The SCIENTIFIC

AMERICAN BOY

OR

The Camp at Willow Clump Island

By

A. RUSSELL BOND

NEW YORK

MUNN & CO., Publishers

1906

COPYRIGHT, 1905, BY

MUNN & CO., NEW YORK

PRESS OF

THE KALKHOFF COMPANY

NEW YORK

PREFACE

All boys are nature lovers. Nothing appeals to them more than a summer vacation in the woods where they can escape from the restraints of civilization and live a life of freedom. Now, it may appear to be a bit of presumption to attempt to advise the boy camper how to spend his time. Surely the novelty of outdoor life, the fascinating charm of his surroundings, will provide him plenty of entertainment.

But, after all, a camp generally affords but two major amusements, hunting and fishing. These have been fully covered by a vast number of books. However, there is another side of camp life, particularly in a boys’ camp, which has been very little dealt with, namely, the exercise of one’s ingenuity in creating out of the limited resources at hand such devices and articles as will add to one’s personal comfort and welfare. It is, therefore, the aim of this book to 1 suggest certain diversions of this character for the boy camper which, aside from affording him plenty of physical exercise, will also develop his mental faculties, and above all stimulate that natural genius which is characteristic of every typical American boy. To this end the story contains descriptions of a large collection of articles which can be made by any boy of average intelligence, not only in the camp but at home as well.

The use of a narrative to connect the various incidents marks a departure in this class of book, and it is believed that the matter will thus be made more realistic and interesting. In all cases full directions are given for making the various articles. While it is not presumed that the directions will be slavishly followed, for this would defeat the general aim of the work, yet all the principal dimensions are given so that they can be used, if desired.

I beg to acknowledge the courtesy of Mr. Daniel C. Beard and Mr. Henry D. Cochrane in supplying a number of photographs. The directions for making the lee boards (page 119) were obtained from data 2 furnished by the latter. Many of the details recorded in the chapter on Tramping Outfits are to be accredited to Mr. Edward Thorpe. In the preparation of this book I have received valuable assistance from my colleague, Mr. A. A. Hopkins.

A. RUSSELL BOND.

New York, October, 1905.

CONTENTS

| CHAPTER I. | |

| PAGE | |

| “Bill” | 17 |

The Old Trunk. Christmas Vacation. “Bill’s” Skate Sail. Willow Clump Island. Organizing the Society. | |

| CHAPTER II. | |

| Skate Sails | 26 |

The Double Swedish Sail. The Single Swedish Sail. The Lanteen Sail. The Danish Sail. Bat’s Wings. | |

| CHAPTER III. | |

| Snow Shoes, Skis and Swamp Shoes | 35 |

Chair Seat Snow Shoe. Barrel Stave Snow Shoe. Barrel Hoop Snow Shoe. The Sioux Snow Shoe. The Iroquois Snow Shoe. The Ainu Snow Shoe. The Norwegian Ski. The Swamp Shoe or Swiss Snow Shoe. | |

| CHAPTER IV. | |

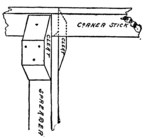

| Tent Making | 44 |

Farewell Meeting. Word from Uncle Ed. The Canvas Tent. Adjustable Ridge Pole. Tie Blocks. The Annex. | |

| CHAPTER V. | |

| Preparing for the Expedition | 53 |

Tent Fly. Provisions and Supplies. Umbrella Rib Crossbow. Megaphone. The Scow. | |

| CHAPTER VI. | |

| Off to the Island | 63 |

A Unique Alarm Clock. The Trip to the Island. Preliminary Exploration. A Rustic Table. The Small Filter. The Barrel Filter. The Klepalo. | |

| CHAPTER VII. | |

| Surveying | 73 |

The Surveying Instrument. Spirit Levels. The Tripod. Surveyor’s Chain. Surveyor’s Rod. A Simple Method of Surveying. Mapping the Island. | |

| CHAPTER VIII. | |

| Swimming | 84 |

Swimming on a Plank. Shooting the Rapids. Restoring the Drowned. How to Work over a Patient Alone. | |

| CHAPTER IX. | |

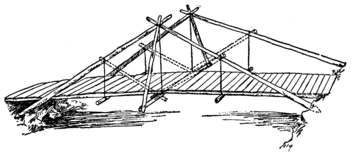

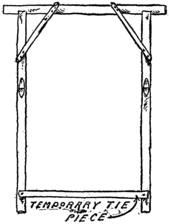

| Bridge Building | 95 |

The Spar Bridge. The Rope Railway. The Suspension Bridge. The Pontoon Bridge. The King Rod Truss. Stiffening the Bridge. The King Post Bridge. | |

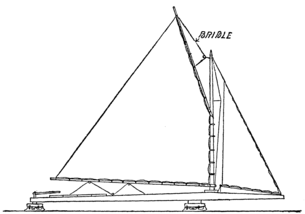

| CHAPTER X. | |

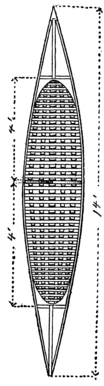

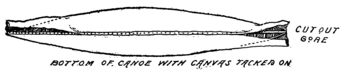

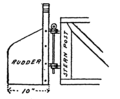

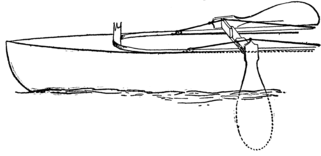

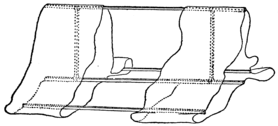

| Canvas Canoes | 109 |

Uncle Ed’s Departure. A Visit from Mr. Schreiner. The Sailing Canoe. Stretching on the Canvas. The Rudder. The Deep Keel. Canoe Sails. Lee Boards. Indian Paddling Canoe. | |

| CHAPTER XI. | |

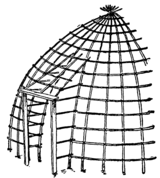

| House Building | 124 |

The Grass Hut. The Goblins’ Dancing Platform. Dutchy Takes a Dare. A Path Up the Fissure. Rope Ladders. The Derrick. The Tree House. Sliding Doors. | |

| CHAPTER XII. | |

| Trouble with the Tramps | 138 |

The Scow is Stolen. A Council of War. Vengeance. A Double Surprise. Tramp-proof Boat Mooring. | |

| CHAPTER XIII. | |

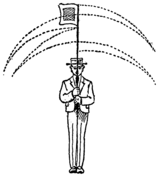

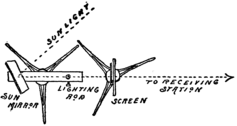

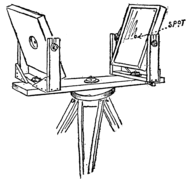

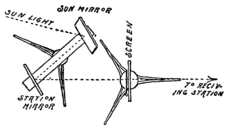

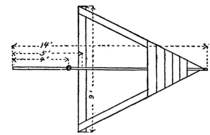

| Wigwagging and Heliographing | 144 |

Wigwag Signals. The Wigwag Alphabet. Abbreviations. Wigwagging at Night. The Heliograph. The Single Mirror Instrument. The Sight Rod. The Screen. Focusing the Instrument. Heliograph Signaling. The International Telegraph Code. The Double Mirror Instrument. | |

| CHAPTER XIV. | |

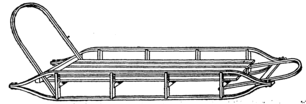

| Ice Boats, Sledges and Toboggans | 158 |

Breaking Camp. The Ice Boat. The Sledge. The Toboggan. The Rennwolf. Ice Creepers. | |

| CHAPTER XV. | |

| The Subterranean Club | 171 |

A Cave-in. Excavating for the Cave. Covering the Cave. The Big Bug Club. Midnight Banquets. The Club Pin. The Combination Lock. | |

| CHAPTER XVI. | |

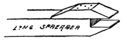

| Scooters | 183 |

A Sail in the Scow. Our Craft Strikes the Ice. The Scooter Scow. A Sprit Sail. Scooter Sailing. A Meeting of the Society. An Interview with Mr. Van Syckel. The Scooter Canoe. | |

| CHAPTER XVII. | |

| An Arctic Expedition | 193 |

Willow Clump Island in Winter. Kindling a Camp Fire. The Outdoor Fireplace. A Stone-paved Fireplace. A Cold Night in the Hut. Mountain Climbing. A Poor Shelter. A Costly Camp Fire. A Friend in Time of Trouble. | |

| CHAPTER XVIII. | |

| Tramping Outfits | 203 |

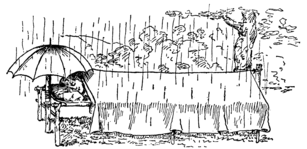

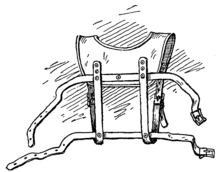

Sleeping Bags. Bill’s “Mummy Case.” The “A” Tent. A Camp Chair. A Camp Bed. The Camp Bed in a Shower. A Nightmare. Pack Harness. Riveting. | |

| CHAPTER XIX. | |

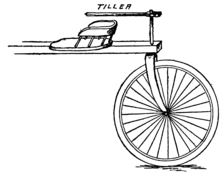

| The Land Yacht | 215 |

The Frame of the Yacht. A Simple Turnbuckle. Stepping the Mast. Mounting the Frame on Bicycle Wheels. The Tiller. A “Leg-of-Mutton” Sail. A Sail Through the Country. | |

| CHAPTER XX. | |

| Easter Vacation | 224 |

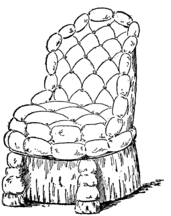

Bill’s Cave. The Barrel Stave Hammock. The Barrel Armchair. The Summer Toboggan. Tailless Kites. A Five-foot Malay Kite. An Eight-foot Malay Kite. The Elastic Belly Band. Putting the Kites to Work. The Diamond Box Kite. | |

| CHAPTER XXI. | |

| The Water Wheel | 240 |

The Water Wheel. Surveying for the Water Wheel. Towers for the Water Wheel. The Wheel. The Buckets. The Paddles. The Receiving Trough. Setting Up the Towers. Mounting the Water Wheel. Cooling the Filter Barrel. The Canvas Bucket. Mr. Halliday’s Water Wheel. | |

| CHAPTER XXII. | |

| The Log Cabin | 254 |

Foundation of Log Cabin. A Logging Expedition. The Log Raft. The Sail-Rigged Raft. Building the Log Cabin. The Roof of the Log Cabin. Door and Window Frames. The Fireplace. The Proper Way to Build a Stone Wall. The Floor of the Cabin. The Door Hinges and Latch. The Window Sash. Bunks. Stopping up the Chinks. | |

| CHAPTER XXIII. | |

| The Windmill | 273 |

Digging the Well. The Windmill Tower. The Crank Shaft. The Wind Wheel. A Simple Brake. The Pump. Pump Valves. Action of the Pump. | |

| CHAPTER XXIV. | |

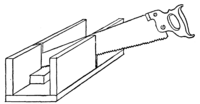

| The Gravity Railroad | 283 |

The Car. The Flanged Wheels. Car Axles. Mounting the Wheels. The Railway Track. The Carpenter’s Miter Box. Laying the Track. The First Railway Accident. Testing the Track. | |

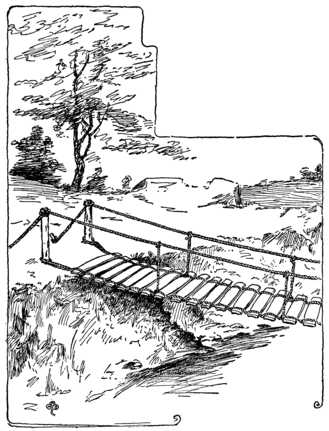

| CHAPTER XXV. | |

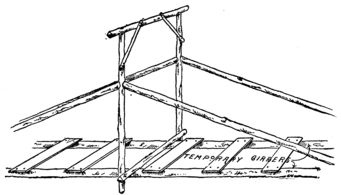

| The Cantilever Bridge | 292 |

Frames for the Cantilever Bridge. Erecting the Towers. Setting up the Frames. Binding and Anchoring the Structure. The Center Panels of the Bridge. A Serious Interruption. Dispossessed. Farewell to Willow Clump Island. Reddy’s Cantilever Bridge. | |

“Bill,” he was it, the Scientific American Boy, I mean. Of course, we were all American boys and pretty scientific chaps too, if I do say it myself, but Bill, well he was the whole show. What he didn’t know wasn’t worth knowing, so we all thought, and even to this day I sometimes wonder how he managed to contrive and execute so many remarkable plans. At the same time he was not a conceited sort of a chap and didn’t seem to realize that he was head and shoulders above the rest of us in ingenuity. But, of course, we didn’t all have an uncle like Bill did. Bill’s Uncle Ed was one of those rare men who take a great interest in boys and their affairs, a man who took time to answer every question put to him, explaining everything completely and yet so clearly that you caught on at once. Uncle Ed (we all called him that) was a civil engineer of very high standing in his profession, which had taken him pretty much all over 18 the world, and his naturally inquisitive nature, coupled with a wonderful memory, had made him a veritable walking encyclopedia. With such an uncle it is no wonder that Bill knew everything. Of course, there were some things that puzzled even Bill. But all such difficulties, after a reasonable amount of brain-work had failed to clear them, were submitted to Uncle Ed. Uncle Ed was always prompt (that was one thing we liked about him), and no matter where he was or what he was doing he would drop everything to answer a letter from the society.

The Old Trunk.

But hold on,

I am getting

ahead of my

story. I was

rummaging

through the

attic the other

day, and came across an

old battered trunk, one

that I used when I went

to boarding-school down in south Jersey. That trunk was

certainly a curiosity shop. It contained a miscellaneous

assortment of glass tubes, brass rods, coils of wire, tools, fish

hooks–in fact, it was a typical collection of all those

“valuables” that a boy is liable to pick up. Down in one

19

corner of the trunk was a black walnut box, marked, with

brass letters, “Property of the S. S. I. E. E. of W. C. I.”

On my key-ring I still carried the key to that box, which had

not been opened for

Fig. 2. The Black Walnut Box.

years. I unlocked

the box and

brought to light

the “Records and

Chronicles of the

Society for the

Scientific Investigation,

Exploration and Exploitation

of Willow

Clump Island.”

For hours I pored over those pages,

carried back to the good old times we used to have as boys

along the banks of the Delaware River, until I was brought

sharply back to the present by the sound of the dinner bell.

It seemed that the matter contained in those “Chronicles”

was too good to be kept locked up in an old trunk. Few

boys’ clubs ever had such a president as Bill, or such a wonderful

bureau of information as Uncle Ed. For the benefit

of boys and boykind in general, I decided then and there to

publish, as fully as practicable, a record of what our

society did.

Christmas Vacation.

This was how the society came to be formed. Bill, whom I met at boarding-school, was an orphan, and that’s why he 20 was sent to boarding-school. His uncle had to go down to Brazil to lay out a railroad, I believe, and so he packed Bill off to our school, which was chosen in preference to some others because one of the professors there had been a classmate of Uncle Ed’s at college. Bill roomed with me, and naturally we became great chums. When Christmas time came, of course I invited him to spend the holidays with me. My home was situated in the little village of Lamington, on the Jersey side of the Delaware River. Here we arrived late at night on the Saturday before Christmas. A cold wind was blowing which gave promise of breaking the spell of warm weather we had been having, and of giving us a chance to try our skates for the first time. True to our expectations, the next day was bitterly cold, and a visit to the canal which ran along the river bank, just beyond our back fence, showed that quite a thick skim of ice had formed on the water. Monday morning, bright and early, found us on the smooth, slippery surface of the canal. “Us” here includes, in addition to Bill and myself, my two younger brothers, Jack and Fred, and also Dutchy Van Syckel and Reddy Schreiner, neighbors of ours. It was the custom at the first of December every year to drain out most of the water in the canal, in order to prevent possible injury to the canal banks from the pressure of the ice. But there was always a foot or two of water covering the bottom of the canal, and this afforded a fine skating park of ample width and unlimited length, while the high canal banks on each side protected us from the bitter wind that was blowing. 21 Toward noon, however, the wind shifted and swept at a terrific rate down the narrow lane between the canal banks. We could scarcely make headway against the blow. It was too much for Bill, who wasn’t as used to skating as we were. He sat down in a sheltered nook and commenced to think. When Bill sat down to think it always meant that something was going to happen, as we soon learned.

“Say, Jim,” said he to me, “have you got any canvas up at the house?”

“No,” I replied. “What do you want it for?”

“I want to rig up a skate sail. If you have an old sheet, that will do just as well.”

“Well, I guess I can find you an old sheet. Do you think you can make one?”

“Sure thing,” answered Bill, and off we went to the house, where I received my first lesson on the practical genius of my chum.

“Bill’s” Skate Sail.

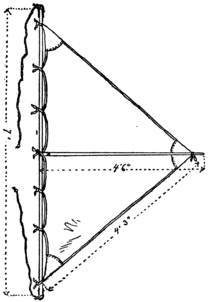

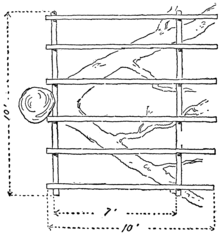

22The old sheet which Mother furnished us was laid out on

the floor and two corners were folded over to the center, as

shown in the drawing, making a triangle with base 7 feet

long and sides each about 4 feet 6 inches long. The surplus

end piece was then cut off, and a broad hem turned and

basted all around the edges of the triangle. Bill wanted

to work the sewing machine himself, but Mother was

afraid he would break something, so she sewed down

the hem for us. Then, under Bill’s supervision,

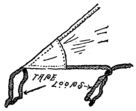

Fig. 4. The Tape Tie Strings.

she re-enforced the corners by

sewing on patches of cloth. Along

the diagonal a strip of heavy tape

was sewed, leaving loops at intervals,

which afterward were

cut and provided means for tying

the sail to the mast. Tie

strings of tape were

Fig. 5. “Bill’s” Sail Complete.

also sewed at the corners, as shown in the

illustration, and then a trip was made to

the garden in search of suitable

spars. A smooth bean pole of

about the right weight

served for the mast,

and another stick

with a crotch at

one end served as the

boom or cross-spar. The

spars were cut to proper length,

and the sail was then tied on, as

illustrated, with the crotch of the

cross-spar fitted against and tied to

the center of the mast. A light

rope, long enough to provide plenty

23

of slack, was tied to the ends of the mast to assist in guiding

the sail when in use. In the meantime I had procured

another sheet from one of our neighbors, and Bill helped me

make a sail for myself. It was not until long after dark

that we finished our work.

Willow Clump Island.

The next day we tried the sails and it didn’t take me very long to learn how to steer the device. The wind had changed again and this time blew up the canal. We took the line of least resistance, and went skimming up the ice lane like birds for several miles before we realized how far we were getting away from home. As we rounded a bend in the canal, much to my astonishment, I saw just before us the bridge at Raven Hill, eight miles from our town. We started to go back, but the wind was too strong for us, and there wasn’t much room in which to do any tacking; nor could we make any progress when the sails were folded. I began to get extremely tired and rather exasperated at Bill for not having thought of the return trip before he led me such a hot pace up the canal. But Bill was getting tired, too.

“Look here, Jim,” he said, “we haven’t covered a mile, and I’m worn out.”

“Why in thunder didn’t you think of this before we started?” I returned.

“How much money have you with you?” was the reply.

“What’s that got to do with it?”

“I’ll tell you in a minute. How much have you?”

24A careful search of my dozen odd pockets netted the sum of twenty-seven cents.

“I have fifty-nine,” said Bill, “and that makes eighty-six altogether, doesn’t it? Isn’t there a railroad depot near here?”

“There is one at Raven Hill, and the next is at Lumberville. That is about eleven miles from home.”

“Well,” said Bill, “at three cents each per mile that would amount to sixty-six cents. Let’s sail on to Lumberville and then take the train back.”

On we sped to Lumberville, only to find that the next train was not due until noon, and it was now just half past ten.

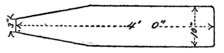

Time never hung heavy on our hands. Out on the river we espied an island. I had heard of this island–Willow Clump Island, it was called–but had never been on it; consequently I fell in with Bill’s suggestion that we make it a visit. Owing to the rapids which separated the island from the Jersey shore, we had to go up stream a quarter of a mile, to where a smooth sheet of ice had formed, over a quiet part of the river; thence we sailed down to the island along the Pennsylvania side.

“What a capital island for a camp,” cried Bill, after we had explored it pretty thoroughly. “Have you ever been out camping?”

I had to confess I never had, and then Bill gave me a glowing account of his experiences in the Adirondacks with his uncle the year before, which so stirred up the romance in me that I wanted to camp out at once.

25“Shucks!” said Bill, “We would freeze in this kind of weather, and besides, we’ve got to make a tent first.”

We then sat down and made elaborate plans for the summer. Suddenly the distant sound of a locomotive whistle interrupted our reveries.

“Jiminy crickets!” I exclaimed. “That’s the train coming through Spalding’s Cut. We’ve got to hustle if we are to catch it.”

We were off like the wind, and a merry chase brought us to the Lumberville depot in time to flag the train. We arrived at Lamington at half past twelve, a trifle late for dinner, rather tired and hungry, but with a glowing and I fear somewhat exaggerated account of our adventure for the credulous ears of the rest of the boys.

Organizing the Society.

The camping idea met with the hearty approval of all, and it was decided to begin preparations at once for the following summer. Dutchy, whose father was a member of a geographical society, suggested that we form a society for the exploration of Willow Clump Island. By general acclamation Bill was chosen president of the society, Dutchy was made vice-president, Reddy was elected treasurer, and they made me secretary. It was Dutchy who proposed the name “The Society for the Scientific Investigation, Exploration and Exploitation of Willow Clump Island.” It was decided to make an expedition of exploration as soon as we could make skate sails for the whole society.

The duties of the secretary, as defined in the constitution which Dutchy Van Syckel drew up, were to keep a record of all the acts of the society, the minutes of every meeting, and accurate detailed descriptions of all work accomplished. Therefore, while the rest of the society was busy cutting up old sheets, levied from the surrounding neighborhood, and sewing and rigging the sails under Bill’s direction, I, with pad and pencil in hand, took notes on all the operations.

The Double Swedish Sail.

Bill evolved some new types of sails which differed materially

from the type described in the first chapter. One

was a double sail–“the kind they use in Sweden,” he explained.

One of the

sheets which the foraging

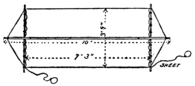

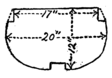

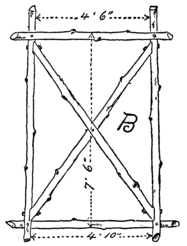

Fig. 6. Dimensions of Double Swedish Sail.

N. B.–The mark (') means feet and (") means inches.

party brought in

was extra large; it

measured approximately

two yards and

a half square. This

was folded on itself,

27

making a parallelogram seven feet six inches long and three

feet nine inches wide. The sheets we had were all rather worn

and some were badly torn, so that we had to make our sails

of double thickness, sewing patches over

Fig. 7. Halyards Looped onto Pole.

the weak spots. A broad hem was turned

down at each end, and heavy tape was

sewed on, leaving loops as before, to attach

them to the

spars. This reduced the length

of our sail to seven feet three

inches. The end spars were spaced apart by a light pole about ten feet long, to which they were

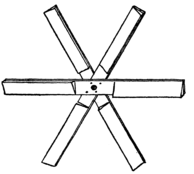

Fig. 8. The Double Swedish Sail.

tied at the points of intersection. The spars were also braced

by halyards looped over the ends of the pole in the manner

indicated in the drawing (Fig. 7). It took a crew of two

boys to manipulate this sail. In use, the pole of the rig was

carried on the shoulders, and the sail was guided by means

of ropes attached to the lower corners of the vertical spars.

28

These ropes in nautical

language are

called “sheets.”

The boy at the rear

was the pilot and

did the steering, because

his position behind the sail gave him an unobstructed

view in all directions. When changing tack the sail was

lifted overhead to the other side of the crew.

The Single Swedish Sail.

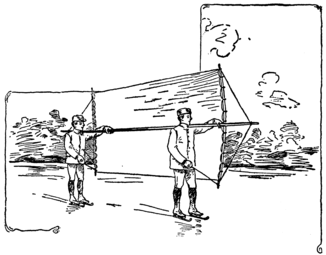

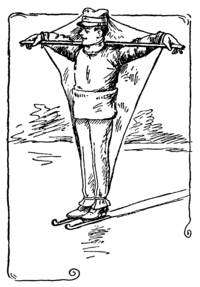

Another sail of similar form, but for use of one boy only, is shown in Fig. 10. This had a height of six and one-half feet at the forward end and three feet at the rear; and its length was five 29 feet. This sail was very satisfactory in light winds, owing to its great area. In use we found that it was very important to keep the lower edge against the leg, as indicated by the arrow. The rig was manipulated just like the double Swedish sail, lifting it over the head when it was desired to change tack.

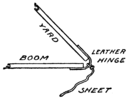

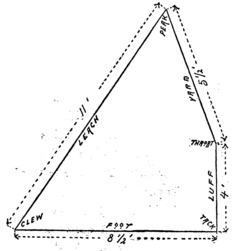

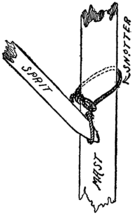

The Lanteen Sail.

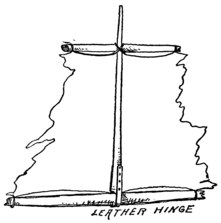

The lanteen sail we

found to be a very good

rig. It was made in

the form of a triangle,

measuring

eight feet on one

side, seven and

one-half feet on

another side and

six and one-half

feet on the third.

The six and one-half

foot side

was secured to a

boom, and the seven and one-half

foot side to a yard. The yard and

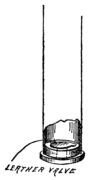

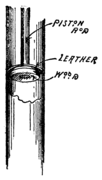

boom were hinged together by a leather strap nailed on as

shown in Fig. 12, and to this hinge a rope was attached, which

served as a sheet. These spars were secured to a mast erected

perpendicularly to the boom and intersecting the yard a little

above its center. We had had some trouble with the first

30

sails we made in keeping the base of the sail against the

body, and to overcome this difficulty Bill proposed tying the

Fig. 12. Hinge for Spars.

bottom of the mast to the leg. This was

a rather risky thing to do, as we learned

later, for in case of accident it

would be difficult to get clear of

Fig. 13. Leather Mast Step.

the sail. It

was Reddy

who finally

solved the

problem by rigging up a step for the mast.

It consisted of a leather tag tied to the leg,

and provided with a hole into which the

bottom of the mast was

fitted. To prevent the

Fig. 14. Wooden Mast Step.

mast from slipping too

far into the step the lower

portion of it was whittled

down, leaving a shoulder

which rested on the leather. Bill later devised

another step, which consisted of a

wooden block (Fig. 14) strapped to the leg

and formed with a shallow socket to receive

the end of the mast.

The Danish Sail.

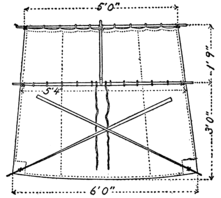

31But the most satisfactory sail we found to be the Danish

sail, though it was not until we had served quite a long

apprenticeship and

Fig. 15. The Danish Sail.

sustained many

pretty bad falls that

we mastered the

art of manipulating

these sails

properly. Our

ideas on this sail

were obtained

from a French illustrated

paper

which Dutchy

Van Syckel picked up in his father’s library. This sail was

formed with a topsail so arranged that it could be lowered

when the wind was too strong. The dimensions of the sail

as we made it are given in the drawing

(Fig. 15). The top of the sail

was lashed to a spar, which

Fig. 16. Topsail of the Danish Rig.

was connected by a short

stick to another spar tied to

the mainsail about eighteen

inches lower down.

The sail was strengthened

with an extra

strip of cloth along

the lower spar,

and the tie strings

were applied in

the usual way. The connecting stick, or topmast we may

call it, was hinged to the lower spar by means of a short piece

of leather strap, which was passed round the spar in the

form of a loop and its two ends nailed to the bottom of the

topmast. The topmast extended above the upper spar a

short distance, and to this we fastened the flag which our

society had adopted. A couple of strong cords were secured

to the center spar to provide for fastening the sail onto the

skater. Tied to the lower corners of the mainsail were two

sticks which were used for guiding the sail when in flight.

Fig. 17. Before the Wind. Fig. 18. Topsail Lowered. Fig. 19. Skating against the Wind. Fig. 20. On the Port Tack.

33The different methods of sailing with this rig are shown in Figs. 17-20. When sailing with the wind the skater would stand very erect, bending backward in proportion as the wind blew fresher. By inclining the sail in one direction or the other, the skater could tack to port or starboard. When moving against the wind by skating in the usual way, the body was bent forward in such manner that the sail lay horizontal, so that it would not offer a purchase for the wind.

Bat’s Wings.

One more sail deserves mention. It was Bill’s idea, and it

came near to ending his career the first day he tried it. It

had no spars at all, but was merely a strip of cloth of somewhat

triangular shape. The upper side was tied to the

head, and the two corners to the wrists, while the lower

portion was tied to the ankles. This converted him into a

huge white-winged bat. Bill had to try it at once, even

though the rest of the sails were not finished, and a very

34

comical spectacle he made as he flapped his wings in his

endeavors to tack. When the wind was too strong for him

he had merely to drop his arms and thus lower sail. At

length he became tired of holding his arms out at full length,

Fig. 21.

and I got him a stick

to put over his shoulders

and rest his arms

on. But that stick was

Bill’s undoing, for

coming around a sudden

bend in the canal

he caught the full

force of the wind,

which knocked him flat

on his back before he

could disentangle himself

from the stick and

lower sail. It took us

some time to bring him

back to consciousness,

and a very scared lot of boys we were for a while. However,

the lesson was a good one, for after that we were very

cautious in experimenting with sails that had to be tied on,

such as the Danish rig and the lanteen rig, before Reddy invented

the mast step.

It was not until the day after Christmas that the sails were all completed, but then there was scarcely any wind blowing and we could not attempt the expedition to the island.

The next day, Sunday, it began to snow, and we realized that our chance of skating up to Willow Clump Island was spoiled. All the afternoon it snowed, and the next morning we woke to find the ground covered to a depth of eight inches and snow still falling. But who ever heard of a boy complaining because there was snow on the ground? Here were new difficulties to overcome, new problems to solve, and new sports provided for our amusement. There was no disappointment shown by any of the members of the S. S. I. E. E. of W. C. I., as they met in the woodshed immediately after breakfast to discuss proceedings for the day. There seemed to be but one way of reaching the island, and that was by means of snow shoes. Bill had only a vague idea of how snow shoes were made.

Chair Seat Snow Shoe.

The first pair was made from a couple of thin wooden chair seats which we found in the shed. They proved quite serviceable, being very light and offering a fairly large bearing surface. The chair seats were trimmed off at each side to make the shoes less clumsy, and a loop of leather was 36 fastened near the center of each shoe, in which the toe could be slipped. This shoe possessed the disadvantage of being too flat and of picking up too much snow when used.

Barrel Stave Snow Shoe.

Another pair of shoes was made from barrel staves. At first one stave was made to serve for a shoe, but we found that two staves fastened together with a pair of wooden cleats were much better. Jack was the proud inventor of these shoes and insisted that they were far more satisfactory than the elaborate ones which were later devised.

Barrel Hoop Snow Shoe.

Now that Jack had shown his ingenuity, Fred thought it was his turn to do something, and after mysteriously disappearing for the space of an hour we saw him suddenly come waddling back to the shed on a pair of barrel hoops covered with heavy canvas. He had stretched the canvas so tightly across the hoops that they were bent to an oval shape. It was claimed for these shoes, and with good reason, that they were not so slippery as the 37 barrel stave shoe, for they permitted the foot to sink slightly into the snow.

After dinner, Dutchy came back with a book of his father’s, a sort of an encyclopedia in which several different kinds of snow shoes were illustrated. Reddy, whose father owned a sawmill, volunteered to provide us with strips of hickory from which to make the frames.

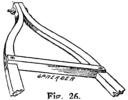

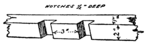

The Sioux Snow Shoe.

The Sioux snow shoe was the first type we

tackled. Two strips of hickory 4 feet long

and 3/4 inch square in section, were bent

over a pair of spreaders and securely

fastened together at each end. The

Fig. 26. Frame of the Sioux Shoe.

spreaders were about 12

inches long and located

about 15 inches apart.

They were

notched at the

ends, as shown in

Fig. 26, to receive

the side strips, which were not fastened

together until after they had been nailed to the spreaders.

We found that the most satisfactory way of fastening together

the ends of the hickory strips was to bolt them together.

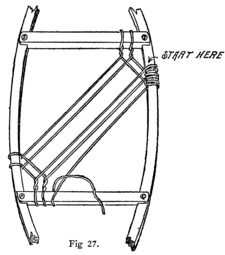

When the frame was completed, we began the

tedious process of weaving in the filling or web of the snow

38

shoe. First we cut notches in the edges of the spreaders,

spacing these notches an inch apart. Then we procured

several balls of heavy twine at the corner store. Tying one

end of the cord to the right side stick about three inches

below the forward spreader, we stretched a strand down to

the notch at the left end of the lower spreader. The strand

was drawn taut, and after making several twists around it

Fig 27. Web of the Sioux Shoe.

the cord was tied to the left

side stick three inches above

the spreader. From

this point the cord

was stretched to the notch at

the right end of the upper

spreader, twisted several

times and brought back to the

starting point. The cord was

now wrapped around the side

stick for a space of about an

inch, and then carried down

to the second notch on the

lower spreader, whence it was

woven through the other two

strands and tied about the left side stick about four inches

from the spreader. Thus the weaving continued, passing

the cord alternately over and under any cross strands encountered.

In order to make the left side correspond with

the right, a separate cord was wound around it, filling up the

space between the strands of the web. The filling above

39

and below the spreaders could not be so methodically done,

but we managed to weave the strands quite neatly with about

the same mesh as used at the

center. To facilitate the weaving

Fig. 28. Weaving Needle

we improvised a rough needle

of a piece of wire. The latter

was bent double to receive the cord which was wedged in between

the two arms of the needle.

The Iroquois Shoe.

But the best snow shoe we made was the Iroquois shoe.

The frame of this shoe was made of hickory strips of the

same width and thickness as used in the Sioux shoe, but

Fig. 29. Bending the Hickory Strips.

8 feet long. The strips were bent in a loop and the ends

were bolted together. How to bend the wood without breaking

it seemed a very difficult problem. Wood, we knew,

could be easily bent without

breaking if boiled or

steamed for a while; but

we had nothing large

enough in

which to boil a

strip of wood

8 feet long.

Bill hit upon

the plan of

wrapping the stick

with burlap and

40

then pouring boiling water on it until it became sufficiently

soft to bend easily. An old oats-sack was cut up into strips

and wound onto the hickory sticks for a distance of 18

inches at each side of the center. We then repaired to the

Fig. 30. Frame of Iroquois Shoe.

kitchen to do the steaming. The hickory stick was held over

a large dish-pan filled with boiling water, and from this we

dipped out the water and

poured it slowly over the

burlap wrapping of the

stick. After a little of this

treatment the stick was sufficiently

steamed to permit

of bending to the required shape. The ends

Fig. 31. Iroquois Snow Shoe.

were then firmly secured by means of bolts

passed through bolt holes which had been

previously drilled. The frame was completed

by fitting the spreader sticks in place,

after which it was laid away to dry. When

the frame was perfectly dry we started

weaving the web. In this case, however,

instead of cord we used cane strips, which

we had bought from a chair caner. This

necessitated drilling holes in the side sticks

to receive the cane strips. The web consisted

of strands crossing each other diagonally,

as illustrated. Our second pair

of Iroquois snow shoes was made with a web of rawhide

which we bought from a hardware store at Millville.

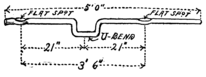

The Ainu Snow Shoe.

41One of the snowshoes described in the book was very much

like Fred’s barrel-hoop snow shoe in appearance. According

to the description, it was a type used by the Ainus, a peculiar

people living in the cold northern islands of Japan. As the

shoe seemed quite simple and rather unique, we thought we

Fig. 32. Ainu Snow Shoe.

would make one like it. Two hickory

strips each 4 feet long were bent to a

U-shape and lashed together, forming

an oval about 2 feet 6 inches long by 18

inches wide. The frame was held to

oval shape by tying the sides together.

Then the filling was woven in, running

the strands diagonally, as shown in

Fig. 32.

We had excellent weather for snow shoes after that snowstorm. A thaw followed by a cold spell caused a thick crust to form on the snow which would nearly hold us up without the aid of our snowshoes. We were rather awkward with those shoes for a while, trying to keep them clear of each other, and we found it particularly hard to turn sharply without causing one shoe to run foul of the other. But with a little practice we soon felt quite at home on them. In order to prevent cutting the web with our heels, we found it necessary to wear rubbers.

42Our vacation came to an end before we were prepared for

the expedition to Willow Clump Island. But before leaving

Fig. 33. The Norwegian Ski.

the subject on snow shoes,

two more shoes remain to

be described, namely the

Swiss snow

shoe and the

Norwegian

ski. The Swiss shoe was made during the summer and the

ski during the following winter.

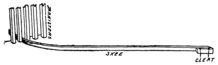

The Norwegian Ski.

The Norwegian ski was made of close-grained wood, 1

inch thick, 3-1/2 inches wide and 6 feet long. About 18

inches from the forward end the wood was planed down to

a thickness of 1/4 of an inch. This end was placed in the

dish-pan of boiling water, and in a short time it was pliable

Fig. 35. The Ski Stick.

enough to permit of bending. It was secured

Fig. 34. Bending the Ski.

in the proper bent position by slipping the toe

end of the shoe between

the banisters

on the back porch

and nailing a cleat back of the heel end. When the ski was

perfectly dry the toe strap was nailed on just back of the

balancing point, and also another strap, to be secured about

the ankle. Then a cleat was nailed onto the ski to fit against

the heel of the shoe. In use we found it best to cut a groove

43

in the bottom of the ski, so as to give us a better

grip on the snow in climbing up hills. With the

skis we had to use short poles or “ski sticks” to assist

in starting, stopping and steering when coasting.

The ski stick was a bean pole provided with a wooden

block near the lower end, to prevent it from being

forced too far through the snow.

The Swiss Snow Shoe or Swamp Shoe.

The Swiss shoe was made primarily to assist us in exploring some boggy land a short distance up the river from our island. The original swamp shoes were made from the bottoms of two old baskets, and they worked so admirably that it was decided to equip the whole society with them. Uncle Ed, when told about them, informed us that that was the kind of snow shoe used in Switzerland. Of course, we could not afford to destroy a pair of baskets for each member of the club, and so we had to weave the shoes from the willows which grew on the island.

We had a farewell meeting of the society the evening before Bill and I had to return to boarding-school. At this meeting plans were made for the Easter vacation. We also considered the matter of getting parental permission for our summer outing. So far we had been afraid to breathe a word of our plans outside of the society, since Fred had said something about it in the presence of Father and had been peremptorily ordered to banish all such hair-brained, Wild West notions from his head. We realized from that incident that the consent of our parents would not be so very easily obtained. But Bill came forward with a promising suggestion. He would write to his Uncle Ed and see if he couldn’t be persuaded to join the expedition. At first we demurred. We didn’t want a “governor” around all the time. But Bill assured us that his uncle was “no ordinary man”; that he would not interfere with our plans, but would enter right into them and give us many valuable pointers. Though not by any means convinced, we told him to go ahead and invite his uncle, as that seemed about the only means of winning over our fathers and mothers. The society was then adjourned until our Easter vacation began, each member 45 promising to earn and save as much money as he could in the meantime to buy the materials for a tent and provisions for the summer outing.

Word From Uncle Ed.

Bill’s letter to Uncle Ed was answered as quickly as the mail could travel to Brazil and back. Uncle Ed heartily approved of our plans, and said that he would be delighted to join the expedition. He could not be on hand before the 1st of July, but that would give us plenty of time to make all necessary preparations. He told us not to worry about gaining the consent of our parents. He would write to them and see them all personally, if necessary to win their approval.

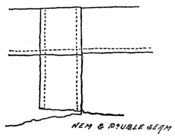

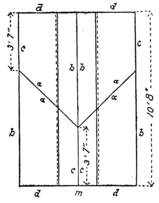

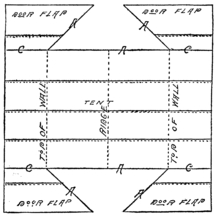

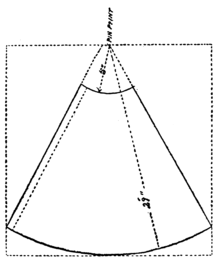

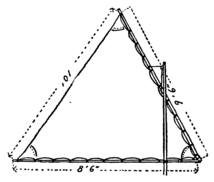

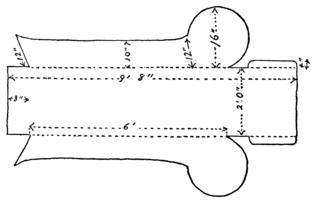

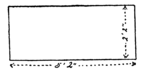

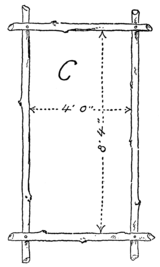

The Canvas Tent.

46When at last spring arrived and we returned to Lamington

on our Easter vacation, quite a sum of money had been

collected, nearly $15.00, if I remember rightly; at any rate

plenty to buy the materials for a good-sized tent and leave a

large surplus for provisions,

Fig. 38. The Sail Stitch.

etc. Bill figured out on paper

just how much canvas we

would need for a tent 7 feet

wide by 9-1/2 feet long, which

he estimated would be about

large enough to hold us.

It took 34 yards, 30

inches wide. Then we

visited the village store to make our purchase. Canvas we

found a little too expensive for us, but a material called drill

seemed about right. It cost ten cents a yard, but since we

wanted such a quantity of it the price was reduced to a total

of $3.00. We repaired to the attic to lay out the material.

First we cut out four lengths of 5 yards and 26 inches

each. The strips were basted together, lapping the edges

Fig. 39. Cutting out the Door Flaps.

1 inch and making a piece 17 feet 2 inches long by 9 feet 9

inches wide. Mother sewed the breadths together on the

machine, using a double seam, as in sail making; that is, two

parallel rows of stitching were sewed in, one along each

overlapping edge, as shown in Fig. 38. A 1-inch hem was

47

then turned and sewed at the

ends of the goods, so that the

piece measured exactly 17 feet

long. It served for the roof

and side walls of the tent.

Our next operation was to cut

three strips 11 feet long, and

sew them together with a

double seam as before. This

piece was now slit along the

center line m, Fig. 39, making

two lengths 3 feet 8

inches wide. The strips were

then cut along the diagonal lines a a, forming the

end walls or doors, so to speak, of the tent. In sewing

Fig. 40. Sewing on the Door Flaps.

on the door flaps we

started first at the

bottom of the side

c, sewing it to the

side edge of the

main piece, as shown

in Fig. 40, and running

the seam up for

a distance of exactly

3 feet 6 inches.

After all the door

strips had been

sewed along their c

edges the sewing was continued up the diagonal or a edges.

In cutting out the door pieces we had allowed 1 inch on each

side for hems and seams, so that the door pieces met without

lapping at the exact center of the main or body piece, that is,

48

at the peak of the tent.

Our next step was to fasten the necessary ropes and loops.

Ten 8-foot lengths of light rope were procured. These

were fastened at the top of the side walls, that is, 3 feet 6

inches from the ends of the main or body piece, one at each

corner and one on each seam. The cloth was

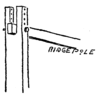

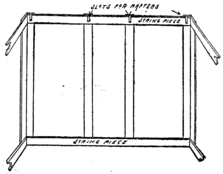

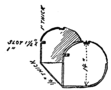

Fig. 41. Adjustable Ridge Pole.

strengthened at these points with

patches sewed on the inside. At

the bottom of the side walls we

sewed on loops of heavy tape.

These were spaced about 15 inches

apart. Along the b edges of the door pieces tie strings of

tape were fastened. A rope 15 feet long was attached to

the peak at the front and at the rear of the tent. The front

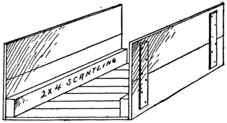

and rear posts of the tent were made from scantlings measuring

2 by 4 inches, which were procured from Mr. Schreiner’s

lumber yard. They were planed smooth and sawed off to a

length of 7 feet 6 inches. A slot was cut in the end of each

stick to a depth of 6 inches and measuring slightly over an

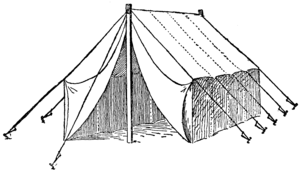

Fig. 42. The Tent Set Up.

inch in width. For the ridge pole a strip 1 inch thick, 2-1/2

inches wide and 10 feet long was secured. This was fitted

into the slotted ends of these posts, where it was fastened

by wooden pegs slipped into holes drilled through the ends

of the posts and the ridge pole. A number of these peg

49

holes were provided, so that if the canvas stretched the ridge

pole could be raised or lowered to prevent the walls from

dragging on the ground. We set up the tent in our back

yard to see if it was properly constructed. Twelve stakes

were required, ten for the sides and one for the ridge stays

at the front and rear. The side stakes were driven into the

ground at a distance of about 8 feet from the center of the

tent. First we tied the guy ropes to the stakes, but later we

found it much easier to secure them with tie blocks.

Tie Blocks.

These were made of wood 1/2 inch thick, 1 inch wide and

each measured 3 inches long. A hole was drilled into the

block at each end and through these holes the rope was

Fig. 44. The Wire Tie.

threaded. A knot in the rope then held the end from slipping

50

out. The loop between the two holes, or the bight, as

sailors would call it, was now slipped over the stake, and

the rope hauled tight by drawing up the tie block, as shown

in Fig. 43. A still later improvement consisted in making

ties of stout galvanized

iron wire, bent to the form

shown in Fig. 44. The

wooden ties were apt to

Fig. 45. Bottom of Tent Wall.

swell and split open when

exposed to the weather, while the wire ties could always be

relied upon.

The walls of the tent were held down along the bottom by railway spikes hooked through the tent loops and driven into the ground. Wooden pegs with notches to catch the loops would have served as well, but Dutchy happened to find a number of the spikes along the track and in his usual convincing manner argued that they were far better than pegs because their weight would hold the cloth down even if they were not firmly embedded in the ground.

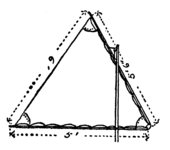

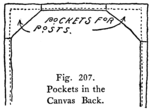

The Annex.

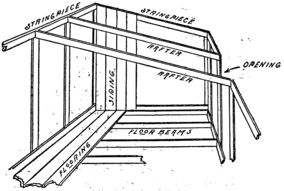

We were surprised to find out how small the tent was after it was set up. We could see at once that when we had put in all the stores and provisions we would need, there would not be room enough for six boys and a man to stretch themselves out comfortably in it. Bill had evidently made a miscalculation, but he suggested that we remedy the error by building an annex for our kitchen utensils and supplies.

51This gave us a two-room tent, which we found to be quite

an advantage. Twelve more yards of drill were bought and

cut into two strips, each 17 feet 2 inches long. The breadths

were then sewed together, and the ends turned up and

Fig. 47. The Annex Applied.

hemmed to make a piece 17 feet long and 4 feet 9 inches

wide. Tape loops were then sewed on as before, and ropes

were fastened on at the top of the side walls, that is, 3 feet

6 inches from the ends of the strips. We thought it would

be better to have a slanting ridge on the annex, so we cut out

a wedge-shaped piece from the center of the two strips, as

shown by dotted lines B B in Fig. 46. This wedge-shaped

piece measured 2 feet at the outer end of the annex, and

52

tapered down to a point at the inner end. The canvas was

then sewed together along these edges. Tie strings were

sewed to the inner edge of the annex and corresponding ones

were attached to the main tent a little ways back from the

edge, so that the two could be tied together, with the annex

lapping well over on the roof and side walls. A notch was

cut out of the peak of the annex, so that it could be tied

around the rear post of the tent, and notches were cut at

the top of the side walls to permit passing the cloth around

the wall ropes. Instead of supporting the ridge of the annex

on a ridge pole, we used the rear guy line of the tent, propping

it up with a scantling about 5-1/2 feet long.

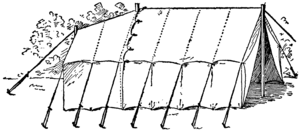

School closed on the 21st of June that year, just ten days before the expected arrival of Uncle Ed. The first thing we did was to set up our tent in the back yard and camp out so as to become acclimatized. It is good that we did this, for the very first night a heavy summer shower came up which nearly drenched us. The water beat right through the thin canvas roof of our tent. Had we been able to afford the best quality of canvas duck, such an occurrence would probably have been avoided. But we solved the difficulty by using a tent fly; that is, a strip of canvas stretched over the tent and spaced a short distance from it to break the fall of the rain drops.

Tent Fly.

54Again we had to visit the village storekeeper; this time we bought out his whole remaining stock, sixteen yards of drill. This was cut into four-yard strips, which were sewed together as before and the ends turned up and hemmed. Tie strings were sewed to the ends of the strips so that the fly could be tied to the wall ropes of the tent. At the ridge the fly was supported about six inches above the tent rope by a second ridge pole held by pegs in the top holes of the tent posts.

Provisions and Supplies.

The ten days before Uncle Ed arrived were busy indeed. We had to gather together the necessary provisions and supplies. Our personal outfits were very simple. Each member supplied himself with a change of underwear, a bathing suit, a blanket and a toothbrush. A single comb and brush served for the entire society, and was used on Sundays, the only day we really dressed up. All the rest of the time we lived in our bathing suits, except, of course, on cold rainy days. Our kitchen outfit consisted of a large cooking pot, two kettles, a frying pan, a coffee pot, a small oil stove, a half-dozen each of plates, cups, saucers, knives and forks, a dozen spoons, two tablespoons, and, in addition, several large 55 plates and bowls for pantry use. We also took with us a dish-pan and several dish-towels. For our larder we collected the following: A bag of flour, ten pounds of sugar, two pounds of salt, three pounds of coffee, four pounds of oatmeal, four pounds of butter, two pounds of lard, six pound of beans, six pounds of rice, three pounds of bacon, six cans of condensed milk, a dozen eggs, box of pepper, and several jars of canned peaches and pears, and also a half dozen glasses of jelly.

It was Dutchy who suggested that we have a chicken yard, in connection with our camp, to supply us with fresh eggs. It was a capital idea, and by the dint of some coaxing we managed to secure the loan of a half dozen hens and a rooster.

Our miscellaneous list included a spade, pick and shovel, an ax, a hatchet, two large pails, a barn lantern, a can of kerosene, a dozen candles, a cocoa box filled with matches, a pair of scissors, needles, buttons, pins and safety pins, a spool of white and another of black cotton, fishing tackle, a roll of heavy twine, a coil of rope, and a set of dominoes and checkers. But most important of all was a chest of tools belonging to Reddy. These were all collected when Uncle Ed arrived. Dutchy also contributed a large compass, which we found very useful later on, for surveying the island.

Crossbow.

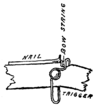

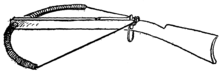

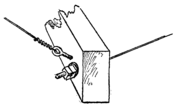

Reddy had a shotgun which he wanted to bring along, but my father, and Dutchy’s as well, wouldn’t let us go camping 56 if there was to be any gunpowder along, so we had to leave it behind. Of course we didn’t miss it at all when we got to the island, because there was so much else to do; but we all agreed with Dutchy, that “it wouldn’t be no sort of a scientific expedition without takin’ a gun along.” As a substitute I suggested a bow and arrow. They all laughed at such a “kiddish” idea; all but Bill, I mean.

“It ain’t such a bad notion,” said he, “only a crossbow

would be better. I’ve seen them made out of umbrella

ribs so they’d shoot like greased lightning.” Of course we

had to have one of these wonderful weapons. Down in the

ash heap we found two broken

umbrellas with 27-inch ribs. Bill

selected ten good ribs, from which

he wrenched off the spreaders with

a pair of pliers. The ribs were

then bound together by winding

Fig. 51. The Trigger.

stout twine around them. The winding was very evenly

and closely done, so that the cord completely covered the

ribs, making a solid rod of spring steel. But before winding

we had laid in between the ribs a piece of heavy twine, to

which the bowstrings could be tied after the bow was all

wound. The stock of our crossbow was cut out of a board

Fig. 52. The Trigger Set for Firing.

of soft wood 1 inch thick to as near the shape of a gun as

we could get it. A hole was drilled through the muzzle

end to receive the bow, and then the bowstring was tied fast.

Along the upper edge of the barrel a V-shaped channel was

cut. The channel was not very deep, only enough to receive

57

a tenpenny nail with the head projecting half-way above the

sides. A notch was cut across the barrel, through this channel,

at the trigger end, and a trigger made of heavy iron wire,

bent to the shape shown in Fig. 51,

was hinged to the gun by a bolt

which passed clear

through the stock and

through both eyes of the

trigger. By using two nuts on the bolt,

and tightening one against the other,

they were prevented from working loose

and coming off. When we wanted to fire the gun the bowstring

was drawn back, and held by slipping it into the notch,

Fig. 53. The Umbrella Rib Crossbow.

and a nail was laid

in the channel with

its head against the

bowstring. Then, on

pulling the trigger, the

bowstring was lifted out of the notch, and sent the nail off

sailing. The long-grooved barrel insured a

very good aim.

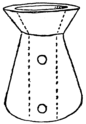

Megaphone.

Another device we made in preparation

for the expedition was a megaphone.

A sheet of light cardboard 30 inches

square was procured. At the center of

one edge a pin was stuck into the

58

cardboard, then a piece of stout thread was looped over

the pin and the two ends were knotted together just

Fig. 55. Layout of the Megaphone.

5 inches from the

pin. Another

knot was also

made 29 inches

from the pin.

Now, with a pencil

hooked into

the loop, and resting

first against

the inner knot

and then against

the outer one, two

arcs were drawn

on the paper, one of 5-inch radius and the other of 29-inch

radius. A line was now drawn from the pin to the point

where the longer arc met the right hand edge of the paper,

and a dotted line was drawn from the pin to a point

Fig. 56. Brass Fastener.

1-1/2 inches from the edge at the

other end of the arc. From a point

1 inch to the left of the pin we

then drew a line to the left end of

the arc. With a scissors we cut the cardboard

Fig. 57. The Mouthpiece.

along the arcs and straight lines, all

but the dotted line, leaving a piece of the

shape shown in Fig. 55. This piece was

rolled into a cone with the right edge

59

lapped over the left edge and lying against the dotted line.

In this position it was held by means of several brass fasteners

of the kind shown in Fig. 56.

A mouthpiece was formed out of a block of wood in which a large hole had been drilled. The block was then cut away until the walls were quite thin. The hole was reamed out at the top, as shown in Fig. 57, and the outer surface was tapered so that the small end of the megaphone would fit snugly on it.

We planned to reach our camping grounds by way of the canal, and had provided for that purpose a large scow, which we expected to tow up to Lumberville and drag over to the river.

The Scow.

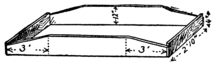

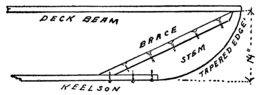

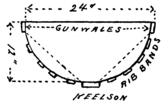

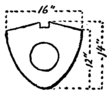

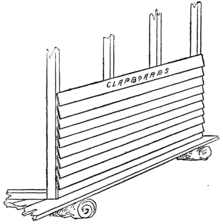

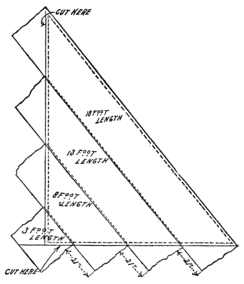

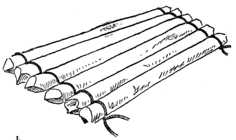

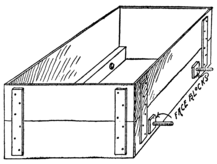

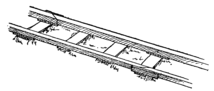

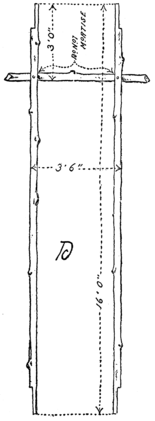

Our scow was made as follows: Two 3/4-inch pine boards,

12 inches wide and 12 feet long, were selected from Reddy’s

Fig. 58. Side pieces of the Scow.

father’s lumber pile. These were used for the side pieces

of the boat, and we tapered

them off at the end to a width

of 3-1/2 inches. This was done

by making a straight cut from the end to a point three feet

back along the edge of the board and then rounding off the

edge with a draw-knife. When one board had been shaped,

it was used as a pattern for the other, which was thus cut to

exactly the same size. For the end pieces two strips, 4

inches wide and 2 feet 10-1/2 inches long, were sawed out of

60

a 1-inch board. Then for the bottom we procured a number

of 3/4-inch boards, 12 feet long and 8 inches wide, which

we cut into 3-foot lengths. At Bill’s suggestion, before

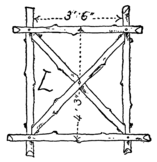

Fig. 59. Frame of the Scow.

nailing the parts together, we secured some strips of flannel,

which were saturated

with paint,

and laid between the

seams so as to make

the boat perfectly

water-tight. The side and end boards were then nailed

together, with the strips of flannel between, the side boards

overlapping the end boards, as shown in Fig. 59. After

planing down the end

Fig. 60. Nailing on the Bottom.

boards until their

edges laid flush with

the edges of the side

pieces, the bottom

boards were nailed on, strips of cloth being inserted between

them, as well as along the edges of the side and end boards.

To brace the bottom a 3/4-inch board was placed at the

center, inside the boat, and bent down against the floor, to

which it was nailed with wire

nails. The nails were driven

Fig. 61. Sockets for Rowlocks.

into the board from the outer

side of the boat and were

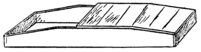

clinched inside. Along the upper edges of the side boards

two strips 2 inches wide and 1 inch thick were nailed. Two

notches were cut in the inner side of each strip before it was

61

nailed on. The notches were 1/2 inch deep, 1-1/2 inches wide,

3 inches apart and about 5-1/2 feet from the stern end. When

Fig. 62. Thole Pin.

the strips were nailed in place these notches formed sockets

to receive the rowlocks. A strip was also nailed

across the stern of the boat and formed with two

central notches, to receive the rowlocks for a

steering oar. This strip, however, was 3 inches

wide, and projected 1 inch above the end board,

so as to lie flush with the deck boards, which were

later applied. Six thole pins, 1/2 inch thick, 4-1/2

inches long and 2 inches

wide, were cut out of an

oak board. The lower

Fig. 63. Nailing on the Decks.

end of each pin was reduced

to a width of 1-1/2

inches for a length of 2

inches. The thole pins

were then fitted snugly in the notches. Two cleats, nailed

to the side boards inside, 7 inches below the upper edge,

served to support a seat board 1 inch thick and 2 feet 10-1/2

inches long. The aft edge of the seat was about 10 inches

forward of the rowlocks. The boat was completed by nailing

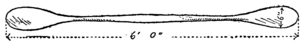

on a couple of deck boards at each end. The oars were

made of 2-inch pine boards, 5 feet long and 5 inches wide.

62

They were blocked out at Mr. Schreiner’s sawmill and then

Fig. 64. The Oar.

shaped and smoothed down with a draw-knife and spoke-shaved.

They were 1-1/4 inches at the handle and 2 inches

immediately below, tapering down to a diameter of 1-1/4

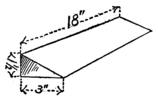

inches at the top of the blade. The blades were 18 inches

long, 5 inches wide, and planed down to a thickness of 1/4

inch along the edges.

The morning of July 2d dawned bright and clear, but long before daybreak the members of the S. S. I. E. E. of W. C. I. were astir. The jolly red sun peeping over the eastern hills witnessed an unaccustomed sight. Six greatly excited boys were running back and forth from the barn to the canal, bearing all manner of mysterious bundles, which were carefully deposited in a freshly painted scow. Yes, all six of us were there.

A Unique Alarm Clock.

We hadn’t expected to see Reddy Schreiner at such an early hour, for he was always a sleepyhead, and no alarm clock would ever wake him. But this was an exceptional day, and, besides, Reddy was quite an original chap. He had taken one of the borrowed roosters into his room the night before, and when, early in the morning, Mr. Chanticleer had mounted the footboard of the bed, flapped his wings and given vent to his opinion of a boy who persisted in sleeping at that late hour of the day, the noise was too much for even Reddy’s drowsy sensibilities.

The Trip to the Island.

64Our scow was not large enough to carry all the things we had to take with us, but as Mr. Schreiner was going to take Uncle Ed up in his wagon, we left the rest of our luggage for him to bring along. We boys walked the eleven miles up the canal to Lumberville, towing the barge. It was a tiresome task; but we divided the work into two-mile shifts, two boys towing at a time and then each taking a mile ride as steersman in the boat. It was about noon when we arrived at Lumberville, and then we had to unload our boat before we could haul it out of the canal and down to the river. The 65 river on the Jersey side of the island was so shallow that we waded across, pushing the boat ahead of us. The current was too swift to permit of rowing, and it was rather hard for us to keep our footing. But we managed to reach our destination finally without any mishap. The island was thickly wooded, except for a small clearing where we landed. The first thing we did was to unpack our eatables, and Jack, the cook, soon had an appetizing pan of bacon and eggs sputtering on the kerosene stove.

Preliminary Exploration.

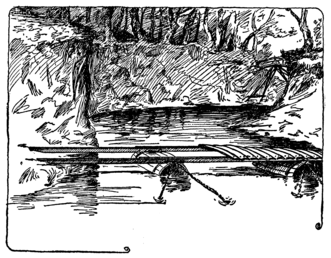

66As no better position offered at the time we pitched our tent in the clearing, pending a thorough search for a more suitable place elsewhere. Around the tent we dug a trench about a foot deep to prevent water from entering our quarters when it rained. It was about time for Uncle Ed and Mr. Schreiner to appear with the rest of our luggage, so we did not have time to do much exploring, but sauntered southward along the shore, always on the lookout for their arrival. About a quarter of a mile from the tent we came across the wreck of an old bridge, which had been washed down by some freshet. This was a great find, and served us many purposes, as will appear later.

While we were examining the wreck we heard a distant “halloa” from the mainland. There was Uncle Ed sitting on a pile of goods on the railroad bank looking for all the world like an Italian immigrant. We answered with a shout and scrambled back to the clearing. Then we ran splashing through the water, pushing the boat before us. It didn’t take us long to load up and carry him back to the island.

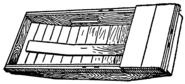

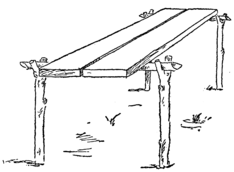

A Rustic Table.

Uncle Ed entered into our fun at once. He was as enthusiastic

as a boy over the surroundings, and when we told

him of the old bridge he started right off to investigate,

67

taking the ax with him. Soon he

Fig. 67. The Rustic Table.

had pried off a number of the

planks, which we used

for a flooring to our

tent. Then he built

us a table out of four

forked sticks, driven

into the ground, and

supporting two

cross sticks, on

which a pair of

planks were laid.

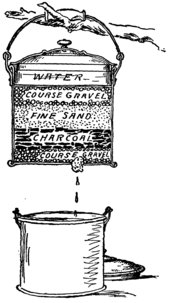

The Small Filter.

“Well, now, boys,” said Uncle Ed, wiping the perspiration from his forehead, “I am as thirsty as a whale. Where do you get your drinking water? Is there a spring on the island?”

We told him that we used the river water.

“What, river water! That won’t do at all,” he cried.

“You’ll all have the typhoid fever. We must build a filter.

Fig. 68. The Small Filter.

I brought some charcoal with me for this very purpose.”

Taking one of our pails he broke a hole in the bottom of it and stuffed a sponge in the hole. A layer of small stones was then placed in the pail, over this a layer of broken charcoal with the dust carefully blown out, then a layer of clean sand, and finally a layer of gravel. Each layer was about two inches thick. The pail was suspended from a branch in a 68 cool place and proved an excellent filter, the water trickling out through the sponge being perfectly pure and sweet, no matter how dirty it had been when poured in; but the capacity of the filter was too small, and Uncle Ed said he would make us a larger one on the morrow if no spring was discovered in the meantime.

The sun was getting low in the west, and we therefore postponed the exploration of our island until the following day. We had been up since four o’clock that morning and had done some pretty hard work; so, immediately after supper, we turned in and, lulled by the murmuring of the river, were soon fast asleep.

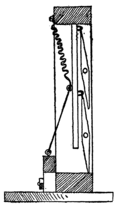

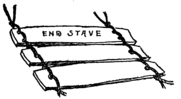

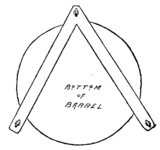

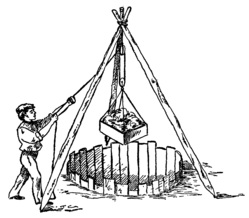

The Barrel Filter.

Immediately after breakfast the next day we started out in

two parties to search the island. The only discovery of any

Fig. 69. The Barrel Filter.

moment was that made by Dutchy’s party, which found a

small island separated from ours by a narrow channel,

through which the water ran like a mill-race. No spring was

69

discovered, so Uncle Ed had to construct his large filter.

Bill and I went over to Lumberville in search of a couple of

cider barrels and a pailful of charcoal. The barrels were

placed one on top of the other after cutting a large hole in the

top of the lower barrel, and a smaller one in the bottom of the

upper one. The latter opening

was covered by an inverted

saucer. Over this we spread a

3-inch layer of coarse sand, then

a 2-inch layer of charcoal, a 4-inch

layer of clear, sharp sand,

and a 2-inch top layer of gravel.

The lower barrel was provided

with a faucet, through which we

could draw off the filtered water

as desired. In order to keep the

water cool we placed the filters

in a shady place near the river,

and piled up earth around the

lower barrel.

“Now, boys,” said Uncle Ed, “form in line there, and we will go through a fire drill.”

He arranged us about five feet apart in a line extending from the filter to the river. We had six pails, and these Dutchy filled one at a time, passing them up the line to Reddy, who emptied them into the upper barrel and then threw them back 70 to Dutchy to be refilled. Working in this way it did not take long to fill up the filter, and the burden of keeping the barrels full, instead of falling on one person, was shared alike by all.

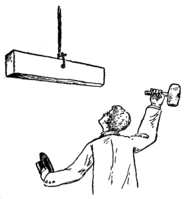

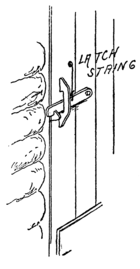

The Klepalo.

Our camp outfit was further augmented by a dinner call. We discovered the necessity of such a call on our very first day of camping. Dutchy was so excited by his discoveries of the morning that he started out alone in the afternoon to make a further search. The rest of us were lazy after the noon meal, and were lolling around taking it easy during the heat of the day, and discussing plans for the future. But Dutchy’s energetic nature would not permit him to keep quiet. He took the scow and waded with it against the strong current to the deeper and quieter water above the 71 island. Then he rowed a long way up stream. He was gone all the afternoon. Supper time came and still he didn’t appear. The sun was high, and I presume he didn’t realize how late it was getting. Finally, just at sunset, he came drifting down with the current, tired and hungry, and ready for a large meal. But we had finished our supper an hour before, and poor Dutchy had to be content with a few cold remnants, because the cook had declared he wouldn’t prepare an extra meal for a fellow who didn’t have sense enough to know when it was meal time.

Then it was that Uncle Ed bethought himself of the klepalo.

“You ought to have some sort of a dinner call,” he declared, “so that any one within a mile of camp will know when dinner is ready.”

“Did you ever hear of a klepalo? No? Well, I was

down in Macedonia a couple of years ago inspecting a railroad,

and I stopped off for the night at a small Bulgarian

village. The next day happened to be a Prasdnik, or

saint’s day, and the first thing in the morning I was awakened

by a peculiar clacking sound which I couldn’t make out. Calling

my interpreter I found out from him that it was a klepalo

for calling the people to church. The people there are too

poor to afford a bell, and so in place of that they use a beam

of oak hung from a rope tied about the center, and this beam

The Klepalo.

is struck with a hammer, first on one side, and then the other.

Sometimes an iron klepalo is used as well, and then they

strike first the beam and then the iron bar, so as to vary the

72

monotony of the call. I found that the wooden klepalo could

be heard for a distance of about one and a half miles over

land, and the iron one for over two miles. Now we can easily

make a wooden klepalo for use in this camp, and then if

Dutchy, or any of the rest of us, keep within a mile and a

half of camp there won’t be any trouble with the cook.”

So we built a klepalo, getting from Lumberville a stick of seasoned oak, 1-1/2 inches thick, 6 inches wide and 4 feet long. A hole was drilled into the stick at the center, and by a rope passed through this hole the beam was suspended from a branch overhanging the camp. Jack, the cook, regularly used this crude device to call the hungry horde to meals.

One of the first things we did after getting fairly settled in our new quarters was to make a complete survey of Willow Clump Island and its immediate surroundings. Our surveying instruments were made as follows:

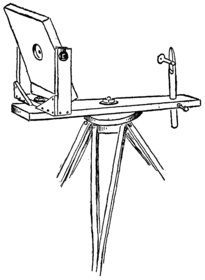

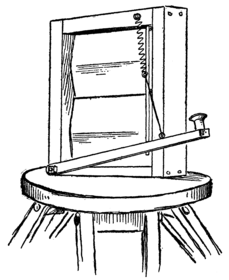

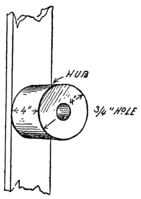

The Surveying Instrument.

Out of a 1-inch board we cut a base 15 inches long and

4 inches wide. In the center we sawed out a circular opening

of about 3 inches diameter and covered this at the bottom by

Fig. 71. Baseboard of the Surveying Instrument.

a circular piece 1 inch

thick and 5 inches in

diameter, thus forming

a socket in which our

compass fitted snugly.

A hole 1 inch in diameter

was drilled through the center of this circular piece

to receive the pivot pin of a tripod. Across each end of the

baseboard we secured a block 4 inches long, 2 inches wide

and 1 inch thick. A 1-inch sight hole was drilled through

each block at its center. A ring of cardboard, on which

74

Uncle Ed marked with radial lines the 360 degrees of the

circle, was placed over the compass socket, with the zero and

180 degree marks pointing toward the sight blocks. The

Fig. 72. Sighting Blocks on the Baseboard.

outer faces of the end blocks were now wet with mucilage

and a hair was stretched vertically across the center of each

sight hole. The hairs were then adjusted by

sighting through the holes and moving the

nearer hair sidewise until it was exactly in line

with both the zero and the 180 degree

marks on the cardboard.

Then a hair

was stretched horizontally

across the

center of each sight

hole. Great care

was taken to place

the hairs at exactly the same height above the baseboard.

To protect the hairs after they were adjusted, they were covered

with a piece of glass, which was secured in place by

tacks driven into the wood with their heads projecting over

the edges of the glass.

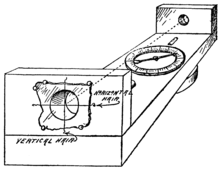

Spirit Levels.

From one of his pockets Uncle Ed produced two small bottles, the kind used for holding homeopathic pills. These he filled nearly to the top with water, corked them and wedged them into grooves cut lengthwise in the baseboard 75 at opposite sides of the cardboard ring. These grooves were filled with putty, and to make sure that the bottles were level with the baseboard the latter was floated on a bit of quiet water and the bottles were pressed down at one end or the other until the bubble within rested at the exact center.

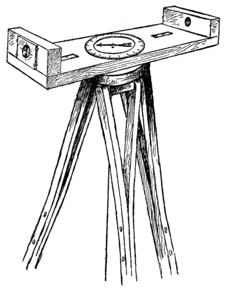

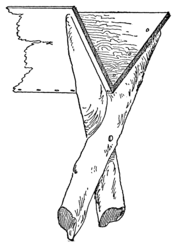

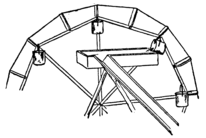

The Tripod.

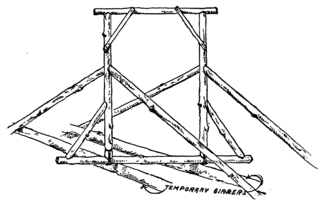

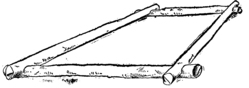

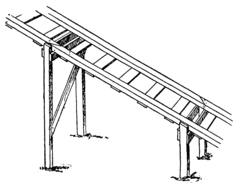

The tripod head was

formed of a wooden disk 5

inches in diameter, with a

wooden pin projecting

from its center

adapted to engage

the hole in the circular

piece above

referred to. To the

bottom of the tripod head were nailed three blocks

Fig. 74. The Tripod Leg.

2 inches long and 1 inch square in cross-section. The

tripod legs were made of light strips of wood, 3/8

inch by 1 inch by 5 feet long, which we secured from

one of the mills at Lumberville. Each leg was

formed of two of these strips, nailed securely together

to within 20 inches of the top. At the upper

ends the strips were spread to receive the blocks on

the tripod head. In this position they were held by

headless wire nails driven into the ends of the blocks

and fitting into holes drilled in the strips. For a

76

plumb line we

Fig. 75. The Surveying Instrument Complete.

tacked a cord to the

center of the tripod

head, and attached

a good-sized sinker to its

lower end. In connection with

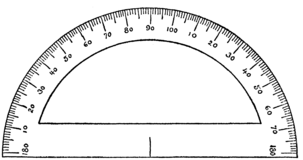

this plumb line we occasionally

used a protractor consisting of

a semicircle of cardboard 5

inches in diameter, on which

the degrees of the circle

Fig. 76. The Protractor.

were marked off with radiating

lines, as illustrated in

Fig. 76. By holding the

straight edge of this protractor

against the base of

the tripod, and noting the number of degrees between the

90 degree mark and the plumb line, we could tell at a glance

at what angle from the horizontal the instrument was tipped.

Surveyor’s Chain.

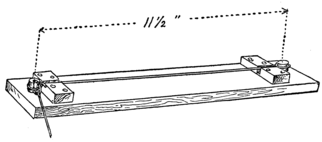

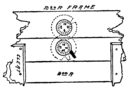

77We made a surveyor’s chain of wire links, each 12

inches long, instead of 7.92 inches, which is the length of a

standard surveyor’s link. The wire we used was No. 16

galvanized iron, which was rather stiff and difficult to bend.

In order to make all the links of exactly the same size and

shape we used a form, around which they were bent. The

Fig. 78. Forming the Links.

form consisted of a 1-inch board in which two 1/2 inch holes

were drilled, just 11-1/2 inches apart, measured from their

centers. An oak pin, 1/2 inch in diameter, was driven into

each hole and projected about an inch above the board. Two

blocks of oak were secured to the baseboard, just before each

pin, as shown in Fig. 78. This form gave great satisfaction.

A groove was cut in the side of one of the pins to receive the

Fig. 79. A Double-Ringed Link.

78

ring of a completed link, while the wire was passed through

this ring and bent around the peg to form the ring of the

new link. After each link was formed it was carefully measured,

and, if too long, was shortened by flattening the rings

endwise, or, if too short, was lengthened by pinching together

the sides of the rings. There were fifty links in our

chain, and every tenth one was formed with a double ring

at the end, so as to distinguish it from the rest (see Fig. 79).

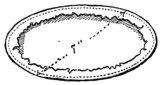

The Surveyor’s Rod.

We completed our outfit by making

a surveyor’s rod out of a straight

stick of wood about 6 feet long. A

target or sighting disk was mounted

on the stick. This disk was 6 inches

in diameter, and was sawed out of a

6-inch square board by making

Fig. 81. The Sighting Disk

straight cuts across the corners and then smoothing off the

edge to a perfect circle with a draw-knife. The thickness of

the disk was only 1/2 inch. At the back of the disk we fastened

a block of wood with a slot cut in it to receive the rod,

as shown in Fig. 81. To hold the disk at different heights

79

on the rod a small bolt was used. The nut on this bolt was

slipped into a hole on the block at the bottom of the slot and

Fig. 82 Nut Fastened in Block.

held in place by driving in nails about it, as illustrated in

Fig. 82. The bolt was then passed through

the hole and threaded through the nut, with

its inner end bearing against the rod. The

disk could thus be held at any desired position

by tightening up the bolt. A piece of

white paper was now pasted over the disk.

The paper was marked off into quarters,

and opposite quarters were

painted black so that it would

be easy to sight, from a distance, the exact center

of the target.

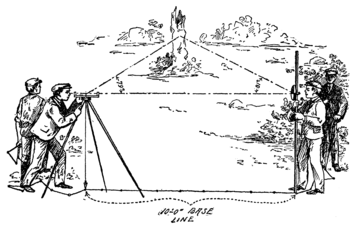

A Simple Method of Surveying.

Of course, none of us had studied trigonometry, but Uncle Ed devised a very simple method by which we could determine distances quite accurately without much figuring.

“If you will tell me the length of one side of a triangle and the angles it makes with the other two sides,” said Uncle Ed, “I’ll tell you the length of the other two sides and the size of the third angle. This is how I will do it:

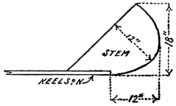

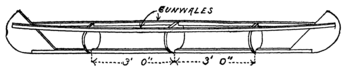

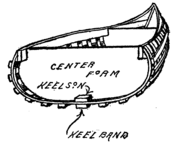

“Say the line is 6 inches long and one angle is 35 degrees, while the other is 117 degrees. Let us draw a 6-inch straight line. This we will call our base line. Now we will place the 80 base edge of our protractor on the base line with its center at the right hand end of the line. At the 37 degree mark we will make a dot on the paper so, and draw a line from the right hand end of the base line through this dot. Now we will do the same thing at the opposite end, making a dot at 107 degrees from the line, and draw a line from the left hand end of the base line through this dot.