This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org

Title: The Romance of the Reaper

Author: Herbert Newton Casson

Release Date: June 5, 2010 [eBook #32702]

Language: English

Character set encoding: ISO-8859-1

***START OF THE PROJECT GUTENBERG EBOOK THE ROMANCE OF THE REAPER***

| Note: |

Images of the original pages are available through

Internet Archive/American Libraries. See

http://www.archive.org/details/romanceofreaper00cass

or Core Historical Literature of Agriculture (CHLA), Albert R. Mann Library, Cornell University. See http://chla.library.cornell.edu/cgi/t/text/text-idx?c=chla;idno=2936480 |

Transcriber’s Note:

Underlined text indicated a correction made by the transcriber. Hover the cursor over the underlined text and the nature of the correction will appear.

A more detailed transcriber's note is at the end of the e-book.

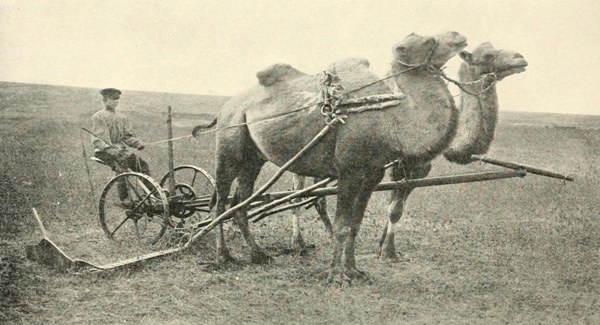

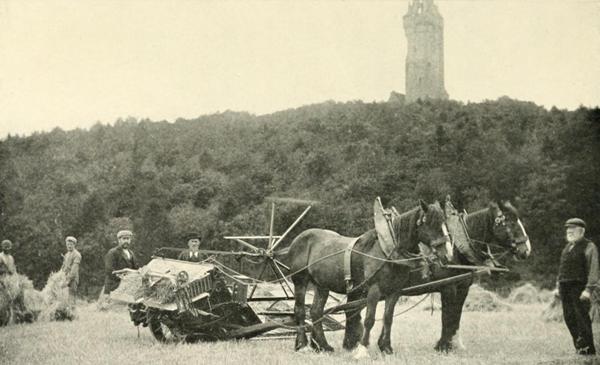

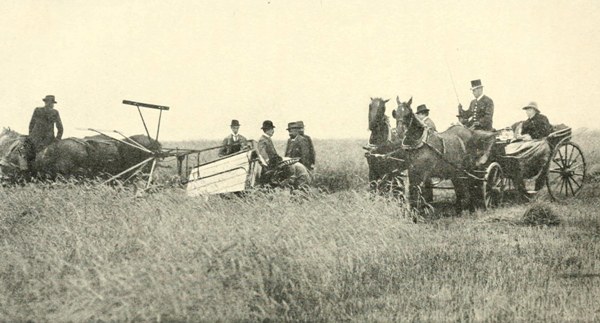

A CHICAGO MOWER IN SIBERIA

Author of “The Romance of Steel.”

Illustrated from Photographs

| “And he gave it for his opinion, that whoever could make two ears of corn, or two blades of grass, to grow upon a spot of ground where only one grew before, would deserve better of mankind, and do more essential service to his country, than the whole race of politicians put together.” —Dean Swift. |

NEW YORK

Doubleday, Page & Company

1908

Copyright, 1907, 1908, by

Everybody’s Magazine

Copyright, 1908, by

Doubleday, Page & Company

Published, May, 1908

ALL RIGHTS RESERVED, INCLUDING THAT OF TRANSLATION

INTO FOREIGN LANGUAGES, INCLUDING THE SCANDINAVIAN

TO THE FARMERS OF THE UNITED STATES

WHOSE ENERGY AND PROGRESSIVENESS HAVE

MADE THIS WONDER-STORY COME TRUE

This is the story of our most useful business. It is a medley of mechanics, millionaires, kings, inventors and farmers; and it is intended for the average man and woman, boy and girl. Although I have taken great pains to make this book accurate, I have written it in the fashion of romance, because it tells a story that every American ought to know.

The fact is that the United States owes much more to the Reaper than it owes to the factory or the railroad or the Wall Street Stock Exchange. Without the magical grain machinery that gives us cheap bread, the whole new structure of our civilisation, with all its dazzling luxuries and refinements, would be withered by the blight of Famine. This may sound strange and sensational to those who have been bred in the cities, but it is true.

The reaper has done more to chase the[Pg viii] wolf from the door—to abolish poverty and drudgery and hand-labour, than any other invention of our day. It has done good without any backwash of evil. It has not developed any new species of social parasite, as so many modern improvements have done. It has not added one dollar to the unclean hoard of a stock-gambler, nor turned loose upon the public a single idle millionaire.

The reaper is our best guarantee of prosperity. In spite of our periodical panics, which prove, by the way, that the men who provide us with banks are not as efficient as the men who provide us with bread, we are certain to rebound into prosperity and social progress as long as we continue to make three hundred harvesting machines every working day—one every two minutes. The rising flood of wheat is bound to submerge the schemers and the pessimists alike.

And it is the reaper, too, which has done most to make possible a nobler human race, by lessening the power of that ancient motive—the Search for Food. Every harvester that clicks its way through the yellow grain means more than bread. It means more[Pg ix] comfort, more travel, more art and music, more books and education. In this large fact lies the real Romance of the Reaper.

In gathering the material for this book I have been greatly assisted by Messrs. E. J. Baker, of the Farm Implement News; B. B. Clarke, of the American Thresherman; Ralph Emerson, of Rockford, Ill; C. W. Marsh, of De Kalb, Ill.; Edwin D. Metcalf and T. M. Osborne, of Auburn, N. Y., Henry Wallace, of Wallace’s Farmer, William N. Whiteley, of Springfield, Ohio; and the officials of the International Harvester Company, who made it possible for me to have free access to all of its works and to familiarise myself with its manner of doing business in this country and abroad.

Also, I take pleasure in reproducing the following editorial note from Everybody’s Magazine, in which four chapters of this book were first printed:

“President Roosevelt in his message of December 3rd said: ‘Modern industrial conditions are such that combination is not only necessary, but inevitable.... Corporation and labour union alike have come to stay. Each, if properly managed, is a source of good, and not evil.’ If capital combinations can be good, there must be some that are good. Would it not be a proper[Pg x] service to the American people to tell them of a trust that, while it had reaped the economical advantages of combination, had yet played fair with the public and with its competitors? Hence this story of the great Harvester combine. Before we began to publish Mr. Casson’s articles, we followed up his investigations with a thorough inquiry of our own, and we are bound to say that the business methods of this institution seem to conform to the highest standards of fair play and square dealing. The International Harvester combine is not a tariff trust. Its members surrendered dominance in their own business only when the trend of ‘modern industrial conditions’ and overstrenuous competition made combination ‘not only necessary, but inevitable.’ The inside history of the ‘Morganising’ of this group of fighters, as narrated here, is as humorous as it is fascinating.”

| PAGE | |||

| Preface | vii | ||

| CHAPTER | |||

| I. | The Story of McCormick | 3 | |

| II. | The Story of Deering | 48 | |

| III. | The International Harvester Company | 90 | |

| IV. | The American Harvester Abroad | 126 | |

| V. | The Harvester and the American Farmer | 161 |

| A Chicago mower in Siberia | Frontispiece |

| FACING PAGE | |

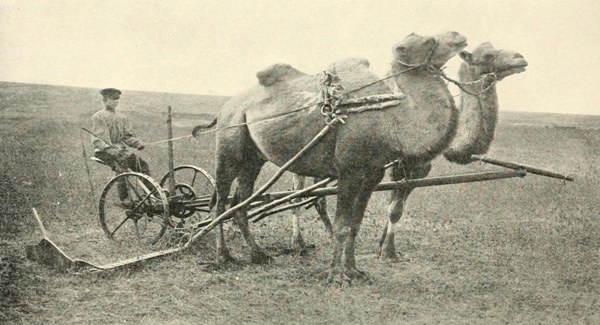

| Cyrus Hall McCormick | 12 |

| The Virginian birthplace of the McCormick reaper | 22 |

| A model of the first practical reaper | 27 |

| William Deering | 51 |

| William N. Whiteley | 53 |

| C. W. Marsh | 53 |

| John F. Appleby | 53 |

| E. H. Gammon | 53 |

| Asa S. Bushnell | 60 |

| Benjamin H. Warder | 60 |

| Hon. Thomas Mott Osborne | 60 |

| David M. Osborne | 60 |

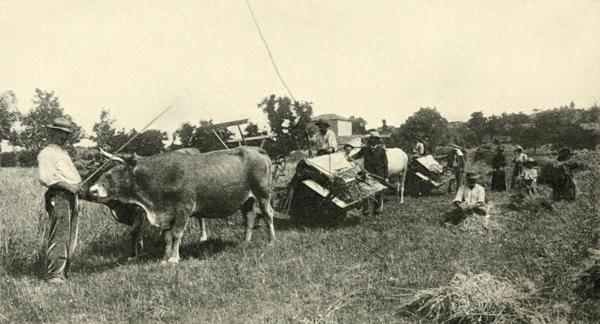

| A self-binder in Scotland, with the Wallace Monument in the background | 62 |

| Cyrus Hall McCormick, Jr. | 85 |

| [Pg xiv]Charles Deering | 85 |

| Harold McCormick | 92 |

| J. J. Glessner | 92 |

| W. H. Jones | 92 |

| James Deering | 92 |

| American self-binders on the estate of President Fallières, in France | 135 |

| King Alphonso of Spain driving an American seeder | 138 |

| Bismarck having his first view of an American self-binder | 147 |

| An American harvester at work in Argentina | 151 |

| Gathering in a Finland harvest | 154 |

| In the ancient fields of Algiers | 158 |

This Romance of the Reaper is a true fairy tale of American life—the story of the magicians who have taught the civilised world to gather in its harvests by machinery.

On the old European plan—snip—snip—snipping with a tiny hand-sickle, every bushel of wheat required three hours of a man’s lifetime. To-day, on the new American plan—riding on the painted chariot of a self-binding harvester, the price of wheat has been cut down to ten minutes a bushel.

“When I first went into the harvest field,” so an Illinois farmer told me, “it took ten men to cut and bind my grain. Now our hired girl gets on the seat of a self-binder and does the whole business.”

[Pg 4]This magical machinery of the wheat-field solves the mystery of prosperity. It explains the New Farmer and the miracles of scientific agriculture. It accounts for the growth of great cities with their steel mills and factories. And it makes clear how we in the United States have become the best fed nation in the world.

Hard as it may be for this twentieth century generation to believe, it is true that until recently the main object of all nations was to get bread. Life was a Search for Food—a desperate postponement of famine.

Cut the Kings and their retinues out of history and it is no exaggeration to say that the human race was hungry for ten thousand years. Even of the Black Bread—burnt and dirty and coarse, there was not enough; and the few who were well fed took the food from the mouths of slaves. Even the nations that grew Galileo and Laplace and Newton were haunted by the ghosts of Hunger. Merrie England was famine-swept in 1315, 1321, 1369, 1438, 1482, 1527, 1630, 1661, and 1709. To have enough to eat, was to the masses[Pg 5] of all nations a dream—a Millennium of Prosperity.

This long Age of Hunger outlived the great nations of antiquity. Why? Because they went at the problem of progress in the wrong way.

If Marcus Aurelius had invented the reaper, or if the Gracchi had been inventors instead of politicians, the story of Rome would have had a happier ending. But Rome said: The first thing is empire. Egypt said: The first thing is fame. Greece said: The first thing is genius. Not one of them said: The first thing is Bread.

In the Egyptian quarter of the British Museum, standing humbly in a glass case between two mummied Pharaohs, is a little group of farm utensils. A fractured wooden plough, a rusted sickle, two sticks tied together with a leathern thong, and several tassels that had hung on the horns of the oxen. A rummaging professor found these in the tomb of Seti I., who had his will on the banks of the Nile three thousand years ago. Egypt had a most elaborate government at that time. She had an army and navy, an art and literature. Yet[Pg 6] her bread-tools were no better than those of the barbarians whom she despised.

It is one of the most baffling mysteries of history, that agriculture—the first industry to be learned, was the last one to be developed. For thousands of years the wise men of the world absolutely ignored the problems of the farm. A farmer remained either a serf or a tenant. He was a stolid drudge—“brother to the ox.” Even the masterful old Pilgrim Fathers had no ploughs at all—nothing but hoes and sharp sticks, for the first twelve years of their pioneering.

Fifty-five years of American Independence went by before the first reaper clicked its way clumsily into fame, on a backwoods farm in Virginia. At that time, 1831, the American people were free, but they held in their hands the land-tools of slaves. They had to labour and sweat in the fields, with the crude implements that had been produced by ages of slavery. For two generations they tried to build up a prosperous Republic with sickles, flails, and wooden ploughs, and they failed.

There are men and women now alive who can remember the hunger year of 1837,[Pg 7] when there were wheat bounties in Maine and bread riots in New York City. Flour mills were closed for lack of wheat. Starving men fell in the streets of Boston and Philadelphia. Mobs of labourers, maddened by the fear of famine, broke into warehouses and carried away sacks of food as though they were human wolves. Even in the Middle West—the prairie paradise of farmers—many a family fought against Death with the serf’s weapon of Black Bread.

Enterprise was not then an American virtue. The few men who dared to suggest improvements were persecuted as enemies of society. The first iron ploughs were said to poison the soil. The first railroad was torn up. The first telegraph wires were cut. The first sewing-machine was smashed. And the first man who sold coal in Philadelphia was chased from the State as a swindler.

Even the railway was a dangerous toy. The telegraph was still a dream in the brain of Morse. John Deere had not invented his steel plough, nor Howe his sewing-machine, nor Hoe his printing-press. There were no stoves nor matches nor oil-lamps. Petroleum[Pg 8] was peddled as a medicine at a dollar a bottle. Iron was $75 a ton. Money was about as reliable as mining stocks are to-day; and all the savings in all the banks would not now buy the chickens in Iowa.

Our total exports were not more than we paid last year for diamonds and champagne. Chicago was a twelve-family village. There was no West nor Middle West. Not one grain of wheat had been grown in Minnesota, the Dakotas, Nebraska, Colorado, Kansas, Washington, Nevada, Idaho, Montana, New Mexico, Oregon, Utah, Arizona, Wyoming, Oklahoma or Texas.

The whole structure of civilisation, as we know it, was unbuilt; and most of its architects and builders were unborn or in the cradle. Spencer was eleven years of age; Virchow was ten; Pasteur nine; Huxley six; Berthelot four; and as for Haeckel, Carnegie, Morgan, Edison and their generation, they had not yet appeared in the land of the living.

Then came the Reaper.

This unappreciated machine, about which so little has been written, changed the face of the world. It moved the civilised nations[Pg 9] up out of the bread line. It made prosperity possible; and elevated the whole struggle for existence to a higher plane.

Life is still a race—always will be; but not for bread. The lowest prizes now are gold watches and steam yachts and automobiles. Even the hobo at the back door scorns bread, unless we apologise for it with meat and jam.

It is so plentiful—this clean, white bread, that it is scarcely an article of commerce any longer. In our hotels it is thrown in free of charge, as though it were a pinch of salt or a glass of water. There is no “penn’orth of bread” in the bill, as there was in Falstaff’s day.

Seven bushels of wheat apiece! That is what we eighty-five million people ate in 1906—twelve thousand million loaves of bread. Such a year of feasting was new in the history of the world. And yet we sent a thousand million dollars’ worth of food to other nations.

Suppose that bread were money, just for one day! What a lesson it would be on the social value of the reaper! Thirty loaves would be the day’s pay of a labourer—as[Pg 10] much as he could carry on his back. Two loaves for a cigar—three for a shave—five for a bunch of violets—forty for a theatre ticket—a hundred for a bottle of champagne! Is there anything cheaper than bread?

The reaper was America’s answer to Malthus—who scared England into abolishing the Corn Laws by his proclamation that “the ultimate check to population is the lack of food.” What would that well-meaning pessimist think were he now alive, if he were told that the human race is growing wheat at the rate of ten bushels a year per family? Or that Minnesota and the Dakotas (names that the world of his day had never heard) produce enough wheat to feed all the people of England?

The reaper was America’s answer to the world’s demand for democracy. Instead of bread riots and red flags and theories of an earthly paradise in which nobody worked but the Government, the United States invented a machine that gave democracy a chance. Instead of a guillotine to cut off the heads of the privileged people who ate too much, it produced a reaper that gave[Pg 11] everybody enough. This was not a complete answer, nor will there ever be one, to the riddle of liberty, equality and fraternity. But it was so much better than theories and riots that it helped to persuade twenty-five million immigrants to cross the ocean and become shareholders in the American Republic.

If it were possible to trace back a strand in the twisted thread of cause and effect, we would find that many a factory and steel-mill owes its origin to the flood of wheat-money that came to us from Europe in 1880 and 1881—every dollar of it made by the humble harvester.

Without this obedient slave of wood and steel, all our railroads and skyscrapers and automobiles could not save us from famine. If we had to reap our grain in the same way as the Romans did, it would take half the men in the United States to feed us on bread alone, to say nothing of the rest of the menu.

Like most great things, the reaper was born among humble people and in a humble way. It was crude at first and dogged by failure. No one man made it. It was the product of a hundred brains.

[Pg 12]The exact truth about its origin is not known and never will be. What few facts there were have been torn and twisted by the bitter feuds of the Patent Office. Every letter and document that exists is controversial. So I cannot say that the story, as I give it, is entirely true, but only that it is as near as I can get to the truth after six months of investigation.

There is evidence to show that Cyrus Hall McCormick completed a practical reaper in 1831, although the first reaper patent was taken out in 1833 by an inventive seaman named Obed Hussey, of Baltimore. The young McCormick did not secure his patent until 1834; but he had given a public exhibition in Virginia three years before.

There were nearly a hundred people who saw this exhibition. Not one of them is now alive; and the story as told by their children has many little touches of imagination. But in the main, it is very likely to be true.

It was in the fall of 1831 when Cyrus McCormick hitched four horses to his unwieldy machine and clattered out of the barnyard into a field of wheat nearby. [Pg 13]Horses shied and pranced at the absurd object, which was unlike anything else on the face of the earth. Dogs barked. Small boys yelled. Farmers, whose backs were bent and whose fingers were scarred from the harvest labour, gazed with contemptuous curiosity at the queer contraption which was expected to cut grain without hands.

CYRUS HALL McCORMICK

A little group of Negro slaves had spasms of uncomprehending delight in one corner of the field, not one of them guessing that “Massa” McCormick’s comical machine was cutting at the chains that bound their children. And a noisy crowd of white labourers followed the reaper up and down the field with boisterous enmity; for here was an invention which threatened to deprive them of the right to work—the precious right to work sixteen hours a day for three cents an hour.

The field was hilly and the reaper worked badly. It slewed and jolted along, cutting the grain very irregularly. Seeing this, the owner of the field—a man who was Ruff by name and rough by nature, rushed up to McCormick and shouted—“Here! This won’t do. Stop your horses! Your[Pg 14] machine is rattling the heads off my wheat.” “It’s a humbug,” bawled one of the labourers. “Give me the old cradle yet, boys!” exclaimed a round-shouldered farmer. The Negroes turned handsprings with delight; and the whole jeering mob gathered around the discredited machine.

Just then a fine-looking man rode up on horseback. The crowd made way as he came near, for they recognised him as the Honourable William Taylor—a conspicuous politician of that day.

“Pull down the fence and cross over into my field,” he said to young McCormick. “I’ll give you a fair chance to try your machine.”

McCormick quickly accepted the offer, drove into Taylor’s field, which was not as hilly, and cut the grain successfully for four or five hours. Although the United States had been established more than fifty years before, this was the first grain that had ever been cut by machinery. The Fathers of the Republic had eaten the bread of hand-labour all their lives, and never dreamed that the human race would ever find a better way.

[Pg 15]When he arrived home that evening, Cyrus thought that his troubles were over. He had reaped six acres of wheat in less than half a day—as much as six men would have done by the old-fashioned method. He had been praised as well as jeered at. “Your reaper is a success,” said his father, “and it makes me feel proud to have a son do what I could not do.”

Two Big Men had given him their approval—William Taylor and a Professor Bradshaw, of the Female Academy in the town of Lexington, Virginia. The professor, who was a pompous and positive individual, made a solemn investigation of the reaper, and then announced, in slow, loud, and emphatic tones—“That—machine—is—worth—a hundred—thousand—dollars.”

But if Cyrus McCormick hoped to wake up the following morning and find himself rich and famous, he was roughly disappointed. The local excitement soon died out, and in a few days the men in the village store were discussing Webster’s last speech against Nullification and Andrew Jackson’s war against the bankers. One old woman expressed the general feeling by saying that[Pg 16] young McCormick’s reaper was “a right, smart curious sort of thing, but it won’t come to much.”

McCormick was at this time a youth of twenty-two. He had been one of four pink, helpless babies, born in 1809, who became, each in his own world, the greatest leader of his day—Darwin, Gladstone, Lincoln, and McCormick. Like Lincoln, McCormick first learned to breathe in a long cabin—but in Virginia. He was bred from a fighting race. His father had wrenched a living from the rocks of Virginia for his family of nine. His grandfather had fought the English in the Revolution. His great-grandfather had been an Indian fighter in Pennsylvania; and his great-great-grandfather battled with a flint-lock against the soldiers of James II., at the siege of Londonderry.

The McCormick family, in 1809, had a good deal of what was then called prosperity. They had enough to eat—a roof that kept out the rain—1,800 acres of land, or near-land—three saw-mills—two flour-mills, and a distillery. They had very little money, because there was little to be had. In the whole United States there was barely as[Pg 17] much money as would buy half of the New York Subway.

The first American McCormicks had a thousand dollars or more when they resolved to leave Ireland, and they were Scotch enough to invest the whole amount in linen, which they sold at a high profit in Philadelphia. This capital enabled them to acquire a small stock of books, tools, and comforts, which were passed along from father to son.

Robert McCormick—the father of Cyrus, was himself a remarkable Virginian. He was quick with his hands in shaping iron and wood. In fact, he was fairly famous in his county as the inventor of a hemp-brake, a clover-sheller, a bellows and threshing machine. His mind was greedy for knowledge; and it was his habit, when the seven children were asleep, to explore into the mysteries of astronomy until his candle had flickered its life out. Twenty or more of his letters, which I have seen, are well written and with a fine use of bookish words.

The one persistent ambition of his life was to invent a reaper. It is also true, and[Pg 18] a titbit of a fact for those who believe in prenatal influences, that during the year in which Cyrus H. McCormick was born, his father first began the actual construction of a reaping machine.

Especially during the harvest months, the topic of conversation in the McCormick home was whether the dream of “reaping grain with horses” could ever come true. “Reaper,” was one of the first words that baby Cyrus learned to say; and his favourite play-toy, when he grew older, was the wreck of his father’s reaper that wouldn’t reap, which lay in rusty disgrace near the barn-door.

“Often I have seen Robert McCormick standing over his machine,” said one of his neighbours. “He would be studying and thinking, drawing down his under lip, as was his habit when he was puzzling over anything.” His friends ridiculed him for wasting so much time on a foolish toy, until he became half ashamed of it himself and quit his experimenting in the daytime. But at night, he and Cyrus hammered away in the little log workshop, as though they were a pair of conspirators.

[Pg 19]The romantic mystery of these midnight labours made an indelible mark on the brain of the boy Cyrus. He grew up to be serious and self-contained—quite unlike the boys of the neighbourhood. He was not popular and never cared to be.

“Cyrus was a natural mechanical genius from a child,” said John Cash, who worked on the McCormick farm. “He invented the best hillside plough ever used in this country. He and his father would lock themselves up in the shop and work for hours on a reaping machine. The neighbours thought they were both unbalanced to have the idea of cutting grain with horses.”

Cyrus was always busy making or mending some piece of machinery. He abhorred the drudgery of the farm; but delighted in any work that had an idea behind it. He surprised his teacher one morning by bringing to school a twenty-inch globe of wood, which turned on its axis as the earth does, and had the seas and continents outlined in ink.

“That young fellow is ahead of me,” said the amazed teacher.

At fifteen Cyrus had invented a new grain[Pg 20] cradle. At twenty-one he improved a machine which his father had made to break hemp. And at twenty-two this young country-boy, who had never seen a college, a city, or a railroad, constructed the first practical American reaper. It was a clumsy makeshift—as crude as a Red River ox-cart; but it was built on the right lines. It was not at all handsome or well made or satisfactory; but it was a reaper that reaped.

But McCormick soon discovered that it was not enough to invent a reaper. What the world needed was a man who was strong and dominating enough to force his reaper upon the unwilling labourers of the harvest fields.

Tenacity! Absolute indifference to defeat! The lust for victory that makes a man unconscious of the blows he gives or takes! This was what was needed, and what Cyrus McCormick possessed, to a greater degree, perhaps, than any other man in American history.

Tenacity! It was in his blood. Back of him was the hardiest breed that was ever mixed into the American blend—the pick of the Scots who fought their way to the[Pg 21] United States by way of Ireland. These Irish Scots, few as they were, led the way across the Alleghanies, founded Pittsburgh, made a trail to Texas, and put five Presidents in the White House.

And tenacity was bred, as well as born, into Cyrus McCormick. He went barefooted as a boy, not for lack of shoes, but to make him tough. “I want my boys to know how to endure hardship,” said his mother. He sat on a slab bench in the little log school house and learned to read from the Book of Genesis. He sang Psalms with forty verses, on Sundays, and sat as still as a graven image during the three-hour sermons, for his father was a Presbyterian of the old Covenanter brand.

So it came to pass that Cyrus McCormick clung to his reaper, as John Knox had to his Bible. “His whole soul was wrapped up in it,” said one of his neighbours. He grew as indifferent to the rough jokes of the farmers as Martin Luther was to the sneers of the village priests. The making of reapers became more than a business. It was a creed—a religion—a new eleventh commandment.

[Pg 22]By the time he was thirty, he had become a nineteenth century Mohammed, ready for a world crusade. His war-cry was—Great is the Reaper, and McCormick is its prophet.

Like Mohammed, he had his visions of future glory. On one occasion, while riding on horseback through a wilderness path, the dazzling thought flashed upon his mind—“Perhaps I may make a million dollars from this reaper.” This idea remained for years the driving wheel of his brain.

“The thought was so enormous,” he said afterward, “that it seemed like a dream—like dwelling in the clouds—so remote, so unattainable, so exalted, so visionary.”

Also, like Mohammed, he had a period of preparatory solitude. Soon after the first exhibition of his reaper, he bought a tract of land and farmed it alone, with two aged Negroes as housekeepers. Here he lived for more than a year with no companion except his reaper. He seemed at this time, too, to have resolved upon a life of celibacy, for I find in one of his letters an allusion to two young ladies of unusual attractiveness. “They are pretty, smart and rich,” he writes, “but alas, I have other business to attend to!”

THE VIRGINIAN BIRTHPLACE OF THE McCORMICK REAPER.

[Pg 23]The two things of which he stood most in need were money and cheaper iron. So, after thinking over the situation in his lonely cabin, he decided to build a furnace and make his own iron. His father and a neighbour joined him in the enterprise. They built the furnace, made the iron, and might have forgotten the reaper, if the financial earthquake of 1839 had not shaken them down into the general wreckage. The neighbour who had been made a partner signed over his property to his mother, and threw the whole burden of the bankruptcy upon the McCormick family, crushing them for a time into an abyss of debt and poverty.

Cyrus McCormick gave up everything he owned to the creditors—everything except his reaper, which nobody wanted. So far his vision of wealth was still a dream. Instead of being the possessor of a million, he was eight years older, and penniless.

There were four sons and three daughters in the family, and the nine of them slaved for five years to save the homestead from the auctioneer. Once the sheriff rode up with a writ, but was so deeply impressed with their[Pg 24] energy and uprightness that he rode away with the dreaded paper still in his pocket.

Up to this time Cyrus had not sold one reaper. As Mohammed preached for ten years without converting anyone except his own relatives, so Cyrus McCormick preached the gospel of the reaper for ten years without success. Then, in 1841, he sold two for $100 apiece. The next year seven daring farmers came to the McCormick homestead, each with $100 in his hands.

This brilliant success brought the whole family into line behind Cyrus, and the farm was transformed into a reaper factory. Twenty-nine machines, “fearfully and wonderfully made,” were sold in 1843, and fifty in 1844. There were troubles, of course. Some buyers failed to pay. A workman who was sent out on horseback to collect $300, ran away with horse, money and all. But none of these things moved Cyrus. At last, after thirteen years of delay, he was selling reapers.

Best of all, an order for eight had come from Cincinnati. These were the first reapers that were sold outside of Virginia. They were seen by the more enterprising[Pg 25] farmers of Ohio and created a sensation wherever they were used. Cyrus, who was now a powerful, broad-chested man of thirty-six, caught a glimpse of his opportunity and sprang to seize it. He saw that the time had come to leave the backwoods farm—forty miles from a blacksmith—sixty miles from a canal—one hundred miles from a railway. So, with $300 in his belt, he set out on horseback for the West.

Here he saw the prairies. To a man who had spent his life in a hollow of the Alleghanies, the West was a new world. It was the natural home of the reaper. The farmers of Virginia might continue forever to harvest their small, hilly fields by hand, but here—in this vast land ocean, with few labourers and an infinity of acres, the reaper was as indispensable as the plough. To reap even one of these new States by hand would require the whole working population of the country.

Also, in Illinois, McCormick saw what made his Scotch heart turn cold within him—he saw hogs and cattle feeding in the autumn wheat-fields, which could not be reaped for lack of labourers. Five million[Pg 26] bushels of wheat had grown and ripened—enough to empty the horn of plenty into every farmer’s home. Men and women, children and grandmothers, toiled day and night to gather in the yellow food. But the short harvest-season rushed past so quickly that tons of it lay rotting under the hoofs of cattle.

It was a puzzling problem. It was too much prosperity—a new trouble for farmers. In Europe, men had been plenty and acres scarce. Here, acres were plenty and men scarce. Ripe grain—the same in all countries, will not wait. Unless it is gathered quickly—in from four to ten days, it breaks down and decays. So, even to the dullest minds, it was clear that there must be some better way of snatching in the ripened grain.

The sight of the trampled wheat goaded McCormick almost into a frenzy of activity. He rode on horseback through Illinois, Wisconsin, Missouri, Ohio, and New York, proclaiming his harvest gospel and looking for manufacturers who would build his reapers. From shop to shop he went with the zeal of a Savonarola.

A MODEL OF THE FIRST PRACTICAL REAPER

One morning, in the little town of[Pg 27] Brockport, New York, he found the first practical men who appreciated his invention—Dayton S. Morgan and William H. Seymour. Morgan was a handy young machinist who had formed a partnership with Seymour—a prosperous store-keeper. They listened to McCormick with great interest and agreed to make a hundred reapers. By this decision they both later became millionaires, and also entered history as the founders of the first reaper factory in the world.

Altogether, in the two years after he left Virginia, McCormick sold 240 reapers. This was Big Business; but it was only a morsel in proportion to his appetite. Neither was it satisfactory. He found himself tangled in a snarl of trouble because of bad iron, stupid workmen, and unreliable manufacturers. He cut the Gordian knot by building a factory of his own at Chicago.

This was one of the wisest decisions of his life, though at the time it appeared to be a disastrous mistake. Chicago, in 1847, showed no signs of its present greatness. As a city, it was a ten-year-old experiment, built in a swamp, without a railway or a canal. It was ugly and dirty, with a river[Pg 28] that ran in the wrong direction; but it was busy. It was the link between the Mississippi and the Great Lakes—a central market where wheat was traded for lumber and furs for iron. It had no history—no ancient families clogging up the streets with their special privileges. And best of all, it was a place where a big new idea was actually preferred to a small old one.

Chicago did not look at McCormick with dead eyes and demand a certified cheque from his ancestors. It sized him up in a few swift glances and saw a thick-set, ruddy man, with the physique of a heavy-weight wrestler, dark hair that waved in glossy furrows, and strong eyes that struck you like a blow. It glanced at his reaper and saw a device to produce more wheat. More wheat meant more business, so Chicago said ——

“Glad to see you. You’re the right man and you’re in the right place. Come in and get busy.” William B. Ogden, the first Mayor of Chicago, listened to his story for two minutes, then asked him how much he wanted for a half interest. McCormick had little money and no prestige. Ogden[Pg 29] had a surplus of both. So a partnership was arranged, and the new firm plunged toward prosperity by selling $50,000 worth of reapers for the next harvest.

At last there had come a break in the clouds, and McCormick found his path flooded with sunshine. He was no longer a wanderer in the night. He was the Reaper King—the founder of a new dynasty. As soon as possible he bought out Ogden, and thenceforth established a one-man business. By 1851 he was making a thousand reapers a year, and owned one-tenth of the million dollars he had dreamed of in the Virginian wilderness.

At this point his life changes. His pioneer troubles are over. There are no more thousand-mile rides on horseback—no more conflicts with jeering crowds—no more smashing of reapers by farm labourers. The repeal of the Corn Laws in England had opened up a new market for our wheat, and the discovery of gold in California was booming the reaper business by making money plentiful and labour scarce.

Suddenly, McCormick looked up from his work in the factory, and saw that he was[Pg 30] not only rich, but famous. One of his reapers had taken the Grand Prize at a World’s Fair in England. Even the London Times, which had first ridiculed his reaper as “a cross between an Astley chariot, a wheelbarrow and a flying machine,” was obliged to admit, several days later, that “the McCormick reaper is worth the whole cost of the Exposition.”

Seventeen years later, on the imperial farm, near Paris, Napoleon III. descended from his carriage and fastened the Cross of the Legion of Honour upon McCormick’s coat. There was a picture that some American-souled artist, when we have one, will delight to put on canvas. How splendid was the contrast, and how significant of the New Age of Democracy, between the suave and feeble Emperor, enjoying the sunset rays of his inherited glory, and the strong-faced, rough-handed Virginian farmer, who had built up a new empire of commerce that will last as long as the human race eats bread!

From first to last, the stout-hearted old Reaper King received no favours from Congress or the Patent Office. He built[Pg 31] up his stupendous business without a land grant or a protective tariff. By the time that his Chicago factory was ten years old, he had sold 23,000 reapers, and cleared a profit of nearly $1,300,00. The dream of his youth had been realised, and more. All told, in 1859, there were 50,000 reapers in the United States, doing the work of 350,000 men, saving $4,000,000 in wages, and cramming the barns with 50,000,000 bushels of grain.

So, on his fiftieth birthday, the battle-scarred McCormick found himself a millionaire. He was also married, having fallen in love with Miss Nettie Fowler, of New York, a young lady of unusual beauty and ability. No history of the reaper can be complete without a reference to this remarkable woman, who has been for fifty years, and is to-day, one of the active factors in our industrial development. No important step has ever been taken either by her husband or her three sons, until it has received her approval. And Mrs. McCormick has been much more than a mere adviser. Her exact memory and keen grasp of the complex details of her husband’s[Pg 32] business made her practically an unofficial manager. She suggested economies at the factory, stopped the custom of closing the plant in midsummer, studied the abilities of the workmen, and on several occasions superintended the field-trials in Europe.

Chicago may not know it, but it is true, that its immense McCormick factory owes its existence to Mrs. McCormick. After the Big Fire of 1871, when his $2,000,000 plant was in ruins, McCormick concluded to retire. He still had a fortune of three or four millions and he was sixty-two years of age. His managers advised him not to rebuild, because of the excessive cost of new machinery.

As soon as the fiery cyclone had passed, he and his wife drove to the wrecked factory. Several hundred of the workmen gathered about the carriage, and the chief engineer, acting as spokesman, said: “Well, Mr. McCormick, shall we start the small engine and make repairs, or shall we start the big engine and make machines?”

Mr. McCormick turned to his wife and said, “Which shall it be?” It was a breathless moment for the workmen.

[Pg 33]“Build again at once,” said Mrs. McCormick. “I do not want our boy to grow up in idleness; I want him to work, as a useful citizen, and a true American.”

“Start The Big Engine,” said McCormick. The men threw their hats in the air and cheered. They sprang at the smoking debris, and began to rebuild before the cinders were cold.

Such was the second birth of the vast factory which, in its sixty years, has created fully 5,000,000 harvesters, and which is now so magically automatic that, with 6,000 workmen, it can make one-third of all the grain-gathering machinery of the world.

Practically nothing has been written about McCormick from the human nature side. He was one of those Cromwellian men who can only be appreciated at a distance. He was too absorbed in his work to be congenial and too aggressive to be popular. He shouldered his way roughly against the slow-moving crowd; and the people whom he thrust out of his way naturally did not consider the importance of his life-task.

Most of the really great men of his day were his friends—Horace Greeley, for[Pg 34] instance, and Peter Cooper, Junius Morgan, Abram S. Hewitt, Cyrus W. Field, and Ferdinand De Lesseps. But among the men of his own trade he stood hostile and alone.

“McCormick wants to keep the whole reaper business to himself. He will not live and let live,” said his competitors. And they had reason to say so. He did want to dominate. He wanted to make all the harvesting machines that were made—not one less. He was not at all a modern “community-of-interest” financier. He was a man of an outgrown school—a consistent individualist, not only in business, but in politics and religion as well. There was no compartment in his brain for mergers and combines—for theories of government ownership—for Higher Criticism and the new theology. He was a Benjamin Franklin commercialist, a Thomas Jefferson Democrat, and a John Knox Presbyterian.

He had worked harder to establish the reaper business than any other man. He was making reapers when William Deering was five years old, and before Ralph Emerson and “Bill” Whiteley were born. He[Pg 35] had graduated into success through a fifteen-year course in failure. The world into which he was born was as hostile to him as the Kentucky wilderness was to Daniel Boone or the Atlantic Ocean to Columbus. He was hard-fibred, because he had to be. He was the thin end of the wedge that split into fragments the agricultural obstacle to social progress.

One careless writer of biographies has said that McCormick began at the foot of the ladder. This is not correct. When he began, there was no ladder. He had to build it as he climbed.

The first man who gave battle to McCormick was an erratic genius named Obed Hussey, who, as we have seen, secured a reaper patent in 1833. No two men were ever more unlike than Hussey and McCormick. Hussey was born in Nantucket; and he had roamed the frozen North as a whaling seaman. He was inventive, poetic, and as whimsical as the weather. His delight was in working out some mechanical problem. His first invention was a machine to make pins. Soon afterward, while he was living in Cincinnati, [Pg 36]constructing a machine to mould candles, a friend said to him:

“Hussey, why don’t you invent a machine to reap grain?”

“Are there no such machines?” he asked in surprise.

“No,” said his friend, “and whoever can invent one will make a fortune.”

Hussey forsook his candle machine, set to work upon a reaper, and within a year had one in the fields. Then came a twenty-five-year war with McCormick, which was waged furiously in the Patent Office, the courts, and a hundred wheat-fields. Hussey won the opening battle by arriving first at the Patent Office, although his machine, as claimed by McCormick, was two years younger. By 1841 Hussey had sold reapers in five states, and ten years later he shared the honours with McCormick at the London World’s Fair.

Both machines were very crude and unsatisfactory. Hussey’s had a better cutting apparatus and McCormicks was more complete. In the long run, each adopted the devices of the other, and a better reaper was evolved. Before many years, it became[Pg 37] apparent that Hussey was outclassed. By 1858 he was left so far behind that he lost his interest in reapers and invented a steam-plough.

His first machine was “really a mower,” says Merritt Finley Miller, one of the two professors who have written on harvesting machinery. It lacked the master-wheel, the reel and the divider, without which the grain cannot be rightly handled. When Hussey gave up the contest, his invention was bought for $200,000 by William F. Ketchum and others, who adapted it into a mowing-machine.

“Hussey was a very peculiar man,” said Ralph Emerson. “His machine was fairly good, but it was a failure in the market, because he would not put on a reel. He refused to do this, saying he did not invent a reel, and it would be a falsehood if he put one on. He said that it was contrary to his principles to sell anything that he had not invented.

“On one occasion I went to buy a shop licence from him. ‘Have you a thousand dollars in your pocket?’ he asked. ‘No,’ said I. ‘Can you get me three thousand[Pg 38] dollars by daylight to-morrow morning?’ ‘No,’ I answered, ‘but I can get it by noon.’ ‘Well,’ said Hussey, ‘I want to be very reasonable with you. If you’ll pay me one thousand dollars before you leave the house, or twenty-five hundred dollars before daybreak to-morrow, I’ll sell you a licence. Otherwise, it will cost you twelve thousand dollars.’

“Several days later I paid him twelve thousand dollars, and as he handed me the licence, he said—‘Now, don’t say that I never offered you this for a thousand dollars.’”

Hussey’s adventurous life was snapped short by a tragic death. While he was on a train at Baltimore, a little girl was crying for a drink of water. The kind-hearted old sailor-mechanic got off the train, brought her a glass of water, and on his way to return the glass, he slipped and fell between the moving wheels.

Of all the men who fought McCormick in the earlier days, I found only two now alive—Ralph Emerson, of Rockford, and William N. Whiteley, of Springfield, Ohio. Both of these men to-day generously give the old warrior his due.

[Pg 39]“McCormick was the first man to make the reaper a success in the field,” said Whiteley, the battle-worn giant of Ohio, where I found him still at work. “McCormick was a fighter—a bulldog, we called him; but those were rough days. The man who couldn’t fight was wiped out.”

Ralph Emerson, now one of the most venerable figures in Illinois, rose from a sick-bed against his doctors orders, so that he might be magnanimous to his former antagonist.

“McCormick’s first reapers were a failure,” said he, speaking slowly and with great difficulty; “and he owed his preëminence mainly to his great business ability. His enemies have said that he was not an inventor, but I say that he was an inventor of eminence.”

So, as the gray haze of years enables us to trace the larger outlines of his work, we can see that McCormick was especially fitted for a task which, up to his day, had never been done, and which will never need to be repeated during the lifetime of our earth. He was absolutely mastered by one idea, as wholly as Copernicus or Columbus.[Pg 40] His business was his life. It was not accidental, as with Rockefeller, nor incidental, as with Carnegie. On one occasion when a friend was joking him about his poor judgment in outside affairs, he whirled around in his chair and said emphatically: “I have one purpose in life, and only one—the success and widespread use of my machines. All other matters are to me too insignificant to be considered.”

He made money—ten millions or more. But a hundred millions would not have bribed him to forsake his reaper. It was as much a part of him as his right hand. In several of his business letters he writes as though he had been a Hebrew prophet, charged with a world-message of salvation.

“But for the fact that Providence has seemed to assist me in all our business,” he writes on one critical occasion, “it has at times seemed that I would almost sink under the weight of responsibility hanging upon me. I believe the Lord will help us out.”

Not that he left any detail to Providence to which he could personally attend. He was a Puritan of the “trust-in-God-and-keep-your-powder-dry” species. A little farther[Pg 41] down, in this same letter, he writes—“Meet Hussey in Maryland and put him down.”

The fountain-springs of his life were wholly within. He acted from a few basic, unchangeable convictions. If public opinion was with him, he was gratified; if it was against him he thought no more of it than of the rustling of the trees when the wind blew.

“When anyone opposed his plans and showed that they were impossible,” said one of his superintendents, “I noticed that he never argued; he just went on working.”

His brain had certain subjects distinctly mapped out. What he knew—he knew. He had no hazy imaginings. He lived in a black and white world and abhorred all half-tints. He was right—always right, and the men who opposed him were Philistines and false prophets, who deserved to be consumed by sudden fire from Heaven.

It was this inward spiritual force that made him irresistible. Small men shrivelled up when he spoke to them.

“The exhibition of his powerful will was at times actually terrible,” said one of his attorneys. “If any other man on this earth[Pg 42] ever had such a will, certainly I have not heard of it.”

Small and easy undertakings had no interest for him whatever. It was the impossibility that enraged and inspired him. At the sight of an obstacle in his path, he rushed forward like a charge of cavalry. When the Civil War was at its height, he and Horace Greeley, who was very similar to him in this respect, actually believed that they could stop it. They had several long conferences in the Fifth Avenue Hotel, New York, and McCormick went so far in 1864 as to prepare a statement of principles which he fully believed would restore peace and harmony between the North and the South.

Such was this massive, unbendable American. As we shall see, he was far from being the only strong, picturesque figure in the industry. But it would make many a book to tell in detail the effect of his life work upon the progress of the United States. It was a New World, truly, that had been created, alike for the people of the farms and of the cities, in the year that the victorious old Reaper King was carried to his grave, with a sheaf of wheat on his breast.

[Pg 43]What if there had been no reapers, and no hunger-insurance, and no cheap bread! What sort of an American nation would we have, if we were still using such food-implements as the sickle and the flail?

Could we have swung through four years of Civil War, as we did, without famine or national insolvency?

Could the West have risen toward its present greatness if its billion acres had to be harvested by hand?

Could the railways alone, which produce nothing, have given us more food for less work—the first necessity of a civilised democracy?

Would our manufacturers be creating new wealth at the rate of sixteen billions a year, if the reaper had not enriched the farmers and sent half the farm-hands into the factories?

And our towering cities—two of them more populous than the thirteen colonies were, how large would they be and how prosperous if bread were twenty cents a pound?

As Seward once said, it was the reaper that “pushed the American frontier [Pg 44]westward at the rate of thirty miles a year.” Most of the western railways were built to the wheat; and it was wheat money that paid for them. The reaper clicked ahead of the railroad, and civilisation followed the wheat, from Chicago to Puget Sound, just as the self-binder is leading the railroad to-day—three hundred miles in front in Western Canada, and eight hundred miles in Siberia. Even so unyielding a partisan of the railroads as Marvin Hughitt admitted to me that “the reaper has not yet received proper recognition for its development of the West.”

During the Civil War the reaper was doing the work of a million men in the grain-fields of the North. It enabled a widow, with five sons, to send them all to the front, and yet gather every sheaf into the barn. It kept the wolf from the door, and more—it paid our European debts in wheat. It wiped out all necessity for Negro labour in the wheat States, just as a cotton-picker will, some day, in the South.

“The reaper is to the North what the slave is to the South,” said Edwin M. Stanton in 1861. “It releases our young[Pg 45] men to do battle for the Union, and at the same time keeps up the supply of the nation’s bread.”

Lincoln called out every third man, yet the crops increased. Europeans could not believe it. They heard in 1861 that we were sending three times as much wheat to England as we had ever done before. They shook their heads and said—“Another American story!” when they were told that we were supporting two vast armies and yet selling other nations enough grain to feed thirty-five million people. Naturally, no country that clung to the sickle and flail could be convinced of such a preposterous miracle.

After the war, the mighty river of wheat that flowed from the West became so wide and so deep that it poured a yellow stream into every American home. It began to turn the wheels of fourteen thousand flour-mills. Rich cities sprang up, like Aladdin palaces, beside its banks—Chicago, St. Louis, Cincinnati, Milwaukee, Minneapolis, Kansas City, St. Paul, Omaha, Des Moines. All of these, and a hundred lesser ones, were nourished into prosperity by the rising[Pg 46] current of reaper-wheat, as it moved from the Mississippi to the sea.

By 1876 we had become the champion food-producers of the world. A Kansas farmer was raising six bushels of wheat with as little labour as an Italian spent to produce one. And there was one doughty Scot—Dalrymple of Dakota, who was guillotining more wheat with four hundred labourers and three hundred harvesters, than five thousand peasants could garner by hand.

Inevitably, the American Farmer became a financier. In 1876 he earned twenty-four per cent. He had twenty-seven hundred millions to spend. By 1880 he had begun to buy so much store goods that the United States was able to write a Declaration of Industrial Independence. Steadily he has grown richer and wiser, until now he is the owner of a billion-acre farm, worth thirty dollars an acre, operated with farm machinery that cost him $900,000,000 and producing, in a single year, seven thousand times the value of a millionaire.

Such, in one country, is the amazing result which the Reaper has helped to create.[Pg 47] And this is not all. It is now more necessary to the human race than the railway. It is fighting back famine in fifty countries. Its click has become the music of an International Anthem. The nations are feeding each other, in spite of their tariffs and armies. The whole world takes dinner at the one long table; and the fear of hunger is dying out of the hearts of men; and the prayer of the Christian centuries is answered—“Give us this day our daily bread.”

Fifty years ago two young farmers named Marsh were cutting grain near DeKalb, Illinois. They were too intelligent—too American—to be fond of work for work’s sake. And of all their drudgery, the everlasting stooping over bundles to bind them into sheaves galled them most. Such back-breaking toil, they thought, might be well enough for kangaroos, but it certainly was not suitable for an erect biped, like man.

“If I didn’t have to walk from bundle to bundle, and hump myself like a horseshoe, I could do twice as much work,” said one of the brothers.

“Well,” said the other, “why can’t we fix a platform on the reaper, and have the grain carried up to us?”

It was a brilliant idea and a new one. Neither of the young fellows had ever seen a reaper factory; but they were handy and[Pg 49] self-reliant. By the next autumn they were in the field with their new machine, and as they had expected, they bound the grain twice as quickly as they had the year before.

So was born the famous Marsh harvester, which proved to be the half-way mark in the evolution of the grain-reaping machine. It was the child of the reaper and the parent of the self-binder. It cut in two the cost of binding grain. But it did more than this—it gave the farmer his first chance to stand erect, and forced him to be quick, for the two men who stood on the harvester were compelled to bind the grain as fast as it was cut. Thus it introduced the factory system, one might say, into the harvest-field. For the first time the Big Minute made its appearance on the farm.

The Marsh boys, never dreaming that they had helped to change the destinies of nations, took out a flimsy patent on their invention, and went on with their farm work. Two summers later, as they were at work with it, their home-made harvester broke down. A farmer from Plano, near DeKalb, named Lewis Steward, was riding by. He stopped, and, being a man of unusual abilities[Pg 50] and discernment, he at once saw the value of the Marsh machine, even in its disabled state.

“Boys, you’re on the right track,” he said. “If you can run your machine ten rods, it can be made to run ten miles. It is superior to anything now in use.”

Thus cheered, the Marsh brothers went to Plano, arranged a partnership with a clever mechanic named John F. Hollister, and began to make harvesters for sale. To their surprise the new machine was not welcomed. It was received with an almost unanimous roar of disapproval. It was a “man-killer,” said the farmers. Now, the Marsh brothers were quick, nervous men, and they had built a machine to suit themselves. But it was undeniably too fast and nerve-racking for most farmers. The labourers refused to work with it.

The Marshes overcame the obstacle in a very ingenious way. They put girls on their harvesters, instead of men. Not ordinary girls, to be sure, but vigorous German maidens, who were swift and skilful binders. Also, they had well-trained men, disguised as hoboes, who mingled in the crowd around [Pg 51]the harvester at times of demonstration, and volunteered to get aboard of it. To see a girl or a “Weary Willie” binding grain on the new machine shamed the labourers into a surrender, and in 1864 two dozen of the Marsh harvesters were sold.

WILLIAM DEERING

In this year one of the Marshes performed a feat that seemed more appropriate for a circus than for a grain-field. Riding alone on a harvester, he bound a whole acre of wheat in fifty-five minutes. Little was heard of this amazing achievement at the time, as the national mind was distraught over the death grapple of Grant and Lee in Virginia.

But there was one quick-eyed man in Chicago named Gammon who heard of the event, and acted upon it so promptly that the goddess of prosperity picked him out as one of her favourites. Several years before, Gammon had been a Methodist preacher in Maine. A weak throat had brought his sermons to an end, and he became a reaper salesman in Chicago. He was shrewd and honest, and in 1864 his profits were very nearly forty thousand dollars.

When he heard that W. W. Marsh had bound an acre of grain in fifty-five minutes,[Pg 52] on a new-fangled reaper, he caught the next train for DeKalb, and bought a licence to manufacture Marsh harvesters. He took in a partner—J. D. Easter—and the business inched ahead slowly, until in 1870 the sales rose to a thousand. Easter and Gammon were driving their small factory ahead at full speed. If they only could secure enough capital, they would surprise the world.

One evening, while Gammon was worrying over this lack, he heard a gentle knock at the door. He opened it to one of his old acquaintances from Maine.

“Mr. Gammon,” said the visitor, “I have about forty thousand dollars of spare money that I would like to invest in Chicago real estate, and I want your advice as to the best place to buy.”

“What!” said Gammon, springing to his feet in delight. “Have you money to invest? Give it to me and I’ll pay you ten per cent. or make you a partner in the best business in Illinois.”

The visitor, whose name was William Deering, knew nothing whatever about reapers nor wheat-fields. He had gained a [Pg 53]fair-sized fortune in the wholesale dry-goods business. But he was a Methodist and had confidence in the ex-reverend E. H. Gammon; so he passed his $40,000 across the table and the next day went home to Maine.

|  |

| WILLIAM N. WHITELEY Photo by Baumgardner, Springfield, O. |

C. W. MARSH |

|  |

| JOHN F. APPLEBY Photo by Rice, Milwaukee |

E. H. GAMMON |

Two years later Deering came down to see how Gammon and the $40,000 were faring. The books showed a profit of $80,000. So Deering requested that he be made a partner. A year afterward Gammon fell sick and begged Deering to come to Illinois and manage the business. Deering consented to be manager for one year only; but Gammon’s sickness continued.

“So,” said William Deering, who told me this story, “in that way I got into the harvester business and had to stay in. But I did not even know, at that time, the appearance of our own machine.”

Deering’s competitors at first called him a greenhorn. But they forgot that he was the only one among them who had been trained in the art of business. He was already a veteran—a prize winner—in the game of finance. For thirty years, ever since he began to earn $18 a month in his father’s woolen mills, he had been a man of affairs. He had,[Pg 54] in fact, established the wholesale dry-goods house of Deering, Milliken & Co., which still stands as one of the largest of its kind. This training was all the more valuable an asset because of the conditions that prevailed when Deering entered the harvester trade. For he arrived in that worst of all years in the last century—1873. The Jay Cooke panic was at its height. The proudest corporations were falling like grass before a mower. It was a year of dread and paralysis. But Deering faced these disadvantages with ability, with sheer, dogged persistence, and with business training. In seven years he had become one of the greatest of the harvester kings, and was leading them all up to a higher level.

We shall understand more clearly what this means if we consider the state of the trade at the time of his entrance. A man of peaceable and kindly inclinations, Deering was dragged into a business that was as turbulent as a bull-fight. For as the reaper had evolved, it had become a bone of contention, and it remained so from the first patent to the last. The opening battle was fought by McCormick and Hussey, each claiming to[Pg 55] have been the Christopher Columbus of the business. After the gold-rush of 1849 new types of reapers sprang up on all sides. The crude machines that merely cut the grain were driven out by others that automatically raked the cut grain into bundles. These were soon followed by a combined reaper and mower, which held the field until the Marsh harvester was invented, as we have seen, at the close of the Civil War.

Among these different types of reapers, and the numerous variations of each type, the bitterest rivalries prevailed. There was no pool, no “gentlemen’s agreement,” no “community of interest.” Indeed, the “harvester business” was not business. It was a riotous game of “Farmer, farmer, who gets the farmer?” The excited players cared less for the profits than for the victories. As fast as they made money, they threw it back into the game. Mechanics became millionaires, and millionaires became mechanics. The whole trade was tense with risk and rivalry and excitement, as though it were a search for gold along the high plateaus of the Rand. And this in spite of the fact that, with the exception of McCormick,[Pg 56] Osborne, and Whiteley, the men who came to be known as reaper kings were not naturally fighters. No business men were ever gentler than Deering, Glessner, Warder, Adriance, and Huntley. But the making of reapers was a new trade. It was like a vast, unfenced prairie, where every settler owned as much ground as he could defend.

Each step ahead meant a struggle for patents. Whoever built a reaper had to defend himself in the courts as well as approve himself in the harvest-fields. Cyrus H. McCormick, especially, as William Deering soon learned, wielded the Big Stick against every man who dared to make reapers. He was the old veteran of the trade, and he gave battle to his competitors as though they were a horde of trespassers. He was their common enemy, and the reaper money that was squandered on lawsuits brought a golden era of prosperity to the lawyers.

Some of these patent wars shook the country with the crash of hostile forces. The tide of battle rolled up to the Supreme Court and even into the halls of Congress. Once, in 1855 when McCormick charged full tilt upon John H. Manny, who was making[Pg 57] reapers at Rockford, Illinois, a three-year struggle began that was the most noted legal duel of the day.

McCormick, to make sure of his victory, went into the fight with a battery of lawyers whom he thought invincible—William H. Seward, E. M. Dickerson, and Senator Reverdy Johnson. Manny made a giant effort at self-defence by hiring Abraham Lincoln, Edwin M. Stanton, Stephen A. Douglas, Peter H. Watson, George Harding, and Congressman H. Winter Davis.

From first to last it was a lawyers’ battle, and McCormick was finally defeated by Stanton, who made an unanswerably eloquent speech. For this speech Stanton received $10,000, and Lincoln, who had made no speech at all, was given $1,000. Yet, in the long run, the man who profited by this lawsuit was Lincoln; for it was this money that enabled him to carry on his famous debate with Douglas, and thus made him the inevitable candidate of the Republican Party.

McCormick’s most disastrous lawsuit was with D. M. Osborne and the Gordon brothers, of Rochester. In 1875 the Gordons had[Pg 58] invented an attachment for a wire self-binder, and in a careless moment McCormick had signed a contract promising to make these self-binders and to pay $10 royalty on every machine. Then a man named Withington appeared with a much better self-binder. McCormick at once began to make the Withington machine and was sued by the Gordons.

At this time McCormick was over seventy years of age, and crippled with rheumatism; but he believed that the Gordons had deceived him and he fought them sternly as long as he lived. After his death, his eldest son, Cyrus, consented to a compromise, whereby Osborne, who was owner of a share in the Gordon concern, and the Gordons were to be paid $225,000. But in order to impress upon them the enormity of this amount, he prepared the money for them in small bills. When they called at the McCormick office in Chicago, they were taken to a small room on the top floor and shown a great pyramid of green currency.

“There is your money,” said McCormick’s lawyer. “Kindly count it and see if it is not a quarter of a million dollars.”

[Pg 59]The three men gasped with mingled ecstasy and consternation. “B—b—but,” stammered one of them, “how can we take it away? Can’t you give us a cheque?”

“That is the right amount, in legal money, gentlemen,” replied the lawyer. “All I will say is that there are a couple of old valises in the closet—and I wish you good afternoon.”

For several hours Osborne and the Gordons literally waded in affluence, counting the money and packing it in the valises. By the time they had finished, it was eight o’clock. The building was dark. The elevator was not running. They were hungry and terrified. Step by step they groped their trembling way downstairs, and staggered with their treasure through the perilous streets to the Grand Pacific Hotel. None of them ever forgot the terror of that night.

Another warlike Reaper King was “Bill” Whiteley, of Ohio. Whiteley had invented a combined mower and reaper in 1858, which he named the “Champion”; and he pushed this machine with an irresistible enthusiasm.

His mode of attack was not the patent suit, but the field test. This was the white-hot[Pg 60] climax of the rivalry among the reaper kings; and it was great sport for the farmers. It was a reaper circus—a fierce chariot-race in a wheat-field; and its influence upon the industry was remarkable. It weeded out the low-grade machines. It spurred on the manufacturers to a campaign of improvement. It developed American harvesters to the highest point of perfection. It swung the farmers into the new path of scientific agriculture. And it piled expenses so high that few of the reaper kings escaped disaster.

A field test was conducted in this fashion: A committee of judges was appointed, and several acres of ripe grain were selected as the battle-field. After the field was marked off into equal sections, each reaper took its place. There were sometimes two reapers and sometimes forty. The signal was given. “Crack”—the horses leaped; the drivers shouted; and hundreds of farmers surged up and down in excited crowds.

|  |

| ASA S. BUSHNELL | BENJAMIN H. WARDER |

|  |

| HON. THOMAS MOTT OSBORNE | DAVID M. OSBORNE |

“All’s fair in a field test,” said the reaper agents who superintended these contests; though each man said it to himself. They were a hardy and reckless body of men, half [Pg 61]cowboy, half mechanic, and no trick was too dangerous or too desperate for them. Often the feud was so bitter that bodyguards of big-fisted “bulldozers” were on the spot to protect the warrior of their tribe who was in danger. “I had four men with me once who together weighed 1,000 pounds,” said A. E. Mayer, who is now the general of an army of 40,000 salesmen. In most tests the machines were shamefully abused. Self-binders were made to cut and bind stubble as though it were grain. Mowers were driven full tilt against stumps and hop-poles. Rival reapers were chained back to back and yanked apart by plunging horses. The warrior agents exposed the weak points in each other’s machines. They photographed each other’s breakdowns, and bragged to the limit of their vocabularies. They raised prices in one town and cut them in the next; for when their fighting blood was aroused—and that was often—they cared no more for profits than a small boy cares for his clothes.

To give only one instance out of hundreds, here is a picture of a field test that I found in the diary of B. B. Clarke, of Madison, who[Pg 62] is now the editor of the American Thresherman, but who was in the eighties a harvester fighter in Indiana.

“We drove fourteen miles to the wheat-field, which was also the battle-field,” he wrote, “and found a heavy crop of rank grain, wild pea vines, morning glories and other vegetation, which tested both machines to the limit. The bundles were twisted together by the vines into almost a continuous rope. After adjusting the machine, we had to ‘open the field.’ This is considered the most severe test, as the machine, the horses and all are in the grain.

“A—— drove the team, a magnificent pair of big grays. McK—— watched the binder, while Y—— and I created sympathy for our cause among the farmers who had come to see the fight. With a crack of his whip and a shout to his team, A—— opened the ball. The machine was so crowded with grain and weeds that the sickle could not be heard fifty feet away. He cleared the first round without a stop. Then the other machine followed, but the driver, failing to recognise the necessity of fast driving, allowed his machine to clog, and [Pg 63]lost the day. We received two hundred dollars in gold on the spot for our victorious binder.

A SELF-BINDER IN SCOTLAND, WITH THE WALLACE MONUMENT IN THE BACKGROUND

“On returning to Fort Wayne we found the E—— people, whose headquarters were separated by a partition wall from ours, had coaxed one of our customers to cancel his order, and substitute their machine. For this act, we retaliated and replaced three of their orders the following week, and while loading these into the farmers’ wagons a fight took place between the opposing factions. I looked as though I had encountered a flax-hackle. The next day hostilities opened early with three on our side to six of the E—— host, requiring a riot alarm and a wagon-load of police to restore order.

“We had swept the enemy before us, using neck-yokes, pitman rods and even six shooters in the grand finale. Our expense account for that week included fifty dollars for lawyers’ fees, which was promptly O. K.’d by the manager. After all, I had only obeyed instructions, which were to get the business and hold up prices, ‘peaceably if you can, but forcibly if you must.’”

[Pg 64]An interesting relic of these fierce days of cut-throat competition was given to me by Mr. John F. Steward. It reads as follows:—

To Agents for the Sale of Harvesting Machinery:

The undersigned, manufacturers of harvesting machinery, call the attention of their travelling experts and local agents to a practice which has grown among them for a few years past, and which has become so disreputable and is carried to such an extent that we feel it necessary to bring it to your special notice. It is the habit of trying to break up sales made by other agents when you have not been successful in securing the sale. It has become a very common practice, as soon as a sale is made by one agent, for the agents of all other machines to try to break up that sale, by misrepresentations or by lowering the price, or by trying to convince the purchaser that the machine which he has bargained for is not as good as the one which the other agent sells. This practice is disreputable, and should not be tolerated by any manufacturer. We wish it now thoroughly understood that we will not tolerate this practice in any agent, and we will be glad to have reports from you of the agents of any machines who have tried to break up your sales of our machines in this way. There is nothing that tends more to demoralise business than this practice, and we wish it stopped.

Machines should be sold upon their merits, and not by disparaging or running down other machines. You will find that your customers will place more reliance upon what you say if you leave all other machines alone, and show the good features of your own and demonstrate them in actual work. An agent never makes any progress by running down or trying to show the defects of others, and you will be better able to sustain your prices and the reputation of your machines by following the course indicated above. Therefore, it is our wish that you should hold to your prices firmly, present your machines in the very best possible light, and use all honourable means for making a fair and honest sale; but if you are unfortunate enough to lose your sale, and some competitor gains it, don’t be persuaded to put yours in the field by the side of your competitor, or try in any way to break up the sale; and do not, until the purchaser has discarded another machine, offer to put one of ours in its place.

Of course we do not mean by this that you shall stand quietly by and see other agents break up your sales, or if others habitually do this that you shall not retaliate, but you must not be the first to inaugurate this practice. We are always ready to meet fair and honest competition.

We want our business conducted in a fair and honourable way, and not descend to ways that are discreditable to us and to you. No one agent can expect to sell all the machines that are wanted in his district, for the poorest machine will have some friends, and, though he may have the very best one, we do not expect he will make every one see it. Let the purchaser take the risk. If he buys an inferior machine he should take the consequences, as if he was deceived or mistaken in his judgment in buying a horse. In such a case you would not think of putting your horse in work the purchaser was doing, to show him yours was the best, with the expectation that he would return the one he had bought because it did not prove quite equal to yours in drawing a load or in driving. If you would not in the case of a horse, why should you, in the case of a mower, reaper, or self-binding harvester? Our advice to you is:

[Pg 65]1st. Hold firmly to your prices.

2d. Sell your own machine. Convince your purchaser that you have the best machine made.

3d. Settle for the machine at time of delivery. A machine works much better after being settled for.

4th. If you lose the sale do not try to break up the sale of your competitor. It won’t pay.

[Pg 66]The king of the field test was William N. Whiteley. No other reaper king, in any country, received as much renown from his personal exploits. He was the Charlemagne of the harvest-field. He was as tall as a sapling and as strong as a tree. As a professor in the great field school of agriculture, he has never been surpassed. He could out-talk, outwork, and generally outwit the men who were sent against him. He was a whole exhibition in himself. “I’ve seen Bill Whiteley racin’ his horses through the grain and leanin’ over with his long arms to pick the mice’s nests from just in front of the knife,” said an old Ohio settler.

The feat that first made Whiteley famous was performed at Jamestown, Ohio, in 1867. His competitor was doing as good work as he was; whereupon he sprang from his seat, unhitched one horse, and finished his course with a single, surprised steed pulling the heavy machine. His competitor followed suit, and succeeded fully as well. This enraged Whiteley, who at that time was as powerful as a young Hercules.

“I can pull my reaper myself,” he shouted, turning his second horse loose, and yoking[Pg 67] his big shoulders into its harness. Such a thing had never been done before, and has never been done since; but it is true that, in the passion of the moment, Whiteley was filled with such strength that he ran the reaper from one side of the field to the other, cutting a full swath—a deed that, had he done it in ancient Greece, would have placed him among the immortals. It was witnessed by five hundred farmers, and fully reported in the press. One of the reporters, as it happened, representing the Cincinnati Commercial, was a young Ohioan named Whitelaw Reid, now the American Ambassador to the Court of St. James.

That ten minutes in a horse collar made $2,000,000 for Whiteley. His antagonist, Benjamin H. Warder, was filled with admiration for Whiteley’s prowess, and at once proposed that they should quit fighting and work in harmony.

“Give me the right to make your reaper and I’ll pay you $5 apiece for all I can sell,” said Warder. “It’s a bargain,” responded Whiteley. And so there arose the first consolidation in the harvester business.

Whiteley and Warder did not merge their[Pg 68] companies; but they divided the United States into three parts—one for Whiteley, one for his brother Amos, who also made reapers in Springfield, and one for Warder. They united in building a malleable iron foundry and a knife works, so that they could use better materials at a lower cost. They made the first handsome and shapely machines.