Fig. 1.—(Full page image)

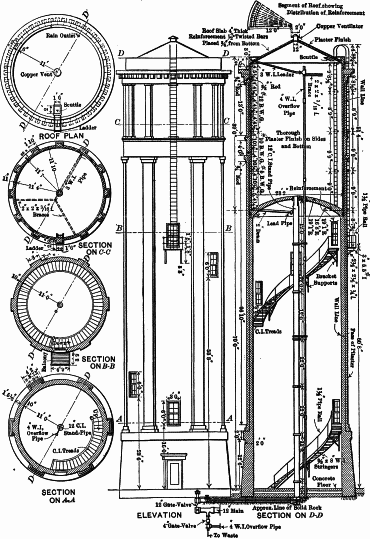

Fig. 1.—(Full page image)WATER TOWER VICTORIA, B.C. WATER-WORKS

The Project Gutenberg EBook of Transactions of the American Society of

Civil Engineers, Vol. LXX, Dec. 1910, by A. Kempkey

This eBook is for the use of anyone anywhere at no cost and with

almost no restrictions whatsoever. You may copy it, give it away or

re-use it under the terms of the Project Gutenberg License included

with this eBook or online at www.gutenberg.org

Title: Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910

A Concrete Water Tower, Paper No. 1173

Author: A. Kempkey

Release Date: July 3, 2006 [EBook #18748]

Language: English

Character set encoding: ISO-8859-1

*** START OF THIS PROJECT GUTENBERG EBOOK AMERICAN SOCIETY OF CIVIL ENGINEERS ***

Produced by Juliet Sutherland, Sigal Alon and the Online

Distributed Proofreading Team at http://www.pgdp.net

The City of Victoria is situated on the southern end of Vancouver Island, in the Province of British Columbia, Canada, and is the capital of the Province.

In common with all cities of the extreme West, its growth has been very rapid within the last few years. The population of the city proper, together with that of the municipality of Oak Bay, immediately adjacent, is now about 35,000.

The Victoria water-works are owned by the city and operated under the direction of a Water Commissioner appointed by the City Council. By special agreement, water is supplied to Oak Bay in bulk, this municipality having its own distributing system.

The rapid increase in population, together with the fact that in recent years very little had been done toward increasing the water supply, resulted in the necessity for remodeling the entire system, and there are very few cities where this would involve as many complex problems or a greater variety of work.

Water is drawn from Elk Lake, situated about five miles north of the city; thence it flows by gravity to the pumping station about four miles distant, and from there is pumped directly to the consumers.

[335] The remodeling of the system, as recently completed, provided for:

1.—Increasing the capacity of Elk Lake by a system of levees.

2.—Increasing the capacity of the main to the pumping station by replacing about two miles of the old 16-in., wrought-iron, riveted pipe with 24-in. riveted steel pipe.

3.—Increasing the capacity of the pumping station by the installation of a 4,500,000-gal. pumping engine of the close-connected, cross-compound, Corliss, crank-and-fly-wheel type.

4.—The construction of a 20,000,000-gal. concrete-lined distributing reservoir in the city.

5.—The entire remodeling of the distributing system, necessitating the laying of about 1/2 mile each of 18-in. and 27-in. pipe, and about 1 mile of 24-in. riveted steel pipe; also about 3,000 tons of cast-iron pipe, varying in size from 4 to 12 in.

6.—The provision for a high-level service by means of an elevated tank of approximately 100,000 gal. capacity, water being supplied to the tank by two electrically-driven triplex pumps, each having a capacity of 100,000 gal. per 24 hours, against a dynamic head of 150 ft., and arranged to start and stop automatically with a variation of 3 ft. in the elevation of the water in the tank. These pumps are located about one mile from the tower, and are controlled by a float-operated auto-start, in the base of the tower.

A description of the elevated tank, which is novel in design, with the reasons for adopting the type of structure used, the method of construction, and the detailed cost, form the basis of this paper.

The tower is on the top of the highest hill in the city, in the heart of the most exclusive residential district, beautiful homes clustering about its base. The necessity for architectural treatment of the structure is thus seen to be of prime importance. In fact, the opposition of the local residents to the ordinary type of elevated tank, that is, latticed columns supporting a tank with a hemispherical bottom and a conical roof, rendered its use impossible, although tenders were invited on such a structure.

It is believed that under the conditions of location, three types of structure should be considered: First, an all-steel structure, the ornamentation being produced by casing in with brick or concrete; second, a brick-and-steel, or a concrete-and-steel, structure, such as the one actually erected; third, a typical reinforced concrete structure.

[336] Considering only that portion below the tank, the amount of material required to case in a structure of the first type would be substantially the same as that used to support the tank in a structure of the second type. Consequently, the steel substructure, for all practical purposes, would represent a dead loss, and, therefore, the economy of this type is open to serious question.

A tender was received for a reinforced concrete structure identical in outward appearance with the one built, but, owing to the natural conservatism of the local residents regarding this type of construction, it was not acceptable.

The tower, as built, consists of a hollow cylinder of plain concrete, 109 ft. high, and having an inside diameter of 22 ft. The walls are 10 in. thick for the first 70 ft. and 6 in. thick for the remaining 39 ft., and are ornamented with six pilasters (70 ft. high, 3 ft. wide, and 7 in. thick), a 4-ft. belt, then twelve pilasters (12 ft. high, 18 in. wide, and 7 in. thick), a cornice, and a parapet wall.

A steel tank of the ordinary type is embedded in the upper 40 ft. of this cylinder. To form the bottom of this tank, a plain concrete dome is thrown across the cylinder at a point about 70 ft. from the base, the thrust of this dome being taken up by two steel rings, 1/2 in. by 14 in. and 3/8 in. by 18 in., bedded into the walls of the tower, the latter ring being riveted to the lower course of the tank.

The tank is covered with a roof of reinforced concrete, 4 in. thick, conical in shape, and reinforced with 1/2-in. twisted steel bars. The design of the structure is clearly shown in Fig. 1.

The tower is built on out-cropping, solid rock. This rock was roughly stepped, and a concrete sub-base built. This sub-base consists of a hollow ring, with an inside diameter of 20 ft., the walls being 5 ft. thick. It is about 2 ft. high on one side and 7 ft. high on the other, and forms a level base on which the tower is built. The forms for this sub-base consist of vertical lagging and circumferential ribs. The lagging is of double-dressed, 2 by 3-in. segments, and the ribs are of 2 by 12-in. segments, 6 ft. long, lapping past one another and securely spiked together to form complete or partial circles. These ribs are 2 ft. from center to center.

Similar construction was used to form the taper base of the tower proper, except, of course, that the radii of the segments forming the successive ribs decreased with the height of the rib. Tapered lagging[338] was used, being made by double dressing 2 by 6-in. pieces to 1-3/4 by 5-13/16 in., and ripping on a diagonal, thus making two staves, 3 in. wide at one end and 2-3/4 in. wide at the other. This tapered lagging was used again on the 4-ft. belt and cornice forms, the taper being turned alternately up and down.

The interior diameter being uniform up to the bottom of the dome, collapsible forms were used from the beginning. These forms were constructed in six large sections, 6 ft. high, with one small key section with wedge piece to facilitate stripping, as shown in Fig. 2. There were three tiers of these, bolted end to end horizontally and to each other vertically.

Above the taper base and except in the 4-ft. belt and cornice, collapsible forms were used on the outside also. There were six sections extending from column to column and six column sections, all[339] bolted together circumferentially and constructed as shown in Fig. 2. Three tiers of these were also bolted together both vertically and horizontally.

Having filled the top tier, the mode of operation was as follows:

All horizontal bolts in the lower inside and outside forms were removed, as was also the small key section on the inside; this left each section suspended to the corresponding one immediately above it by the vertical bolts before mentioned. It is thus seen that in each case the center tier performed the double duty of holding the upper tier, which was full of green concrete, and the sections of the lower tier, until they were hoisted up and again placed in position to be filled.

These lower forms were then hoisted by hand—four-part tackles being used—and placed in position on the top forms, their bottom edges being carefully set flush with the top edge of the form already in position, and then bolted to it. On the outside, the column forms, and on the inside, the wedge and key sections were set last. A 3-lb. plumb-bob on a fine line was suspended from the inner scaffold and carefully centered over a point set in the rock at the base. This line was in the exact center of the tower, and the tops of all the forms, after each shift, were carefully set from it by measurement, thus keeping the structure plumb.

The first 23 in. of the barrel of the tower was moulded with special outside forms, constructed so as to form the bases of the large pilasters. After eleven applications of the 6-ft. forms, these 23-in. sections were reversed to form the capitals, thus making these pilasters, 69 ft. 10 in. over all.

The forms of the 4-ft. belt and beading were made in twelve sections of simple segments and vertical lagging, as shown in Fig. 2.

Two sets of the outside forms were split longitudinally, as shown in Fig. 2, and used to form the small pilasters. The first set was put in place, filled, and the concrete allowed to harden. The bolts were loosened and the forms raised 5-1/2 in. vertically, again bolted up, and the second set was placed in position, bringing the top of the second set up to the bottom of the cornice. The bases and capitals of the small pilasters were moulded on afterward.

The cornice forms are clearly shown in Fig. 2. The small boxes separating the dentils are made of light stuff, and tacked into the[340] cornice forms so that, in stripping, they would remain in place and could be taken out separately, in order to prevent breaking off the corners of the dentils. A number of outside and inside sections were sawed in half horizontally in order to provide forms for the parapet wall.

The inside diameter of the tank is 8 in. greater than the inside diameter of the base. Two sets of inside forms were split longitudinally and opened out, as shown in Fig. 2, and another small section was added to complete the circle. The remaining set was left in place to support the dome forms.

The dome forms were made in twelve sections, bolted together to facilitate stripping. All ribs and segments were cut to size on the ground, put together in place, and then covered with lagging and two-ply tar paper. The lagging on the lower sharp curve was formed of a double thickness of 3/8-in. spruce, the remainder being 1 by 4-in. pine, sized to a uniform thickness of 7/8 in. Fig. 3 shows the construction of these forms and the method of putting on the lagging.

The roof forms were made in eight sections and bolted together to facilitate stripping. All ribs and segments were cut to size on the ground, put together in place, and covered with 1 by 4-in. lagging, dressed to a uniform thickness of 7/8 in., and two-ply tar paper. Fig. 3 shows the construction of these forms. The segments being put in horizontally instead of square with the lagging, gave circles instead of parabolas, making them much easier to lay out, and giving a form which was amply stiff.

The question of using an inside scaffold only was carefully considered, but owing to the considerable amount of ornamentation on the outside, necessitating a large number of individual forms, it was not thought that any economy would result.

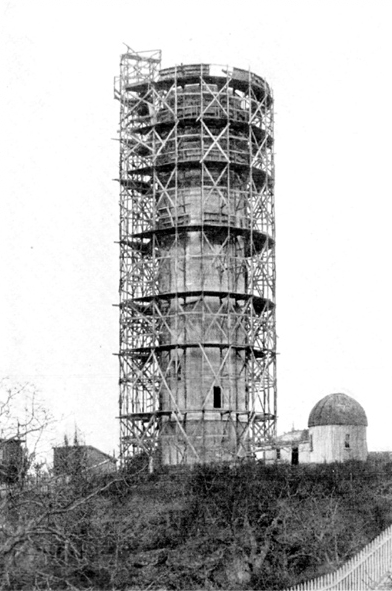

Fig. 4 and Figs. 1 and 2, Plate XXIII, show clearly the construction of the scaffolding.

Plate XXIII, Fig. 1.—Scaffolding for Water Tower.

Plate XXIII, Fig. 1.—Scaffolding for Water Tower.

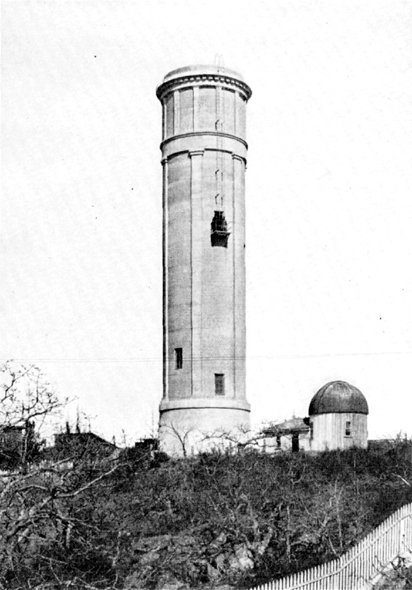

Plate XXIII, Fig. 2.—Completed Water Tower.

Plate XXIII, Fig. 2.—Completed Water Tower.

All concrete was mixed wet, in a motor-driven, Smith mixer, and handled off the outside scaffold, being sent up in wheel-barrows on the ordinary contractor's hoist and placed in the forms through an iron chute having a hopper mouth. This chute was built in three sections bolted together, either one, two, or three sections being used, depending on the distance of the forms below the deck. When the top of the forms reached the elevation of any deck, the concrete was put[341] in through the chute from the deck above. The chute was light and easily shifted by the wheel-barrow men, assisted by the man placing the concrete, during the interval between successive wheel-barrows.

The concrete, except that for the roof and parapet, was composed of sand and broken rock, the run of the crusher being used. That for the roof and parapet was composed of sand and gravel. The only reason for using gravel for the concrete of the roof was the ease with which it could be obtained in small quantities, the supply of broken rock having been used up, and this being the last concrete work to be done.

The concrete used was as follows: 1:3:6 for the sub-base and taper base; 1:3:5 for the barrel of the tower and tank casing; and 1:2:4 for the dome and roof. The dome was put in at one time, there being no joint, the same being true of the roof. Vancouver Portland cement,[342] manufactured on the island about 15 miles from the city, was used throughout the work.

Before filling, the inside of the tank was given a plaster coat, consisting of 1 part cement to 1-3/4 parts of fine sand. This proved to be insufficient to prevent leakage, the water seeping through the dome and appearing on the outside of the structure along the line of the bottom of the rings. Three more coats were then applied over the entire tank, and two additional ones over the dome and about 8 ft. up on the sides, and, except for one or two small spots which show just a sign of moisture, the tank is perfectly tight.

The barrel of the tower was carried up to a height of 66 ft. A special set of inside forms, about 2 ft. high, extending to the springing line of the dome, was then put in, and the dome forms were set up on it. The idea was that this 2-ft. form could be knocked out piece by piece and the weight of the dome form taken on wedges to the last 6-ft. form, these wedges being gradually slackened down in order to allow the dome form to settle clear of the dome. As a matter of fact, this was done, but the dome forms, being very tight, did not settle, and had to be pried off a section at a time. A similar method was used for slacking down the roof forms, with similar results.

After the dome forms had been put in, the concrete was carried up approximately to the elevation of the bottom of the rings. Small neat cement pads were then put in and accurately leveled, and on these the steel rings were placed, and the steel tank was erected.

In order to insure a perfectly round tank, each course was erected against wooden templates accurately centered and fastened to the inside scaffold. The tank is the ordinary type of light steel, the lower course being 3/16-in., the next, No. 8 B. w. gauge, the next, No. 10 B. w. gauge, and the remaining four, No. 12 B. w. gauge.

Work on the foundation was started on August 15th, 1908, and the tower was not completed until April 1st, 1909. Much time was lost waiting for the delivery of the steel, and also owing to a period of very cold weather which caused entire cessation of work for about one month.

The tower as completed presents a striking appearance. In order to obliterate rings due to the successive application of the forms and to cover the efflorescence so common to concrete structures, the outside was given two coats of neat cement wash applied with ordinary calcimining[344] brushes, and, up to the present time, this seems to have been very effective in accomplishing the desired result.

Irregularities due to forms are unnoticeable at a distance of 200 or 300 ft., and the grouting gave a very uniform color.

The application of two coats of cement wash cost, for labor, $97.68, and for material, $15.18, or $1.32 per 100 sq. ft., labor being at the rate of $2.25 per 8 hours and cement costing $2.53 per bbl. delivered on the work.

The tower was designed by Arthur L. Adams, M. Am. Soc. C. E., under whose direction the plans for all the work of remodeling the water-works system were prepared and executed. The forms, scaffolding, etc., were designed by the writer, who was also in immediate charge of the erection.

Tenders received for the construction of the tower covered an extremely wide range, and indicated at once the utter lack of knowledge on the part of the bidders of the cost of a structure of this kind. Inasmuch as none of them had had previous experience in this class of construction, the engineer deemed it the part of wisdom and economy to retain the construction under his immediate supervision, and, therefore, the work was done by days' labor.

Table 1 gives the cost of the structure. The total herein given will not coincide with the total cost as shown by the city's books, for the reason that various items not properly chargeable to the structure itself have been omitted, the principal ones of which are the cost of the site, the laying of about 600 ft. of sewer pipe to connect with the overflow, and considerable expense incident to the construction of a wagon road to the tower.

The rates of wages paid, all being on a basis of an 8-hour day, were as follows:

| Common labor | $2.25 and $2.50 |

| Carpenter | 4.00 |

| Carpenter's helper | 2.75 |

| Boiler-maker | 3.50 |

| Holders on | 2.50 |

| Boiler-maker foreman | 5.00 |

| Plasterers | 6.00 |

| Plasterers' helpers | 3.00 |

[345] The cost of material was as follows:

| Cement, per barrel | $2.53 |

| Sand, per yard | 1.47 |

| Rock, per yard | 0.80 |

| Lumber, per 1,000 ft. b. m. | 14.00 and 16.00 |

All these prices are for material delivered on the work.

An examination of the cost data, as given, will show that for the most part the unit costs are very high. This is due chiefly to the continued interruption of the work, during its later stages, owing to bad weather, particularly in the case of the erection of the steel tank. The material cost in this case was also exceedingly high.

In the case of the concreting, inability to purchase a hoist and motor and the high cost of renting the same, together with the delays mentioned, added greatly to the unit cost.

When it is considered that the cost of plastering covers that of four coats over the entire inside of the tank and three more over about one-third of it, it does not appear so high, especially in view of the high rate of wages paid.

The cost per yard for concrete alone was $25.126, and this is probably about 25% in excess of the cost of the same class of work executed under more favorable conditions as to location, weather conditions, etc.[346]

| Total Cost. | Unit Cost. | ||||

| Rate per hour. | Amount. | Complete. | Labor. | Material. | |

| Preliminary Work: | |||||

| Labor, Carpenter | $0.50 | $11.00 | |||

| Labor | 0.344 | 64.94 | |||

| " | 0.281 | 249.67 | $325.61 | $0.790 | |

| Material | 133.62 | 133.62 | $0.324 | ||

| Forms: | |||||

| Buildings, shifting and stripping: | |||||

| Labor, Carpenter | 0.50 | 1,832.99 | |||

| Labor | 0.344 | 80.85 | |||

| " | 0.281 | 563.84 | 2,477.68 | 6.014 | |

| Material: | |||||

| Lumber | 583.49 | ||||

| Hardware | 325.51 | ||||

| Miscellaneous | 13.90 | 922.90 | 2.240 | ||

| Scaffold: | |||||

| Erecting and tearing down: | |||||

| Labor, Carpenter | 0.50 | 693.00 | |||

| Labor | 0.344 | 350.59 | |||

| " | 0.281 | 117.27 | 1,160.86 | 2.818 | |

| Material: | |||||

| Lumber | 487.77 | ||||

| Hardware | 202.79 | 690.56 | 1.676 | ||

| Concreting: | |||||

| Labor | 0.50 | 142.00 | |||

| " | 0.344 | 11.00 | |||

| " | 0.281 | 947.81 | 1,100.81 | 2.672 | |

| Material: | |||||

| Rock | 317.30 | ||||

| Sand | 385.72 | ||||

| Cement | 1,581.97 | ||||

| Motor and Hoist: | |||||

| Rental | 406.56 | ||||

| Power | 83.53 | 2,735.08 | 6.638 | ||

| Plastering (3,000 sq. ft.): | |||||

| Labor, Plasterers | 0.75 | 116.50 | |||

| Labor | 0.46-7/8 | 15.00 | |||

| " | 0.37-1/2 | 198.52 | |||

| " | 0.281 | 105.66 | 435.68 | 14.52 per sq. ft. | |

| Material: | |||||

| Sand | 8.64 | ||||

| Cement | 66.10 | ||||

| Alum and Potash | 16.00 | 90.74 | 3.25 per sq. ft. | ||

| Cement Wash (8,560 sq. ft.): | |||||

| Labor | 0.48-3/4 | 50.00 | |||

| " | 0.281 | 47.68 | 97.68 | 1.14 per 100 sq ft. | |

| Material: | |||||

| Cement | 15.18 | 15.18 | 0.18 " " " " | ||

| Windows, doors, and scuttle: | |||||

| Labor | 0.50 | 49.00 | 49.00 | ||

| Material: | |||||

| 1 door, 7 windows, etc. | 47.26 | 47.26 | |||

| Equipment: | |||||

| 40% of $461.46 | 184.58 | 184.58 | 0.448 | ||

| Superintendence | 1,241.45 | 1.506 | [347] | ||

| Steel Tank: | |||||

| Labor, Carpenter | $0.50 | $124.24 | |||

| Helper | 0.344 | 2.75 | |||

| Boiler-makers | 382.57 | ||||

| Holders on | 147.33 | ||||

| Labor | 40.61 | ||||

| Foreman | 0.625 | 186.25 | $883.75 | $0.0441 per lb. | |

| Material: | |||||

| Tank, rivets, etc. (20,000 lb.) | 1,740.69 | $0.0875 | |||

| Iron-work: | |||||

| Spiral stairway, inlet, and overflow pipes, ventilator, reinforcing steel, etc.: | |||||

| Labor, Machinists | 0.50 | 89.50 | |||

| Helper | 0.344 | 240.16 | |||

| Labor | 0.281 | 100.79 | 430.45 | ||

| Material | 1,814.71 | 1,814.71 | |||

| Total | $16,578.29 | ||||

Maurice C. Couchot, M. Am. Soc. C. E. (by letter).—It appears to the writer that in the design of this structure two features are open to criticism. The first is that such a high structure was built of plain concrete without any reinforcement. Even if the computation of stresses did not show the necessity for steel reinforcement, some should have been embedded in the work. As a matter of fact, the writer believes that, with the present knowledge of the benefit of reinforced concrete, a structure such as this should not be built without it. This applies mainly to the tower below the tank.

The second feature, which is still more important, refers to the insertion of a shell of smooth steel plate to take the stresses due to the hydrostatic pressure, and also to insure against leakage in the walls of the tank. The 6-in. shell of plain concrete outside the steel shell, and the 3-in. shell inside, do not work together, and are practically of no value as walls, but are simply outside and inside linings. Although the designer provided lugs to insure the adhesion of the concrete to the plate, such precaution, in the writer's opinion, will not prevent the separation of the concrete from the smooth steel plate, and, at some future time, the water will reach and corrode the steel. It would have been better to have reinforced the wall of the tank with rods, as is generally done. The full thickness would have been available, and less plastering would have been required. Furthermore, the adhesion of concrete to a smooth steel plate is of doubtful value, for, in reinforced concrete, it is not the adhesion which does the work, but the gripping of the steel by the concrete in the process of setting.

L. J. Mensch, M. Am. Soc. C. E. (by letter).—This water-tower is probably the sightliest structure of its kind in North America; still, it does not look like a water-tower, and, from an architectural point of view, the crown portion is faulty, because it makes the tank appear to be much less in depth than it really is.

The cost of this structure far exceeds that of similar tanks in the United States. The stand-pipe at Attleboro, 50 ft. in diameter and 100 ft. high, cost about $25,000. Several years ago the writer proposed to build an elevated tank, 60 ft. in diameter and 40 ft. deep, the bottom of which was to be 50 ft. above the ground, for $21,000.

Among other elevated tanks known to the writer is one having a capacity of 100,000 gal., the bottom being 60 ft. above the ground.[C] The total quantities of material required for this tank are given as 4,480 cu. ft. of concrete, 23,200 lb. of reinforcing steel, and 27,600 ft., b. m., of form lumber and staging. Calculating at the abnormally[349] high unit prices of 40 cents per cu. ft. for concrete, 4 cents per lb. for steel, and $50 per 1,000 ft., b. m., for lumber, the cost of the concrete would be $1,792, the steel, $928, and the form lumber and staging, $1,380. Adding to this the cost of a spiral staircase, at the high figure of $7 per linear foot in height, the total cost of this structure would be $4,598. The factor of safety used in this structure was four, but some engineers who are not familiar with concrete construction may require a higher factor. By doubling the quantities of concrete and steel, which would mean a tensile stress in the steel of only 8,000 lb. per sq. in., and a compressive stress in the concrete of only 225 lb. per sq. in., the cost of the tank would be only $7,318, as compared with the $16,578 mentioned in the paper. This enormous discrepancy between a good design and an amateur design, and between day-labor work and contract work should be a lesson which consulting engineers and managers of large corporations, who prefer their own designs and day-labor work, should take to heart.

A. H. Markwart, Assoc. M. Am. Soc. C. E. (by letter).—It is the writer's opinion that the steel tank enclosed within the concrete of the upper cylinder, to take up the hoop tension and presumably to provide a water-tight tower, will not fulfill this latter requirement. If a plastered surface on the dome-shaped bottom provided the necessary imperviousness, it would seem that plastered walls would have proved satisfactory.

Apparently, the sheet-metal tank is intended to exclude the possibility of exterior leakage, but it occurs to the writer that it will fail to be efficient in this particular, because, under pressure, the water will force itself under the steel tank and the dome thrust rings and out to the exterior of the tower just below the tank, thus showing that insurance against leakage is actually provided by the plastered interior surfaces and not by the sheet-metal tank, and, for this reason, ordinary deformed rod reinforcement, in the writer's opinion, would have proved cheaper and better, and more in line with other parts of the reinforcement.

Mr. Kempkey states:

"Before filling, the inside of the tank was given a plaster coat, consisting of 1 part cement to 1-3/4 parts of fine sand. This proved to be insufficient to prevent leakage, the water seeping through the dome and appearing on the outside of the structure along the line of the bottom of the rings. Three more coats were then applied over the entire tank, and two additional ones over the dome and about 8 ft. up on the sides, and, except for one or two small spots which show just a sign of moisture, the tank is perfectly tight."

This substantiates the writer's contention that water-tightness was actually obtained by a liberal use of cement plaster, which would also have been true had the reinforcement been rods.[350]

As a further comment, it might be stated that a water-tight concrete for the tank could have been obtained by adding from 8 to 10% of hydrated lime to the 1:2:4 mixture. This seems advisable in all cases where a water-tight concrete is necessary. The interior plastering could then have been done as a further precaution.

A. Kempkey, Jr., Jun. Am. Soc. C. E. (by letter).—Mr. Couchot's statement, that the 3-in. inside and outside sheets forming the tank casing do not act together, is quite true, and it was not expected that they would, other than to protect the steel and form an ornamental covering for it.

There is certainly adhesion between concrete and steel, even though the steel be in the form of a thin shell, and in a structure of this kind where the steel is designed, with a low unit stress, to take all the strain, and where the load is at all times quiescent, it is difficult to see how this bond can be destroyed; the writer feels no concern on this score.

Mr. Markwart's statement, that the steel tank enclosed within the concrete of the upper cylinder, presumably to provide a water-tight tower, will not fulfill this latter requirement, is not true, as shown by the statement in the paper that the only leakage which occurred was that which passed under the tank, the entire remaining portion being absolutely tight. The amount of leakage, while insignificant, was, until remedied, sufficient to spot the outside of the tower, making it unsightly; and this, in the writer's opinion, is just what would have happened had the tank been constructed in the ordinary manner, with deformed bars, except that it would have extended over more or less of the entire surface, instead of being localized, as was actually the case, and would have required more instead of less plastering. It is also doubtful whether the addition of hydrated lime would have produced a tight tank, in the sense that this structure was required to be tight.

In the paper the writer endeavored to bring out the fact that this is one of the few instances where the æsthetic design of a structure of this sort is of prime importance, and cost a secondary consideration. There is, therefore, no use in comparing its cost with that of a structure in no way its equal in this respect and the use of which would not have been permitted any more than the use of the ordinary type of steel structure, even though the estimated cost were 75% less.

Mr. Mensch has been pleased to term this design amateurish, presumably because of the conservative character of the stresses used and because of its cost; at the same time, he sets up the design to which he makes reference as a good one simply because of its cheapness. He will find the "enormous discrepancy," to which he calls attention, accounted for by the fact that the "good design" would not have been tolerated because of its appearance and because of the fact that[351] the excessively high unit stresses, of which Mr. Mensch is an exponent, did not commend themselves either to the designer, in common with most engineers, or to Victorian taste; while the design used has proven eminently satisfactory to a more than usually conservative and discriminating community.

Mr. Mensch's statement of unit costs, even though applied to a much plainer structure, is not calculated to inspire confidence in the soundness of his deductions in any one familiar with Victoria conditions.

[A] Presented at the meeting of March 16th, 1910.

[B] Now Assoc. M. Am. Soc. C. E.

[C] "The Reinforced Concrete Pocket Book," p. 124.

End of the Project Gutenberg EBook of Transactions of the American Society

of Civil Engineers, Vol. LXX, Dec. 1910, by A. Kempkey

*** END OF THIS PROJECT GUTENBERG EBOOK AMERICAN SOCIETY OF CIVIL ENGINEERS ***

***** This file should be named 18748-h.htm or 18748-h.zip *****

This and all associated files of various formats will be found in:

http://www.gutenberg.org/1/8/7/4/18748/

Produced by Juliet Sutherland, Sigal Alon and the Online

Distributed Proofreading Team at http://www.pgdp.net

Updated editions will replace the previous one--the old editions

will be renamed.

Creating the works from public domain print editions means that no

one owns a United States copyright in these works, so the Foundation

(and you!) can copy and distribute it in the United States without

permission and without paying copyright royalties. Special rules,

set forth in the General Terms of Use part of this license, apply to

copying and distributing Project Gutenberg-tm electronic works to

protect the PROJECT GUTENBERG-tm concept and trademark. Project

Gutenberg is a registered trademark, and may not be used if you

charge for the eBooks, unless you receive specific permission. If you

do not charge anything for copies of this eBook, complying with the

rules is very easy. You may use this eBook for nearly any purpose

such as creation of derivative works, reports, performances and

research. They may be modified and printed and given away--you may do

practically ANYTHING with public domain eBooks. Redistribution is

subject to the trademark license, especially commercial

redistribution.

*** START: FULL LICENSE ***

THE FULL PROJECT GUTENBERG LICENSE

PLEASE READ THIS BEFORE YOU DISTRIBUTE OR USE THIS WORK

To protect the Project Gutenberg-tm mission of promoting the free

distribution of electronic works, by using or distributing this work

(or any other work associated in any way with the phrase "Project

Gutenberg"), you agree to comply with all the terms of the Full Project

Gutenberg-tm License (available with this file or online at

http://gutenberg.org/license).

Section 1. General Terms of Use and Redistributing Project Gutenberg-tm

electronic works

1.A. By reading or using any part of this Project Gutenberg-tm

electronic work, you indicate that you have read, understand, agree to

and accept all the terms of this license and intellectual property

(trademark/copyright) agreement. If you do not agree to abide by all

the terms of this agreement, you must cease using and return or destroy

all copies of Project Gutenberg-tm electronic works in your possession.

If you paid a fee for obtaining a copy of or access to a Project

Gutenberg-tm electronic work and you do not agree to be bound by the

terms of this agreement, you may obtain a refund from the person or

entity to whom you paid the fee as set forth in paragraph 1.E.8.

1.B. "Project Gutenberg" is a registered trademark. It may only be

used on or associated in any way with an electronic work by people who

agree to be bound by the terms of this agreement. There are a few

things that you can do with most Project Gutenberg-tm electronic works

even without complying with the full terms of this agreement. See

paragraph 1.C below. There are a lot of things you can do with Project

Gutenberg-tm electronic works if you follow the terms of this agreement

and help preserve free future access to Project Gutenberg-tm electronic

works. See paragraph 1.E below.

1.C. The Project Gutenberg Literary Archive Foundation ("the Foundation"

or PGLAF), owns a compilation copyright in the collection of Project

Gutenberg-tm electronic works. Nearly all the individual works in the

collection are in the public domain in the United States. If an

individual work is in the public domain in the United States and you are

located in the United States, we do not claim a right to prevent you from

copying, distributing, performing, displaying or creating derivative

works based on the work as long as all references to Project Gutenberg

are removed. Of course, we hope that you will support the Project

Gutenberg-tm mission of promoting free access to electronic works by

freely sharing Project Gutenberg-tm works in compliance with the terms of

this agreement for keeping the Project Gutenberg-tm name associated with

the work. You can easily comply with the terms of this agreement by

keeping this work in the same format with its attached full Project

Gutenberg-tm License when you share it without charge with others.

1.D. The copyright laws of the place where you are located also govern

what you can do with this work. Copyright laws in most countries are in

a constant state of change. If you are outside the United States, check

the laws of your country in addition to the terms of this agreement

before downloading, copying, displaying, performing, distributing or

creating derivative works based on this work or any other Project

Gutenberg-tm work. The Foundation makes no representations concerning

the copyright status of any work in any country outside the United

States.

1.E. Unless you have removed all references to Project Gutenberg:

1.E.1. The following sentence, with active links to, or other immediate

access to, the full Project Gutenberg-tm License must appear prominently

whenever any copy of a Project Gutenberg-tm work (any work on which the

phrase "Project Gutenberg" appears, or with which the phrase "Project

Gutenberg" is associated) is accessed, displayed, performed, viewed,

copied or distributed:

This eBook is for the use of anyone anywhere at no cost and with

almost no restrictions whatsoever. You may copy it, give it away or

re-use it under the terms of the Project Gutenberg License included

with this eBook or online at www.gutenberg.org

1.E.2. If an individual Project Gutenberg-tm electronic work is derived

from the public domain (does not contain a notice indicating that it is

posted with permission of the copyright holder), the work can be copied

and distributed to anyone in the United States without paying any fees

or charges. If you are redistributing or providing access to a work

with the phrase "Project Gutenberg" associated with or appearing on the

work, you must comply either with the requirements of paragraphs 1.E.1

through 1.E.7 or obtain permission for the use of the work and the

Project Gutenberg-tm trademark as set forth in paragraphs 1.E.8 or

1.E.9.

1.E.3. If an individual Project Gutenberg-tm electronic work is posted

with the permission of the copyright holder, your use and distribution

must comply with both paragraphs 1.E.1 through 1.E.7 and any additional

terms imposed by the copyright holder. Additional terms will be linked

to the Project Gutenberg-tm License for all works posted with the

permission of the copyright holder found at the beginning of this work.

1.E.4. Do not unlink or detach or remove the full Project Gutenberg-tm

License terms from this work, or any files containing a part of this

work or any other work associated with Project Gutenberg-tm.

1.E.5. Do not copy, display, perform, distribute or redistribute this

electronic work, or any part of this electronic work, without

prominently displaying the sentence set forth in paragraph 1.E.1 with

active links or immediate access to the full terms of the Project

Gutenberg-tm License.

1.E.6. You may convert to and distribute this work in any binary,

compressed, marked up, nonproprietary or proprietary form, including any

word processing or hypertext form. However, if you provide access to or

distribute copies of a Project Gutenberg-tm work in a format other than

"Plain Vanilla ASCII" or other format used in the official version

posted on the official Project Gutenberg-tm web site (www.gutenberg.org),

you must, at no additional cost, fee or expense to the user, provide a

copy, a means of exporting a copy, or a means of obtaining a copy upon

request, of the work in its original "Plain Vanilla ASCII" or other

form. Any alternate format must include the full Project Gutenberg-tm

License as specified in paragraph 1.E.1.

1.E.7. Do not charge a fee for access to, viewing, displaying,

performing, copying or distributing any Project Gutenberg-tm works

unless you comply with paragraph 1.E.8 or 1.E.9.

1.E.8. You may charge a reasonable fee for copies of or providing

access to or distributing Project Gutenberg-tm electronic works provided

that

- You pay a royalty fee of 20% of the gross profits you derive from

the use of Project Gutenberg-tm works calculated using the method

you already use to calculate your applicable taxes. The fee is

owed to the owner of the Project Gutenberg-tm trademark, but he

has agreed to donate royalties under this paragraph to the

Project Gutenberg Literary Archive Foundation. Royalty payments

must be paid within 60 days following each date on which you

prepare (or are legally required to prepare) your periodic tax

returns. Royalty payments should be clearly marked as such and

sent to the Project Gutenberg Literary Archive Foundation at the

address specified in Section 4, "Information about donations to

the Project Gutenberg Literary Archive Foundation."

- You provide a full refund of any money paid by a user who notifies

you in writing (or by e-mail) within 30 days of receipt that s/he

does not agree to the terms of the full Project Gutenberg-tm

License. You must require such a user to return or

destroy all copies of the works possessed in a physical medium

and discontinue all use of and all access to other copies of

Project Gutenberg-tm works.

- You provide, in accordance with paragraph 1.F.3, a full refund of any

money paid for a work or a replacement copy, if a defect in the

electronic work is discovered and reported to you within 90 days

of receipt of the work.

- You comply with all other terms of this agreement for free

distribution of Project Gutenberg-tm works.

1.E.9. If you wish to charge a fee or distribute a Project Gutenberg-tm

electronic work or group of works on different terms than are set

forth in this agreement, you must obtain permission in writing from

both the Project Gutenberg Literary Archive Foundation and Michael

Hart, the owner of the Project Gutenberg-tm trademark. Contact the

Foundation as set forth in Section 3 below.

1.F.

1.F.1. Project Gutenberg volunteers and employees expend considerable

effort to identify, do copyright research on, transcribe and proofread

public domain works in creating the Project Gutenberg-tm

collection. Despite these efforts, Project Gutenberg-tm electronic

works, and the medium on which they may be stored, may contain

"Defects," such as, but not limited to, incomplete, inaccurate or

corrupt data, transcription errors, a copyright or other intellectual

property infringement, a defective or damaged disk or other medium, a

computer virus, or computer codes that damage or cannot be read by

your equipment.

1.F.2. LIMITED WARRANTY, DISCLAIMER OF DAMAGES - Except for the "Right

of Replacement or Refund" described in paragraph 1.F.3, the Project

Gutenberg Literary Archive Foundation, the owner of the Project

Gutenberg-tm trademark, and any other party distributing a Project

Gutenberg-tm electronic work under this agreement, disclaim all

liability to you for damages, costs and expenses, including legal

fees. YOU AGREE THAT YOU HAVE NO REMEDIES FOR NEGLIGENCE, STRICT

LIABILITY, BREACH OF WARRANTY OR BREACH OF CONTRACT EXCEPT THOSE

PROVIDED IN PARAGRAPH F3. YOU AGREE THAT THE FOUNDATION, THE

TRADEMARK OWNER, AND ANY DISTRIBUTOR UNDER THIS AGREEMENT WILL NOT BE

LIABLE TO YOU FOR ACTUAL, DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE OR

INCIDENTAL DAMAGES EVEN IF YOU GIVE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGE.

1.F.3. LIMITED RIGHT OF REPLACEMENT OR REFUND - If you discover a

defect in this electronic work within 90 days of receiving it, you can

receive a refund of the money (if any) you paid for it by sending a

written explanation to the person you received the work from. If you

received the work on a physical medium, you must return the medium with

your written explanation. The person or entity that provided you with

the defective work may elect to provide a replacement copy in lieu of a

refund. If you received the work electronically, the person or entity

providing it to you may choose to give you a second opportunity to

receive the work electronically in lieu of a refund. If the second copy

is also defective, you may demand a refund in writing without further

opportunities to fix the problem.

1.F.4. Except for the limited right of replacement or refund set forth

in paragraph 1.F.3, this work is provided to you 'AS-IS' WITH NO OTHER

WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO

WARRANTIES OF MERCHANTIBILITY OR FITNESS FOR ANY PURPOSE.

1.F.5. Some states do not allow disclaimers of certain implied

warranties or the exclusion or limitation of certain types of damages.

If any disclaimer or limitation set forth in this agreement violates the

law of the state applicable to this agreement, the agreement shall be

interpreted to make the maximum disclaimer or limitation permitted by

the applicable state law. The invalidity or unenforceability of any

provision of this agreement shall not void the remaining provisions.

1.F.6. INDEMNITY - You agree to indemnify and hold the Foundation, the

trademark owner, any agent or employee of the Foundation, anyone

providing copies of Project Gutenberg-tm electronic works in accordance

with this agreement, and any volunteers associated with the production,

promotion and distribution of Project Gutenberg-tm electronic works,

harmless from all liability, costs and expenses, including legal fees,

that arise directly or indirectly from any of the following which you do

or cause to occur: (a) distribution of this or any Project Gutenberg-tm

work, (b) alteration, modification, or additions or deletions to any

Project Gutenberg-tm work, and (c) any Defect you cause.

Section 2. Information about the Mission of Project Gutenberg-tm

Project Gutenberg-tm is synonymous with the free distribution of

electronic works in formats readable by the widest variety of computers

including obsolete, old, middle-aged and new computers. It exists

because of the efforts of hundreds of volunteers and donations from

people in all walks of life.

Volunteers and financial support to provide volunteers with the

assistance they need, is critical to reaching Project Gutenberg-tm's

goals and ensuring that the Project Gutenberg-tm collection will

remain freely available for generations to come. In 2001, the Project

Gutenberg Literary Archive Foundation was created to provide a secure

and permanent future for Project Gutenberg-tm and future generations.

To learn more about the Project Gutenberg Literary Archive Foundation

and how your efforts and donations can help, see Sections 3 and 4

and the Foundation web page at http://www.pglaf.org.

Section 3. Information about the Project Gutenberg Literary Archive

Foundation

The Project Gutenberg Literary Archive Foundation is a non profit

501(c)(3) educational corporation organized under the laws of the

state of Mississippi and granted tax exempt status by the Internal

Revenue Service. The Foundation's EIN or federal tax identification

number is 64-6221541. Its 501(c)(3) letter is posted at

http://pglaf.org/fundraising. Contributions to the Project Gutenberg

Literary Archive Foundation are tax deductible to the full extent

permitted by U.S. federal laws and your state's laws.

The Foundation's principal office is located at 4557 Melan Dr. S.

Fairbanks, AK, 99712., but its volunteers and employees are scattered

throughout numerous locations. Its business office is located at

809 North 1500 West, Salt Lake City, UT 84116, (801) 596-1887, email

business@pglaf.org. Email contact links and up to date contact

information can be found at the Foundation's web site and official

page at http://pglaf.org

For additional contact information:

Dr. Gregory B. Newby

Chief Executive and Director

gbnewby@pglaf.org

Section 4. Information about Donations to the Project Gutenberg

Literary Archive Foundation

Project Gutenberg-tm depends upon and cannot survive without wide

spread public support and donations to carry out its mission of

increasing the number of public domain and licensed works that can be

freely distributed in machine readable form accessible by the widest

array of equipment including outdated equipment. Many small donations

($1 to $5,000) are particularly important to maintaining tax exempt

status with the IRS.

The Foundation is committed to complying with the laws regulating

charities and charitable donations in all 50 states of the United

States. Compliance requirements are not uniform and it takes a

considerable effort, much paperwork and many fees to meet and keep up

with these requirements. We do not solicit donations in locations

where we have not received written confirmation of compliance. To

SEND DONATIONS or determine the status of compliance for any

particular state visit http://pglaf.org

While we cannot and do not solicit contributions from states where we

have not met the solicitation requirements, we know of no prohibition

against accepting unsolicited donations from donors in such states who

approach us with offers to donate.

International donations are gratefully accepted, but we cannot make

any statements concerning tax treatment of donations received from

outside the United States. U.S. laws alone swamp our small staff.

Please check the Project Gutenberg Web pages for current donation

methods and addresses. Donations are accepted in a number of other

ways including checks, online payments and credit card donations.

To donate, please visit: http://pglaf.org/donate

Section 5. General Information About Project Gutenberg-tm electronic

works.

Professor Michael S. Hart is the originator of the Project Gutenberg-tm

concept of a library of electronic works that could be freely shared

with anyone. For thirty years, he produced and distributed Project

Gutenberg-tm eBooks with only a loose network of volunteer support.

Project Gutenberg-tm eBooks are often created from several printed

editions, all of which are confirmed as Public Domain in the U.S.

unless a copyright notice is included. Thus, we do not necessarily

keep eBooks in compliance with any particular paper edition.

Most people start at our Web site which has the main PG search facility:

http://www.gutenberg.org

This Web site includes information about Project Gutenberg-tm,

including how to make donations to the Project Gutenberg Literary

Archive Foundation, how to help produce our new eBooks, and how to

subscribe to our email newsletter to hear about new eBooks.