The Project Gutenberg EBook of Scientific American Supplement, No. 810, July 11, 1891, by Various This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org Title: Scientific American Supplement, No. 810, July 11, 1891 Author: Various Release Date: February 14, 2005 [EBook #15050] Language: English Character set encoding: ISO-8859-1 *** START OF THIS PROJECT GUTENBERG EBOOK SCIENTIFIC AMERICAN *** Produced by Juliet Sutherland and the PG Online Distributed Proofreading Team at www.pgdp.net.

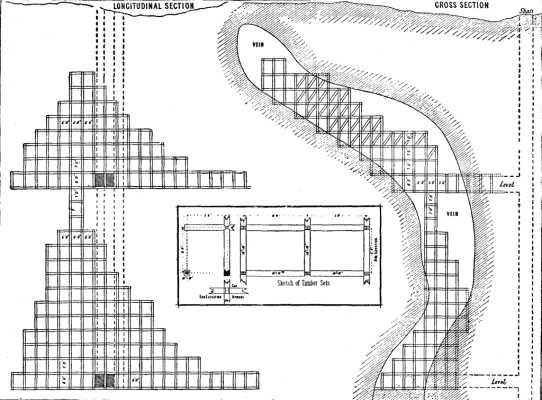

The square system of timbering, in use in most of our large mines on the Pacific coast, was first introduced in Australia by Mr. W.H. Patton, who adopted it in the Broken Hill Proprietary mines, although it does not seem to be so satisfactory to the people there as to our miners, who are more familiar with it. The accompanying description and plans were furnished by Mr. Patton to the report of the Secretary of Mines for Victoria:

"The idea is supposed to have originated in the German mines, but in a crude form. It was introduced among the mines of the Pacific coast of America some 20 years ago, by a gentleman named Diedesheimer. Its use there is universal, and experience has evolved it from the embryo state to its present perfection. The old system and its accompanying disadvantages are well known. A drive would be put in for a certain distance, when it had to be abandoned until it could be filled up with waste material and made secure. This process entailed much expense. The stuff had first to be broken on the surface, then sent below, trucked along the drives, and finally shoveled into place. Ventilation was impaired and the drives were filled with dust. The men worked in discomfort, and were not in a condition to perform a full measure of labor. Under the system as adopted in the Proprietary mine, these disadvantages disappear. The cost is one-third less, ventilation is perfect, and every portion of the faces are accessible at all times. Sawn timber is used throughout; the upright and cross pieces are 10 inches by 10 inches, and stand 4 feet 6 inches apart; along the course of the drive, the cross pieces are five feet in length, and the height of the main drives and sill floor sets are 7 feet 2 inches in the clear. In blocking out the stopes, the uprights are 6 feet 2 inches, just one foot shorter than those in the main drives. The caps and struts are of the same dimensions and timber as the sill floor. The planks used as staging are 9 inches by 2½ inches; they are moved from place to place as required, and upon them the men stand when working in the stopes and in the faces. A stope resembles a huge chamber fitted with scaffolding from floor to roof. The atmosphere is cool and pure, and there is no dust. Stage is added to stage, according as the stoping requires it, and ladders lead from one floor to the other; the accessibility to all the faces is a great advantage.

If, while driving, a patch of low grade ore is met with, it can be enriched by taking a higher class from another face, and so on. Any grade can be produced by means of this power of selection. Opinions have been expressed that this system of timbering is not secure, and that pressure from above would bring the whole structure down in ruins. But an opinion such as this is due to miscomprehension of the facts. If signs of weakening in the timbers become apparent, the remedy is very simple. Four or more of the uprights are lined with planks, and waste material is shot in from above, and a strong support is at once formed, or if signs of crushing are noticed, it is possible to go into the stope, break down ore, and at once relieve the weight."

THE SQUARE SYSTEM OF TIMBERING IN MINES.

The methods of handling the travel and traffic in the city of London form a very interesting subject for the study of the engineer. The problem of rapid transit and transportation for a city of five millions of inhabitants is naturally very complicated, and a very difficult one to solve satisfactorily.

The subject may be discussed under two divisions: first, how the suburban travel is accommodated, that is, the great mass of people who come into the business section of the city every morning and leave at night; second, how the strictly local traffic from one point to another is provided for. Under the first division it will be noted in advance that London is well provided with suburban railroad accommodation upon through lines radiating in every direction from the center of the city, but the terminal stations of these roads, as a rule, do not penetrate far enough into the heart of the city to provide for the suburban travel without some additional methods of conveyance.

The underground railroad system is intended to relieve the traffic upon the main thoroughfares, affording a rapid method of transportation between the residential and business portions, and in addition to form a communicating link between the terminals of the roads referred to. These terminal stations are arranged in the form of an irregular ellipse and are eleven in number.

One of the most noticeable features of the underground system in London is that it connects these stations by means of a continuous circuit, or "circle," as it is there called. The line connecting the terminal stations is called the "inner circle." There is also an extension at one end of this elliptical shaped circle which also makes a complete circuit, and which is called the "middle circle," and a very much larger circle reaching the northern portions of the city, which is called the "outer circle." The eastern ends of these three circles run for a considerable distance on the same track. In addition to this the road branches off in a number of directions, reaching those parts of the city which were not before accommodated by the surface roads, or more properly the elevated or depressed roads, as there are no grade crossings.

With regard to the accommodation afforded by this system: it is a convenience for the residents of the western and southern parts of London, especially where they arrive in the city at any of the terminal stations on the line of the "circle," as they can change to the underground. They can reach the eastern end of the "circle," at which place is located the bank and the financial section of London, in a comparatively short time. For example, passengers arriving at Charing Cross, Victoria or Paddington stations, can change to the underground, and in ten, fifteen and thirty minutes respectively, reach the Mansion House or Cannon street stations, which are the nearest to the Bank of England. In a similar manner those arriving at Euston, St. Pancras or King's Cross on the northern side of the "circle," can reach Broad Street station in ten or fifteen minutes, which station is nearest the bank on that side of the "circle."

In a number of cases the underground station is in the same building or directly connected by passages with the terminal stations of the roads leading into the city. Examples of this kind would be such stations as Cannon Street, Victoria or Paddington. They are not, however, sufficiently convenient to allow the transference of baggage so as to accommodate through passengers desiring to make connection from one station to another across the city. Hand baggage only is carried, about the same as it is on the elevated road in New York. The method of cross town transfer, passengers and baggage, is invariably done by small omnibuses, which all the railroads maintain on hand for that special purpose. A very large proportion of the travel, however, if not the largest, is obtained by direct communication by means of the "circle" on branch lines with the various residential portions of north, west and south London.

Approximately on the underground railroad the fare is one cent per mile for third class, one cent and a half for second class, and two cents for first class, but no fare is less than a penny, or two cents. Omnibus fares in some instances are as low as a penny for two miles. This is not by any means the rule, and is only to be found on competing lines. The average fare would be a penny a mile or more.

The fares on the main lines which accommodate the suburban traffic are somewhat higher than on the underground, perhaps 50 per cent. more. In every case, on omnibus, tram cars or railroads, the rates are charged according to distance. The system such as in use on our electric, cable and horse cars and on the elevated road in New York, of charging a fixed fare, is not in use anywhere.

The ticket offices of the underground roads are generally on a level with the street. In some instances both the uptown and downtown trains are approached from one entrance, but generally there is an entrance at either side of the railroad, similar to the elevated railroad system. In purchasing a ticket, the destination, number of the class, and whether it is a single or return ticket have to be given. The passenger then descends by generally well lighted stairways to the station below, and his ticket is punched by the man at the gate. He then has to be careful about two things; first, to place himself on that part of the platform where the particular class which he wishes to take stops, and secondly, to get on to the right train. In the formation of the train the first class coaches are placed in the center, the second and third class respectively at the front and rear end. There are signs which indicate where passengers are to wait, according to the class. There is a sign at the front end of the engine, which to those initiated sufficiently indicates the destination of the train. The trains are also called out, and at some stations there is an obscure indicator which also gives the desired information. The stations are from imperfectly to well lighted, generally from daylight which sifts down from the smoky London atmosphere through the openings above. The length of the train averages about eight carriages of four compartments, each compartment holding ten persons, making a carrying capacity of 320 passengers. The equipment of the cars is very inferior. The first class compartments are upholstered and cushioned in blue cloth, the second class in a cheaper quality, while most of the third class compartments have absolutely nothing in the way of a cushion or covering either on the seat or back, and are little better than cattle pens. The width of the compartment is so narrow that the feet can easily be placed on the opposite seat, that is, a very little greater distance than would be afforded by turning two of our seats face to face. The length of the compartment, which is the width of the car, is about a foot and a half less than the width of our passenger cars, about equal to our freight cars. Each compartment is so imperfectly lighted by a single lamp put into position through the top of the car that it is almost impossible to read.

The length of time which a train remains at a station is from thirty to forty seconds, or from three to four times the length of time employed at the New York elevated railroad stations. The reason for this is that a large proportion of the doors are opened by passengers getting in or out, and all these have to be shut by the station porter or guard of the train before the train can start. If the train is crowded one has to run up and down to find a compartment with a vacant seat, and also hunt for his class, and as each class is divided into smoking and non-smoking compartments, making practically six classes, it will be observed that all this takes time, especially when you add the lost time at the ticket office and gate.

The ventilation of the tunnels and even the stations is oftentimes simply abominable, and although the roads are heavily patronized there is a great amount of grumbling and disfavor on this account. The platforms of the stations are flush with those of the cars, so that the delay of getting in or out is very small, but the doors are so low that a person above the average height has to stoop to get in, and cannot much more than stand upright with a tall hat on when he is once in the car. The monitor roof is unknown.

The trains move with fair speed and the stations are plainly and liberally marked, so that the passenger has little difficulty in knowing when to get out. There are two signs in general use on English railroads which are very simple and right to the point, namely, "Way Out" and "Way In," so that when a passenger arrives at a station he has no question how to get out of it. The ticket is given up as the passenger leaves the station. There is nothing to prevent a passenger with a third class ticket getting into a first class compartment excepting the ominous warning of 40 shillings fine if he does so, and the liability of having his sweet dreams interrupted by an occasional inspector who asks to see the denomination of his ticket. All compartments intended for the use of smokers are plainly marked and are to be found in each class. Almost the entire part of the railroads within the thickly settled portions of the city run in closed tunnels. Outside of this they frequently run in open cuttings, and still further out they run on to elevated tracks.

With regard to the equipment of the suburban or surface lines not belonging to the underground system the description is about the same. The cars are generally four compartments long and sometimes not exceeding three. They are coupled together with a pair of links and fastened to the draw bar on one car and the other thrown over a hook opposite and brought into tension by a right and left hand screw between the links. This is obviously very inconvenient for shunting purposes, especially as the cars are not provided with hand brakes and no chance to get at them if there were any. Consequently it appears that when a train is made up it stays so for an indefinite period. A load of passengers is brought into the station and the train remains in position until it is ready to go out. As the trains run very frequently this appears to be a very economical arrangement, as no shunting tracks are needed for storage. The engine which brings the train in of course cannot get out until the train goes out with the next load. Turn tables for the locomotives are but very little used, as they run as double enders for suburban purposes.

In conclusion it will be safe to say that the problem of rapid transit for a city as large as London is far from solved by the methods described. Although there are a great many miles of underground lines and main lines, as they have been called throughout the paper, and although grade crossings have been entirely abolished, allowing the trains to run at the greatest speed suitable to their frequency, still there are a great many sections which have to depend entirely upon the omnibus or tram car. The enormous expense entailed by the construction of the elevated structures can hardly be imagined. We have but one similar structure in this country, which is that running from the Schuylkill River to Broad Street station, in Philadelphia. The underground system is even more expensive, especially in view of the tremendous outlay for damages. This goes to show that money has not been spared to obtain rapid transit.

After all, the means to be depended upon when one desires to make a rapid trip from one part of the city to another is the really admirable, cheap, always ready, convenient and comfortable London hansom; while the way to see London is from the top of an omnibus, the most enjoyable, if not the most expeditious, means of conveyance.

[1][Continued from SUPPLEMENT, NO. 809, page 12930.]

FIG. 11.

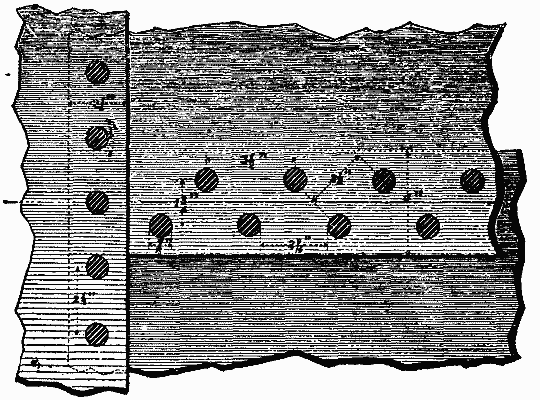

Fig. 11 represents the spacing of rivets composed of steel plates three-eighths inch thick, averaging 58,000 pounds tensile strength on boiler fifty-four inches diameter, secured by iron rivets seven-eighths inch diameter. Joints of these dimensions have been in constant use for the last fourteen years, carrying 100 pounds per square inch.

Punching Rivet Holes.—Of all tools that take part in the construction of boilers none are more important, or have more to do, than the machine for punching rivet holes.

That punching, or the forcible detrusion of a circular piece of metal to form a rivet hole, has a more or less injurious effect upon the metal plates surrounding the hole, is a fact well known and admitted by every engineer, and it has often been said that the rivet holes ought all to be drilled. But, unfortunately, at present writing, no drilling appliances have yet been placed on the market that can at all compare with punching apparatus in rapidity and cheapness of working. A first-class punching machine will make from forty to fifty holes per minute in a thick steel plate. Where is the drilling machine that will approach that with a single drill?

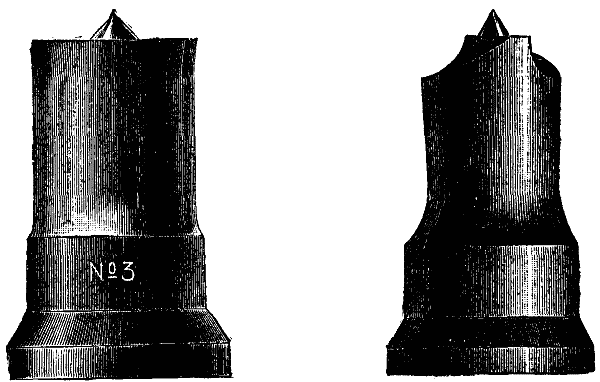

The most important matter in punching plates is the diameter of the opening in the bolster or die relatively to that of the punch. This difference exercises an important influence in respect not only of easy punching but also in its effect upon the plate punched. If we attempt to punch a perfectly cylindrical hole, the opening in the die block must be of the same diameter as the point of the punch, or, at least, a very close fit. The point of the punch ought to be slightly larger in diameter than the neck, or upper part, as shown in Figs. 12 and 13, so as to clear itself easily. When the hole in the bolster or die block is of a larger diameter than the punch, the piece of metal thrust out is of larger diameter on the bottom side, and it comes out with an ease proportionate to the difference between the lower and upper diameters; or, in other words, it produces a taper hole in the plate, but allows the punching to be done with less consumption of power and, it is said, with less strain on the plate.

FIG. 12. and FIG. 13.

As to the difference which should exist between the diameter of the punch and the die hole, this varies a little with the thickness of the plate punched, or should do so in all carefully executed work, for it is easy to understand that the die which might give a suitable taper in a three-fourths inch plate would give too great a taper in a three-eighths inch plate. There is no fixed rule; practical experience determines this in a rough and ready way—often a very rough way, indeed, for if a machine has to punch different thicknesses of plate for the same size of rivets, the workman will seldom take the trouble to change the die with every variation of thickness. The maker of punches and dies generally allows about three sixty-fourths or 0.0468 of an inch clearance.

The following formula is also used by punch and die makers:

Clearance = D = d + 0.2t

where

D = diameter of hole in die block;

d = diameter of cutting edge of punch;

t = thickness of plate in fractions of an inch;

that is to say, the diameter of the die hole equals diameter of punch plus two-tenths the thickness of the plate to be punched.

Example.—Given a plate 3/8 or 0.375 of an inch thick, the diameter of the punch being 13/16 or 0.8125 of an inch, then the diameter of the die hole will be as follows:

Diameter of die hole = 0.8125 + 0.375 X 0.2 = 0.8875 inch diameter,

or say 7/8 or 0.875 inch diameter.

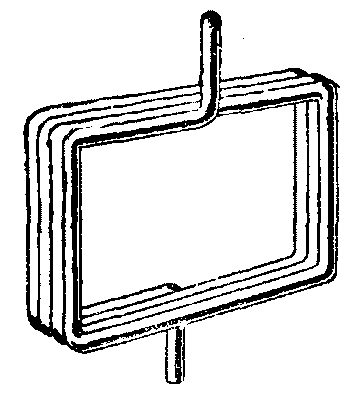

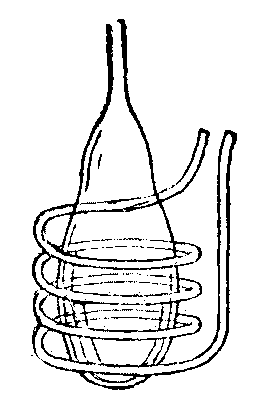

Punches are generally made flat on their cutting edge, as shown in Fig. 12. There are also punches made spiral on their cutting edge, as shown in Fig. 13. This punch, instead of being flat, as in Fig. 12, is of a helical form, as shown in Fig. 13, so as to have a gradual shearing action commencing at the center and traveling round to the circumference. Its form may be explained by imagining the upper cutter of a shearing machine being rolled upon itself so as to form a cylinder of which its long edge is the axis. The die being quite flat, it follows that the shearing action proceeds from the center to the circumference, just as in a shearing machine it travels from the deeper to the shallower end of the upper cutter. The latter is not recommended for use in metal of a thickness greater than the diameter of the punch, and is best adapted for thicknesses of metal two-thirds the diameter of the punch.

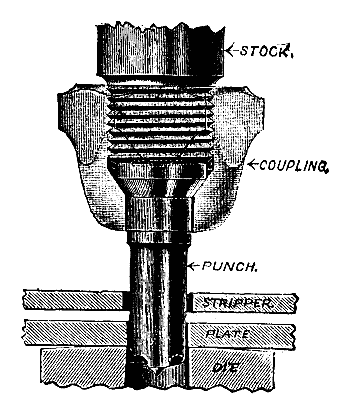

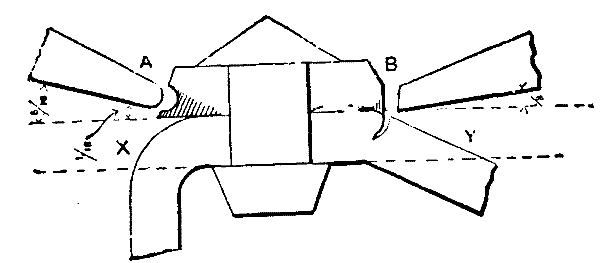

Fig. 14 shows positions of punch and attachments in the machine.

FIG. 14.

It is of the greatest importance that the punch should be kept sharp and the die in good order. If the punch is allowed to become dull, it will produce a fin on the edge of the rivet hole, which, if not removed, will cut into the rivet head and destroy the fillet by cutting into the head. When the punch is in good condition it will leave a sharp edge, which, if not removed, will also destroy the fillet under the head by cutting it away.

Punching possesses so many advantages over drilling as to render it extremely important that the operation should be reduced to a system so as to be as harmless as possible to the plate. In fact, no plate should be used in the construction of a boiler that does not improve with punching, and further on I will show by the experiments made by Hoopes & Townsend, of Philadelphia, that good material is improved by punching; that is to say, with properly made punches and dies, by the upsetting around the punched hole, the value of the plate is increased instead of diminished, the flow of particles from the hole into the surrounding parts causing stiffening and strengthening.

Drilling Rivet Holes.—In the foregoing I have not referred to the drilling of rivet holes in place of punching. The great objection to drilling rivet holes is the expense, from the fact that it takes more time, and when drilled of full rivet size we are met with the difficulty of getting the rivet holes to correspond, as they are when punched of full rivet diameter. When two plates are drilled in place together, the drill will produce a burr between the two plates—on account of their uneven surfaces—which prevents them being brought together, so as to be water and steam tight, unless the plates are afterward separated and the burr removed, which, of course, adds greatly to the expense.

The difference in strength between boiler plates punched or drilled of full rivet size may be either greater or less than the difference in strength between unperforated plates of equal areas of fracture section. When the metal plates are very soft and ductile, the operation of punching does no appreciable injury. Prof. Thurston says he has sometimes found it actually productive of increased strength; the flow of particles from the rivet hole into the surrounding parts causing stiffening and strengthening. With most steel and hard iron plates the effect of punching is often to produce serious weakening and a tendency to crack, which in some cases has resulted seriously. With first class steel or iron plates, punching is perfectly allowable, and the cost is twenty-five per cent. less than drilling; in fact, none but first class metal plates should be used in the construction of steam boilers.

In the original punching machines the die was made much larger than the punch, and the result was a conical taper hole to receive the rivet. With the advanced state of the arts the punch and die are accurately fitted; that is to say, the ordinary clearance for a rivet of (say) three-fourths of an inch diameter, the dies have about three sixty-fourths of an inch, the punch being made of full rivet size, and the clearance allowed in the diameter of the die.

Take, for example, cold punched nuts. Those made by Messrs. Hoopes & Townsend, Philadelphia, when taken as specimens of "commercial," as distinguished from merely experimental punching, are of considerable interest in this connection, owing to the entire absence of the conical holes above mentioned.

When the holes are punched by machines properly built, with the punch accurately fitted to the die, the effect is that the metal is made to flow around the punch, and thus is made more dense and stronger. That some such action takes place seems probable, from the appearance of the holes in the Hoopes & Townsend nuts, which are straight and almost as smooth as though they were drilled.

Therefore I repeat that iron or steel that is not improved by proper punching machinery is not of fit quality to enter into the construction of steam boilers.

STRENGTH OF PUNCHED AND DRILLED IRON BARS.

HOOPES & TOWNSEND.

| Thickness of bar in inches. |

Thickness outside of hole in inches. |

Punched bars broke in pounds. |

Drilled bars broke in pounds. | ||

|---|---|---|---|---|---|

| 3/8 or | 0.375 | 3/8 or | 0.375 | 31,740 | 28,000 |

| 3/8 or | 0.375 | 3/8 or | 0.375 | 31,380 | 26,950 |

| 5/8 or | 0.625 | 1/4 or | 0.25 | 18,820 | 18,000 |

| 5/8 or | 0.625 | 1/4 or | 0.25 | 18,750 | 17,590 |

| 5/8 or | 0.625 | 3/16 or | 0.1875 | 14,590 | 13,230 |

| 5/8 or | 0.625 | 3/16 or | 0.1875 | 15,420 | 13,750 |

| 5/8 or | 0.625 | 1/8 or | 0.125 | 10,670 | 9,320 |

| 5/8 or | 0.625 | 1/8 or | 0.125 | 11,730 | 9,580 |

It will be seen from the above that the punched bars had the greatest strength, indicating that punching had the effect of strengthening instead of weakening the metal. These experiments have given results just the reverse of similar experiments made on boiler plates; but the material, such as above experimented upon, is what should be placed in boilers, tough and ductile, and the manner of, and care taken in, punching contribute to these results.

It is usual to have the rivet holes one-sixteenth of an inch in diameter larger than the rivets, in order to allow for their expansion when hot; it is evident, however, that the difference between the diameters of the rivet hole and of the rivet should vary with the size of the rivet.

The hole in the die is made larger than the punch; for ordinary work the proportion of their respective diameters varies from 1:1.5 to 1:2.

As I have before stated, the best plate joint is that in which the strength of the plate and the resistance of the rivet to shearing are equal to each other.

In boilers as commercially made and sold the difference in quality of the plates and rivets, together with the great uncertainty as to the exact effect of punching the plates, have, so far, prevented anything like the determination either by calculation or experiment of what might be accepted as the best proportions of riveted joints.

In regard to steel plates for boilers Mr. F.W. Webb, of Crewe, England, chief engineer of the London and Northwestern Railway, has made over 10,000 tests of steel plates, but had only two plates fail in actual work; these failures he thought were attributable solely to the want of care on the part of the men who worked the plates up.

All their rivet holes for boilers were punched in a Jacquard machine, the plates then annealed, and afterward bent in rolls; they only used the reamer slightly when they had three thicknesses of plate to deal with, as in butt joints with inside and outside covering strips. These works turn out two locomotive boilers every three days.

The Baldwin Locomotive Works, which turn out on an average three locomotives per day, punch all their rivet holes one sixteenth inch less in diameter and ream them to driven rivet size when in place. They also use rivets with a fillet formed under head made in solid dies.

Rivets.—Rivets of steel or iron should be made in solid dies. Rivets made in open dies are liable to have a fin on the shank, which prevents a close fit into the holes of the plates. The use of solid dies in forming the rivet insures a round shank, and an accurate fit in a round hole. In addition, there is secured by the use of solid dies, a strong, clean fillet under the head, the point where strength is most needed.

Commencing with a countersunk head as the strongest form of head, the greater the fillet permissible under the head of a rivet, or bolt, the greater the strength and the decrease in liability to fracture, as a fillet is the life of the rivet.

If rivets are made of iron, the material should be strong, tough, and ductile, of a tensile strength not exceeding 54,000 pounds per square inch, and giving an elongation in eight inches of not less than twenty-five per cent. The rivet iron should be as ductile as the best boiler plate when cold. Iron rivets should be annealed and the iron in the bar should be sufficiently ductile to be bent cold to a right angle without fracture. When heated it should be capable of being flattened out to one-third its diameter without crack or flaw.

FIG. 15. Solid Die Rivet. and FIG. 16. Open Die Rivet.

If rivets are made of steel they must be low in carbon, otherwise they will harden by chilling when the hot rivets are placed in the cold plates. Therefore, the steel must be particularly a low grade or mild steel. The material should show a tensile strength not greater than 54,000 pounds per square inch and an elongation in eight inches of thirty per cent. The United States government requirements are that steel rivets shall flatten out cold under the hammer to the thickness of one-half their diameter without showing cracks or flaws; shall flatten out hot to one-third their diameter, and be capable of being bent cold in the form of a hook with parallel sides without cracks or flaws. These requirements were thought at first to be severe, but the makers of steel now find no practical difficulty in meeting these specifications.

The forming of the head of rivets, whether of steel or iron, and whether the heads are conical or semi-spherical, should not be changed by the process of riveting. The form of the head is intended to be permanent, and this permanent form can only be retained by the use of a "hold fast," which conforms to the shape of the head. In the use of the flat hold fast (in general use in a majority of boiler shops) the form of the head is changed, and if the rivet, by inadequate heating, requires severe hammering, there is danger that the head of the rivet may be "punched" off. By the use of a hold fast made to the shape of the rivet head, this danger is avoided and the original form of the head is retained. This feature of the use of proper rivet tools in boiler shops has not received the attention it deserves. Practical use of the above named hold fast would soon convince the consumers of rivets of its value and efficiency.

The practice of driving rivets into a punched rivet hole from which the fin or cold drag, caused by the movement of the punch, has not been removed by reaming with a countersunk reamer, or better still a countersunk set, should be condemned, as by driving the hot rivet head down against the fin around the hole in the cold plate caused by the action of punching the countersunk fillet is not only destroyed, but it is liable to be driven into the head of the rivet, partially cutting the head from the shank. If the rivet is driven into a hole that has been punched with a sharp punch and sharp die, the result is that the fillet is cut off under the head, and the riveted end is also cut, and does not give the clinch or hold desired. That is to say, rivet holes in plates to be riveted should have the burr or sharp edge taken off, either by countersinking, by reamer, or set.

Heating of Rivets.—Iron rivets are generally heated in an ordinary blacksmith's or rivet fire having a forced blast; they are inserted with the points down into the fire, so that the heads are kept practically cool.

Steel rivets should be heated in the hearth of a reverberatory furnace so arranged that the flame shall play over the top of the rivets, and should be heated uniformly throughout the entire length of the rivet to a cherry red. Particular attention must be given to the thickness of the fire in which they are heated.

Steel, of whatever kind, should never be heated in a thin fire, especially in one having a forced blast, such as an ordinary blacksmith's or iron rivet furnace fire. The reason for this is that more air passes through the fire than is needed for combustion, and in consequence there is a considerable quantity of free oxygen in the fire which will oxidize the steel, or in other words, burn it. If free oxygen is excluded steel cannot burn; if the temperature is high enough it can be melted and will run down through the fire, but burning is impossible in a thick fire with a moderate draught.

This is an important matter in using steel rivets and should not be overlooked; the same principle applies to the heating of steel plates for flanging.

Riveting.—There are four descriptions of riveting, namely:

(1) Hammered or hand riveting.

(2) Snapped or set.

(3) Countersunk..

(4) Machine.

For good, sound work, machine riveting is the best.

Snapped riveting is next in quality to machine riveting.

Countersunk riveting is generally tighter than snapped, because countersinking the hole is really facing it; and the countersunk rivet is, in point of fact, made on a face joint. But countersinking the hole also weakens the plate, inasmuch as it takes away a portion of the metal, and should only be resorted to where necessary, such as around the front of furnaces, steam chests or an odd hole here and there to clear a flange, or something of that sort.

Hammered riveting is much more expensive than machine or snapped riveting, and has a tendency to crystallize the iron in the rivets, causing brittleness.

In the present state of the arts all the best machine riveters do their work by pressure, and not by impact or blow.

The best machines are those of the hydraulic riveting system, which combines all of the advantages and avoids all the difficulties which have characterized previous machine systems; that is to say, the machine compresses without a blow, and with a uniform pressure at will; each rivet is driven with a single progressive movement, controlled at will. The pressure upon the rivet after it is driven is maintained, or the die is retracted at will.

FIG. 17.

Hydraulic riveting has demonstrated not only that the work could be as well done without a blow, but that it could be better done without a blow, and that the riveted material was stronger when so secured than when subjected to the more severe treatment under impact.

What is manifestly required in perfect riveting is that the metal of the rivet while hot and plastic shall be made to flow into all the irregularities of the rivet holes in the boiler sheets; that the surplus metal be formed into heads as large as need be, and that the pressure used to produce these results should not be in excess of what the metal forming the boiler shall be capable of resisting.

It is well known that metals, when subjected, either cold or hot, to sufficient pressure, will obey almost exactly the same laws as fluids under similar conditions, and will flow into and fill all the crevices of the chamber or cavity in which they are contained. If, therefore, a hot rivet is inserted into the holes made in a boiler to receive it, and is then subjected to a sufficient pressure, it will fill every irregularity of the holes, and thus fulfill one of the conditions of perfect riveting. This result it is impossible to accomplish with perfection or certainty by ordinary hand riveting, in doing which the intermittent blows of an ordinary hammer are used to force the metal into the holes. With a hydraulic riveting machine, however, an absolutely uniform and continuous pressure can be imparted to each rivet, so as to force the hot metal of the rivet into all the irregularities of the holes in the same way as a hydraulic ram will cause water to fill any cavity, however irregular.

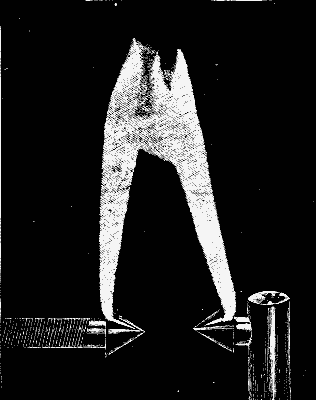

FIG. 18.

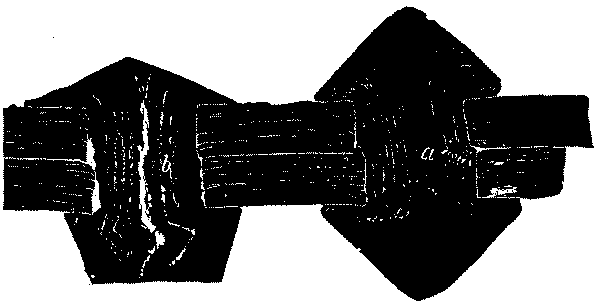

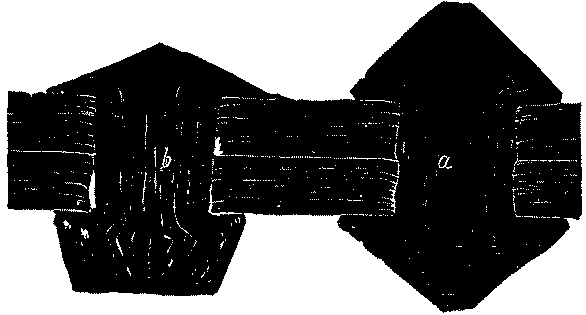

In order to illustrate the relative advantages of machine over hand riveting, two plates were riveted together, the holes of which were purposely made so as not to match perfectly. These plates were then planed through the center of the rivets, so as to expose a section of both the plates and rivets. From this an impression was taken with printer's ink on paper and then transferred to a wooden block, from which Figs. 17 and 18 were made.

The machine-driven rivet is marked a, and b represents the hammered rivet.

It will be observed that the machine rivet fills the hole completely, while the hand rivet is very imperfect. This experiment was tried several times, with similar results each time.

The hand rivet, it will be observed, filled up the hole very well immediately under the head formed by the hammer; but sufficient pressure could not be given to the metal—or at least it could not be transferred far enough—to affect the metal at some distance from the driven head. So great is this difficulty that in hand riveting much shorter rivets must be used, because it is impossible to work effectively so large a mass of metal with hammers as with a machine. The heads of the machine rivets are, therefore, larger and stronger, and will hold the plates together more firmly than the smaller hammered heads.

To drive rivets by hand, two strikers and one helper are needed in the gang, besides the boy who heats and passes the rivets; to drive each five-eighths inch rivet, an average of 250 blows of the hammer is needed, and the work is but imperfectly done. With a machine, two men handle the boiler, and one man works the machine; thus, with the same number of men as is required in riveting by hand, five rivets are driven each minute.

The superior quality of the work done by the machine would alone make its use advantageous; but to this is added greatly increased amount of work done.

The difference in favor of the riveting machine over hand riveting is at least ten to one.

In a large establishment a record of the number of rivets driven by the hand-driving gang, also by the gang at the steam-riveting machine for a long period of time, in both cases making no allowances of any kind of delays, the rivets driven per month by each was—for the hand driven rivets at the rate of twelve rivets per hour, and for the machine driven rivets, 120 per hour. In the case of the hand driven rivets the boiler remains stationary and the men move about it, while the machine driven rivets require the whole boiler to be hoisted and moved about at the riveting machine to bring each hole to the position required for the dies. Notwithstanding the trouble involved in handling and moving the boiler, it shows that it is possible to do ten times as much work, and with less skilled labor, by the employment of the riveting machine.

Calking.—One great source of danger in boiler making is excessive joint calking—both inside and out—where a sharp nosed tool is employed, and for the reason that it must be used so close to the inner edge of plate as to indent, and in many cases actually cut through the skin of the lower plate. This style of calking puts a positive strain upon the rivets, commencing distortion and putting excessive stress upon rivets—already in high tension before the boiler is put in actual use. It is, I hope, rapidly becoming a thing of the past.

With a proper proportion of diameter and pitch of rivet, all that is required is the use of a light "fuller tool" or the round-nosed tool used in what is known to the trade as the "Connery system."

There is but little need of calking if means are taken to secure a clean metal-to-metal face at the joint surfaces. When the plates are put together in ordinary course of manufacture, a portion of the mill scale is left on, and this is reduced to powder or shaken loose in the course of riveting and left between the plates, thus offering a tempting opening for the steam to work through, and is really cause of the heavy calking that puts so unnecessary a pressure on both plate and rivet. A clean metallic joint can be secured by passing over the two surfaces a sponge wet with a weak solution of sal-ammoniac and hot water, an operation certainly cheap enough both as to materials and labor required.

FIG. 19.

The above cut, Fig. 19, gives an illustration of calking done by sharp-nosed and round nosed tools, respectively. It will be seen by Fig. 20 that the effect of a round-nosed tool is to divide the plate calked, and as the part divided is well driven toward the rivets, a bearing is formed at a, from one-half to three-fourths of an inch, which increases the strength of joint, and will in no way cut or injure the surface of the under plate. A perfect joint is thus secured.

FIG. 20.

The launching of this first-class battle ship was successfully carried out at Pembroke Dockyard on May 7. She is the second of a class of eight battle ships built and building under the Naval Defense Act of 1889, which were specially designed to take part in general fleet actions in European waters. The leading dimensions are: Length, between perpendiculars, 380 ft.; breadth, extreme, 75 ft.; mean draught of water, 27 ft. 6 in.; and displacement at this draught, 14,150 tons, which surpasses that of any other ship in the navies of the world. Previous to the launching of the Royal Sovereign—a sister vessel—which took place at Portsmouth in February last, the largest war ships in the British navy were the Nile and Trafalgar, each of 12,500 tons, and these were largely exceeded in displacement by the Italia, of 13,900 tons, and the Lepanto, of 13,550 tons, belonging to the Italian navy.

The Empress of India is built throughout of mild steel, the stem and stern post, together with the shaft brackets, being of cast steel. Steel faced armor, having a maximum thickness of 18 in., extends along the sides for 250 ft. amidships, the lower edge of the belt being 5 ft. 6 in. below the normal water line. The belt is terminated at the fore and after ends by transverse armored bulkheads, over which is built a 3 in. protective steel deck extending to the ends of the vessel and terminating forward at the point of the ram. Above the belt the broadside is protected by 5 in. armor, the central battery being inclosed by screen bulkheads of the same thickness. The barbettes, which are formed of armor 17 in. thick, rise from the protective deck at the fore and after ends of the main belt. The principal armor throughout is backed by teak, varying in thickness from 18 in. to 20 in., behind which is an inner skin of steel 2 in. thick. The engines are being constructed by Messrs. Humphreys, Tennant & Co, London, and are of the vertical triple expansion type, capable of developing a maximum horse power of 13,000 with forced draught and 9,000 horse power under natural draught, the estimated speeds being 16 and 17½ knots respectively at the normal displacement. The regular coal supply is 900 tons, which will enable the ship to cover a distance of 5,000 knots at a reduced speed of ten knots and about 1,600 knots at her maximum speed. The main armament of the Empress will consist of four 67 ton breechloading guns mounted in pairs en barbette. The secondary armament includes ten 6 in. 100 pounder quick firing guns, four being mounted on the main deck and six in the sponsons on the upper deck, sixteen 6 pounder and nine 3 pounder quick-firing guns, in addition to a large number of machine guns.

The largest guns at present mounted in any British warship are the 110 ton guns mounted in the Benbow class, and the difference between these weapons and those to be carried by the Empress of India is very marked.

The projectile fired from either of the Benbow's heavy gun weighs 1,800 lb., and is capable of penetrating 35 in. of unbacked wrought iron at a distance of 1,000 yards. The projectile fired from the 67 ton guns of the Empress of India will have much less penetrating power, being only equal to 27 in. of wrought iron with a full charge of 520 lb. of prismatic brown powder, the missile weighing 1,250 lb. or about one-half less than the weight of the shot used with the 110 ton gun. It will thus be seen that the ordnance of the Benbow can penetrate armor that would defy the attack of the guns of the Empress. It should be said, however, that the heavy artillery of the latter vessel is capable of penetrating any armor at present afloat, and is carried at a much greater height above the designed load water line than in any existing battle ship, either in the British or foreign navies. The armor being of less weight, too, enables the new ship, and others of her class, to carry an auxiliary armament of unprecedented weight and power.

The Empress will be lighted throughout by electricity, the installation comprising some 600 lights, and will be provided with four 25,000 candle power search lights, each of which will be worked by a separate dynamo. The ship has been built from the designs of Mr. W.H. White, C.B., Director of Naval Construction, and will be fitted out for the use of an admiral, and when commissioned her complement of officers and men will number 700.—Industries.

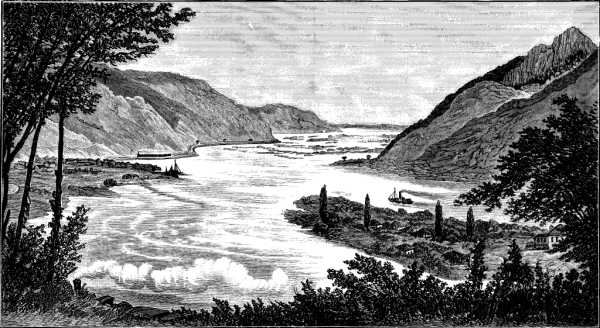

The work of blowing up the masses of rock which form the dangerous rapids known as the Iron Gates, on the Danube, was inaugurated on September 15, 1890, when the Greben Rock was partially blown up by a blast of sixty kilogrammes of dynamite, in the presence of Count Szapary, the Hungarian premier; M. Baross, Hungarian minister of commerce; Count Bacquehem, Austrian minister of commerce; M. Gruitch, the Servian premier; M. Jossimovich, Servian minister of public works; M. De Szogyenyi, chief secretary in the Austro-Hungarian ministry of foreign affairs; and other Hungarian and Servian authorities. Large numbers of the inhabitants had collected on both banks of the Danube to witness the ceremony, and the first explosion was greeted with enthusiastic cheers. The history of this great scheme was told at the time the Hungarian Parliament passed the bill on the subject two years ago. It is known that the Roman Emperor Trajan, seventeen centuries ago, commenced works, of which traces are still to be seen, for the construction of a navigable canal to avoid the Iron Gates.

For the remedy of the obstruction in the Danube, much discussed of late years, there were two rival systems—the French, which proposed to make locks, and the English and American, which was practically the same as that of Trajan, namely, blasting the minor rocks and cutting canals and erecting dams where the rocks were too crowded. The latter plan was in principle adopted, and the details were worked out, in 1883, by the Hungarian engineer Willandt. The longest canal will be that on the Servian bank, with a length of over two kilometers and a width of eighty meters. It will be left for a later period to make the canal wider and deeper, as was done with the Suez Canal. For the present it is considered sufficient that moderate sized steamers shall be able to pass through without hindrance, and thus facilitate the exchange of goods between the west of Europe and the east.

The first portion of the rocks to be removed, and of the channels to be cut, runs through Hungarian territory; the second portion is in Servia. The new waterway will, it is anticipated, be finished by the end of 1895, and then, for the first time in history, Black Sea steamers will be seen at the quays of Pesth and Vienna, having, of course, previously touched at Belgrade. The benefit to Servian trade will then be quite on a par with that of Austria-Hungary. Even Germany will derive benefit from this extension of trade to the east. These, however, are by no means the only countries which will be benefited by the opening of the great river to commerce. Turkey, Southern Russia, Roumania, and Bulgaria, not to speak of the states of the west of Europe, will reap advantage from this new departure. England, as the chief carrier of the world, is sure to feel the beneficial effects of the Danube being at length navigable from its mouth right up to the very center of Europe.

The removal of the Iron Gates has always been considered a matter of European importance. The treaty of Paris stipulated for freedom of navigation on the Danube. The London treaty of 1871 again authorized the levying of tolls to defray the cost of the Danube regulation; and article 57 of the treaty of Berlin intrusted Austria-Hungary with the task of carrying out the work. By these international compacts the European character of the great undertaking is sufficiently attested.

THE "IRON GATES" OF THE DANUBE.

The work of blasting the rocks will be undertaken by contractors in the employ of the Hungarian government, as the official invitation for tenders brought no offers from any quarter. The construction of the dams, however, and the cutting of several channels to compass the most difficult rocks and rapids, will be carried out by an association of Pesth and other firms. The cost, estimated altogether at nine million florins, will be borne by the Hungarian exchequer, to which will fall the tolls to be levied on all vessels passing through the Gates until the original outlay is repaid.

Very few persons know, says the American Architect, what an enormous work has been undertaken at the Iron Gates of the Danube, where operations are rapidly progressing, mainly in accordance with a plan devised many years ago by our distinguished countryman, Mr. McAlpine. The total length of that part of the river to be regulated is about two hundred and fifty miles, so that the enterprise ranks with the cutting of the Panama and Suez canals as one of the greatest engineering feats ever attempted. Work has been begun simultaneously at three points: at Greben, where there are reefs to be taken care of; at the cataract, near Jucz, and at the Iron Gate proper, below Orsova. At Greben, where the stream is shallow, but swift, a channel two hundred feet wide is to be blasted out of the rock, and below it a stone embankment wall is to be built more than four miles long. From a reef which projects into the river a piece is to be blasted away, measuring five hundred feet in length, and about nine feet in depth. The difficulties of working in this part of the river are very great. Not only is the current extremely rapid, but in certain places ridges of rock barely covered at low water alternate with pools a hundred and forty feet deep, which give rise, in the rapid current, to frightful whirlpools and eddies. These deep pools are to be filled at the same time that the reefs are cut away, and it is estimated that nearly three million cubic feet of loose stonework will be needed for this purpose alone. In addition to the excavation, artificial banks and breakwaters, for modifying the course of the stream, are to be built; so that it is estimated that the masonry to be executed in this section will amount to about five and one-half million cubic feet.

In the cataract section, at Jucz, a channel two hundred feet wide, and more than half a mile long, is to be blasted out of the rock, and a breakwater built, to moderate the suddenness of the fall. This breakwater is to be about two miles long, and ten feet thick at the top, increasing in thickness toward the bottom. The rock in which the channel must be cut at this point is partly serpentine greenstone, partly chrome iron ore, and is intensely hard. In the section of the Iron Gate, the work to be done consists in "canalizing" the river for a distance of a mile and a half, by building a wall on each side, and excavating the bed of the river between. The channel between the walls will be two hundred and fifty feet wide. It is estimated that nearly three million cubic feet of rock will have to be excavated here, all of which will be used to fill in behind the embankment walls. Of course, the greater part of the rock will be removed by means of blasting with high explosives, but some of it is to be attacked with a novel instrument, which was first tried, on a small scale, on the Panama Canal, and is to be used for serious work here. This instrument, as it is to be employed on the Danube, consists of an enormous steel drill, thirty-three feet long, and weighing ten tons. By means of a machine like a pile driver, this monstrous tool is raised to a height of about fifty feet, and allowed to drop, point first. So heavy a mass of metal, falling from a considerable height, meets with comparatively little resistance from the water, and the point shatters and grinds up the rock on which it strikes. Fifty or sixty blows per minute can be struck with a tool of this kind, and ten thousand blows in all can be inflicted before the tool is so worn as to be past service. Several of these drills will be at work at the same time, and to remove the fragments of rock which they break off, a huge dredge of three hundred and fifty horse power is to be employed. For excavating by means of explosives, arrangements have been made for drilling the holes for the cartridges with the greatest possible rapidity, as on this depends the celerity with which the work can be pushed forward. Much of the work will be done by means of diamond drills, which are mounted on boats. Five of these boats have been provided, each with seven diamond drills, arranged so as to work perfectly in twenty feet of water. Other boats are fitted with pneumatic drills, which are operated by means of air, compressed to a tension of seven hundred and fifty pounds to the square inch. The pressure of the compressed air is transmitted by means of water to the drills, which act by percussion, and work very rapidly. These drills are curiously automatic in their operation. After boring the holes to the allotted depth, the machine automatically sets in each a tube, washes out the dust, inserts a dynamite cartridge, withdraws the tube, and connects the wire of the electric fuse in the cartridge with the battery wire in the boat. The cartridges are charged with a pound of dynamite to each. In hard rock only one charge is fired at a time, but in softer material four are fired at once. If the water over the work is deep, the boat is not moved from its position, but in shallow water it is towed a few yards away from the spot where the explosion is to take place. The drill holes are about six feet deep, and are spaced at the rate of about one to every three square feet, something, of course, depending upon the character of the rock. The whole work is now under contract, the mechanical engineering firm of Luther, of Brunswick, having undertaken to complete it in five years, for a payment of less than four million dollars.

The gates which admit the water into the new canal which is to connect the Baltic with the North Sea have been recently opened by the Emperor William. This canal is being constructed by the German government principally for the purpose of strengthening the naval resources of Germany, by giving safer and more direct communication for the ships of the navy to the North German ports. The depth of water will be sufficient for the largest ships of the German navy. The canal will also prove of very great advantage to the numerous timber and other vessels trading between St. Petersburg, Stockholm, Dantzic, Riga, and all the North German ports in the Baltic and this country. The passage by the Kattegat and Skager Rack is exceedingly intricate and very dangerous, the yearly loss of shipping being estimated at half a million of money. In addition to the avoidance of this dangerous course, the saving in distance will be very considerable. Thus, for vessels trading to the Thames the saving will be 250 miles, for those going to Lynn or Boston 220, to Hull 200, to Newcastle or Leith 100. This means a saving of three days for a sailing vessel going to Boston docks, the port lying in the most direct line from the timber ports of the Baltic to all the center of England. The direction of the canal is shown by the thick line in the accompanying sketch map of the North Sea and Baltic. Considering that between 30,000 and 40,000 ships now pass through the Sound annually, the advantage to the Baltic trade is very apparent.

The new canal starts at Holtenau, on the north side of the Kiel Bay, and joins the Elbe fifteen miles above the mouth. From Kiel Bay to Rendsborg, at the junction with the Eider, the new canal follows the Schleswig and Holstein Canal, which was made about one hundred years ago, and is adapted for boats drawing about eight feet; thence it follows the course of the Eider to near Willenbergen, when it leaves that river and turns southward to join the Elbe at Brunsbuttel, about forty miles below Hamburg. The canal is 61 miles long, 200 ft. wide at the surface, and 85 ft. at the bottom, the depth of water being 28 ft. The surface of the water in the two seas being level, no locks are required; sluices or floodgates only being provided where it enters the Eider and at its termination. The country being generally level there are no engineering difficulties to contend with, except a boggy portion near the Elbe; the ground to be removed is chiefly sandy loam. Four railways cross the canal and two main roads, and these will be carried across on swing bridges. The cost is estimated at £8,000,000. About six thousand men are employed on the works, principally Italians and Swiss.—The Engineer.

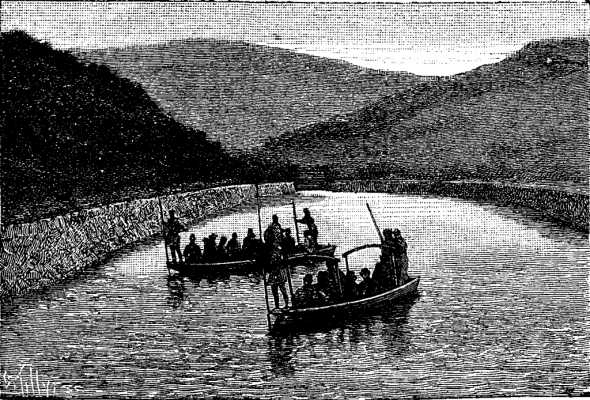

Japan is already traversed by a system of railways, and its population is entering more and more into the footsteps of western civilization. This movement, a consequence of the revolution of 1868, is extending to the public works of every kind, for while the first railway lines were being continued, there was in the course of excavation (among other canals) a navigable canal designed to connect Lake Biwa and the Bay of Osaka, upon which is situated Kioto, the ancient capital of Japan.

The work, which was begun in 1885, was finished last year, and one of our readers has been kind enough to send us, along with some photographs which we herewith reproduce, a description written by Mr. S. Tanabe, engineer in chief of the work.

The object of the Kioto-Fu Canal is not only to provide a navigable watercourse, putting the interior of the country in connection with the sea, but also to furnish waterfalls for supplying the water works of the city of Kioto with the water necessary for the irrigation of the rice plantations, and that employed for city distribution. It starts from the southwest extremity of Lake Biwa, the largest lake in Japan, and the area of which is 800 square kilometers. This lake, which is situated at 84 meters above the level of the sea, is 56 kilometers from the Bay of Osaka. As this bay is already in communication with Kioto by a canal, the Kioto-Fu forms a junction with the latter after a stretch of 11 kilometers and a difference of level of 45 meters between its extremities.

FIG. 1.—EXTREMITY OF LAKE BIWA AND BEGINNING OF THE CANAL.

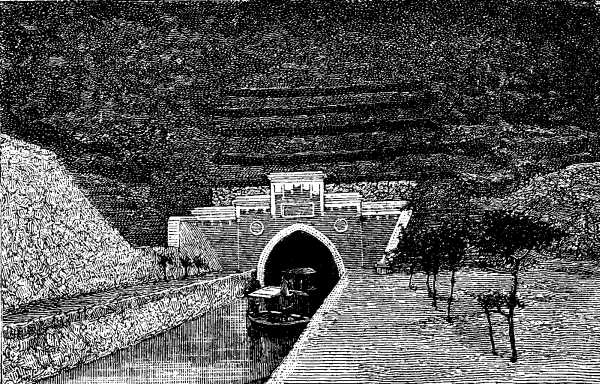

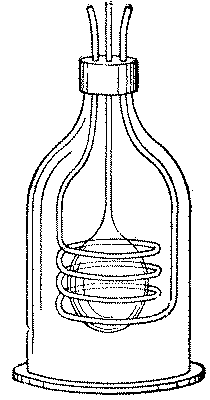

The lake terminates in a marshy plain (Fig. 1), in which the first excavation was made. This is protected by longitudinal dikes which lead back the water to it in case of freshets. At the end of this cutting, which is 100 meters in length, begins the canal properly so called, with a width of 5.7 meters, at the surface, and a depth of 1.5 meters, for a length of 540 meters. It then reaches the first tunnel for crossing the Nagara-yama chain. This tunnel is 2,500 meters in length, 4.8 in width and 4.2 in height. The water reaches a depth of 1.8 meters upon the floor. It was pierced through very varied materials, such as clay, schists, sandstone and porphyry, and is lined throughout with brick masonry. The construction was effected by means of a working shaft 45 meters in depth, sunk in the axis of the work, at a third of its length from the west side. At the upper extremity are established sluices that permit of securing to the canal a constant discharge of 8.5 cubic meters per second. Fig. 2 represents the head of this work.

FIG. 2.—HEAD OF THE PRINCIPAL TUNNEL.

Starting from the tunnel, the canal extends in the open air for a length of 4,500 meters. To reach the basin of Kioto, it traverses the Hino-oko-yama chain of hills, through two tunnels of the same section and construction as the one just mentioned, and of the respective lengths of 125 and 841 meters. Traction in the tunnels is to be effected by means of an immersed chain.

On leaving tunnel No. 3, at about 8,400 meters from its origin, the canal divides into two branches. The first of these, which is designed to serve as a navigable way, has a slope 0.066 per meter for a length of 540 meters. It is a true inclined plane, which the boats pass over by means of a cradle carried by trucks and drawn by a cable actuated by the fall furnished by the other branch. At the foot of the inclined plane, the canal widens out to 18 meters at the surface, with a depth of 1.5 meter, and, through a sluice, joins the Osaka Bay Canal, after a stretch of 2 kilometers.

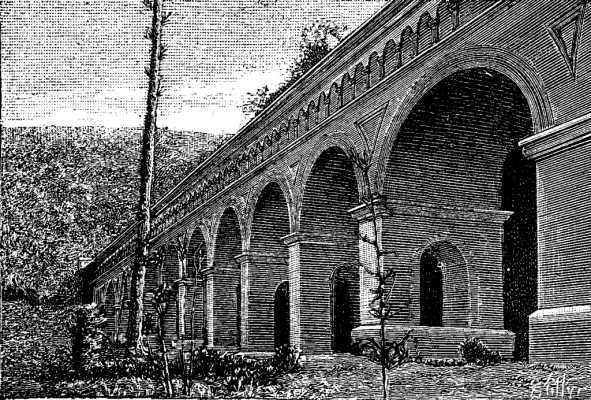

FIG. 3.—AQUEDUCT OVER THE VALLEY OF THE TOMBS OF THE EMPERORS.

The second branch traverses a small tunnel, crosses the valley of the emperors' tombs upon an aqueduct of 14 arches (Fig. 3), and reaches Kogawa, a faubourg north of Kioto, after a stretch of 8 kilometers. Its slope is greater than that of the main canal, from which it derives but 1.4 cubic meter. The 7 cubic meters remaining may be employed for the production of motive power under a fall of 56 meters. It is proposed to utilize a portion of it, at the point of bifurcation and at the top of the inclined plane, in a hydraulic installation that will drive electric machines. The total cost of the work was one million dollars, a third of which was furnished by the imperial treasury, a quarter by the central government, and the rest by various taxes.—La Nature.

HOW TO FIND THE CRACK.—Most mechanics know that by drilling a hole at the inner end of a crack in cast metal its extension can be prevented. But to find out the exact point where the crack ends, the Revue Industrielle recommends moistening the cracked surface with petroleum, then, after wiping it, to immediately rub it with chalk. The oil that has penetrated into the crack will, by exudation, indicate the exact course and end of the crack.

As it is with many other arts, the origin of dyeing is shrouded in the obscurity of the past; but no doubt it was with the desire to attract his fellow that man first began to imitate the variety of color he saw around him in nature, and colored his body or his dress.

Probably the first method of ornamenting textile fabrics was to stain them with the juices of fruits, or the flowers, leaves, stems, and roots of plants bruised with water, and we may reasonably assume that the primitive colors thus obtained would lack durability.

By and by, however, it was found possible to render some of the dyes more permanent, probably in the first instance by the application of certain kinds of earth or mud, as we know to be practiced by the Maori dyers of to-day, and in this way, as it appears to me, the early dyers learnt the efficacy of what we now call "mordants," which I may briefly describe as fixing agents for coloring matters.

At a very remote period therefore, I imagine, the subject of fast and fugitive dyes engaged the attention of textile colorists.

Our European knowledge of dyeing seems to have come to us from the East, and although at first indigenous dyestuffs were largely employed, with the discovery of new countries many of these fell slowly and gradually into disuse, giving way to the newly imported dyestuffs of other lands, which possessed some advantage, being either richer in coloring matter, yielding brighter or faster colors, or being capable of more easy application. Thus kermes gave way to cochineal, woad to indigo, and so on.

Down to about the year 1856, natural dyestuffs alone, with but one or two exceptions, were employed by dyers; but in that year a present distinguished member of this Society, Dr. Perkin, astonished the scientific and industrial world by his epoch-making discovery of the coal tar color mauve. From that time down to the present, the textile colorist has had placed before him an ever increasing number of coloring matters derived from the same source.

Specially worthy of notice are the discoveries of artificial alizarin, in 1868, by Graebe and Liebermann, and of indigotin, in 1878, by Adolf Baeyer, both coloring matters being identical with the respective dyes obtained from plants.

In view of the vast array of coal tar colors now at our disposal, and their almost universal application in the decoration of all manner of textile fabrics, threatening even the continued use of well known dyestuffs of vegetable origin, it becomes of the greatest importance to examine most thoroughly, and to compare the stability of both old and new coloring matters.

The first point in discussing this question of fast and fugitive dyes is to define the meaning of these terms "fast" and "fugitive." Unfortunately, as frequently employed, they have no very definite signification. The great variety of textile fabrics to which coloring matters are applied, the different stages of manufacture at which the coloring matter is applied, and the many uses to which the fabrics are ultimately put, all these are elements which cause dyed colors to be exposed to the most varied influences.

The term a "fast color," then, may convey a different meaning to different individuals. To one it implies that the color will not fade when exposed to light and atmospheric conditions; to another that it is not impoverished by washing with soap and water; to a third it may indicate that the color will withstand the action of certain manufacturing operations, such as scouring, milling, stoving, etc.; while a fourth person might be so exacting as to demand that a fast color should resist all the varied influences I have named.

It is well to state at once that no dyed color is absolutely fast, even to a single influence, and it certainly cannot pass unscathed through all the operations to which it may be necessary to submit individual colors applied to this or that material. Many colors are fast to washing or milling, and yet very fugitive to light; others are fast to light, but fugitive toward milling; while others again are fast to both influences. In short, each color has its own special, characteristic properties, so that colors may be classified with respect to each particular influence, and may occupy a very different rank in the different arrangements.

It is, however, by no means necessary to demand absolute fastness from any color. A color may "bleed" in milling, and therefore be very unsuitable for tweeds, and yet be most excellent for curtains and hangings, because of its fastness to light. So, too, a dye capable of yielding rich or delicate tints, but only moderately fast to light, may still be perfectly well adapted for the silks and satins of the ball room, or even the rapidly changing fashion, although it would be quite inadmissible for the pennon at the masthead.

The colors of carpets, curtains, and tapestry should certainly be fast to light, but no one expects them to undergo the fatigue of the weekly washtub; and just as little as we look for the exposure of flannels and hosiery, day by day and week by week, to the glare of sunlight, much as we desire that the colors shall not run in washing.

For all practical purposes, then, it seems reasonable to define a "fast color" as one which will not be materially affected by those influences to which, in the natural course of things, it will be submitted. Hence, in speaking of a fast color, it becomes necessary to refer specially to the particular influences which it resists before the term acquires a definite meaning. To be precise, one should say that a color is "fast to light," or "fast to washing," or "fast to light and washing," and so on. Further, it is necessary, as we shall see afterward, to give always the name of the fiber to which the color is applied.

All that I have said with respect to the term "fast" may be applied with equal propriety to the term "fugitive." This, too, has no very definite meaning until a qualifying statement, such as I have referred to, gives it precision.

The most important question to be considered is

That light can effect radical changes in many substances was known to the ancients. Its destructive action on artists' pigments, e.g., the blackening of vermilion, was recorded 2,000 years ago by Vitruvius. Since that time it has been well established, by numerous observations and experiments, that light possesses, in a high degree, the power of exerting chemical action, i.e., causing the combination or decomposition of a large number of substances. The union of chlorine with hydrogen gas, the blackening of silver salts, the reduction of bichromate of potash and of certain ferric salts in contact with organic substances, are all familiar instances of the action of light. In illustration of this, I show here some calico prints produced by first preparing the calico with a solution of potassium bichromate, then exposing the dried calico under a photographic negative, and, after washing, dyeing with alizarin or some similar coloring matter. During the exposure under the negative, the light has reduced and fixed the chromium salt upon certain parts of the fiber as insoluble chromate of chromium (Cr2O3CrO3) in the more protected portions, the bichromate remains unchanged, and is subsequently removed by washing. During the dyeing process, the coloring matter combines with the chromium fixed on the fiber, and thus develops the colored photograph.

The prints in Prussian blue are produced in a similar manner, the sensitive salt with which the calico is prepared being ammonium ferricitrate, and the developer potassium ferricyanide.

Investigation has shown that the most chemically active rays are those situated at the blue end of the solar spectrum; and although all the rays absorbed by a sensitive colored body affect its change, it is doubtless the blue rays which are the chief cause of the fading of colors. Experiments are on record, indeed, which prove this.

Depierre and Clouet (1878-82) exposed a series of colors, printed and dyed on calico, to light which had passed through glasses stained red, orange, yellow, green, blue, and violet, corresponding to definite parts of the spectrum. They found that the blue light possessed the greatest fading power, red light the least.

More recently (1886-88) Abney and Russell exposed water colors under red, green, and blue glass, and came to the same conclusion.

But the chemical energy of the sun's rays is not the sole cause of the fading of colors. There are certain contributory causes as important as the light itself.

About fifty years ago, Chevreul showed what these accessory causes are, by exposing to light a number of dyed colors under varied conditions, e.g., in a vacuum, in dry and moist hydrogen, dry and moist air, water vapor, and the ordinary atmosphere. He found that such fugitive colors as orchil, safflower, and indigo-carmine fade very rapidly in moist air, less rapidly in dry air, and that they experience little or no change in hydrogen or in a vacuum. The general conclusion arrived at was, that light, when acting alone, i.e., without the aid of air and moisture, exercises a very feeble influence. Further, it was determined that the air and moisture, without aid of light, have also comparatively little effect on dyed colors. Abney and Russell, in their experiments with water colors, obtained similar results.

These conclusions are exactly in accordance with our common knowledge of the old fashioned method of bleaching cotton and linen, in which the wetted fabric is exposed to light on the grass, and frequently sprinkled with water. If the material becomes dry through the absence of dew or rain, or the want of sprinkling, little or no bleaching takes place.

The one color which Chevreul found to behave abnormally was Prussian blue. This faded even in a vacuum; but, strange to say, on keeping the faded color in the dark, and exposed to air, the color was restored. It was shown that, during the exposure to light, the color lost cyanogen, or hydrocyanic acid, while in the dark and exposed to the air, oxygen was absorbed. Chevreul concluded, therefore, that the fading of Prussian blue was due to a process of reduction.

The prevailing opinion, however, is that the fading of colors is a process of oxidation, caused by the ozone, or hydrogen peroxide, which is probably formed in small quantity during the evaporation of the moisture present, and both these substances are powerful bleaching agents.

It would be extremely convenient to have some rapid method of testing colors for fastness to light, and I believe it is the custom with some to apply certain chemical tests with this object in view. The results of my own experiments in this direction lead me to the conclusion that at present we have no sufficient substitute for sunlight for this purpose, since I have not found any oxidizing or reducing substance which affects dyed colors in all respects like the natural color-fading agencies; further, I am inclined to the opinion that the action of light varies somewhat with the different coloring matters, according to their chemical constitution and the fiber upon which they are applied.

With respect to this last point, Chevreul actually found that colors are faster to light on some fibers than on others, and this fact, which is generally known to practical men, is abundantly shown in the diagrams on the wall. As a rule we may say that colors are most fugitive on cotton and most permanent on wool, those on silk holding an intermediate position. Still there are many exceptions to this order, especially as between silk and wool.

Since the time of Chevreul, the action of light on dyed colors has not been seriously and exhaustively studied. From time to time, series of patterns dyed with our modern colors have been exposed to light, e.g., by Depierre and Clouet, Joffre, Muller, Kallab, Schmidt, and others; but the published results must at best be considered as more or less fragmentary. Under the auspices of the British Association, and a committee appointed at its last meeting in Leeds, I hope to have the pleasure during the next few years of studying this interesting subject.

To-night I propose to give you some of the prominent results already obtained in past years, in the dyeing department of the Yorkshire College, where it has been our custom to expose to light and other influences the patterns dyed by our students. Further, I wish to give you an ocular demonstration of the action of light or dyed colors, by means of these silk, wool, and cotton patterns, portions of which have been exposed for 34 days and nights on the sea coast near Bombay, during the month of February of this year.

I may remark that this test has been a very trying one, for I estimate that it is equal to more than a year's exposure in this country. During the whole period there was cloudless sunshine, without any rain, and each evening heavy dew. I have pleasure in acknowledging the services of Mr. W. Reid, a former student, who superintended the exposure of the patterns, and from time to time took notes of the rate at which individual patterns faded.

These diagrams contain, perhaps, the most complete series of both old and new dyes, on the three fibers, which have been simultaneously exposed to sunlight, and they form an instructive object lesson.

Let me first direct your attention to the diagram containing the natural coloring matters—those dyestuffs which were in use previous to 1856. Broadly speaking, they are of two kinds; those which dye textile materials "direct," and those which give no useful color without the aid of certain metallic salts, called "mordants."

Now, among the natural coloring matters, these "mordant dyes," as they may be conveniently termed, are much more numerous than the "direct dyes;" but be it observed, we have fast and fugitive colors in both classes.

Referring first to the wool patterns and to the "direct dyes," we find that the only really fast colors are Prussian blue and Vat indigo blue. Turmeric, orchil, catechu, and indigo carmine are all extremely fugitive.

As to the "mordant dyes," some yield fast colors with all the usual mordants, e.g., madder, cochineal, lac dye, kermes, viz., reds with tin and aluminum, claret browns with copper and chromium, and dull violets with iron.

Other dyestuffs, like camwood, brazilwood, and their allies, also young fustic, give always fugitive colors whatever mordant be employed; others again, e.g., weld, old fustic, quercitron bark, flavin, and Persian berries, give fast colors with some mordants and fugitive colors with others; compare, for example, the fast olives of the chromium, copper, and iron mordants with the fugitive yellows given by aluminum and tin. A still more striking case is presented by logwood, which gives a fast greenish-black with copper and very fugitive colors with aluminum and tin. Other experiments have shown that the chromium and iron logwood blacks hold an intermediate position. Abnormal properties are found to be exhibited by camwood and its allies, with aluminum and tin, the colors at first becoming darker, and only afterward fading in the normal manner.

When we examine the silk patterns, we find, generally speaking, a similar degree of fastness among the various natural dyes, as with wool; in some instances the colors appear even faster, notice, for example, the catechu brown and the colors given by brazilwood and its allies, with iron mordant.

On examining the cotton patterns, we are at once struck with the marked fugitive character of nearly all the natural dyes. The exceptions are: the madder colors, especially when fixed on oil-prepared cotton, as in Turkey red; the black produced by logwood, tannin, and iron; and a few mineral colors, e.g., iron buff, manganese brown, chromate of lead orange, etc., and Prussian blue. Cochineal and its allies, which are such excellent dyes for wool and silk, give only fugitive colors on cotton.

The main point which arrests our attention in connection with the natural dyes seems to me to be the comparatively limited number of fast colors. Very remarkable is the total absence of any really fast yellow vegetable dye, and it is probably on this account that gold thread was formerly so much introduced into textile fabrics. Notice further the decided fastness of Prussian blue, especially on wool and silk; while we cannot but remark the comparatively fugitive character of vat indigo blue on cotton, and even on silk, compared with the fastness of the same color when fixed on wool.

Now, let us turn our attention to the artificial coloring matters, derived with few exceptions from coal tar products.