The Project Gutenberg EBook of Woodwork Joints, by William Fairham

This eBook is for the use of anyone anywhere at no cost and with

almost no restrictions whatsoever. You may copy it, give it away or

re-use it under the terms of the Project Gutenberg License included

with this eBook or online at www.gutenberg.org

Title: Woodwork Joints

How they are Set Out, How Made and Where Used.

Author: William Fairham

Release Date: May 19, 2007 [EBook #21531]

Language: English

Character set encoding: ISO-8859-1

*** START OF THIS PROJECT GUTENBERG EBOOK WOODWORK JOINTS ***

Produced by Chris Curnow and the Online Distributed

Proofreading Team at http://www.pgdp.net

| WOODWORK JOINTS. |

| CABINET CONSTRUCTION. |

| STAINING AND POLISHING. |

| WOODWORK TOOLS. |

| PRACTICAL UPHOLSTERY. |

| WOOD TURNING. |

| WOODCARVING. |

| TIMBERS FOR WOODWORK. |

| FURNITURE REPAIRING AND RE-UPHOLSTERY. |

| HOUSEHOLD REPAIRS AND RENOVATIONS. |

| CARPENTRY FOR BEGINNERS. |

| KITCHEN FURNITURE DESIGNS. |

| BUREAU AND BOOKCASE DESIGNS. |

| LIGHT CARPENTRY DESIGNS. |

| DOORMAKING. |

To be successful in woodwork construction the possession of two secrets is essential—to know the right joint to use, and to know how to make that joint in the right way. The woodwork structure or the piece of cabinet-work that endures is the one on which skilful hands have combined to carry out what the constructive mind planned. And it is just here that the present Volume will help, not alone the beginner who wishes preliminary instruction, but also the expert who desires guidance over ground hitherto unexplored by him.

In the preparation of this new edition the Publishers have secured the services of Mr. William Fairham, by whom the chapters have been carefully revised and re-illustrated. Although intended for the practical man, and not professing to be a graded course of "educational woodwork," the Volume is one which Handicraft Instructors will find of the greatest value in conducting woodwork classes. No book hitherto published contains such a variety of illustrations of joints, almost all of which will form suitable exercises of practical educational importance in a woodworking course.

J. C. S. B.

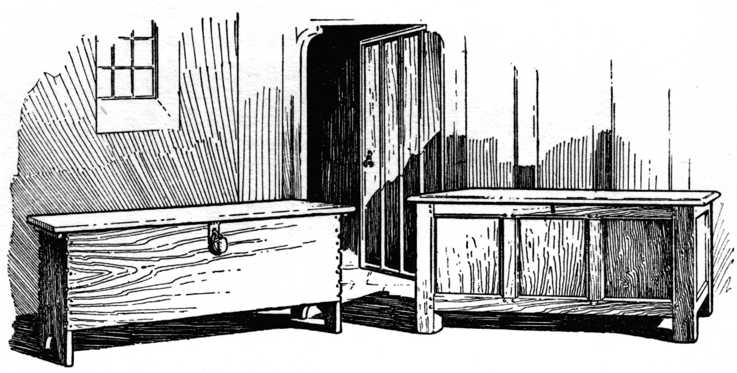

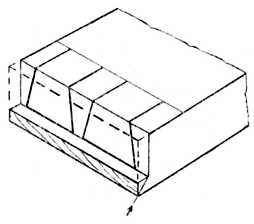

Old Oak Chests, showing the Method of Structure

which forms the origin of most of our English Furniture.

Old Oak Chests, showing the Method of Structure

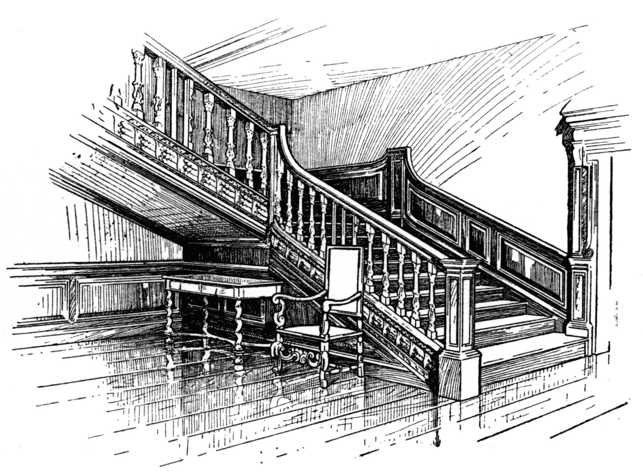

which forms the origin of most of our English Furniture. Staircase of the Second Half of Seventeenth Century.

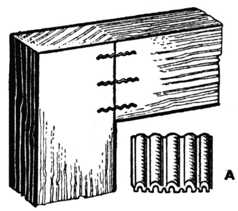

Staircase of the Second Half of Seventeenth Century.The glued joint in its various forms is in use in every country in the world, and is frequently met with in mummy cases and other examples of ancient woodwork. Alternative names under which it is known are the butt joint, the rubbed joint, the slipped joint, whilst in certain localities it is known as the slaped (pronounced slayped) joint.

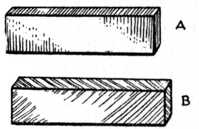

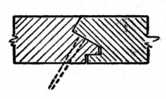

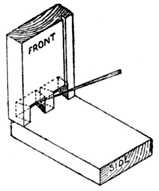

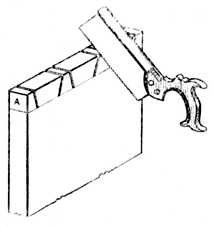

The glued joint is made by planing two pieces of timber so that when placed together they are in contact with each other at every point; they are then usually united with glue. Fig. 1 shows a sketch of a butt joint in its simplest form. In Fig. 2 is indicated the method of holding the joint whilst being glued; the upright portion is held rigid in the bench vice, thus leaving the left hand to hold the piece which is to be jointed, whilst the right hand operates the glue brush. The pieces of wood which form a butt joint may be glued together with or without the aid of cramps or artificial pressure. If the joint is to be made without cramping, the two surfaces of the timber are warmed so as not to chill the[Pg 2] glue. The surfaces are then glued and put together and rubbed backwards and forwards so as to get rid of the superfluous glue. They are then put aside to dry.

Glueing.—The better the glue penetrates into the pores of the wood, the stronger the joint will be; for this reason timber of the loose-fibred variety, such as pine, etc., will hold up at the joint better than hardwoods like teak and rosewood. The glue used for jointing should be neither too thick nor too thin; the consistency of cream will be found suitable for most purposes. It should be nice and hot, and be rapidly spread over the surface of the wood.

If light-coloured woods, such as pine, satinwood, sycamore, etc., have to be jointed, a little flake white should be procured and mixed into the liquid glue. This will prevent the glue showing a thin black line on the joint.

Broad surfaces of close-grained hardwood having a shiny surface are usually carefully roughened with a fine toothing plane blade previous to glueing.

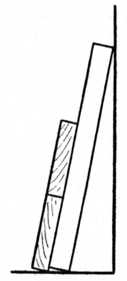

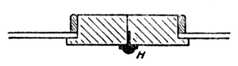

Supporting the Joint.—The jointed boards should not be reared up against a "bench leg" or wall without having any support in the centre, as dotted line at Fig. 5, because in all probability they will fracture before the glue has time to set; and, when we go to take them up to renew working operations, we shall be[Pg 3] annoyed to find that they have assumed a position similar to that at Fig. 5 (shown exaggerated), and this will, of course, necessitate re-jointing.

Fig. 3.—Correct Jointing. |

Fig. 4.—Faulty Jointing. |

Fig. 5.—Boards unsupported. |

Fig. 6.—Boards supported. |

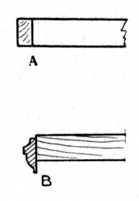

Fig. 7.—(A) Glued Slip, (B) Glued Moulding. |

Fig. 8.—Grain alternating. |

A correct method to adopt is seen at Fig. 6. Here we have supported the joint by rearing up against the wall[Pg 4] a couple of pieces of batten, one at each end of the board, thus supporting it throughout its entire width until the glue is thoroughly set. The two or more pieces of timber in a butt joint adhere by crystallisation of the glue and atmospheric pressure. A well-fitted joint made with good quality glue is so strong that, when boards of 3 feet and upwards are jointed together by this method, the timber in most cases will break with the grain sooner than part at the joint.

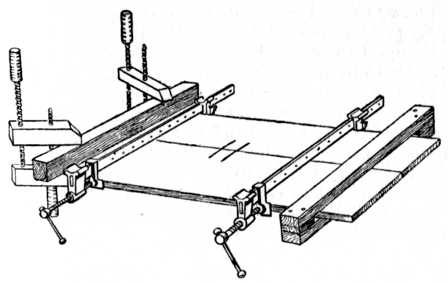

Butt joints may be cramped up, if desired, and it is customary to warm them as previously stated. In the absence of the usual iron cramp, the amateur may make an excellent wooden arrangement out of any odd pieces of timber that happen to be handy. Two blocks of hardwood are screwed on the base board at a suitable distance for the work in hand; the boards to be jointed are glued and placed in position between the blocks; and the two hardwood wedges are inserted and hammered in opposite directions to each other, thus exerting the desired pressure. An example of this method of cramping is shown in Fig. 25, which also indicates the use of iron "dogs."

When jointing, care should be taken to first plane up the boards true on one side—i.e., take them out of winding. The method of testing for this is shown at Fig. 9, and it may with advantage be used when jointing the edges of the boards. Two laths or strips of wood are planed up to exactly the same width, having their edges straight and parallel. One edge of each lath may, if desired, be bevelled a little. The method of using these "twist sticks" or "winding laths" is to put them on the board as indicated, and sight along their top edges. The winding laths, being much longer than the width of the board, show up the irregularity greatly pronounced.[Pg 5]

The Tools generally used for making the butt joints are:—

The jack plane, for roughing the edges, etc.

The wooden trying plane (or iron jointing plane) for trueing up the work.

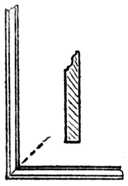

The try square for testing purposes.

The winding laths and straight edge.

The Method of Work is as follows: Each board is in turn put in the vice and planed straight lengthwise; it is then tested with winding laths and a try square (the latter method is shown at Fig. 22).

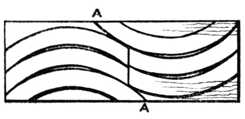

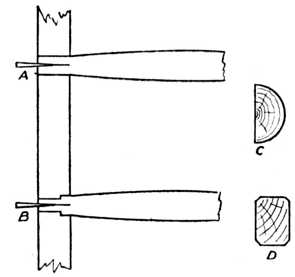

The boards are then put on the top of one another as at Fig. 1 and tested with a straight edge; they should appear true as shown at Fig. 3; if they show faulty as at Fig. 4 the joints must be again fitted until the required degree of accuracy is obtained. Difficulties may be avoided by care in selecting timber suitable for jointing, and it must be remembered that timber shrinks circumferentially (the heart side becoming curved) as dotted lines in Fig. 10. If the timber be jointed with all the heart side one way as at Fig. 10, the tendency will be for it to cast as shown by the[Pg 6] dotted line. If the timber be alternated as at Fig. 11, the tendency will be to cast wavy, whereas if quartered timber can be obtained it will stand practically straight as the tendency to shrink is in thickness only. The grain of quartered timber is shown in Fig. 12.

Fig. 11.—Heart side of Timber shown alternated. |

Fig. 12.—Grain of Quartered Timber. |

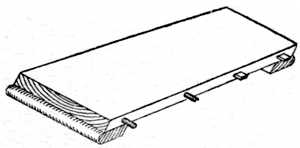

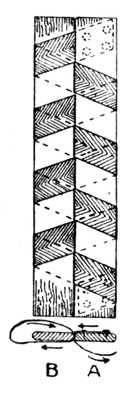

Judgment should also be exercised to avoid jointing in which one piece of timber is wild and large in the grain, and the adjoining piece of a mild-grained nature. Jointed boards should always be glued up with the[Pg 7] grain running in the same direction if possible; this we show at Fig. 13, and nothing looks worse than a dressing chest end or similar piece of work in which the grain runs haphazard. When jointing thin timber (say, 1⁄4-in., 3⁄8-in., 1⁄2-in. and 5⁄8-in. boards) the best method is to use a shooting board (Fig. 26). It must be noted, however, that a shooting board and plane practically never give a true right angle, owing to wear and the grinding of the blade. Therefore, the boards should not all be laid with the "face mark" on the shooting board whilst the edges are shot, because any inequality would be multiplied by the number of pieces jointed. A better method is to alternate the boards, face side up, then face side down, whilst shooting the edges; this will prevent convexity or concavity on the face of the jointed board, because any slight error in the angle is neutralised (see Fig. 8).

Applications of the Joint.—The following show various applications of the butt or glued joint:—

Fig. 7A shows a mahogany or other hardwood slip glued on the edge of a cheaper wood, such as pine or whitewood, as is the case on bookcase shelves when only the front edge is seen and polished.

Fig. 7B shows a moulding glued on a shelf, both mould and shelf in this instance being of polished hardwood. A shelf of this type might be used in a recess, the object of the overhanging moulding being to hide a small 3⁄8-in. iron rod which would carry the curtain[Pg 8] rings and heading of the curtain which covers the recess. The shelf would be fixed about 3 ft. 9 ins. to 4 ft. 3 ins. from the floor.

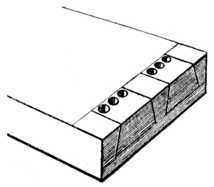

Fig. 14 shows the wing pieces glued on the top bearer of carcase work. The application of this bearer in its position will be shown in the chapter on Dovetailing.

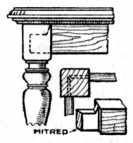

Fig. 15 shows a butt joint planed at an angle of 45 degrees (commonly called a mitre), used for box feet, etc.

Fig. 16 shows jointing up of an ogee-shaped panel. The dotted lines indicate the thickness of the timber previous to its being worked up to the finished shape. Bow-fronted and semicircular panels are jointed in a similar manner.

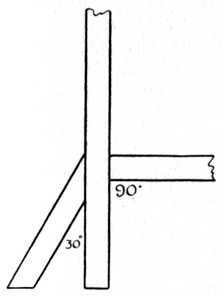

Fig. 17 shows timber jointed at right angles to the upright piece, and at an angle of 30 degrees.[Pg 9]

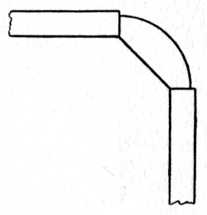

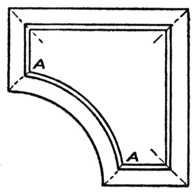

Fig. 18 indicates quarter-circle jointing, as used in round-cornered chests of drawers, wardrobes, cupboards, etc.

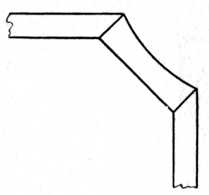

Fig. 19 is similar to Fig. 18, but with hollow (or concave) corners.

Fig. 17.—Jointed Timber at 30° and 90° angles. |

Fig. 18.—Convex Corner. |

Fig. 19.—Concave Corner. |

Fig. 20.—Jointing a shaped Spandrel. |

Fig. 21.—Building up Case of Piano Front. |

Fig. 22.—Use of the Try-square for Testing Edge. |

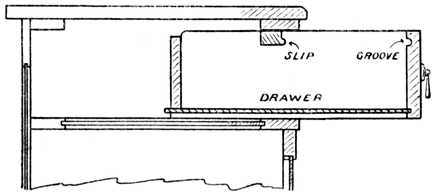

Fig. 24.—Glueing Ploughslips to Drawer. |

Fig. 25.—Method of holding Glued Joints with Iron Dogs. |

Fig. 20 gives us the jointing up of a shaped spandrel to the required width. In a case of this description suitably grained and coloured wood should be selected, otherwise the bad match will at once draw attention to the joint.

Fig. 21 shows the application of butt or glued jointing to the building up of the core of a piano fall previous to shaping up and veneering.

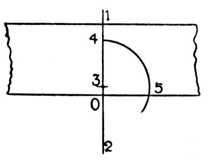

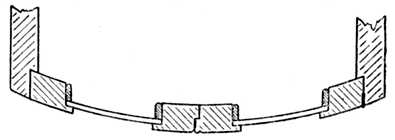

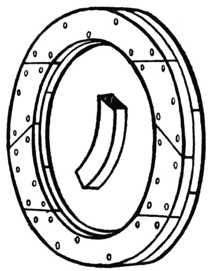

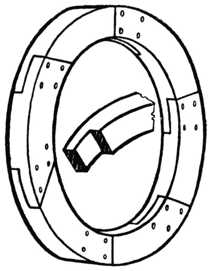

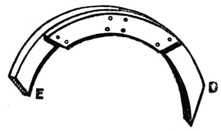

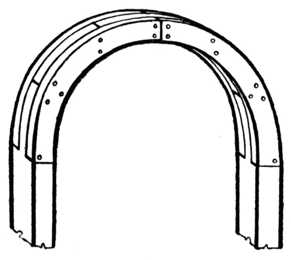

Fig. 23.—Laminated work—the building up of circular rims for cabinet and joinery work. Plan and elevation show rim pattern of a pulley as used in the pattern-making trade.

Fig. 27.—Cramping Glued Joints: Handscrews and

Batten shown at left; temporary Batten at right to

keep the wood flat.

Fig. 27.—Cramping Glued Joints: Handscrews and

Batten shown at left; temporary Batten at right to

keep the wood flat.

Fig. 24.—The glueing of a ploughslip to a drawer side is seen here, the ploughslip being used to carry the drawer bottom.

Fig. 26 shows the method of jointing with shooting board and trying plane; the right hand operates the[Pg 12] plane whilst the left hand holds the wood firm upon the shooting board.

Owing to the importation of narrow and faulty timber the necessity of jointing is greater to-day than ever it was, wide timber of course meaning higher cost for raw material.

The method of using iron dogs is illustrated in Fig. 25, and it will be observed that owing to the wedge-like formation of each fang (see enlarged sketch) the dog exerts the necessary pressure to close the joint. At the centre of this illustration is suggested the home-made hardwood blocks, baseboard and wedges referred to on page 4.

Fig. 27 shows how the iron sash cramps are used to apply pressure to the joint. As this method is in some cases apt to bend and distort thin boards it is wise practice to fix (as a temporary measure) a stout piece of straight wood on to the board to be joined by using two handscrews as shown at the left hand of the illustration. At the right hand of the sketch a wooden cramping arrangement of the box type is given, and by wedging up the boards are closed together. It is obvious that if this type of box cramp be used it will prevent the boards buckling and the handscrew method at the left may be dispensed with.[Pg 13]

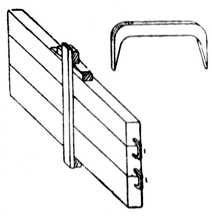

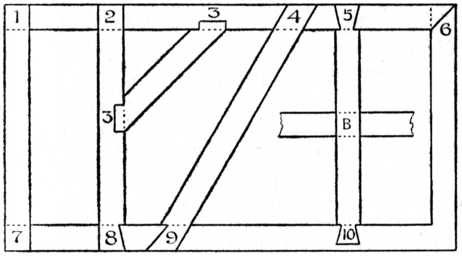

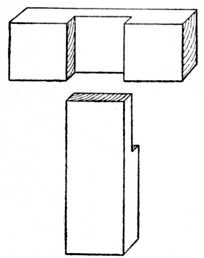

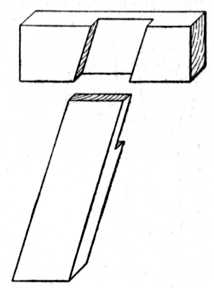

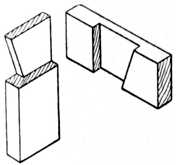

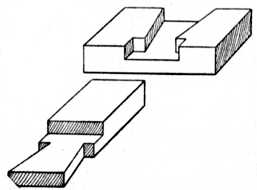

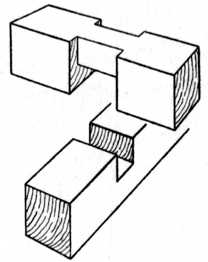

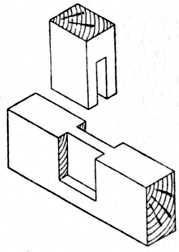

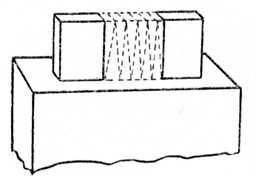

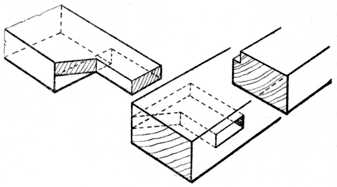

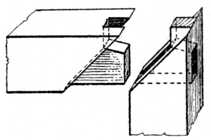

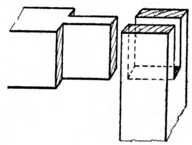

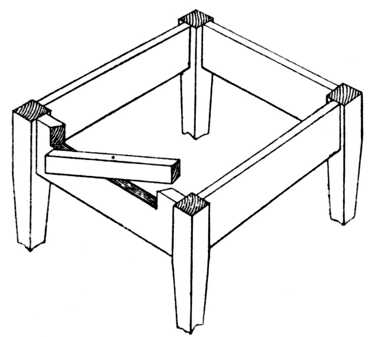

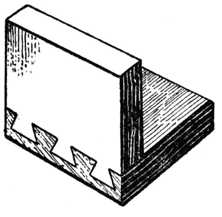

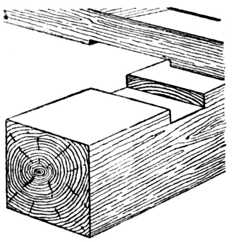

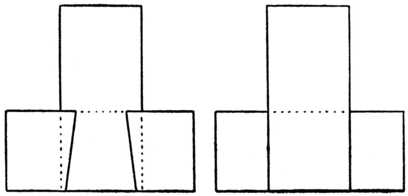

T he halved joint is frequently known as half-lapping, and sometimes as checking and half-checking. In the majority of cases it is made by halving the two pieces, i.e., by cutting half the depth of the wood away. There are, however, exceptions to this rule, as in the case of "three-piece halving" (or, as it is sometimes called, "third lapping") and in the halving of timber with rebated or moulded edges. Halving is one of the simplest methods of connecting two pieces of timber, especially where it is desired to make frames and bracket supports for either inside or outside use.

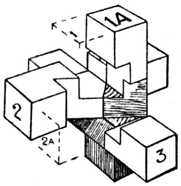

Fig. 28.—Frame, with various halved joints. These joints,

numbered 1, 2, 3, etc., are shown in detail in Figs.

29 to 38.

Fig. 28.—Frame, with various halved joints. These joints,

numbered 1, 2, 3, etc., are shown in detail in Figs.

29 to 38.

Fig. 28 shows the elevation of an imaginary frame which is indicated as made up of a number of halving joints; it shows also the application of the various joints to this class of work. Each joint used in the construction of this frame may be dealt with separately. The numbers marked on Fig. 28 refer to the individual joints, shown separately in Figs. 29 to 38.

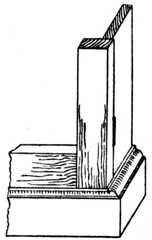

Fig. 29.—Halved Corner Joint. |

Fig. 30.—Halved T Joint. |

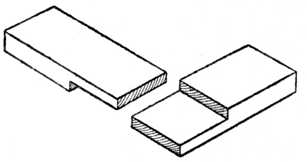

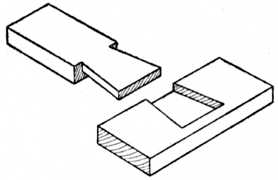

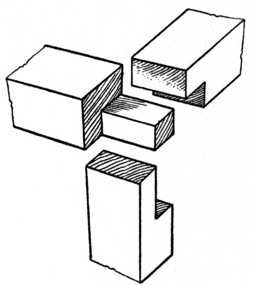

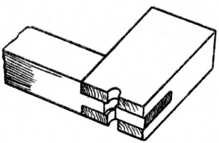

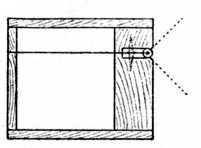

Fig. 29 shows the "Halved Joint" at the corner of the frame where the two pieces form a right angle (see Fig. 28, 1). Each piece is halved and shouldered at opposite sides, thus forming a perfect fit one with the other and giving a strong joint with a minimum amount of labour. For inside work the joint would be glued and screwed together, the screw heads being countersunk so as not to come in contact with the cutting iron of the plane when levelling off the work. For outside work, in exposed positions where the work will have to withstand the weather, the alternative method of smearing the joint with paint or with a mixture of varnish and white lead would be advisable, the joint[Pg 15] being nailed or screwed. Fig. 29 shows the two pieces separated.

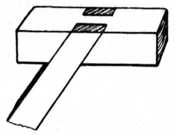

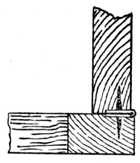

Fig. 30 shows a similar joint to the above, but in this case the top rail runs through and it is generally spoken of as a "Halved T Joint" (Fig. 28, 2). It may be used in nearly all cases where a top or bottom rail runs through an upright. The method of securing the joint is as before. Fig. 30 shows a sketch of the joint separated.

Fig. 31.—Oblique Halving with Shoulder. |

Fig. 32.—Oblique Halving. |

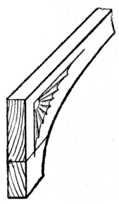

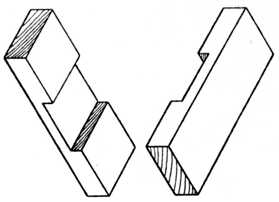

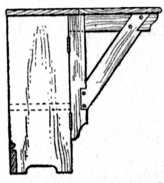

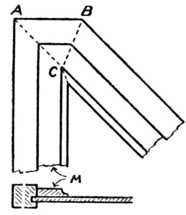

At Fig. 31 is shown an "Oblique Halving Joint," where the oblique piece, or strut, does not run through (Fig. 28, 3). This type of joint is used for strengthening framings and shelf brackets; an example of the latter is shown at Fig. 48. A strut or rail of this type prevents movement or distortion to a frame diagonally (generally spoken of in the trade as "racking"). Fig. 31 shows the joint apart.

Fig. 32 is an example of Oblique Halving with the upper piece running through (Fig. 28, 4). This joint is[Pg 16] used in similar positions to Fig. 31, and has in some cases the disadvantage of showing end grain at the top of the frame. The sketch shows the two pieces separated.

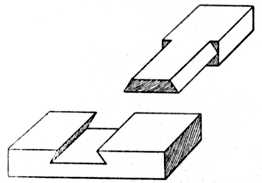

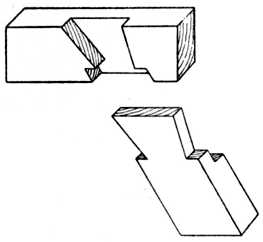

Fig. 33 is "Dovetail Halving," the dovetail running through the top piece (Fig. 28, 5). This is a strong joint, used where outside strain is likely to occur in the top piece, the dovetail preventing the rail from being drawn away from the shoulder. The two pieces are shown separate.

Fig. 33.—Dovetail Halving. |

Fig. 34.—Mitre Halving. |

At Fig. 34 is seen "Mitred Halving," a somewhat weak joint, but necessary in mirror frames, etc., where good appearance is required on the face side (Fig. 28, 6). Its use is obvious if the face of the frame be moulded with beads or other sections which require to intersect one with the other. This also applies if the frame be moulded on its face edges.

Fig. 35 is a halved joint with one side of the piece dovetailed (Fig. 28, 8). This joint is used in similar positions to Fig. 33, and rather less labour is required in the making. The two pieces are shown separate for clearness.[Pg 17]

Fig. 36 indicates the "Halved Joint," the pieces at one end showing a double dovetail (Fig. 28, 7). This particular joint is seldom used except for Manual Training purposes. The illustration shows a sketch of the joint apart.

Fig. 37 is "Oblique Dovetail Halving," one side of the piece being dovetailed. The joint is used to prevent "racking," and as a cross brace to framing. It is occasionally made with both its sides dovetailed as shown at Fig. 33. (For reference, see Fig. 28, 9).

Fig. 35.—Halved Joint with one side Dovetailed. |

Fig. 36.—Halved Joint with Double Dovetail. |

Fig. 37.—Oblique Dovetail Halving. |

Fig. 38.—Stopped Dovetail Halving. |

Fig. 38 shows "Stopped Dovetail Halving." In this[Pg 18] case the dovetail is similar to Fig. 33, with the exception that it does not run through the bottom rail. This is an advantage if the bottom edge of the rail is in evidence, or if it is required to glue a moulding or hardwood facing slip on the lower edge. The glue adheres better with the grain than it would end way of the grain, and if slight shrinkage occurs across the width of the bottom rail the moulding would not be forced away by the upright (see example at Fig. 28, 10).

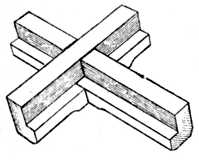

Fig. 39.—Cross Halving Joint. |

Fig. 40.—Cross Halving Joint Edgeways. |

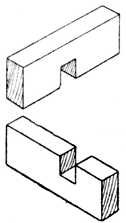

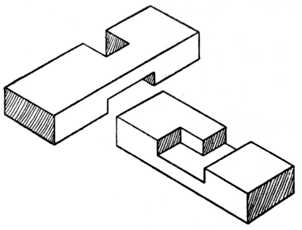

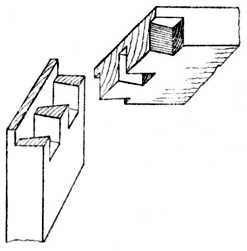

The joint lettered B in Fig. 28 is a "Cross Halving Joint" where each piece runs through the other. Fig. 39[Pg 19] shows this joint separated, and Fig. 40 shows a similar joint separated where the joint is made edgeways.

Fig. 41 shows a "Tee Halving Joint" with a dovetail cut on the edge. This is seldom used except as a woodwork exercise.

Fig. 42 is a "Dovetailed Halving Joint" used for lengthening timber, and is also a favourite Manual Training model. It might also come under the heading of scarf joint, although rarely used in actual practice as such. As a practical woodwork exercise it calls for accurate marking out and careful fitting.

Fig. 43.—Dovetailed and Halved Joint. |

Fig. 44.—Dovetailed Halved Joint with Shoulders. |

Fig. 43 shows a combination of a halved joint dovetailed edgeways, whilst Fig. 44 shows a dovetailed[Pg 20] halved joint with the shoulders housed. This latter is seldom used in actual work.

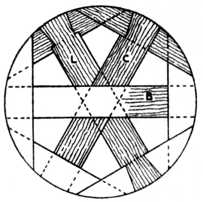

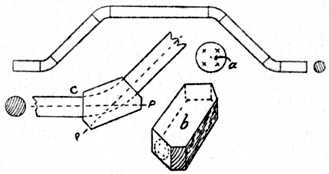

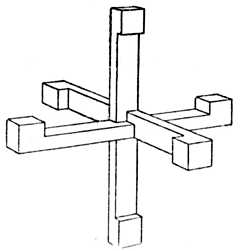

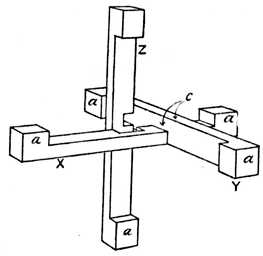

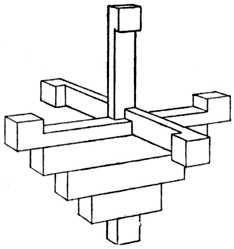

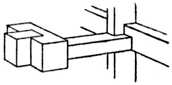

At Fig. 45 we have the application of halving joints when constructing a barrow wheel. The centre portion is an example of three pieces half-lapped or, as it is sometimes called, one-third lapped. A sketch of the three pieces separated is shown at L, B, C, Fig. 46.

This joint is extensively used in the pattern making trade for lap-jointing the arms of pulley patterns, etc. It is probably the most difficult of the halving joints to mark out and construct with the desired degree of accuracy.

Fig. 45.—Halved Joints on Barrow Wheels. |

Fig. 46.—Detail of Halved Joints in Fig. 45. |

Fig. 47 shows a combination of a bevelled dovetail half-lapped joint. This is only used as a puzzle joint. When neatly constructed and glued together it is apparently impossible to make it, showing as it does a half lap on one side and a dovetailed half lap on the reverse side.

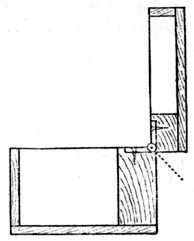

Fig. 48 is the end view of a kitchen table with drop leaf, showing the skirting board scribed to the solid side. A table of this type is fastened to the wall with two iron holdfasts which engage the ends of the table.[Pg 21]

Fig. 47.—Bevelled Dovetailed Half Lap. |

Fig. 48.—Bracket of Drop Table. |

[Pg 22] The hinged bracket frame shows the application of the halving joint to bracket supports for this and similar purposes, such as brackets to support shelving, etc. In this example the hinged brackets turn underneath the table top, and allow the leaf to drop out of the way when not required. The dotted lines show the position of a shelf for boots and shoes.

Fig. 52.—Manual Training Halved Exercise Joint. |

Fig. 53.—Exercise Dovetail Joint. |

Figs. 49 and 50 indicate the halving of cross pieces which have their edges moulded; the pieces are shown separately, the moulding being omitted to give a clearer representation of the method of construction.

Fig. 55.—Cross Halving Joint with Housed Corners. |

Fig. 56.—The parts of Fig. 55 shown separate. |

Fig. 51 is an "Oblique Cross Halving Joint" where the two pieces are not at right angles. A plan and elevation of the joint are shown at the left, whilst a sketch of one piece of the joint is given in the right-hand illustration.

Figs. 52 and 53 are principally used as Manual Training models, and call for patience and manual dexterity.

Fig. 54 is used in carpentry and joinery where a tie or cross piece ties joists or beams at an angle.

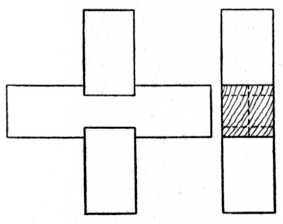

Fig. 55 shows the elevation and end view of a "Cross Halving Joint" with housed or notched shoulders. This joint is seldom used in actual practice. The separate parts are given in Fig. 56.

At Fig. 57 are shown two cross rails and an upright halved together. This type of joint is used where three[Pg 24] pieces meet, as is the case in building the framing of a poultry house. The joint is nailed together.

Fig. 57.—Cross Rail and Upright Halved Joint. |

Fig. 58.—Workshop Trestle Joint. |

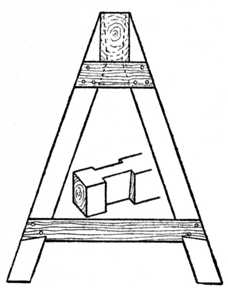

Fig. 58 is the end view of an ordinary workshop trestle, showing the application of dovetailed halving[Pg 25] where the legs have a tendency to strain outwards. The inset sketch of joint shows the housing of the top rail to receive the legs.

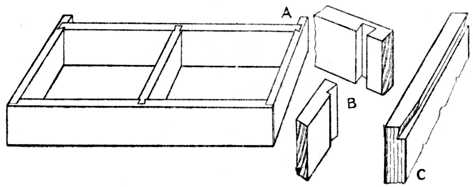

Fig. 59 shows a deep drawer, generally known as a cellarette, and used in a sideboard to accommodate wine bottles. Here we have a good example of halving the cross pieces so as to form compartments. The part shown separately illustrates the method of construction. The ends of these pieces engage the housings or grooves of the drawer sides. Pigeon holes or compartments in stationery cases, bookcases and writing bureaux are constructed in a similar manner, although the method of housing, or combined halving and housing, is to be preferred in some cases.

At Fig. 60 is the plan of a circular table having a small circular shelf with the top removed. The rims or[Pg 26] framing are built by the method known as laminating (see Fig. 23 in chapter on the The Glued Joint), after which they are veneered on the face sides. The application[Pg 27] of the halving joint to the shaped bottom rails, which in this case carry and support the small shelf, is shown in the part elevation.

Fig. 61 (B).—Halved Joint of Oxford Frame with front edges champered. |

Fig. 61 (C).—Back view of Oxford Frame. |

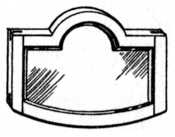

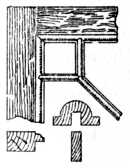

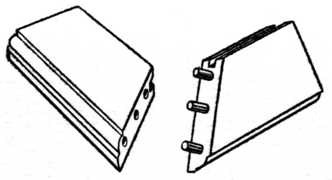

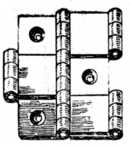

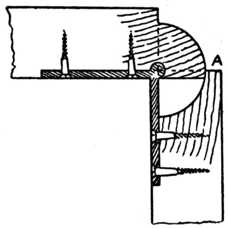

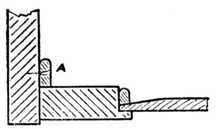

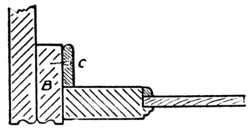

Fig. 61 (A) shows the well-known "Oxford frame," illustrating halved joints when the edge is rebated. Figs. 61 (B) and 61 (C) make clear the construction of this type of joint. Alternative suggestions are shown for the treatment of the corners, the simple inlay being black and white (ebony and holly or boxwood). Frames of this type are made in various widths and sizes and are used for pictures, mirrors, etc.

The tools used for making joints of the above class are: planes, the gauge, tenon or other saw, chisels, try square, and in some cases a joiner's bevel to obtain and mark the necessary angles, pencil and marking knife.

Plane up the face side and face edge of the timber, gauge and plane to both thickness and width; mark shoulders with pencil or marking knife; gauge to the thickness of the required halving; saw waste portions away; pare up with chisel to a good fit; glue or glue and screw, or use paint as previously mentioned, and then level off the surfaces.[Pg 28]

Setting out the Halved Joint.—Although at first sight the halved joint may appear to be a very easy item of construction, it requires much care and attention in marking out and sawing. Fig. 62 shows the two pieces which form the joint separated, and it will be noticed that each piece of wood has half its thickness cut away, so as to accommodate the other piece. This type of joint is used where two pieces of wood cross each other at right angles, or at an angle as shown in Fig. 51. The halving joint is used also for joining two pieces of wood at their ends, as, for instance, the corner of a frame, one half of this joint being shown at Fig. 65 (B).

To make the joint, the timber should be carefully[Pg 29] planed to its exact width and thickness. The two pieces may then be placed upon the bench (as shown at Fig. 63) or fixed in the vice.

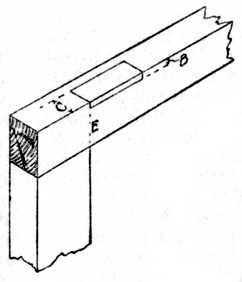

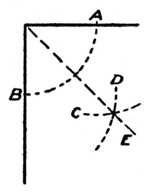

Find the centre of the timber, C, Fig. 63, and set out half the width of the wood on each side of the dotted centre line. Thus, suppose the wood (W) to be 2 ins. wide, then set 1 in. on each side of the centre line. Take a square as at Fig. 64, and with a sharp penknife blade score or cut a line all round each piece of timber.

Next take up a marking gauge, and set the marking point to half the thickness of the wood. The distance may be measured, and its exactness tested, by pricking a small hole from each side of the wood with the marking gauge and carefully noting that the pricked holes coincide. The gauge mark is clearly shown in the various illustrations. Now, take a pencil and scribble or mark "waste" on the parts you intend to cut away. This will save trouble later on, especially if you are making several joints at once. Take your sharp penknife or marking knife blade, and cut fairly deeply into the marked line on the portion you are going to pare away.[Pg 30]

Fix the wood firmly in your vice, or against your cutting board or bench stop, as may be more convenient to you, and with a sharp chisel cut away the wood up to the marked line, as at Fig. 66. The channel in the sketch is exaggerated, so as to show the method clearly. The object of using a penknife or marking knife to mark your work, instead of using a pencil, will[Pg 31] be obvious. Owing to the knife having scored about 1⁄16 in. deep across the fibres of the wood, the timber will come away cleanly when the chisel is used, as at Fig. 66. The small channel thus made will form a guide in which to start your tenon or dovetail saw; it prevents the saw cutting on the wrong side of the marked line and thus making the halving too wide.

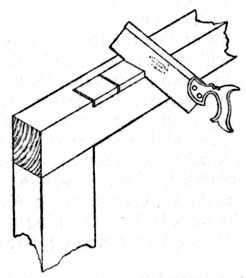

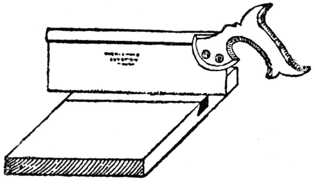

Sawing.—Lay the work on the cutting board as at Fig. 67; or, if you prefer, put the work in the vice. Carefully saw down the work until you just touch the gauge line. Do not press heavily with the saw; use it lightly; the weight of the back iron which is fixed on the saw will ensure the saw feeding into the work quite fast enough. If the saw is newly sharpened it will, in fact, be an advantage to slightly ease the weight of the[Pg 32] saw from off the wood, owing to the keenness of its edge. If the halving is a very wide one, additional cuts may be sawn between the outside marks, and these will greatly facilitate the removal of the waste wood when paring it away. For sawing the joint reference may be made to the chapter on Dovetailing.

Paring away the waste material with a chisel is the next step, and this is shown at Fig. 68. The work may be chiselled either in a vertical or a horizontal position. The horizontal position is the easiest for the amateur who has a vice or handscrew, because he may hold the work securely with a mechanical device and so avoid the unnecessary risk to his fingers.

Take the chisel and cut away A, Fig. 68; now turn[Pg 33] the chisel and cut away B; after which keep the chisel horizontal and cut off "the top of the hill," as it were, C. Repeat the three operations until you gradually pare the wood away exactly to the gauge line. When chiselling, if you find a tendency for the work to chip or crumble at the back edge owing to the forward pressure of the chisel, turn your wood round and begin to cut from the other edge, allowing the chisel to finish paring at the centre.

Joints Other than a Right Angle.—If the halving joint is at an angle similar to the sketch shown at Fig. 69, great care will have to be exercised in the use of the chisel, owing to the change in the direction of the grain of the wood. The arrow marks in this sketch distinctly indicate the direction in which the chiselling must be done so as to give a smooth result. This change of direction for cutting also applies to the bottom of the halving joint.

Cutting Joint at End of Timber (Fig. 70).—Should the halving joint be used at the end of a piece of wood, as at Fig. 30, the waste material may be roughly sawn away and the flat surface trimmed up with a chisel.

To saw out this type of halving joint, proceed to work the shoulder line as already described; then place the piece of wood obliquely in the vice as shown (Fig. 70) and proceed to saw down the vertical line, carefully watching the gauge line to see that you saw on the waste side of the lines. Then turn the piece of timber with its opposite edge towards you, and again use the saw as illustrated. You will this time only have to watch the gauge mark on the edge of the wood, because the saw will readily follow in the saw kerf already made. Now place the wood vertically in the vice, and keeping the saw in a horizontal position, saw down to the shoulder line.

Halving joints properly made and fitted should knock together with the weight of the clenched fist; the use of a heavy mallet or hammer will deface the work.[Pg 34]

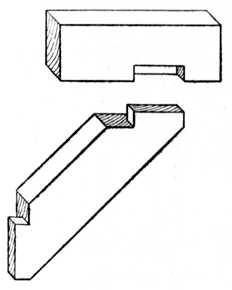

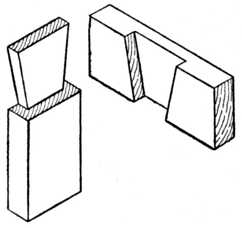

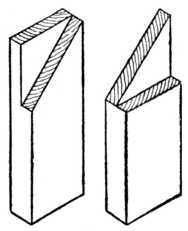

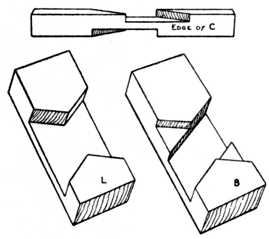

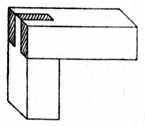

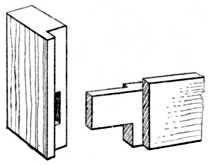

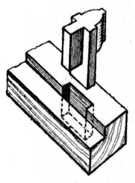

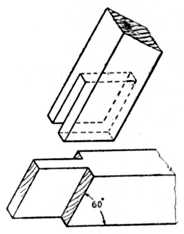

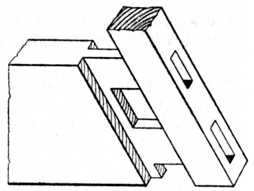

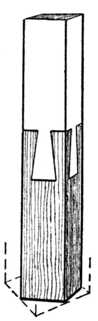

A bridle joint is often defined as the reverse of a mortise and tenon, and is chiefly used in the carpentry and joinery trades. The name probably originated from the fact that it bears some resemblance to the manner in which a bit slips into the horse's mouth and is fastened to the bridle. There are fewer varieties of the bridle joint than of the halved or the mortise and tenon; and this being the case we may take the opportunity of giving a few detailed directions, with explanatory illustrations, on the setting out and the making.

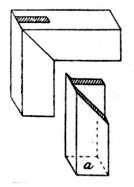

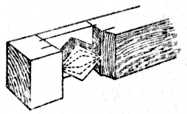

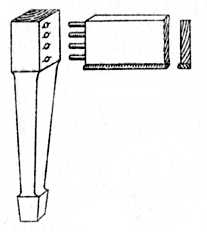

Fig. 72 shows a bridle joint in what is perhaps its simplest form, the separate pieces being given at the left and the completed joint at the right. A joint of[Pg 36] this type may be applied in nearly all cases where a halved or a mortise and tenon joint could be used. Bridle joints have an advantage as regards appearance over the mortise and tenoned variety in cases such as Fig. 73, which shows an occasional table leg fitted to the circular top framing. The bridle joint here allows the grain of the leg to run through to the top, and gives a better and more workmanlike appearance to the completed article.

Fig. 74 is a "Mitred bridle joint," the part a showing the upright portion separated. This is a most useful joint for positions similar to that shown in the small glass frame, Fig. 75. The wood framing in this case is only 13⁄8 in. in width, and if a mortise were used it would have to[Pg 37] be exceptionally small. The shaped rail at the bottom of this frame again shows the application of the bridle joint.

Fig. 76 shows an "Oblique bridle joint," used in many instances as a brace, or strut, to prevent framing from racking. (See also Figs. 31 and 32.)

Fig. 77 is a "Stopped bridle joint," used in positions where the top or bottom edge of the work meets the eye, and where, if the rail were allowed to run through, the end grain would appear unsightly.

Fig. 74.—Mitre Bridle Joint. |

Fig. 75.—Mirror Frame with Bridle Joints. |

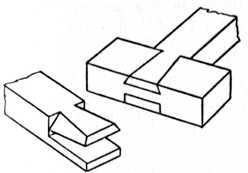

Fig. 78 is a so-called bridle-joint at the corner of a frame. This is also called an "Open slot mortise and tenon joint," a good strong, serviceable joint which can be used instead of the closed mortise and tenon type, its advantage being that less labour is required in the making. (See also Fig. 169.)

Fig. 79 is an "Oblique angle bridle joint," used in similar positions to the above, but when the two pieces meet at an acute angle at the end of a frame.

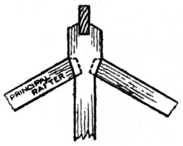

Fig. 80 shows the application of the bridle joint to a roof truss. Two sketches are shown at the joining of the tie beam and the principal rafter. The joint a is the type generally used. (See also Fig. 71 for the joints in a queen post roof.)[Pg 38]

Fig. 76.—Oblique Bridle Joint. |

Fig. 77.—Stopped Bridle Joint. |

Fig. 78.—Bridle Joint at Corner of Frame. |

Fig. 79.—Oblique Angle Bridle Joint. |

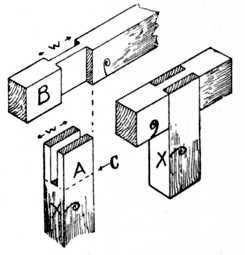

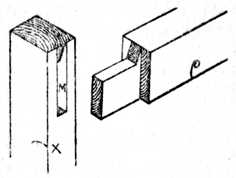

Setting Out and Marking.—It is a safe rule, when setting out a bridle joint, to divide the thickness of the timber into three equal parts. This will leave the timber on each side of the tongue equal to the thickness of the tongue, thus giving uniform strength to the joint. The bridle joint is chiefly used for connecting the internal parts of wooden frames. It is stronger than the halving joint, and, owing to its peculiar construction, requires little in the way of pegs, screws or nails to secure it in position. Fig. 81 illustrates the joint, both open and closed.

To understand the method of setting out and marking, glance at the sketch, Fig. 81. It is not necessary that the bridle piece A be the same width as the cross piece B; but it must be remembered when setting out the joint with the marking knife or pencil that the width marked W on piece B must be equal to the width W on the piece A. The timber should be fairly accurately sawn or planed to the same thickness, and all edges should be square and true.

The wood is placed upon the bench, and the joint marked out by using a marking knife or penknife blade and the try square. A knife blade is much better than a pencil, as the sharp edge severs the fibres of the wood and gives a finer line than the pencil. It is not always necessary to exactly square and trim the end of piece A; it may with advantage in many cases be left at least 1⁄4 in. longer than necessary and levelled off with the saw, plane and chisel after the joint is put together. (See Method of Cutting in Fig. 92, page 47.)

When the piece A has to have a bridle joint fitted at each end, it is customary to cut the timber about 3⁄8 in. longer than necessary, and mark the shoulder lines C to the exact length, after which the joints are cut. This leaves the ends standing over the horizontal[Pg 40] rails, and, after fixing the complete frame together, the small projecting ends are levelled off flush with the cross rails.

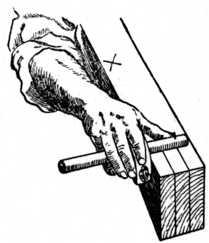

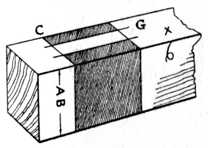

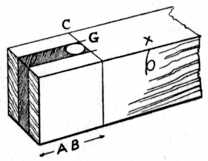

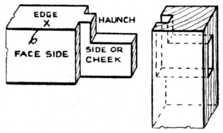

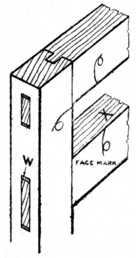

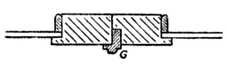

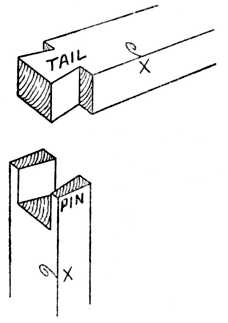

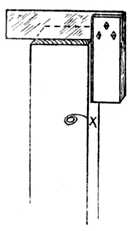

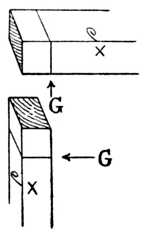

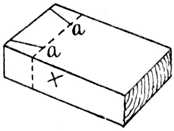

Gauging.—After squaring all the shoulder lines round the timber with the knife and try square, the mortise gauge should be set so as to strike the two gauge lines marked G, Figs. 83 and 84, at one operation. If the worker does not possess a mortise gauge the lines may be marked at two distinct operations with the aid of the marking gauge (Fig. 82). The gauge should be adjusted so as to mark the wood into thirds, and the stock of the gauge (the portion of the gauge containing the thumb screw in Fig. 82) must be used from the face side of the timber when gauging up the whole of the pieces forming a frame. The face mark on the work is indicated by a glorified comma, and the edge mark is shown by X, as in the various illustrations. Fig. 82 shows the method of holding the gauge in the right hand whilst gauging the lines on the work.

Fig. 81.—Bridle Joint, open and closed. |

Fig. 82.—Gauging the Timber. |

The joint, when marked out, will appear as at[Pg 41] Figs. 83 and 84, and the portions which are to be cut away may be shaded with a pencil as indicated; this will prevent mistakes arising whilst cutting the work, especially by one who is not thoroughly familiar with the joint.

The distance A B, in Fig. 84, must not be less than the distance A B in Fig. 83.

Fig. 83. |

Fig. 84. |

The Two Parts of the Joint Marked.

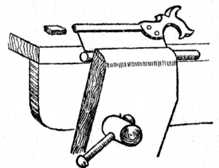

Boring Away Waste.—Examine Fig. 84; the shaded portion in the centre has to be cut away, and it will greatly facilitate the removal of this waste piece by boring a hole with a twist bit at the position shown. The twist bit should be about 1⁄8 in. less in diameter than the width between the gauge lines G. The easiest method of boring out this hole is shown at Fig. 85, which gives the correct position of the worker.

Sawing.—The wood should be put in the vice as Fig. 86. Taking up a saw, with the index finger on the side of the handle, commence sawing, and proceed until you come to the position indicated by the dotted hand and saw A; this will leave a saw kerf or cut running diagonally from the shoulder line to corner of the wood. Release the vice and refix the wood so that it leans in exactly the opposite direction to Fig. 86; then reverse your own position and repeat the sawing, so as to cut[Pg 42] another diagonal saw cut from the shoulder line to the corner. Fix the wood upright, as shown at Fig. 87, and saw as shown, when you will find that the saw has no tendency to run out of the guide cuts already formed by the method used at Fig. 86. Remember, when commencing to saw at Fig. 86, that it is necessary to saw inside the gauge line; otherwise the joint will be too slack, owing to the amount of sawdust removed by the thickness of the saw blade. The index finger on the side of the saw, pointing in the direction of the saw cut,[Pg 43] will greatly help the worker to saw in a straight line, as it is natural to point with this finger to any object that is to be aimed at.

Cut down the other line in a similar manner, and then with a chisel of suitable width carefully chop away the waste material. The wood may be placed edge way upon the bench, or in the vice, and the chisel should be held vertically. The hole which has been bored with the twist bit will allow the chips which are cut away to offer little or no resistance to the chisel blade. The chiselling should not all be done from one side, or a chipped under-edge will be the result; it is better to chisel the work until half-way through and then turn the other edge of the wood uppermost and again begin to chisel from the top. This method will finish the cutting in the centre of the work and prevent burred and ragged or chipped edges at the shoulder.[Pg 44]

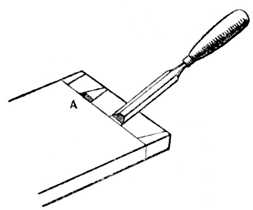

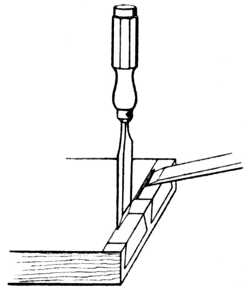

Cutting the Shoulders.—With regard to working the piece B, Fig. 81, place the wood against the bench stop or in the vice, and taking up a 3⁄4-in. chisel carefully cut away a small channel, as shown at Fig. 88; treat the other shoulder lines in a similar manner. If the[Pg 45] marking knife or penknife blade has been used with a fair amount of pressure so as to score the fibres of the wood, this small channel, which is to form a guide for the saw, will quickly and easily be cut. Next place the wood in the vice or on the cutting board as shown at Fig. 89, and begin by sawing lightly at the back edge as shown. When the saw has entered the wood 1⁄4 in. gradually bring the handle down from position A to position B (dotted lines) whilst the saw is in motion. Continue sawing until just on the gauge line; then treat the other shoulder lines in a similar manner.

Chiselling away Waste.—Fix your wood firmly in any suitable manner, vice or otherwise, and, holding[Pg 46] your chisel tilted as at Fig. 90, pare away the blacked portion 1; then pare away the blacked portion 2; after which hold the chisel flat and by gradual operations pare away the dotted lines 3, until you come down to the gauge line; then repeat the method of cutting on the opposite side of the wood. If any difficulty be experienced by chipped or ragged edges whilst chiselling, it can easily be overcome by chiselling alternately from the outside of the wood, so that the finish of the chisel cut takes place in the centre of the work. Some prefer to chisel away the waste by placing the wood on its edge and using the chisel vertically instead of horizontally. The same methods (1, 2 and 3) hold good in this case.

Joints Other than at 90°.—The two pieces forming a bridle joint are not always at right angles, as at Fig. 81; in many instances it is necessary that the joint be at other than 90 degrees. The work, however, is treated in a similar manner, with the exception that an adjustable joiner's bevel is used instead of a try[Pg 47] square to mark out the shoulder lines, and that a change of direction in the grain of the wood will occur when chiselling out the work. Fig. 91 indicates the change in the grain of the wood, and the adjustable joiner's bevel is also shown.

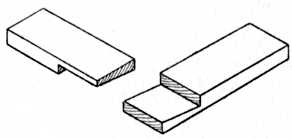

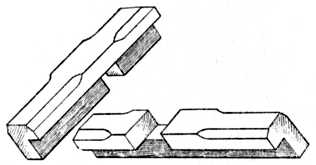

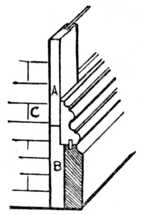

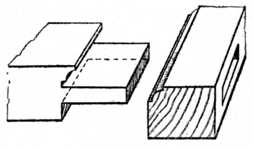

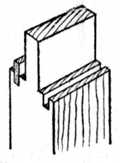

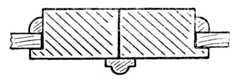

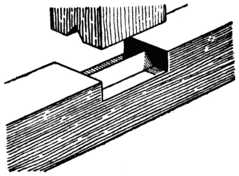

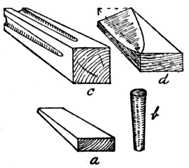

T he tongued and grooved joint is used in one form or another throughout the whole of the woodworking trades, covering, as it does, a great variety of work from the laying of flooring boards to the construction of dressers, bookcases and other cabinet work.

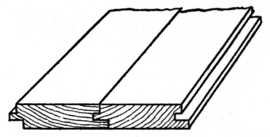

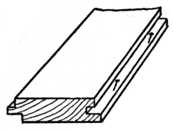

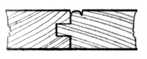

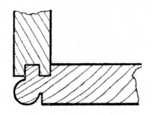

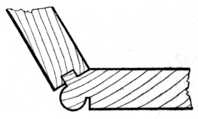

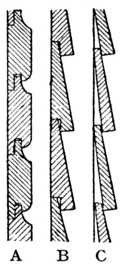

Flooring and match boarding generally have the tongues worked on the solid board, and examples of a few of the various types are shown as follows:—

Fig. 94. |

Fig. 95. |

Method of Nailing Hardwood Floors.

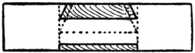

Fig. 93 shows the end view of the ordinary 7⁄8-in. "Tongued and Grooved Flooring board," as used in the construction of floors for mills, workshops and cottage[Pg 49] property. This type of flooring is nailed to the joists in the ordinary manner, no attempt being made to conceal the nails used.

Fig. 94 is a section of flooring which is generally made of hardwood, such as maple, oak, or jarrah. It is used in positions such as ballroom and skating rink floors, etc., the tongue and groove being worked in such a manner that the joint covers the nails as shown. Each nail is driven into its position at one edge of the board, the groove holding the next board and hiding the nail (Fig. 95).

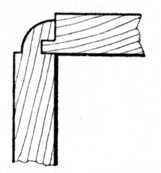

Fig. 96.—Tongued and Grooved Matchboarding, with Bead on One Side. |

Fig. 97.—Tongued and Grooved Matchboarding, with Bead at Each Side. |

Fig. 98.—Matchboarding, Tongued, Grooved and Vee'd. |

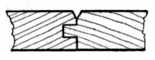

Fig. 96 shows an example of matchboarding known as "Tongued, Grooved and Beaded" on one side only, and Fig. 97 shows a similar type tongued, grooved and beaded on both sides. This variety of matchboarding is known in the trade as "T. G. and B." It is used for nailing on framing to form partitions for rooms, offices, etc., for panelling corridors, etc., and for making framed and ledged doors, building tool houses, cycle sheds and other outhouses.

Fig. 98 is an example of matchboarding that is tongued, grooved and vee'd on one side, and Fig. 99 shows tongued, grooved and vee'd both sides. These are used for similar purposes to Figs. 96 and 97, and many prefer the V matchboarding variety because it is more easily painted than the beaded variety.[Pg 50]

The object of working a bead or beads on matchboarding is to break the jointing of the various pieces and to aim at ornamental effect; also to prevent unsightliness should the timber shrink slightly. When a moderate amount of shrinkage takes place, as is nearly always the case, the joint at the side of the bead appears to the casual observer to be the fillet or channel worked at the side of the bead. If the tongues are not painted before the work is put together, the shrinkage will cause the raw wood to show and thus make the joint too much in evidence.

Fig. 99.—Matchboarding Vee'd Both Sides. |

Fig. 100.—Double-tongued Matchboarding. |

Fig. 101.—Double-dovetailed, Tongued and Grooved. |

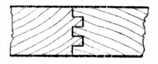

Fig. 100 shows a "Double tongued and grooved" joint used in the wholesale cabinet factories. It is preferred for the jointing of cabinet stock, and the amateur can make a similar joint by working two grooves and inserting loose tongues.

Fig. 101 is the end view of a "Double-dovetailed, tongued and grooved" joint, and Fig. 102 is a sketch of a similar joint having only one dovetailed tongue.

From a constructional point of view Fig. 101 is far and away the best joint that has yet been produced. Unfortunately, however, there is not at the present time any hand tool that will economically produce it, owing probably to the fact that the joint is the subject of a patent. The dovetail tongue tapers slightly throughout its entire length, gripping the joint on the principle of the wedge and squeezing the glue into the pores of the wood.[Pg 51]

Fig. 103.—(A) Cross Tongue. (B) Feather Tongue. |

Fig. 104.—Method of Secret-nailing Hardwood Flooring Boards. |

Cabinet-work Joints.—With regard to tongued and grooved joints which apply more particularly to the jointing of cabinet work, Fig. 93 is produced by planes which are specially made for the purpose. One plane makes the tongue and another the groove. The handiest sizes to buy are those which joint 3⁄8 in., 5⁄8 in., and 3⁄4 in. timber, it being usual to dowel or loose-tongue thicker boards. The 3⁄8 in. partitions (or, as they are sometimes called, dustboards) between the drawers of a sideboard or dressing chest are in good work jointed in this manner. The 5⁄8 in. and 3⁄4 in. ends and tops of[Pg 52] pine or American whitewood dressing tables, wardrobes, etc., call for the larger sized plane.

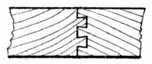

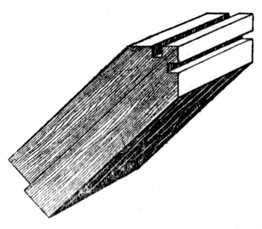

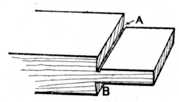

Loose Tongues.—There are two methods of jointing with loose tongues, viz., the use of the cross tongue, Fig. 103 A, and the use of the feather tongue, Fig. 103 B. Cross tongues are the stronger when glued in their position and can be used very much thinner than feather tongues. Feather tongues are cut diagonally across the grain as illustrated.

Fig. 105 is a cradle for planing up loose tongues to the required width (generally 7⁄8 in.). Two grooves are made in a piece of 11⁄4 in. hardwood; one groove is used for planing the width way of the tongue and the other for planing the edge way. These tongues can be cut to accurate size on a circular saw bench if power and machinery are at hand.

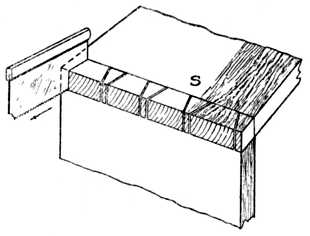

Applications of the Joint.—Fig. 106 is a sketch of a portion of a sideboard top, showing the plough groove ready worked out to receive the tongue; the other half of the top is treated in a similar manner. It will be noticed that the groove is not worked through the full length of the board, but stopped about 11⁄4 in. from each end; this leaves a square joint at each end of the top on which the moulding is worked. If the groove be run through the board it looks very unsightly when the mould is finished.

Fig. 107 is a shaped spandrel, such as is fixed in the[Pg 53] recess of a sideboard or cupboard or shop window fitment. It is of such a width that, were it cut from a wide board, the shaped portion would be apt to break off owing to the short grain at C. The shaping is therefore built up out of three separate pieces, the grain running as indicated. The loose tongue is represented by the dotted line and a section is shown of the joint at the line A B. At the opposite corner the tongue is left blind, i.e., not run through the edge. This is the method that should be used when the shaping is above the level of the eye.

Fig. 108 shows part of a carcase of a dressing table. The drawer runner A is shown grooved across the end to receive a cross tongue; this cross tongue engages a[Pg 54] similar groove in the front bearer. This method of fastening the runner to the bearer is in everyday use.

Fig. 109 is a writing table top. The centre boards are first jointed and glued up, after which the ends and sides are grooved ready to receive the cross tongues. The hardwood margins are shown at one end and at the front, and the grooves are arranged so that, on completion, the marginal frame stands above the top just the amount of the thickness of the leather which will cover the table. In some cases the margin at the end runs the same way of the grain as the top, thus allowing for slight shrinkage. Cross tongues would of course be used in this case.[Pg 55]

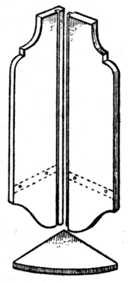

Fig. 110 is a sketch showing one-quarter of a barred or tracery cabinet door. An enlarged section of the astragal mould which is grooved to fit on the bar which forms the rebate is also shown.

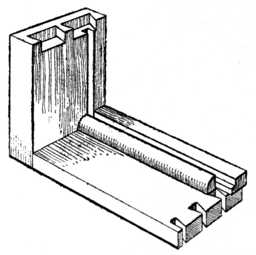

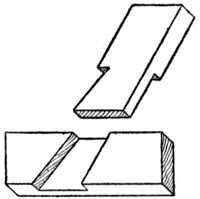

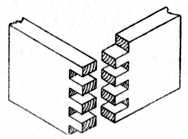

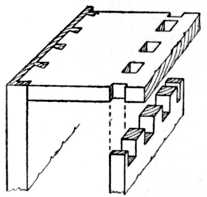

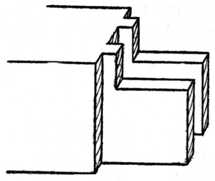

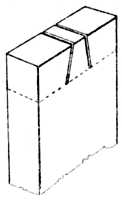

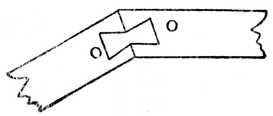

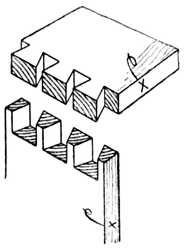

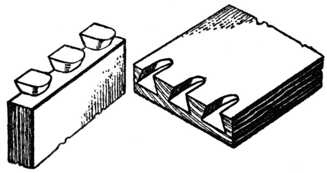

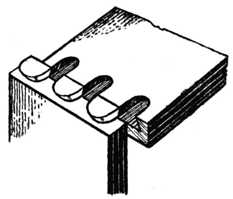

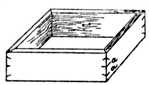

Fig. 111 is a "Combing or corner locking" joint, a method of making boxes by means of a continuous use of tongues and grooves instead of dovetails. This type of joint is generally machine made. The amateur, however, who is not proficient to undertake a dovetailed box frequently uses this method.

Fig. 110.—Corner of Barred Door. |

Fig. 111.—Combing or Locking Joint. |

Fig. 112.—Single Loose Tongue and Double-tongue Joint. |

Corner Joints.—Fig. 112 shows both a single loose tongue and a double solid tongue. Both are methods used to connect circular cornered work, such as a counter end, to the front framing.

Fig. 113 indicates a tongued and grooved joint suitable for edge or end jointing, such as fitting matchboarding round a chimney breast, making small jewel drawers, etc.

Fig. 114 is a tongued and grooved joint with a bead worked on same to hide the joint, sometimes called a staff-bead. It would be used in positions such as[Pg 56] boarding around an upright iron pillar, etc., the bead giving a neat finish at each corner.

Fig. 115 is a similar joint, but at an obtuse angle. An example of its use is in fixing boarding around an octagonal column of brickwork.

Fig. 113. |

Fig. 114. |

Fig. 115. |

Examples of Tongued and Grooved Corner Joints.

Fig. 116 shows a tongued and grooved mitre as used for strengthening the corners of cabinet work, such as tea caddies, small boxes, plinths, etc. Two pieces of wood are glued in position and allowed to set prior to glueing and cramping the joint proper. These pieces are afterwards planed away, thus leaving a clear surface to the box sides.

Fig. 117 shows the method of working the groove in the above joints. The pieces are turned back to back, the mitres thus making a right angle. The guide on the grooving plane thus works against each face of the joint, and this ensures correct jointing.

Fig. 118 is somewhat similar to Fig. 113, but with a quarter circle mould to hide the joint.

Fig. 119 indicates the building up of a double skirting mould. C represents the brickwork, A the oak-framed panelling, and B the packing and fixing block. A wide skirting of this type is made in two portions for convenience in working the moulding and to prevent undue shrinkage.[Pg 57]

Fig. 117.—Working a Groove. |

Fig. 118.—Corner Joint with Corner Mould. |

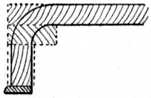

Fig. 120 illustrates the use of a tongued and grooved joint for fixing together the sides of a corner bracket, and the same method holds good when jointing a corner cupboard. A capping mould or top shelf will conceal the joint; it then has the appearance of a glued butt joint, but is of course considerably stronger. No screws or nails are required if this joint be used.[Pg 58]

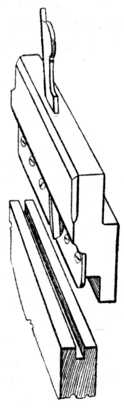

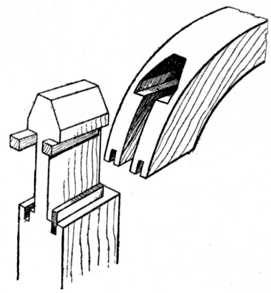

Ploughing.—When grooves have to be worked in the edge or face of a board to receive tongues, the process is generally called ploughing, and it is usually accomplished by a special tool called a plough (or, as it is occasionally spelt, "plow"). When a plough plane is bought it is usual to procure eight plough bits or blades of various sizes to fit the plane. In Fig. 121 is given the sketch of a plough plane with the names of the various parts lettered thereon.

Fig. 119.—Double Skirting Mould. |

Fig. 120.—Joint for Corner Bracket or Cupboard. |

The board or boards which it is desired to groove are first planed straight and true, exactly as though it were desired to make a glued or butt joint. One of the boards is now placed edge way up in the vice and with the face side to the worker.

Take the plough plane and select a suitably-sized[Pg 59] blade; fix it in the plane in the usual way, allowing the cutting edge to project beyond the steel skate about 1⁄32 in., and securely drive up the wedge. Next loosen the small boxwood wedges at the side of each stem, and adjust the plane by tapping the stems with a hammer until the cutting iron is in the desired position; then knock up the small wedges nice and tight. When setting the fence to or from the blade it is a wise precaution to measure the distance from the fence to the skate at each end of the plane; this will ensure the skate being parallel to the fence. The neglect of this is a source of annoyance to many amateurs. Now adjust the depth stop by turning the screw at the top of the plane, measuring the depth of the required groove from the edge of the blade to the stop, and carefully lock the screw which adjusts this stop.

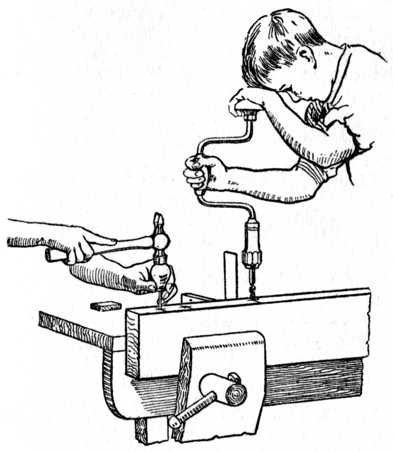

The plane is now ready for use. Hold the fence close up to the side of the timber, the hands in position as shown at Fig. 122, the position of the body being that[Pg 60] generally assumed in planing. Move the plane backwards and forwards in the usual manner, beginning the cut at the end of the board nearest to the vice jaws (the front), and proceed with the planing until the depth stop is in contact with the wood. Then take a step backwards and repeat the process until the whole length of the groove is ploughed. Care must be taken to force the fence up to the board with the left hand, whilst the right hand thrusts the plane backwards and forwards, and the plane must be kept vertical.

Tongueing.—The grooves having been completed, the tongues have to be made. Fig. 123 shows a sketch of a board and the method of marking out cross tongues (A) and feather tongues (B). The usual procedure for making cross tongues is to plane the end of the board and use a cutting gauge to give a line the required distance from the end (see sketch). The board is sawn with a tenon or panel saw, and the piece of timber for the tongue is thus procured. If a feather tongue is to be used it is cut diagonally from the board (B) and the ends cut square as shown by the dotted line.

Feather tongues can be obtained in fairly long lengths out of narrow boards, whilst on the other hand cross tongues are limited by the width of the board. After cutting off the tongues, they require planing with nicety to fit the grooves, and the advantage of a grooved board (Fig. 105) will be appreciated. A glue spoon similar to a plumber's ladle is generally used to pour the glue into the grooves, and it is customary to glue the tongue into one board first; after allowing this to set, the joint is completed in the usual manner.

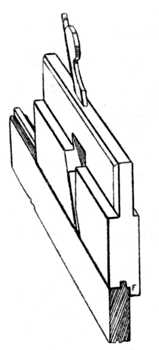

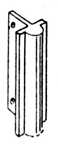

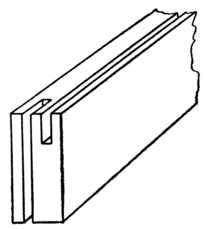

Tongueing Planes.—Fig. 124 shows the end view of a tongueing plane for working matched joints out of[Pg 62] the solid. The method of holding and using the plane is similar to the directions given for using the plough. The part lettered F (in front) represents the fence, which in this case is not adjustable.

Fig. 124. |

Fig. 125. |

End Views of Tongueing and Grooving Planes.

In description Fig. 125 is similar to Fig. 124. The steel skate runs in the groove and supports the cutting blade similar to that in the plough plane, and provided a grooving plane of this type is of suitable width it may be used for making grooves for loose tongues. There is on the market a metal plane which is specially[Pg 63] designed with handles at both ends. This plane carries a grooving iron on one side and a tongueing iron on the other side; thus with one plane both the tongue and the groove can be worked.

Fig. 126 shows the method of tongueing the shoulders of tenons as used in thick timber which is to be veneered on the face. A temporary piece of wood (A) is put between the tenon cheek and the saw, thus forming a guide for the latter. After cutting one saw kerf a thicker piece is made and a second saw kerf cut; the waste between the saw kerfs is now removed with an 1⁄8 in. chisel and this completes the groove. A tongue of this type acts as an extra tenon and prevents the joint from "lipping" (becoming uneven) on the face side.[Pg 64]

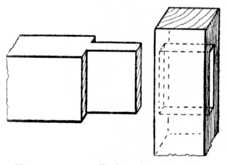

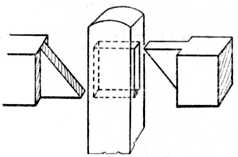

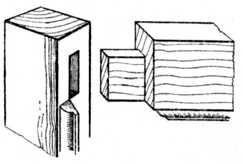

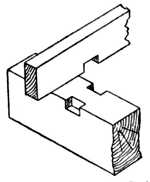

A mortise and tenon joint is the method of joining timber by working a solid rectangular projection in the one piece and cutting a corresponding cavity to receive it in the adjoining piece. The projection is called the tenon, and the cavity the mortise. Joints of this type are secured in various ways. Small wedges, wooden dowels, metal dowel pins, glue and paint are frequently used, and prior to the introduction of glue we have examples of Egyptian furniture in which the mortise and tenon joints were united by a composition of cheese.

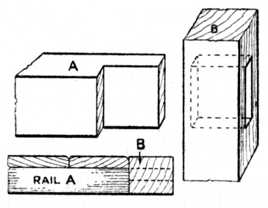

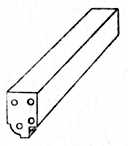

Fig. 127.—Barefaced Tenon Joint. |

Fig. 128.—Stub Tenon. |

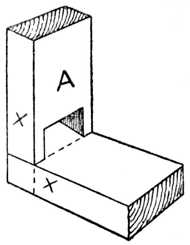

Barefaced Tenons.—Fig. 127 illustrates the joint in its simplest form and shows a tenon having only one shoulder. This is called a barefaced tenon, and it will[Pg 65] be noticed that the portion which carries the mortise is thicker than the rail on which the tenon is cut. The joint is therefore level (or flush as it is called) on one side only, and it should never be used at the corner of a frame. It is a useful interior joint for framing that has to be covered on the back side with matchboarding, and allows the work to finish level at the back when the boarding has been applied (see plan, Fig. 127).

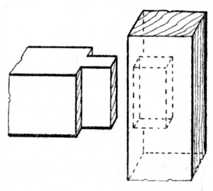

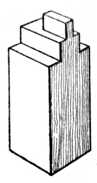

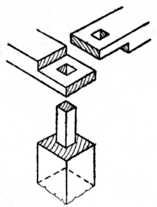

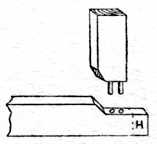

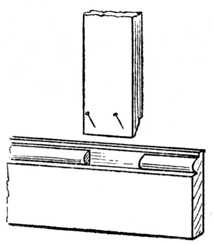

Stub or Stump Tenon (Fig. 128; also occasionally called a joggle tenon).—The illustration shows a tenon as used in the interior of a frame. The tenon is not allowed to run through the stile, and unslightliness on the edge is thus avoided. This type of tenon is often used at the corner of a frame, and it then requires to be haunched. A good workshop method of gauging the depth of the mortise for a stub tenon is shown in Fig. 129; a piece of gummed stamp paper is stuck on the side of the mortise chisel, indicating the desired depth of the mortise. This greatly facilitates the work, as it is not necessary to be constantly measuring.

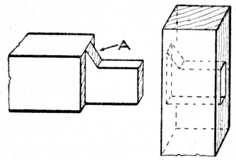

A Haunched Tenon as used at the end of a door frame is shown at Fig. 130.—In this case it will be seen that the width of the tenon is reduced, so that sufficient timber will be left at the end of the stile to resist the pressure of the tenon when the joint is driven together. The short portion (A) which is left on the tenon is called the haunch, and the cavity it engages is termed the haunching. The haunch and haunching prevent the two pieces of timber lipping, or becoming uneven on the face side, as would be the result if it were cut away entirely up to the shoulder.

Fig. 131 shows the type of tenon and haunch used when the stile or upright rail is grooved to receive[Pg 66] a panel. In this and similar cases the haunch is made[Pg 67] the same width and the same depth as the groove; the groove therefore acts as the haunching. An application of this joint is shown in the top rail of the door frame, Fig. 132.

This type of joint is also used to connect the rail to the leg of an ordinary kitchen table (see Fig. 167).

Fig. 130.—Haunched Tenon used at end of Door Frame. |

Fig. 131.—Haunched Tenon used when Stile is Grooved for Panel. |

Fig. 132.—Application of Haunched Tenon Joint to Door Frame. |

Fig. 133.—Occasional Stump Tenon. |

Fig. 133 is a variation of the stump tenon, occasionally used where the work in hand demands a thin tenon and a stout stump to take heavy strains.

Fig. 134.—Joint for Inside Framing. |

Fig. 135.—Haunched Barefaced Tenon. |

A joint used for inside framing is seen at Fig. 134. The rails may be used as shown, but in the case of a door frame (as Fig. 132) they would have the inside edges grooved to receive the panels; the tenons would therefore be slightly narrower than shown, owing to the groove at each edge.

A Haunched Barefaced Tenon, used in similar positions to Fig. 131, is shown at Fig. 135. The door or frame in this case would be made of matchboarding nailed on the back as shown in the plan at Fig. 127.

Wedges.—Fig. 136 shows the method of cutting wedges which are to be used to wedge the tenons; this avoids waste of material. Some workers cut the wedges[Pg 68] from the pieces left out of the haunching of the lock rail, or the bottom rail.

Fig. 136.—Cutting Wedges from Waste of Haunching. |

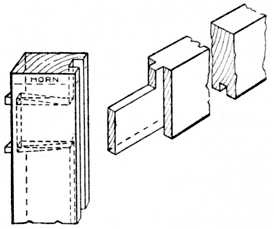

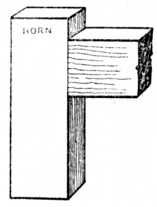

Fig. 137.—Stile and Cross Rail with Horn. |

A Stile and Cross Rail, framed together, are shown at Fig. 137. The portion above the rail is called the horn, and it is usual to leave sufficient length of stile to project above and below the cross rails, so that there will be no tendency for the stile to burst out at the end whilst the cramping and wedging of the frame is in progress. On completing the framing the horn is cut away.

In Fig. 138 we have a type of joint frequently used for garden gates. The illustration shows the method of tenoning the three pieces to the top rail, barefaced tenons being employed.

Fig. 138.—Joint used for Garden Gates. |

Fig. 139.— Sprocket Wheel. |

Fig. 140.— Boring Tool. |

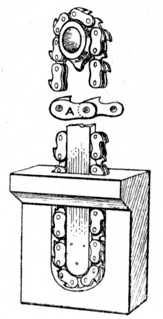

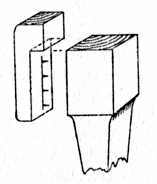

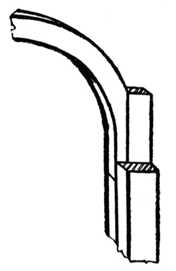

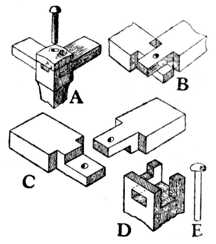

Sprocket Wheel.—At Fig. 139 are shown the guide bar and chain of a chain-mortising machine, two enlarged links of the chain being indicated at A. The chain is similar in construction to the driving chain of a bicycle, with the exception that it is provided with teeth which cut away the timber as the chain revolves.[Pg 69] When using a chain mortiser the portion of the machine carrying the chain is fed downwards into the timber, thus cutting a clean and true mortise. If, however, a stump mortise is required it is necessary to pare away a certain amount of timber by hand, because the machine obviously leaves a semicircular bottom to the mortise. To overcome this difficulty the latest types of mortising machines have a square hole-boring attachment fixed alongside the chain. This tool, the working portion of which is illustrated in Fig. 140, consists of a square hollow chisel (E), which is sharpened from the inside, and a revolving twist bit (D) fitted with spurs or nickers, but without a point (one spur can be seen at the bottom of the illustration). This bit revolves inside the shell like a chisel, and bores away the superfluous timber,[Pg 70] whilst the pressure exerted on the chisel causes the corners to be cut away dead square. A mortise 3⁄8 in. square by 6 ins. in depth may thus be cut. The portion marked A is the shank of the chisel (Fig. 140), where it is fixed into the body of the machine, and the hole at E allows the boring bit to free itself.

Fig. 142.—Haunched Tenon for Skylight or Garden Frame. |

Fig 143.—Long and Short Shouldered Tenon. |

Fig. 141 indicates the method of fixing an interior leg to a table having a circular or straight top rail. The inlaid leg in this case is stump-tenoned into the top rail, and the inlaid portion of the leg is allowed to run through the rail, thus giving continuity of design.

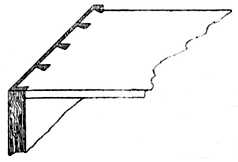

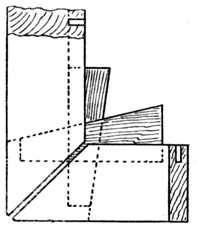

Fig. 142 shows the application of the haunched tenon[Pg 71] (Fig. 135) to the making of a skylight or garden frame. In this and similar cases the side rails are rebated as shown in the section, and the bottom rail is thinner than the side rails to allow the glass to finish level upon it.

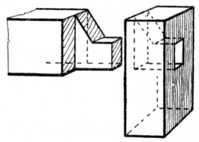

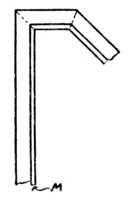

Long and Short Shouldered Joint.—Fig. 143 shows a haunched mortise and tenon joint having a long and short shoulder. This is a fairly common joint in framed partitions for offices, framing for greenhouses, tool sheds, etc., and is a frequent source of annoyance to the amateur. It is necessary to use this joint when both the stiles and uprights are rebated, and it calls for accurate marking out and great care in the making.

Fig. 144.—Joint for Fencing. |

Fig. 145.—Example of Faulty Tenon. |

Fig. 144 shows the upright and rails of common garden or field fencing. The tenons are bevelled to fit and wedge each other in the mortise. The illustration gives both cross rails as shouldered, but in many cases shoulders are omitted when the rails are not thick enough to carry them.

Fig. 145 indicates faulty methods of working a tenon. At A the saw has been allowed to run too far when cutting the shoulder, thus greatly weakening the tenon. At B faulty sawing has again occurred, and to remedy this defect the worker has resorted to paring the shoulder with a chisel. Had the chisel been used[Pg 72] vertically an undercut shoulder (as at B) would not have occurred. The trouble now is that the slightest amount of shrinkage in the width of the stile will show an open joint. The result will be the same if it is necessary to remove a shaving or two when planing or levelling up the face of the frame.

Fig. 146.—Self-wedging Japanese Tenon Joint. |

Fig. 147.—Tenoned and Scribed Joint. |

Fig. 148.—Mitred and Moulded Tenon Joint. |

Fig. 149.—Twin Tenons. |

A Japanese Tenoned Joint, little known and rarely used in this country, is shown at Fig. 146. For clearness the two parts are here shown separate. The joint is self-wedging and will be of interest to Handicraft Instructors.

A Tenoned and Scribed Joint is seen at Fig. 147. The cross rail is cut at the shoulder, so as to fit the moulding[Pg 73] which is worked on the stile. This is a good joint in everyday use.

Mitred and Moulded Joint.—Fig. 148 shows a type of joint largely used in light cabinet work. The method of mitreing the moulding and tenoning the stile to rail is indicated.

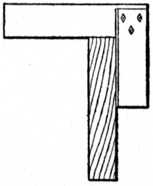

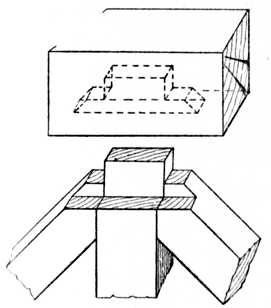

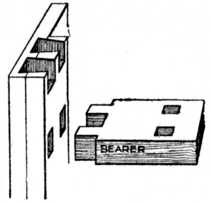

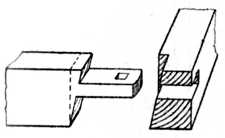

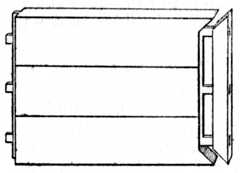

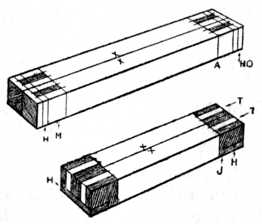

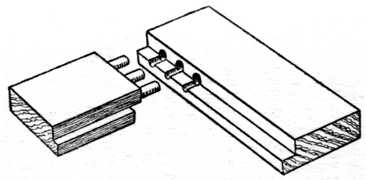

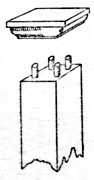

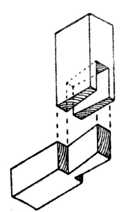

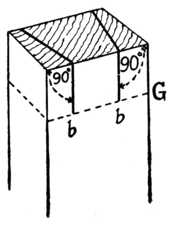

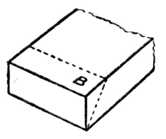

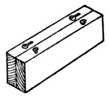

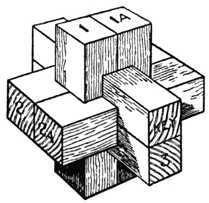

Twin Tenons (Fig. 149).—The method of tenoning the bearers which carry the drawers, or the midfeather between two drawers, in a dressing table or similar carcase is here shown. On completion, the tenons on the midfeather are wedged diagonally.

Fig 150.—Method of Pinning. |

Fig. 151.—Joining Top Rails to Upright Post. |

Pinning.—Fig. 150 shows the tenoning of the inside end of a wardrobe to the top of the carcase. This is also called pinning. The tenons should be wedged diagonally. The tenons and the distance between the tenons are more satisfactory if made equidistant, because if slight shrinkage occurs this is partially equalised. The width between the tenons should in no case exceed 3 ins.

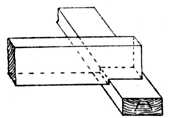

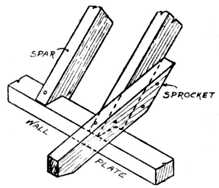

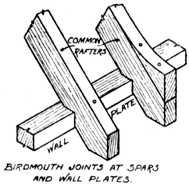

Top Rails.—At Fig. 151 is shown the method of joining the top rails to the post of a tool shed or similar outhouse. The two rails, which are at right angles to[Pg 74] each other, are half-lapped and mortised; the tenon on the post runs entirely through them.

A Tusk Tenon Joint, with wedge, as used to secure the binder to the girder when making floors, is indicated at Fig. 153. The tenon here is narrow and engages the mortise, which is situated in the compressional fibres immediately adjoining the neutral layer. Fig. 152 shows a tusk tenon furnished with a drawbore pin.

Fig. 154 is a variation of Fig. 152.[Pg 75]

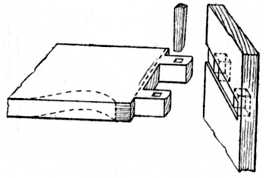

Fig. 155 shows tusk and wedged tenons as used when making a portable book or medicine cabinet. The shelf is housed into the end, and the tenons run through the end and are secured by wedges. This allows the article to be quickly and easily taken to pieces for removal or re-polishing. The dotted line in Fig. 155 indicates that the shelf may be shaped if desired.

Fig. 154.—Another Type of Tusk Tenon. |

Fig. 155.—Tusk Tenon and Wedge. |

In Fig. 156 a self-wedging mortise and tenon joint used by wheelwrights is shown. The dotted line (left-hand diagram) will indicate the amount of taper given to the mortise.

Dovetailed and Wedged Tenon (Fig. 157).—When two pieces such as the cross rail and leg of a carpenter's[Pg 76] bench are required to be held together by a mortise and tenon, and to be readily taken apart, the tenon is dovetailed on one side and the mortise is made of sufficient width to permit the widest part of the dovetailed tenon to pass into it. When the tenon is in its position a hardwood wedge is driven in above the tenon, as shown.

Fox Wedged Tenon (Fig. 158).—This is the method of securing a stub tenon by small wedges. The mortise is slightly dovetailed and two saw cuts are made in the tenon about 3⁄16 in. from each side. Into each saw kerf a wedge is inserted and the joint glued up. The cramping operation forces the wedges into the saw cuts, thus causing the end of the tenon to spread and tightly grip the mortise.[Pg 77]

Mortise and Tenon with Mitred Face (Fig. 159).—This is a useful method of jointing framing which has square edges as shown; and it is equally useful even if the face edges have moulds worked upon them. If the joint has square edges a rebate may be formed to accommodate a panel by fixing a bolection moulding around the frame. A section of the bolection mould planted on the frame is shown in the lower figure.

Fig. 160.—Rafter Joint. |

Fig. 161.—Roof Joints. |

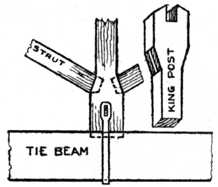

Roof Joints.—Fig. 160 shows the method of tenoning the principal rafter to the king post, whilst Fig. 161 illustrates the tenoning of the struts to the king post, and the king post to the tie beam. Both these examples are used in roof work. (See also Fig. 71.)[Pg 78]

Fig. 163. |

Fig. 164. |

Operation of Pegs in Drawbore Pinning.

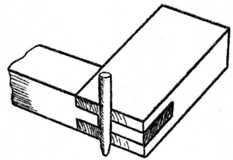

Drawbore Pinning.—At Fig. 162 is seen the method of securing a tenon by drawbore pinning, employed when it is not convenient to obtain the necessary pressure by using a cramp. The joint is made in the usual manner, and a 3⁄8-in. twist bit is used to bore a hole through piece A. The tenon is driven home and the hole is marked on the side of the tenon (B); the tenon is then withdrawn and the hole bored about 1⁄8 in. nearer to the shoulder than as marked on the separate diagram[Pg 79] at C. When the tenon is finally inserted the holes will not register correctly, and if a hardwood pin be driven into the joint it will draw the shoulders of the tenon to a close joint and effectually secure the parts.

Sash Bars.—Fig. 165 shows how to tenon a moulded sash bar to the rebated cross rail. In this illustration both shoulders of the moulded bar are shown square, but in the best class work these shoulders may be slightly housed into the cross rail to prevent side play. This type of joint is used for horticultural buildings, etc. If the lower rail be moulded with the same members as the sash bar, the end of the sash bar will have to be scribed on to it to make a fit.

Fig. 165.—Tenoning Moulded Sash Bar. |

Fig. 166.—Tenon with Tongued and Grooved Shoulder. |

Fig. 167.—Detail of Table Framing. |

Tenon with Tongued and Grooved Shoulders (Fig. 166).—The object of the tongues and grooves here is to prevent the face of the work casting, or becoming warped, and thus spoiling the appearance of the surface of the work. If framing is to be veneered on the face side this is an exceptionally good method.

Table Framing.—Fig. 167 indicates the framing of a rail to a dining-table leg. In cases similar to this the tenons run into the leg and almost touch each other.[Pg 80] They are therefore mitred on the end as shown in the inset. Chair frames often call for similar treatment.

Twin Tenons with haunch, as used when the timber is of great thickness, are shown in Fig. 168.

An Open Slot Mortise at the end of a right-angled frame is seen in Fig. 169. Fig. 170 shows an open slot mortise and tenon joint at the end of a frame of 60°. Both these joints are occasionally called end bridle joints.

Fig. 168.—Twin Tenons for Thick Timber. |

Fig. 169.—The Open-slot Mortise Joint. |

Hammer Head Tenons.—At Fig. 171 is shown the method of jointing framing having semicircular or segmental heads. The left-hand diagram indicates the method of wedging the joint so as to draw up the shoulders; the right-hand view shows the tongueing of the shoulders, which is necessary if thick timber has to be wrought. The sketch depicts the stile when taken apart from the shaped head of the frame.

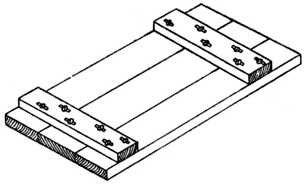

Clamping.—Fig. 172 shows the method of tenoning drawing boards, desk tops and secretaire falls. This is commonly called clamping. The method is used to prevent wide surfaces from winding. A variation of the joint is shown at the left-hand side, the corners in this[Pg 81] example not being mitred. Fig. 173 shows the tenoning of a wide to a narrow rail when the joint is at an angle.

Inserted Tenons (Fig. 174).—Where two pieces of timber run together at an acute angle it becomes necessary to use inserted tenons. Both pieces of the timber are mortised and the inserted tenons are secured into the widest piece. On the left is shown the inserted tenon, secured by the method known as fox-wedging; on the right the inserted tenon has been let into the wide rail from the edge. The narrow rail is secured by wedging the tenons from the outside edge in the ordinary manner.

Fig. 170.—Open-Slot Mortise at 60 degrees. |

Fig. 171.—Hammer-Head Tenon Joint. |

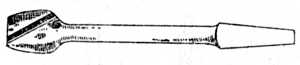

Dreadnought File.—At Fig. 175 is a sketch of a portion of a dreadnought file. This has superseded the old-fashioned home-made float used to clean out the sides of a mortise.[Pg 82]

Fig. 172.—Clamping. |

Fig. 173.—Tenoning Narrow Rail. |

Fig. 174.—Inserted Tenons. |

Fig. 175.— Dreadnought File. |

Fig. 176.—External and Internal Joints. |

Fig. 177.—Setting out Stiles and Rails for Tenoning. |

General Rule.—In practically all cases where a single tenon is used the thickness of the tenon should be one-third the thickness of the timber. This leaves the timber at each side of the mortise the same strength as the tenon.

Mortise and tenon joints for inside work may be united with glue. If, however, the work has to stand the weather a better method is to unite the joint with white lead, which is run down to the required consistency with good outside varnish.

Setting Out the Joint.—The principal use of the[Pg 83] mortise and tenon joint is in the construction of various types of framing, such as door and window frames. In one or other of its many and varied forms it may be classed as the most important joint in the general woodworking trade. The joint may be used as an internal one, as shown at the lower rail, Fig. 176, or as an external joint, as the upper rail of the same illustration.

Whatever type of framing has to be made, it is necessary that the face side of the wood be planed up straight and out of winding, and the face mark (as shown in Fig. 176) pencilled upon it. The best edge of the timber should next be planed up true in length, and square to the face side, and the edge mark (X) clearly placed upon it.

The marking gauge is now set to the desired width, and gauge lines are marked on the wood, after which the waste wood is planed off until the timber is the required width. The thickness is gauged and treated in a similar manner, except in such cases where the finished work is to be of a rough and ready character.

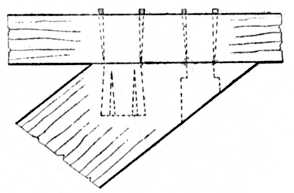

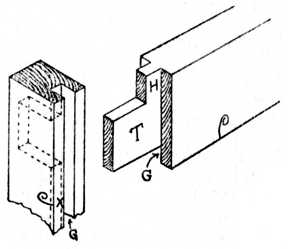

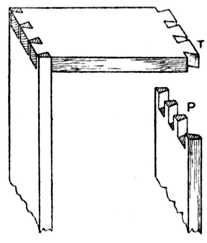

The Two Stiles (or uprights) have their faces turned to touch each other, as shown at Fig. 177, and their length may be anything from 1 in. to 3 ins. longer than[Pg 84] the required finished size. This waste wood at each end of the stiles (see arrow HO) is of importance to the work, as it prevents to a great extent the bursting of the mortise whilst cutting the hole or when knocking together[Pg 85] the work. The small projection is called the "horn," and it is cut off after the frame has been put together.

The two Cross Rails (Fig. 177), have their faces placed together as shown in the sketch. These rails may with advantage be left 1⁄2 in. longer than the finished size, and the portion of the tenon (which will protrude through the stile 1⁄4 in. at each end) may be cut off after the work is put together. (See Fig. 92.)

Set out the stiles with a marking knife or penknife and a try square, as shown at Fig. 178. In this sketch only one stile is shown for clearness of representation, but two or more stiles (as at Fig. 177) may be marked out at the same time, provided a 12-in. try square be used; in fact, marking out the stiles in pairs is to be recommended, as all cross lines will be exact owing to their being marked at the same operation. The cut made by the marking knife should be lightly carried all round the work as the mortising is cut from each edge of the stile, the cutting of the mortising being finished in the centre. The lettering on Fig. 177 is as follows:—HO, horn; M, position of mortise; H, position of haunching; A, inside line, or sight size, as it is occasionally called.

Set out the cross rails as at Fig. 177, lower sketch. The lettering in this figure is as follows:—T, tenons; the small piece of the tenon lettered J is called the haunch, and the shaded portion H is cut away to allow the haunch J to fit the haunching of the stile.

The Tenons (as already stated) are generally one-third the thickness of the timber, thus leaving the same amount of substance at each side of the tenon as the tenon itself is composed of. The mortise gauge is set to the required distance and used as in the case of the marking gauge (Fig. 82).[Pg 86]

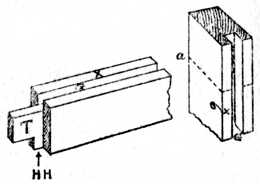

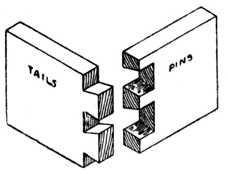

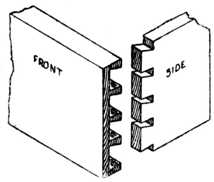

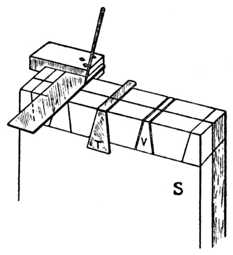

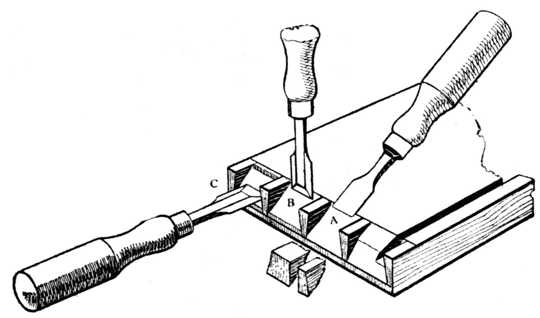

To saw the tenons, place the rail in the vice as at Fig. 179 and, with a panel, tenon, or hand saw, according to the size of the work, cut down the outside of the tenon line as shown. Reverse your position and cut as shown at Fig. 180, then place the rail in a vertical position, and you will find little or no difficulty in sawing down square with the shoulder line. Repeat the above methods of sawing until all the tenons are sawn.