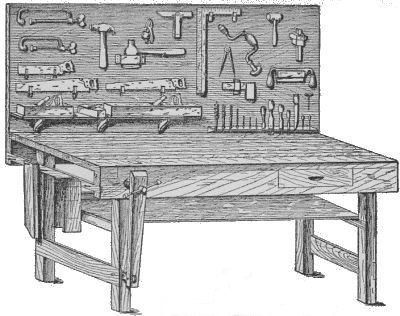

Fig. 1. A Typical Work Bench.

Fig. 1. A Typical Work Bench.

The Project Gutenberg EBook of Carpentry for Boys, by J. S. Zerbe

This eBook is for the use of anyone anywhere at no cost and with

almost no restrictions whatsoever. You may copy it, give it away or

re-use it under the terms of the Project Gutenberg License included

with this eBook or online at www.gutenberg.org

Title: Carpentry for Boys

In a Simple Language, Including Chapters on Drawing, Laying

Out Work, Designing and Architecture With 250 Original

Illustrations

Author: J. S. Zerbe

Release Date: March 7, 2007 [EBook #20763]

Language: English

Character set encoding: ISO-8859-1

*** START OF THIS PROJECT GUTENBERG EBOOK CARPENTRY FOR BOYS ***

Produced by Ross Wilburn, Curtis Weyant and the Online

Distributed Proofreading Team at http://www.pgdp.net

[Pg i]

| LIST OF ILLUSTRATIONS | |

| INTRODUCTORY | |

| I. Tools and Their Uses | Page 5 |

| |

| II. How to Grind and Sharpen Tools | Page 16 |

| |

| III. How to Hold and Handle Tools | Page 29 |

| |

| IV. How to Design Articles | Page 39 |

| |

| V. How work is Laid Out | Page 43 |

| |

| VI. The Uses of the Compass and the Square | Page 59 |

| |

| VII. How the Different Structural Parts are Designated | Page 65 |

| |

| VIII. Drawing and Its Utility | Page 73 |

| |

| IX. Moldings, with Practical Illustrations in Embellishing Work | Page 93 |

| |

| X. An Analysis of Tenoning, Mortising, Rabbeting and Beading | Page 104 |

| |

| XI. House Building | Page 113 |

| |

| XII. Bridges, Trussed Work and Like Structures | Page 130 |

| |

| XIII. The Best Woods for the Beginner | Page 134 |

| |

| XIV. Wood Turning | Page 138 |

| |

| XV. On the Use of Stains | Page 147 |

| |

| XVI. The Carpenter and the Architect | Page 152 |

| XVII. Useful Articles to Make | Page 155 |

| |

| XVIII. Special Tools and Their Uses | Page 170 |

| |

| XIX. Roofing Trusses | Page 185 |

| |

| XX. On the Construction of Joints | Page 197 |

| |

| XXI. Some Mistakes and a Little Advice in Carpentry | Page 205 |

| |

| GLOSSARY OF WORDS | |

| THE "HOW-TO-DO-IT" BOOKS |

| FIG. | |

| 1. A typical work bench[Pg vii] | Frontispiece |

| PAGE | |

| 2. Hatchet | 6 |

| 3. Hammer | 7 |

| 4. Common saw | 7 |

| 5. Plane | 8 |

| 6. Jack plane bit | 9 |

| 6a. Fore plane bit | 10 |

| 7a. Firmer chisel | 11 |

| Mortising chisel | 12 |

| 8. Trestle | 12 |

| 9. Miter box | 13 |

| 10. Incorrect saw setting | 17 |

| 10a. Correct saw setting | 17 |

| 11. Saw setting device | 17 |

| 12. Filing angle | 18 |

| 13. Rip saw | 19 |

| 14. Cross cut | 20 |

| 15. Filing clamp | 21 |

| 16. Grindstone | 23 |

| 17. Correct manner of holding tool | 24 |

| 18. Incorrect way of holding tool | 24 |

| 19. Gage | 26 |

| 20. Starting a saw | 31 |

| 21. Wrong sawing angle | 32 |

| 22. Correct sawing angle | 33 |

| 23. Thrust cut | 34 |

| 24. Chinese saw | 34 |

| 25. Moving angle for plane | 35 |

| 26. Holding gage | 36 |

| 27. Laying out table leg | 43 |

| 28. The first marking line | 44 |

| 29. Scribing mortise line | 44 |

| 30. The corner[Pg viii] mortises | 44 |

| 31. The side rail | 46 |

| 32. Scribing the tenons | 46 |

| 33. Cross scoring | 47 |

| 34. The tenon | 47 |

| 35. Finishing the tenon | 47 |

| 36. The tenon and mortise | 48 |

| 37. The drawer support | 48 |

| 38. Drawer cleats | 49 |

| 39. Assembled table frame | 50 |

| 40. The top | 51 |

| 41. The drawer | 52 |

| 42. Bevel joint | 53 |

| 43. Miter joint | 53 |

| 44. Picture frame joint | 54 |

| 45. Initial marks for dovetails | 55 |

| 46. End marks for dovetails | 55 |

| 47. Angles for dovetails | 55 |

| 48. Cutting out recesses for dovetails | 56 |

| 49. Tongues for dovetails | 56 |

| 50. Recess for dovetails | 56 |

| 51. Determining angles | 61 |

| 52. Marking degrees | 63 |

| 53. Angles from base lines | 63 |

| 54. Stepping off spaces | 63 |

| 55. Arcade | 67 |

| 56. Arch | 67 |

| 57. Buttress | 67 |

| 58. Chamfer | 67 |

| 59. Cooter | 67 |

| 60. Crenelated | 67 |

| 61. Crosses | 67 |

| 62. Curb roof | 67 |

| 63. Cupola | 67 |

| 64. Console | 67 |

| 65. Corbels | 67 |

| 66. Dormer | 67 |

| 67. Dowel | 67 |

| 68. Drips | 67 |

| 69. Detail[Pg ix] | 68 |

| 70. Extrados | 68 |

| 71. Engrailed | 68 |

| 72. Facet | 68 |

| 73. Fret | 68 |

| 74. Frontal | 68 |

| 75. Frustrums | 68 |

| 76. Fylfat | 68 |

| 77. Gambrel | 68 |

| 78. Gargoyle | 68 |

| 79. Gudgeon | 68 |

| 80. Guilloche | 68 |

| 81. Half timbered | 68 |

| 82. Hammer beam | 68 |

| 83. Haunches | 69 |

| 84. Header | 69 |

| 85. Hip roof | 69 |

| 86. Hood molding | 69 |

| 87. Inclave | 69 |

| 88. Interlacing arch | 69 |

| 89. Invected | 69 |

| 90. Inverted arch | 69 |

| 91. Keystone | 69 |

| 92. King post | 69 |

| 93. Label | 69 |

| 94. Louver | 69 |

| 95. Lintel | 70 |

| 96. Lug | 70 |

| 97. M-roof | 70 |

| 98. Mansard roof | 70 |

| 99. Newel post | 70 |

| 100. Parquetry | 70 |

| 101. Peen, or pein | 70 |

| 102. Pendant | 70 |

| 103. Pentastyle | 70 |

| 104. Pedestal | 70 |

| 105. Pintle | 70 |

| 106. Portico | 70 |

| 107. Plate | 70 [Pg x] |

| 108. Queen post | 71 |

| 109. Quirk molding | 71 |

| 110. Re-entering | 71 |

| 111. Rafter | 71 |

| 112. Scarfing | 71 |

| 113. Scotia molding | 71 |

| 114. Sill | 71 |

| 115. Skew back | 71 |

| 116. Spandrel | 71 |

| 117. Strut | 71 |

| 118. Stud, studding | 71 |

| 119. Stile | 72 |

| 120. Trammel | 72 |

| 121. Turret | 72 |

| 122. Transom | 72 |

| 123. Valley roof | 72 |

| 125. Plain line | 74 |

| 126. Concave shading | 74 |

| 127. Convex shading | 74 |

| 128. Wave shading | 75 |

| 129. Light past concave surface | 75 |

| 130. Light past convex surface | 75 |

| 131. Plain surface | 75 |

| 132. Outlines | 76 |

| 133. Raised surface | 77 |

| 134. Depressed surface | 77 |

| 135. Shading raised surfaces | 78 |

| 136. Shading depressed surfaces | 78 |

| 137. Plain cubical outline | 79 |

| 138. Indicating cube | 79 |

| 139. Confused lines | 79 |

| 140. Heavy horizontal lines | 80 |

| 141. Heavy vertical lines | 80 |

| 142. Isometric cube | 81 |

| 143. Cube and circle | 81 |

| 144. Flattened perspective | 82 |

| 145. Angles in isometric cube | 83 |

| 146. Plain circle | 84 |

| 147. Sphere shading | 84 [Pg xi] |

| 148. Drawing regular ellipse | 86 |

| 149. Drawing irregular ellipse | 88 |

| 150. Drawing spiral | 89 |

| 151. Abscissa | 90 |

| 152. Angle | 91 |

| 153. Apothegm | 91 |

| 154. Apsides, or apsis | 91 |

| 155. Chord | 91 |

| 156. Convolute | 91 |

| 157. Conic sections | 91 |

| 158. Conoid | 91 |

| 159. Cycloid | 91 |

| 160. Ellipsoid | 91 |

| 161. Epicycloid | 91 |

| 162. Evolute | 91 |

| 163. Focus | 91 |

| 164. Gnome | 91 |

| 165. Hyperbola | 91 |

| 167. Hypothenuse | 91 |

| 168. Incidence | 92 |

| 169. Isosceles triangle | 92 |

| 170. Parabola | 92 |

| 171. Parallelogram | 92 |

| 172. Pelecoid | 92 |

| 173. Polygons | 92 |

| 174. Pyramid | 92 |

| 175. Quadrant | 92 |

| 176. Quadrilaterale | 92 |

| 177. Rhomb | 92 |

| 178. Sector | 92 |

| 179. Segment | 92 |

| 180. Sinusoid | 92 |

| 181. Tangent | 92 |

| 182. Tetrahedron | 92 |

| 183. Vertex | 92 |

| 184. Volute | 92 |

| 185. Band (molding)e | 94 |

| 186. Astragal (molding) | 94 |

| 187. Cavetto (molding) | 94 [Pg xii] |

| 188. Ovolo (molding) | 94 |

| 189. Torus (molding) | 95 |

| 190. Apophyges (molding) | 95 |

| 191. Cymatium (molding) | 95 |

| 192. Ogee-recta (molding) | 95 |

| 193. Ogee-reversa (molding) | 96 |

| 194. Bead (molding) | 96 |

| 195. Casement (molding) | 97 |

| 196. The Doric column | 98 |

| 197. Front of cabinet | 100 |

| 198. Facia board | 100 |

| 199. Molding on facia board | 100 |

| 200. Ogee-recta on facia | 101 |

| 201. Trim below facia | 101 |

| 202. Trim below ogee | 101 |

| 203. Trim above base | 102 |

| 204. Trim above base molding | 102 |

| 205. Shadows cast by plain moldings | 103 |

| 206. Mortise and tenon joint | 105 |

| 207. Incorrect mortising | 105 |

| 208. Steps in mortising | 106 |

| 209. The shoulders of tenons | 108 |

| 210. Lap-and-butt joint | 108 |

| 211. Panel joint | 109 |

| 212. Scarfing | 109 |

| 213. Tongue and groove | 110 |

| 214. Beading | 110 |

| 215. Outside beading finish | 110 |

| 216. Edge beading | 111 |

| 217. Corner beading | 111 |

| 218. Point beading | 111 |

| 219. Round edge beading | 111 |

| 220. Beading and molding | 111 |

| 221. First square house plan | 117 |

| 222. First rectangular house plan | 118 |

| 223. Square house to scale | 119 |

| 224. Rectangular house to scale | 120 |

| 225. Front elevation of square house | 121 |

| 226. Elevation of rectangular house | 121 [Pg xiii] |

| 227. Illustrating one-third pitch | 122 |

| 228. Illustrating half pitch | 122 |

| 229. The sills at the corner | 123 |

| 230. The joist and sills | 123 |

| 231. The plate splice | 124 |

| 232. The rafters | 124 |

| 233. The gutter | 126 |

| 234. The cornice | 127 |

| 234a. The finish without gutter | 128 |

| 235. Common truss | 130 |

| 236. Upright truss | 131 |

| 237. Vertical upright truss | 131 |

| 238. Warren girder | 132 |

| 239. Extended Warren girder | 132 |

| 240. Bowstring girder | 132 |

| 241. Frame details of wood turning lathe | 139 |

| 242. Tail stock details | 133 |

| 243. Tool rest details | 142 |

| 244. Section of mandrel | 143 |

| 245. View of turning lathe | 145 |

| 246. Turning tools | 146 |

| 247. Bench | 155 |

| 248. Stool | 156 |

| 249. Blacking box | 156 |

| 250. Easel | 157 |

| 251. Hanging book rack | 158 |

| 252. Book shelf | 159 |

| 253. Wood box | 160 |

| 254. Horizontal bars | 161 |

| 255. Mission desk | 161 |

| 256. Screen frame | 162 |

| 257. Mission chair | 162 |

| 258. Grandfather's clock | 163 |

| 259. Frame for bookcase | 164 |

| 260. Coal scuttle case | 165 |

| 261. Mission arm chair | 165 |

| 262. Dog house | 166 |

| 263. Settle | 167 |

| 264. Towel rack | 168 [Pg xiv] |

| 265. Mission sofa frame | 168 |

| 266. Bit and square level | 170 |

| 267. Metal miter box | 171 |

| 268. Parts of metal miter box | 172 |

| 269. Angle dividers | 173 |

| 270. An "odd job" tool | 174 |

| 271. Universal-jaw brace | 176 |

| 272. Taper-shank bit brace | 176 |

| 273. Alligator-jaw brace | 176 |

| 274. Steel frame breast drill | 177 |

| 275. Steel frame breast drill | 177 |

| 276. Steel frame breast drill | 177 |

| 277. Details of metal plane | 179 |

| 278. Rabbet, matching and dado plane | 180 |

| 279. Molding and beading plane | 181 |

| 280. Dovetail tongue and groove plane | 182 |

| 281. Router planes | 183 |

| 282. Router planes | 183 |

| 283. Door trim plane | 184 |

| 284. Gambrel roof | 187 |

| 285. Purlin roof | 188 |

| 286. Princess truss | 189 |

| 287. Arched, or cambered, tie beam | 190 |

| 288. The mansard | 191 |

| 289. Scissors beam | 192 |

| 290. Braced collar beam | 193 |

| 291. Rib and collar truss | 194 |

| 291½. Hammer-beam truss | 195 |

| 292. Bridle joints | 197 |

| 293. Spur tenons | 198 |

| 294. Saddle joints | 198 |

| 295. Joggle joints | 199 |

| 296. Framing joints | 199 |

| 297. Heel joints | 200 |

| 298. Stub tenon | 200 |

| 299. Tusk tenon | 201 |

| 300. Double tusk tenon | 202 |

| 301. Cogged joints | 203 |

| 302. Anchor joint | 203 |

| 303. Deep anchor joint | 204 |

[Pg 1]

Carpentry is the oldest of the arts, and it has been said that the knowledge necessary to make a good carpenter fits one for almost any trade or occupation requiring the use of tools. The hatchet, the saw, and the plane are the three primal implements of the carpenter. The value is in knowing how to use them.

The institution of Manual Training Schools everywhere is but a tardy recognition of the value of systematic training in the use of tools. There is no branch of industry which needs such diversification, in order to become efficient.

The skill of the blacksmith is centered in his ability to forge, to weld, and to temper; that of the machinist depends upon the callipered dimensions of his product; the painter in his taste for harmony; the mason on his ability to cut the stone accurately; and the plasterer to produce a uniform surface. But the carpenter must, in order to be an expert, combine all these qualifications, [Pg 2] in a greater or less degree, and his vocation may justly be called the King of Trades. Rightly, therefore, it should be cultivated in order to learn the essentials of manual training work.

But there is another feature of the utmost importance and value, which is generally overlooked, and on which there is placed too little stress, even in many of the manual training schools. The training of the mind has been systematized so as to bring into operation the energies of all the brain cells. Manual training to be efficient should, at the same time, be directed into such channels as will most widely stimulate the muscular development of the child, while at the same time cultivating his mind.

There is no trade which offers such a useful field as carpentry. It may be said that the various manual operations bring into play every muscle of the body.

The saw, the plane, the hammer, the chisel, each requires its special muscular energy. The carpenter, unlike the blacksmith, does not put all his brawn into his shoulders, nor develop his torso at the expense of his other muscles, like the mason. It may also be said that, unlike most other occupations, the carpenter has both out-of-door and indoor exercise, so that he is at all times able to follow his occupation, summer or [Pg 3] winter, rain or shine; and this also further illustrates the value of this branch of endeavor as a healthful recreation.

It is the aim of this book to teach boys the primary requirements—not to generalize—but to show how to prepare and how to do the work; what tools and materials to use; and in what manner the tools used may be made most serviceable, and used most advantageously.

It would be of no value to describe and illustrate how a bracket is made; or how the framework of a structure is provided with mortises and tenons in order to hold it together. The boy must have something as a base which will enable him to design his own creations, and not be an imitator; his mind must develop with his body. It is the principal aim of this book to give the boy something to think about while he is learning how to bring each individual part to perfection.

If the boy understands that there is a principle underlying each structural device; that there is a reason for making certain things a definite way, he is imbued with an incentive which will sooner or later develop into an initiative of his own.

It is this phase in the artisan's life which determines whether he will be merely a machine or an intelligent organism.

This work puts together in a simple, concise [Pg 4] form, not only the fundamentals which every mechanic should learn to know, but it defines every structural form used in this art, and illustrates all terms it is necessary to use in the employment of carpentry. A full chapter is devoted to drawings practically applied. All terms are diagrammed and defined, so that the mind may readily grasp the ideas involved.

Finally, it will be observed that every illustration has been specially drawn for this book. We have not adopted the plan usually followed in books of this class, of taking stock illustrations of manufacturers' tools and devices, nor have we thought it advisable to take a picture of a tool or a machine and then write a description around it. We have illustrated the book to explain "how to do the work"; also, to teach the boy what the trade requires, and to give him the means whereby he may readily find the form of every device, tool, and structure used in the art.

[Pg 5]

Knowledge of Tools.—A knowledge of tools and their uses is the first and most important requirement. The saw, the plane, the hatchet and the hammer are well known to all boys; but how to use them, and where to use the different varieties of each kind of tool, must be learned, because each tool grew out of some particular requirement in the art. These uses will now be explained.

A Full Kit of Tools.—A kit of tools necessary for doing any plain work should embrace the following:

1. A Hatchet.

2. A Claw Hammer—two sizes preferred.

3. Cross-cut Saw, 20 inches long.

4. Rip Saw, 24 inches long.

5. Wooden Mallet.

6. Jack Plane.

7. Smoothing Plane.

8. Compass Saw.

9. Brace.

10. Bits for Brace, ranging from ¼ inch to 1 inch diameter.

11. Several small Gimlets.

12. Square.

13. Compass.

14. Draw-knife.

15. Rule.

16. Two Gages.

17. Set of Firmer Chisels.

18. Two Mortising Chisels.

19. Small Back Saw.

20. Saw Clamps.

21. Miter Box.

22. Bevel Square.

23. Small Hand Square.

24. Pliers.

25. Pair of Awls.

26. Hand Clamps.

27. Set Files.

28. Glue Pot.

29. Oil Stone.

30. Grindstone.

31. Trusses.

32. Work Bench.

33. Plumb Bob.

34. Spirit Level.

[Pg 6]

The Hatchet.—The hatchet should be ground with a bevel on each side, and not on one side only, as is customary with a plasterer's lathing hatchet, because the blade of the hatchet is used for trimming off the edges of boards. Unless ground off with a bevel on both sides it cannot be controlled to cut accurately. A light hatchet is preferable to a heavy one. It should never be used for nailing purposes, except in emergencies. The pole of the hammer—that part which is generally used to strike the nail with—is required in order to properly balance the hatchet when used for trimming material.

The Claw Hammer.—This is the proper tool for driving nails and for drawing them out. Habits should be formed with the beginner, which will be of great service as the education proceeds. [Pg 7] One of these habits is to persist in using the tool for the purpose for which it was made. The expert workman (and he becomes expert because of it) makes the hammer do its proper work; and so with every other tool.

About Saws.—There are four well-defined kinds. First, a long, flat saw, for cross-cutting. Second, a slightly larger saw for ripping purposes. Third, a back saw, with a rib on the rear edge to hold the blade rigid, used for making tenons; and, fourth, a compass or keyhole saw.

>[Pg 8]

Cross-cuts.—The difference between a cross-cut and a rip saw is, that in the latter the teeth have less pitch and are usually larger than in the cross-cut saw. The illustrations (Figs. 13 and 14) will distinctly show the difference in the teeth. When a cross-cut saw is used for ripping along the grain of the wood, the teeth, if disposed at an angle, will ride over the grain or fiber of the wood, and refuse to take hold or bite into the wood. On the other hand, if the rip saw is used for cross-cutting purposes, the saw kerf will be rough and jagged.

The back saw is used almost exclusively for making tenons, and has uniformly fine teeth so as to give a smooth finish to the wood.

Planes.—The plane may be called the æsthetic tool in the carpenter's kit. It is the most difficult tool to handle and the most satisfactory when thoroughly mastered. How to care for and [Pg 9] handle it will be referred to in a subsequent chapter. We are now concerned with its uses only. Each complete kit must have three distinct planes, namely, the jack plane, which is for taking off the rough saw print surface of the board. The short smoothing plane, which is designed to even up the inequalities made by the jack plane; and the long finishing plane, or fore plane, which is intended to straighten the edges of boards or of finished surfaces.

The Jack Plane.—This plane has the cutting edge of its blade ground so it is slightly curved (Fig. 6), because, as the bit must be driven out so it will take a deep bite into the rough surface of the wood, the curved cutting edge prevents the corner edges of the bit from digging into the planed surface.

On the other hand, the bits of the smoothing and finishing planes are ground straight across their cutting edges. In the foregoing we have not enumerated the different special planes, designed [Pg 10] to make beads, rabbets, tongues and grooves, but each type is fully illustrated, so that an idea may be obtained of their characteristics. (Fig. 6a).

Gages.—One of the most valuable tools in the whole set is the gage, but it is, in fact, the least known. This is simply a straight bar, with a sharpened point projecting out on one side near its end, and having an adjustable sliding head or cheekpiece. This tool is indispensable in making mortises or tenons, because the sharpened steel point which projects from the side of the bar, serves to outline and define the edges of the mortises or tenons, so that the cutting line may readily be followed.

This is the most difficult tool to hold when in use, but that will be fully explained under its proper head. Each kit should have two, as in making mortises and tenons one gage is required for each side of the mortise or tenon.

Chisels.—Two kinds are found in every kit—one [Pg 11] called the firmer (Fig. 7) and the mortising chisel. The firmer has a flat body or blade, and a full set ranges in width from three-eighths of an inch to two inches. The sizes most desirable and useful are the one-half inch, the inch and the inch-and-a-half widths. These are used for trimming out cross grains or rebates for setting door locks and hinges and for numerous other uses where sharp-end tools are required.

The Mortising Chisel.—The mortising chisel (Fig. 7a), on the other hand, is very narrow and thick, with a long taper down to the cutting edge. They are usually in such widths as to make them stock sizes for mortises. Never, under any circumstances, use a hammer or hatchet for driving chisels. The mallet should be used invariably.

Trusses.—There should be at least two, each three feet in length and twenty inches in height.

Saw Clamps.—These are necessary adjuncts, and should be made of hard wood, perfectly [Pg 12] straight and just wide enough to take in the narrow back saw. The illustration shows their shape and form.

The Grindstones.—It is better to get a first-class stone, which may be small and rigged up with a foot treadle. A soft, fine-grained stone is most serviceable, and it should have a water tray, and never be used excepting with plenty of water.

An Oil Stone is as essential as a grindstone. For giving a good edge to tools it is superior to a water stone. It should be provided with a top, and covered when not in use, to keep out dust [Pg 13] and grit. These are the little things that contribute to success and should be carefully observed.

The Miter Box.—This should be 14 inches long and 3" by 3" inside, made of hard wood ¾" thick. The sides should be nailed to the bottom, as shown.

The Work Bench.—In its proper place we show in detail the most approved form of work bench, fitted with a tool rack to hold all the tools, conveniently arranged. In this chapter we are more particularly concerned with the uses of tools than their construction; and we impress on boys the necessity of having a place for everything, and that every tool should be kept in its proper place. A carpenter's shop filled with chips, shavings and other refuse is not a desirable place for the indiscriminate placing of tools. If correct habits are formed at the outset, by carefully putting each tool in its place after using, it will save many an hour of useless hunting and annoyance.

One of the most important things in laying off [Pg 14] work, for instance, on trusses, is the disposition of the saw and square. Our illustration shows each truss with side cleats, which will permit the user temporarily to deposit the saw or the square so that it will be handy, and at the same time be out of the way of the work and prevent either of the tools from being thrown to the floor.

In the same way, and for the same purpose, the work bench has temporary holding cleats at the end and a shelf in front, which are particularly desirable, because either a saw or a square is an encumbrance on a work bench while the work is being assembled, and tools of this kind should not be laid flat on a working surface, nor should they be stood in a leaning position against a truss or work bench.

Strictly observe these fundamentals—Never place a tool with the cutting edge toward you. Always have the racks or receptacles so made that the handle may be seized. Don't put a tool with an exposed cutting edge above or below another tool in such a manner that the hand or the tool you are handling can come into contact with the edge. Never keep the nail or screw boxes above the work bench. They should always be kept to one side, to prevent, as much as possible, the bench from becoming a depository for nails. Keep the top of the bench free from tools. Always [Pg 15] keep the planes on a narrow sub-shelf at the rear of the bench.

If order was Heaven's first law, it is a good principle to apply it in a workman's shop, and its observance will form a habit that will soon become a pleasure to follow.

[Pg 16]

Care of Tools.—Dull tools indicate the character of the workman. In an experience of over forty years, I have never known a good workman to keep poorly sharpened tools. While it is true that the capacity to sharpen tools can be acquired only by practice, correct habits at the start will materially assist. In doing this part of the artisan's work, it should be understood that there is a right as well as a wrong way.

There is a principle involved in the sharpening of every tool, which should be observed. A skilled artisan knows that there is a particular way to grind the bits of each plane; that the manner of setting a saw not only contributes to its usefulness, but will materially add to the life of the saw; that a chisel cannot be made to do good work unless its cutting edge is square and at the right working angle.

First Requisite.—A beginner should never attempt a piece of work until he learns how the different tools should be sharpened, or at least learn the principle involved. Practice will make perfect.

[Pg 17] Saws.—As the saw is such an important part of the kit, I shall devote some space to the subject. First, as to setting the saw. The object of this is to make the teeth cut a wider kerf than the thickness of the blade, and thereby cause the saw to travel freely. A great many so-called "saw sets" are found in the market, many of them built on wrong principles, as will be shown, and these are incapable of setting accurately.

How to Set.—To set a saw accurately, that is, to drive out each tooth the same distance, is the first requirement, and the second is to bend out the whole tooth, and not the point only.

In the illustration (Fig. 10), the point is merely bent out. This is wrong. The right way is shown [Pg 18] in Fig. 10a. The whole tooth is bent, showing the correct way of setting. The reasons for avoiding one way and following the other are: First, that if the point projects to one side, each point or tooth will dig into the wood, and produce tooth prints in the wood, which make a roughened surface. Second, that if there are inequalities in setting the teeth (as is sure to be the case when only the points are bent out), the most exposed points will first wear out, and thereby cause saw deterioration. Third, a saw with the points sticking out causes a heavy, dragging cut, and means additional labor. Where the whole body of the tooth is bent, the saw will run smoothly and easily through the kerf and produce a smooth-cut surface.

Our illustration (Fig. 11) shows a very simple setting block, the principal merit of which is that any boy can make it, and in the use of which he cannot go wrong in setting a tooth.

Simple Saw Setter.—Take a block of wood, a 4 by 4 inch studding, four inches long. Get a [Pg 19] piece of metal one-half inch thick and two inches square. Have a blacksmith or machinist bore a quarter-inch hole through it in the center and countersink the upper side so it may be securely fastened in a mortise in the block, with its upper side flush with the upper surface of the block. Now, with a file, finish off one edge, going back for a quarter of an inch, the angle at A to be about 12 degrees.

Filing Angles.—In its proper place will be shown how you may easily calculate and measure degrees in work of this kind. Fig. 12 shows an approximation to the right angle. B, B (Fig. 11) should be a pair of wooden pegs, driven into the wooden block on each side of the metal piece. The teeth of the saw rest against the pegs so that they serve as a guide or a gage, and the teeth of the saw, therefore, project over the inclined part (B) of the metal block. Now, with [Pg 20] an ordinary punch and a hammer, each alternate tooth may be driven down until it rests flat on the inclined face (A), so that it is impossible to set the teeth wrongly. When you glance down the end of a properly set saw, you will see a V-shaped channel, and if you will place a needle in the groove and hold the saw at an angle, the needle will travel down without falling out.

Filing.—The next step is the filing. Two things must be observed: the pitch and the angle. By pitch is meant the inclination of the teeth. Note the illustration (Fig. 13), which shows the teeth of a rip saw. You will see at A that the pitch of the tooth is at right angles to the edge of the saw. In Fig. 14, which shows the teeth of a cross-cut saw, the pitch (B) is about 10 degrees off. The teeth of the rip saw are also larger than those of the cross-cut.

The Angle of Filing.—By angle is meant the cutting position of the file. In Fig. 12, the lines [Pg 21] B represent the file disposed at an angle of 12 degrees, not more, for a rip saw. For a cross-cut the angle of the file may be less.

Saw Clamps.—You may easily make a pair of saw clamps as follows:

Take two pieces of hard wood, each three inches wide, seven-eighths of an inch thick, and equal in length to the longest saw. Bevel one edge of each as shown in A (Fig. 15), so as to leave an edge (B) about one-eighth of an inch thick. At one end cut away the corner on the side opposite the bevel, as shown at C, so the clamps will fit on the saw around the saw handle.

When the saw is placed between these clamps and held together by the jaws of the vise, you are ready for the filing operation. Observe the following filing suggestions: Always hold the file horizontal or level. In filing, use the whole length of the file. Do the work by a slow, firm sweep.

Do not file all of the teeth along the saw at one operation, but only the alternate teeth, so as to [Pg 22] keep the file at the same angle, and thus insure accuracy; then turn the saw and keep the file constantly at one angle for the alternate set of teeth.

Give the same number of strokes, and exert the same pressure on the file for each tooth, to insure uniformity. Learn also to make a free, easy and straight movement back and forth with the file.

The File.—In order to experiment with the filing motion, take two blocks of wood, and try surfacing them off with a file. When you place the two filed surfaces together after the first trial both will be convex, because the hands, in filing, unless you exert the utmost vigilance, will assume a crank-like movement. The filing test is so to file the two blocks that they will fit tightly together without rolling on each other. Before shaping and planing machines were invented, machinists were compelled to plane down and accurately finish off surfaces with a file.

In using the files on saws, however small the file may be, one hand should hold the handle and the other hand the tip of the file.

A file brush should always be kept on hand, as it pays to preserve files by cleaning them.

The Grindstone.—As most of the tools require a grindstone for sharpening purposes, an illustration is given as a guide, with a diagram to show the proper grinding angle. In Fig. 16 the upright [Pg 23] (A) of the frame serves as a line for the eye, so that if the point of the tool is brought to the sight line, and the tool (C) held level, you will always be able to maintain the correct angle. There is no objection to providing a rest, for instance, like the cross bars (D, D), but the artisan disdains such contrivances, and he usually avoids them for two reasons: First, because habit enables him to hold the tool horizontally; and, second, by holding the tool firmly in the hand he has better control of it. There is only one thing which can be said in favor of a rest, and [Pg 24] that is, the stone may be kept truer circumferentially, as all stones have soft spots or sides.

In the Use of Grindstones.—There are certain things to avoid and to observe in the use of stones. Never use one spot on the stone, however narrow the tool may be. Always move the tool from side to side. Never grind a set of narrow tools successively. If you have chisels to grind intersperse their grinding with plane bits, hatchet or other broad cutting tools, so as to prevent the stone from having grooves therein. Never use a tool on a stone unless you have water in the tray.

Correct Way to Hold Tool for Grinding.—There is a correct way to hold each tool; see illustration (Fig. 17). The left hand should grasp the tool firmly, near the sharp edge, as shown, and the right hand should loosely hold the tool behind [Pg 25] the left hand. There is a reason for this which will be apparent after you grind a few tools. The firm grasp of the left hand gives you absolute control of the blade, so it cannot turn, and when inequalities appear in the grindstone, the rigid hold will prevent the blade from turning, and thus enable you to correct the inequalities of the stone. Bear in mind, the stone should be taken care of just as much as the tools. An experienced workman is known by the condition of his tools, and the grindstone is the best friend he has among his tools.

Incorrect Way to Hold Tool for Grinding.—The incorrect way of holding a tool is shown in Fig. 18. This, I presume, is the universal way in which the novice takes the tool. It is wrong for the reason that the thumbs of both hands are on top of the blade, and they serve as pivots on which the tool may turn. The result is that the corners of the tool will dig into the stone to a greater or less degree, particularly if it has a narrow blade, like a chisel.

Try the experiment of grinding a quarter-inch chisel by holding it the incorrect way; and then grasp it firmly with the left hand, and you will at once see the difference.

The left hand serves both as a vise and as a [Pg 26] fulcrum, whereas the right hand controls the angle of the tool.

These remarks apply to all chisels, plane bits and tools of that character, but it is obvious that a drawknife, which is always held by the handles in grinding, and hatchets, axes and the like, cannot be held in the same manner.

A too common error is to press the tool too hard on the stone. This is wrong. Do not try to force the grinding.

Then, again, it is the practice of some to turn the stone away from the tool. The stone should always move toward the tool, so as to prevent forming a feather edge.

[Pg 27] The Plane.—Indiscriminate use of planes should be avoided. Never use the fore or smoothing planes on rough surfaces. The jack plane is the proper tool for this work. On the other hand, the fore plane should invariably be used for straightening the edges of boards, or for fine surfacing purposes. As the jack plane has its bit ground with a curved edge, it is admirably adapted for taking off the rough saw print surface.

The Gage.—The illustration (Fig. 19) shows one of the most useful tools in the kit. It is used to scribe the thickness of the material which is to be dressed down, or for imprinting the edges of tenons and mortises. Two should be provided in every kit, for convenience.

The scribing point should be sharpened with a file, the point being filed to form a blade, which is at right angles to the bar, or parallel with the movable cheekpiece.

Chisels.—I have already pointed out, in general, how to hold tools for grinding purposes, this description applying particularly to chisels, but several additional things may be added.

Always be careful to grind the chisel so its cutting edge is square with the side edge. This will be difficult at first, but you will see the value of this as you use the tool. For instance, in making [Pg 28] rebates for hinges, or recesses and mortises for locks, the tool will invariably run crooked, unless it is ground square.

The chisel should never be struck with a hammer or metal instrument, as the metal pole or peon of the hammer will sliver the handle. The wooden mallet should invariably be used.

General Observations.—If the workman will carefully observe the foregoing requirements he will have taken the most important steps in the knowledge of the art. If he permits himself to commence work without having his tools in first-class condition, he is trying to do work under circumstances where even a skilled workman is liable to fail.

Avoid making for yourself a lot of unnecessary work. The best artisans are those who try to find out and know which is the best tool, or how to make a tool for each requirement, but that tool, to be serviceable, must be properly made, and that means it must be rightly sharpened.

[Pg 29]

Observation may form part of each boy's lesson, but when it comes to the handling of tools, practice becomes the only available means of making a workman. Fifty years of observation would never make an observer an archer or a marksman, nor would it enable him to shoe a horse or to build a table.

It sometimes happens that an apprentice will, with little observation, seize a saw in the proper way, or hold a plane in the correct manner, and, in time, the watchful boy will acquire fairly correct habits. But why put in useless time and labor in order to gain that which a few well-directed hints and examples will convey?

Tools are made and are used as short cuts toward a desired end. Before the saw was invented the knife was used laboriously to sever and shape the materials. Before planes were invented a broad, flat sharpened blade was used to smooth off surfaces. Holes were dug out by means of small chisels requiring infinite patience and time. Each succeeding tool proclaimed a shorter and an easier way to do a certain thing. [Pg 30] The man or boy who can make a new labor-saving tool is worthy of as much praise as the man who makes two blades of grass grow where one grew before.

Let us now thoroughly understand how to hold and use each tool. That is half the value of the tool itself.

The Saw.—With such a commonplace article as the saw, it might be assumed that the ordinary apprentice would look upon instruction with a smile of derision.

How to Start a Saw.—If the untried apprentice has such an opinion set him to work at the task of cutting off a board accurately on a line. He will generally make a failure of the attempt to start the saw true to the line, to say nothing of following the line so the kerf is true and square with the board.

How to Start on a Line.—The first mistake he makes is to saw on the line. This should never be done. The work should be so laid out that the saw kerf is on the discarded side of the material. The saw should cut alongside the line, and the line should not be obliterated in the cutting. Material must be left for trimming and finishing.

The First Stroke.—Now, to hold the saw in starting is the difficult task to the beginner. Once mastered it is simple and easy. The only time in [Pg 31] which the saw should be firmly held by the hand is during the initial cut or two; afterwards always hold the handle loosely. There is nothing so tiring as a tightly grasped saw. The saw has but one handle, hence it is designed to be used with one hand. Sometimes, with long and tiresome jobs, in ripping, two hands may be used, but one hand can always control a saw better than two hands.

The Starting Cut.—In order to make our understanding of the starting cut more explicit, we refer to Fig. 20, in which the thumb of the left hand is shown in the position of a guide—the end of the thumb being held up a sufficient distance to [Pg 32] clear the teeth. In this position you need not fear that the teeth of the saw (A) will ride up over the thumb if you have a firm grasp of the saw handle.

The first stroke should be upwardly, not downwardly. While in the act of drawing up the saw you can judge whether the saw blade is held by the thumb gage in the proper position to cut along the mark, and when the saw moves downwardly for the first cut, you may be assured that the cut is accurate, or at the right place, and the thumb should be kept in its position until two or three cuts are made, and the work is then fairly started.

For Cross-cutting.—For ordinary cross-cutting the angle of the saw should be at 45 degrees. For ripping, the best results are found at less than 45 degrees, but you should avoid flattening down the angle. An incorrect as well as a correct angle are shown in Figs. 21 and 22.

Forcing a Saw.—Forcing a saw through the wood means a crooked kerf. The more nearly the saw is held at right angles to a board, the greater [Pg 33] is the force which must be applied to it by the hand to cause it to bite into the wood; and, on the other hand, if the saw is laid down too far, as shown in the incorrect way, it is a very difficult matter to follow the working line. Furthermore, it is a hard matter to control the saw so that it will cut squarely along the board, particularly when ripping. The eye must be the only guide in the disposition of the saw. Some boys make the saw run in one direction, and others cause it to lean the opposite way. After you have had some experience and know which way you lean, correct your habits by disposing the saw in the opposite direction.

The Stroke.—Make a long stroke, using the full blade of the saw. Don't acquire the "jerky" style of sawing. If the handle is held loosely, and the saw is at the proper angle, the weight of the saw, together with the placement of the handle on the saw blade, will be found sufficient to make the requisite cut at each stroke.

[Pg 34] You will notice that the handle of every saw is mounted nearest the back edge. (See Fig. 23.) The reason for so mounting it is, that as the cutting stroke is downward, the line of thrust is above the tooth line, and as this line is at an angle to the line of thrust, the tendency is to cause the saw teeth to dig into the wood.

The Chinese Saw.—This saw is designed to saw with an upward cut, and the illustration (Fig. 24) shows the handle jutting out below the tooth line, in order to cause the teeth to dig into the material as the handle is drawn upwardly. Reference is made to these features to impress upon beginners the value of observation, and to demonstrate the reason for making each tool a particular way.

[Pg 35] Things to Avoid.—Do not oscillate the saw as you draw it back and forth. This is unnecessary work, and shows impatience in the use of the tool. There is such an infinite variety of use for the different tools that there is no necessity for rendering the work of any particular tool, or tools, burdensome. Each in its proper place, handled intelligently, will become a pleasure, as well as a source of profit.

The Plane.—The jack plane and the fore plane are handled with both hands, and the smoothing plane with one hand, but only when used for dressing the ends of boards. For other uses both hands are required.

Angles for Holding Planes.—Before commencing to plane a board, always observe the direction in which the grain of the wood runs. This precaution will save many a piece of material, because if the jack plane is set deep it will run into the wood and cause a rough surface, which can [Pg 36] be cured only by an extra amount of labor in planing down.

Never move the jack plane or the smoothing plane over the work so that the body of the tool is in a direct line with the movement of the plane. It should be held at an angle of about 12 or 15 degrees (see Fig. 25). The fore plane should always be held straight with the movement of the plane, because the length of the fore plane body is used as a straightener for the surface to be finished.

Errors to Be Avoided.—Never draw back the plane with the bit resting on the board. This [Pg 37] simply wears out the tool, and if there should be any grit on the board it will be sure to ruin the bit. This applies particularly to the jack plane, but is bad practice with the others as well.

A work bench is a receptacle for all kinds of dirt. Provide a special ledge or shelf for the planes, and be sure to put each plane there immediately after using.

The Gage.—A man, who professed to be a carpenter, once told me that he never used a gage because he could not make it run straight. A few moments' practice convinced him that he never knew how to hold it. The illustration shows how properly to hold it, and the reason why it should so be held follows.

You will observe (Fig. 26) that the hand grasps the stem of the gage behind the cheekpiece, so that the thumb is free to press against the side of the stem to the front of the cheekpiece.

Holding the Gage.—The hand serves to keep the cheekpiece against the board, while the thumb pushes the gage forward. The hand must not, under any circumstances, be used to move the gage along. In fact, it is not necessary for the fingers to be clasped around the gage stem, if the forefinger presses tightly against the cheekpiece, since the thumb performs all the operation of moving it along. Naturally, the hand grasps the tool in [Pg 38] order to hold it down against the material, and to bring it back for a new cut.

The Draw-knife.—It is difficult for the apprentice to become accustomed to handle this useful tool. It is much more serviceable than a hatchet for trimming and paring work. In applying it to the wood always have the tool at an angle with the board, so as to make a slicing cut. This is specially desirable in working close to a line, otherwise there is a liability of cutting over it.

This knife requires a firm grasp—firmness of hold is more important than strength in using. The flat side is used wholly for straight edges, and the beveled side for concave surfaces. It is the intermediate tool between the hatchet and the plane, as it has the characteristics of both those tools. It is an ugly, dangerous tool, more to be feared when lying around than when in use. Put it religiously on a rack which protects the entire cutting edge. Keep it off the bench.

[Pg 39]

Fundamentals of Designing.—A great deal of the pleasure in making articles consists in creative work. This means, not that you shall design some entirely new article, but that its general form, or arrangement of parts, shall have some new or striking feature.

A new design in any art does not require a change in all its parts. It is sufficient that there shall be an improvement, either in some particular point, as a matter of utility, or some change in an artistic direction. A manufacturer in putting out a new chair, or a plow, or an automobile, adds some striking characteristic. This becomes his talking point in selling the article.

The Commercial Instinct.—It is not enough that the boy should learn to make things correctly, and as a matter of pastime and pleasure. The commercial instinct is, after all, the great incentive, and should be given due consideration.

It would be impossible, in a book of this kind, to do more than to give the fundamental principles necessary in designing, and to direct the mind [Pg 40] solely to essentials, leaving the individual to build tip for himself.

First Requirements for Designing.—First, then, let us see what is necessary to do when you intend to set about making an article. Suppose we fix our minds upon a table as the article selected. Three things are necessary to know: First, the use to which it is to be put; second, the dimensions; and, third, the material required.

Assuming it to be the ordinary table, and the dimensions fixed, we may conclude to use soft pine, birch or poplar, because of ease in working. There are no regulation dimensions for tables, except as to height, which is generally uniform, and usually 30 inches. As to the length and width, you will be governed by the place where it is to be used.

If the table top is to have dimensions, say, of 36" × 48", you may lay out the framework six inches less each way, thus giving you a top overhang of three inches, which is the usual practice.

Conventional Styles.—Now, if you wish to depart from the conventional style of making a table you may make variations in the design. For instance, the Chippendale style means slender legs and thin top. It involves some fanciful designs in the curved outlines of the top, and in the crook [Pg 41] of the legs. Or if, on the other hand, the Mission type is preferred, the overhang of the top is very narrow; the legs are straight and heavy, and of even size from top to bottom; and the table top is thick and nearly as broad as it is long. Such furniture has the appearance of massiveness; it is easily made and most serviceable.

Mission Style.—The Mission style of architecture also lends itself to the making of chairs and other articles of furniture. A chair is, probably, the most difficult piece of household furniture to make, because strength is required. In this type soft wood may be used, as the large legs and back pieces are easily provided with mortises and tenons, affording great rigidity when completed. In designing, therefore, you may see how the material itself becomes an important factor.

Cabinets.—In the making of cabinets, sideboards, dressers and like articles, the ingenious boy will find a wonderful field for designing ability, because in these articles fancy alone dictates the sizes and the dimensions of the parts. Not so with chairs and tables. The imagination plays an important part even in the making of drawers, to say nothing of placing them with an eye to convenience and artistic effect.

Harmony of Parts.—But one thing should be observed in the making of furniture, namely, harmony [Pg 42] between the parts. For instance, a table with thin legs and a thick top gives the appearance of a top-heavy structure; or the wrong use of two different styles is bad from an artistic standpoint; moreover, it is the height of refined education if, in the use of contrasting woods, they are properly blended to form a harmonious whole.

Harmonizing Wood.—Imagine a chiffonier with the base of dark wood, like walnut, and the top of pine or maple, or a like light-colored wood. On the other hand, both walnut and maple, for instance, may be used in the same article, if they are interspersed throughout the entire article. The body may be made of dark wood and trimmed throughout with a light wood to produce a fine effect.

[Pg 43]

Concrete Examples of Work.—A concrete example of doing any work is more valuable than an abstract statement. For this purpose I shall direct the building of a common table with a drawer in it and show how the work is done in detail.

For convenience let us adopt the Mission style, with a top 36" × 42" and the height 30". The legs should be 2" × 2" and the top 1", dressed. The material should be of hard wood with natural finish, or, what is better still, a soft wood, like birch, which may be stained a dark brown, as the Mission style is more effective in dark than in light woods.

Framework.—As we now know the sizes, the first thing is to build the framework. The legs should be dressed square and smoothed down with the fore plane to make them perfectly straight. Now, lay out two mortises at the upper end of each [Pg 44] leg. Follow the illustrations to see how this is done.

Laying Out the Legs.—Fig. 27 shows a leg with square cross marks (A) at each end. These marks indicate the finished length of the leg. You will also see crosses on two sides. These indicate what is called the "work sides." The work sides are selected because they are the finest surfaces on the leg.

The Length of the Mortises.—Then take a small try square (Fig. 28) and add two cross lines (B, C) on each of the inner surfaces, the second line (B) one-half inch from the finish line (A), and the other line (C) seven inches down from the line (A). The side facing boards, hereafter described, are seven inches wide.

When this has been done for all the legs, prepare your gage (Fig. 29) to make the mortise scribe, and, for convenience in illustrating, the leg [Pg 45] is reversed. If the facing boards are 1" thick, and the tenons are intended to be ½" thick, the first scribe line (E) should be ½" from the work side, because the shoulder on the facing board projects out ¼", and the outer surface of the facing board should not be flush with the outer surface of the leg. The second gage line (F) should be 1" from the work side.

The Mortises.—When the mortises have been made they will appear as shown in the enlarged cross section of the leg (Fig. 30), the total depth of each mortise being 1½". The depth of this mortise determines for us the length of the tenons on the facing boards.

The Facing Boards.—These boards are each 1 inch thick and 7 inches wide. As the top of the table is 42 inches long, and we must provide an overhang, say of 2 inches, we will first take off 4 inches for the overhang and 4 inches for the [Pg 46] legs, so that the length of two of the facing boards, from shoulder to shoulder, must be 34 inches; and the other two facing boards 28 inches. Then, as we must add 1½ inches for each tenon, two of the boards will be 37 inches long and two of them 31 inches long.

The illustration (Fig. 31) shows a board marked with the cross lines (B) at each end for the end of the tenons, or the extreme ends of the boards.

The Tenons.—Do not neglect first to select the work side and the working edge of the board. The outer surface and the upper edges are the sides to work from. The cheekpiece (A) of the gage must always rest against the working side.

[Pg 47] The cross marks (B, C) should be made with the point of a sharp knife, and before the small back saw is used on the cross-cuts the lines (B), which indicate the shoulders, should be scored with a sharp knife, as shown in Fig. 33. This furnishes a guide for the saw, and makes a neat finish for the shoulder.

Tools Used.—The back saw is used for cutting the tenon, and the end of the board appears as [Pg 48] shown in the enlarged Fig. 34. Two things are now necessary to complete the tenons. On the upper or work edge of each board use the gage to mark off a half-inch slice, and then cut away the flat side of the tenon at the end, on its inner surface, so it will appear as shown in Fig. 35.

Chamfered Tenons.—The object of these chamfered or beveled tenons is to permit the ends to approach each other closely within the mortise, as shown in the assembled parts (Fig. 36).

The Frame Assembled.—The frame is now ready to assemble, but before doing so a drawer opening and supports should be made. The ends [Pg 49] of the supports may be mortised into the side pieces or secured by means of gains.

Mortises and tenons are better.

The Drawer Supports.—Take one of the side-facing boards (Fig. 37) and cut a rectangular opening in it. This opening should be 4 inches wide and 18 inches long, so placed that there is 1 inch of stock at the upper margin and 2 inches of stock at the lower margin of the board. At each lower corner make a mortise (A), so that one side of the mortise is on a line with the margin of the opening, and so that it extends a half inch past the vertical margin of the opening.

You can easily cut a gain (B) in a strip, or, as in Fig. 38, you may use two strips, one (C) an inch wide and a half inch thick, and on this nail a strip (D) along one margin. This forms the guide and rest for the drawer.

At the upper margin of the opening is a rebate or gain (E) at each corner, extending down to the top line of the drawer opening, into which are fitted the ends of the upper cross guides.

[Pg 50] The Table Frame.—When the entire table frame is assembled it will have the appearance shown in Fig. 39, and it is now ready for the top.

The Top.—The top should be made of three boards, either tongued and grooved, or doweled and glued together. In order to give a massive appearance, and also to prevent the end grain of the boards from being exposed, beveled strips may be used to encase the edges. These marginal cleats are ¾ inch thick and 2 inches wide, and joined by beveled ends at the corners, as shown in Fig. 40.

The Drawer.—The drawer (Fig. 41) shown in cross section, has its front (A) provided with an overlapping flange (B).

[Pg 51] It is not our object in this chapter to show how each particular article is made, but simply to point out the underlying principles, and to illustrate how the fastening elements, the tenons and mortises, are formed, so that the boy will know the proper steps in their natural order.

How Any Structure Is Built Up.—It should be observed that each structure, however small, is usually built from the base up. Just the same as the more pretentious buildings are erected: First, the sill, then the floor supports, then the posts and top plates, with their connecting girders, and, finally, the roof.

The chapter on House Building will give more detailed illustrations of large structures, and how they are framed and braced. At this point we are more concerned in knowing how to proceed in order to lay out the simple structural details, and if one subject of this kind is fully mastered the complicated character of the article will not be difficult to master. [Pg 52]

Observations About a Box.—As simple a little article as a box frequently becomes a burden to a beginner. Try it. Simply keep in mind one thing; each box has six sides. Now, suppose you want a box with six equal sides—that is, a cubical form—it is necessary to make only three pairs of sides; two for the ends, two for the sides and two for the top and bottom. Each set has dimensions different from the other sets. Both pieces of the set, representing the ends, are square; the side pieces are of the same width as the end pieces, and slightly longer; and the top and bottom are longer and wider than the end pieces.

A box equal in all its dimensions may be made out of six boards, properly cut. Make an attempt in order to see if you can get the right dimensions.

Joints.—For joining together boards at right angles to each other, such as box corners, drawers and like articles, tenons and mortises should never be resorted to. In order to make fine work the joints should be made by means of dovetails, rabbets [Pg 53] or rebates, or by beveling or mitering the ends.

Beveling and Mitering.—There is a difference in the terms "beveling" and "mitering," as used in the art. In Fig. 42 the joint A is beveled, and in Fig. 43 the joint B is mitered, the difference being that a bevel is applied to an angle joint like a box corner, while a miter has reference to a joint such as is illustrated in Fig. 43, such as the corner of a picture frame.

Proper Terms.—It is the application of the correct terms to things that lays the foundation for accurate thinking and proper expressions in describing work. A wise man once said that the basis of true science consists in correct definitions.

Picture Frames.—In picture frames the mitered corners may have a saw kerf (C) cut across the corners, as shown in Fig. 44, and a thin blade [Pg 54] of hard wood driven in, the whole being glued together.

Dovetail Joints.—It is in the laying out of the more complicated dovetail joints that the highest skill is required, because exactness is of more importance in this work than in any other article in joinery. In order to do this work accurately follow out the examples given, and you will soon be able to make a beautiful dovetail corner, and do it quickly.

Preparing a Box Joint.—In order to match a box joint for the inner end of a table drawer, the first step is to select two work sides. One work side will be the edge of the board, and the other the side surface of the board, and on those surfaces we will put crosses, as heretofore suggested.

First Steps.—Now lap together the inner surfaces of these boards (Y, Z), so the ends are toward you, as shown in Fig. 45. Then, after measuring [Pg 55] the thickness of the boards to be joined (the thinnest, if they are of different thicknesses), set your compasses, or dividers, for ¼ inch, providing the boards are ½ inch thick, and, commencing at the work edge of the board, step off and point, as at A, the whole width of the board, and with a square make the two cross marks (B), using [Pg 56] the two first compass points (A), then skipping one, using the next two, and so on.

When this is done, turn up the board Z (Fig. 46), so that it is at right angles to the board Y, and so the outer surface of the board Z is flush with the end of the board X, and with a sharp knife point extend the lines B along with the grain of the wood on board Z,up to the cross mark C. This cross mark should have been previously made [Pg 57] and is located as far from the end of the board Z as the thickness of the board Y.

We now have the marks for the outer surface of the board Z, and the end marks of board Y. For the purpose of getting the angles of the end of the board Z and the outer side of board Y, a cross line (D, Fig. 47) is drawn across the board X near the end, this line being as far from the end as the thickness of the board Z, and a vertical line (E) is drawn midway between the two first cross marks (A).

Now, with your compass, which, in the meantime, has not been changed, make a mark (F), and draw down the line (G), which will give you the working angle at which you may set the bevel gage. Then draw down an angle from each alternate cross line (A), and turn the bevel and draw down the lines (H). These lines should all be produced on the opposite side of the board, so as to assure accuracy, and to this end the edges of the board also should be scribed.

Cutting Out the Spaces.—In cutting out the intervening spaces, which should be done with a sharp chisel, care should be observed not to cut over the shoulder lines. To prevent mistakes you should put some distinctive mark on each part to be cut away. In this instance E, H show the parts [Pg 58] to be removed, and in Fig. 48 two of the cutaway portions are indicated.

When the end of the board Z is turned up (Fig. 49), it has merely the longitudinal parallel lines B. The bevel square may now be used in the same manner as on the side of the board Y, and the fitting angles will then be accurately true.

This is shown in Fig. 50, in which, also, two of the cutaway parts are removed.

Tools Used in Laying Out Tenons and Mortises.—A sharp-pointed knife must always be used for making all marks. Never employ an awl for this work, as the fiber of the wood will be torn up by it. A small try square should always be used (not the large iron square), and this with a sharp-pointed compass and bevel square will enable you to turn out a satisfactory piece of work.

The foregoing examples, carefully studied, will enable you to gather the principles involved in laying off any work. If you can once make a presentable box joint, so that all the dovetails will accurately fit together, you will have accomplished one of the most difficult phases of the work, and it is an exercise which will amply repay you, because you will learn to appreciate what accuracy means.

[Pg 59]

The Square.—The square is, probably, the oldest of all tools, and that, together with the compass, or dividers, with which the square is always associated, has constituted the craftsman's emblem from the earliest historical times. So far as we now know, the plain flat form, which has at least one right angle and two or more straight edges, was the only form of square used by the workman. But modern uses, and the development of joinery and cabinet making, as well as the more advanced forms of machinery practice, necessitated new structural forms in the square, so that the bevel square, in which there is an adjustable blade set in a handle, was found necessary.

The Try Square.—In the use of the ordinary large metal square it is necessary to lay the short limb of the square on the face of the work, and the long limb must, therefore, rest against the work side or edge of the timber, so that the scribing edge of the short limb does not rest flat against the work. As such a tool is defective in work requiring accuracy, it brought into existence [Pg 60] what is called the try square, which has a rectangular handle, usually of wood, into which is fitted at one end a metal blade, which is at right angles to the edge of the handle. The handle, therefore, always serves as a guide for the blade in scribing work, because it lies flat down on the work.

The T-Square is another modification of the try square, its principal use being for draughting purposes.

The Compass.—The compass is one of the original carpenter's tools. The difference between compass and dividers is that compasses have adjustable pen or pencil points, whereas dividers are without adjustable points. Modern work has brought refinements in the character of the compass and dividers, so that we now have the bow-compass, which is, usually, a small tool, one leg of which carries a pen or pencil point, the two legs being secured together, usually, by a spring bow, or by a hinged joint with a spring attachment.

Proportional Dividers.—A useful tool is called the proportional dividers, the legs of which are hinged together intermediate the ends, so that the pivotal joint is adjustable. By means of this tool the scale of work may be changed, although its widest field of usefulness is work laid off on a [Pg 61] scale which you intend to reduce or enlarge proportionally.

Determining Angles.—Now, in order to lay out work the boy should know quickly and accurately how to determine various angles used or required in his work. The quickest way in which to learn this is to become familiar with the degree in its various relations.

Definition of Degree.—A degree is not a measure, as we would designate a foot or a pound to determine distance or quantity. It is used to denote a division, space, interval or position. To illustrate, look at the circle, Fig. 51. The four cardinal points are formed by the cross lines (A, B), and in each one of the quadrants thus formed the circle is divided into 90 degrees. Look at the radial lines (C, D), and you will find that the distance between these lines is different along the [Pg 62] curved line (E) than along the curved line (F). The degree is, therefore, to indicate only the space, division or interval in the circle.

The Most Important Angle.—Most important for one to know at a glance is that of 45 degrees, because the one can the more readily calculate the other degrees, approximately, by having 45 degrees once fixed in the mind, and impressed on the visual image. With a square and a compass it is a comparatively easy matter accurately to step off 45 degrees, as it is the line C, midway between A and B, and the other degrees may be calculated from the line C and the cardinal lines A or B.

Degrees Without a Compass.—But in the absence of a compass and when you do not wish to step off a circle, you will in such case lay down the square, and mark off at the outer margin of the limbs two equal dimensions. Suppose we take 2 inches on each limb of the square. The angle thus formed by the angle square blade is 45 degrees. To find 30 degrees allow the blade of the angle square to run from 2 inches on one limb to 3½ inches on the other limb, and it will be found that for 15 degrees the blade runs from 2 inches on one limb to 7½ inches on the other limb. It would be well to fix firmly these three points, at least, in your mind, as they will be of the utmost value to you. It is a comparatively easy matter now to [Pg 63] find 10 degrees or 25 degrees, or any intermediate line.

What Degrees Are Calculated From.—The question that now arises is what line one may use from which to calculate degrees, or at what point in the circle zero is placed. Degrees may be calculated either from the horizontal or from the vertical line. Examine Fig. 53. The working margin indicated by the cross mark is your base line, and in specifying an angle you calculate it from the work edge. Thus, the line A indicates an angle of 30 degrees. The dotted line is 45 degrees.

[Pg 64] The Dividers.—The dividers are used not only for scribing circles, but also for stepping and dividing spaces equally. There is a knack in the use of the dividers, where accuracy is wanted, and where the surface is of wood. Unless the utmost care is observed, the spaces will be unequal, for the reason that the point of the dividers will sink more deeply into the wood at some places than at others, due to the uneven texture of the wood grain. It will be better to make a line lengthwise, and a cross line (A) for starting (see Fig. 54). You may then insert one point of the dividers at the initial mark (B), and describe a small arc (C). Then move the dividers over to the intersection of the arc (C) on the line, and make the next mark, and so on.

Some useful hints along this same line will be found under the chapter on Drawing, which should be carefully studied.

[Pg 65]

The Right Name for Everything.—Always make it a point to apply the right term to each article or portion of a structure. Your explanation, to those who do know the proper technical terms, will render much easier a thorough understanding; and to those who do not know, your language will be in the nature of an education.

Proper Designations.—Every part in mechanism, every point, curve and angle has its peculiar designation. A knowledge of terms is an indication of thoroughness in education, and, as heretofore stated, becomes really the basis of art, as well as of the sciences. When you wish to impart information to another you must do it in terms understood by both.

Furthermore, and for this very reason, you should study to find out how to explain or to define the terms. You may have a mental picture of the structure in your mind, but when asked to explain it you are lost.

Learning Mechanical Forms.—Suppose, for example, we take the words segment and sector. [Pg 66] Without a thorough understanding in your own mind you are likely to confuse these terms by taking one for the other. But let us assume you are to be called upon to explain a sector to some one who has no idea of terms and their definitions. How would you describe it? While it is true it is wedge-shaped, you will see by examining the drawing that it is not like a wedge. The sector has two sides running from a point like a wedge, but the large end of the sector is curved.

If you were called upon to define a segment you might say it had one straight line and one curve, but this would not define it very lucidly. Therefore, in going over the designations given, not only fix in your mind the particular form, but try to remember some particular manner in which you can clearly express the form, the shape or the relation of the parts.

For your guidance, therefore, I have given, as far as possible, simple figures to aid you in becoming acquainted with structures and their designations, without repeating the more simple forms which I have used in the preceding chapters.

55. Arcade.—A series of arches with the columns or piers which support them, the spandrels above, and other parts.

[Pg 67] 56. Arch.—A curved member made up, usually, of separate wedge-shaped solids, A. K, Keystone; S, Springers; C, Chord, or span.

57. Buttress.—A projecting mass of masonry. A, used for resisting the thrust of an arch, or for ornamentation; B, a flying buttress.

58. Chamfer.—The surface A formed by cutting away the arris or angle formed by two faces, B, C, of material.

59. Cotter or Cotter Pin.—A pin, A, either flat, square or round, driven through a projecting tongue to hold it in position.

60. Crenelated.—A form of molding indented or notched, either regularly or irregularly.

61. Crosses.—1. Latin cross, in the Church of Rome carried before Bishops. 2. Double cross, carried before Cardinals and Bishops. 3. Triple or Papal cross. 4. St. Andrew's and St. Peter's cross. 5. Maltese cross. 6. St. Anthony or Egyptian cross. 7. Cross of Jerusalem. 8. A cross patté or fermé (head or first). 9. A cross patonce (that is, growing larger at the ends). 10. Greek cross.

62. Curb Roof.—A roof having a double slope, or composed on each side of two parts which have unequal inclinations; a gambrel roof.

63. Cupola.—So called on account of its resemblance to a cup. A roof having a rounded form. When on a large scale it is called a dome.

Crown Post.—See King Post.

64. Console.—A bracket with a projection not more than half its height.

65. Corbels.—A mass of brackets to support a shelf or structure. Largely employed in Gothic architecture.

66. Dormer.—A window pierced in a roof and so set as to be vertical, while the roof slopes away from it. Also called a Gablet.

67. Dowel.—A pin or stud in one block, or body, designed to engage with holes in another body to hold them together in alignment.

68. Drip.—That part of a cornice or sill course A, or other horizontal member which projects beyond the rest, so as to divert water.

[Pg 68] 69. Detents.—Recesses to lock or to serve as a stop or holding place.

70. Extrados.—The exterior curve of an arch, especially the upper curved face A. B is the Intrados or Soffit.

71. Engrailed.—Indented with small concave curves, as the edge of a bordure, bend, or the like.

72. Facet.—The narrow plain surface, as A, between the fluting of a column.

73. Fret, Fretwork.—Ornamental work consisting of small fillets, or slats, intersecting each other or bent at right angles. Openwork in relief, when elaborated and minute in all its parts. Hence any minute play of light and shade. A, Japanese fretwork. B, Green fret.

74. Frontal, also called Pediment.—The triangular space, A, above a door or window.

75. Frustums.—That part of a solid next the base, formed by cutting off the top; or the part of any solid, as of a cone, pyramid, etc., between two planes, which may either be parallel or inclined to each other.

76. Fylfat.—A rebated cross used as a secret emblem and worn as an ornament. It is also called Gammadium, and more commonly known as Swastika.

77. Gambrel Roof.—A curb roof having the same section in all its parts, with a lower, steeper and longer part. See Curb Roof and distinguish difference.

78. Gargoyle.—A spout projecting from the roof gutter of a building, often carved grotesquely.

79. Gudgeon.—A wooden shaft, A, with a socket, B, into which is fitted a casting, C. The casting has a gudgeon, D.

80. Guilloche.—An ornament in the form of two or more bands or strings twisted together or over or through each other.

81. Half Timbered.—Constructed of a timber frame, having the spaces filled in with masonry.

82. Hammer Beam.—A member of one description of roof truss, called hammer-beam truss, which is so framed as not to have a tie beam [Pg 69] at the top of the wall. A is the hammer beam, and C the pendant post.

83. Haunches.—The parts A, A, on each side of the crown of an arch. Each haunch is from one-half to two-thirds of the half arch.

84. Header.—A piece of timber, A, fitted between two trimmers, B, B, to hold the ends of the tail beams, C, C.

85. Hip Roof.—The external angle formed by the meeting of two sloping sides or skirts of a roof which have their wall plates running in different directions.

86. Hood Molding.—A projecting molding over the head of an arch, as at A, forming the outer-most member of the archivolt.

87. Inclave.—The border, or borders, having a series of dovetails. One variation of molding or ornamentation.

88. Interlacing Arch.—Arches, usually circular, so constructed that their archivolts, A, intersect and seem to be interlaced.

89. Invected.—Having a border or outline composed of semicircles or arches, with the convexity outward. The opposite of engrailed.

90. Inverted Arch.—An arch placed with the crown downward; used in foundation work.

91. Keystone.—The central or topmost stone, A, of an arch, sometimes decorated with a carving.

92. King Post.—A member, A, of a common form of truss for roofs. It is strictly a tie intended to prevent the sagging of the tie beam, B, in the middle. If there are struts, C, supporting the rafters, D, they extend down to the foot of the King Post.