop in an aircraft works. ‘Look what they can do at this kind of job, and yet many of them are ladies, from homes where they sat about and were waited upon.’ The wonder of it cannot fail to impress a visitor, since only four years ago women were allowed to undertake in aircraft construction merely those parts which convention deemed suitable for feminine fingers: such processes, for instance, as the sewing of the wings by hand, or by machine, or the painting of the woodwork.

ENGRAVING METAL PARTS FOR COMPASSES

COLOURING AEROPLANE PLANES

CHIPPING AND GRINDING BLADES OF CAST IRON PROPELLER WITH PORTABLE TOOLS

WOMAN ACTING AS MATE TO JOINER. MAKING SEA-PLANE FLOATS

[Pg 29]To-day, they undertake almost every other process both at the carpenter’s bench and in the engineering shop, and the chief impression you carry away from a stroll through such a factory is that the women are thoroughly at home in the work. The operations are often so clean that the workers’ overalls and caps of the daintiest shades of pink, blue, white, and heliotrope, remain fresh; the material for aeroplane parts is usually so light that the handling of it presents no difficulty to a slip of a girl. When within the works, the visitor is constantly stimulated to the thought that the hand which rocks the cradle should obviously be the one to make the air-machine.

One expects, of course, women’s familiarity with the occupation in the room where the fine Irish linen is cut out and fashioned into wings. One is not surprised at the facility with which the measuring and cutting out are accomplished, and, maybe, an emotion of admiration arises, similar to that evoked by the contemplation of old tapestries, when one watches the hand-sewing of a seam in a wing of some 10 feet in length. Not a stitch of the button-holing of such a seam deviates by a hairbreadth from its fellows. Such work has, however, been women’s province through the ages.

But a new sensation is awakened in the carpenter’s shop where women are working with dexterity at the bench, handling woodwork like the men, now dealing with delicate wooden ribs, or again, fashioning propellers out of mahogany or walnut with such nicety that there is not the slightest deviation between the dimensions of a pair. In the room where the linen is stretched over the wooden ribs, I have seen women working with tiny hammers, giving fairy blows that never miss their mark on tiny nails.

It is with fascination that a visitor stands by be-goggled women as they undertake the welding of metal joints by the oxy-acetylene process. Here, conscientiousness is a vital quality in the operator, since an undetected flaw in the weld, as a works foreman recently remarked, ‘might easily send an airman to Kingdom Come’. For this process, women of education are more often selected.

It is with awe that you watch the women at work on the metal parts of the aeroplane, drilling, grinding, boring, milling on the machine, or soldering tiny aluminum parts for the fuselage, and in each process gauging and re-gauging, measuring and re-measuring. Women also work on aero-engines, and help in the manufacture of the magneto, the very heart of the machine. They even undertake special processes, which before the war were only entrusted to a select body of men. I stood one day, for example, watching a woman splicing steel rope, a process [Pg 30]undertaken in pre-war days by sailors. She was working with extraordinary speed and unconcern, and had learned the job in three or four days. Before then, she told me, she had been her employer’s cook.

But the most alluring scene of all is the assembling of aircraft. The infinite number of separate parts are now ready; they have been tested by factory overlookers and retested by Government inspectors. The greatest care is taken in these examinations: it is the only possible insurance of the lives of the brave youths on their journey above the clouds. All the workers know this, and the seriousness of the job is reflected on their faces. But now all the parts are ready and to hand in the Erecting shop. Then wings and propeller are added to body, the engine and leather-upholstered seats introduced, the electric apparatus fitted up, the compass, ammunition box and other instruments and weapons placed in position.

The aeroplane is at length complete, and stands in the hangar like some great bird, with outstretched pinions, awaiting its first flight into the Unknown. Women undertake every process of this assembling, and have acquired familiarity with all the parts. This was put to the test recently in a certain works when a woman operator was directed to dismantle a machine. Without hesitation, she stripped the complex network of the structural stay-wires and the control wires, and then re-assembled them, correct in every particular, at the first attempt.

Optical Instruments

Of the many industries developed by the war, the production of optical instruments offers a striking example of rapid progress. Before 1914, the optical glass industry of Europe was largely in the hands of Germany and Austria, and the outbreak of hostilities meant the total closing of that market to the Allies. The lack of optical instruments thus occasioned was at first a source of grave national peril, since optical glass provides, as it were, eyes for both Navy and Army. The eyes of the guns are the range-finder, the director, the sighting telescope, periscope, prism binoculars, and other instruments for observing fire and correcting the aim; the tank would be blind without its periscope, and observations are made from aircraft by means of photographic cameras and lenses.

At sea, the tale is repeated; the submarine requires at least one eye, and the submarine chaser needs many, while, by means of optical instruments, the naval gunner can fire at a target which is about 15 to 20 miles away. The very health of the army depends, in great measure, on optical glass, since the Royal Army Medical Corps fights malaria and other diseases[Pg 31] due to parasites, which must be magnified by a microscope a thousand times before they can be identified. Hence, the solution of the problem of optical munitions was a vital matter in the early days of the war.

With characteristic energy, Great Britain set to work and soon restored a languishing trade. The task was enormous; the industry had to be revived from its very foundations. The production of the peculiar types of glass required for optical instruments in itself presented a formidable obstacle, even its principal ingredient, a special quality of sand, being formerly derived mainly from Fontainebleau and Belgium. But by widespread investigation efficient substitutes were soon discovered, the problem of mixing the ingredients was at length solved, formulæ for special glasses devised, and we are now producing large quantities of optical glass of perfect quality. The production of the raw material was, however, only a first step in obtaining an adequate supply of optical instruments.

Numbers of delicate processes stand between the rough glass and the finished implement. The glass must be cut, ground, and curved exactly to the requisite design, which in itself takes many days of high mathematical computation; it must be smoothed and polished, cleaned with meticulous care, and adjusted to a nicety in the particular instrument for which it is fashioned. The difficulties and pitfalls are incalculable; from start to finish the glass obeys no fixed laws, but answers only to the skilled handling of the scientist and craftsman. ‘Optical glass is the mule of materials’, comments a recent writer with sincerity.

The absence of requisite labour for what was practically a new industry was a serious menace, and it is to the credit of Englishwomen that, as soon as the need for their services in this direction was made known, they stepped without hesitation into this unfamiliar and highly skilled industry. Their success therein is remarkable, and many, from such callings as high-class domestic service, kindergarten instruction, music teaching, blouse and dressmaking, have achieved a wonderful record in the delicate and highly technical processes of lens-smoothing and polishing and in the production of prisms of faultless polish and cut.

There is, I take it, no more interesting munitions development than in factories where these lenses and prisms are produced. The work is so fine and so delicate that one feels it might be more suitably transferred for manipulation to elves, or fairy folk, who might undertake the various processes standing at a large-sized toad-stool. But with the stern reality of war upon us, willing feminine fingers have had to be trained to handle these lenses, the smallest of which, when ranged in trays, resemble a collection[Pg 32] of dewdrops, and the largest of which would easily fill the port-hole of an ocean-liner.

Optical glass when it comes into the workshop has the appearance of small blocks of rough ice of a greyish hue. These blocks are roughly sliced and cut into shape by a rotating metal disk charged with diamond dust. The prisms and lenses in their initial stage are then handed on to women, who complete the work on their surfaces. Each process has its particular lure for the interested visitor. You may watch the slices of glass being shaped into prisms by handwork against the tool; you may follow these embryo prisms through the various processes of smoothing and polishing until a small magnifying prism is obtained for use in a magnetic compass, or until a large prism is completed suitable for a submarine periscope. You may follow the creation of a lens from the roughing and grinding of the glass slices with emery, or carborundum, until the approximate shape is given, or you may follow a later process of sticking the smaller lenses on to pitch, so that they may form a single surface for smoothing and polishing.

Again, you may watch the superlatively difficult operation of centring a lens. This task is necessary to ensure the polished surfaces of the lens running perfectly true and it requires a skilled touch and a trained eye to undertake it satisfactorily.

In a shop in a certain optical munitions factory I met the first woman who worked a centring machine in that area. She was formerly a housemaid, and told me that, at first, all the men had discouraged her from the job and had said it was ‘impossible for a woman to do such work’. But she ‘stuck it’—so she said—and in a few weeks, to her own surprise and the men’s dismay, this peculiarly skilled job became familiar to her. ‘Now I feel I am doing something,’ she said in triumph. This sentiment was echoed by another worker in that factory who was accomplishing the surprising task of ‘chamfering’, or putting a tiny bevel onto the edge of a lens.

The large lenses measure only 2 inches in diameter; the smaller ones are about the size of a threepenny bit, and every operation, whether grinding, trueing, smoothing, polishing, or centring, must be accomplished with the utmost care. Even the final process in the manufacture of the lens or prism, ‘wiping off’, is fraught with responsibility to the operator. ‘Wiping off,’ or cleaning the lens, can only be done with a silken duster, for the finished glass, like a dainty lady, will tolerate the touch of nothing coarse.

In cases where the glass is graticulated, or marked with fine lines for measurement purposes, the task of ‘wiping off’ is of extraordinary [Pg 33]difficulty; in the opinion of at least one foreman with whom I have discussed this question, the operation is only perfectly successful when performed by a girl’s fingers. It is of supreme importance that no speck of dirt or hint of grease from a finger-mark be left on the glass when finally adjusted, or the instrument would become a source of danger to the user. No wonder that the feeling of the optical instrument workshop expresses itself in the words: ‘Cleanliness is more than godliness at this job.’

The completed glass at length reaches the stage where it is set in its instrument, be it periscope, dial-sight, telescope, and so on. Although the most exact measurements have been observed both in the metal part and on the glass, small adjustments are necessary; for the fit must be so perfect that even if the metal case suffers shell-shock, the glass must still not rattle. But it is the metal alone which is submitted to alteration, and it is wonderful how women have been able to obtain sufficient dexterity to make these infinitesimal changes in the metal parts. One can see a mere girl undertaking such a task by giving the metal three or four delicate strokes from a file so fine that it would not hurt a baby’s skin. Meantime, the lens or prism is finally examined (also by women) for size, scratches, and other imperfections, and is then re-cleaned. Girls and women take a full share in the production of the metal parts for the optical instruments and also assemble, or collect the parts, for the adjustment of the glass, but so far they do not generally adjust or test the completed instrument.

The operations used in the production of optical instruments for war purposes are, of course, similar to those required in the manufacture of implements used in peace-time, such as opera-glasses, telescopes, microscopes, surveying instruments, photographic and cinematograph apparatus, &c., and it is expected that women who have entered the new war-time industry will happily find themselves, when peace dawns, in possession of a permanent means of livelihood in a skilled occupation.

In the Shipyards

‘Ships, ships, and still ships’: such is the main need of the Allies in this, the fourth year of the war. To answer this demand, every dockyard in the country is working at the highest pressure. Into this work, strange as it may seem to those familiar with the rough-and-tumble life of a shipyard, women have penetrated and have so far surmounted all obstacles in the tasks to which they have been allocated.

At first, dilution in shipyards was looked upon as a hazardous experiment. The work is mostly heavy and clumsy, and the type of men undertaking it, splendid fellows enough in their physique and general outlook,[Pg 34] are mainly accustomed to dealings with the boisterous elements and with men comrades of their own pattern. Their attitude towards women, it was feared, would make for trouble immediately that the other sex was introduced as fellow-workers. Even the most optimistic amongst shipbuilders were aghast at the idea of women working shoulder to shoulder with men on board ship. Yet here and there a pioneer employer has arisen, and the experiment has been tried. It is succeeding unquestionably.

I have been into the shipyards and seen the amazing sight and am convinced of its expediency, at all events as a war-time measure. Special care must, of course, be taken in the planning and the supervision of women’s work on board ship, but given the right type of inspectress, charge hand, and workers, there is no reason why women should not, in increasing numbers, fill the gaps in the shipyards, as in the factories. The women chosen to undertake such tasks are well aware of the service they are rendering to the nation at this juncture, and to the women workers the first day on board ship is one of supreme happiness. ‘They are so excited when they actually get on board,’ said a dockyard inspectress to me recently ‘that they forget all about the difficulties and objections to the work.’ It is well that this is so, for it is not too easy for the novice to move about below, even on a big battleship.

I was taken over one where the women were working. It was in a big yard crammed with shipping of every kind—so full that one could echo the words of the old Elizabethan, who said of a crowd: ‘There was not room for a snail to put out its horns.’ A stiff breeze was blowing, and the sea beyond ran full and blue. The great battleship along the dock lay serene and stately, bearing, as it were, with grim humour the meddlesome tappings and chippings of impertinent human beings, who presumed to furbish her up. There were men on the conning-tower, busy with paint-pots, and there was a tangle of ropes and pots on the upper decks where the guns were biding their time. Men were calling lustily to each other, and were darting here and there as brisk and wholesome as the breeze.

‘We go down here,’ said the inspectress, pointing to a ladder as steep as the side of a house. She bounded down with the ease of an antelope. Another ladder, and yet another. The inspectress seemed to have forgotten their steep incline and I was left, a helpless landlubber, cautiously descending step by step. When I joined her in the engine-room she was already deep in conversation with one of her staff. And then I noticed the secret aid to her agility. All the women aboard ship were dressed in trouser suits. The suits, of blue drill for the supervisors, and of a similar material in brown for the labourers, were made with a short tunic, and the trousers were buckled securely at the ankle. A tight-fitting cap to match completed[Pg 35] the smart workmanlike costume which permits of perfect freedom of movement in confined places. Without such a costume it would be hardly possible for women to work on board.

The women workers on this particular battleship were engaged in renewing electric wires and fittings, a job which requires a good deal of care and accuracy. On the lower deck, they were fitting up new cables and were perched in high places, here ‘sweating in’ a distribution box, there marking off the position for the wires. Others were drilling holes, others again were ‘tapping’, or making a thread in the holes. In the engine-room the women were busy stripping worn-out electric wiring and were working by the light of tall candles, as merry as a party preparing a Christmas tree.

Everywhere the women were working in pairs, an arrangement found especially advisable on board. Behind a small iron door we found one couple working on a fire-control in a nook where the entrance of a single visitor caused bad overcrowding. ‘These are my mice’, said the inspectress; ‘they always get away into the cupboard-jobs, and very well they work there too. But we have to maintain a strict discipline on board, far stricter than anything known in the factories.’

No talking, I was informed, is allowed in that dockyard, during the working hours on board, between the sailors or men labourers and the women and there is constant supervision of the women employed. These work on board in parties of 20-22, each party being under the care of a charge hand. When the staff included three charge hands for supervision on board, an inspectress was appointed for this special branch of the work. The system seems to work well, and I noticed how the men and women had evidently accepted each other as comrades. Coming into a secluded gangway a man-labourer, who had finished his job, was unconcernedly shaving before a square of mirror, while two or three women just beyond went on, just as unconcernedly, tap, tapping at the electric fittings. There was no chaffing, no ‘larking’, between the men and women, but a sense of comradeship, such as one notices in a Co-education School.